Patents

Literature

47results about How to "Won't catch fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

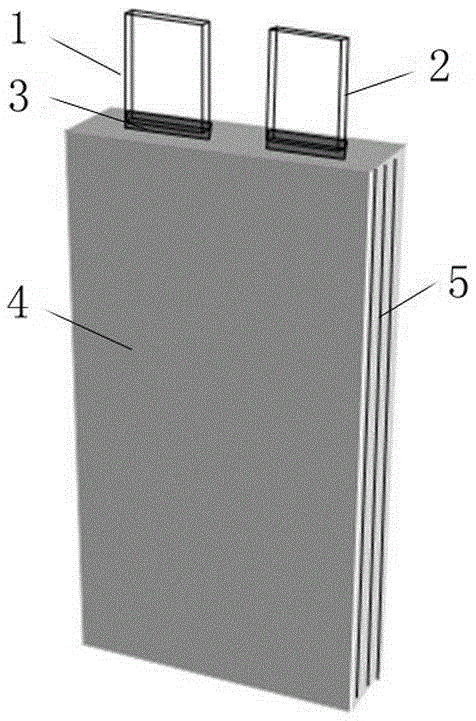

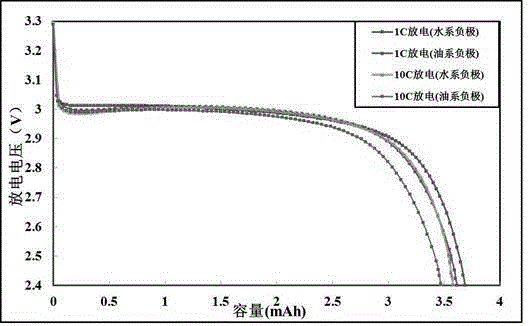

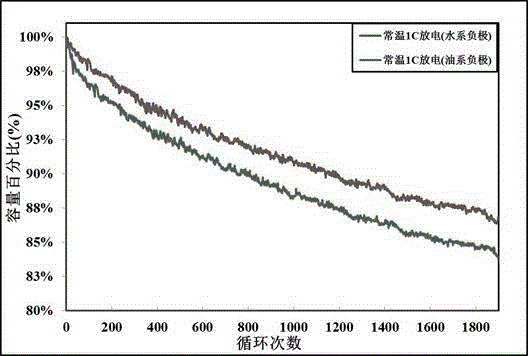

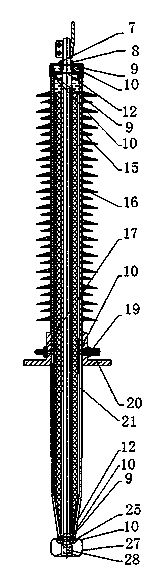

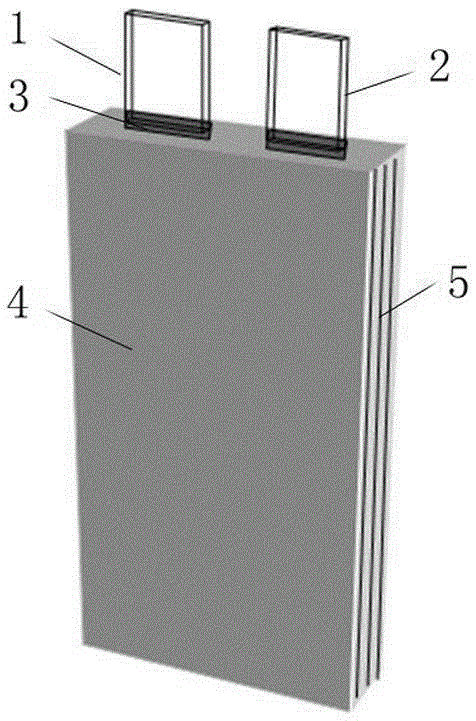

Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

InactiveCN105336943ALong cycle lifeFast cycle lifeFinal product manufactureCell electrodesElectrolytic agentElectrical battery

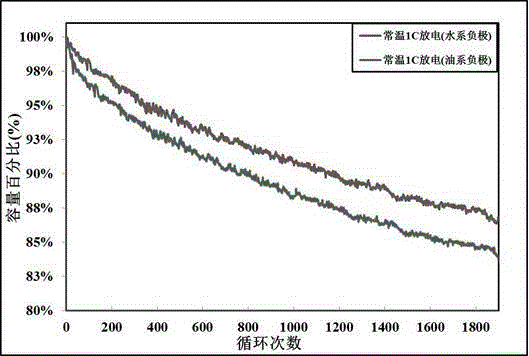

The invention discloses a lithium battery formed on the basis of lithium nickel manganese oxide and lithium titanate and a preparation method of the lithium battery. The lithium battery comprises an aluminum-plastic film casing, an anode lug, a cathode lug and a tab film, wherein the aluminum-plastic film casing contains a battery cell and electrolyte; the battery cell comprises an anode piece, a diaphragm and a cathode piece; materials of the anode piece comprise an anode slurry coating consisting of a positive active material, a binding agent, a conductive agent and a solvent and an anode current collector; the positive active material adopts an Al2O3 coating of lithium nickel manganese oxide; the binding agent adopts one or two of polyvinylidene fluoride and polytetrafluoroethylene; the conductive agent adopts one or more of conductive carbon black, conductive graphite and carbon nanotubes; the solvent adopts N-methyl-2-pyrrolidinone; the anode current collector adopts an aluminum foil; the cathode piece adopts an aqueous cathode or an oil-based cathode. According to the designed lithium battery, the purposes of improvement of the reversible specific capacity, the energy density and the rapid charge-discharge capability, the cycle performance and the safety performance of the battery are achieved while the production cost is reduced.

