Patents

Literature

32results about How to "No processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

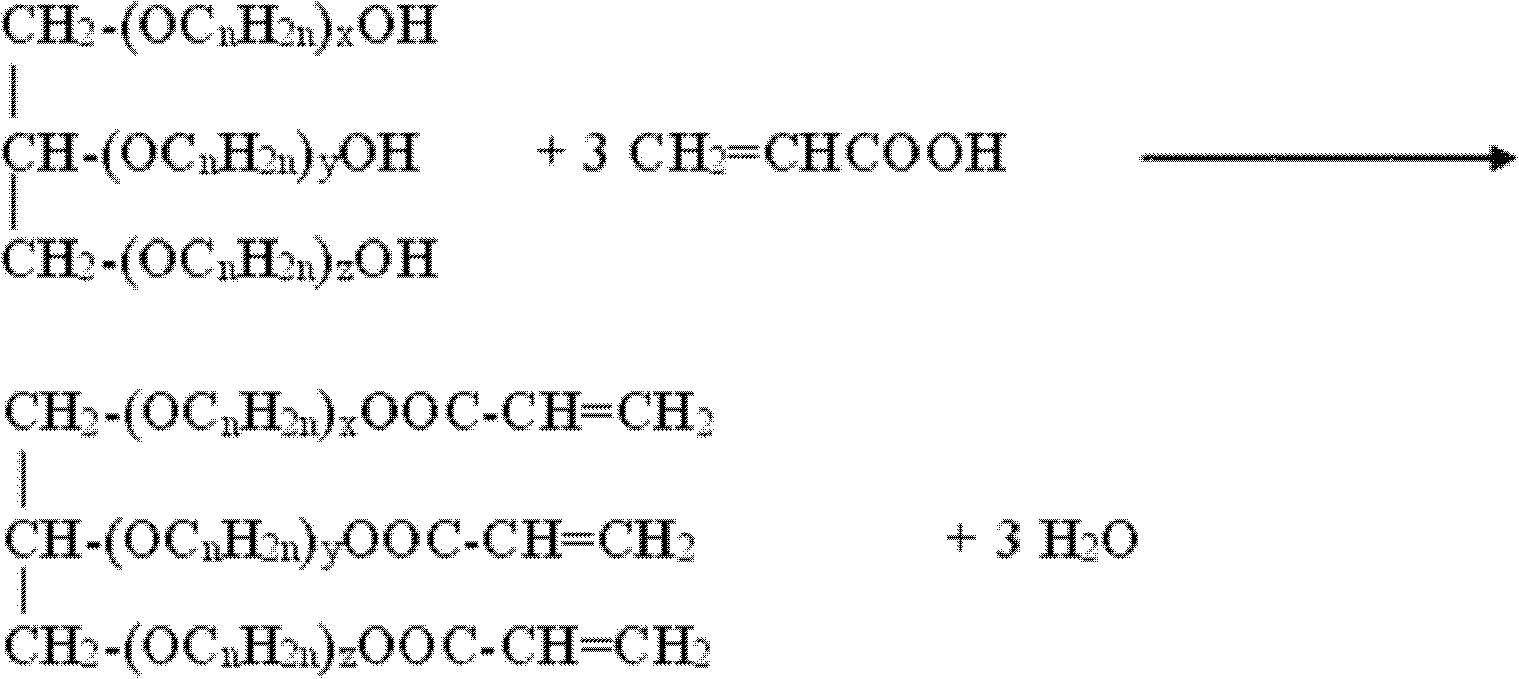

Clean production method of alkoxylation glycerol triacrylate

ActiveCN102503821ANo emissionsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSodium BentoniteAntioxidant

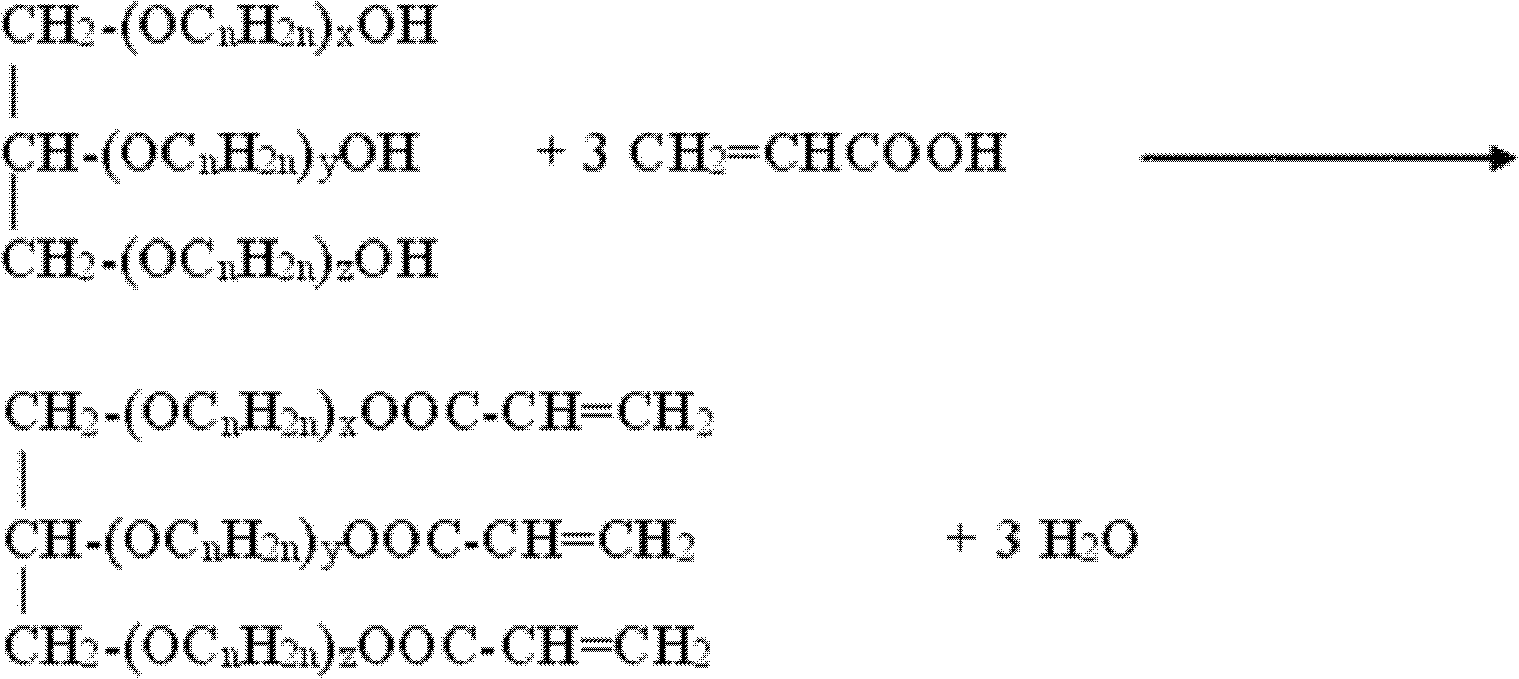

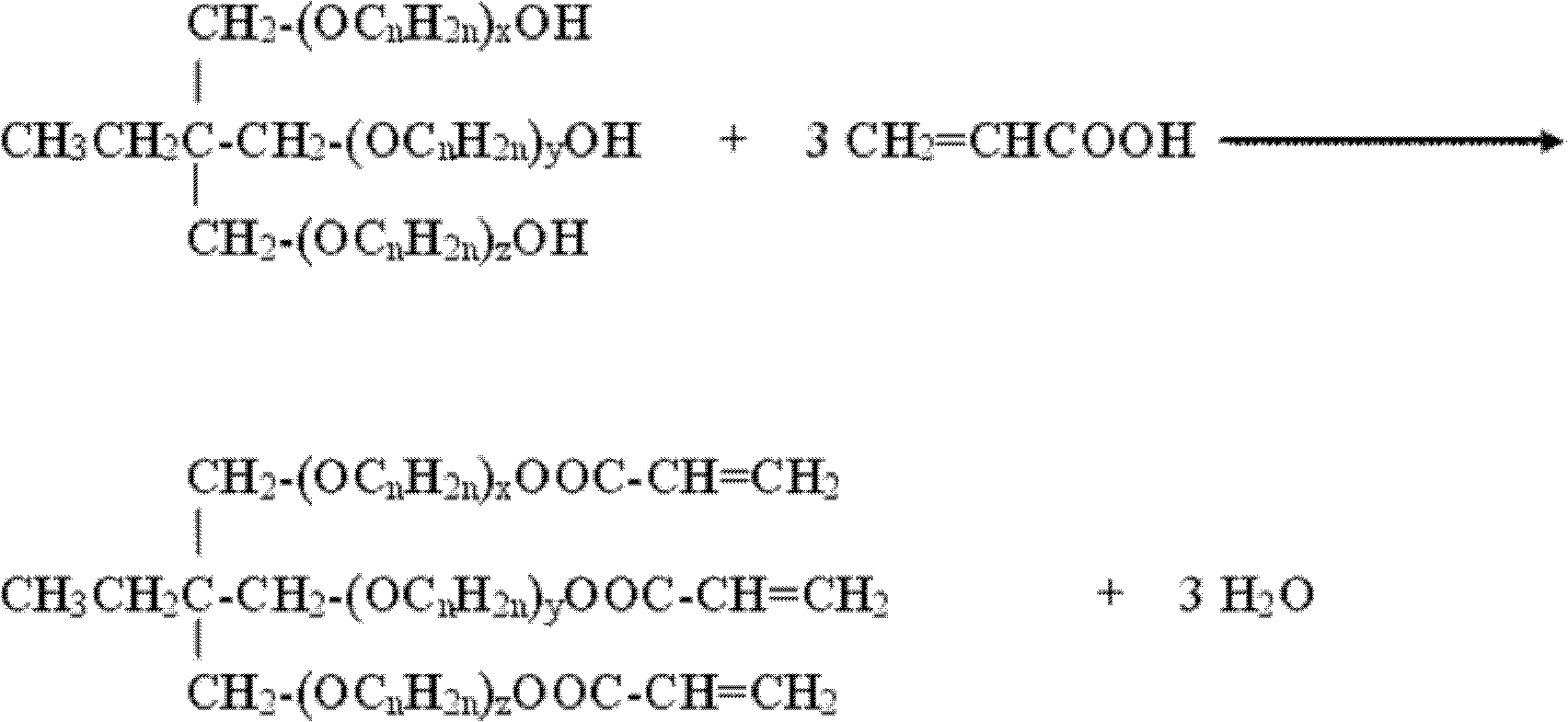

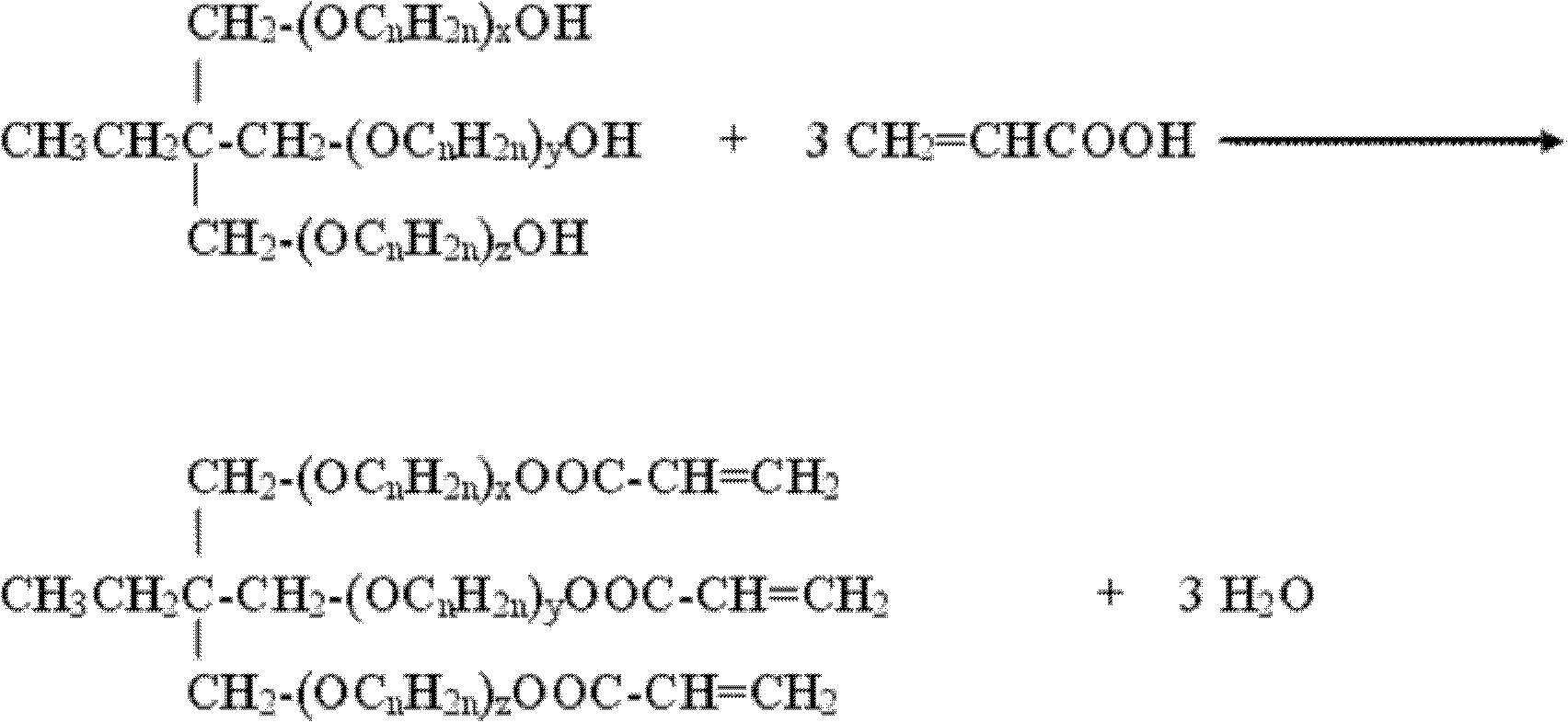

The invention belongs to the field of photocuring materials and relates to a clean production method of alkoxylation glycerol triacrylate. The method comprises the following steps that: (1) ethoxylation glycerol / propoxylation glycerol, acrylic acid, catalysts, solvents, polymerization inhibitors and antioxidants are subjected to esterification backflow dehydration; (2) soda flakes and a small quantity of water are added for neutralization; (3) magnesium polysilicate absorbing agents are added for absorbing salt generated during the neutralization; (4) the pressure reduction dehydration is carried out, and solvents are removed; (5) press filtering is carried out, and the magnesium polysilicate and the salt absorbed by the magnesium polysilicate are filtered away; (6) alkaline calcium bentonite and calcium bentonite are added, and decoloration, trace moisture removal and trace acid removal are carried out; (7) press filtering is carried out; and (8) product index detection is carried out. The method belongs to the high-yield clean production method of the ethoxylation glycerol triacrylate and propoxylation glycerol triacrylate and has the advantages that economic benefits and environment benefits are realized, and the problem of organic waste water pollution in the production process of the ethoxylation glycerol triacrylate and the propoxylation glycerol triacrylate is fundamentally solved.

