Patents

Literature

106results about How to "Not discharged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydro-conversion catalyst for heavy oil and residual oil and its preparing process

The present invention belongs to the field of heavy oil and residual oil hydrotransforming technology. The heavy oil and residual oil hydrotransforming catalyst has siliceous alumina carrier, relatively strong acidity and especially protonic acid amount higher than that in available residual oil hydrotransforming catalyst. The siliceous alumina carrier is prepared through one colloid forming process, during and after which silicon is added to make alumina possess more strong acid centers and ideal pore structure. The catalyst of the present invention is used in the hydrotransforming treatment of heavy oil, residual oil and other inferior oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

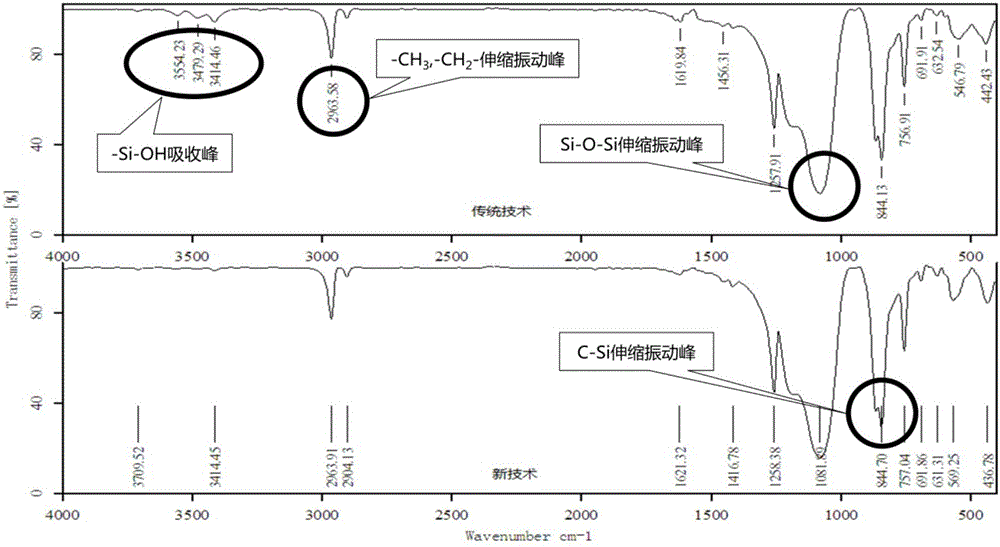

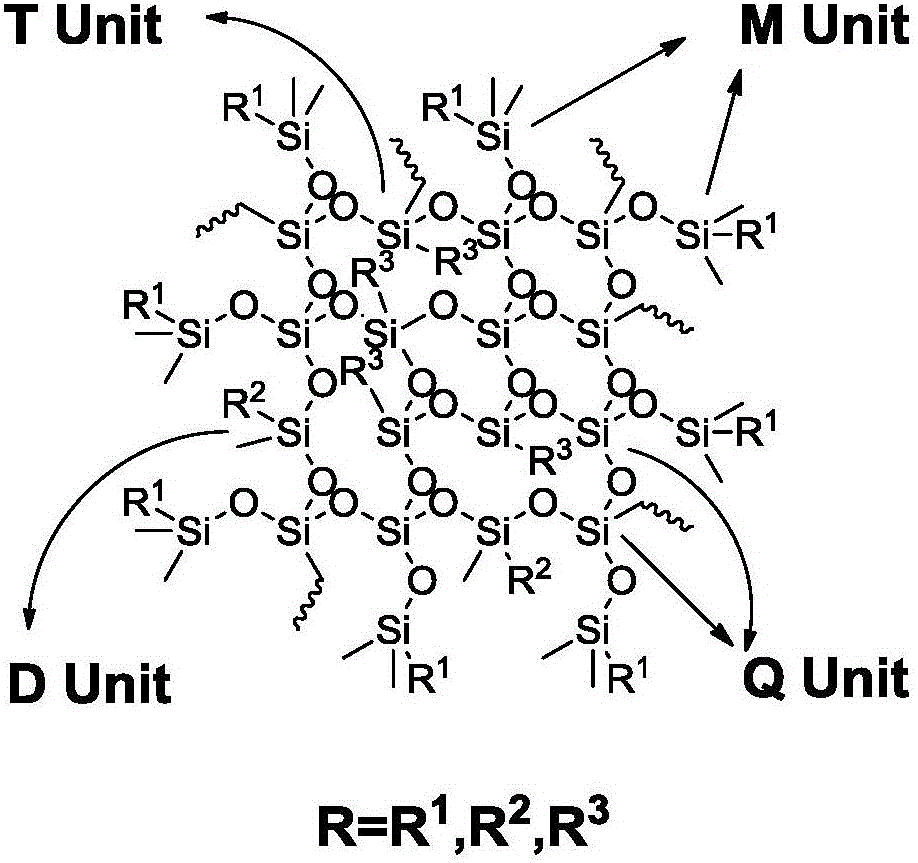

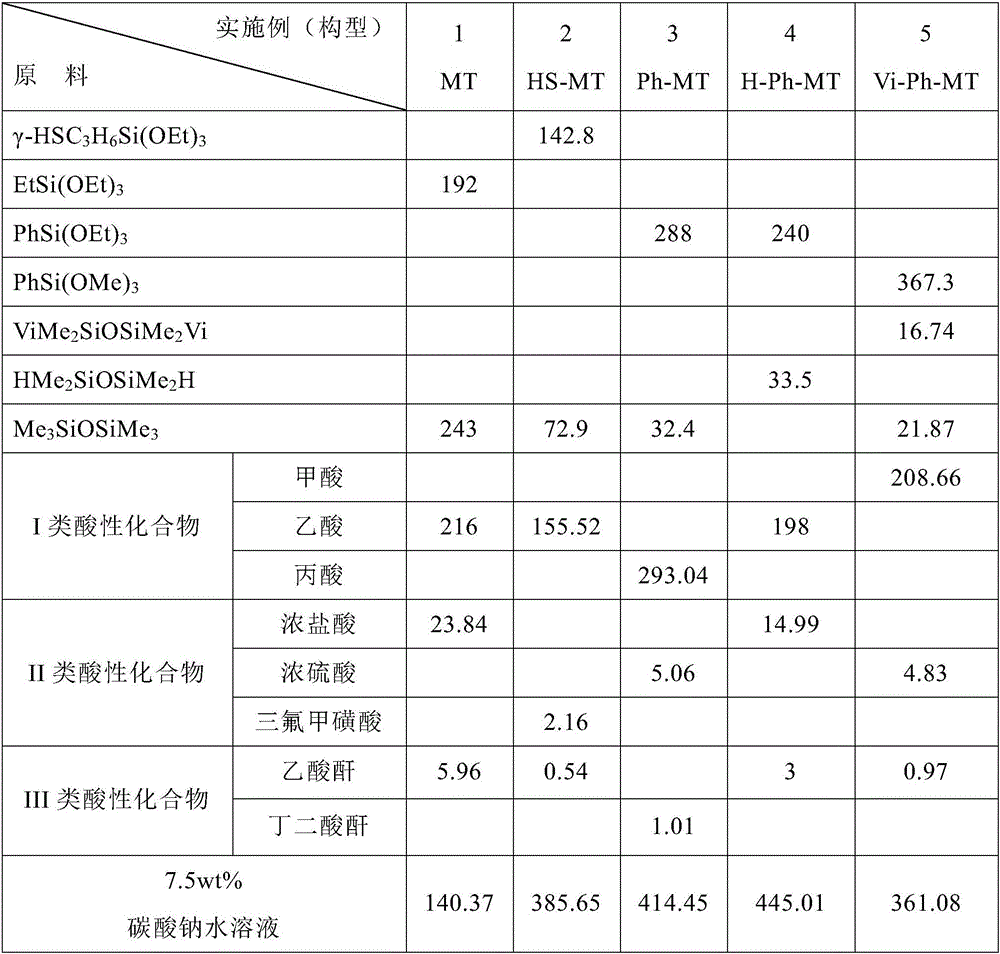

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Preparation method of vanadium nitride nano powder body

InactiveCN1380247AHigh yieldControl granularityNitrogen-metal/silicon/boron binary compoundsMicrometerVanadium nitride

The preparation method of vanadium nitride nano powder body includes the following steps: using industrial-grade V2O5 to make reduction reaction to prepare VOCl2 solution, making said solution react with (NH4)2CO3 or NH4HCO3 to synthesize vanadyl (IV) basic ammonium carbonate precursor, in the atmosphere of NH3 and under the moderate condition making the above-mentioned precursor undergo the processes of ammonization and nitrogenation so as to obtain the invented vanadium nitride nano powder body whose grain size is 20nm-1 micrometer, distribution of particle size is uniform and vanadium nitride content is greater than 98%.

