Fluidized bed processing device of printing and dyeing waste water

A printing and dyeing wastewater and treatment device technology, applied in the field of environmental technology and water treatment, can solve the problems of low three-phase separation efficiency, excessive shedding of biofilm, high cost of anaerobic reaction, etc., to improve carrier loss, solve easy clogging, and quickly The effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

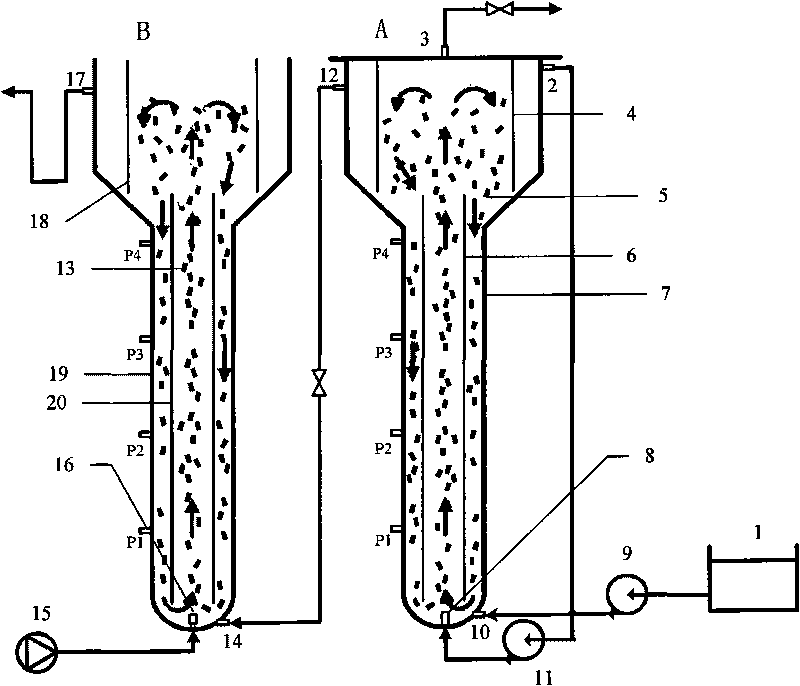

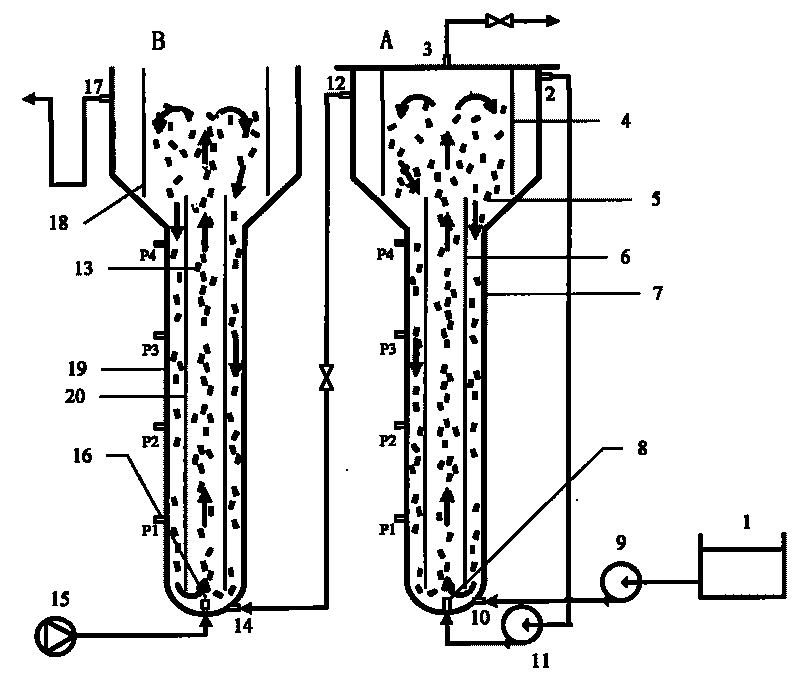

[0019] The fluidized bed treatment device for printing and dyeing wastewater of the present invention is used to treat wastewater containing various dyes with a total concentration of 100 mg / L, a COD of 1000 mg / L, and an initial pH of 7.5. The operating parameters of the fluidized bed are: the circulating water flow rate of the anaerobic fluidized bed is 70L / h, the aerobic aeration rate is 0.4m3 / h, and the total hydraulic retention time is 30 hours. The effluent COD removal rate reaches 94.3%, and the chromaticity removal rate reaches 87.5%. The data show that printing and dyeing wastewater can be treated quickly and thoroughly by using anaerobic-aerobic combined biological fluidized bed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com