Owner:四川省有色冶金研究院有限公司

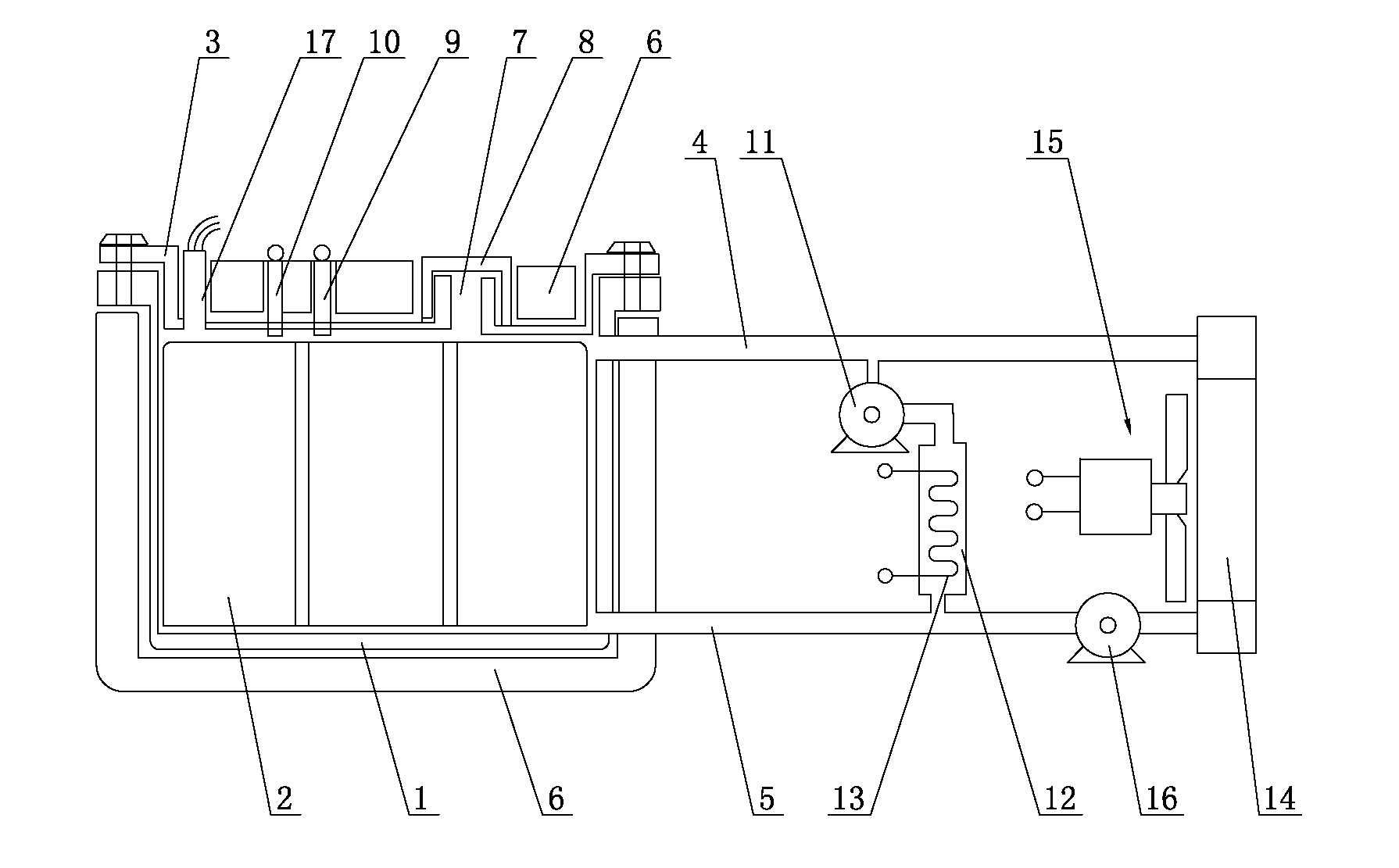

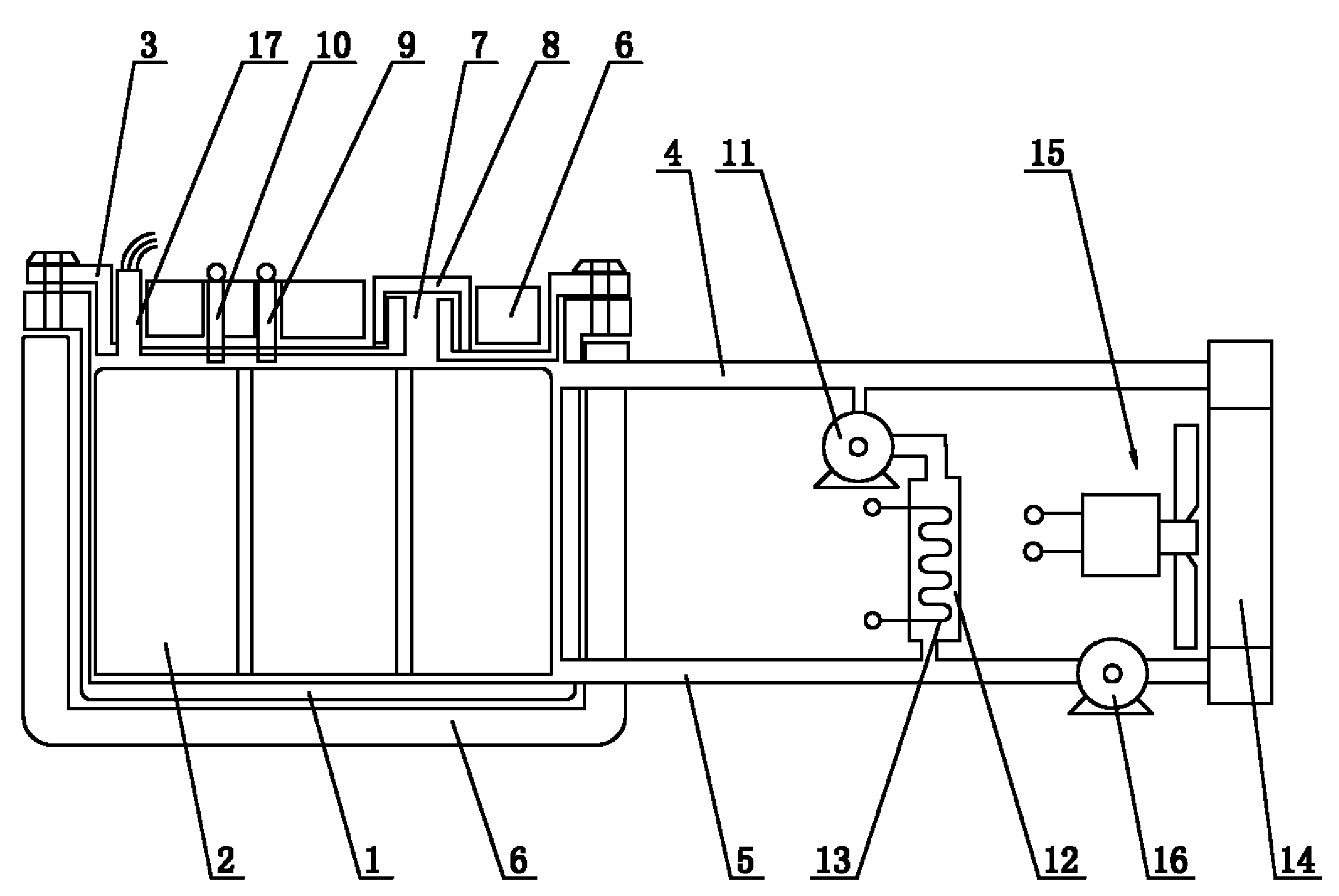

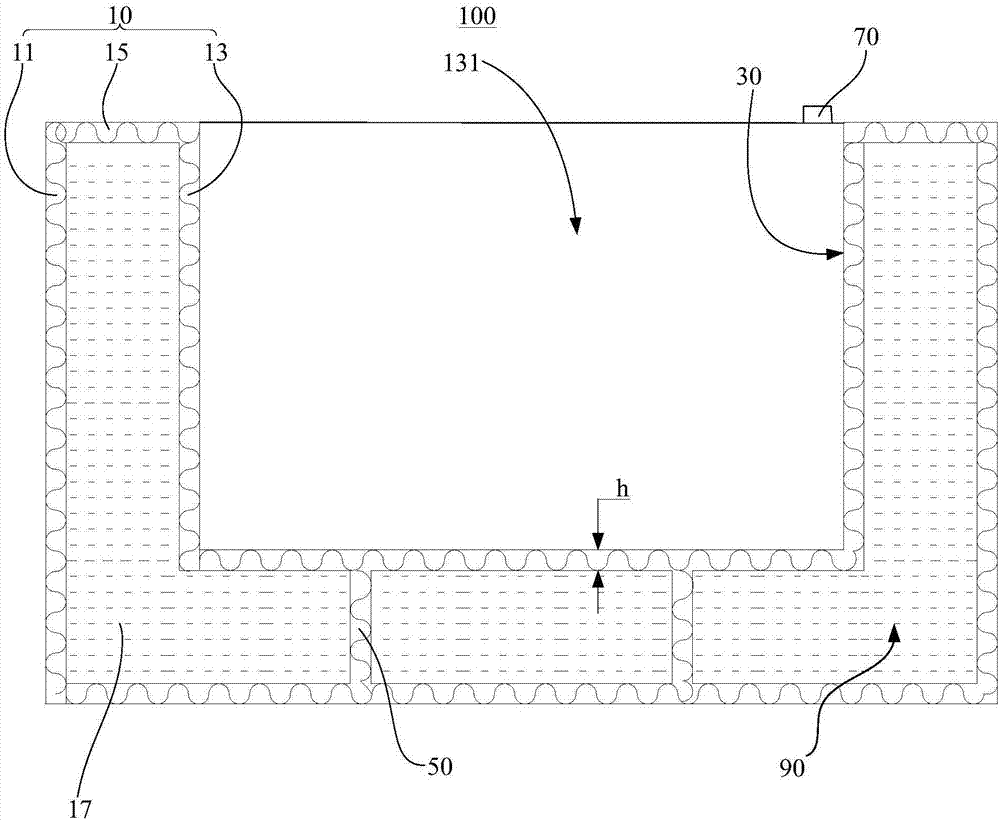

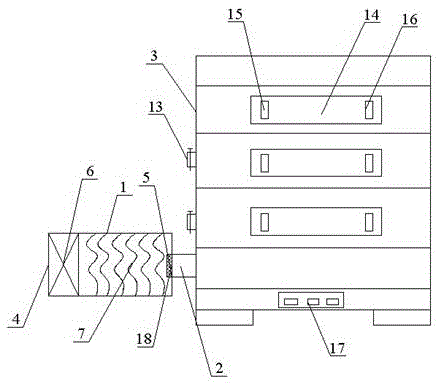

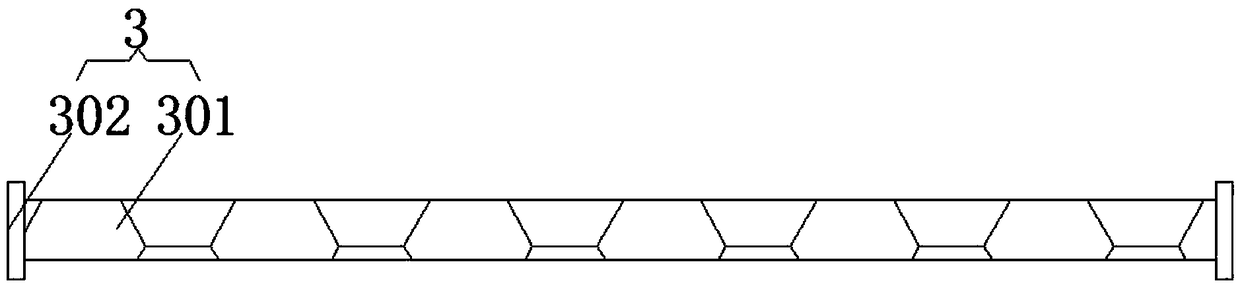

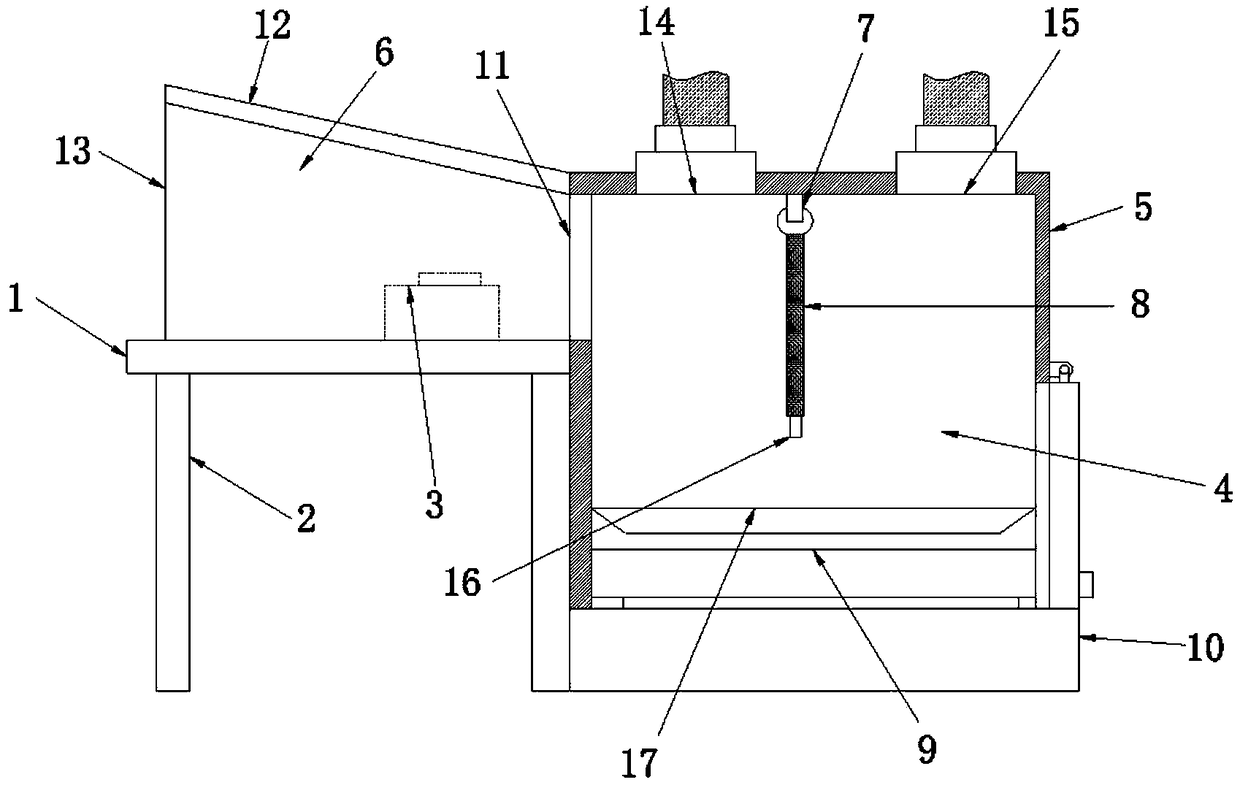