Owner:SUN YAT SEN UNIV

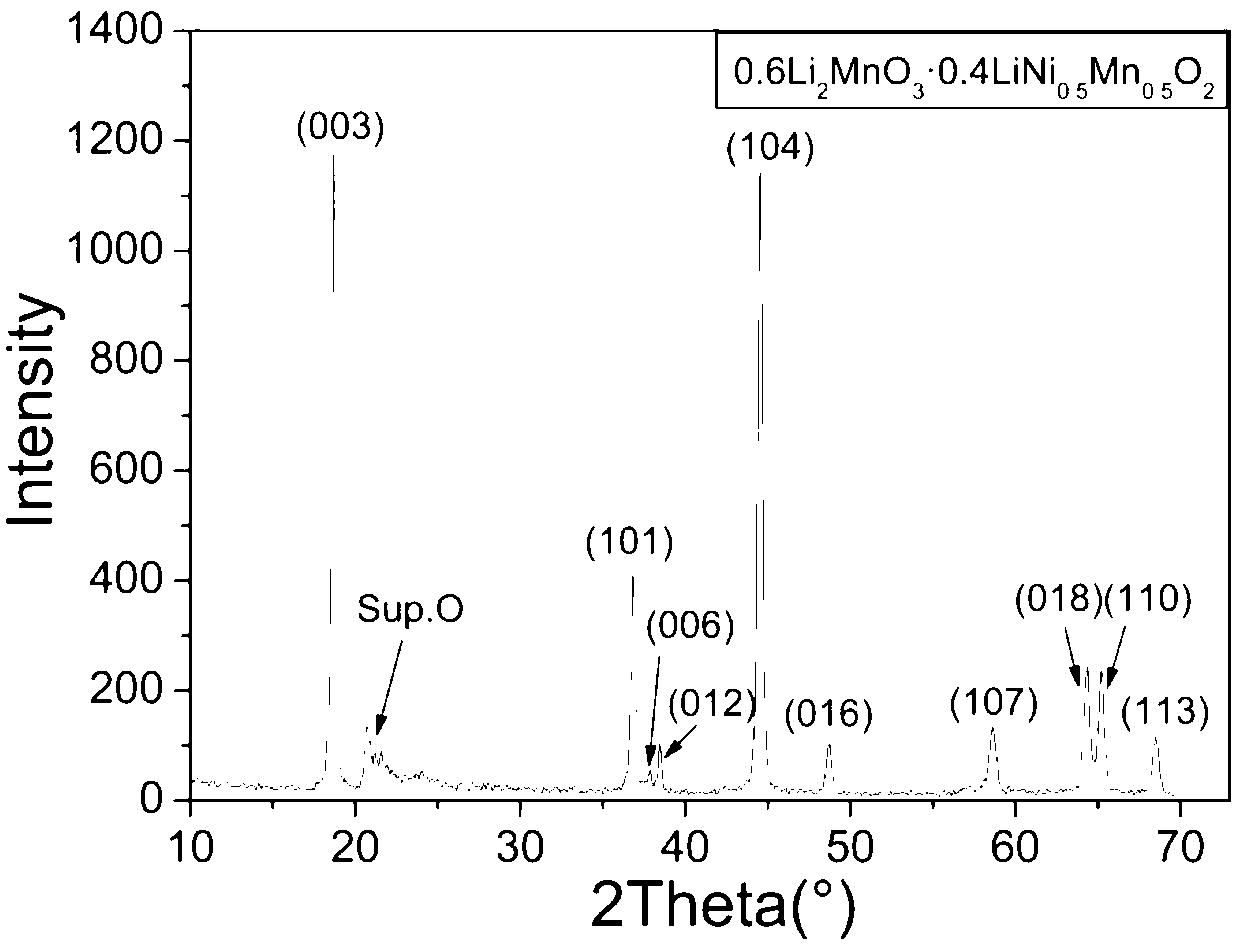

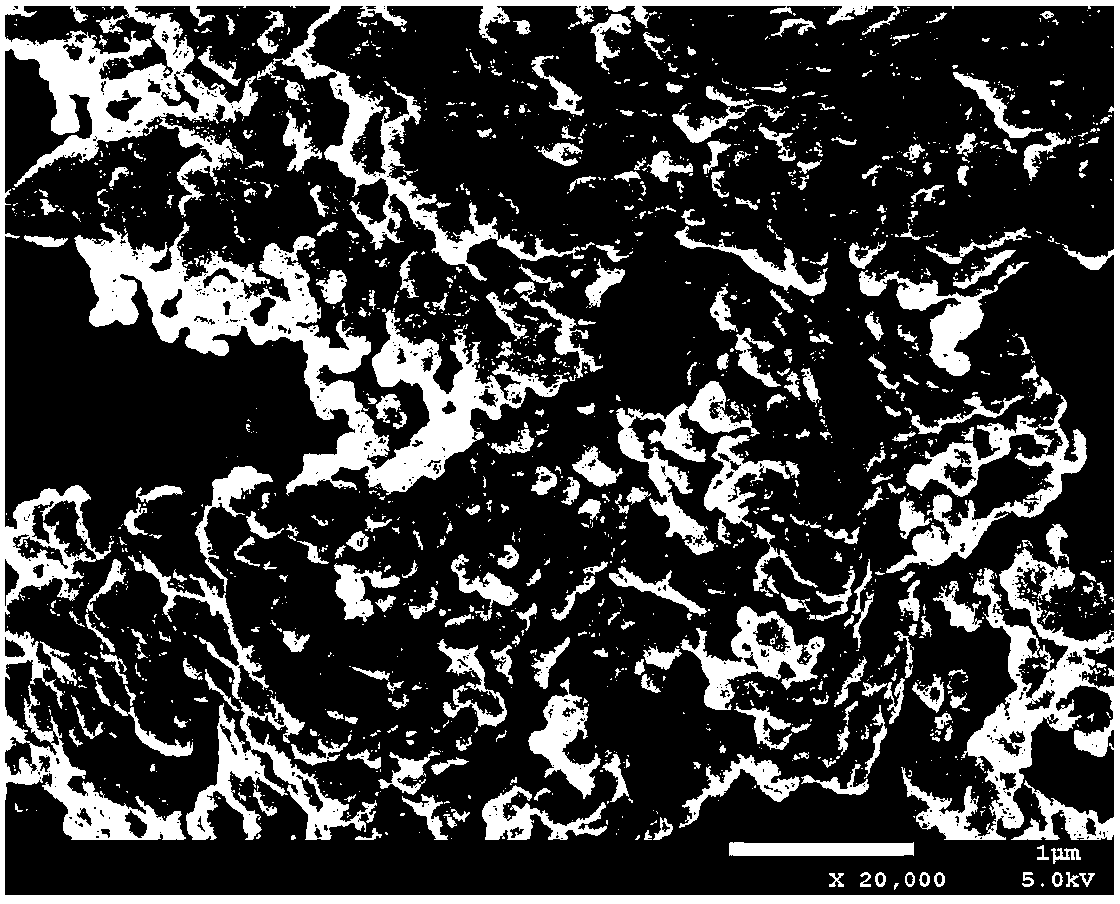

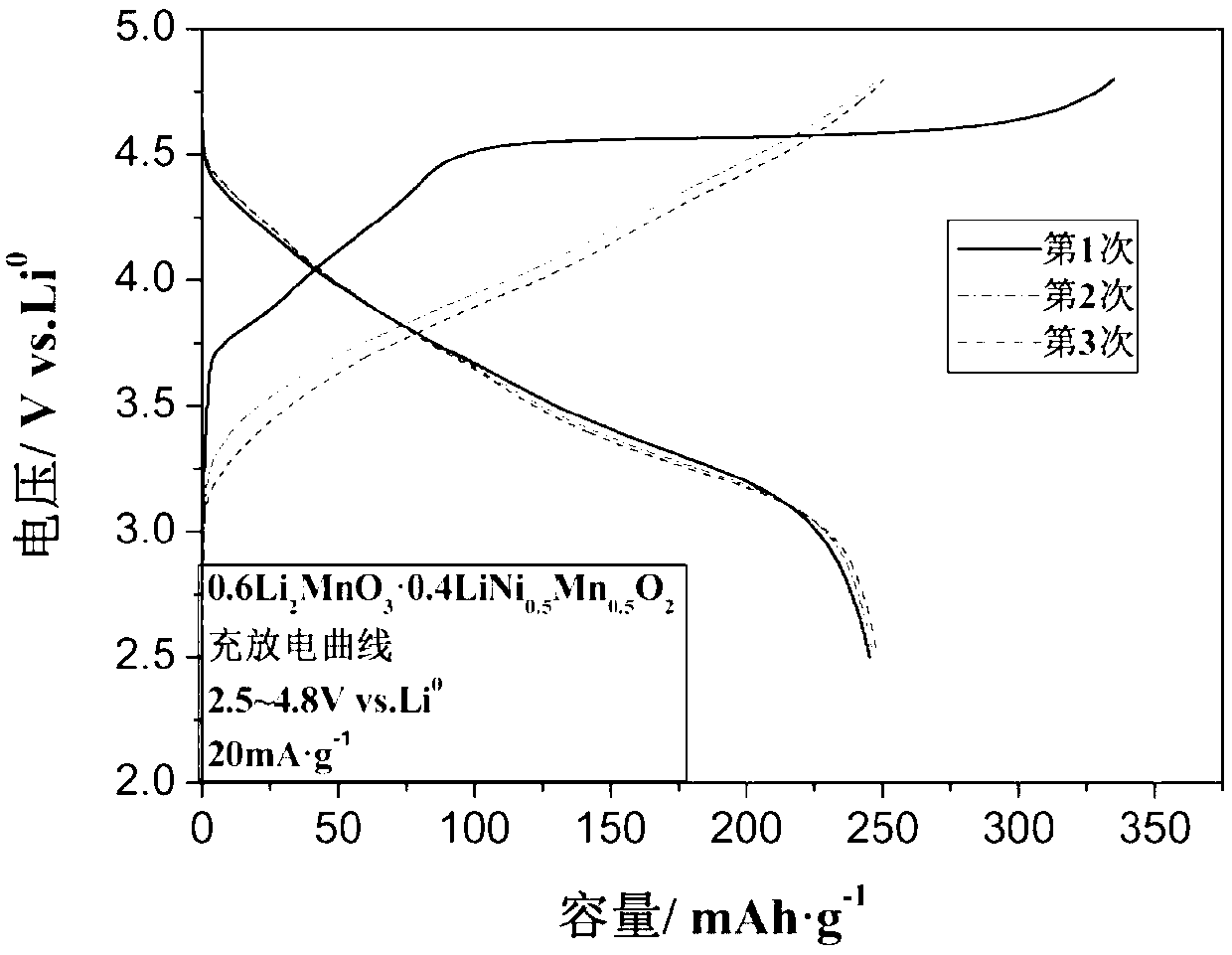

Lithium-rich manganese-based material and preparation method thereof

The invention relates to a lithium-rich manganese-based material and a preparation method thereof. The preparation method is a sol-spray pyrolysis method and comprises the steps of precursor sol preparation, spray drying, high-temperature calcining and the like. The preparation method disclosed by the invention has the advantages of simple process flow, less equipment input, high continuous degree and no exhaust of tail gas or discharge of waste liquid. The lithium-rich manganese-based anode material disclosed by the invention has excellent electrochemical performance, discharge capacity as high as 225-250A.h.g<-1> and favorable excellent performance; and under the multiplying power of 0.5C, the discharge capacity of the lithium-rich manganese-based material can be maintained over 150mA.h.g<-1>.

Owner:SICHUAN UNIV

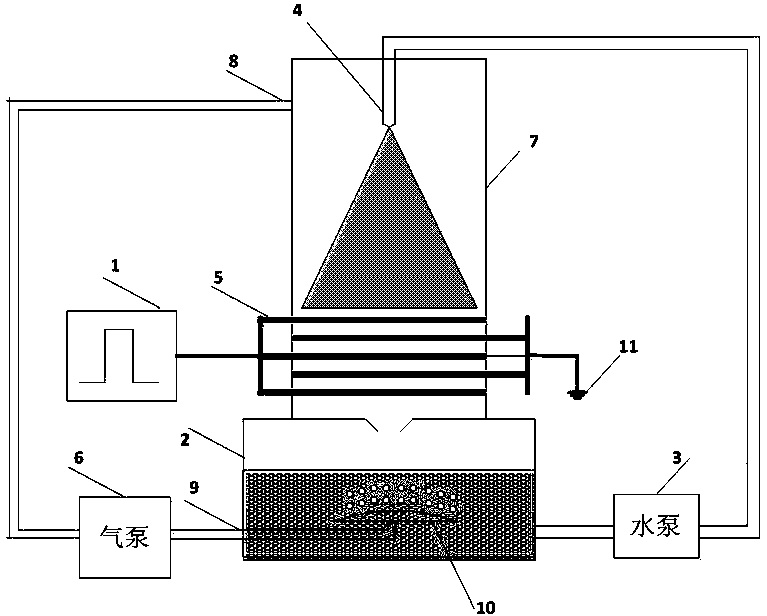

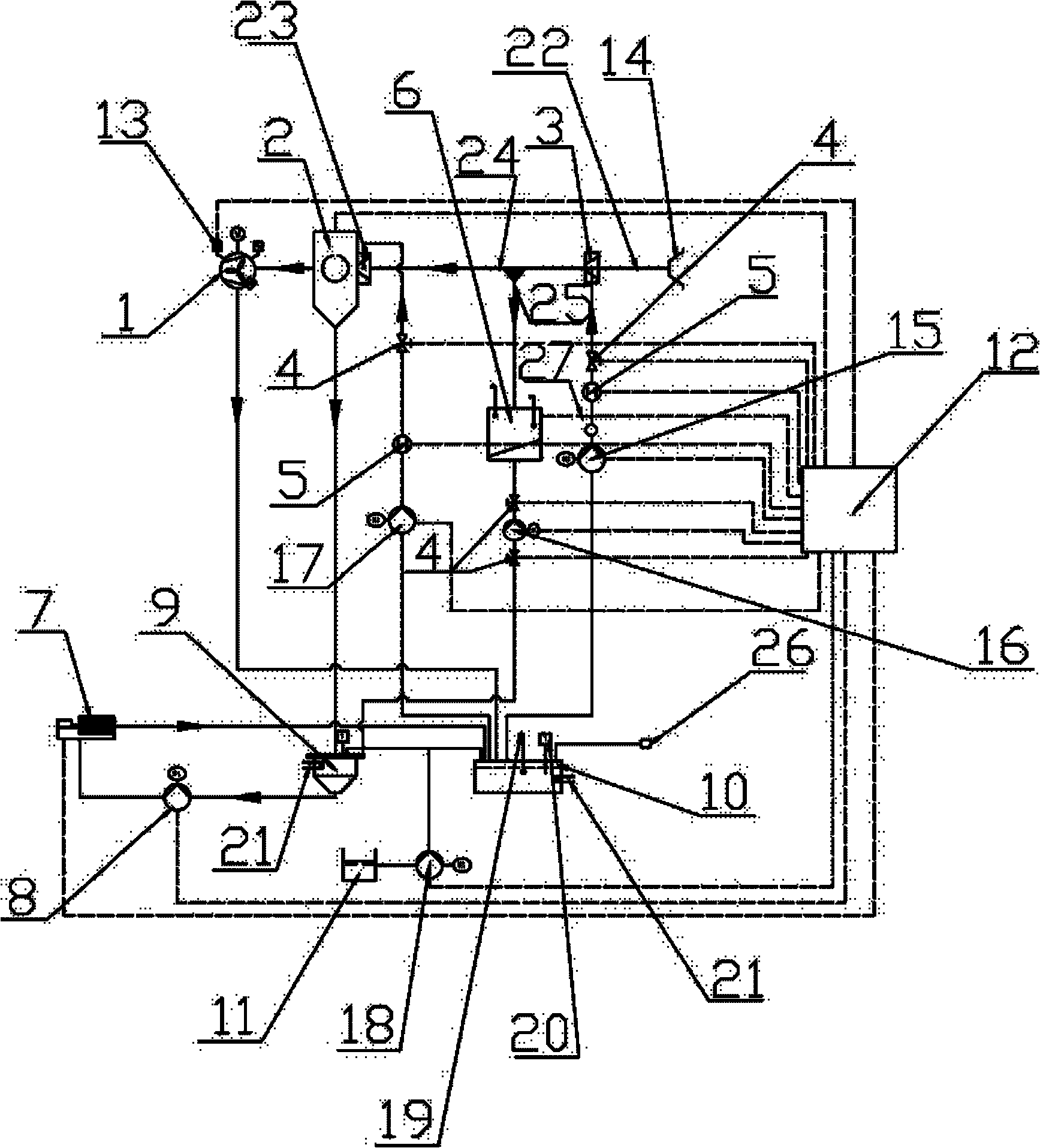

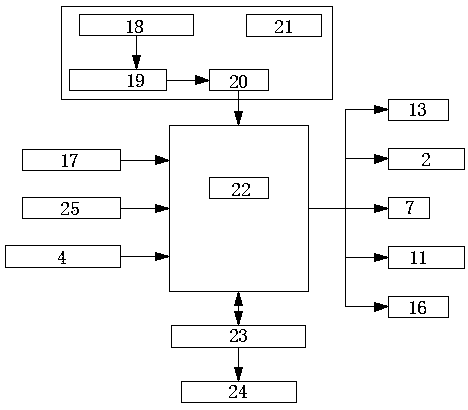

Device for removing toxicity in traditional Chinese medicine wastewater by plasma discharge

InactiveCN103466747AAvoid corrosionLarge amount of processingWater/sewage treatment by irradiationWater/sewage treatment by oxidationBiochemical engineeringWastewater

The invention belongs to the technical field of wastewater treatment, and particularly relates to a device for removing toxicity in traditional Chinese medicine wastewater by plasma discharge. The device is mainly composed of a plasma reactor, a pulse power supply, a sewage receiving tank, am air pump and a water pump. Traditional Chinese medicine wastewater is pumped from a sewage tank to the top of the reactor by the water pump; the middle part is provided with a discharge electrode, and the bottom is provided with the sewage receiving tank. The discharge electrode is connected with the external pulse power supply, and is the core of the whole device. The outer wall of the reactor is connected to the ground, thereby ensuring the electric safety of the whole device. Meanwhile, the air pump connects the upper part of the reactor with the top of the sewage receiving tank, and the gas generated by discharge is recycled and connected to an aeration tank by the air pump and introduced into the sewage receiving tank, thereby further enhancing the treatment efficiency. The device can effectively remove toxic groups in the traditional Chinese medicine sewage, is beneficial to subsequent biochemical degradation of the traditional Chinese medicine sewage to finally achieve the discharge standard, and has the advantages of simple treatment method, low cost and high efficiency.