Owner:JIANGSU LITIAN TECH

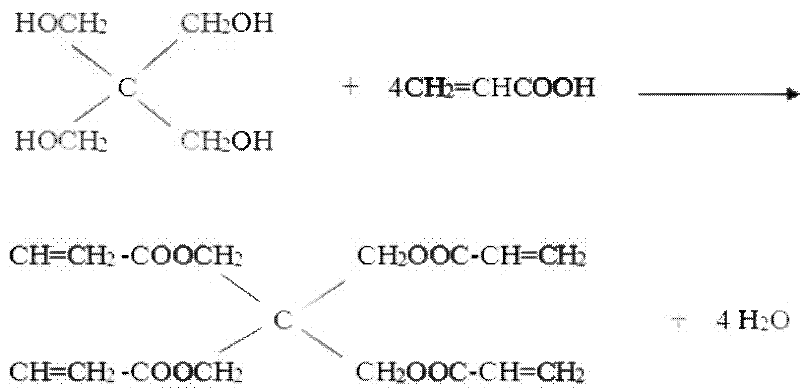

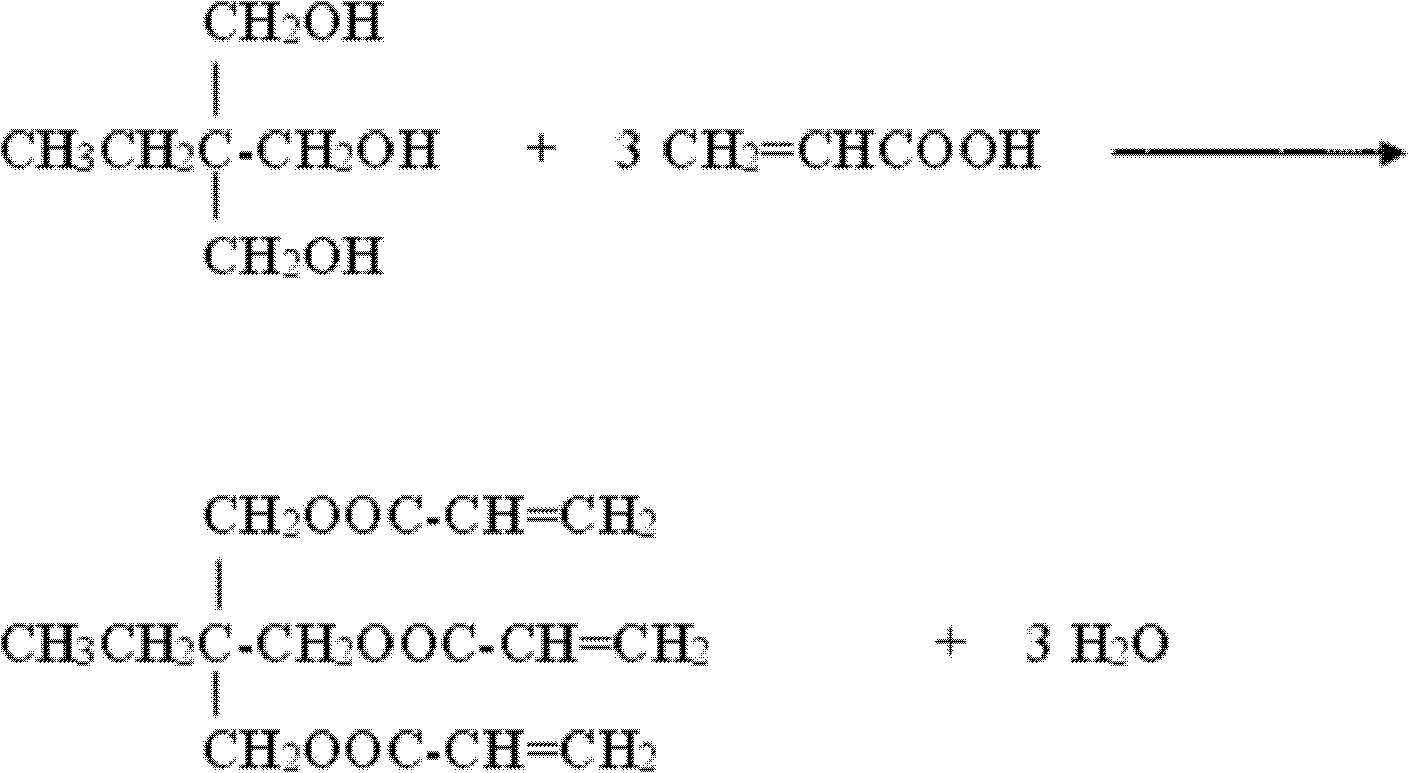

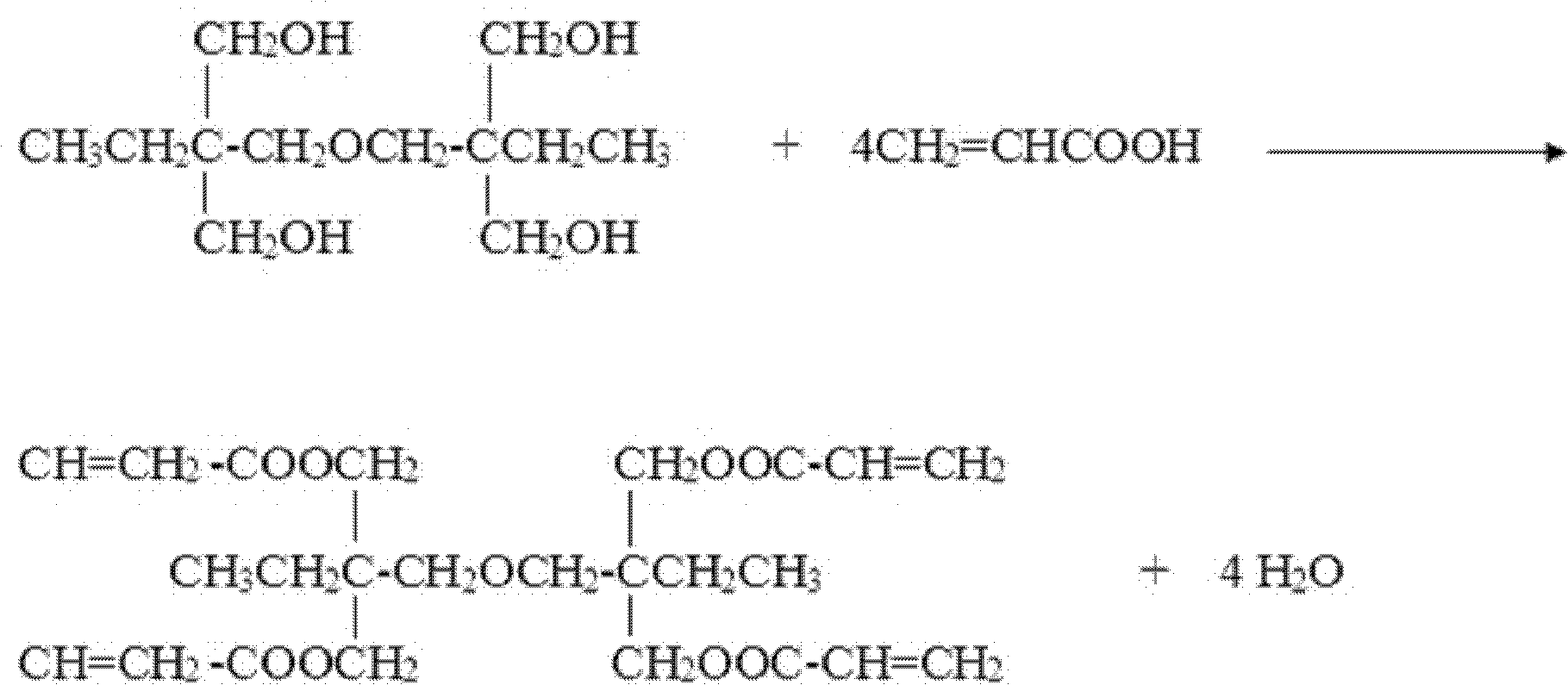

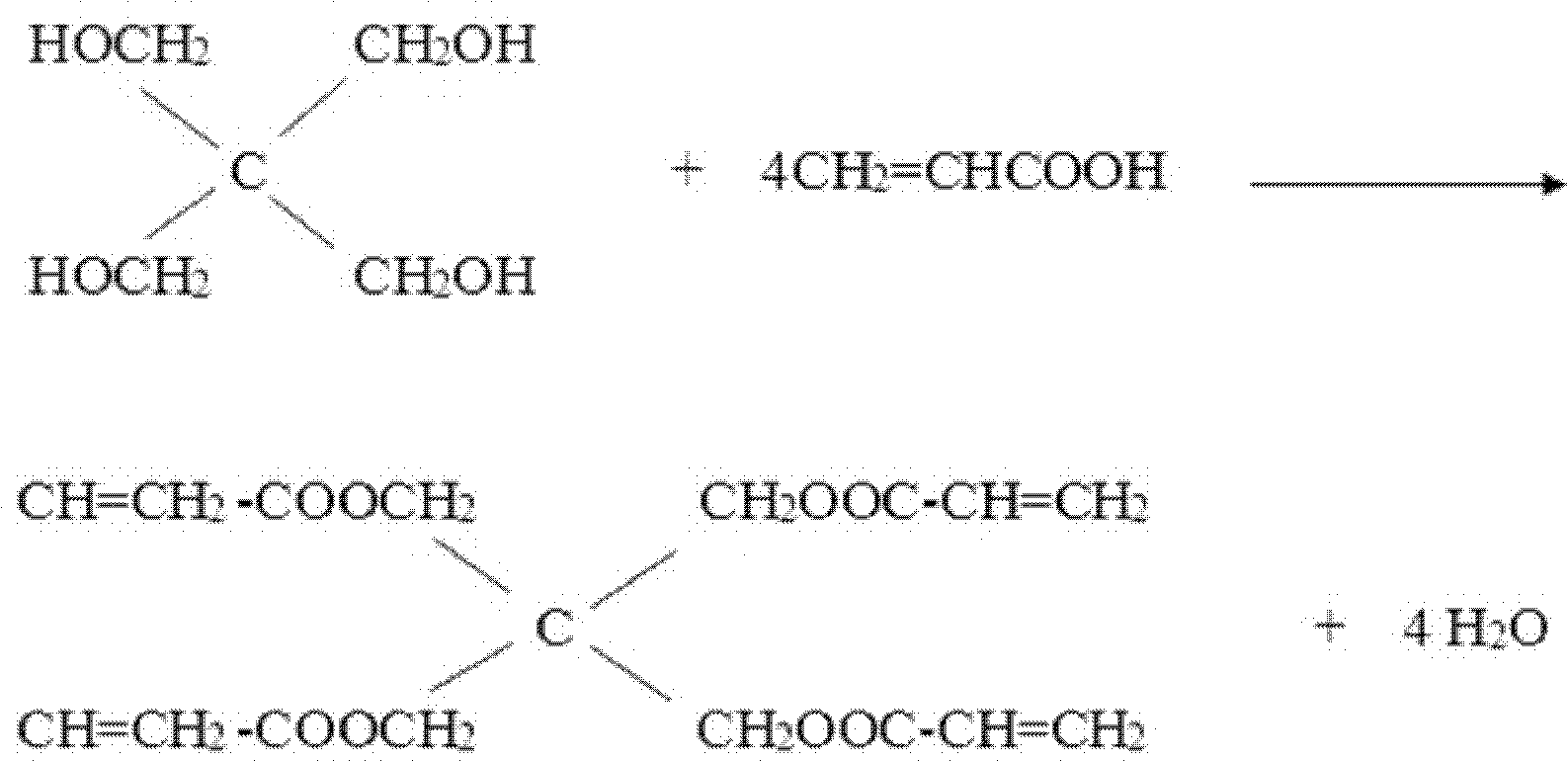

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSorbentSolvent

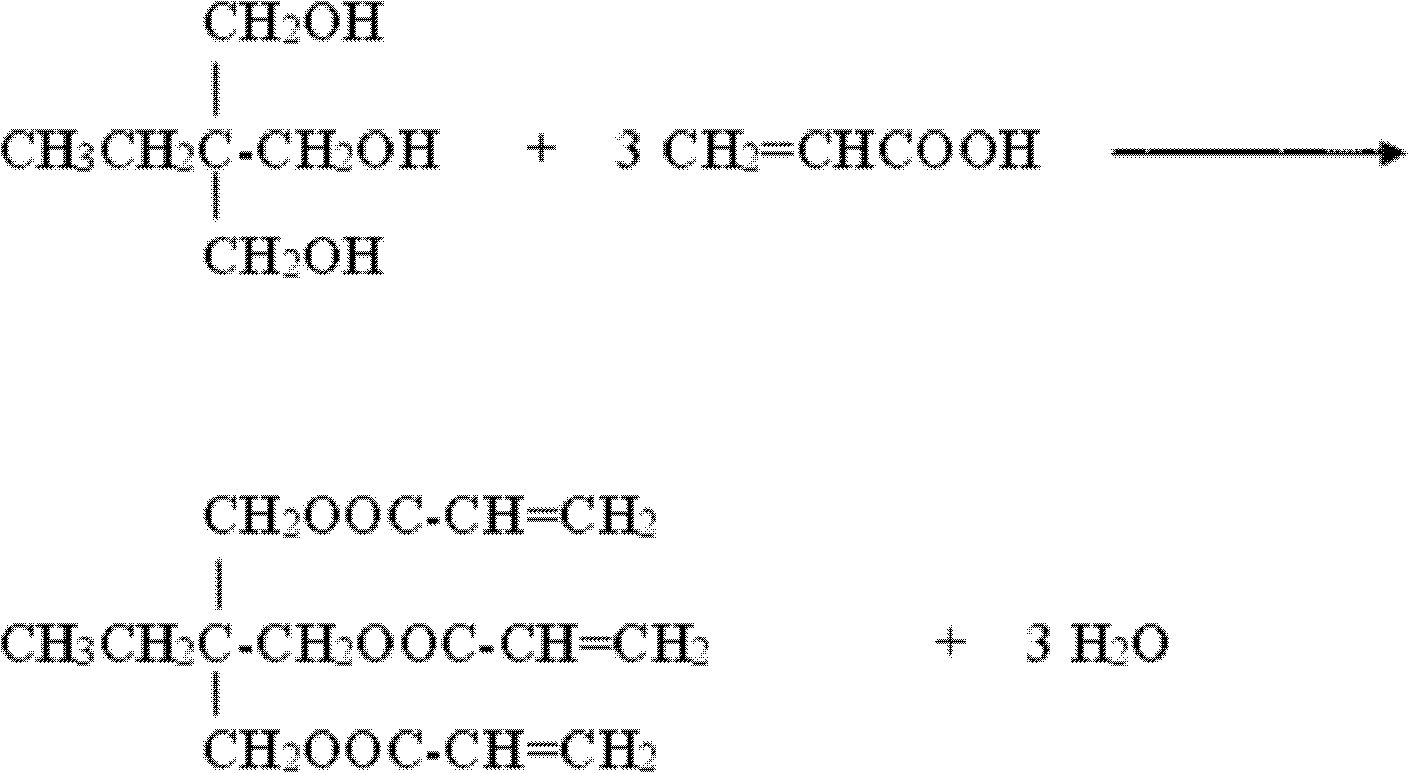

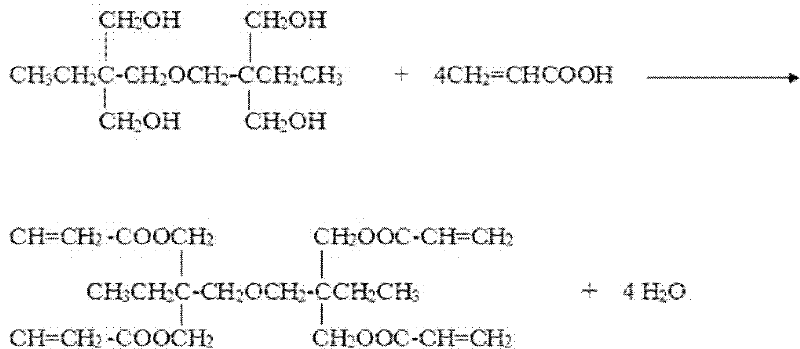

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

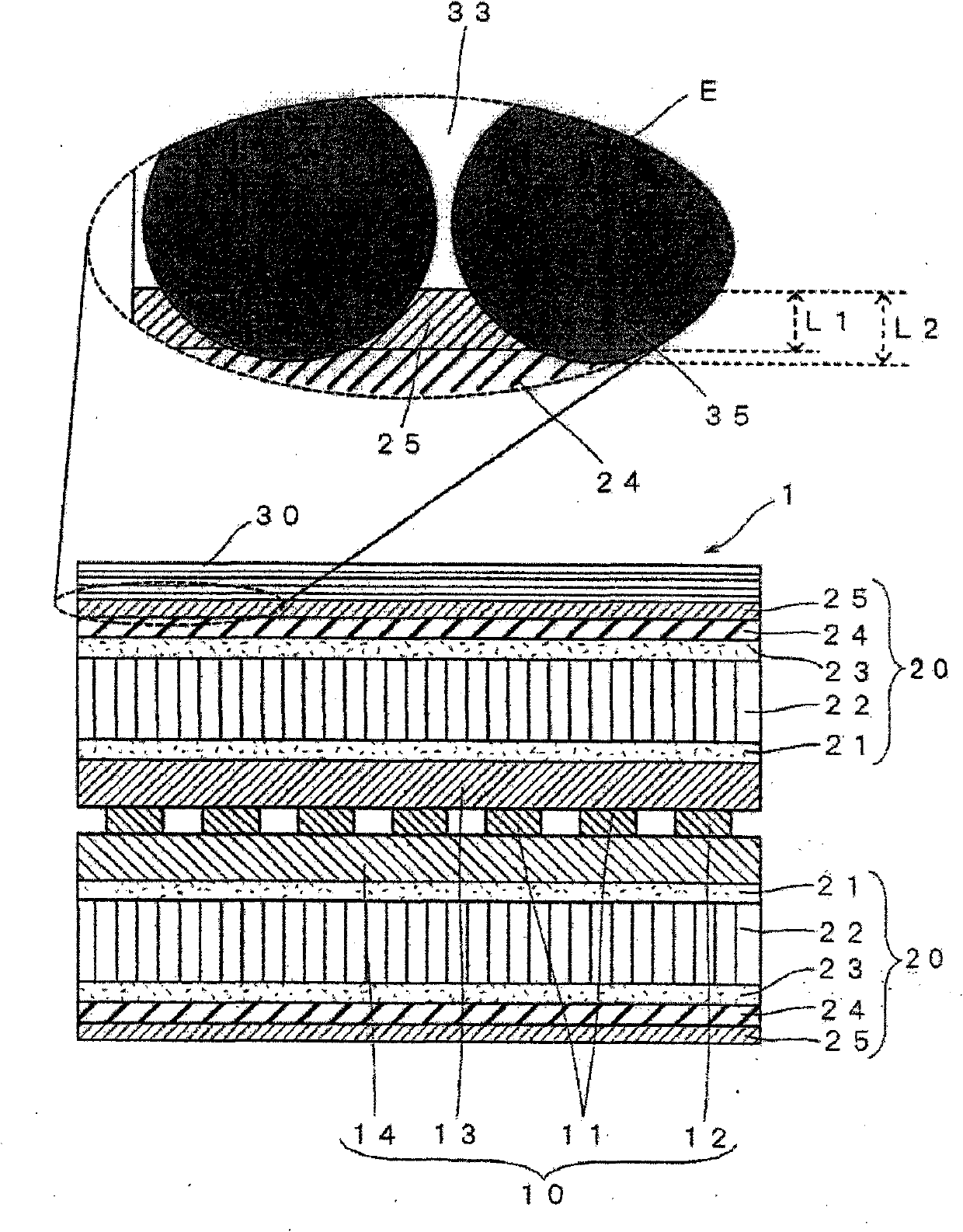

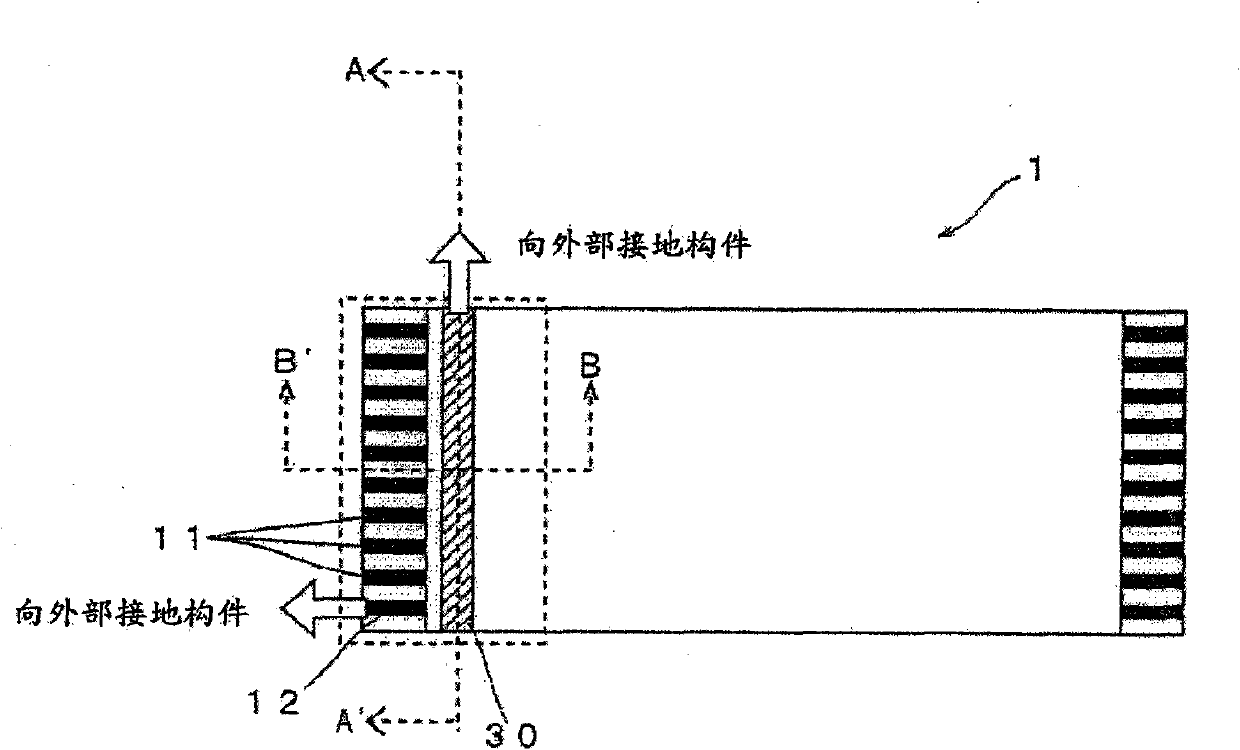

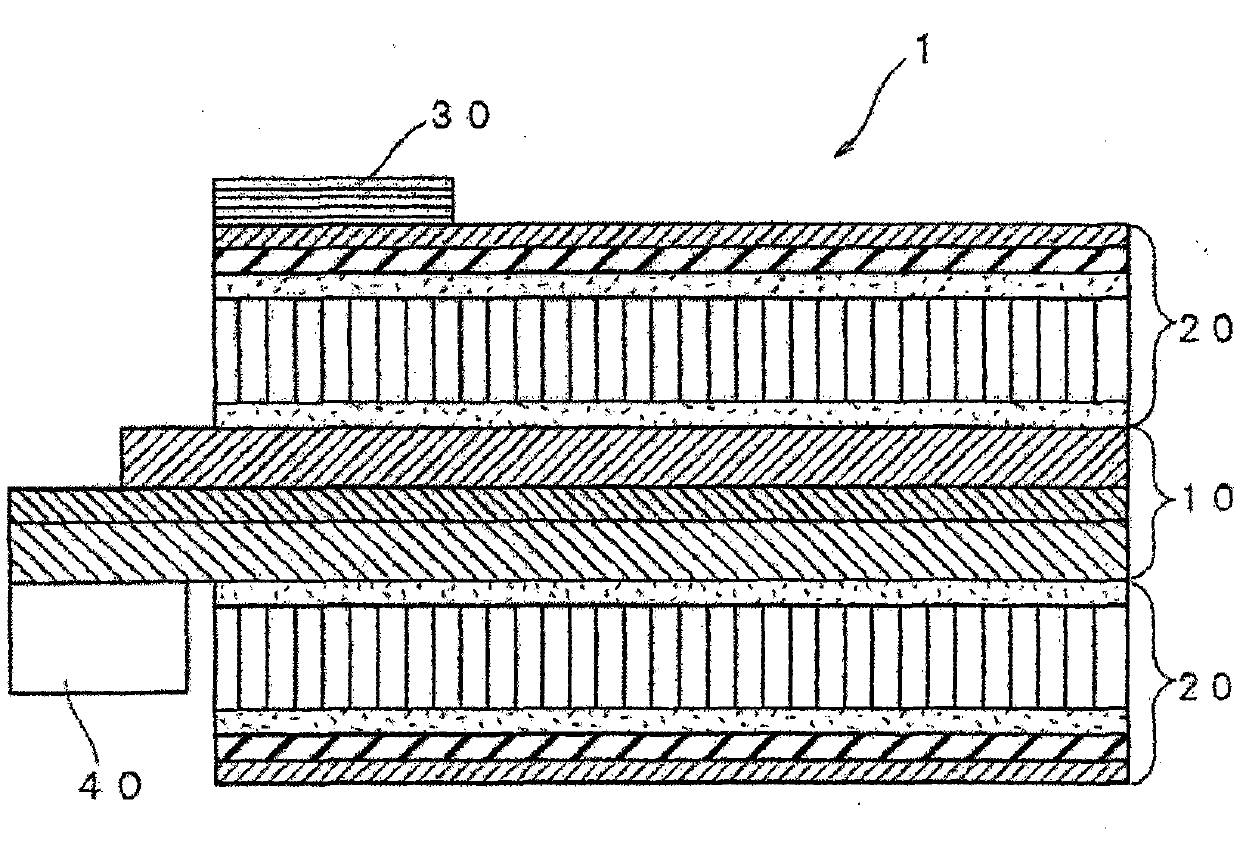

Shielding film, shielding distribution board having the same and grounding method thereof

InactiveCN102026529ANo processing costsMagnetic/electric field screeningFlat/ribbon cablesElectrical conductorLayer thickness

The invention discloses a shielding film which prevents the grounding conductor of the substrate being the adhering object of the shielding film from revealing and facilitates the grounding, a shielding distribution board which uses the shielding film and possesses a shielding function and resistance control function through one step, and the grounding method of using the shielding film. The shielding film (20) which is connected to a conducting member (30) by means of heating and pressurization is composed by resin whose melting point is higher than the heating temperature. The shielding film (10) comprises a covering film (25) which forms a layer thickness (L1) that is thinner than the average protruding length (L2) of the conducive particle (35) protruding from a conductive bonding layer (33), a metal film layer (24) which stacks on the covering film (25) in order and a bonding layer (23).

