Lithium-rich manganese-based material and preparation method thereof

A lithium-rich manganese-based, nitrate-based technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high investment in equipment, difficulty in continuous production, and large environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

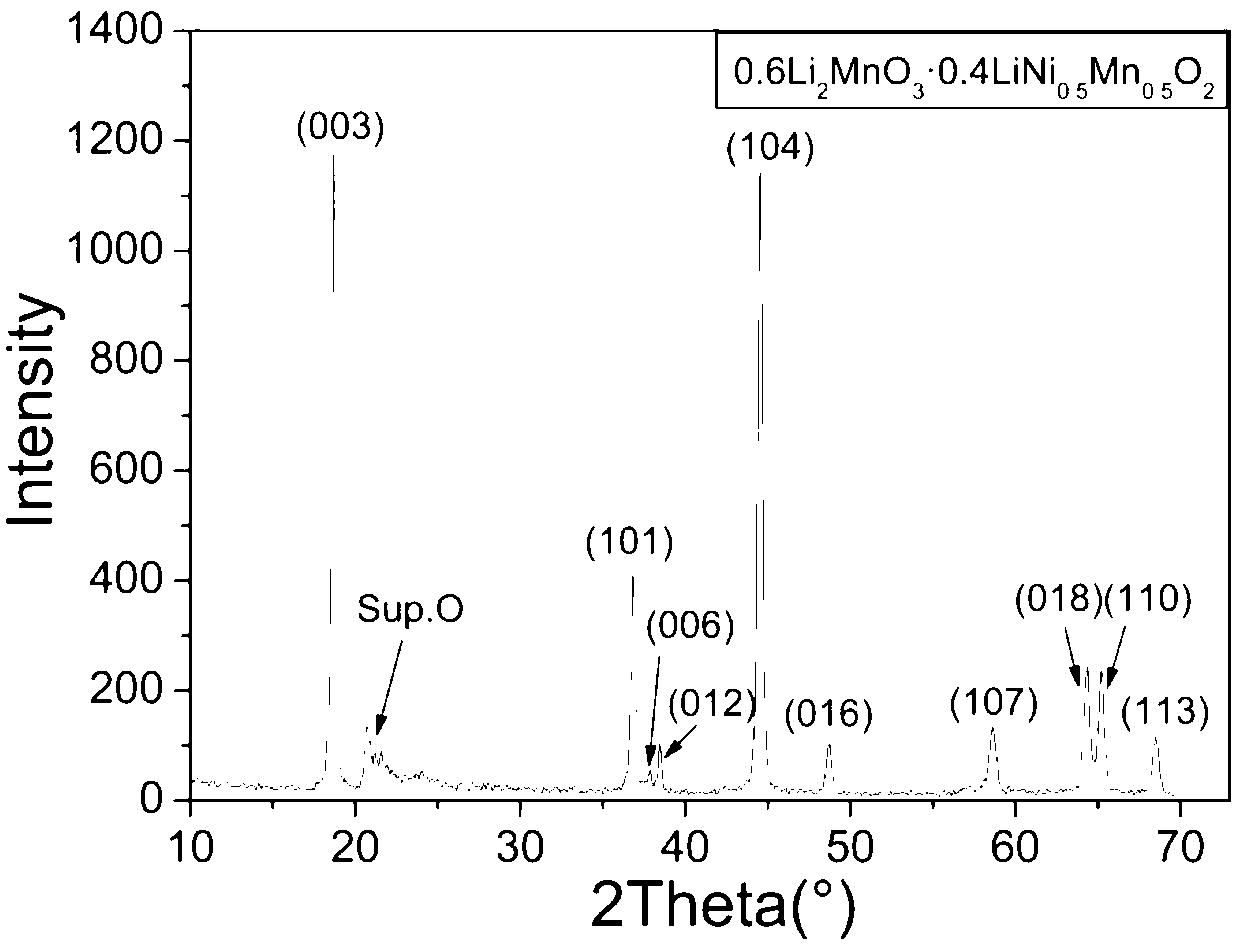

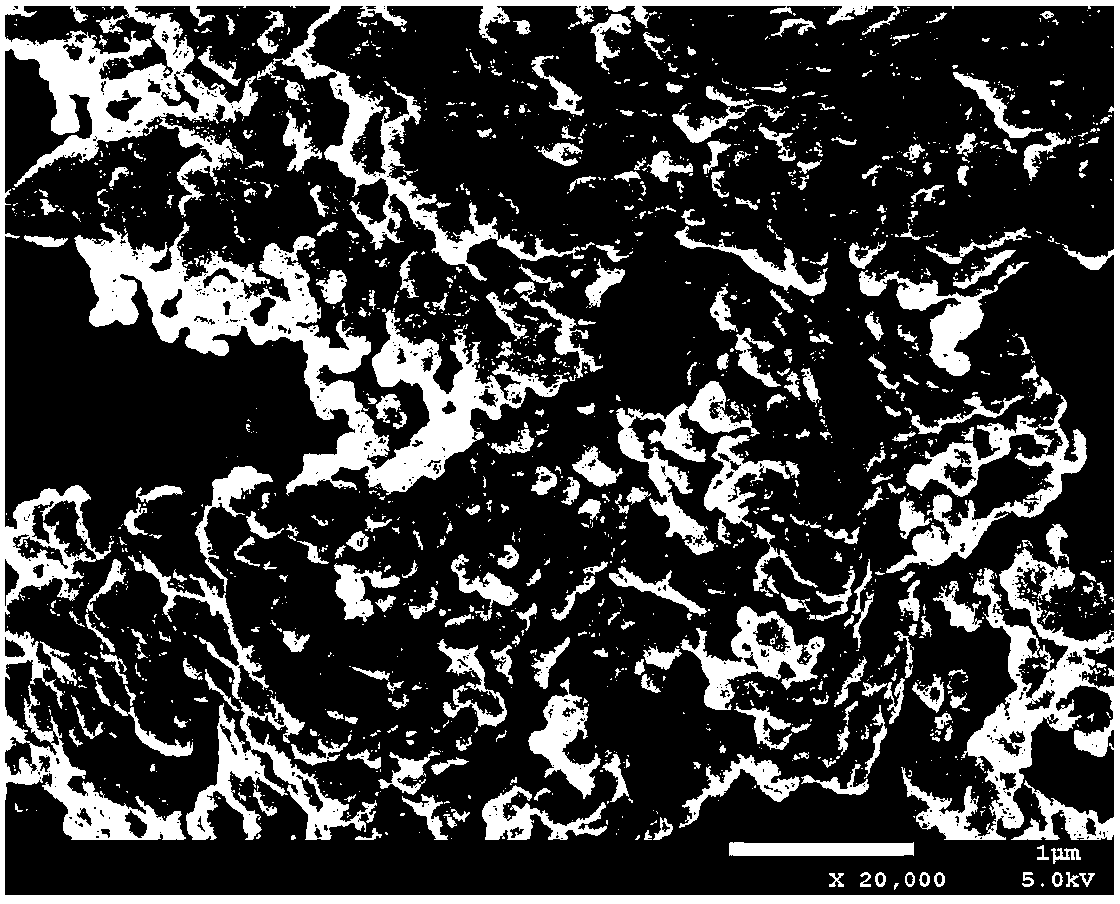

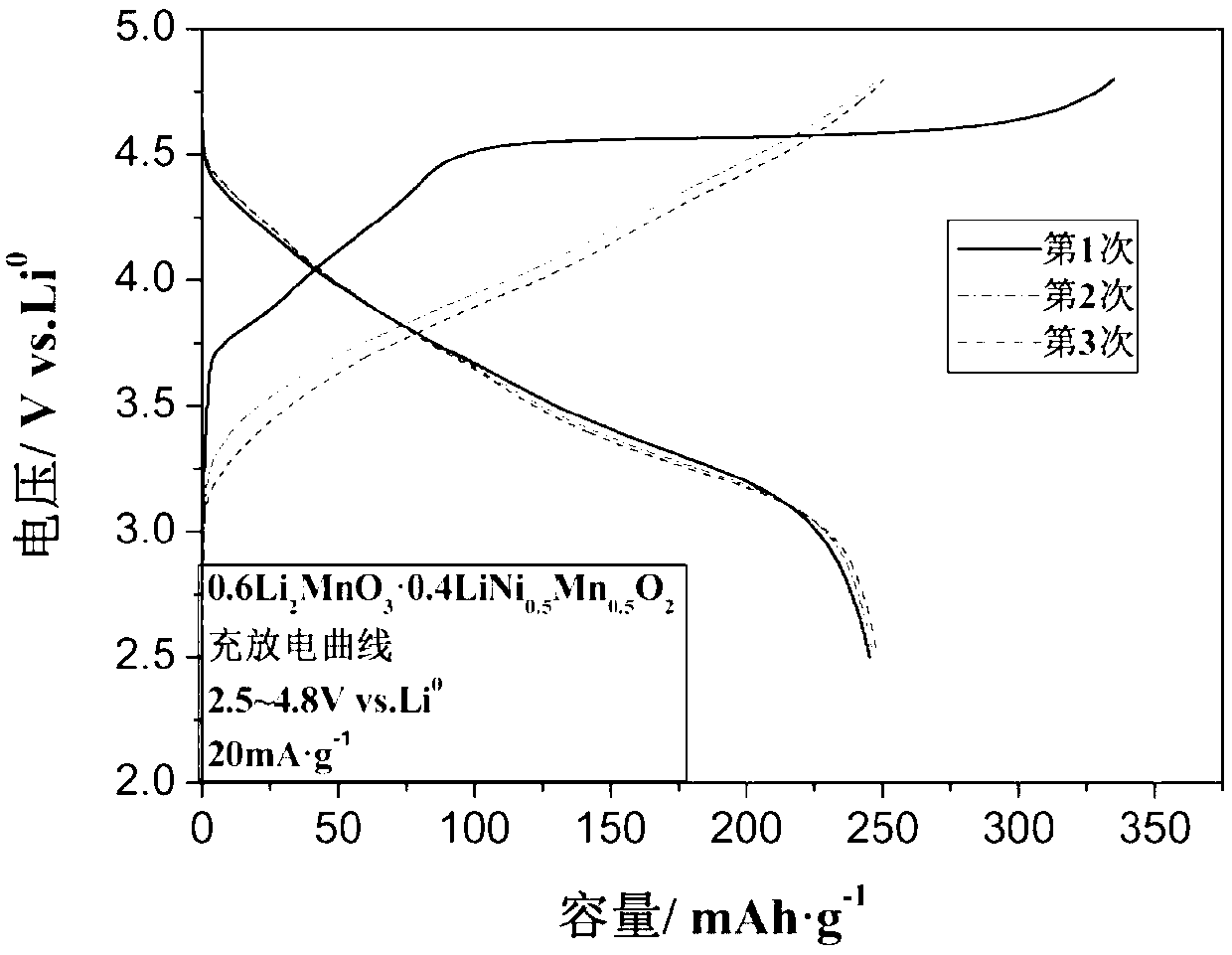

[0088] Example 1: Preparation of lithium-rich manganese-based materials

[0089] According to the chemical formula xLi 2 MnO 3 ·(1-x)LiMO 2 (x=0.6) Measure and weigh lithium nitrate, manganese acetate, nickel nitrate, M is Ni transition metal; dissolve these compounds in deionized water to obtain a solution with a total concentration of 3mol / L;

[0090] Add a citric acid dispersant to the solution, and stir for 3 hours at a temperature of 50°C. The amount of the dispersant added is 16% based on the total weight of the lithium nitrate, manganese acetate and nickel nitrate;