Owner:FUDAN UNIV +1

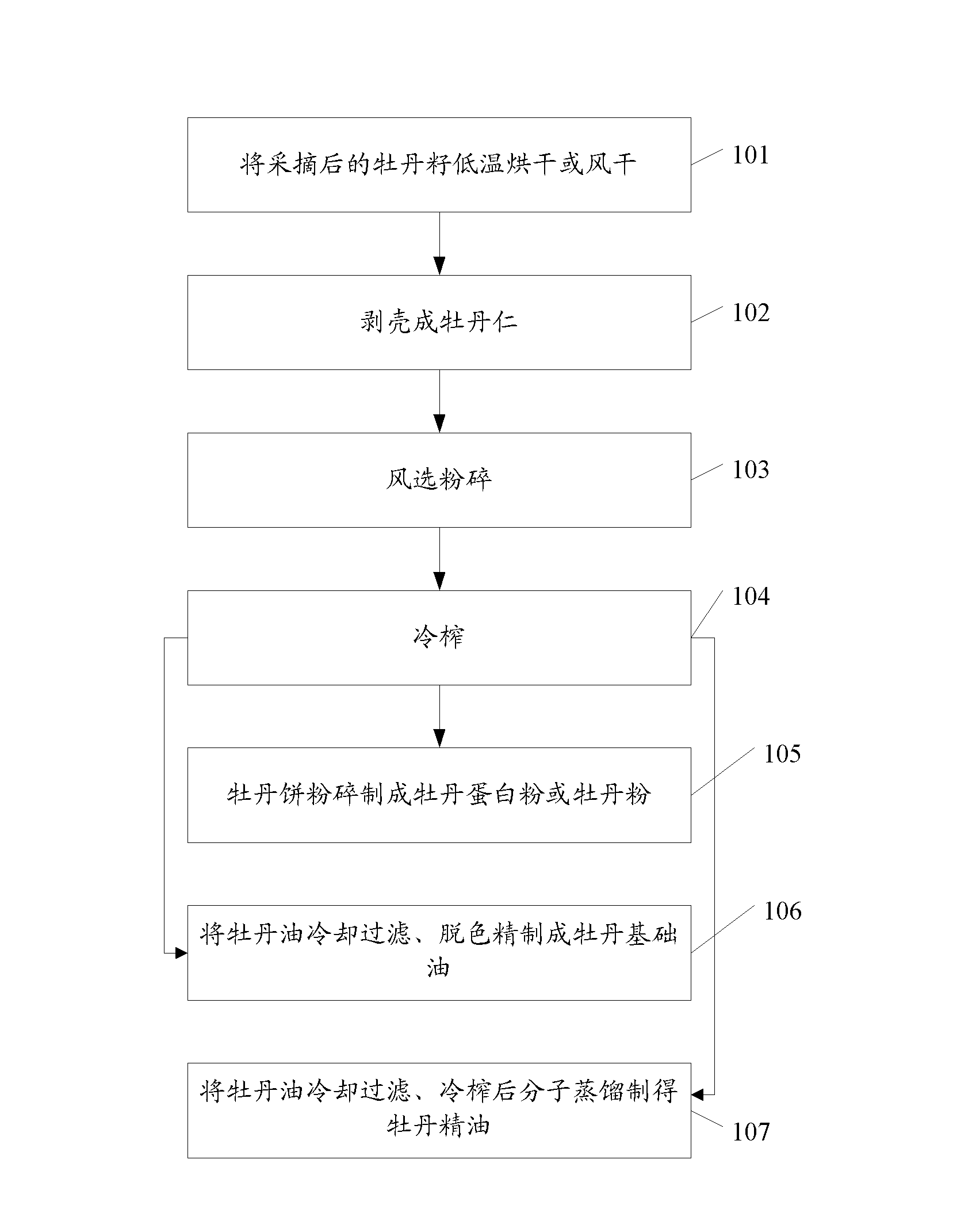

Extraction method of peony product

InactiveCN102994208ANot dischargedShort operation processProtein composition from vegetable seedsFatty-oils/fats refiningSolventPollution

The invention provides an extraction method of a peony product. According to the invention, picked peony seeds are subjected to low-temperature bake-drying or air-drying; the seeds are shelled, such that peony seed kernels are obtained; winnowing is carried out; and cold-pressing is carried out, such that peony cake or peony oil is obtained. In prior arts, impurities in peony products are hard to remove; an extraction temperature is high; toxic solvent and organic chemical substance residues are easy to occur; effective component is easy to consume, such that natural activity is lost, and physiological role and pharmacological activity of the product are damaged; and severe pollution. With the peony product extraction method provided by the invention, the problems are solved.

Owner:LUOYANG TIANXIANG MUDAN DEV CO LTD

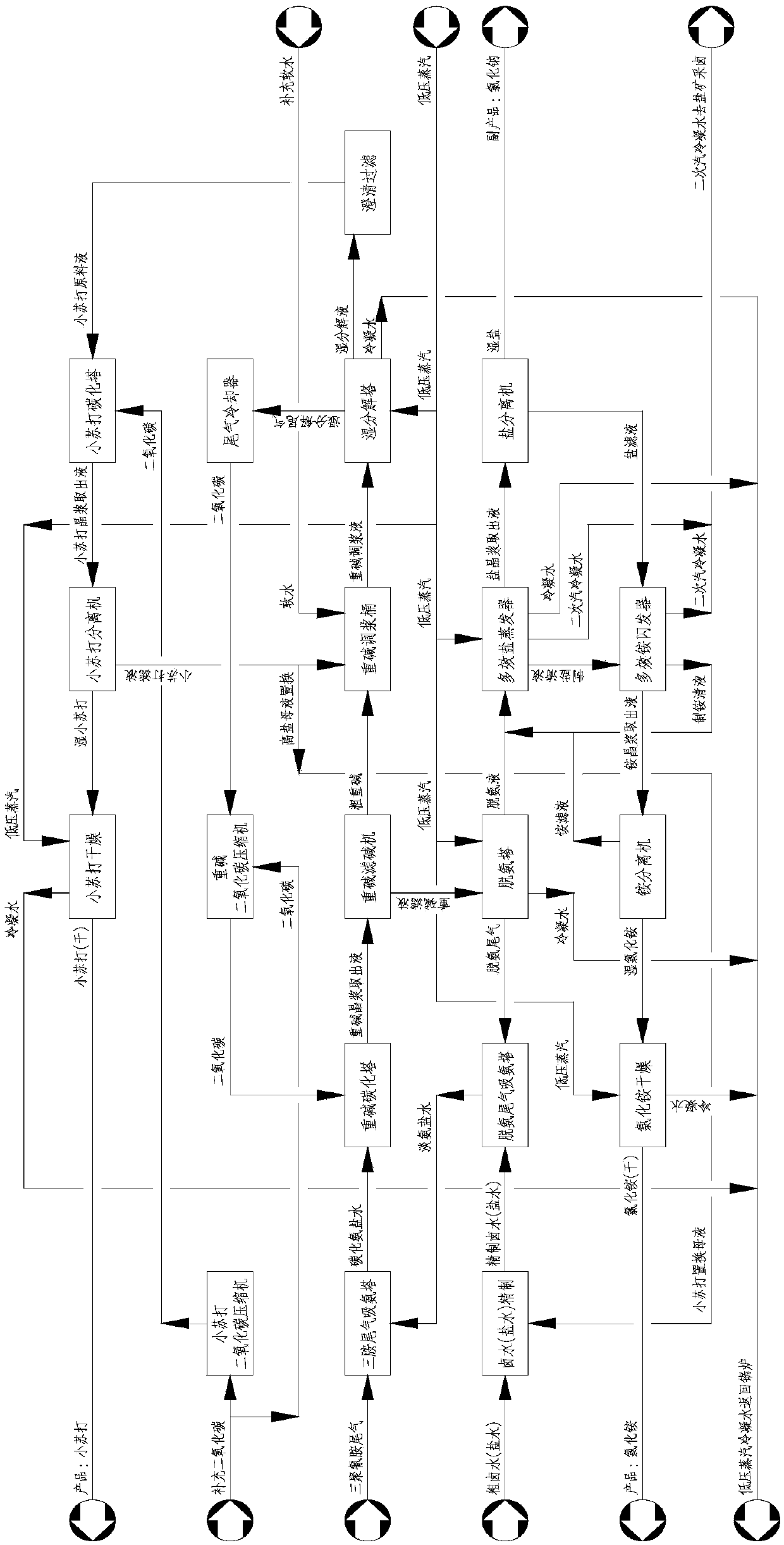

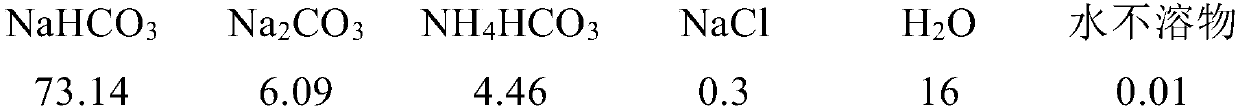

Technology for producing sodium bicarbonate and ammonium chloride by using triamine tail gas

InactiveCN107934996AIncrease profitNot dischargedAlkali metal chloridesAmmonium chlorideSodium bicarbonateFiltration

The invention discloses a technology for producing sodium bicarbonate and ammonium chloride by using triamine tail gas. The technology takes ammonia and carbon dioxide-containing melamine tail gas aswell as bittern or brine as raw materials, and adopts the technical processes of bittern or brine purification, tail gas deamination, triamine tail gas ammonia suction, ammoniacal brine carbonation, sodium bicarbonate separation, sodium bicarbonate pulp-mixing, wet decomposition, clarification and refined filtration, alkali liquor re-carbonation, sodium bicarbonate centrifugal drying, sodium bicarbonate filtrate deamination, multiple-effect evaporation and concentration salt manufacturing, multiple-effect flash vaporization ammonium manufacturing and separating and drying and the like to enable the tail gas generated through melamine production by urea is effectively used. The technology provided by the invention overcomes the defects that the spent liquor discharge amount of an ammonia-soda process is large and the mother solution of a combined alkaline manufacturing method is difficult to balance, the floor space of a device is small, and only low grade steam is used.