Owner:TATSUTA ELECTRICWIRE & CABLE

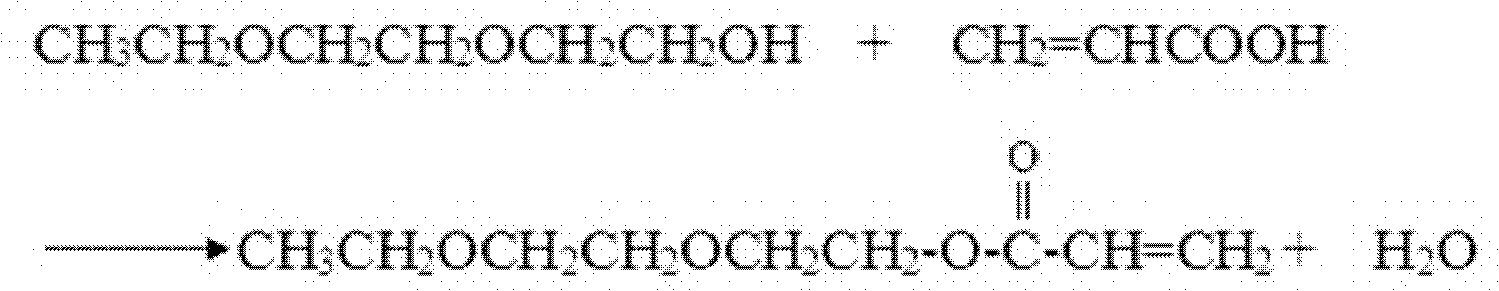

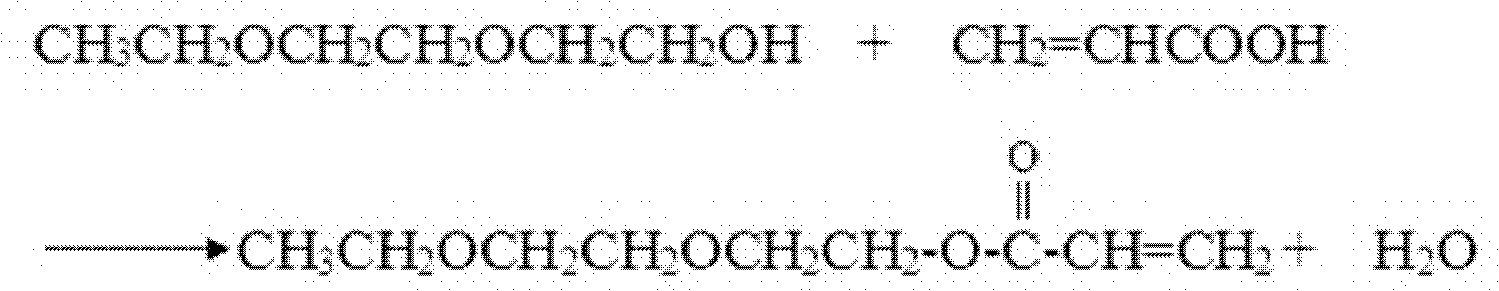

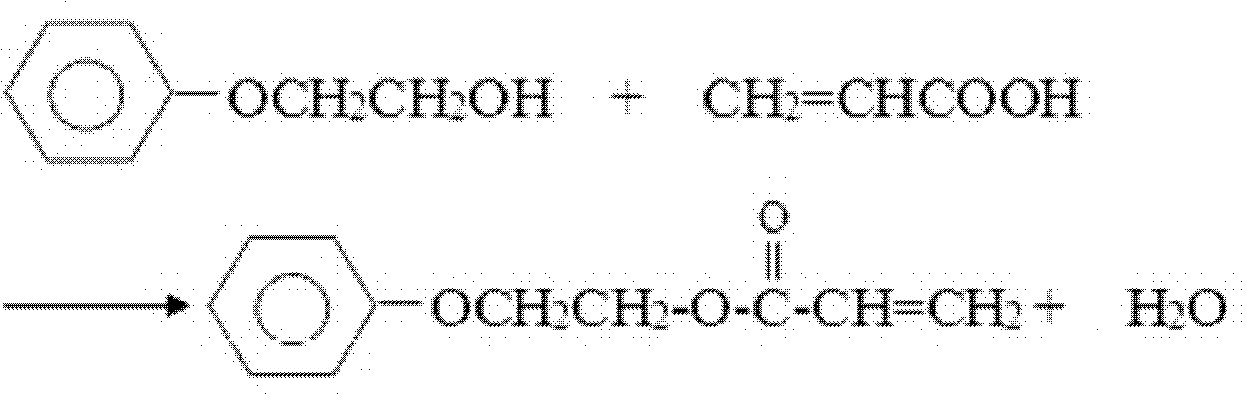

Cleaning production method of 2-(Ethoxyethoxy) ethyl acrylate (EOEOEA) or phenoxyethyl acrylate (PHEA)

ActiveCN102633634ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationSodium BentonitePhenyl Ethers

The invention belongs to the field of photocuring materials and relates to a cleaning production method of 2-(Ethoxyethoxy) ethyl acrylate (EOEOEA) or phenoxyethyl acrylate (PHEA). The method comprises the following steps: (1) carrying out esterification, backflow and dehydration on diethylene Glycol monoethylether or ethylene glycol phenyl ether, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; (2) adding caustic soda flakes and little water for neutralization; (3) adding a polymagnesium silicate adsorbent for adsorbing and neutralizing the generated salt; (4) reducing pressure for dehydration and removing the solvent; (5) carrying out filter pressing so as to filter polymagnesium silicate and the salt adsorbed by polymagnesium silicate; (6) adding alkaline Ca-based bentonite and calcium oxide for decoloration, micro water removal and trace acid removal; (7) carrying out filter pressing; and (8) detecting product indexes. The cleaning production method disclosed by the invention has high yield and social and environmental benefits, thus thoroughly solving the organic waste water pollution problem during the production process of EOEOEA or PHEA.

Owner:JIANGSU LITIAN TECH

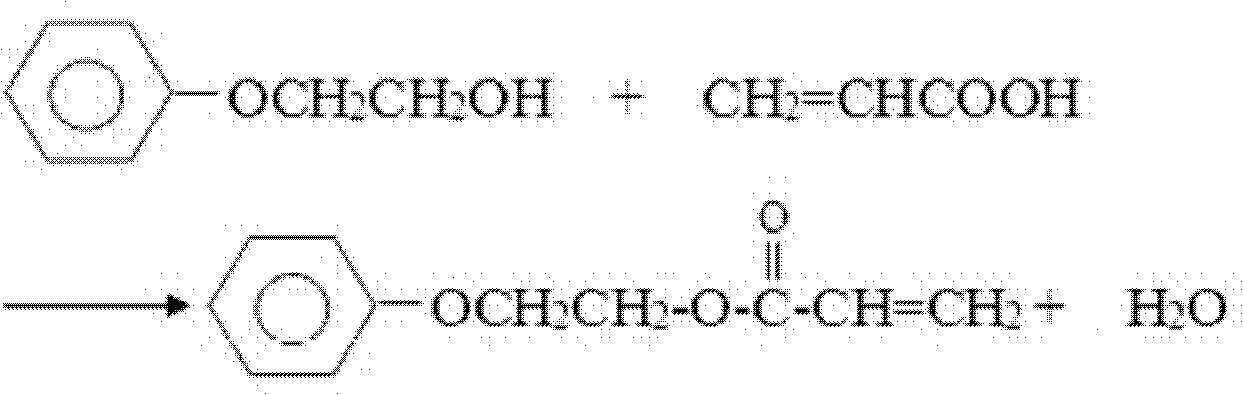

Method for embedding thin plate metallographic sample

InactiveCN106769317ALow costLess consumablesPreparing sample for investigationSmooth surfaceEngineering

The invention discloses a method for embedding a thin plate metallographic sample. The method comprises the following steps: binding a thin plate test sample to an old test sample, which is higher than the thin plate test sample, through an adhesive tape or glue; putting the overall bound test samples into a hot embedding machine, and feeding a proper amount of embedding resin for sample embedding. According to the method, the thin plate test sample with a flat smooth surface can be successfully embedded; meanwhile, the method is low in cost and easy to operate.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Energy-saving recovery technology of 3-dimethylaminopropylamine (DMAPA)

InactiveCN103073433AReduce energy consumptionEasy to manufactureAmino compound purification/separationRelative pressureDistillation

The invention relates to an energy-saving recovery technology of DMAPA. The technology has the characteristics of energy consumption reduction, environmental protection benefiting, easy equipment making, and low production cost. A technical scheme adopted in the invention is characterized in that the energy-saving recovery technology of the DMAPA sequentially comprises the following steps: 1, allowing a DMAPA-water mixed solution from a condenser to enter a separator through a pipeline, adding a water removal agent through a feed inlet, stirring, and allowing the obtained mixture to stand for layering, wherein the addition amount of the water removal agent is 10-90% of the weight of the DMAPA-water mixed solution; 2, conveying the supernatant obtained in step 1 to a distillation kettle through a pipeline, carrying out reduced pressure distillation at a temperature of 60-140DEG C under a relative pressure of 0MPa - -0.085MPa, and collecting the obtained distillation condensate which is the DMAPA; and 3, discharging the lower-layer liquid obtained in step 1 from the material outlet at the bottom of the separator, wherein the lower-layer liquid is the aqueous solution of the water removal agent.

Owner:ZANYU TECH GRP CO LTD +1

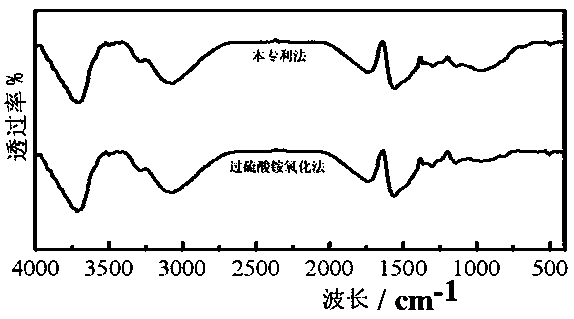

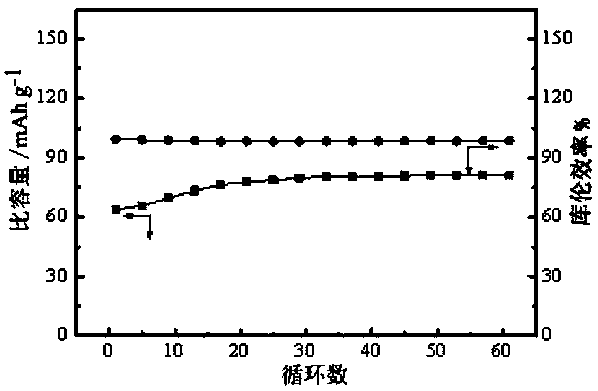

Synthetic method of polyaniline

InactiveCN109824891AReduce manufacturing costShorten the incubation periodEnvironmental resistanceAniline

The invention relates to the technical field of polyaniline, in particular to a low-price environmental-friendly synthetic technique of polyaniline. The synthetic technique herein comprises mixing a mixed solution of aniline and hydrochloric acid and a saline solution with ferrous ions, and adding hydrogen peroxide solution to obtain a mixed system; introducing air to the mixed system, and allowing to react under stirring; washing with reacted solid with water, and drying to obtain polyaniline. The method herein can provide low-price green synthesis of polyaniline; filtrate and washing water are reused for synthesis of polyaniline during synthesis, no environmental pollution is caused, wastewater treatment cost is avoided, and polyaniline production cost is greatly reduced.

Owner:扬州大学广陵学院

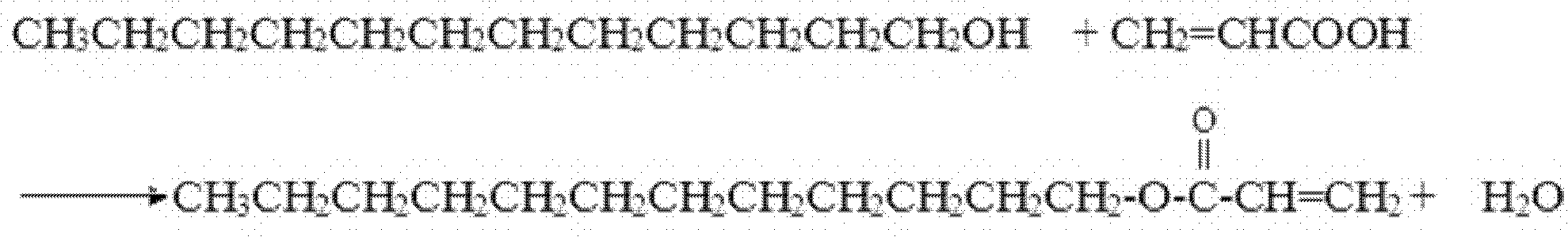

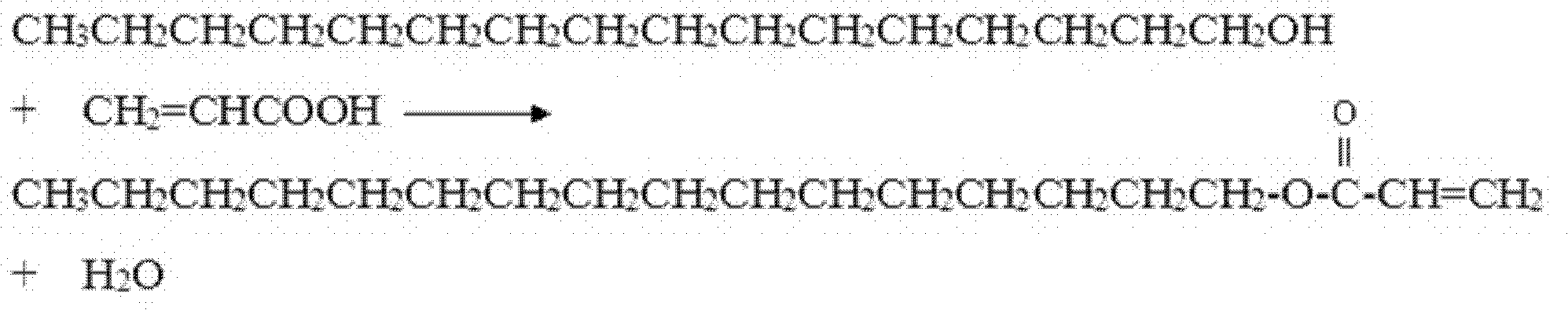

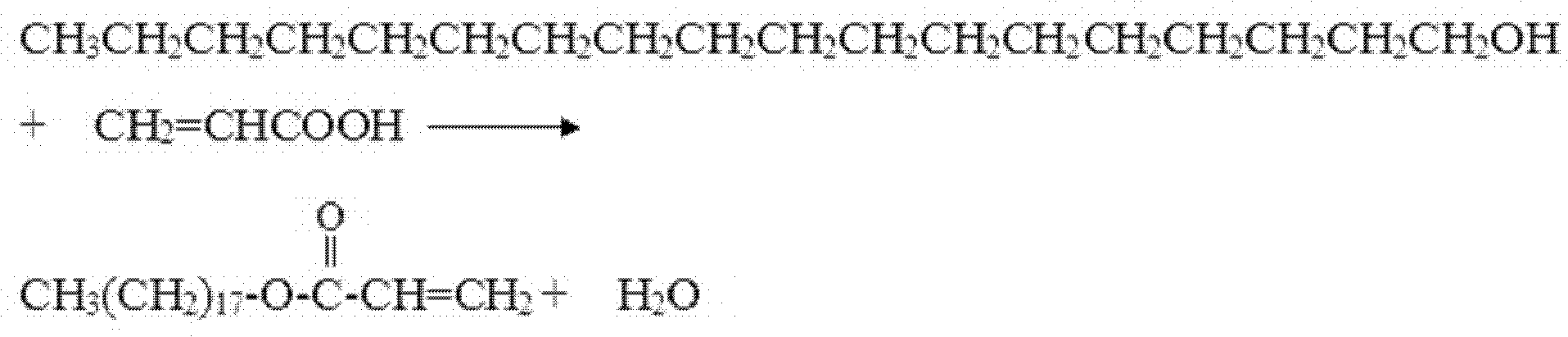

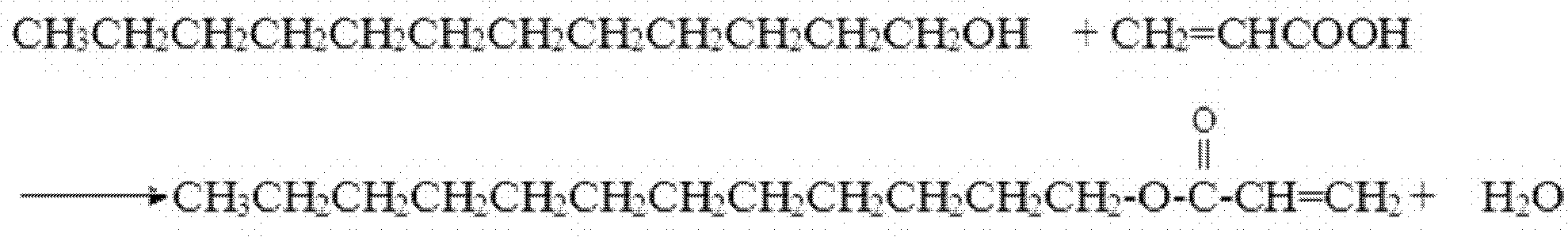

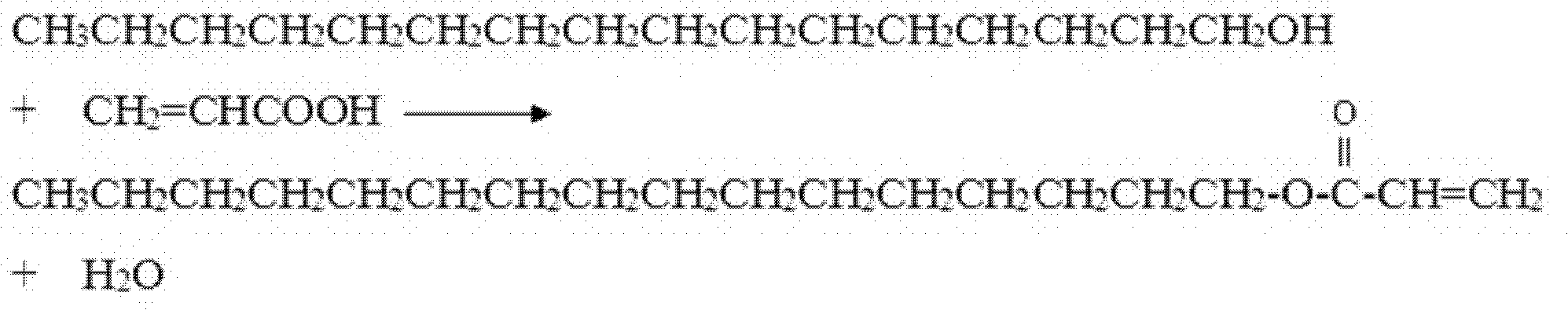

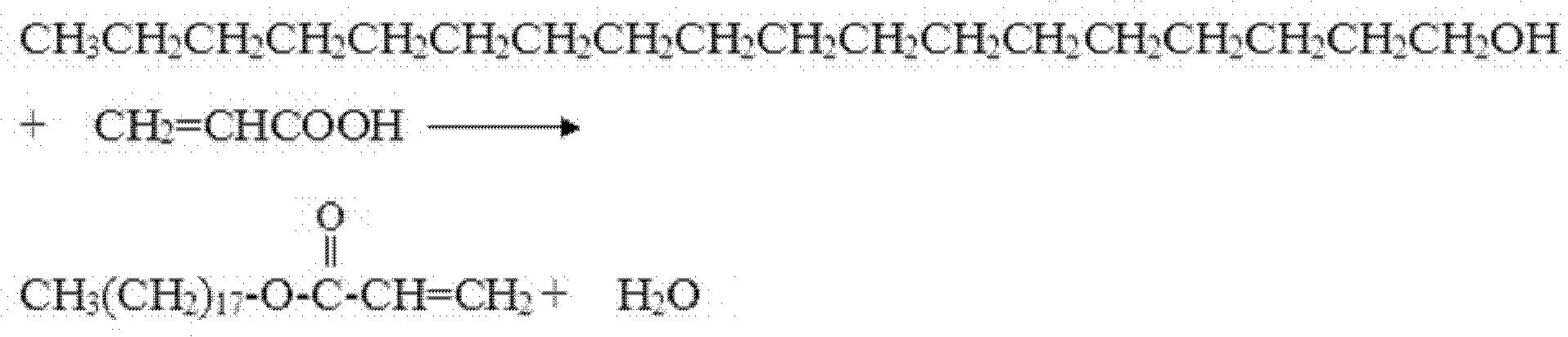

Pollution-free production method of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate

ActiveCN102633633ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationSorbentAntioxidant

The invention belongs to the field of photo-curing materials, and relates to a pollution-free production method of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate. The production method comprises the specific steps as follows: (1) carrying out esterification, refluxing and dehydration on lauryl alcohol / hexadecanol / stearyl alcohol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; (2) adding flake caustic soda and a small amount of water for neutralizing; (3) adding magnesium silicate adsorbent to adsorb salt generated by neutralizing; (4) decompressing to dehydrate and desolventize; (5) carrying out filter pressing to filter out magnesium silicate and the adsorbed salt; (6) adding alkaline Ca-bentonite and calcium oxide for decolouring, and removing trace water and acid; (7) carrying out filter pressing; and (8) detecting the product index. The invention provides the pollution-free production method of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate, which has high yield as well as economic and environmental benefits, and fundamentally solves the problem of organic wastewater pollution in the production process of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate.