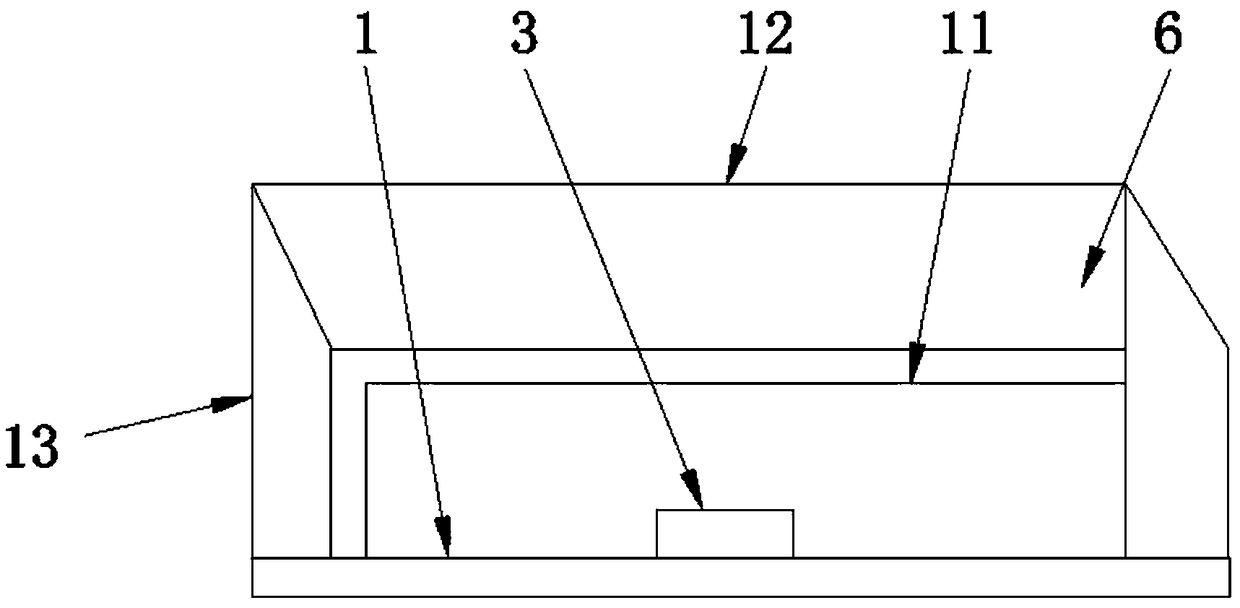

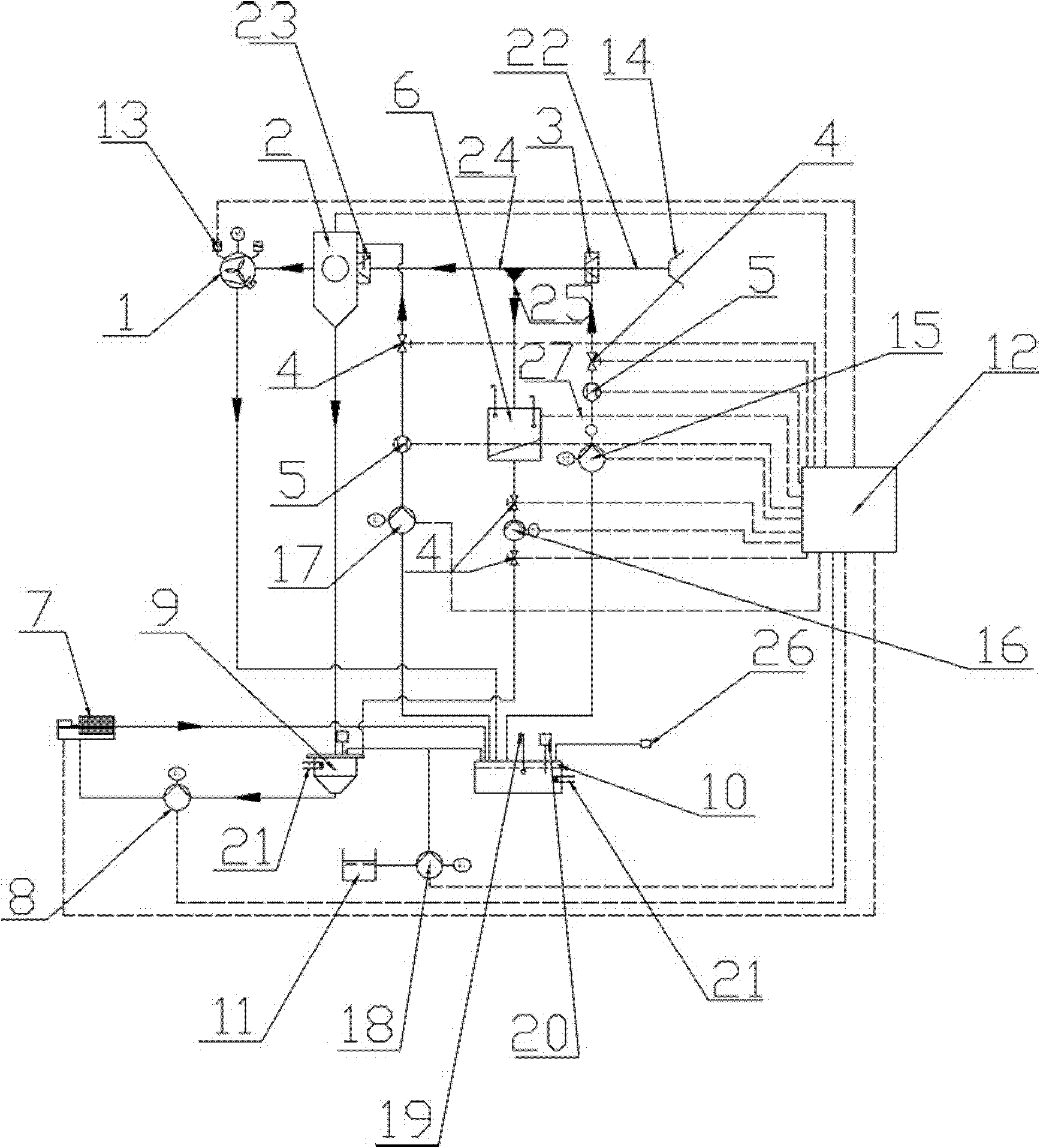

Constant temperature control battery pack

InactiveCN102324591AIncrease capacityExtend your lifeCell temperature regulationTemperature controlElectric aircraft