Owner:DALIAN RES & DESIGN INST OF CHEM IND +1

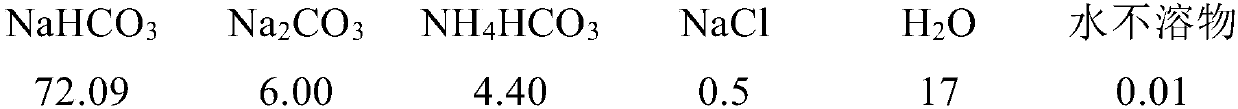

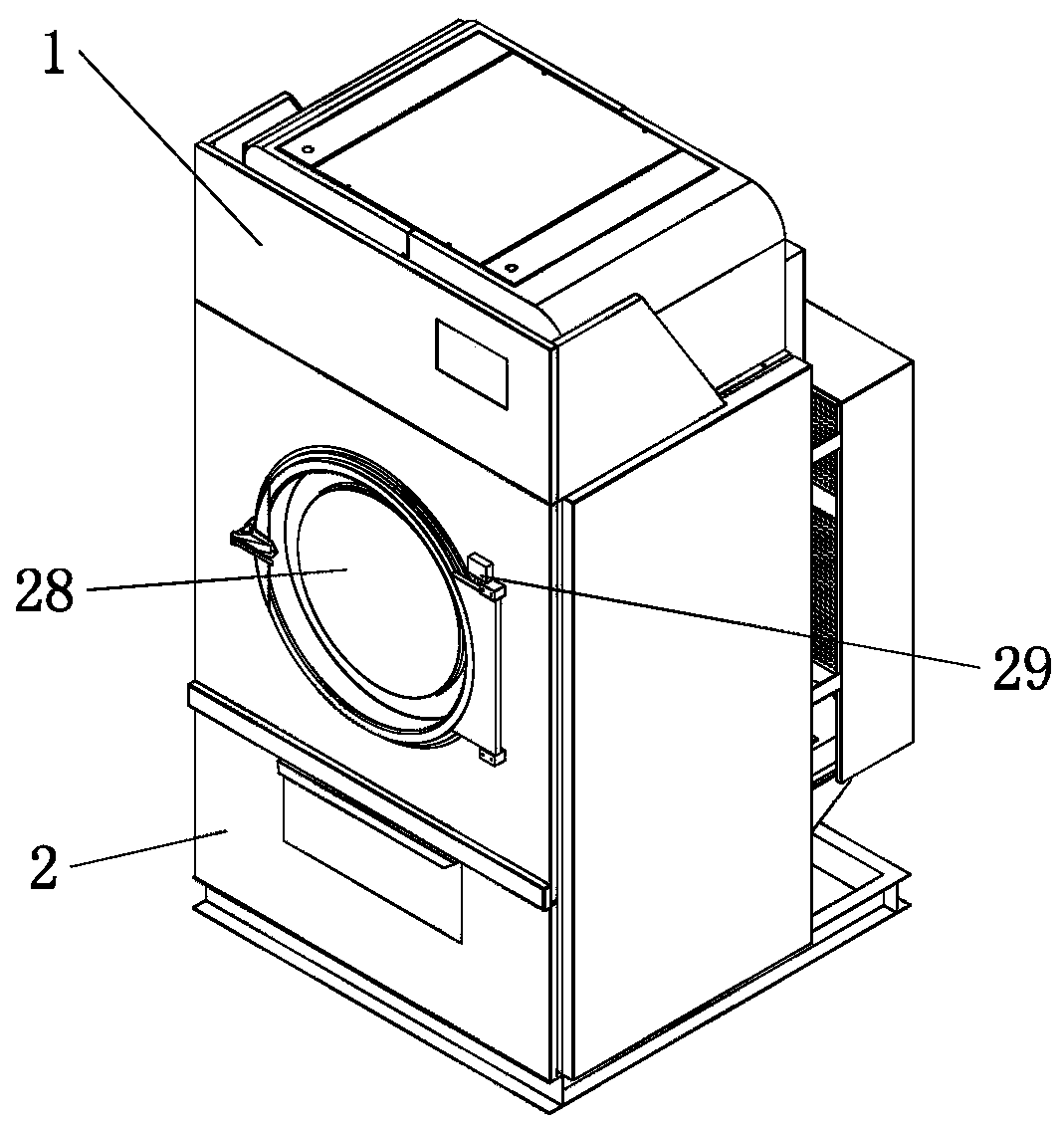

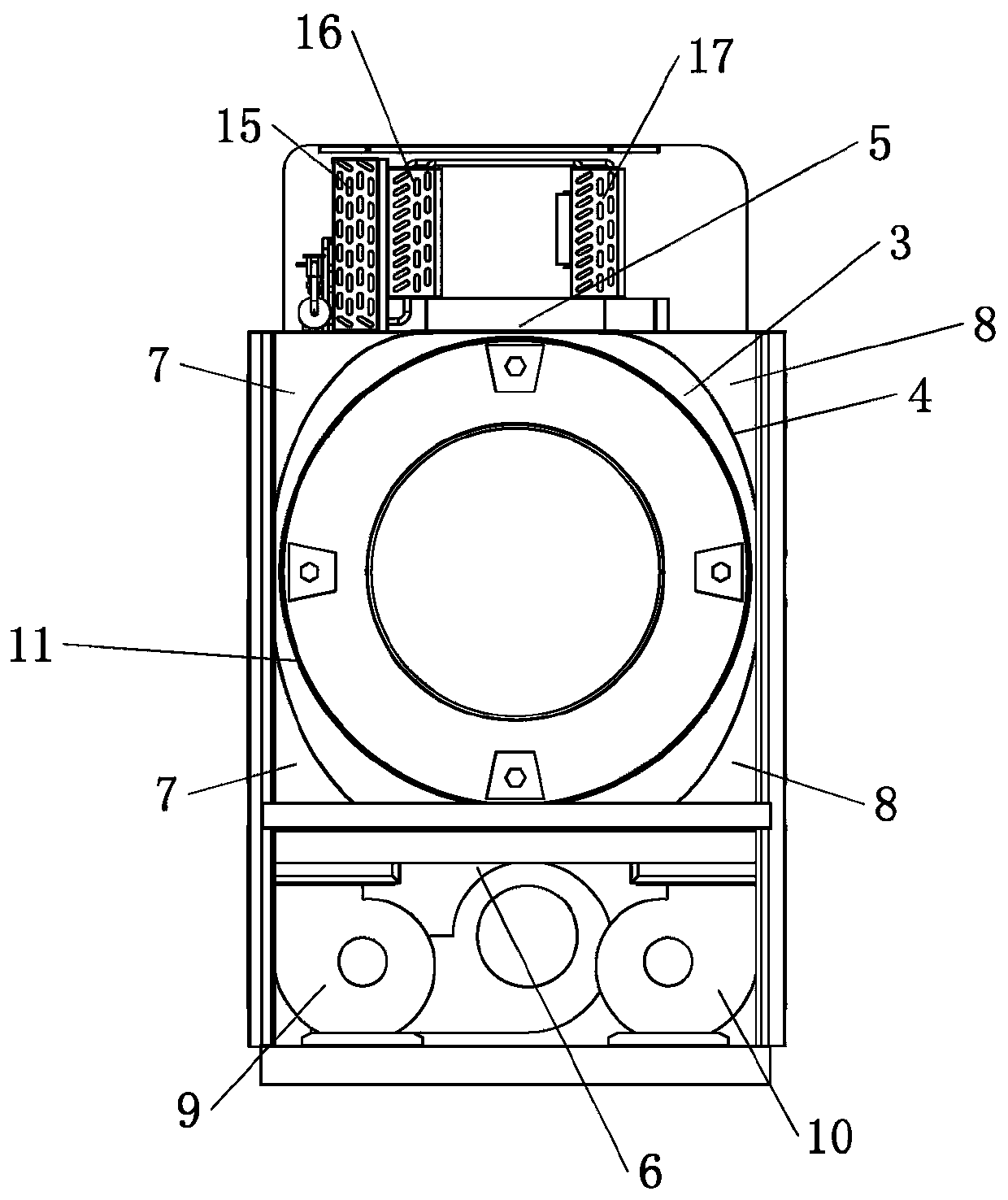

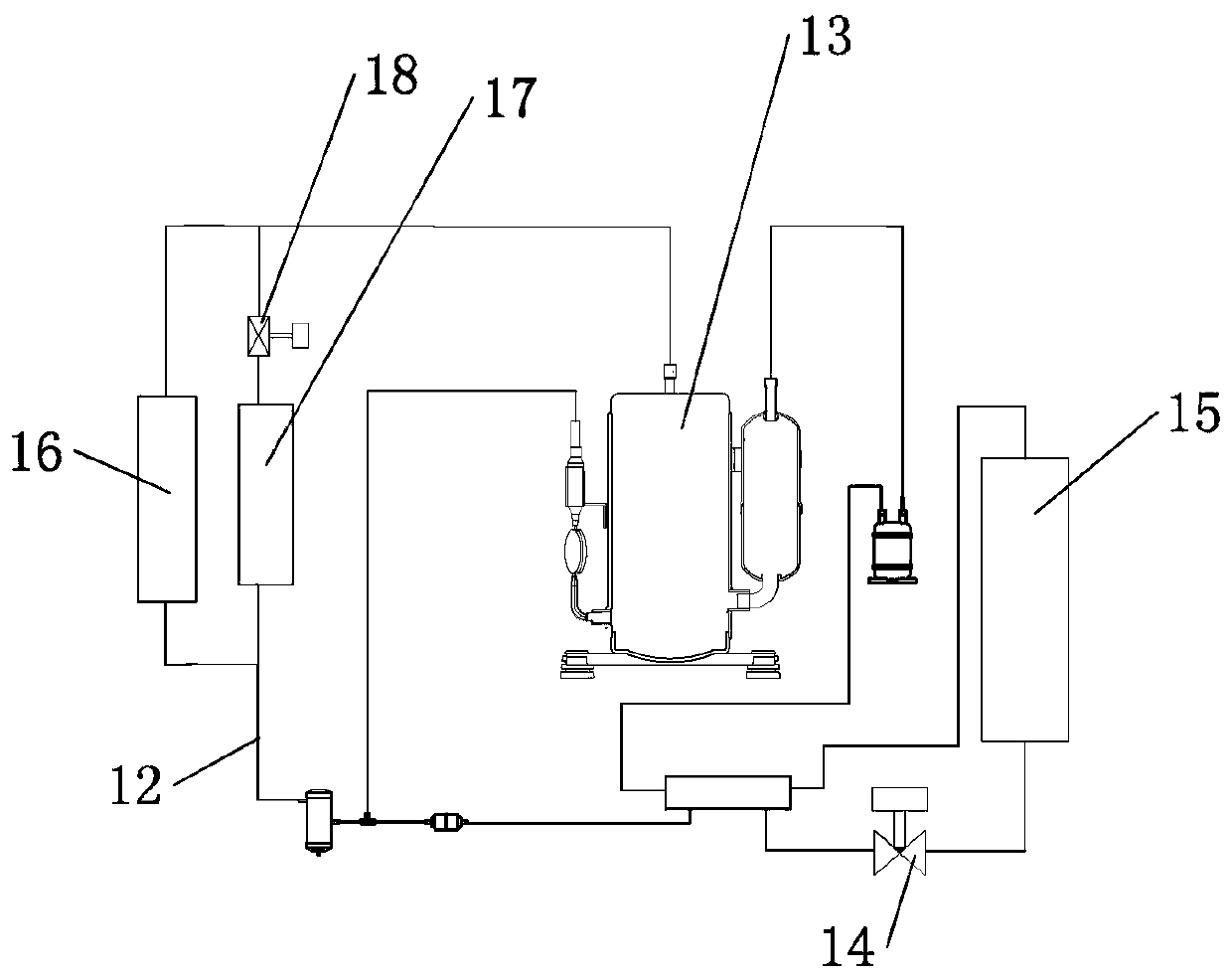

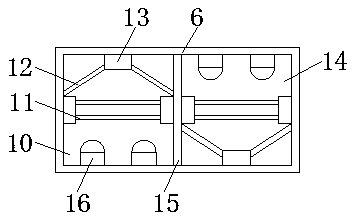

Semiconductor heating drying device

InactiveCN102182051AReduce the temperature difference between the hot and cold endsIncrease contact heat exchange areaTextiles and paperLaundry driersPlate heat exchangerThermopile

The invention discloses a semiconductor heating drying device, which belongs to drying equipment and solves the problem that the cold energy of cooled dry air cannot be reclaimed and the problem that the temperature difference between the cold end face and the hot end face of a semiconductor thermopile in the traditional drier. The semiconductor heating drying device comprises a box type shell, the semiconductor thermopile, a cold end heat exchanger, a hot end heat exchanger, a circulating pipeline and a pre-heating cylinder, wherein the circulating pipeline passes through the pre-heating cylinder along the axial direction; an inlet of the circulating pipeline is connected with an air outlet of a drying chamber in the shell; and an outlet of the circulating pipeline is communicated with the upper end face of the cold end heat exchanger; the lower end face of the cold end heat exchanger is connected with an inlet of the pre-heating cylinder through a pre-heating pipeline; and an outlet of the pre-heating cylinder is communicated with the lower end face of the hot end heat exchanger through a backheating pipeline. The semiconductor heating drying device has a compact structure, is easy to mount, does not exhaust wet and hot air and does not pollute environment. Compared with electric heating or positive temperature coefficient (PTC) heating and drying equipment, the semiconductor heating drying device is lower in electric power consumption. The whole device has few mechanical motion parts, is high in reliability, is easy to repair and maintain, has long service life, has a good effect of dehumidifying and drying articles and is suitable to be used in houses or hotels.