Owner:JIANGSU LITIAN TECH

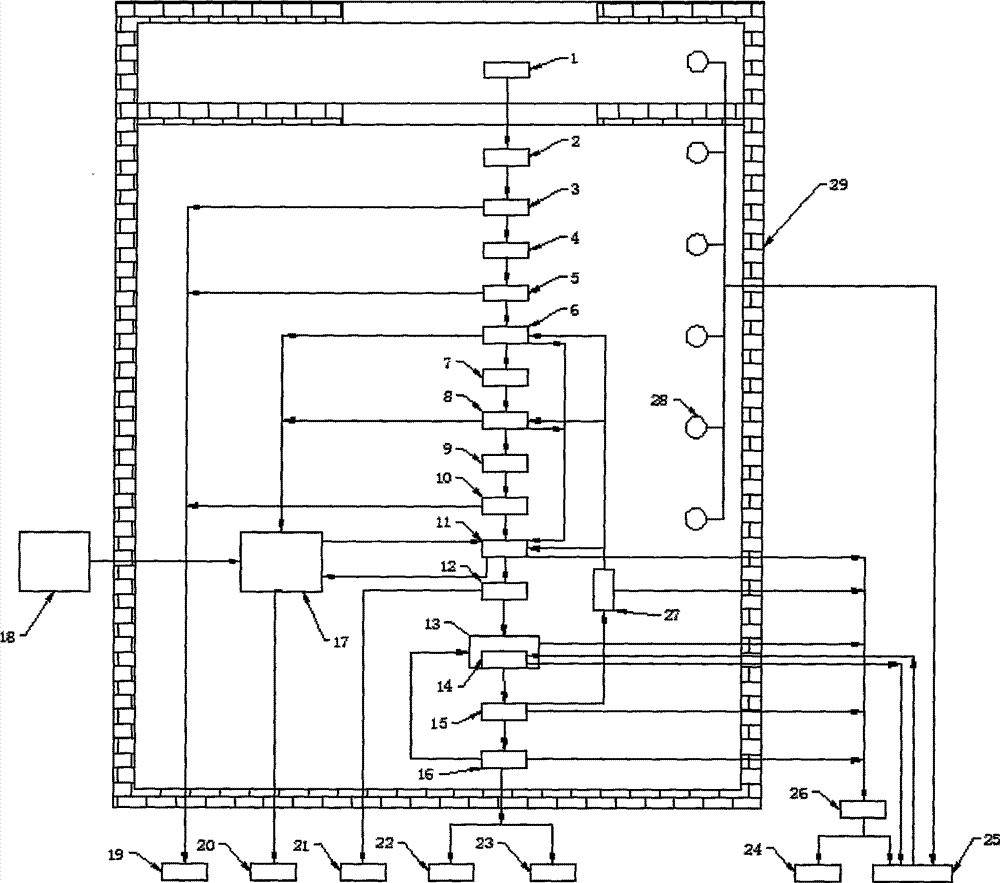

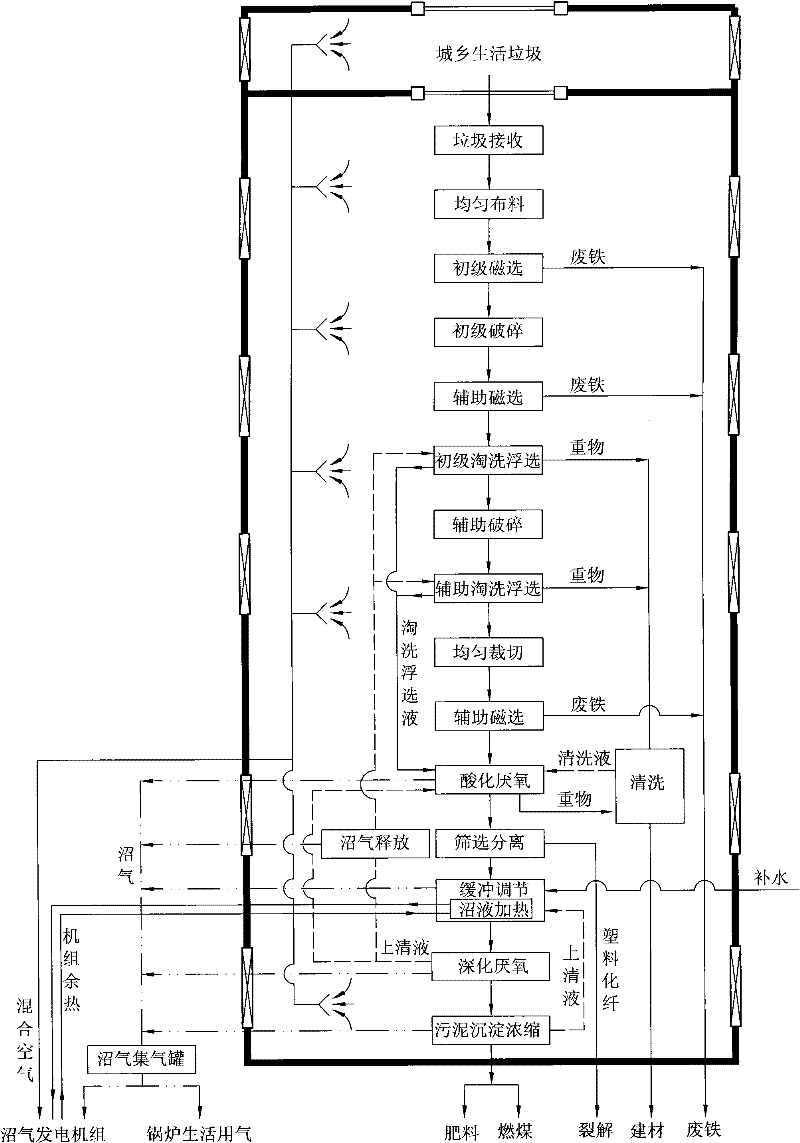

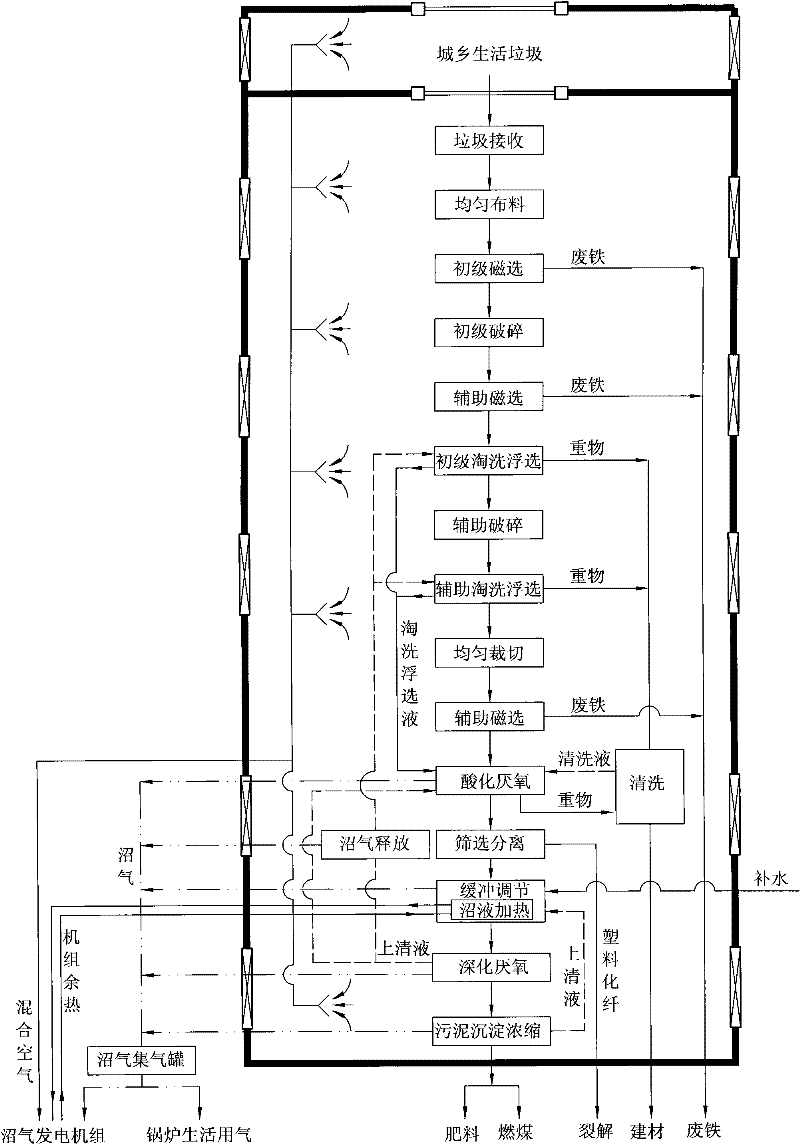

Household garbage integrated treatment and resource utilization environmental protection system

InactiveCN104259176ANot dischargedOvercoming the biggest bottleneckBio-organic fraction processingSolid waste disposalFiberResource utilization

The invention discloses a household garbage integrated treatment and resource utilization environmental protection system which comprises a garbage bin, a uniform feeding device, a first-stage magnetic separator, a first-stage crusher, a second-stage magnetic separator, a primary treating pond, a second-stage crusher, a second-stage treating pond, a punching cutting machine, a third-stage magnetic separator, an acidification anaerobic tank, screening equipment, a buffer regulating tank, a deep anaerobic tank and a sludge settling tank which are sequentially arranged in an equipment room. According to the household garbage integrated treatment and resource utilization environmental protection system, no garbage sorting is needed, the garbage sorting and screening are performed in the whole process of garbage utilization, the great bottleneck of restraining the garbage treatment is overcome, and the practicability is relatively strong; the treatment cost is not increased, the huge economic benefit can be obtained; the serialization of treating garbage by using an anaerobic method can be achieved, the treatment amount is relatively large; the problem that non-anaerobic garbage such as waste plastics and waste chemical fibers in the garbage can not be recycled is thoroughly solved, so that resources in the garbage are completely recycled.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Straw biomass fiber-plastic composite material

The invention relates to the technical field of resource utilization of waste textiles and fiber-reinforced composite materials, and discloses a straw biomass fiber-plastic composite material comprising organic straw biomass fibers, textile fibers, plastic and auxiliary materials, and formed by compounding the components in percentage by weight: 40%-60% of the total fibers, 25%-45% of the total plastic, and the balance being the auxiliary materials. Through a specific formula, the optimal composite state of the textile fibers and the plastics is realized, and the composite material has better strength and hardness.

Owner:上海纤苏新材料科技有限公司

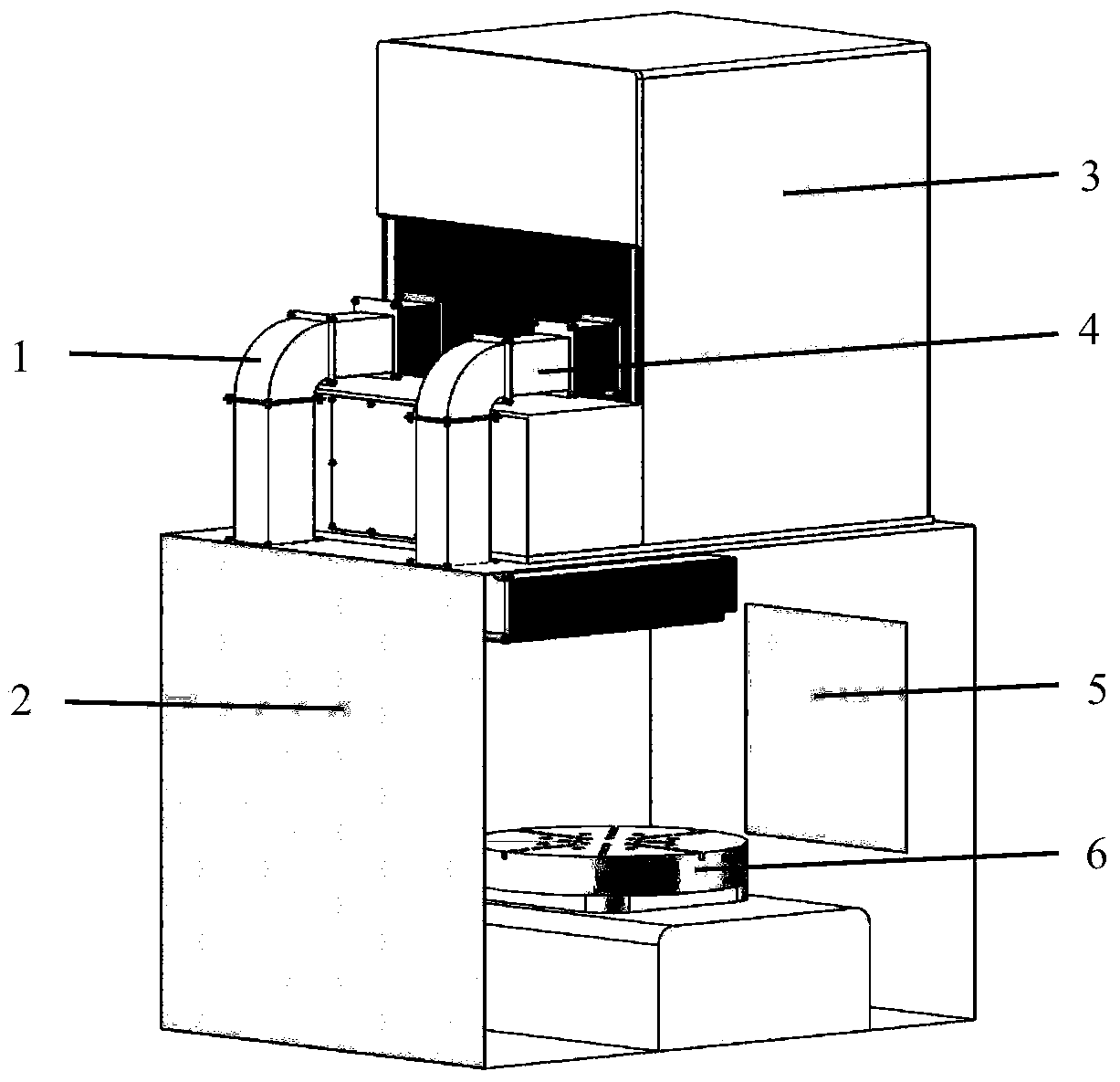

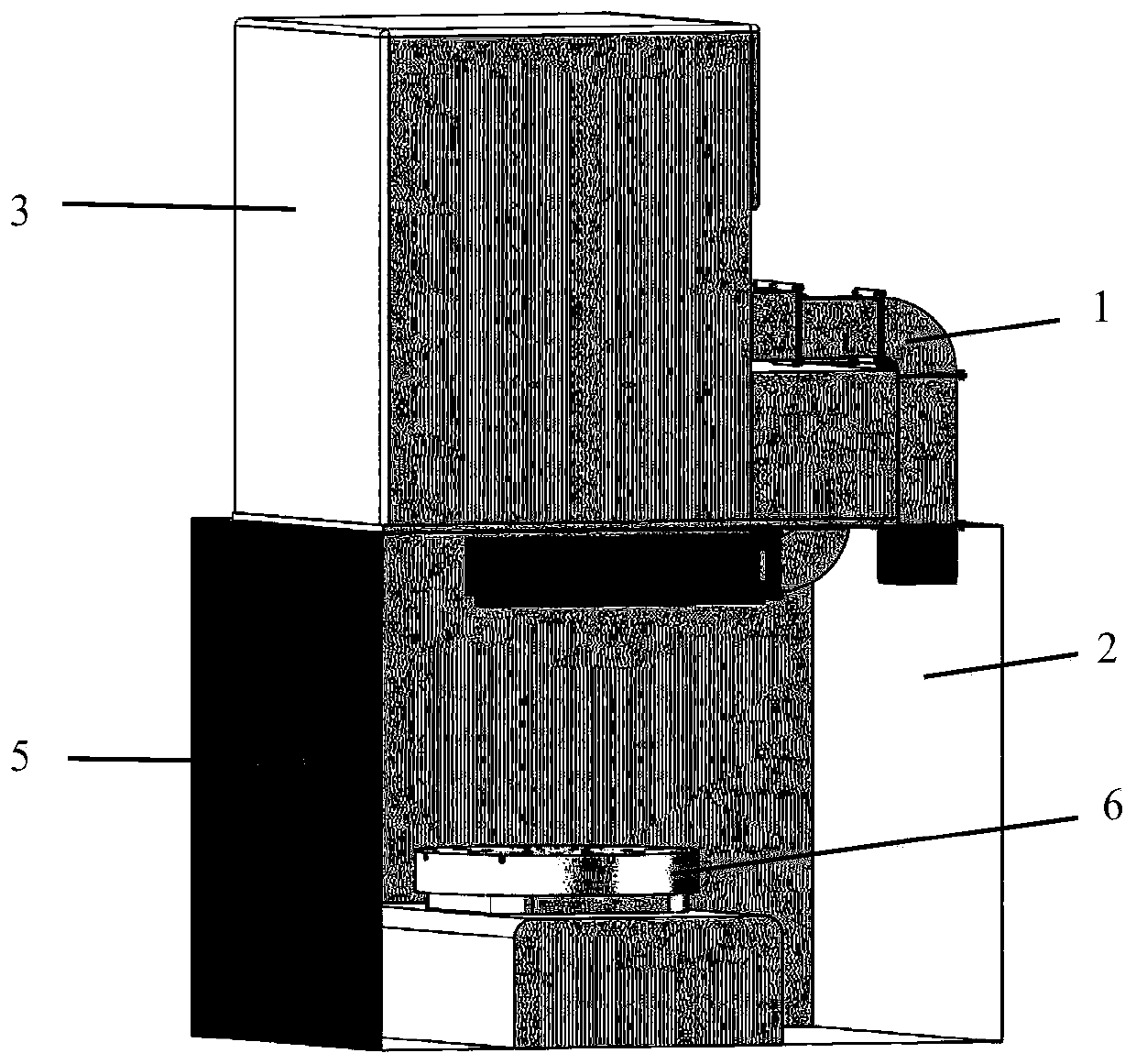

Method and device for reducing oil mist leakage of airtight machining chamber

PendingCN111331421AReduce leakageImprove barrier propertiesDispersed particle filtrationCleaning using gasesNumerical controlMachine parts

The invention discloses a method and device for reducing oil mist leakage of an airtight machining chamber. After a tool inside the airtight machining chamber of a numerical control machine tool or aCNC machining center stops rotating, and before a part taking door is opened, a device with changeable volume is taken for use, the device with changeable volume is enlarged in volume to generate negative pressure inside so as to suck oil mist from the inside of the airtight machining chamber and stores the oil mist inside temporarily, and then less oil mist leaks out of the airtight machining chamber while the part taking door is open; and after a machined part in the airtight machining chamber is taken away, a worker places a raw material to be machined well, and the part taking door is closed, the device with the changeable volume discharges the oil mist stored inside out, the oil mist flows back into the airtight machining chamber, then the whole cycle of oil mist suction and backflowis completed, and it is implemented that the oil mist is transferred while the part taking door of the machining chamber is open. The device for reducing oil mist leakage of the airtight machining chamber is composed of an oil mist collection port, an oil mist collection pipe, an oil mist buffer, an oil mist backflow pipe and an oil mist backflow port. According to the method and device for reducing oil mist leakage of the airtight machining chamber, because the oil mist is temporarily transferred but not purified locally, and oil mist leakage while the part taking door of the machining chamber is open is reduced with relatively low cost.

