Energy-saving recovery technology of 3-dimethylaminopropylamine (DMAPA)

A dimethylaminopropylamine and process technology, applied in the field of surfactant production process, can solve the problems of large project investment, high recovery cost, and high energy consumption, and achieve low investment, no waste liquid treatment cost, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

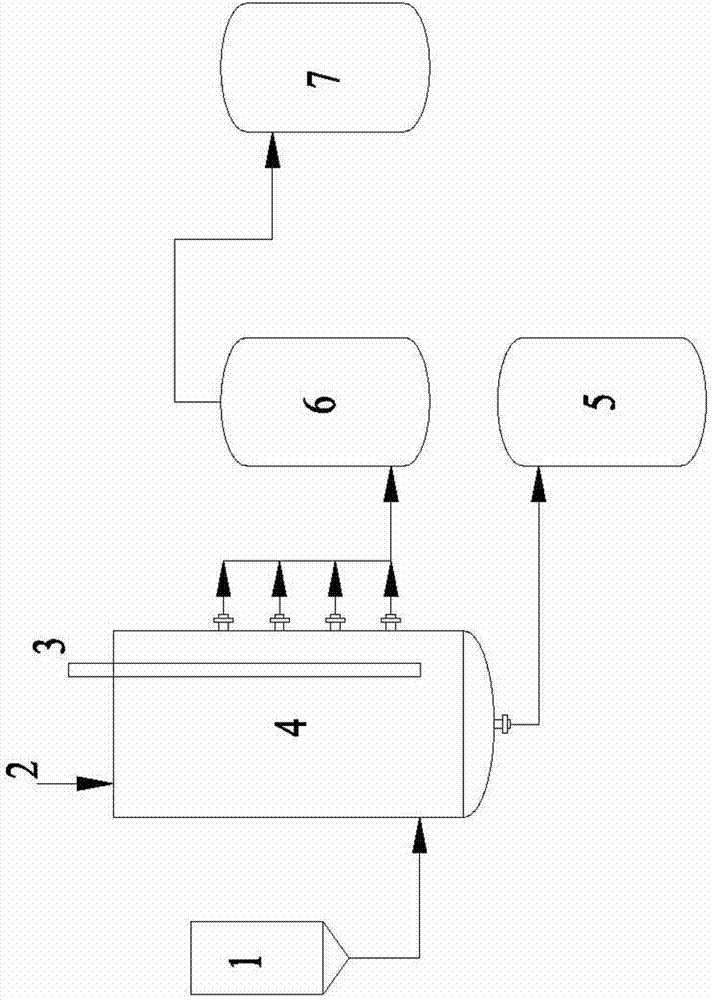

Embodiment 1

[0031] Pump 720kg of DMAPA aqueous solution (amine value 431.2mgKOH / g) from condenser 1 to separator device 4, turn on the stirring, and add 204kg of solid sodium hydroxide and 5kg of calcium hydroxide from feed port 2 and check through the discharge port sight glass When the material is completely dissolved, stop stirring and let it stand for about 2 hours. Take the upper material from the discharge port to determine the amine value. The amine value is 1059mgKOH / g. Check the height of the upper material through the interface level gauge 3. DMAPA is conveyed to distillation kettle 6 through the discharge port for vacuum distillation; at the same time, the heating, condensation and vacuum system of distillation kettle 6 is turned on, so that the temperature of the material is controlled at 60~65℃, the relative pressure is controlled at -0.065~-0.08MPa, and DMAPA is collected The condensate is about 293kg (content 98.3%). The DMAPA condensate is directly transported to storage ta...

Embodiment 2

[0033] The 579kg DMAPA solution (amine value 215.6mgKOH / g) from the condenser 1 enters the separator 4 through the pipeline, and directly adds 158kg of anhydrous sodium chloride to the propylene diamine separation tank 4 through the feed port 2, and stirs for about 1 hour After standing for stratification, take the upper liquid to determine the amine value of 1063mgKOH / g; check the height of the upper material through the interface level gauge 3, send the upper DMAPA through the discharge port to the distillation kettle 6, turn on the vacuum and heating system, The temperature of the material is raised to 80~85℃, the relative pressure is controlled at -0.06~-0.07MPa, and about 118kg of DMAPA condensate is collected (DMAPA content is 98.6%); DMAPA is directly piped to storage tank B; the lower liquid is 618kg directly through the lower discharge port Pipeline to storage tank A.

Embodiment 3

[0035] The 540kg DMAPA aqueous solution (amine value 323.4mgKOH / g) from the condenser is pumped into the separation tank 4, 208kg potassium hydroxide is added from the feeding port 2, and stirred for about 1 hour, after uniformity, stand still for stratification, take the upper liquid to determine the amine value 1057.5mgKOH / g; Check the height of the upper material through the interface level gauge 3, and transport the upper DMAPA to the distillation kettle 6 through the right discharge port, and heat the material to 70~75℃, and control the relative pressure at -0.075~-0.08MPa , Collect a total of about 165kg of DMAPA condensate (DMAPA content 98.1%); transport DMAPA condensate to storage tank B; 582kg of lower layer liquid is directly piped to storage tank A through the lower discharge port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com