Owner:HUAZHONG UNIV OF SCI & TECH

A comprehensive utilization method for low-grade bauxite

InactiveCN104340998AEfficient separationAchieve cycleElectrolysis componentsAluminium hydroxide preparationFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method for bauxite and particularly relates to a comprehensive utilization method for low-grade bauxite. The method includes following steps of: (1) mixing the low-grade bauxite with hydrochloric acid after ore grinding; (2) performing solid liquid separation and washing after the reaction is cooled; (3) adding the solution obtained in the step (2) into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; (4) preparing the aluminium hydroxide and iron hydroxide solid obtained in the step (3) into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; (5) subjecting the sodium chloride solution obtained in the step (3) to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; and (6) returning the sodium hydroxide solution that is discharged from an ionic membrane cathode zone in the step (5) into the step (3) and recycling. The method is obvious in environment protection effects, and effectively separates aluminum, iron and silicon in the low-grade bauxite to achieve comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Pure biomass barbecue charcoal and manufacturing method thereof

InactiveCN103275783AHigh dry basis fixed carbon contentHigh calorific valueBiofuelsSolid fuelsCelluloseCarboxymethyl cellulose

The invention discloses pure biomass barbecue charcoal and a manufacturing method thereof. The pure biomass barbecue charcoal consists of the following components in parts by weight: 0-80 parts of bamboo chip charcoal powder, 0-70 parts of wood chip charcoal powder, 20-80 parts of cotton stalk charcoal powder, 20-25 parts of adhesive and 1-2 parts of boron mud, wherein the adhesive is prepared by uniformly mixing carboxymethyl cellulose, alpha starch and water according to a weight ratio of 0.5:1:5. The manufacturing method comprises the following steps of: preparing the wood chip charcoal powder, bamboo chip charcoal powder, cotton stalk charcoal powder and an adhesive; mixing the bamboo chip charcoal powder, wood chip charcoal powder and cotton stalk charcoal powder, and adding the boron mud for uniformly mixing and stirring; and finally, adding the adhesive, fully and uniformly stirring, pressing the mixture in a molding abrasive tool, demolding to obtain the molded carbon block, drying to the moisture content of 2-5 percent, and obtaining the pure biomass barbecue charcoal which is non-toxic, safe, environment-friendly, easily ignitable and high in heat value. The pure biomass barbecue charcoal has the characteristics of simple manufacturing method, wide raw material source and low production cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

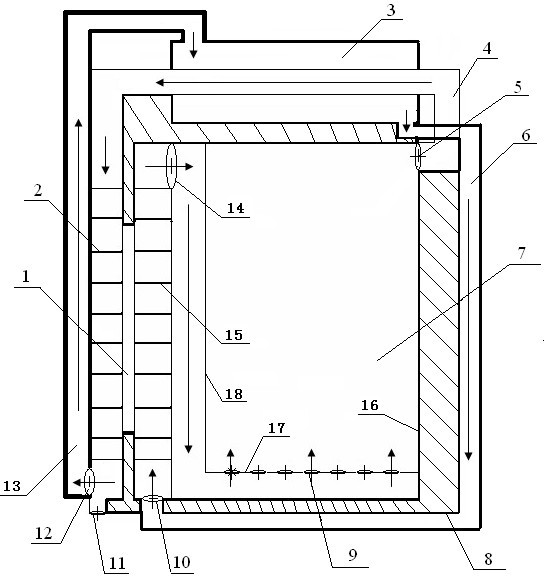

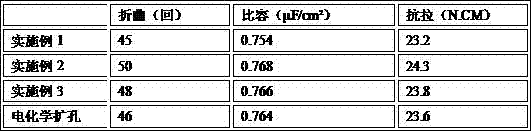

Novel etched foil chambering technology

InactiveCN107502948AExtended service lifeEasy to handleElectrolytic capacitorsMetal surface removal provisionCopperMaterials science

The invention relates to a novel etched foil chambering technology. The novel etched foil chambering technology comprises the following steps that (1) pretreatment is carried out; (2) first-stage etching hole forming is carried out; (3) medium treatment is carried out; (4) second-stage pure chemistry chambering etching is carried out; and (5) aftertreatment is carried out. The novel etched foil chambering technology is mainly used for solving the problem that in the existing chambering technology, electrocorrosion is adopted, and therefore the factors like high cost, large heat generating amount, short copper bar using service life and the like exist.

Owner:江苏国瑞科技有限公司

Carbon-based wave absorbing material prepared from aluminosilicate polymer and preparation method of carbon-based wave absorbing material

The invention discloses a carbon-based wave absorbing material prepared from aluminosilicate polymer and a preparation method of the carbon-based wave absorbing material. The carbon-based wave absorbing material is formed by using metakaolin, a carbon material and an alkali activating solution to synthesize the aluminosilicate polymer and curing, wherein a mole ratio of metakaolin and the carbon material is 1:(3-24), and a mole ratio of silicon and aluminum in the aluminosilicate polymer is (1-2):1. The preparation method includes: activating kaolin; preparing mixed powder; preparing the alkali activating solution; preparing the aluminosilicate polymer; curing for forming. The preparation method is simple in process, capable of realizing direct forming of complex or large parts at low temperature and wide in application range. The carbon-based wave absorbing material is low in cost and high in unit thickness absorptivity and meets requirements on thinness, lightness, width and strength.

Owner:智合(深圳)新材科技有限公司

Preparation method for hydrotreatment catalyst

ActiveCN103801346AGood penetrationConducive to diffusionPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryEther

The invention discloses a preparation method for a hydrotreatment catalyst. The method comprises the following steps: in the process of gel formation by concurrent flow of an alkaline solution containing aluminum and an acidic solution containing aluminum, adding an additive and an organic template agent in the manner of concurrent flow at the same time, controlling proper reaction conditions and carrying out gel formation, wherein the organic template agent is cellulose ethers; then adding an alkaline solution to adjust a pH value; then carrying out filtering, washing and drying so as to obtain the alumina dry gel; carrying out molding, drying and calcining so as to obtain an alumina carrier; and loading active metal components. The catalyst prepared by using the method has the advantages of a large specific surface area, a great pore volume and a reasonable pore structure and is particularly applicable as a catalyst for hydrodesulfurization or hydro-conversion of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

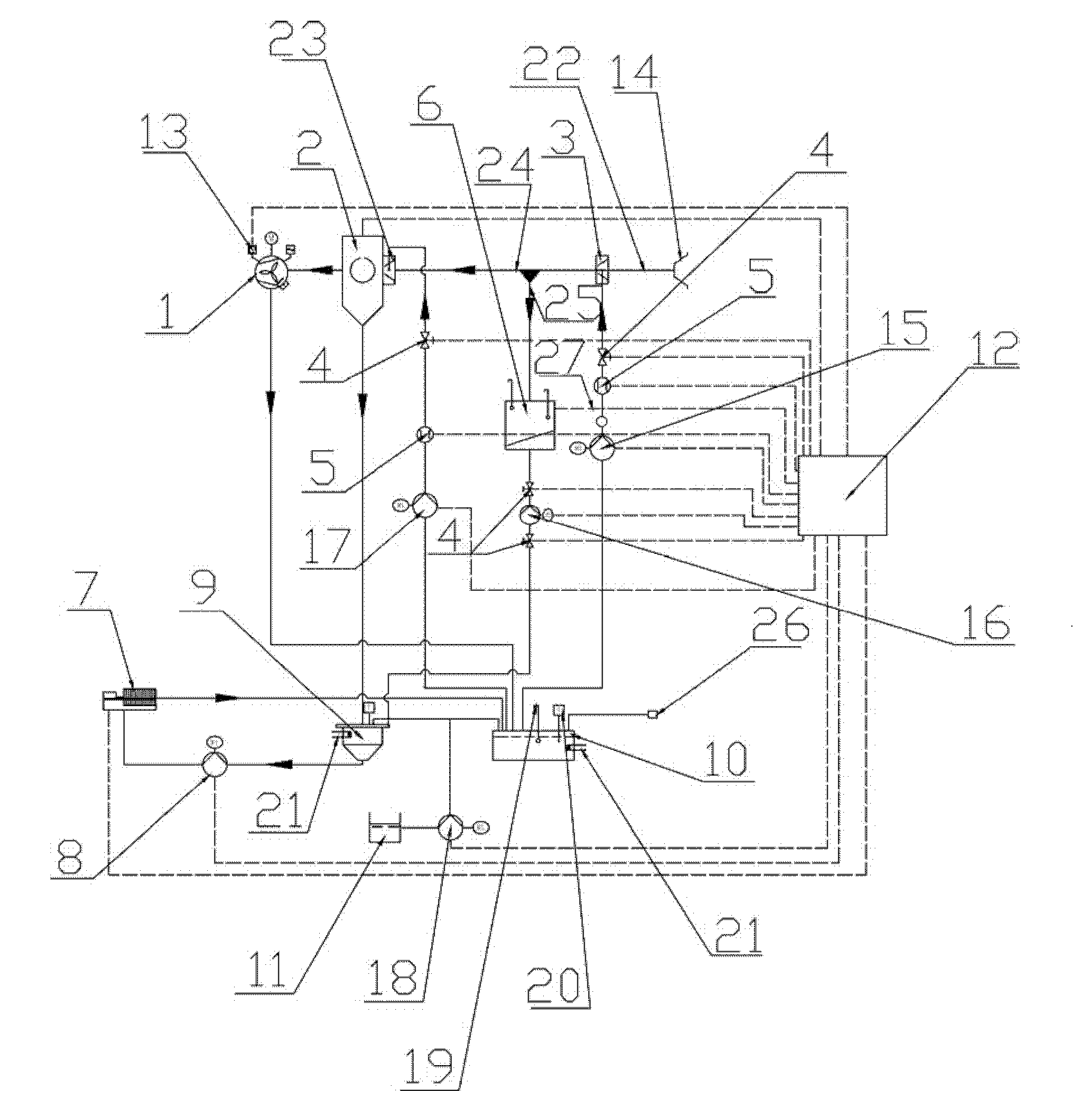

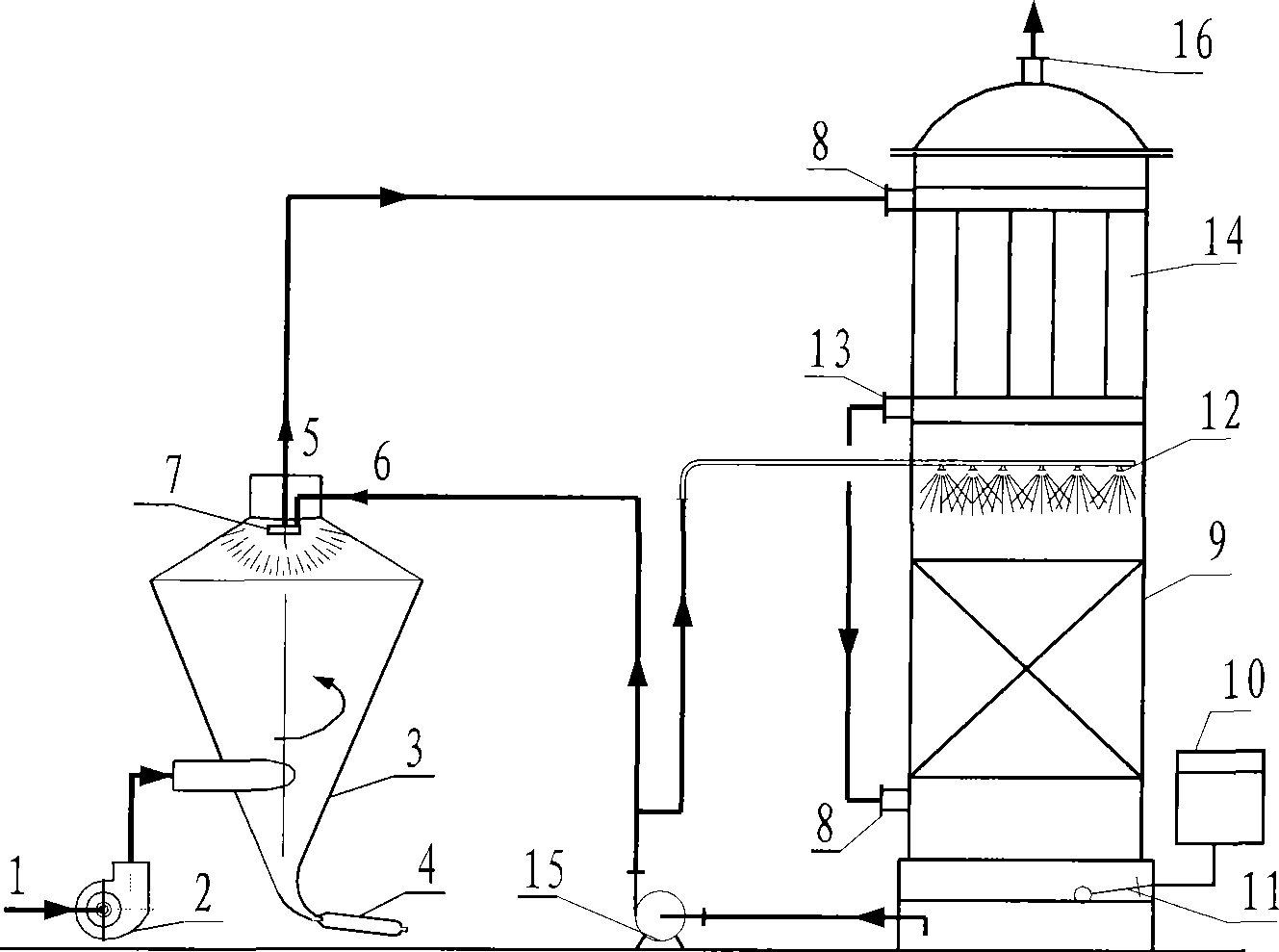

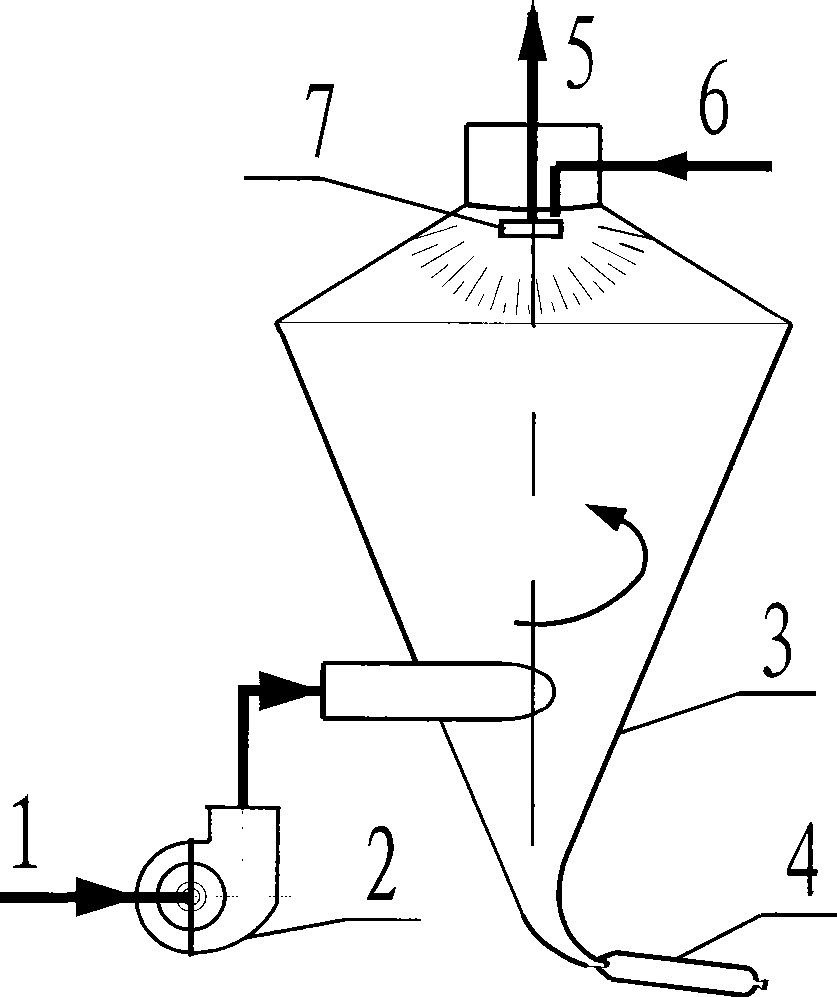

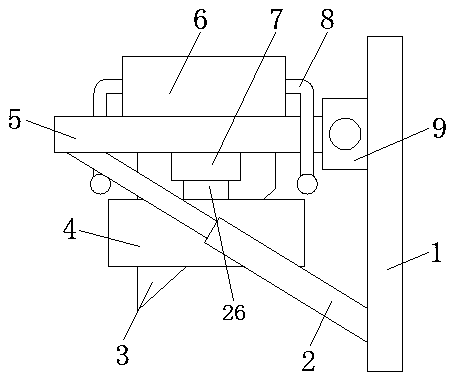

A method and equipment for treating waste gas of a hot press

ActiveCN102284220AImprove processing efficiencyWon't catch fireUsing liquid separation agentSewageWater spray