Owner:TIANJIN UNIV

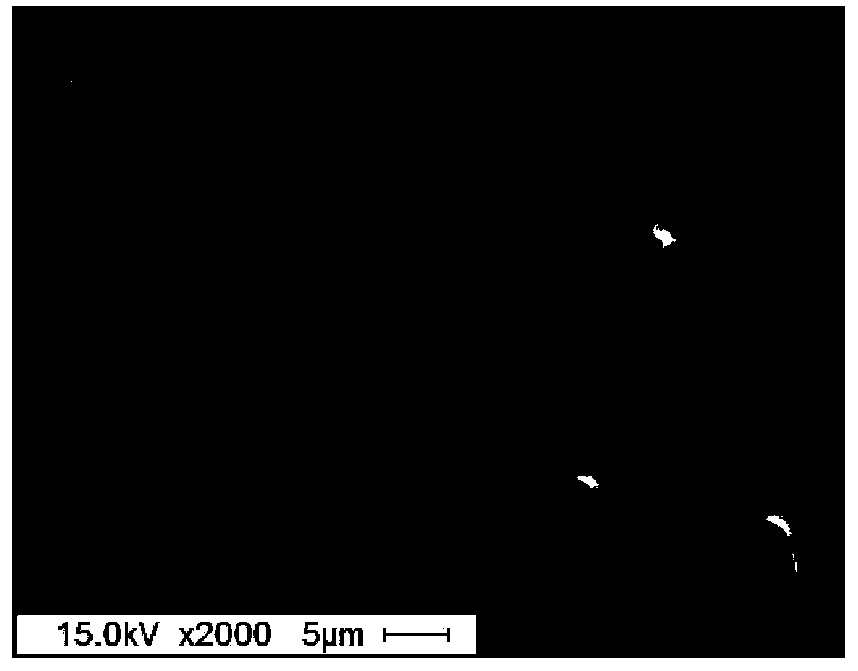

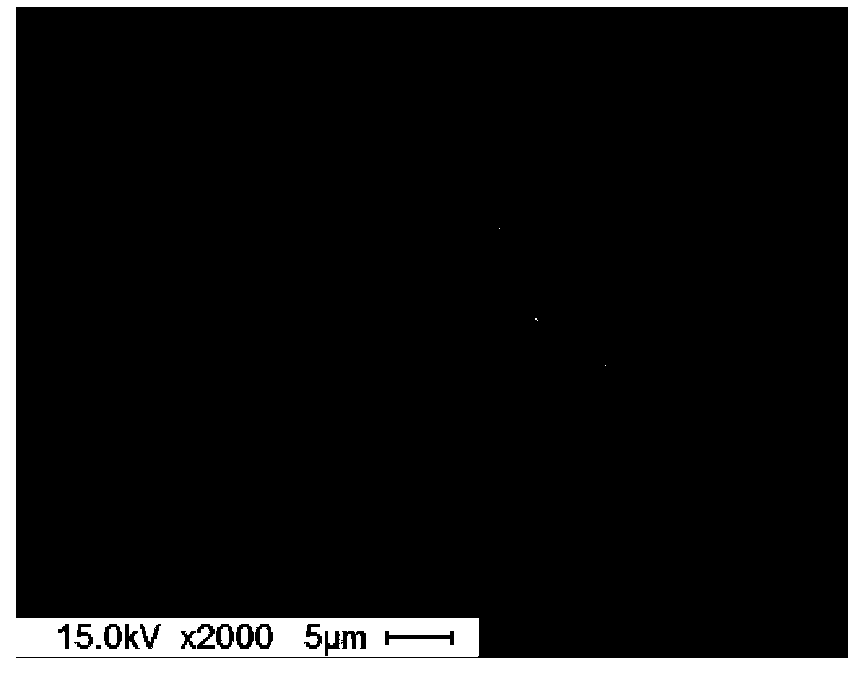

Sample preparation method for detecting particle size of blast furnace slag particles

PendingCN110987549AReduce sizeImprove distributionPreparing sample for investigationParticle size analysisSlagAdhesive

The invention discloses a sample preparation method for detecting the particle size of blast furnace slag particles. The method comprises the following steps: putting a small amount of blast furnace slag powder sample into absolute ethyl alcohol, carrying out ultrasonic oscillation for 10-15 minutes, taking a small amount of suspension, dripping the suspension on an auxiliary metal sample adheredwith a conductive carbon adhesive, standing, and blowing an ear washing ball after the sample is solidified and dried, so as to obtain a sample for detection and analysis by putting a scanning electron microscope. According to the sample preparation method, powder samples are dispersed, agglomeration of the powder samples is reduced, the actual particle size of powder is reduced, and therefore particle size analysis errors are reduced, and meanwhile, electron microscope dust pollution is reduced.

Owner:BAOTOU IRON & STEEL GRP

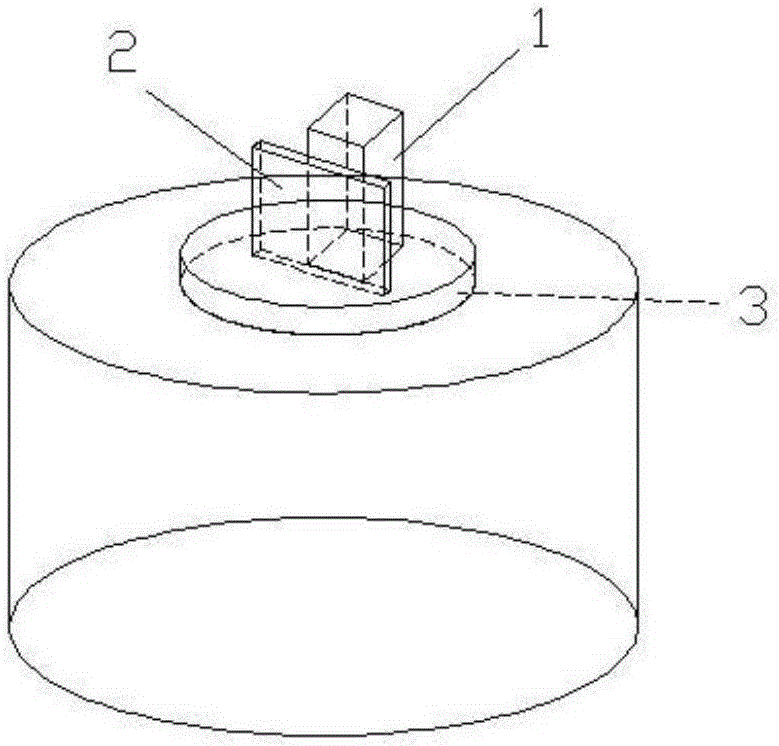

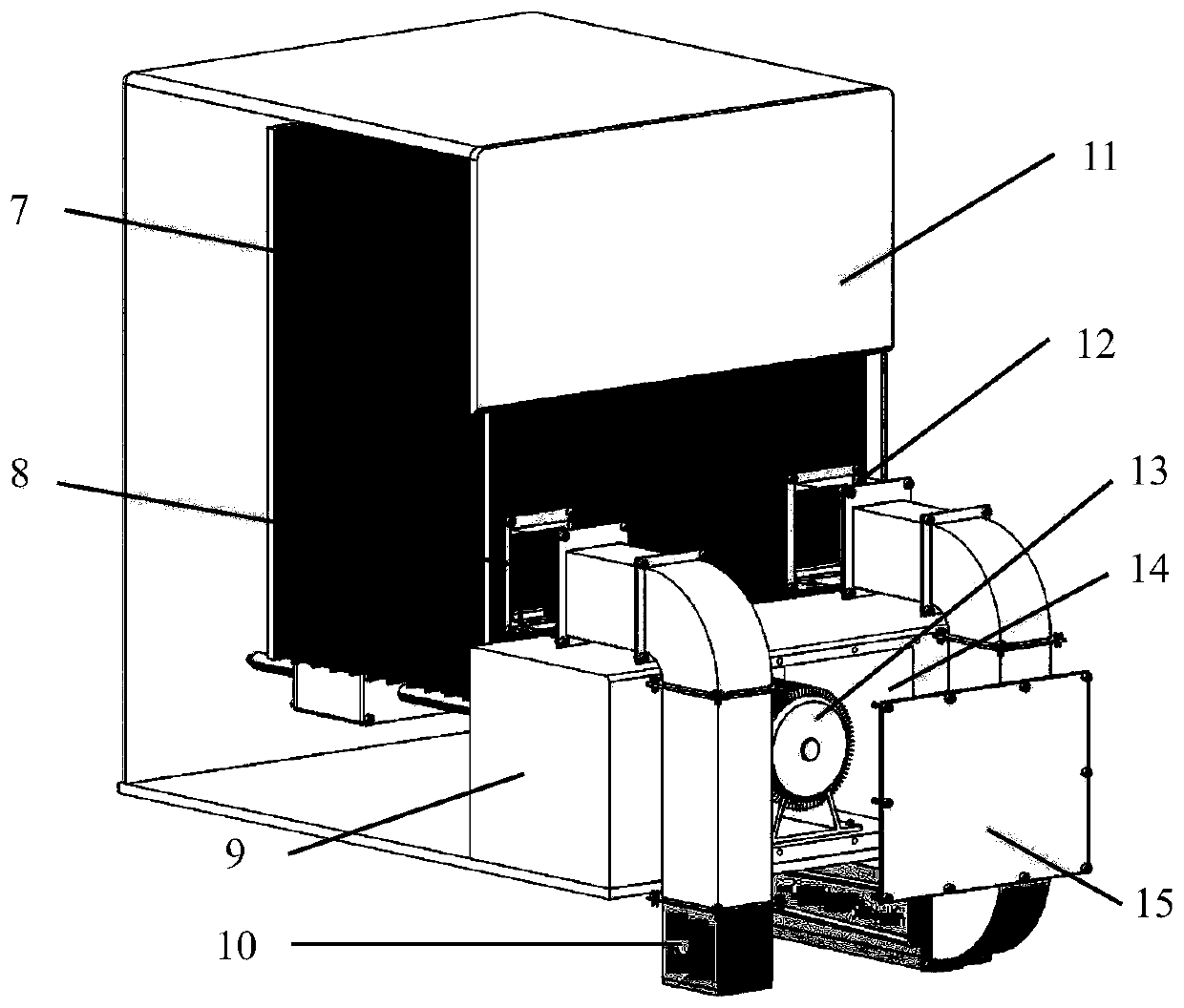

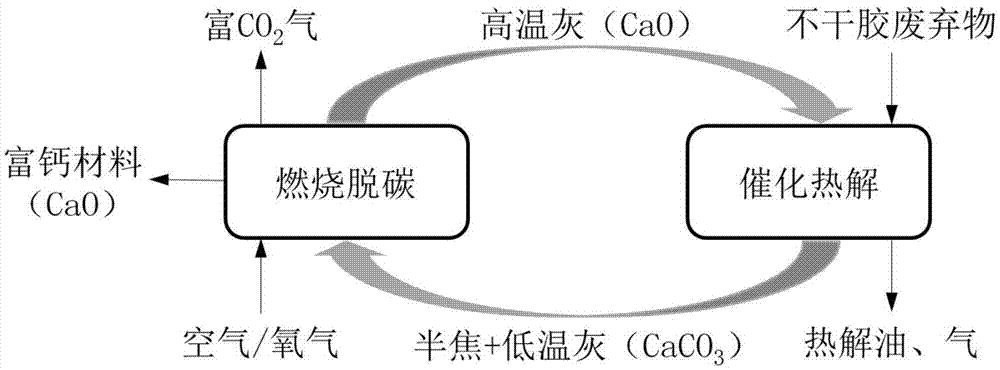

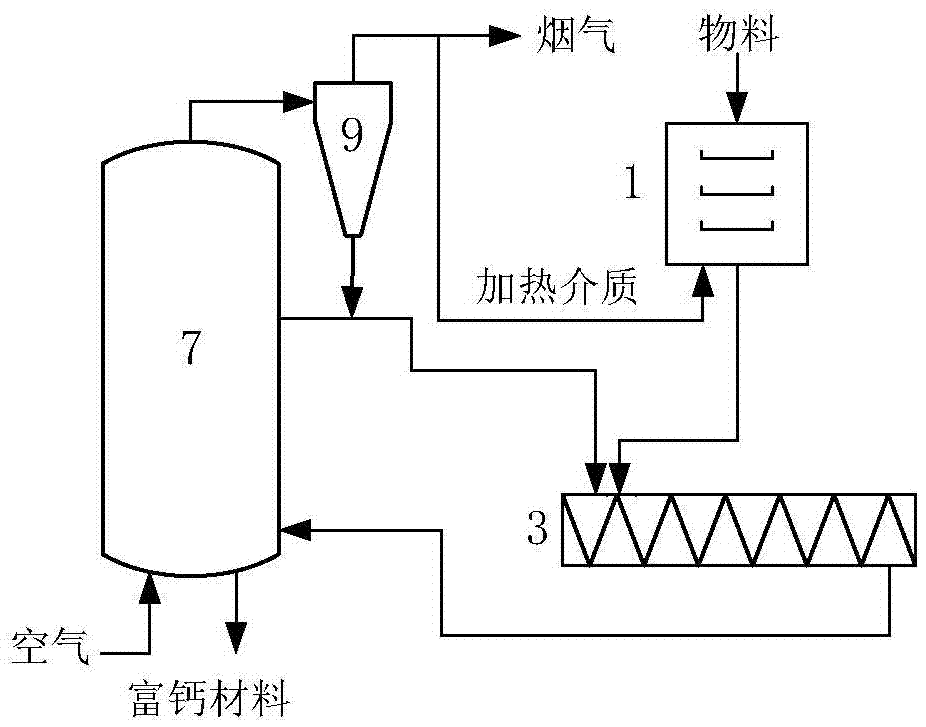

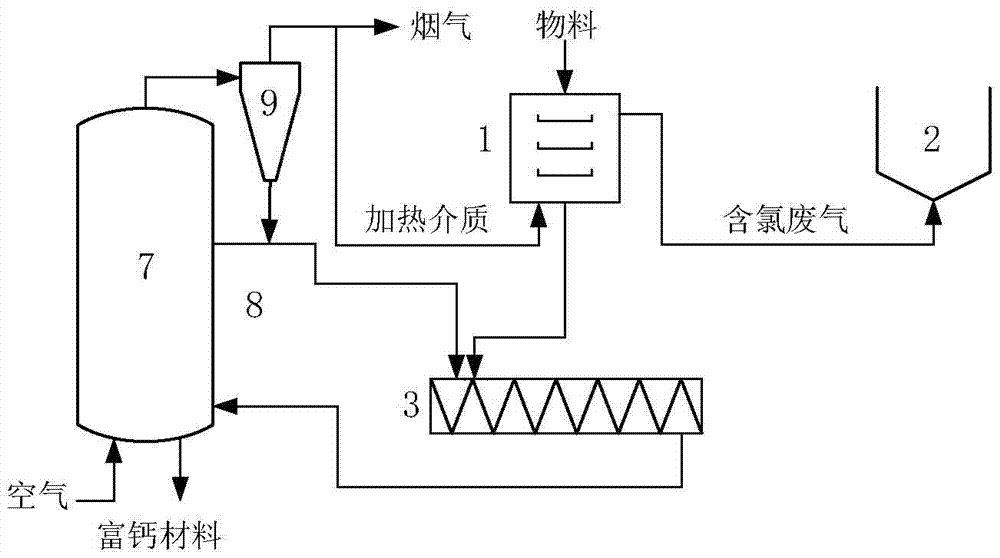

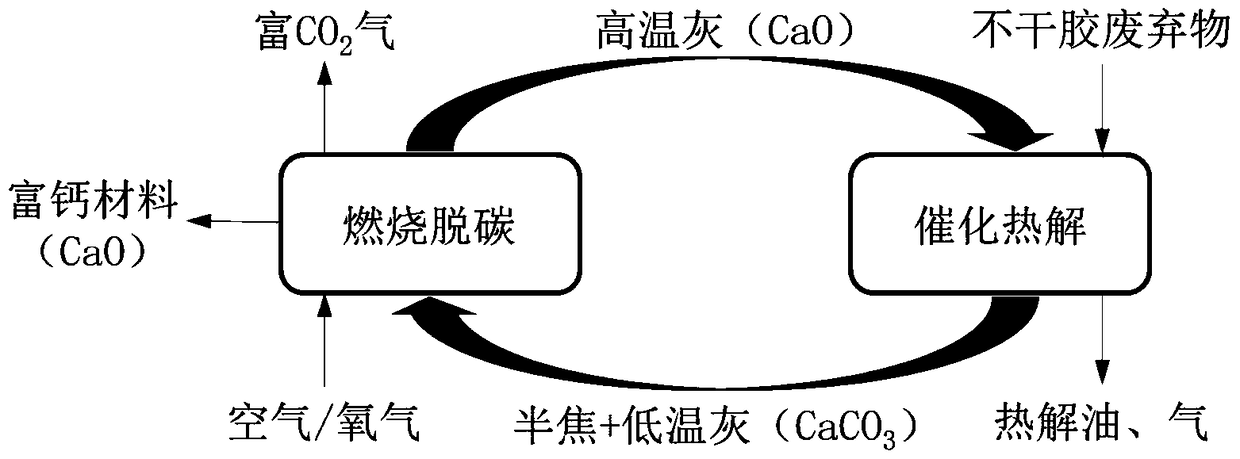

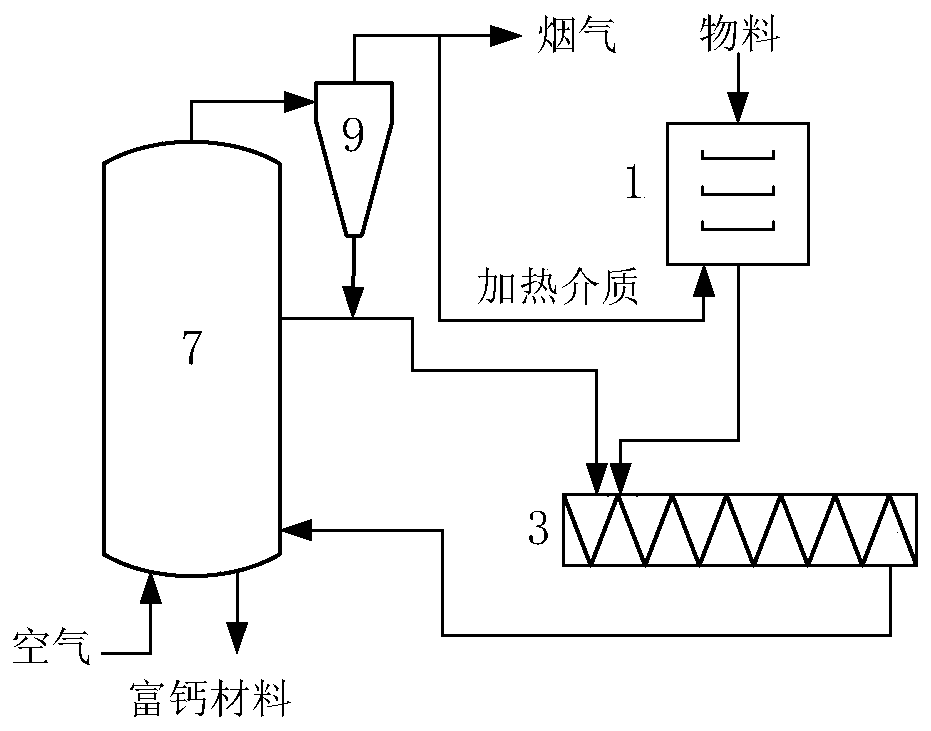

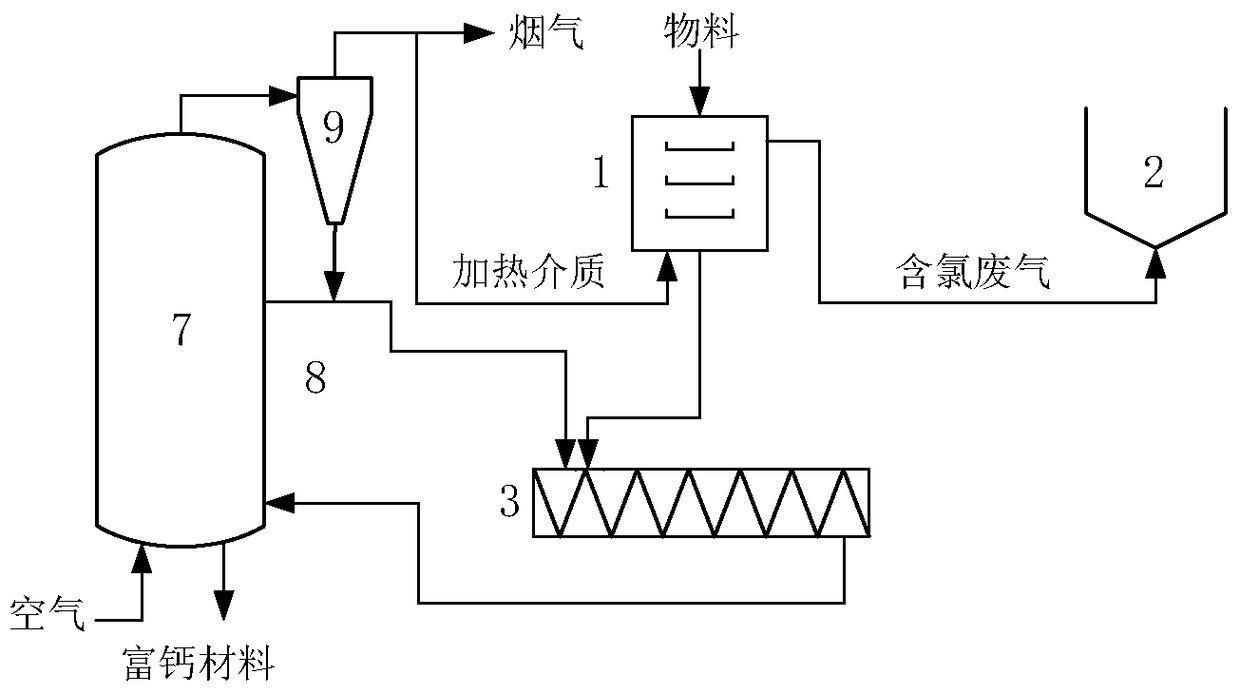

Self-adhesive waste pyrolysis conversion utilization system and self-adhesive waste pyrolysis conversion utilization method

ActiveCN107022368ANo processing costsLow costLiquid hydrocarbon mixture productionSpecial form destructive distillationCatalytic pyrolysisHeat carrier