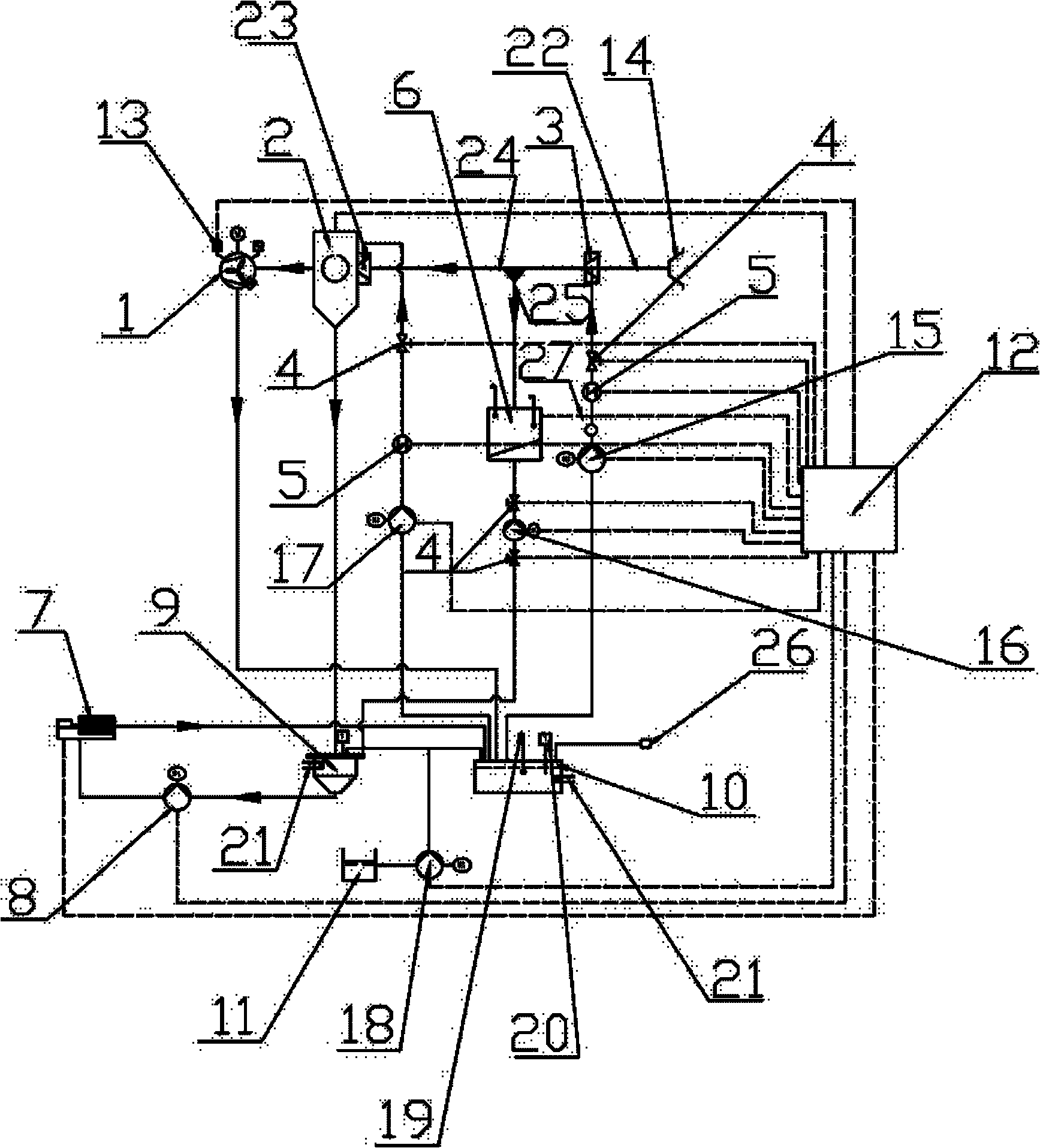

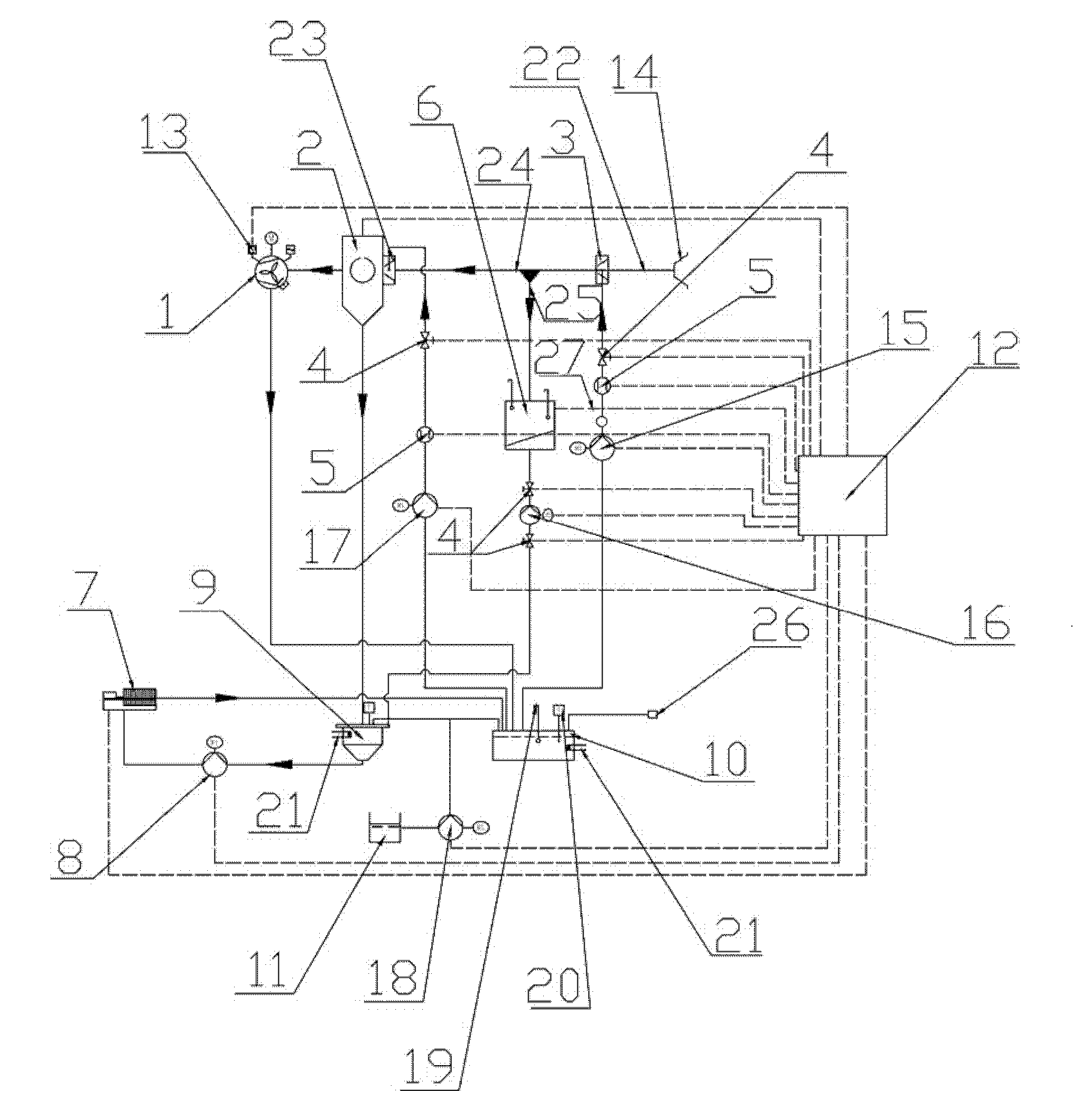

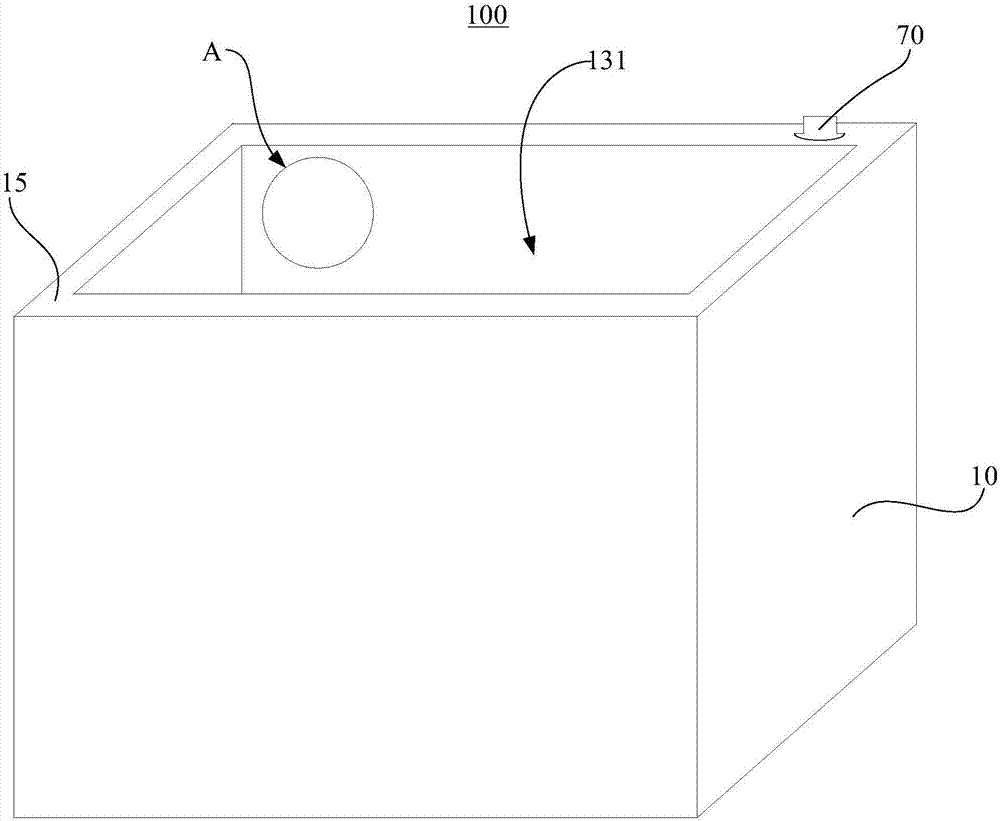

The present invention relates to the technical field of power supplies of electric vehicles, hybrid electric vehicles and electric aircrafts, especially to a constant temperature control battery pack. The constant temperature control battery pack comprises an inner box and a battery pack. Heat exchange liquid is arranged inside the inner box. A temperature detection device is arranged on an upper cover of the box. The constant temperature control battery pack further comprises a heating apparatus, a cooling apparatus, a first pipeline and a second pipeline. According to the present invention, the automatic constant temperature control system is provided for the relation between the electrochemical characteristics of the battery pack and the temperature changing, wherein the automatic constant temperature control system can be provided for heating the battery pack, cooling the battery pack, and holding the temperature of the battery pack to enable the battery pack to work in an optimal temperature range; the battery pack is prevented from influence due to the environmental temperature changing; the battery pack using is prevented from influence due to the using area; the performance of the battery pack can be provided at maximum at any temperature; the generated heat can be rapidly dissipated when the battery has the short-circuit fault, such that the misfire and the burning can not be generated; the capacity, the efficiency, the service life and the safety of the battery pack are improved; the constant temperature control battery pack provided by the present invention provides significant advances than the battery pack in the prior art.