[0091] Then add the Tween-80 additive, the addition of the additive is 1.0% based on the total weight of the lithium nitrate, manganese acetate and nickel nitrate solution; stir and mix, then let the mixture solution stand for 6.2 hours, then add Deionized water solvent, the amount of deionized water is 2.0 times the volume of the mixture solution, diluted to obtain a precursor sol;

[0092] B. Spray dr...

Embodiment 2

[0105] Embodiment 2: Preparation of lithium-rich manganese-based materials

[0106] According to the chemical formula xLi 2 MnO 3 ·(1-x)LiMO 2 (x=0.3) Measure and weigh lithium nitrate, manganese acetate, nickel nitrate, chromium acetate, M is Ni, Mn and Cr (the mass ratio is 2:2:1) transition metal; dissolve these compounds in deionized water, Obtaining a solution with a total concentration of 2.5mol / L;

[0107] Add glucose dispersant to the solution, and stir for 2.4 hours at a temperature of 70°C. The amount of dispersant added is 12% based on the total weight of lithium nitrate, manganese acetate, nickel nitrate and chromium acetate;

[0108] Then add the polyacrylamide additive, the addition of the additive is 0.5% based on the total weight of the lithium nitrate, manganese acetate, nickel nitrate and chromium acetate solution; stir and mix, then allow the mixture solution to stand for 8 hours, Then add absolute ethanol solvent, the amount of its absolute ethanol is 1...

Embodiment 3

[0115] Embodiment 3: Preparation of lithium-rich manganese-based materials

[0116] According to the chemical formula xLi 2 MnO 3 ·(1-x)LiMO 2 (x=0.5) Measure and weigh lithium nitrate, manganese acetate, nickel nitrate, cobalt nitrate, M is Ni, Mn and Co (the mass ratio is 1:1:1) transition metal; dissolve these compounds in deionized water, Obtaining a solution with a total concentration of 3.5mol / L;

[0117] Adding a sucrose dispersant to the solution, stirring at a temperature of 85° C. for 1.0 hour, the amount of the dispersant added is 20% based on the total weight of the lithium nitrate, manganese acetate, nickel nitrate and cobalt nitrate;

[0118] Then add the tributyl phosphate additive, the addition of the additive is 2.0% based on the total weight of the lithium nitrate, manganese acetate, nickel nitrate and cobalt nitrate solution; stir and mix, then allow the mixture solution to stand for 5 hours , then add acetone solvent, the amount of acetone is 0.8 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com