Novel color 3D printer

A 3D printer and printer technology, applied in the field of 3D printing, can solve the problems of short development period, low production cost, poor color mixing effect, etc., and achieve the effect of avoiding back suction and wire drawing at the end, increasing mixing time, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0052] The difference between embodiment two and embodiment one is:

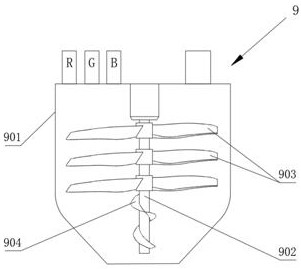

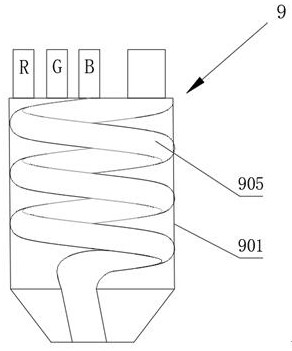

[0053] see image 3 and 4 , the mixing unit 9 is provided with a spiral mixing pipeline 905, the upper end of the mixing pipeline 905 is connected with the RGB three-color supply tank 10 and the first resin supply tank 11, and the outlet of the lower end of the mixing pipeline 905 is connected with the main The feeding port of the nozzle 7 is connected, and the RGB dyeing material and the resin raw material are mixed through the spiral mixing pipeline 905. The spiral mixing pipeline 905 increases the mixing time and ensures the mixing quality; the mixing pipeline 905 is provided with a The mixing blades 906 spirally distributed along the inner wall of the mixing pipe 905 improve the mixing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com