Owner:DONGGUAN LONGXING AVIATION TECH

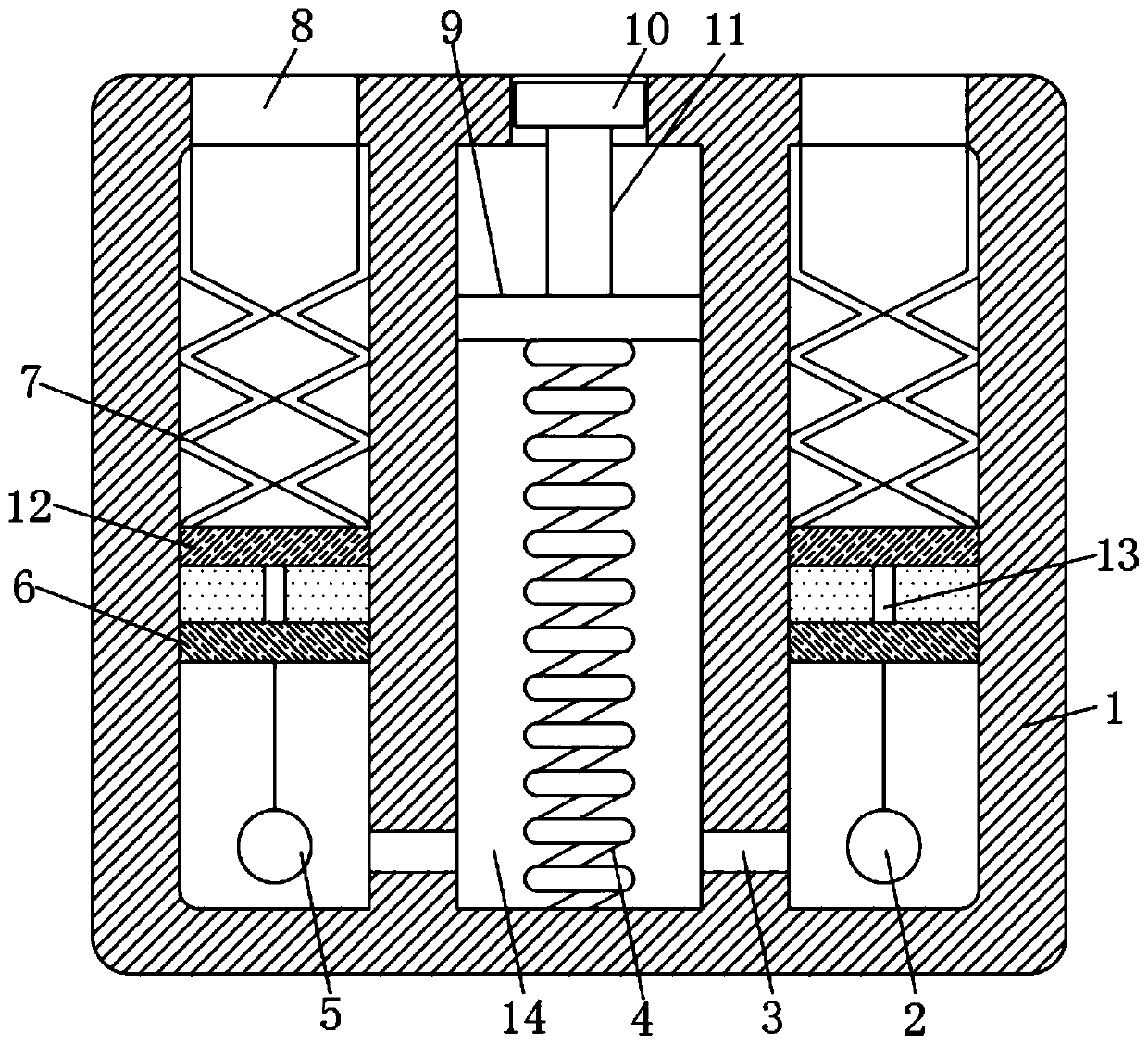

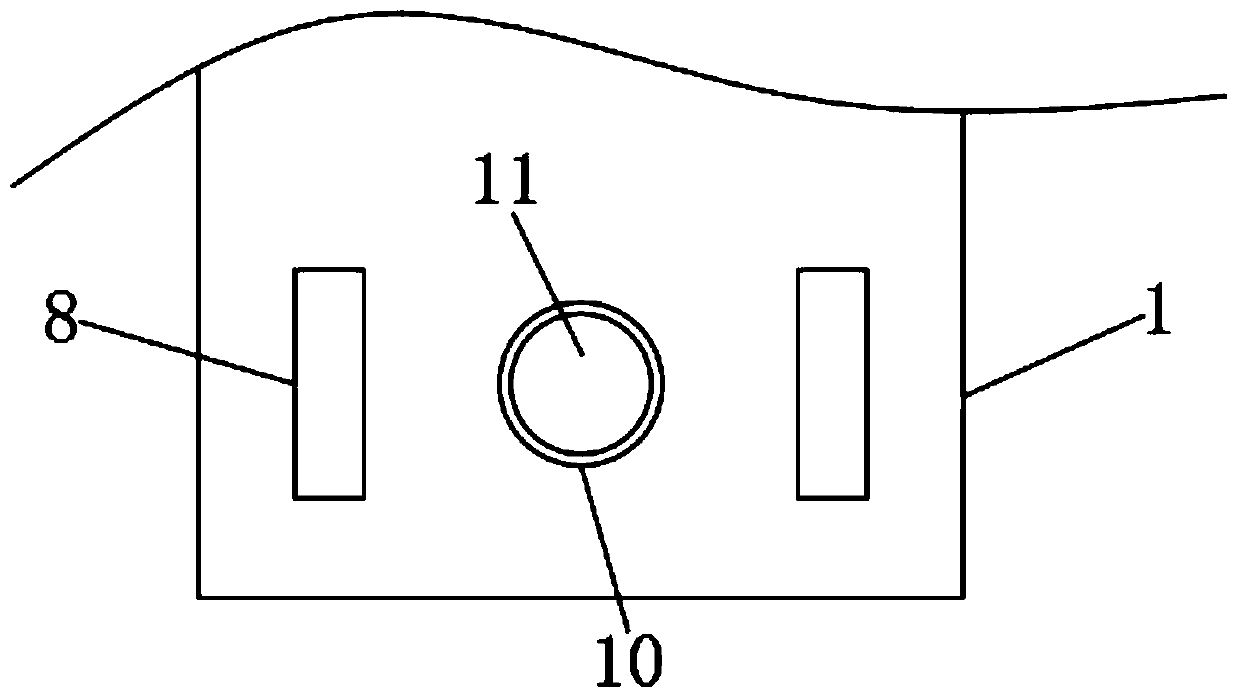

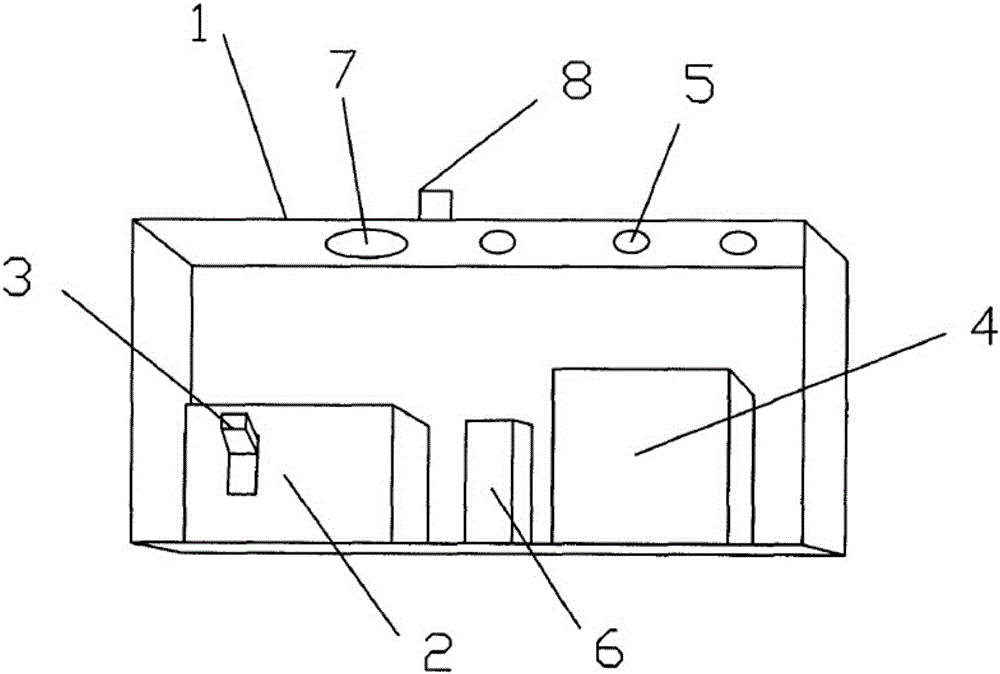

Overload protection type socket

ActiveCN110867707ASo as not to damageWon't catch fireCoupling device detailsHemt circuitsMechanical engineering

The invention discloses an overload protection type socket, which comprises a base shell and a pair of jacks formed in a panel of the base shell, wherein a device cavity is formed in the base shell; plugging reeds are arranged in the jacks; a zero line connector and a live line connector are arranged in the two jacks respectively; and a push-out mechanism used for pushing a plug away from the socket when current is overloaded is installed in the device cavity. As a control mechanism and the push-out mechanism are arranged, when the temperature rises sharply due to the overload of the circuit current in the socket, the expansion liquid expands to push an iron sheet to move downwards so as to enable the plugging reed to be powered off, electrical apparatus elements are ensured not to be damaged or on fire, the plug can be pushed to separate the plug pin from the plugging reed, the phenomenon that current overload occurs again when a circuit is conducted after temperature recovery and dangerous cases are thus caused is prevented, and personal and property safety of users is guaranteed.

Owner:临沂新科置业有限公司

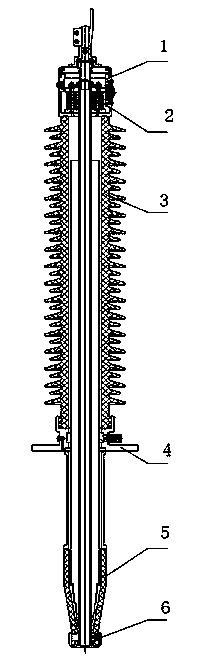

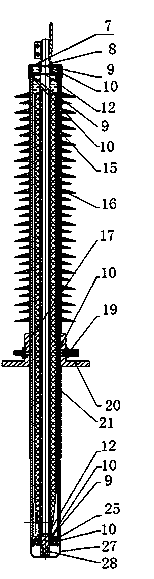

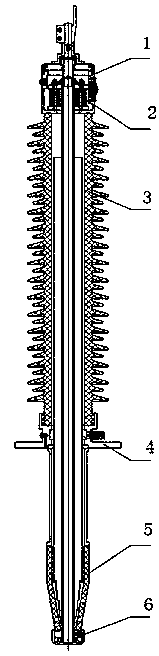

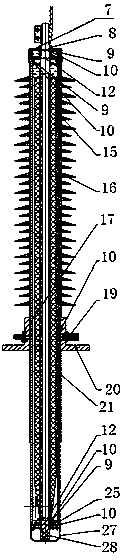

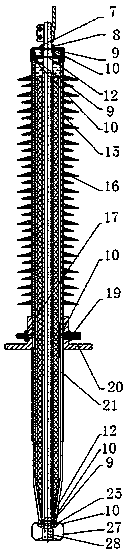

Integral type oil-paper high-voltage bushing

ActiveCN103456473AReduced probability of insulation failureWon't catch fireTransformers/inductances coils/windings/connectionsLead-in/lead-through insulatorsTransformerShock resistance

The invention discloses an integral type oil-paper high-voltage bushing which comprises a glass reinforced plastic cylinder, a conducting rod, an expander, a mounting flange, a base and a voltage-sharing ball, wherein the mounting flange for being connected with a transformer is hermetically arranged in the middle position of the glass reinforced plastic cylinder in a sleeving manner; a silicone rubber umbrella cover is cast on the outer side of the glass reinforced plastic cylinder at a position above the mounting flange, and semi-conductive