The present invention relates to a self-adhesive waste pyrolysis conversion utilization system and a self-adhesive waste pyrolysis conversion utilization method, wherein the self-adhesive waste pyrolysis conversion utilization system comprises a catalytic pyrolysis unit and a combustion and catalyst regeneration unit. The self-adhesive waste pyrolysis conversion utilization method comprises that self-adhesive waste is rapidly heated by a high-temperature combustion ash circulation heat carrier, and is subjected to rapid catalytic pyrolysis under the action of the calcium oxide in the high-temperature combustion ash to obtain a high carbon conversion rate and produce a pyrolysis oil product and a pyrolysis gas product; and the calcium carbonate in the combustion ash can be decomposed into calcium oxide through the heat generated by the high temperature combustion of pyrolysis semi-coke so as to achieve the calcium-based catalyst regeneration without the supplementation and the additional addition of the catalyst. According to the present invention, with the system and the method, the treatment and the disposal of the self-adhesive waste are effectively solved, and through the thermal conversion technology, the high quality pyrolysis oil product and the high quality pyrolysis gas product are prepared and the calcium-rich material is co-produced so as to achieve the harmless treatment and the resource utilization of the self-adhesive waste.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Cleaning production method of 2-(Ethoxyethoxy) ethyl acrylate (EOEOEA) or phenoxyethyl acrylate (PHEA)

ActiveCN102633634BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationSodium BentonitePhenyl Ethers

Owner:JIANGSU LITIAN TECH

Pollution-free production method of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate

ActiveCN102633633BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationSorbentAntioxidant

Owner:JIANGSU LITIAN TECH

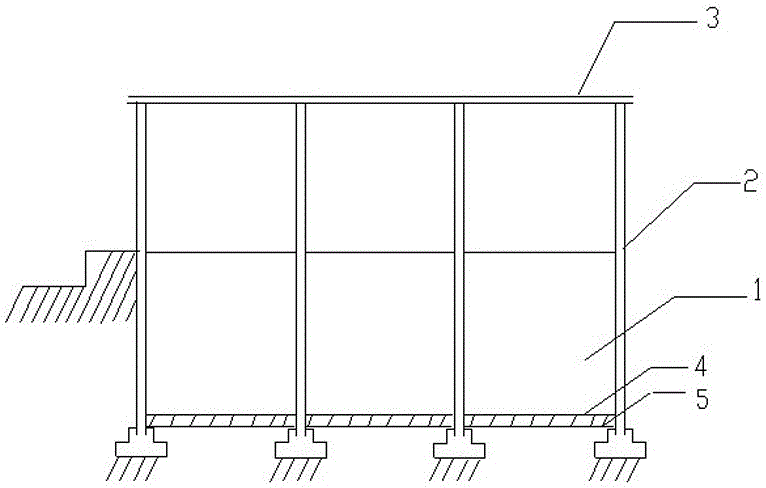

Construction method of a rainproof and seepage-proof indoor solid waste landfill

ActiveCN103485555BNo erosionNo processing costsProtective foundationIndustrial buildingsEnvironmental engineeringEngineering

The invention discloses a construction method of an indoor-type solid waste landfill. Buildings are constructed while the landfill is built. The method includes excavation, building foundation construction and anti-seepage treatment, building structure construction, landfill subsoil anti-seepage treatment and project film anti-seepage treatment on the above. Compared with the prior art, the method solves the problem of difficulty in site selection of solid waste and particularly dangerous waste landfills, and is rain-proof, anti-seepage, energy-saving and environment-friendly, the buildings can further be used as factory buildings or warehouses after the landfill is filled and closed, and land source is effectively saved.

Owner:湖南景翌湘台环保高新技术开发有限公司 +1

Urban and rural household garbage resource utilizing method

InactiveCN102172596BSolving the problem of not being able to recycleOvercoming the biggest bottleneckBio-organic fraction processingSolid waste disposalFiberSludge

The invention discloses an urban and rural household garbage resource utilizing method which comprises an acidification anaerobic tank, a deepening anaerobic tank, a biogas collection tank and a fuel gas generating unit, wherein a fuel gas inlet of the fuel gas generating unit is connected to the biogas collection tank through a pipeline. The method comprises a step of garbage receiving, a step of uniform material distribution, a step of primary magnetic separation, a step of primary crushing, a step of primary elutriation and flotation, a step of uniform cutting, a step of anaerobic acidification, a step of screening and separation, a step of buffering and adjustment, a step of anaerobic deepening and a step of sludge precipitation and concentration. Through the invention, the garbage does not need to be classified, the classification and screening of garbage run through the entire process of garbage utilization, and the biggest bottleneck restraining garbage treatment is overcome; and moreover, the method disclosed by the invention can realize continuous garbage treatment with an anaerobic method, and thoroughly solves the problem that the non-anaerobic garbage such as waste plastics, waste fibers and the like in the garbage cannot be recycled so that resources in the garbage are completely recovered.

Owner:刘振亮

Method for reducing nickel content in bicarbonate mineral water of Wudalianchi

InactiveCN113023821AInhibition of reproductionInhibit killOther chemical processesWater contaminantsActivated carbonMineralogy

The invention discloses a method for reducing the nickel content in bicarbonate mineral water of Wudalianchi, and relates to a method for removing nickel in water. The invention aims to solve the problem that the existing water treatment technology is mostly applied to sewage and is not suitable for reducing nickel in mineral water. The method comprises the following steps: immersing activated carbon into a nitric acid solution to obtain modified activated carbon; and adding the modified activated carbon into the bicarbonate mineral water of the Wudalianchi for adsorption to obtain the nickel-removed bicarbonate mineral water of the Wudalianchi. When the method is used for removing the nickel in the bicarbonate mineral water of the Wudalianchi, the removal rate of the nickel can reach 13.81%. The method is suitable for removing nickel in the bicarbonate mineral water of the Wudalianchi.

Owner:HEILONGJIANG ACAD OF SCI INST OF NATURAL RESOURCES

Clean production method of alkoxylation glycerol triacrylate

ActiveCN102503821BHigh yieldNo emissionsOrganic compound preparationCarboxylic acid esters separation/purificationSodium BentoniteAntioxidant

The invention belongs to the field of photocuring materials and relates to a clean production method of alkoxylation glycerol triacrylate. The method comprises the following steps that: (1) ethoxylation glycerol / propoxylation glycerol, acrylic acid, catalysts, solvents, polymerization inhibitors and antioxidants are subjected to esterification backflow dehydration; (2) soda flakes and a small quantity of water are added for neutralization; (3) magnesium polysilicate absorbing agents are added for absorbing salt generated during the neutralization; (4) the pressure reduction dehydration is carried out, and solvents are removed; (5) press filtering is carried out, and the magnesium polysilicate and the salt absorbed by the magnesium polysilicate are filtered away; (6) alkaline calcium bentonite and calcium bentonite are added, and decoloration, trace moisture removal and trace acid removal are carried out; (7) press filtering is carried out; and (8) product index detection is carried out. The method belongs to the high-yield clean production method of the ethoxylation glycerol triacrylate and propoxylation glycerol triacrylate and has the advantages that economic benefits and environment benefits are realized, and the problem of organic waste water pollution in the production process of the ethoxylation glycerol triacrylate and the propoxylation glycerol triacrylate is fundamentally solved.

Owner:JIANGSU LITIAN TECH

Projection lamp assembly

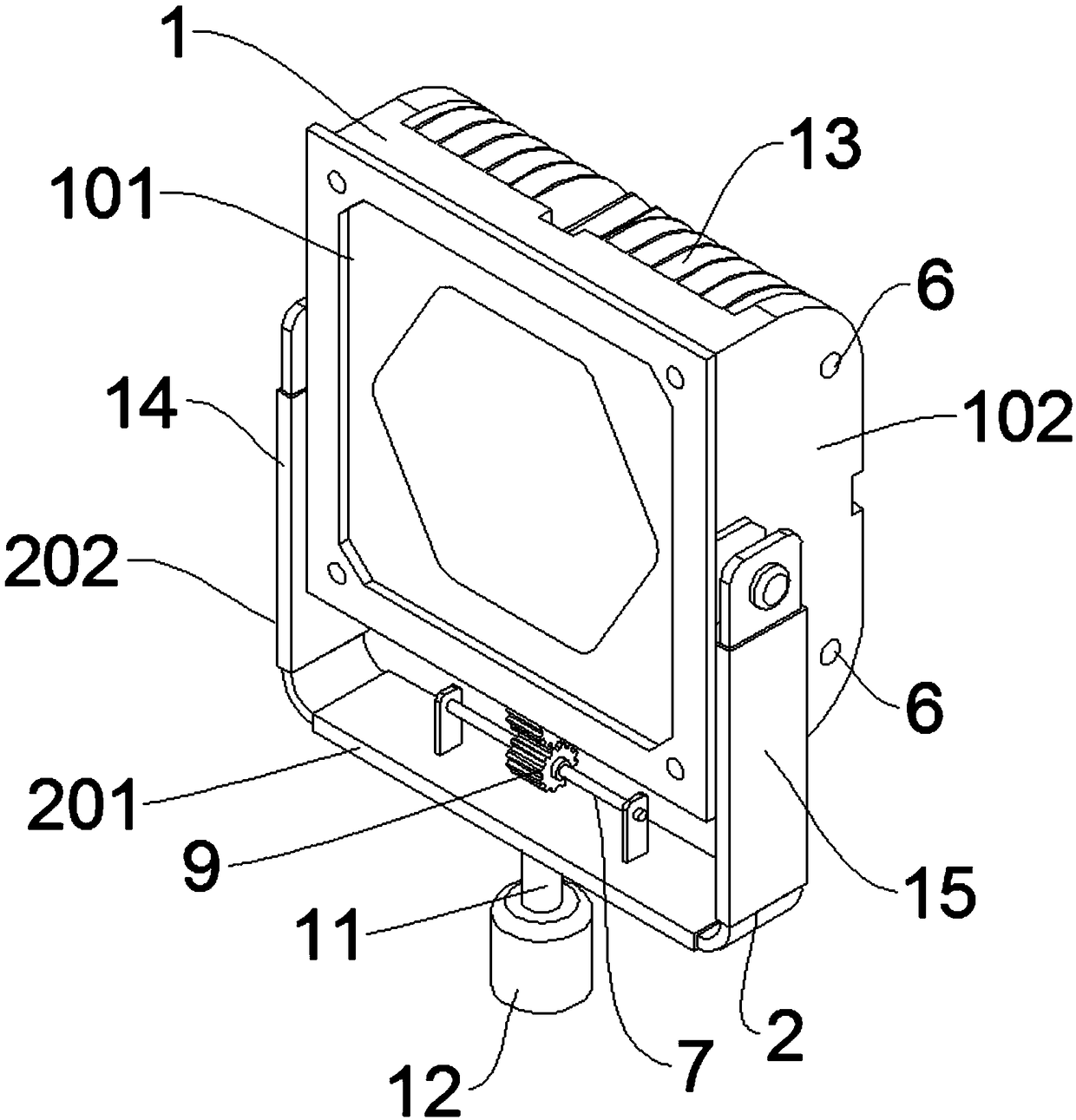

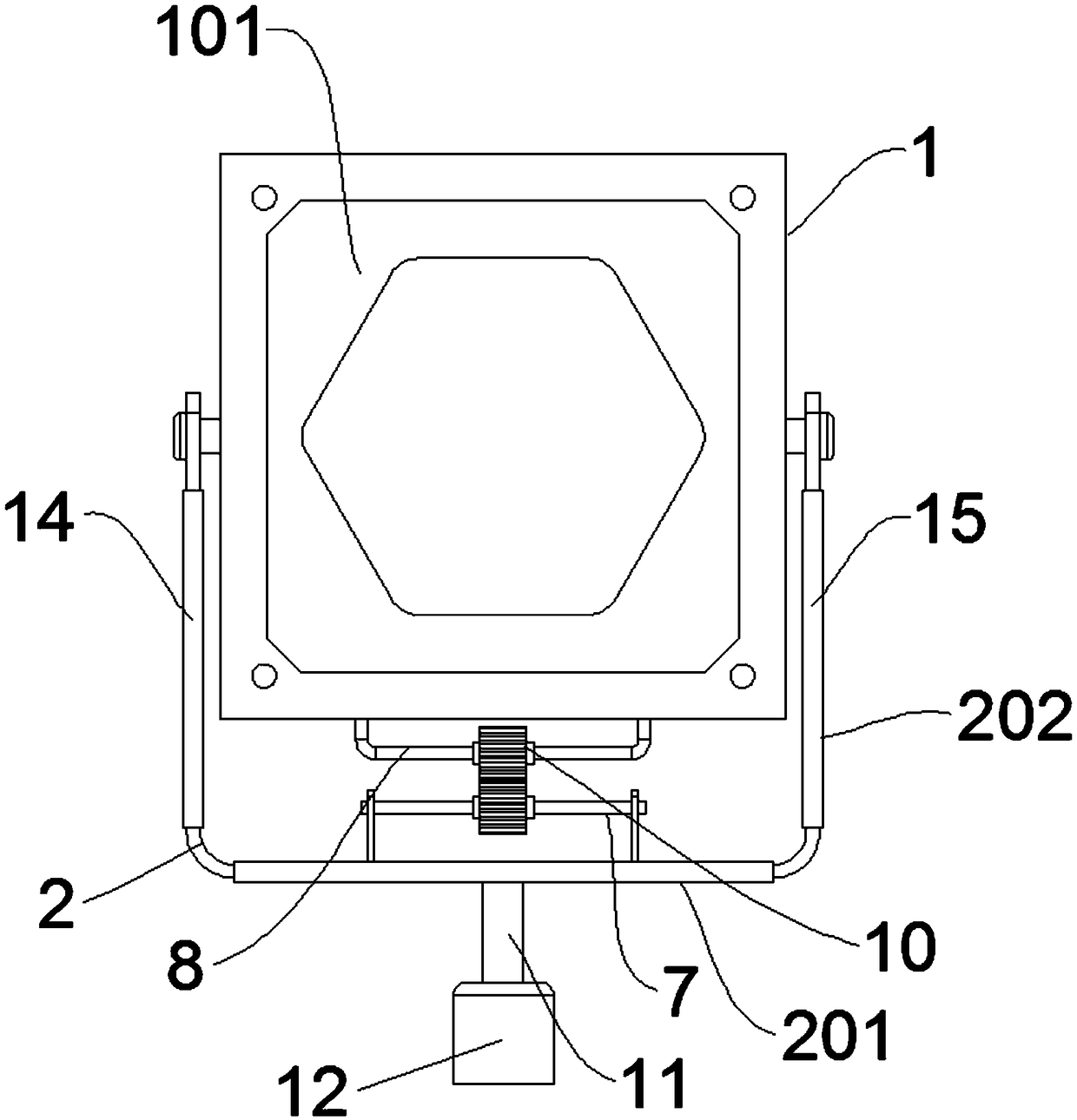

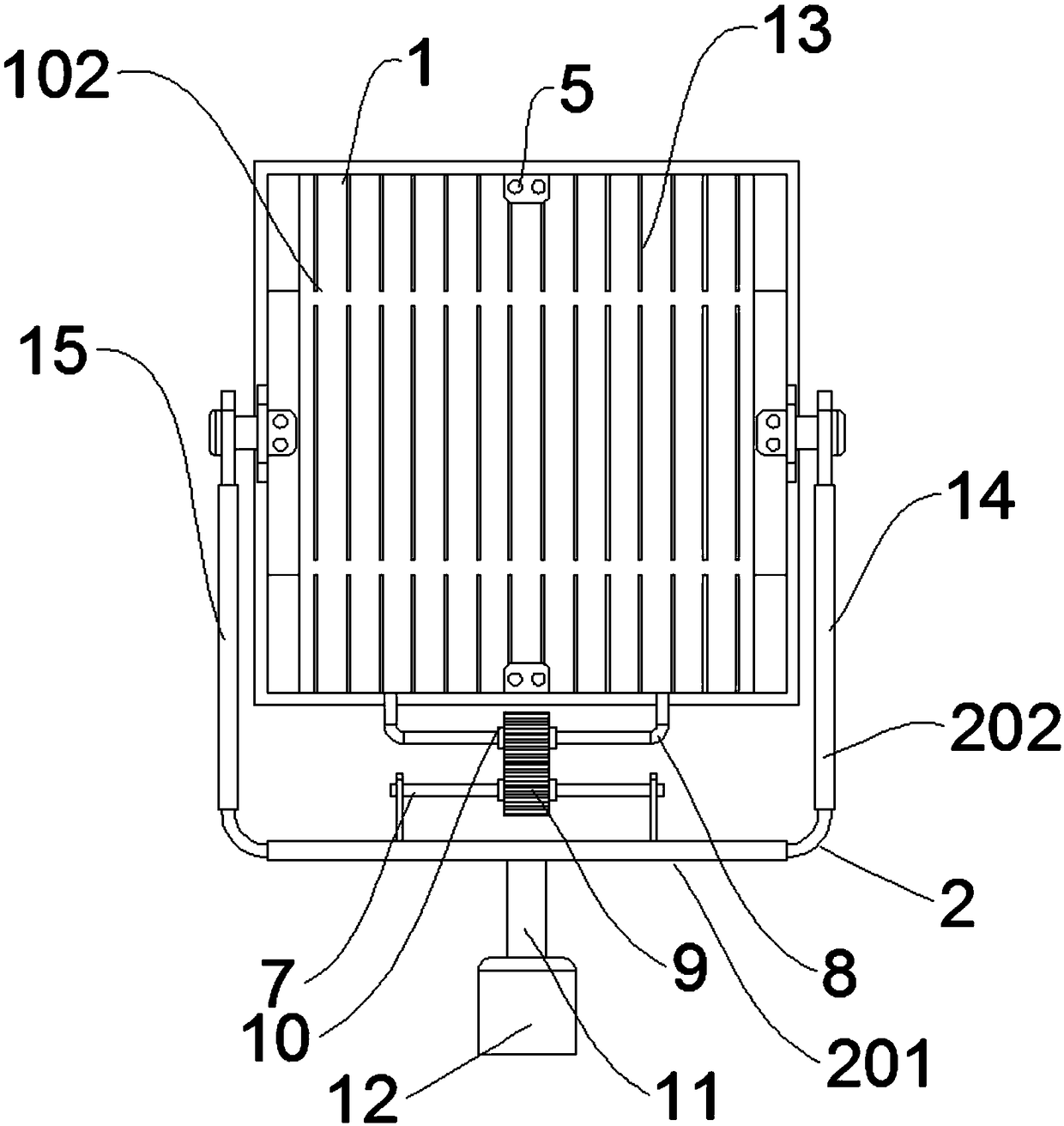

InactiveCN109027802AEasy to set upSet stableLighting support devicesLighting heating/cooling arrangementsAgricultural engineeringProcessing cost

The invention provides a projection lamp assembly and relates to the technical field of lamps. The projection lamp assembly comprises a plurality of lamp bodies, a telescopic bracket, a plurality of connecting blocks and a plurality of fixing bolts; the plurality of lamp bodies are connected with the bracket; each lamp body comprises a front shell and a rear shell; each front shell and the corresponding rear shell are fixedly connected to form a cuboid-shaped lamp body; first threaded holes are formed in the four edges of each rear shell correspondingly; second threaded holes are formed in thetwo ends of each connecting block; the fixing bolts penetrate through the first threaded holes and the second threaded holes, so that the connecting blocks are fixedly connected with the rear shells;and the two ends of each connecting block are fixedly connected with the rear shells of the adjacent lamp bodies correspondingly. Through the arrangement of the projection lamp assembly, multiple projection lamps can be fixedly connected, the number of the projection lamps is adjusted according to the actual demands, that is, the power of the projection lamp assembly is adjusted, the mold processing cost is avoided, and the cost is low.