The invention relates to a method and equipment for treating waste gas of a hot press. The method comprises the following steps of: S1, injecting water into a dust absorption pipeline to ensure that gas and water are fully contacted and mixed; and S2, allowing water spray carrying waste gas to enter a water dust scrubber, collecting sewage carrying impurities, and discharging purified gas. A water injection device is arranged in the dust absorption pipeline; the dust is not stuck onto the dust absorption pipeline easily so the pipeline is prevented from being blocked and fire is avoided; the waste gas treatment efficiency is high; and the dust, and a large amount of high-temperature volatile matter of formaldehyde and transmission lubricant are collected, the collected waste gas and waterare treated further ad separated reasonably, water is recycled, and no sewage is discharged, so secondary pollution is avoided. Meanwhile, the invention also provides equipment for treating the wastegas of the hot press.

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

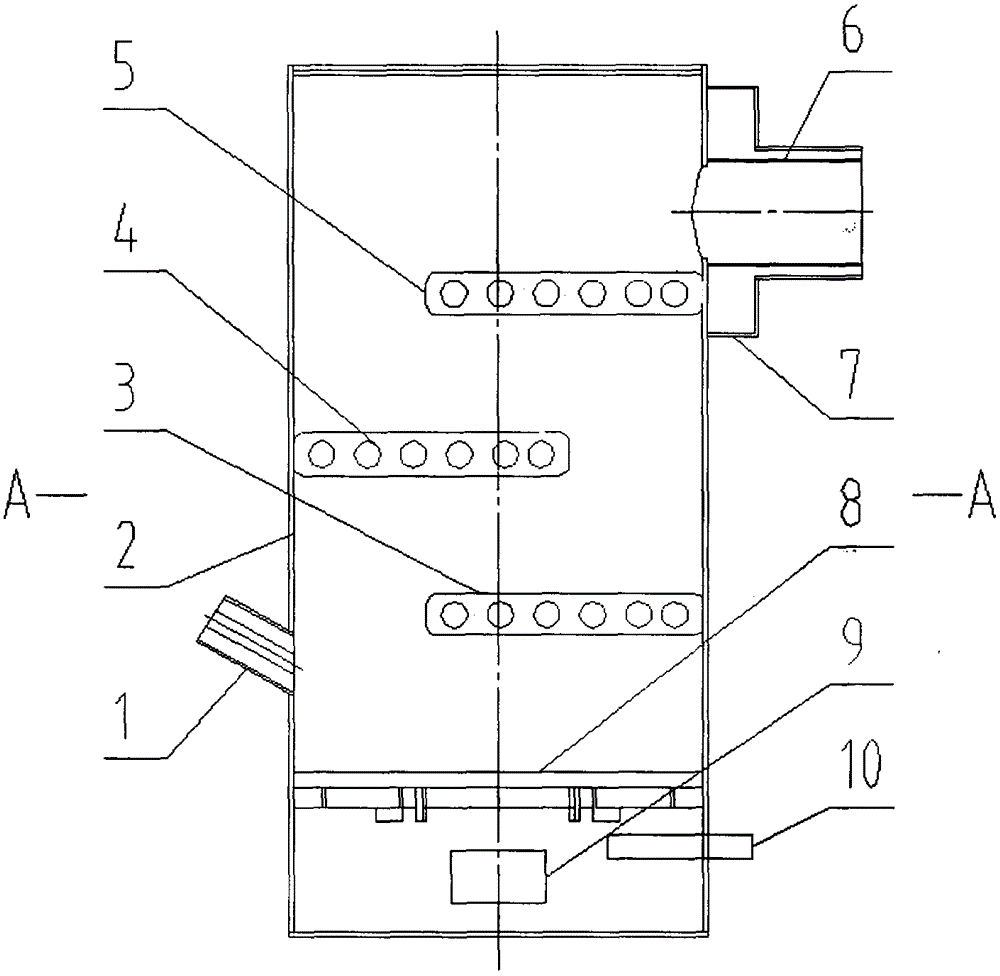

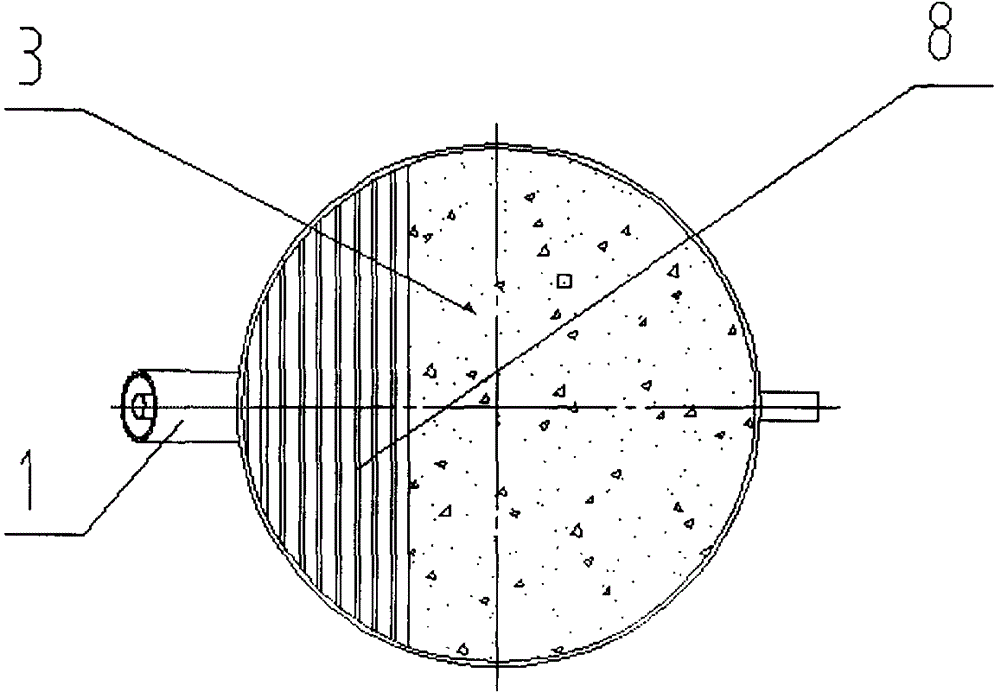

Multi-pass biomass pellet combustion technology and multi-pass biomass pellet combustion device

InactiveCN104566343ABurn fullyExtended combustion strokeSolid fuel combustionBafflesCombustorRenewable energy

Disclosed are a multi-pass biomass pellet combustion technology and a multi-pass biomass pellet combustion device. Three fire stopping walls are arranged above an inner container of a biomass combustor, biomass pellet combustion flames form four passes under action of the three fire stopping walls, combustion stroke is increased, combustion time is lengthened, and sufficient combustion of biomass pellets is guaranteed. A feeding port, a primary-air inlet, a fire outlet and an igniter of the device are fixed on the cylinder wall of the inner container of the biomass combustor, and a fire grate and the three fire stopping walls are fixed in a hollow cavity of the inner container of the biomass combustor. Biomass pellets enter the fire grate in the biomass combustor through the feeding port and start to be combusted under action of primary air, the stroke is increased remarkably when the combustion flames are blocked off by the three fire stopping walls, the biomass pellets are combusted quite sufficiently, and the combustion flames reach the fire outlet finally and are further combusted under action of secondary air, so that sufficient combustion of the biomass pellets is achieved without emission of carbon monoxide and other harmful substances, and the purposes of renewable energy development and environmental protection are achieved.

Owner:JIANGSU DONGDA THERMAL ENERGY MACHINERY MFG

Novel production method of rubber vulcanization accelerant CZ

The present invention discloses a novel production method of thiofide CZ. The method comprises the following steps: the mixed solution of water and cyclohexane with a volume ratio of 1 to (0.5 to 2.0) is added into an oxidization reactor; under the conditions with the temperature between 20 DEG C and 200 DEG C and the rotating speed of 100 to 4000 rounds per minute, 10 to 30 ml of an accelerant M material slurry with a weight content between 50 percent and 99 percent is added at a flow rate between 5 ml / m and 500 ml / m; hydrogen peroxide solution with a weight content between 1 percent and 35 percent is dropped at a flow rate between 10 ml / m and 150 ml / m; after 1 to 90 minute(s), the accelerant M material slurry with a weight content between 50 percent and 99 percent is dropped into the solution at a flow rate between 10 ml / m and 200 ml / m; after 5 to 300 minutes, a sample is taken, starch KI test paper is used for testing the reaction end point; when the color of the starch KI test paper is changed, the hydrogen peroxide solution and the accelerant M are stopped to be added; the thiofide CZ can be produced after pumping, washing, filtering and drying, and the yield rate of the thiofide CZ reaches above 99 percent. The present invention has the advantages that the process is simple, the industrialization of the process can be easily realized, a small amount of cyclohexane is used, no wastewater with salt is discharged, and the yield rate of the thiofide CZ reaches above 99 percent.

Owner:KEMAI CHEM

Preparation method for hydrotreatment catalyst

ActiveCN103801312AExtended service lifeLarge hole volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationResidual oil

The invention discloses a preparation method for a hydrotreatment catalyst. The method comprises the following steps: in the process of gel formation by cocurrent flow of an alkaline solution containing aluminum and an acidic solution containing aluminum, adding an additive and an organic template agent in the manner of cocurrent flow at the same time, controlling proper reaction conditions and carrying out gel formation; then adding an alkaline solution to adjust a pH value; then carrying out filtering, washing and drying so as to obtain alumina dry gel; carrying out molding, drying and calcining so as to obtain an alumina carrier; and loading active metal components. The catalyst prepared by using the method has the advantages of a large specific surface area, a great pore volume and a reasonable pore structure and is particularly applicable as a catalyst for hydrodesulfurization or hydro-conversion of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

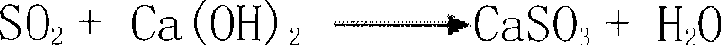

High-efficiency synthetic desulphurization technique without waste liquid

InactiveCN101439258ALittle or no dischargeNot dischargedDispersed particle separationLiquid wasteWater treatment system

A main spray device of a wet process is combined with a main part of spray drying equipment for dry desulfurization, and the dry process and the wet process are used in tandem, thus avoiding a cooling system and a heating system of flue gas, and a complex sewage treatment system. The flue gas first passes through a dry-process spray device for desulfurization and then passes through a wet-process spray device for secondary desulfurization, thus achieving the purpose that the desulfurization effect is better than that of the dry process and the wet process. Alkali liquor is only recycled in operation; finally, the liquid is dried by the heat of high-temperature flue gas to become solid powder which is collected then, thus the purpose of no effluent discharge is achieved and the consumed alkali liquor is automatically refilled.