paint is sprayed on the outer side of the glass reinforced plastic cylinder at a position below the mounting flange and forms an isoelectric cylinder which has the same diameter as the flange; the base is hermetically arranged at the bottom of the glass reinforced plastic cylinder; the conducting rod is inserted in the glass reinforced plastic cylinder and integrated with the mounting flange, the glass reinforced plastic cylinder and the base; the expander is arranged at the top of the glass reinforced plastic cylinder, and the voltage-sharing ball is arranged at the bottom of the glass reinforced plastic cylinder. The integral type oil-paper high-voltage bushing is simple in structure; oil in the bushing is completely isolated from that in the transformer; the probability of failure of the product is greatly reduced; the transformer can be effectively prevented from catching fire and burning; the product has a light weight; the mounting is convenient; the shock resistance and bending resistance are good; maintenance is basically avoided.

Owner:JIANGSU ZHIDA ELECTRIC

Nickel lithium manganate-based positive electrode material of lithium ion battery and preparation method thereof

InactiveCN105355903AHigh reversible specific capacityFast charge and dischargeCell electrodesSecondary cellsSlurry coatingCarbon nanotube

The invention discloses a nickel lithium manganate-based positive electrode material of a lithium ion battery and a preparation method thereof. A material used for a positive plate comprises a positive electrode current collector and a positive electrode slurry coating which is composed of a positive electrode active substance, a binder, a conductive agent and a solvent, wherein the positive electrode active substance is an Al2O3 coating of nickel lithium manganate, the binder is one or more selected from the group consisting of polyvinylidene fluoride and polytetrafluoroethylene, the conductive agent is one or more selected from the group consisting of conductive carbon black, conductive graphite and a carbon nanotube, the solvent is N-methylpyrrolidone, and the positive electrode current collector employs an aluminum foil. The lithium ion battery designed in the invention has reduced cost, and the purposes of improving reversible specific capacity, energy density, rapid charging and discharging capability, cycle performance and safety performance are achieved.