Owner:SHENZHEN SIGNCOMPLEX

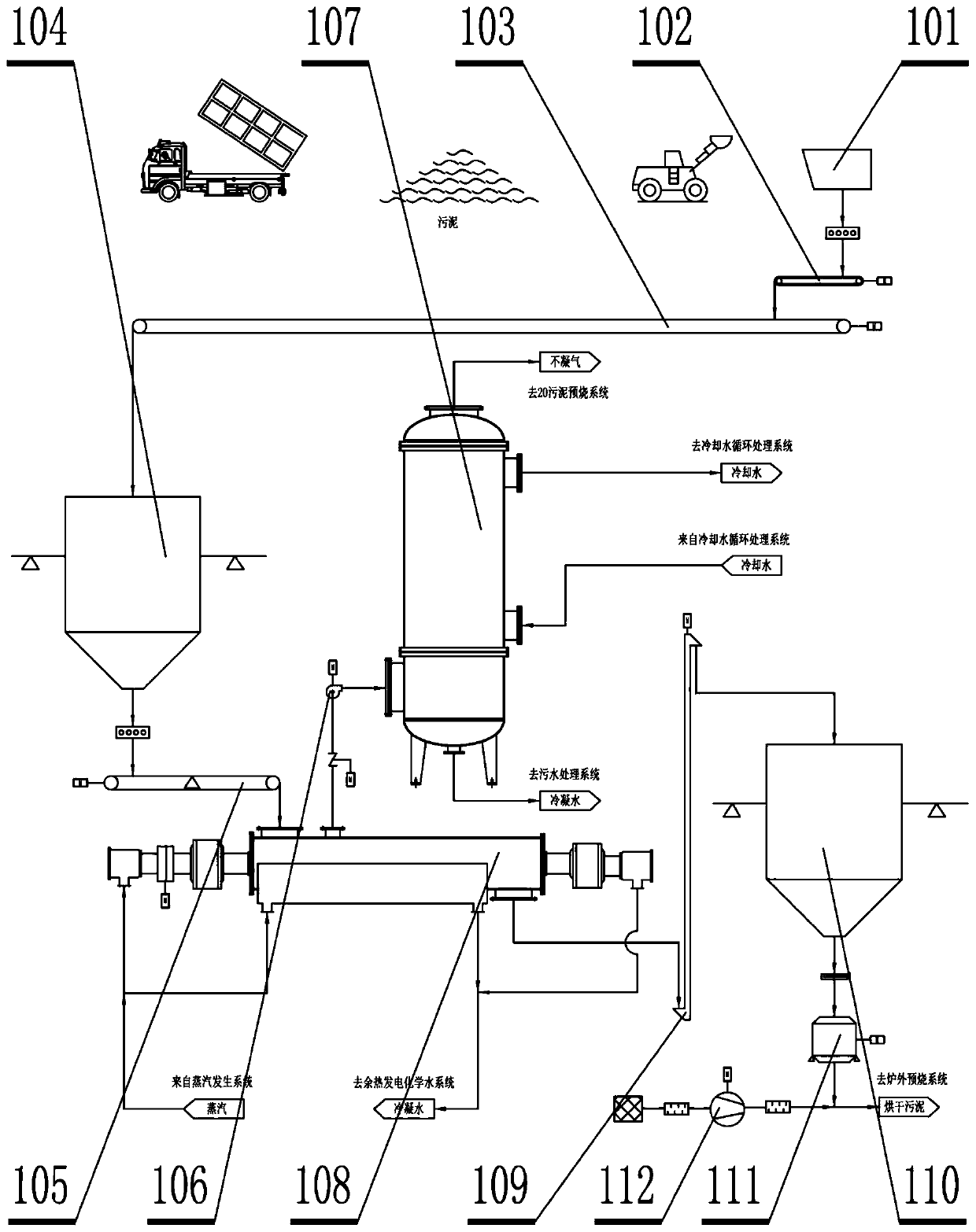

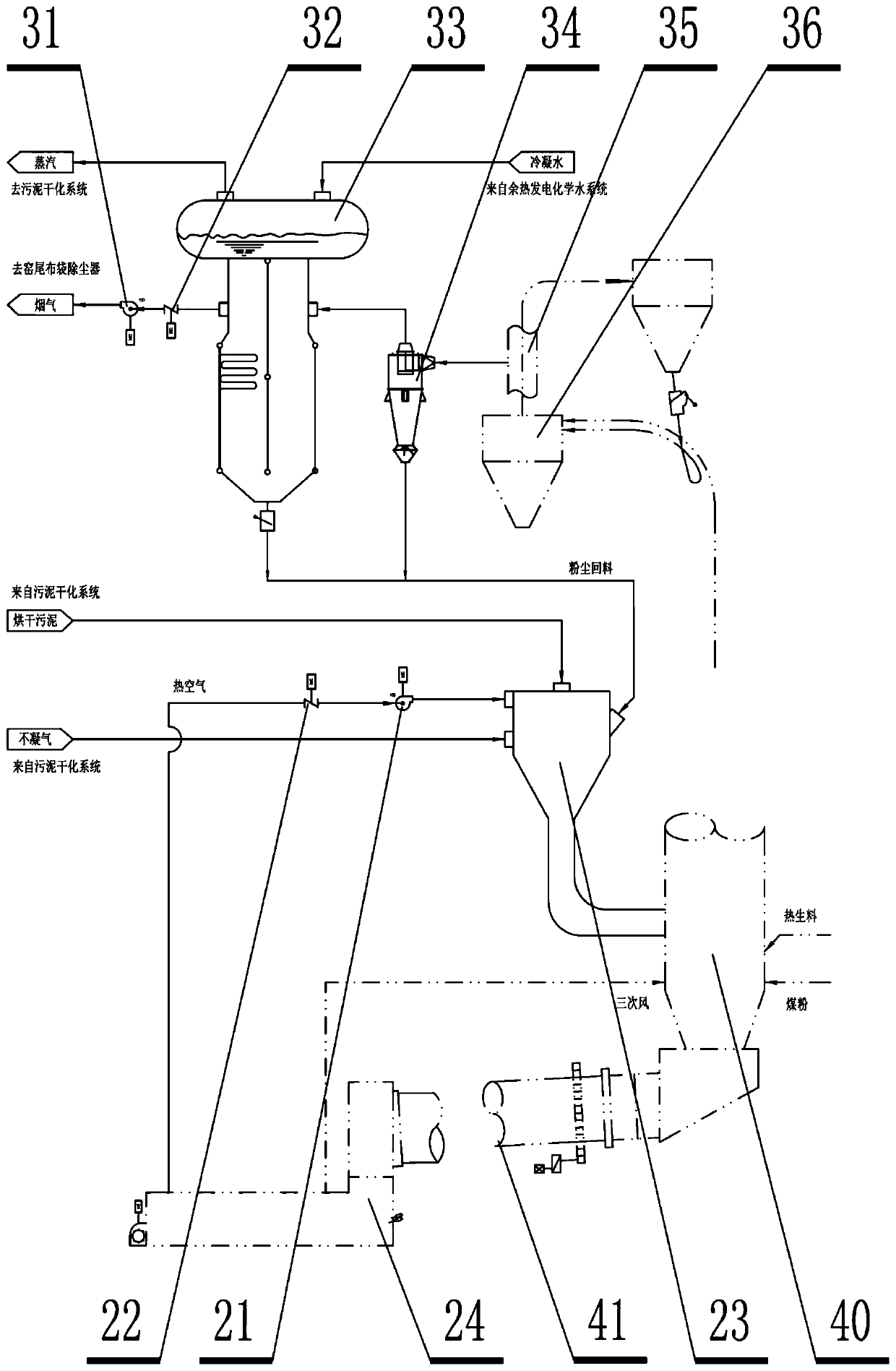

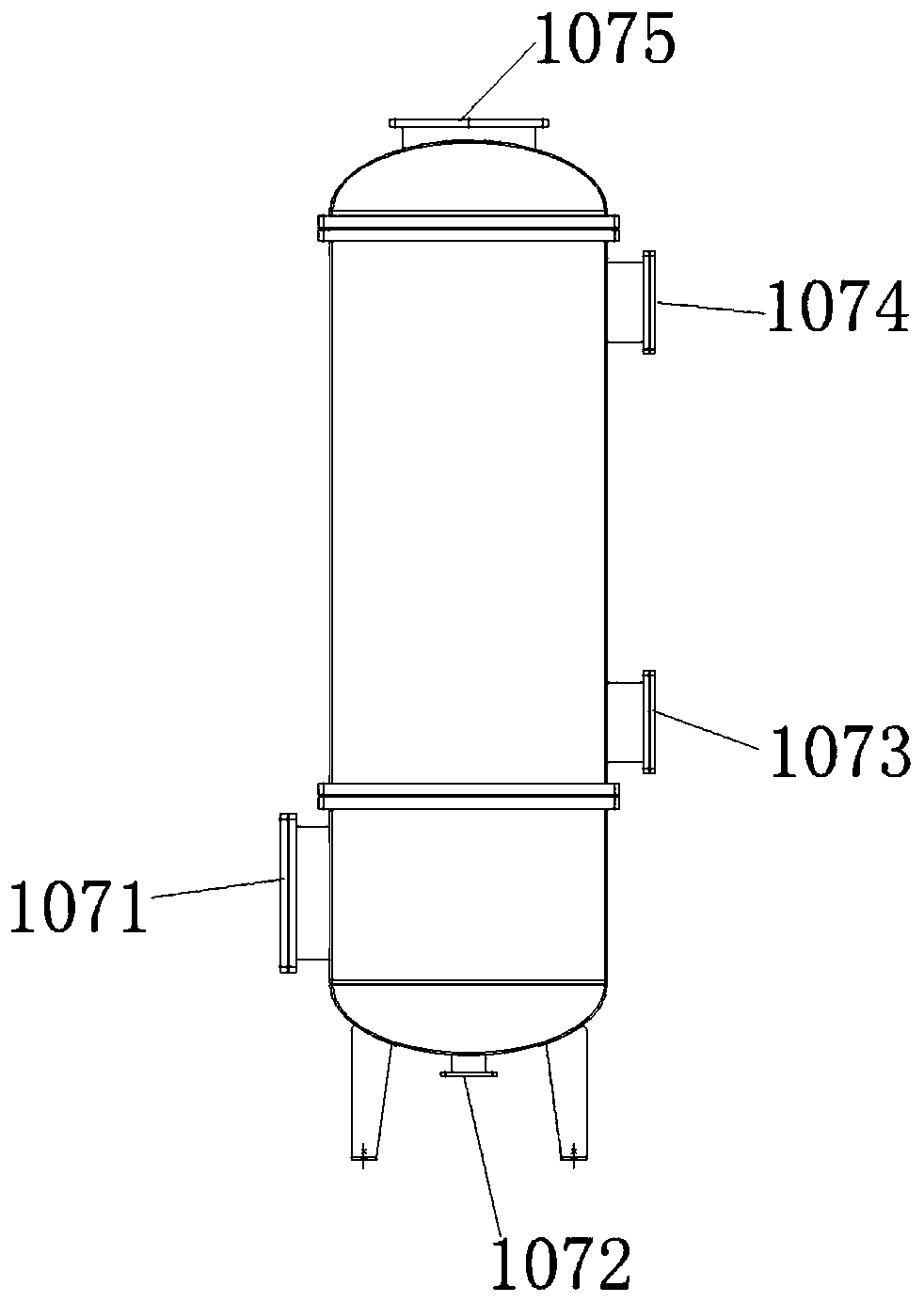

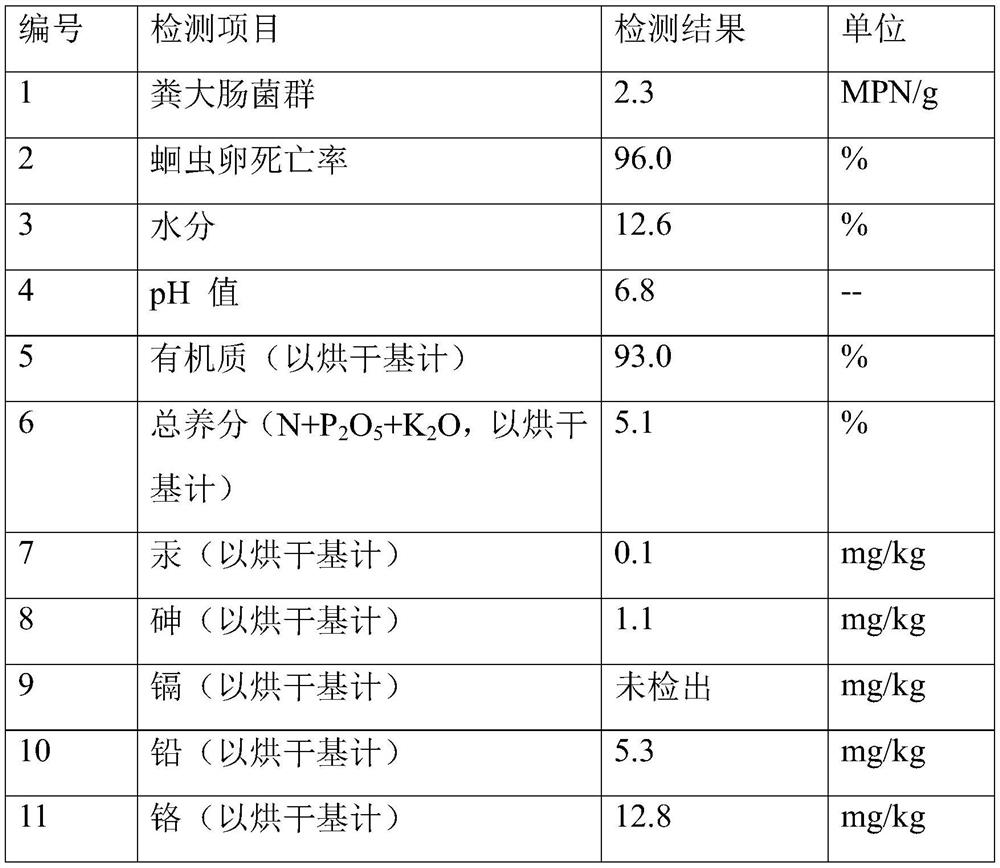

Treatment process and treatment system for municipal sludge

PendingCN111268888ARealize resource utilizationRealize harmless disposalSludge treatment by de-watering/drying/thickeningWater/sewage treatment by electrochemical methodsCement factorySludge

The invention discloses a treatment process and a treatment system for municipal sludge. The treatment system is arranged outside a decomposing furnace, is connected with the decomposing furnace and cement plant equipment, and comprises a sludge drying system, an out-of-furnace pre-sintering system and a steam generation system, the steam generation system is connected with the sludge drying system, and the out-of-furnace pre-sintering system is connected with the sludge drying system and the steam generation system respectively. According to the treatment process, the processes of sludge heating, water evaporation, organic matter incineration and the like are transferred into the pre-sintering furnace and are completed, the furnace capacity of the decomposing furnace is not occupied, conditions are created for large-scale cooperative sludge treatment of a cement kiln, recycling of sludge is achieved, and final treatment of sludge is also achieved.

Owner:广州绿泰环境科技有限公司

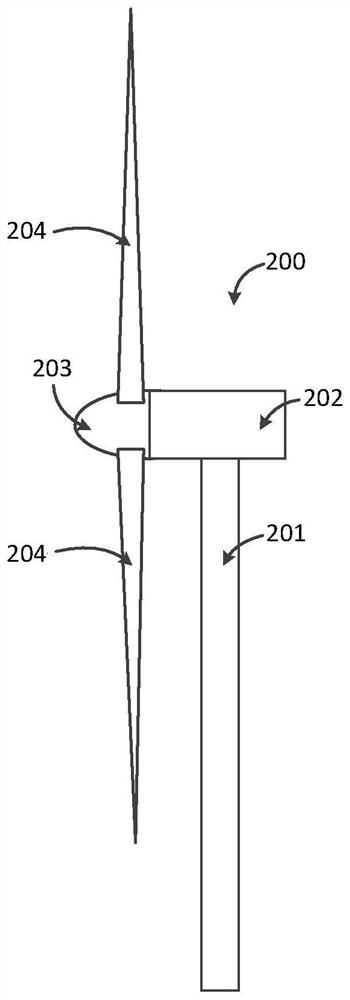

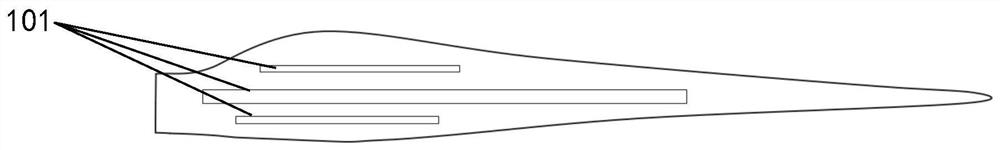

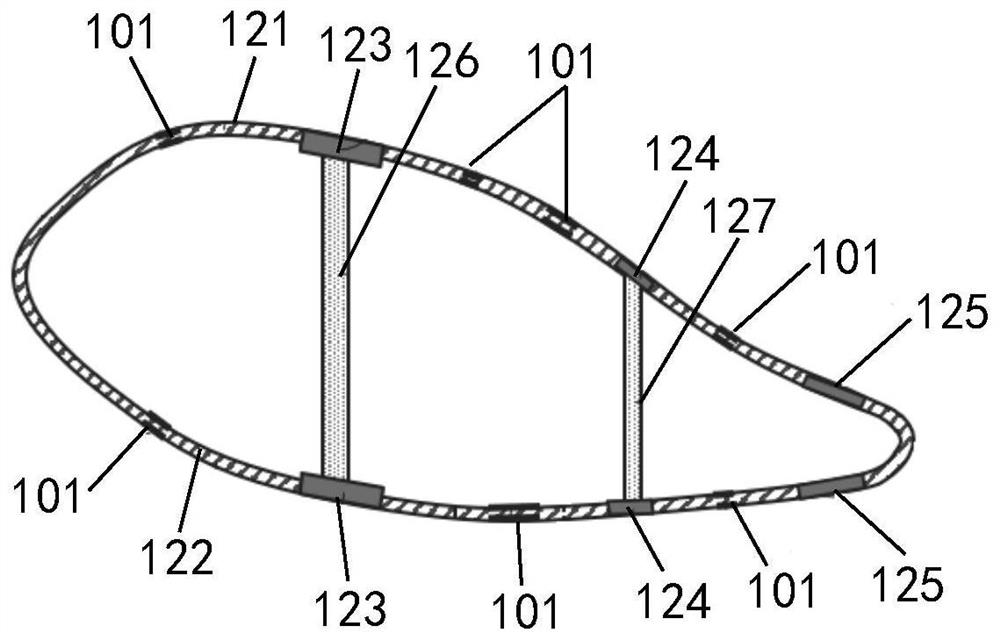

Fan blade with stiffeners and manufacturing method thereof

PendingCN113454334ALow costOptimize topologyFinal product manufactureMachines/enginesStructural engineeringFan blade

The invention discloses a fan blade with stiffeners and a manufacturing method thereof. The fan blade comprises a plurality of groups of stiffeners, and the stiffeners are arranged on the upper side, the lower side or both sides of the thickness direction of a core material of the fan blade and comprise a plurality of layers of sheets, and each layer of sheet forms staggered layers along the chordwise direction and the spanwise direction of the fan blade. And the reinforcing strip, a core material of the fan blade and other cloth layers are poured and cured together.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

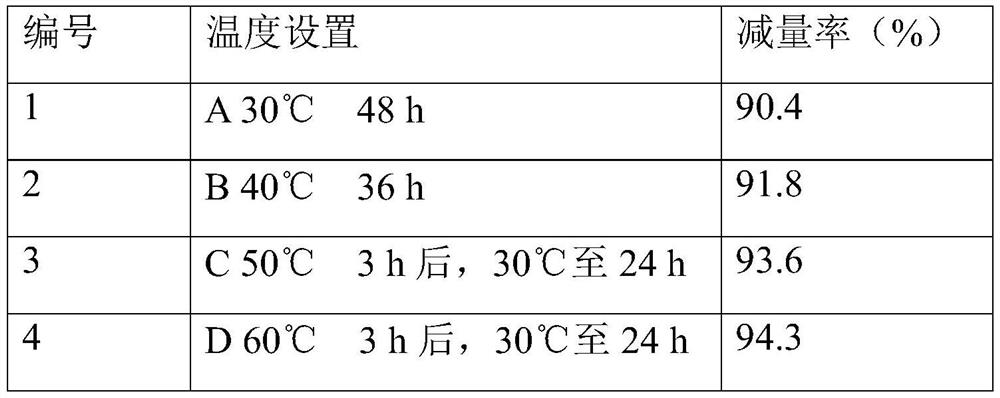

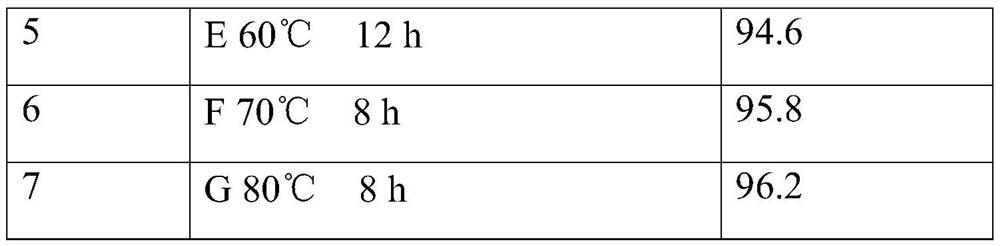

Bacterial agent used for processing organic garbage, and preparation method and utilization method of bacterial agent

PendingCN113278539AEasy to handleReduce processing costsFungiBacteriaBiotechnologyBacillus licheniformis

The invention discloses a bacterial agent used for processing organic garbage. The bacterial agent comprises 30-60 parts of salt-tolerant halobacillus halophilus, 30-60 parts of bacillus licheniformis, 30-60 parts of bacillus natto, 10-40 parts of azotobacter chroococcum and 5-15 parts of pichia pastoris. The invention also discloses a preparation method and a utilization method of the above bacterial agent. The bacterial agent disclosed by the invention is suitable for high-temperature, intermediate-temperate and low-temperature aerobic fermentation processes, and can effectively process organic rotten garbage to realize harmlessness, minimization and reclamation. Meanwhile, a processing process is simple and effective, a fermentation period is short, a processing cost is low, and the bacterial agent is friendly to the environment and is free from secondary pollution.