Owner:刘荣甫

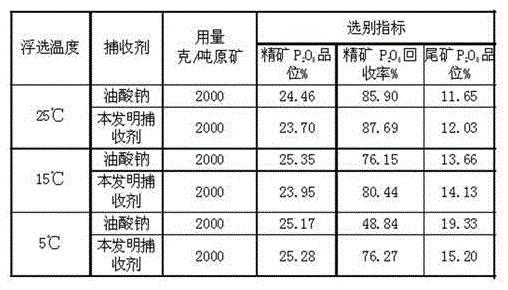

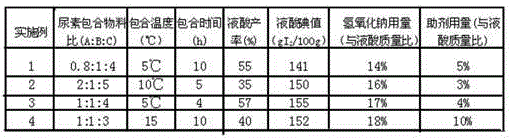

Obverse flotation collecting agent for low temperature-resistant collophanite and preparation method thereof

The invention relates to an obverse flotation collecting agent for low temperature-resistant collophanite and a preparation method thereof. The preparation method comprises the following technological steps of using plant oil residue acidified oil fatty acid as a raw material, utilizing a urea inclusion fractionating method to remove the saturated fatty acid with high melting point and low solubility, and preparing liquid acid with iodine value range of 140-165I2 / 100g, low melting point and high solubility and without saturated fatty acid; adding NaOH (sodium hydroxide) into the liquid acid to saponify, and then adding an additive, so as to obtain the obverse flotation collecting agent for the low temperature-resistant collophanite. The obverse flotation collecting agent for the low temperature-resistant collophanite has the characteristics that the chemical property is stable, the low temperature-resistant property is good, the solution and dispersing properties in water are good, the usage amount is less, the collecting property is strong, the selectivity is good, and the like; the grade of the concentrate can be effectively improved at the lower flotation temperature, and the content of impurities of the concentrate product can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Low formaldehyde release volume urea formaldehyde resin preparation method

This invention relates to a preparation method for urea-formaldehyde resin with low emission of formaldehyde, belonging to a wood processing industrial field. The present method or lower molar ratio causes other negative effects; or formaldehyde-containing wastewater discharge, environmental pollution, long cycle and high cost of equipment; or high cost of additives introduced. The invention uses the process of adding formaldehyde (F) once and urea (U) for four times, which includes: (1) adding formaldehyde solution into ammonium chloride solution with pH of 1.5-2.5 and heating to 60-70DEG C; (2) keeping the formaldehyde / urea molar ratio at 0 .9-1.25 / 1.0; (3) adding the first batch of urea 36.4% -36.8%, heating to 90-95DEG C and maintaining for 55-65 minutes, and adjusting pH to 8.5-10.0 with sodium hydroxide, (4) adding the second batch of urea 13.4% -18.4% and maintaining for 40 minutes; (5) adding the third batch of urea 5.0% -14.1%, adjusting pH to 3.0-5.5 with ammonium chloride and reacting for 5-10 minutes, and adjusting pH to 8 .5-10.0 with sodium hydroxide; and (6) adding the fourth batch of urea 30.1% -45.0% and reacting for 30 minutes, and cooling to room temperature to obtain the final product. The invention makes the free formaldehyde content lower than the national standard: free formaldehyde content less than 0.1%, no discharge of formaldehyde-containing wastewater, environmental friendliness, and reduced cost.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

Method for co-production of feed manganese sulfate by using wastewater of crude indium production

ActiveCN103613141AReduce dosageReduce manufacturing costManganese sulfatesEcological environmentIndium

The invention discloses a method for co-production of feed manganese sulfate by using wastewater of crude indium production. According to the method, on the basis of production of feed manganese sulfate through a wet method, the influence of excessive sulfuric acid and heavy metals including arsenic, cadmium and the like in the wastewater of the crude indium production through a wet method on the environment is thoroughly eliminated while the feed manganese sulfate is produced, so that the production of crude indium and the feed manganese sulfate through the wet method achieves comprehensive and full utilization of wastes, and the pollution caused by waste acid water containing heavy metals to the environment is thoroughly eliminated. The method comprises the steps of 1, performing leaching reaction on manganese ash in a leaching tank by using indium preparation wastewater; 2, performing pressure filtration; 3, adjusting the pH value of the filtrate to 4-4.5, and then pressing liquid; 4, adding barium sulfide to improve the pH value of a stock solution to 5-5.4, and then filtering; 5, cooling and standing the stock solution, adding an SDD (sodium dimethyl dithiocarbamate) solution and a flocculating agent, then performing pressure filtration, concentrating the filtrate, performing evaporative crystallization, and drying to obtain a feed manganese sulfate product. By adopting the method, the indium preparation wastewater and waste residues causing environmental pollution can be fully and comprehensively used, and a raw material for producing manganese sulfate is provided, so that the method is favorable for reducing the production cost and protecting the ecological environment.

Owner:JIANGXI RUIDA NEW ENERGY TECH CO LTD

Color toner and method for making same

The invention discloses a colorful anti-counterfeiting dry toner and preparation method thereof, specially a colorful anti-counterfeiting dry toner for color copying machine, color printer, colour facsimile apparatus, colorful digit integrated machine and chromatic press and preparation method thereof. The dry toner takes the latex polymerized polymer colophony, colouring paint, wax and exterior additive as materials. Firstly the latex polymerized polymer colophony, colouring paint, fluorescent powder and wax are mixed together, uniformly agitated to produce a mix solution; and then a spray drying machine is used to spray and dry the mix solution into granular material at the temperature from 160 to 300 DEG C; finally, an airflow hierarchical equipment is adopted to execute hierarchical screen selecting to the granular material, and an exterior additive is added to produce the dry toner by uniform mixing. The color toner not only has low production cost, but also will not pollute the environment.

Owner:王恒来

Clothes dryer and clothes drying method thereof

ActiveCN110670322AQuick bakeHeating up fastTextiles and paperLaundry driersThermodynamicsHigh energy

The invention provides a clothes dryer and a clothes drying method thereof, belongs to the technical field of clothes drying, and solves the problems of the existing electrothermal clothes dryer, including high energy consumption, no environmental protection and the like. The clothes dryer comprises a case and a heat pump unit; a drying cavity is arranged in the case; a drum is arranged in the drying cavity, and a first air channel and a second air channel are also arranged in the case; the heat pump unit comprises a compressor, a condenser set and an evaporator; the condenser set comprises afirst condenser and a second condenser; the first condenser is arranged in parallel with the second condenser; a valve is arranged between the second condenser and the compressor, and an evaporator and the first condenser are arranged in the first air duct and sequentially arranged along the air flow direction of the first air channel; the second condenser is arranged in the second air channel, and the cold released by the evaporator in unit time is less than the total heat released by the first condenser and the second condenser. The clothes dryer and the clothes drying method thereof have the advantages of full-closed internal circulation type drying, high heating efficiency, high clothes drying efficiency, good energy efficiency and good environmental friendliness.

Owner:浙江慧升热能科技有限公司

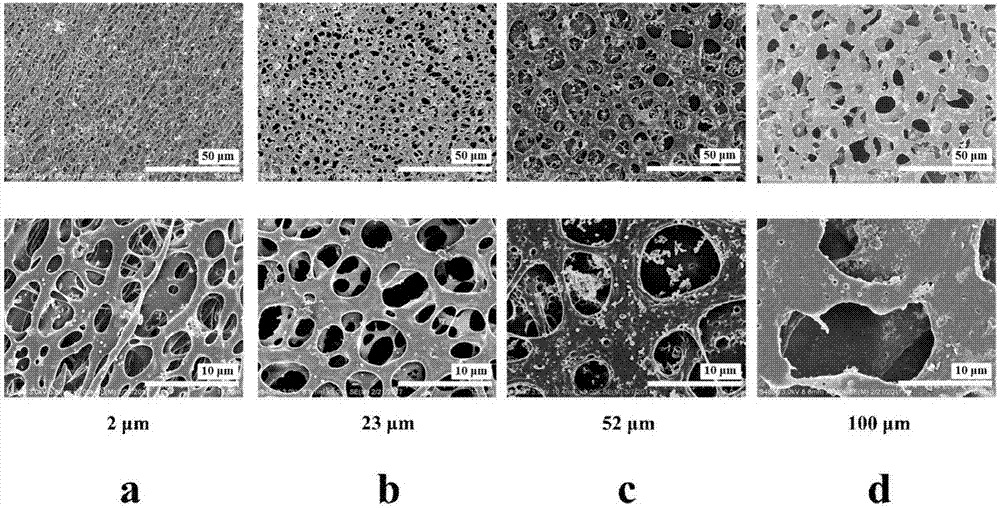

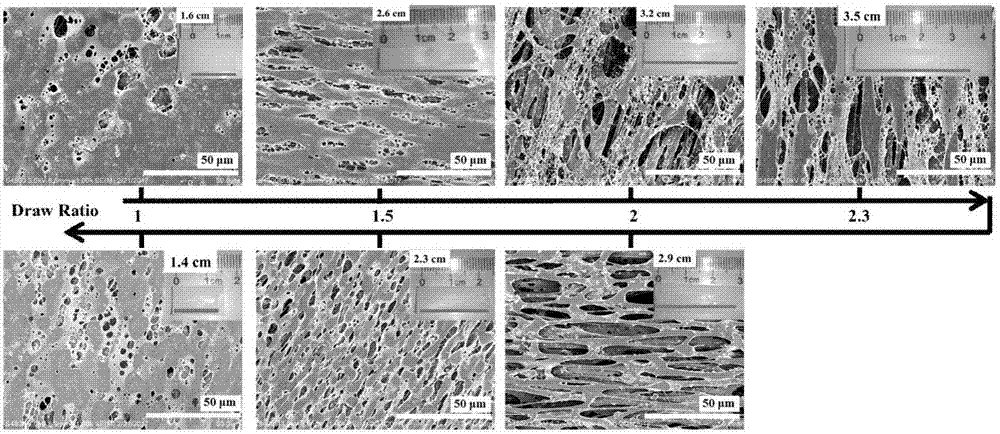

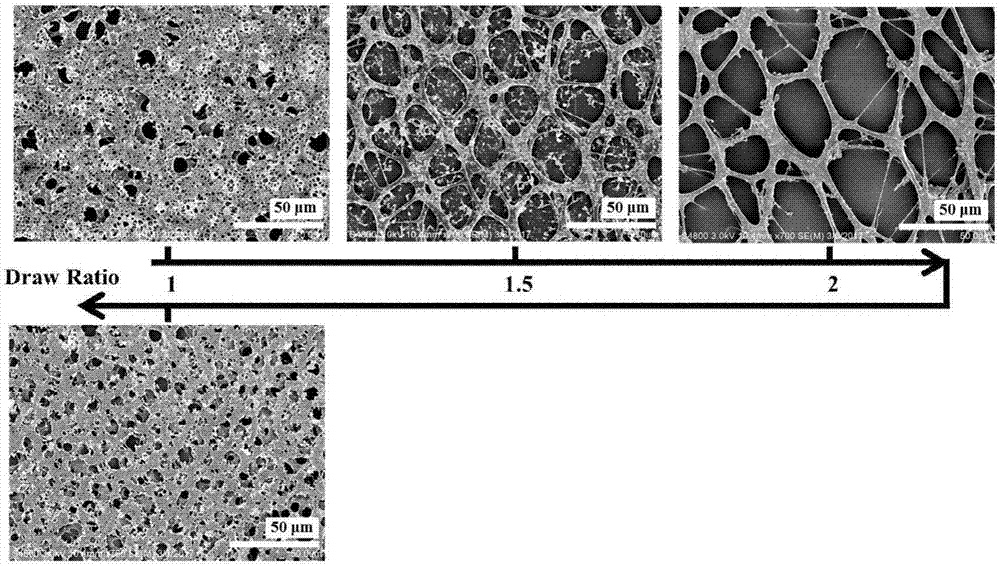

Preparation method for polylactic acid porous shape memory film

ActiveCN107090097ANot dischargedThe preparation method is fast and efficientMicron scalePolyethylene oxide

The invention discloses a preparation method for a polylactic acid porous shape memory film. The polylactic acid porous shape memory film in the invention is formed under the synergic effect of crystallization and phase separation. The method specifically comprises the following steps: dissolving polylactic acid and polyethylene oxide at a certain weight ratio in a co-solvent, and stirring under room temperature, thereby forming a homogeneous polymer solution; scraping the polymer solution into a film by using film scrapers of different thickness; etching a polyethylene oxide phase in the film; after etching, placing the film into a vacuum oven and drying, thereby acquiring the biodegradable polylactic acid porous shape memory film. The polylactic acid porous shape memory film has a micron-scale penetrated porous structure and a shape memory property. The sizes of formed holes are correspondingly changed according to different film thickness, and meanwhile, the polylactic acid porous shape memory film macroscopically and microscopically has better shape memory effect and is expected to be applied to the fields of separation filtering, medical materials, and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Water-based ink for intaglio printing process of aluminum foil and preparation method of water-based ink

The invention provides water-based ink for the intaglio printing process of aluminum foil. The ink is prepared from, by mass, 20-30% of water-based organic pigment, 20-25% of water-based acrylic resin, 20-25% of water-based acrylic emulsion, 0.5-1.5% of flatting agent, 0.1-0.3% of defoaming agent, 10-15% of ethyl alcohol and 10-20% of water. A preparation method includes the steps of evenly dispersing water, acrylic resin, acrylic emulsion, water-based pigment and ethyl alcohol, heating the materials till the temperature is 30-55 DEG C, evenly stirring and grinding the materials, adding flatting agent and defoaming agent, controlling the viscosity of ink for 10-20 seconds, and obtaining the water-based ink. The water-based ink is excellent in performance, safe and environmentally friendly, harms to a user can be reduced, the preparation method of the water-based ink is simple, the viscosity of the ink is easy to control, and the ink has wide application prospects.