Owner:四川省有色冶金研究院有限公司

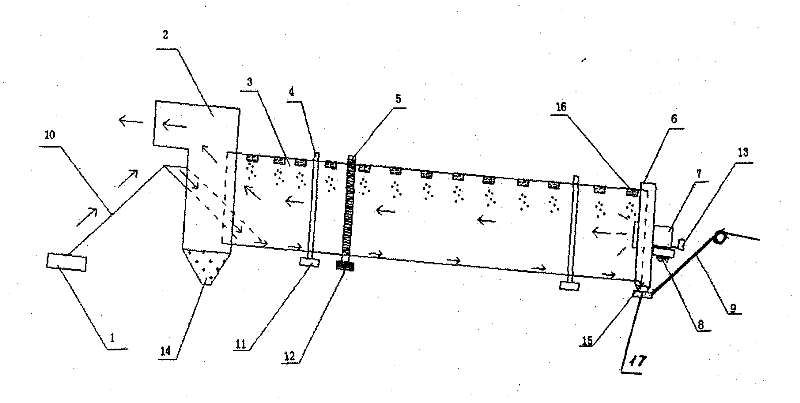

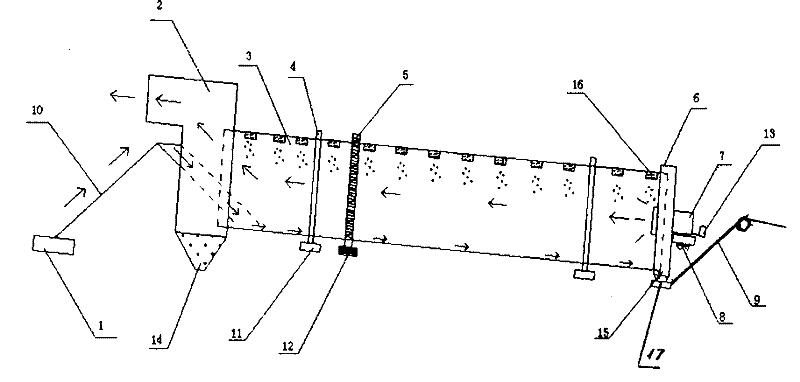

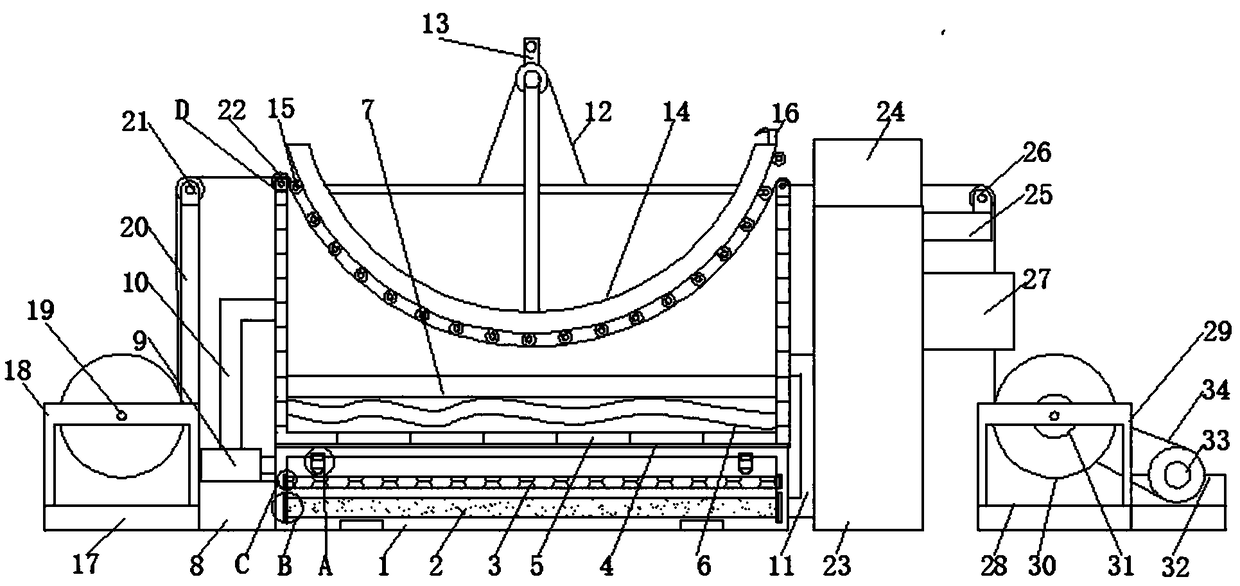

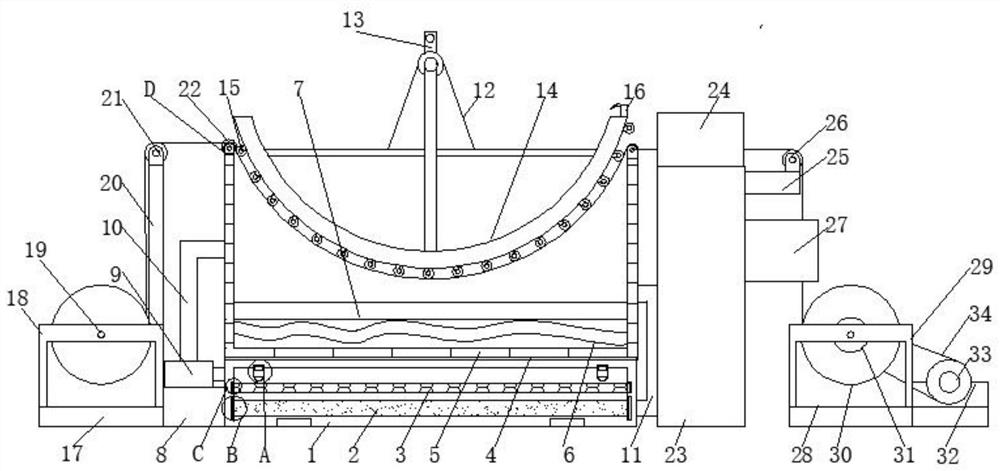

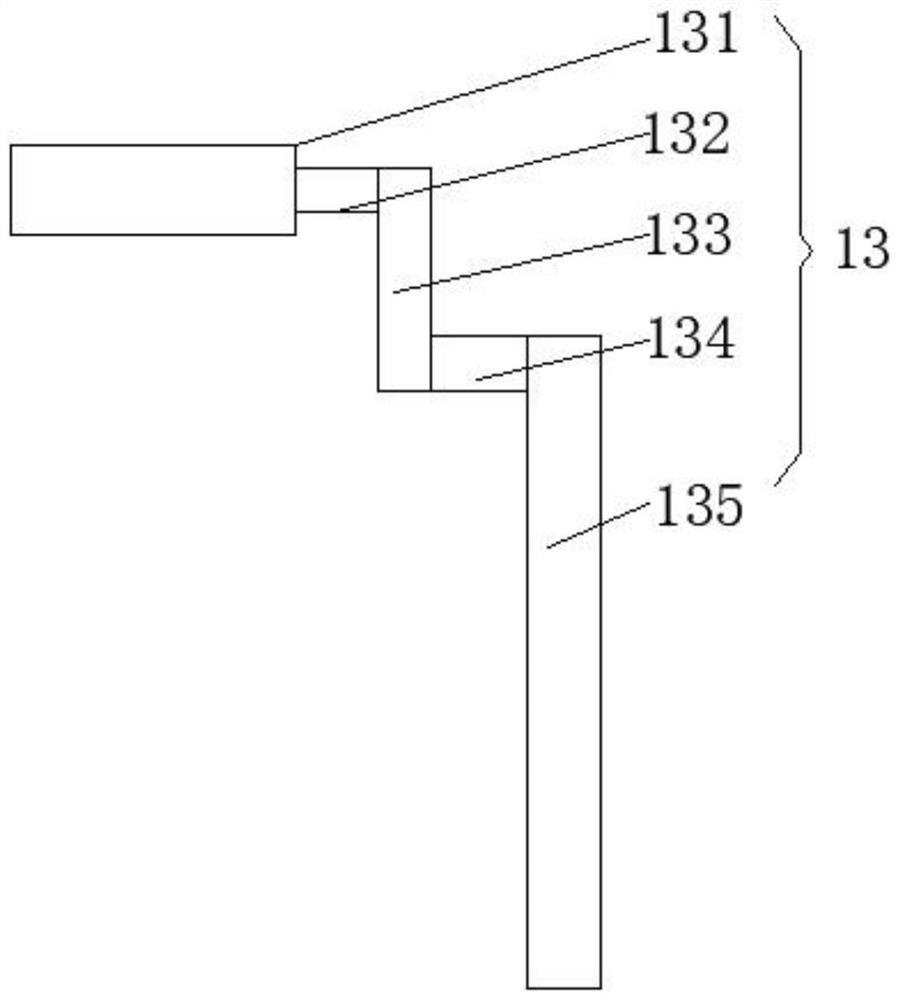

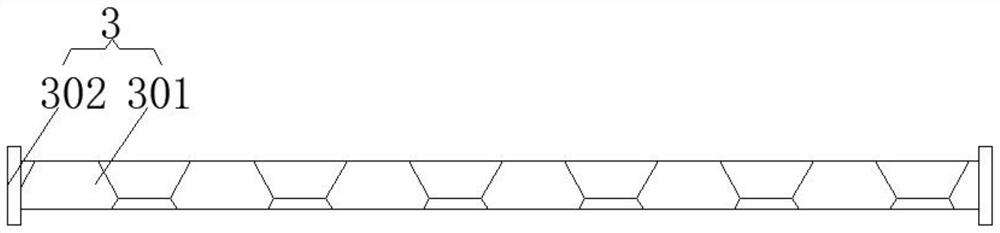

A method and equipment for treating waste gas of a hot press

ActiveCN102284220AImprove processing efficiencyWon't catch fireUsing liquid separation agentSewageWater spray

The invention relates to a method and equipment for treating waste gas of a hot press. The method comprises the following steps of: S1, injecting water into a dust absorption pipeline to ensure that gas and water are fully contacted and mixed; and S2, allowing water spray carrying waste gas to enter a water dust scrubber, collecting sewage carrying impurities, and discharging purified gas. A water injection device is arranged in the dust absorption pipeline; the dust is not stuck onto the dust absorption pipeline easily so the pipeline is prevented from being blocked and fire is avoided; the waste gas treatment efficiency is high; and the dust, and a large amount of high-temperature volatile matter of formaldehyde and transmission lubricant are collected, the collected waste gas and waterare treated further ad separated reasonably, water is recycled, and no sewage is discharged, so secondary pollution is avoided. Meanwhile, the invention also provides equipment for treating the wastegas of the hot press.