Owner:惠州市通用机电设备有限公司

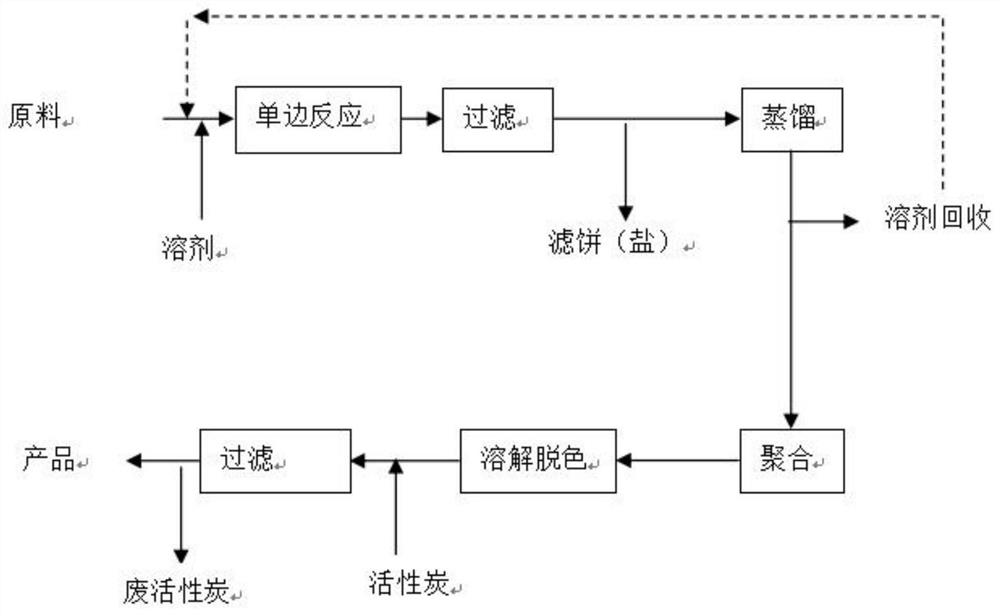

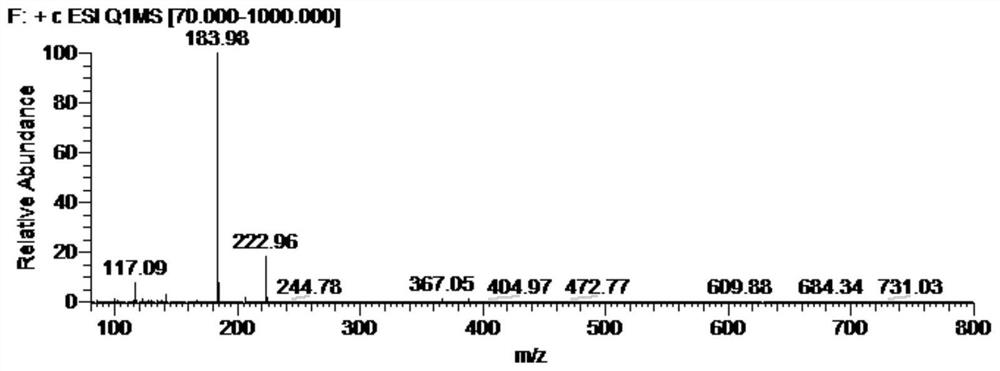

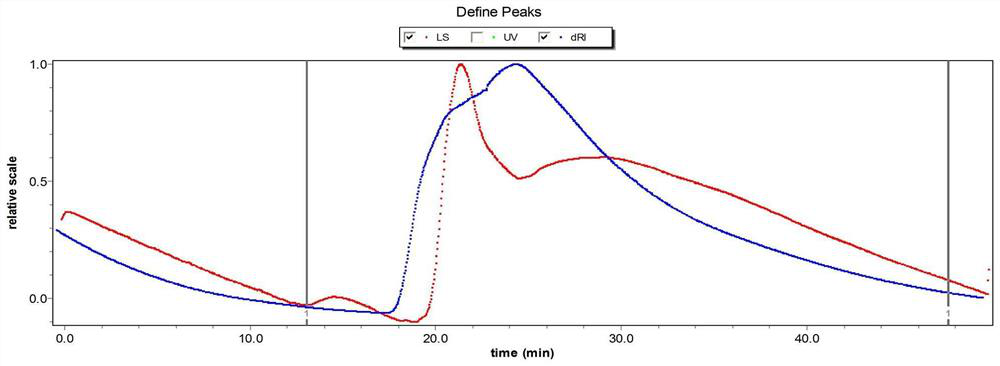

Method for synthesizing polyhexamethylene biguanide from monoguanidine intermediate

ActiveCN113773490AAvoid purification processEliminates quantitative testing processBiochemical engineeringHexamethylenediamine

The invention provides a method for synthesizing polyhexamethylene biguanide from a monoguanidine intermediate, and relates to the technical field of synthesis of polyhexamethylene biguanide compounds. The method comprises the following steps: firstly, taking dicyandiamide salt and hexanediamine or hexanediamine salt as raw materials, carrying out unilateral reaction to generate a monoguanidine intermediate, carrying out simple treatment, and conducting heating and auto-polymerization to obtain PHMB. The method not only can avoid the complicated treatment process in the traditional synthesis of the biguanide intermediate, but also can avoid the defects that the salt content of the product produced by a one-pot method is too high and is difficult to remove, the synthesis and post-treatment processes are simple, the product quality is easy to control, and the method is a simple, convenient and efficient synthesis method.

Owner:DALIAN BIO CHEM

A system and method for pyrolysis conversion and utilization of self-adhesive waste

ActiveCN107022368BNo processing costsLow costLiquid hydrocarbon mixture productionSpecial form destructive distillationCatalytic pyrolysisPtru catalyst

The present invention relates to a self-adhesive waste pyrolysis conversion utilization system and a self-adhesive waste pyrolysis conversion utilization method, wherein the self-adhesive waste pyrolysis conversion utilization system comprises a catalytic pyrolysis unit and a combustion and catalyst regeneration unit. The self-adhesive waste pyrolysis conversion utilization method comprises that self-adhesive waste is rapidly heated by a high-temperature combustion ash circulation heat carrier, and is subjected to rapid catalytic pyrolysis under the action of the calcium oxide in the high-temperature combustion ash to obtain a high carbon conversion rate and produce a pyrolysis oil product and a pyrolysis gas product; and the calcium carbonate in the combustion ash can be decomposed into calcium oxide through the heat generated by the high temperature combustion of pyrolysis semi-coke so as to achieve the calcium-based catalyst regeneration without the supplementation and the additional addition of the catalyst. According to the present invention, with the system and the method, the treatment and the disposal of the self-adhesive waste are effectively solved, and through the thermal conversion technology, the high quality pyrolysis oil product and the high quality pyrolysis gas product are prepared and the calcium-rich material is co-produced so as to achieve the harmless treatment and the resource utilization of the self-adhesive waste.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSolventTrimethylolpropane

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

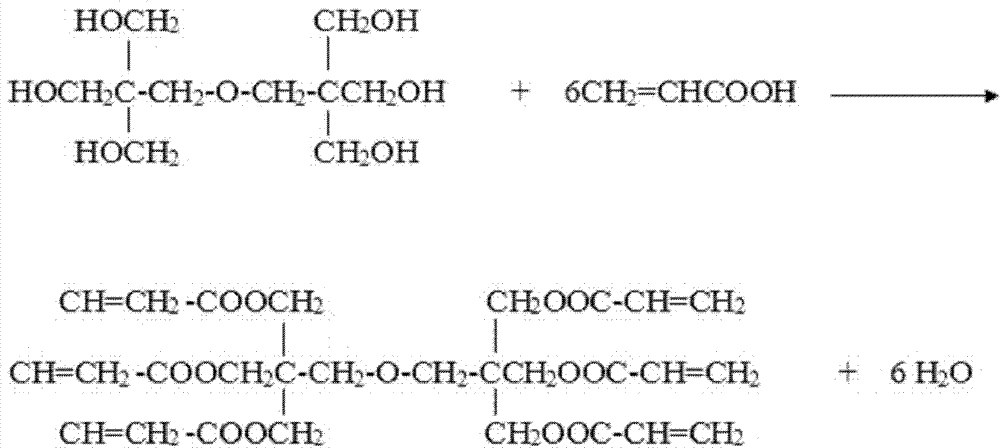

Clean production method of dipentaerythritol hexaacrylate

ActiveCN102633635BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationPtru catalystSilicic acid

The invention belongs to the field of a photo-curing material and relates to a clean production method of dipentaerythritol hexaacrylate. The method comprises the following concrete steps: (1) carrying out esterification and reflux dehydration on dipentaerythritol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; (2) adding caustic soda flakes and a little amount of water to neutralize; (3) adding a magnesium polysilicate adsorbent to absorb salt generated by neutralization; (4) dewatering and removing the solvent at reduced pressure; (5) carrying out filter pressing to filter out magnesium polysilicate and absorbed salt thereof; (6) adding alkaline Ca-bentonite and calcium oxide, destaining, and removing trace water and trace acid; (7) carrying out filter pressing; and (8) detecting a product index. The clean production method disclosed by the invention is the clean production method of dipentaerythritol hexaacrylate, with high yield, economic benefit and environmental benefit, so the pollution problem of organic waste water in the production process of dipentaerythritol hexaacrylate is fundamentally solved.

Owner:JIANGSU LITIAN TECH

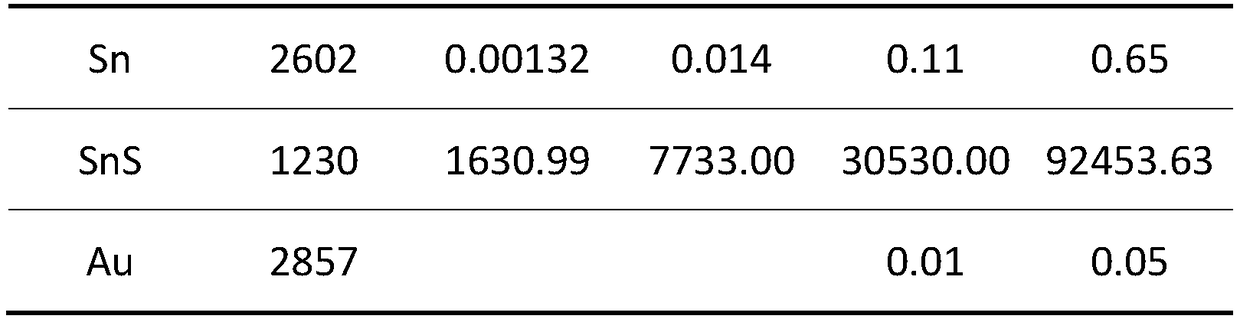

A kind of method of gold-tin alloy separation

The invention relates to a gold-tin alloy separation method and belongs to the technical field of nonferrous metal pyrometallurgy. The gold-tin alloy separation method comprises the following steps that gold-tin alloy and a vulcanizing agent are uniformly mixed, a mixture is placed in a sealed vessel to be sealed, vulcanizing reaction is performed under the oxygen-free stirring environment, and tin in the gold-tin alloy is vulcanized to become stannous sulfide; and vacuum distillation is performed on a material after vulcanization under a certain condition to enable the stannous sulfide to volatilize, and thus separation of gold and tin is realized. By adopting the gold-tin alloy separation method, the process flow is short, and the gold-tin alloy can be separated by two process steps of vulcanization and vacuum distillation.

Owner:KUNMING DIBOO TECH

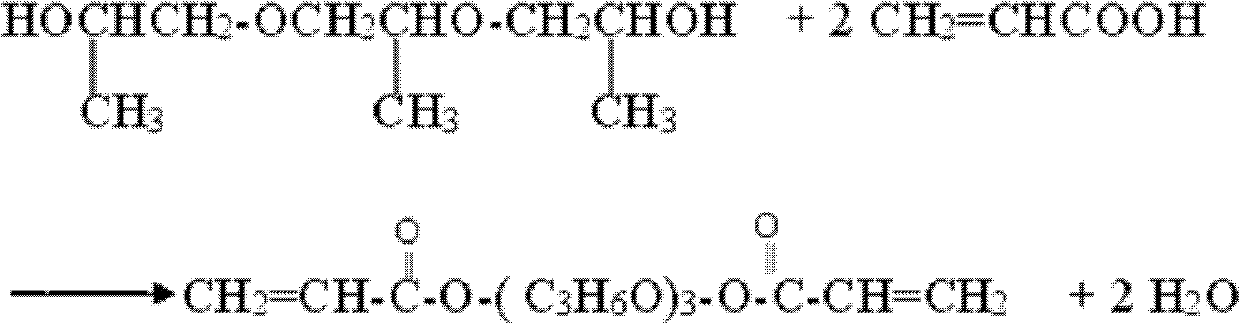

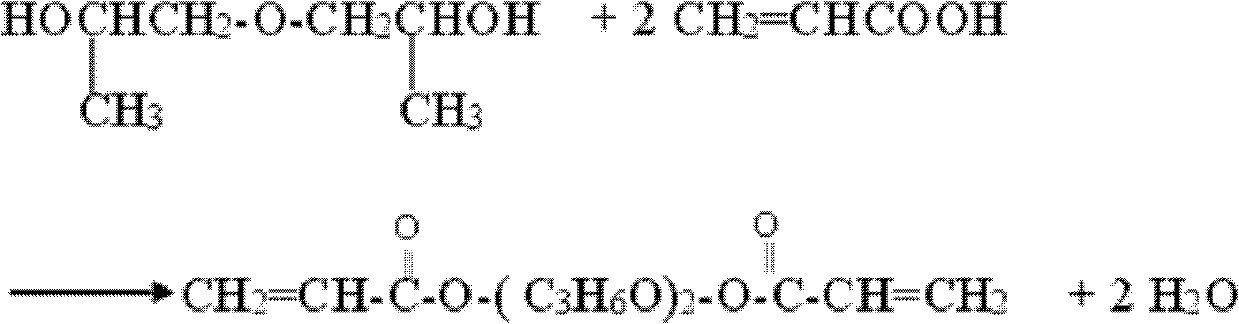

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationDipropylene glycol diacrylateSolvent

Owner:JIANGSU LITIAN TECH

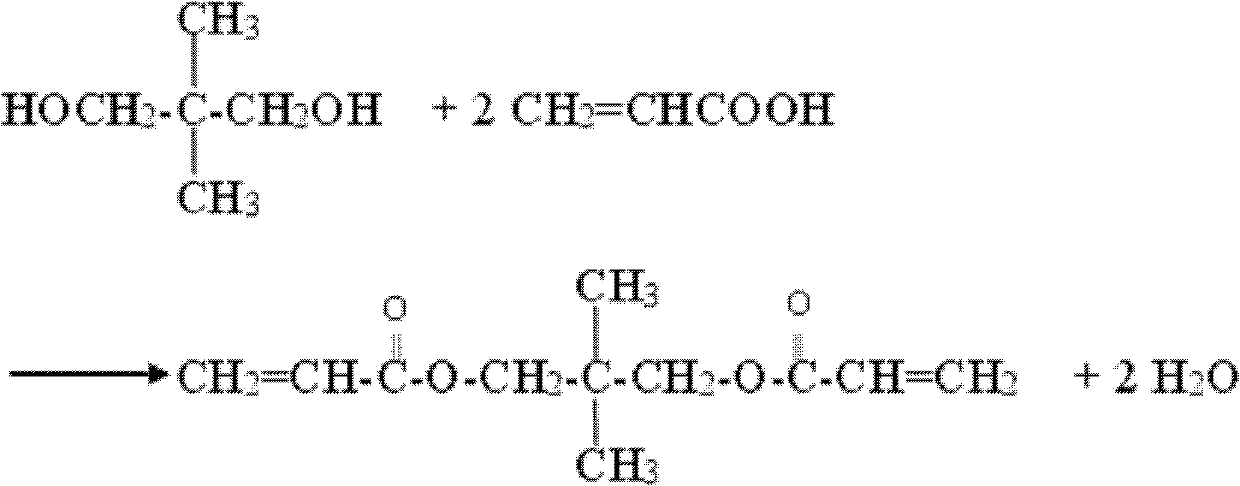

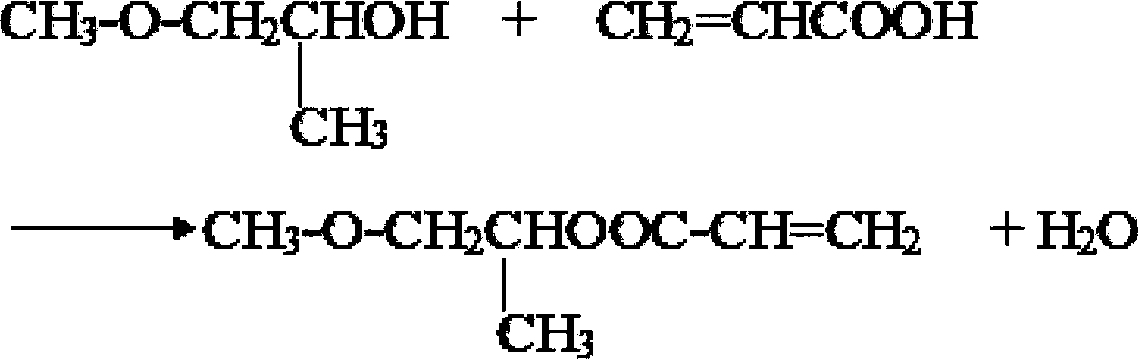

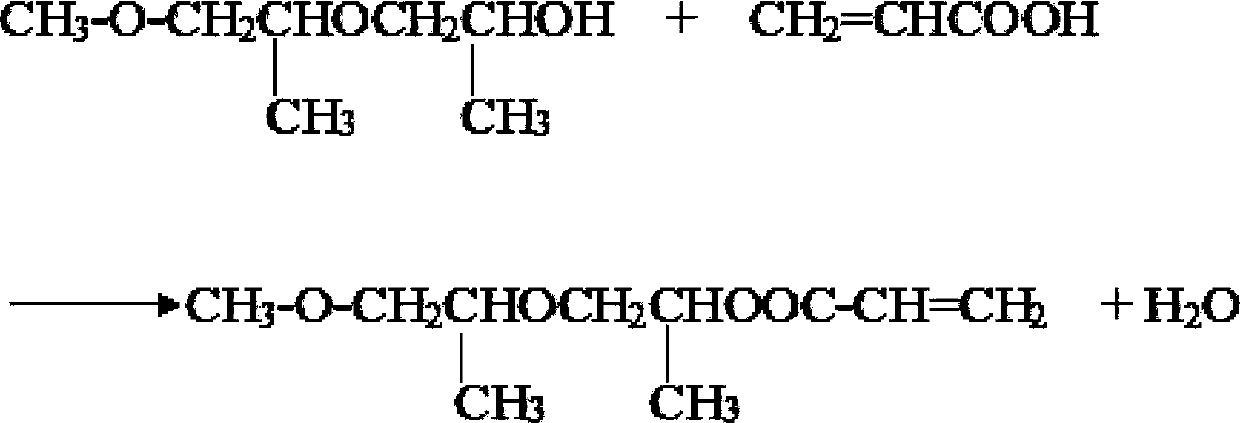

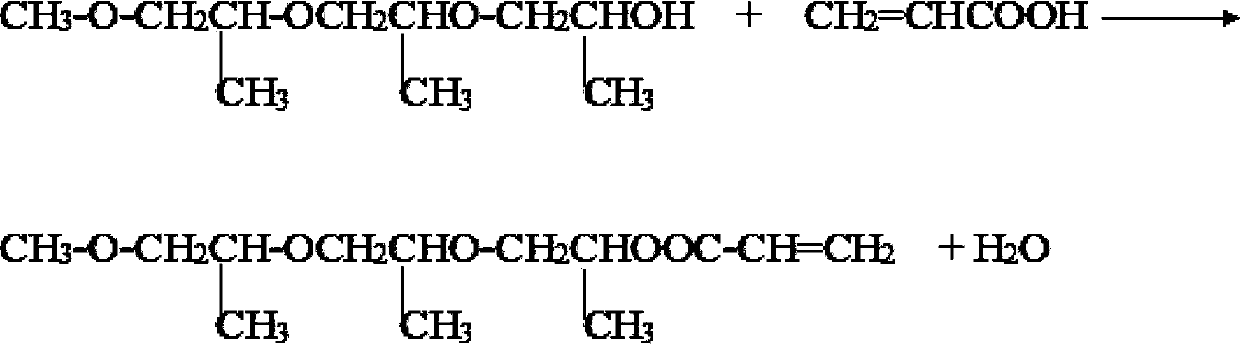

Method for cleanly producing methoxyl propanediol acrylate and analogs thereof

ActiveCN102675097BNo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolSorbent

The invention discloses a method for cleanly producing methoxyl propanediol acrylate, methoxyl dipropylene glycol acrylate or methoxyl tripropylene glycol acrylate. The method comprises the following steps of: (1) refluxing and dehydrating methoxyl propanediol / methoxyl dipropylene glycol / methoxyl tripropylene glycol, acrylic acid, catalyst, solvent, polymerization inhibitor and antioxidant; (2) adding caustic soda flakes and little water for neutralizing; (3) adding magnesium polysilicate adsorbent to adsorb salt which is generated in neutralization; (4) dehydrating in reduced pressure, and removing solvent; (5) performing filter pressing to filter the magnesium polysilicate and the salt adsorbed by the magnesium polysilicate; (6) adding basic calcium-based bentonite and calcium oxide for decoloring and removing trace water and trace acid; (7) performing filter pressing; and (8) detecting product indexes. The invention is the method for cleanly producing methoxyl propanediol acrylate, methoxyl dipropylene glycol acrylate or methoxyl tripropylene glycol acrylate with economical benefit and environmental benefit, and the problem of organic wastewater contamination in the producing process can be fundamentally solved.

Owner:JIANGSU LITIAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com