Owner:董耀辉

Anti-counterfeit durable colorful ink powder and method for producing the same

The invention discloses an anti-counterfeit color ink powder and a preparation method thereof and concretely provides the anti-counterfeit color ink powder used for a color duplicating machine, a color printer, a color electrograph, a color digital integral machine and a color printing machine and the preparation method thereof. The anti-counterfeit color ink powder is made from the raw materials of latex polymerized macromolecular resin, colored pigment, electric charge regulator, phosphor powder, wax, external additive etc. The latex polymerized macromolecular resin, the colored pigment, the electric charge regulator, the phosphor powder and the wax are put together to be mixed uniformly and made into a mixed solution, and then a spray drier is used for spraying and drying the mixed solution into granular material under the temperature between 160 DEG C and 300 DEG C. Then the granular material is processed for a grading filtering by an air current grading device, and the external additive is added to be mixed uniformly to be made into the anti-counterfeit color ink powder. The color ink powder not only has the low production cost but also can not cause the environmental pollution.

Owner:王恒来

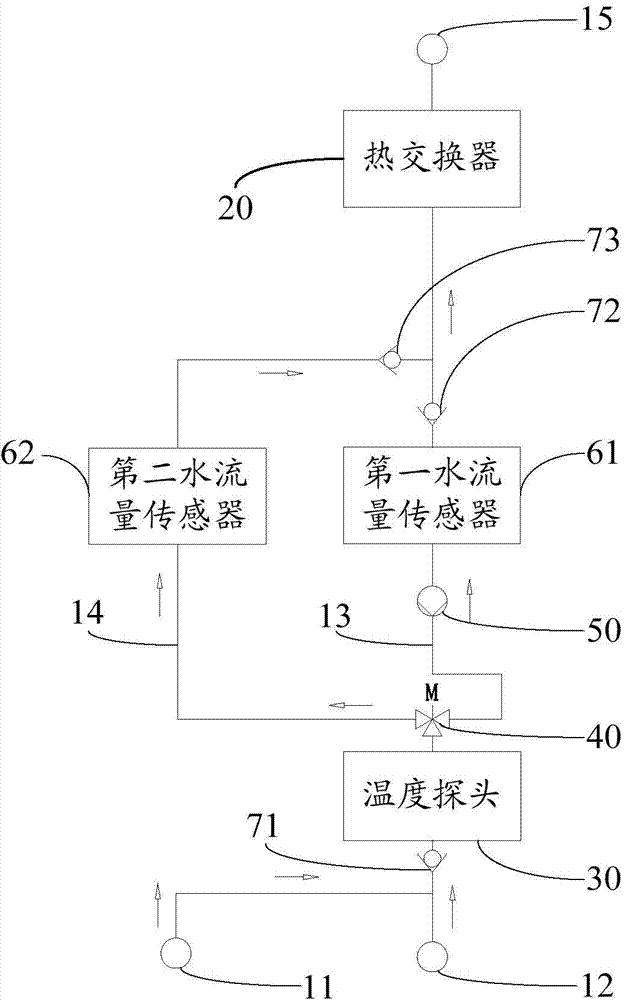

Water control device and gas water heater

The invention discloses a gas water heater. The gas water heater comprises a burner, a heat exchanger, a water inlet, a water outlet and a controller, wherein the heat exchanger is connected between the water inlet and the water outlet, and the burner is used for heating water in the heat exchanger. The gas water heater further comprises a main pipe and a by-pass pipe. The main pipe and the by-pass pipe are parallelly connected between the heat exchanger and the water inlet; a water pump and a first water flow sensor are arranged on the main pipe; a second water flow sensor is arranged on the by-pass pipe; the water pump, the first water flow sensor, the second water flow sensor and the burner are electrically connected with the controller. According to the water control device provided by the invention, by arranging the main pipe and the by-pass pipe which are connected in parallel and internally arranging the water pump, water paths can be switched through a three-way valve, so that a pre-heating mode and a bathroom mode can be freely switched, and no cold water is discharged when the gas water heater is used.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

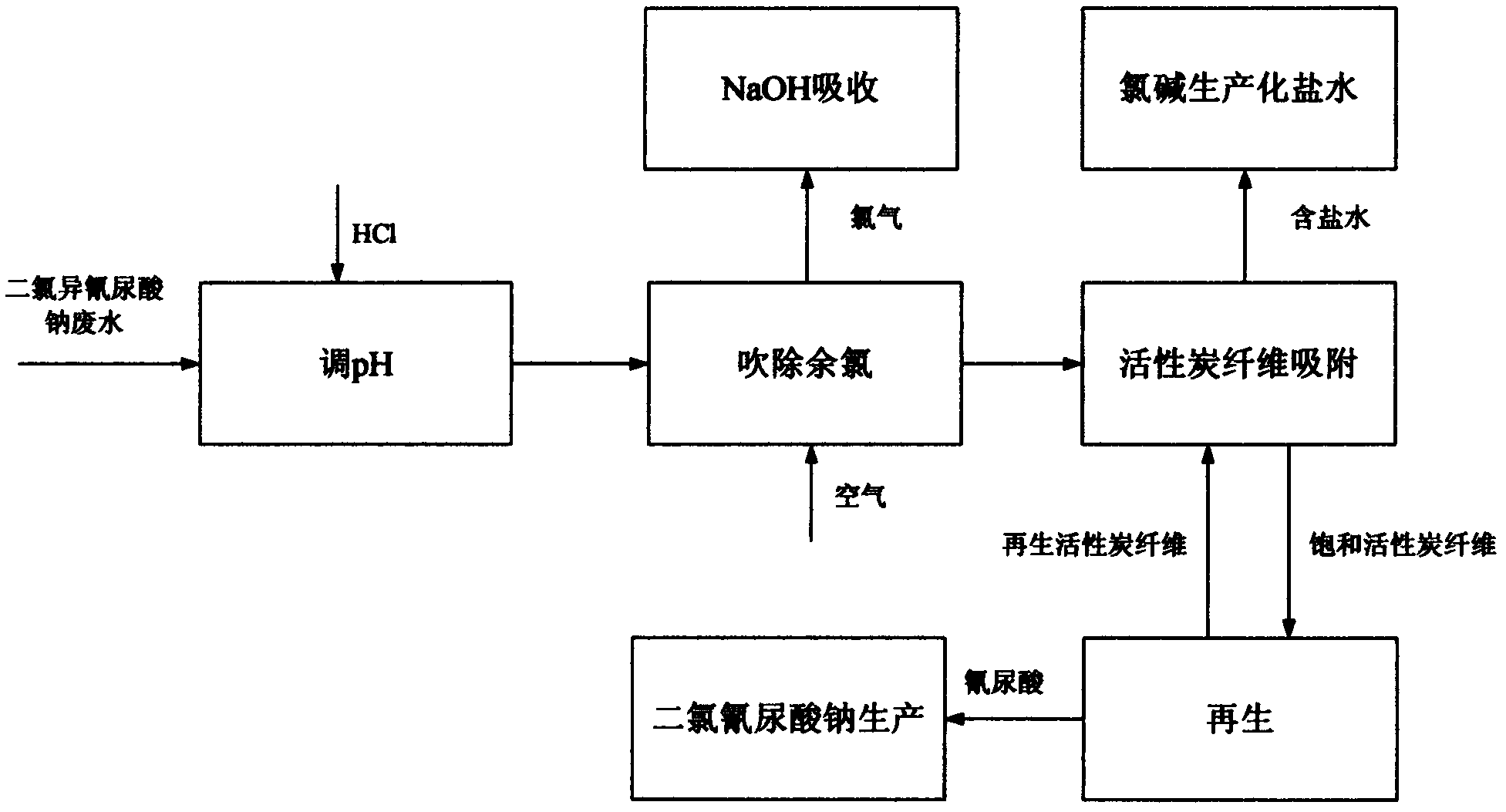

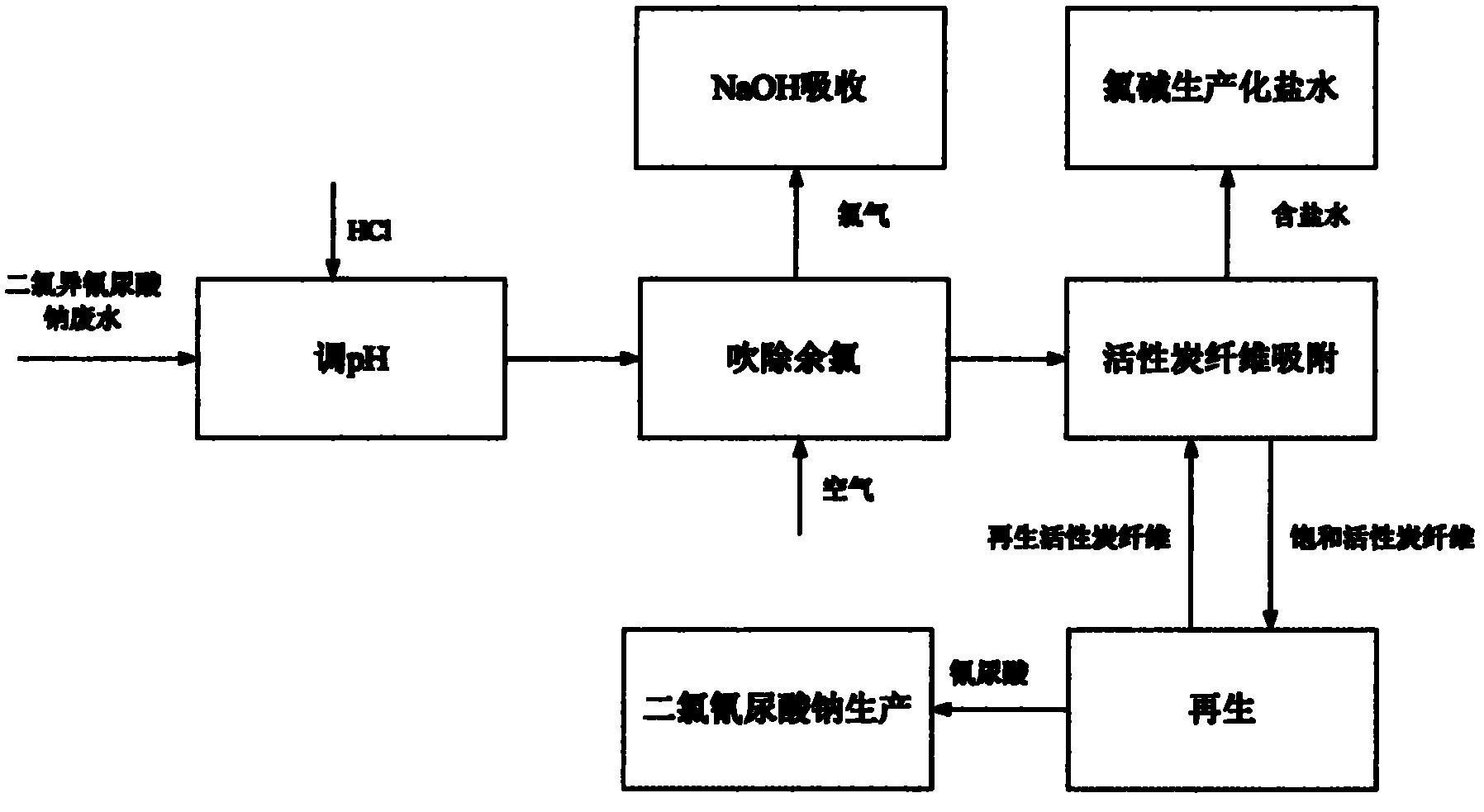

Method for recovering waste water from sodium dichloroisocyanurate production

InactiveCN102491565ANot dischargedNo secondary pollutionOrganic chemistryMultistage water/sewage treatmentSaline waterFiber

The invention provides a method for recovering waste water from sodium dichloroisocyanurate production, which comprises the following steps: waste water from sodium dichloroisocyanurate production is added with hydrochloric acid for acidifying, then chlorine in the waste water is blown out, active carbon fiber adsorbs cyanuric acid, alkali regenerates active carbon fiber and recovers sodium cyanurate, sodium cyanurate is sent to the sodium dichloroisocyanurate production process, brine is sent to chlor-alkali production process. waste water is subjected to the adsorption treatment, and can be salt-dissolving water in the chlor-alkali production operation for repetitive usage. The active carbon fiber is capable of being regenerated multiple times, the repetitive usage is realized, the cost is low, the method process is simple and the industrial method is easy to realize.

Owner:YANTAI UNIV

Intelligent monitoring camera device with defrosting function

PendingCN107566705AWeaken the impactExtended service lifeTelevision system detailsBatteries circuit arrangementsFrostInfrared

The invention discloses an intelligent monitoring camera device with a defrosting function. The device comprises a fixed plate and a controller, wherein a connecting base is fixedly arranged at the left side of the fixed plate; a support plate is arranged at one side far away from the fixed plate of the connecting base; the support plate is hinged to the connecting base through a rotating shaft arranged at the left end of the support plate; a rotating disc is fixedly arranged at the bottom of the support plate; an infrared camera is arranged at the lower side of the support plate; the infraredcamera is hinged to the rotating disc through a connecting rod arranged at the top of the infrared camera; and baffles are both arranged at two sides of the infrared camera. The device detects the outside weather situation through a temperature sensor and a humidity sensor and controls the interior of a regulating box to generate heat through the controller in order to remove falling snow on theinfrared camera, so that the formation of frost after melting, which is caused by accumulating rainwater on the camera, can be avoided, and thus the influence of the external environment on the cameracan be weakened to be helpful for prolonging the service life of the camera.

Owner:HENAN HAOWEI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com