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

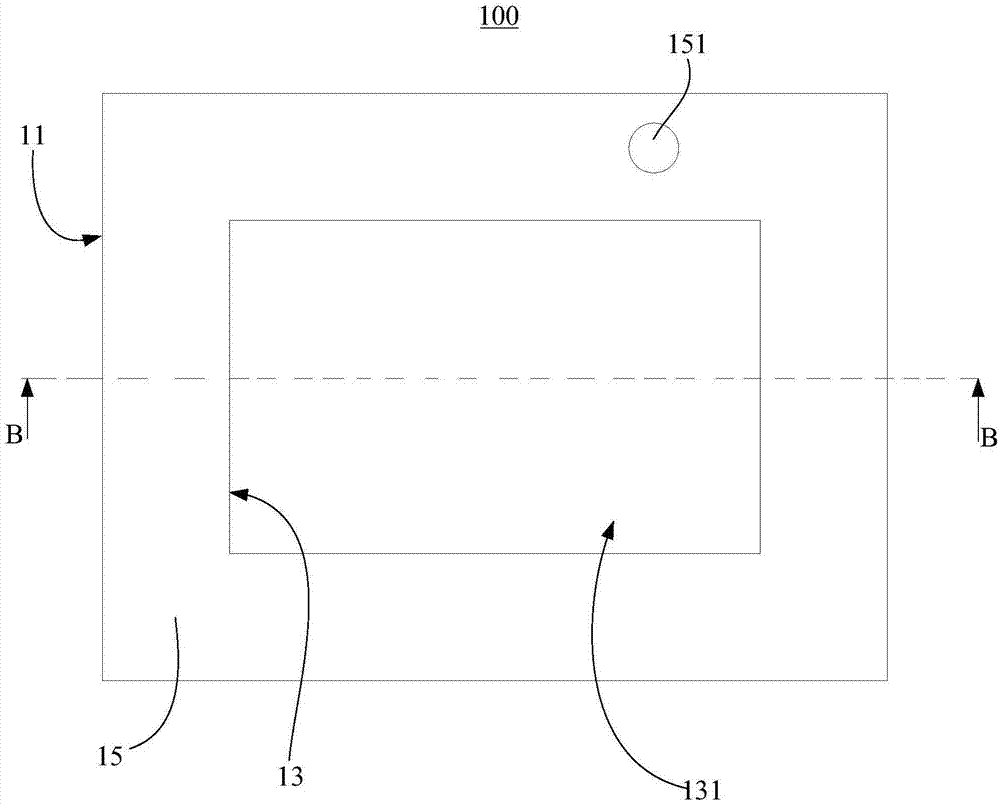

Automatic fire extinguishing device for battery boxes

The invention discloses an automatic fire extinguishing device for battery boxes. The automatic fire extinguishing device for the battery boxes comprises a shell and a thermoplastic material layer; aplurality of first through holes penetrating through the shell are formed in the surface of the shell; thermoplastic materials cover the first through holes of the shell; the shell is provided with afirst accommodating cavity and a second accommodating cavity for containing batteries, the second accommodating cavity is accommodated in the first accommodating cavity, and the first accommodating cavity is filled with an fire extinguishing agent; and after the batteries are out of control and catch a fire, the thermoplastic material layer softens with head, a crack is formed, and the first accommodating cavity releases the fire extinguishing agent towards the second accommodating cavity. By means of the technical scheme, the structure of the automatic fire extinguishing device for the battery boxes can be simplified, and the performance of the automatic fire extinguishing device for the battery boxes is improved.

Owner:深圳市鸿嘉利消防科技有限公司

An air cooling device matched with drying equipment

InactiveCN102261831ASolve the above problemsWon't catch fireDrying solid materialsCold airGear wheel

The invention provides an air cooling device matched with drying equipment. The feeding unit is connected to the rotating drum unit, and the rotating drum unit is connected to the cold air supply unit, the discharging unit and the carrying unit; the feeding conveyor is connected to the feeding conveyor belt, and the heat and dust discharge port is connected to the dust storage hopper and the rotating drum. The installation inclination angle between the type drum and the ground is 3° to 5°, the discharge conveyor is connected to the discharge conveyor belt, the cold air supply nozzle is connected to the fan, the fan is connected to the motor, the roller belt is connected to the roller, and the large gear is connected to the gear transmission combination. The lifting plate installed in the rotary drum continuously lifts the material to be refrigerated from top to bottom, and receives the cold air sent by the tail fan for cooling, so that the material reaches a condensed state. The invention adopts the principle of air cooling to cool down the lignite and dust with high temperature and recover the dust, so that there is no fire and no dust during transportation, and the environmental protection and low carbon meet the standard.

Owner:王远大

Novel circuit breaker with built-in smoke transducer

InactiveCN105160798AFaster and safer containment and suppressionWon't catch fireProtective switch detailsFire alarm smoke/gas actuationEngineeringAccess port

The invention discloses a novel circuit breaker with a built-in smoke transducer. The circuit breaker comprises an outer shell and a circuit breaker body. The circuit breaker body is provided with a power source positive electrode access port, a power source negative electrode access port and a circuit breaker hand switch. The circuit breaker further comprises the smoke transducer, and the smoke transducer is installed inside the outer shell. The outer shell is provided with at least one air inlet hole which is communicated with the outside. The air inlet holes are communicated with the smoke transducer. The smoke transducer and the power source negative electrode access end of the circuit breaker are connected in parallel. The novel circuit breaker with the built-in smoke transducer has the advantages that the smoke transducer is installed inside the circuit breaker, so that outage treatment is achieved by the circuit breaker under the condition that smoke reaches a preset concentration, it is guaranteed that fire breaking out cannot happen to circuits, and fires can be controlled and extinguished by rescue workers more rapidly and safely.

Owner:朱文军

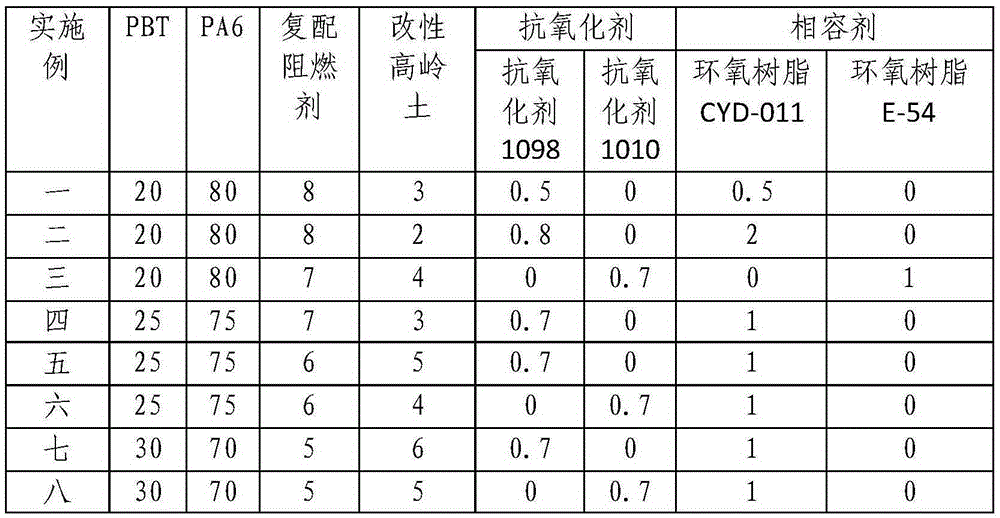

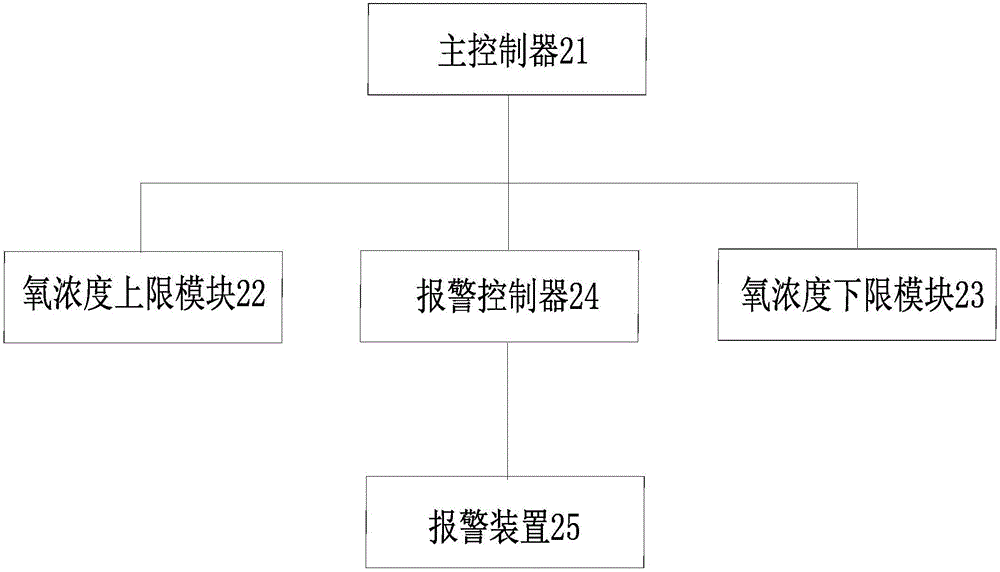

Novel nylon 6-polybutylene terephthalate flame retardant alloy material and preparation method thereof

Belonging to the technical field of high polymer materials, the invention provides a novel nylon 6-polybutylene terephthalate flame retardant alloy material and a preparation method thereof. According to the invention, an appropriate formula process is adopted, and a unique compound flame retardant is employed for cooperation to prepare the environment-friendly high-performance flame retardant PA6-PBT alloy material, compared with general PBT / PA6 flame retardant materials, the alloy material has obvious advantages in the aspects of rigidity, toughness, heat resistance, flame resistance and dimensional stability, and is easy for molding processing. Also, the added modified kaolin is well compatible with all polymers, the alloy material can stably pass the UL94-V0 flame retardant grade, can stably pass 850DEG C glowing filaments without fire breakout, also can satisfy a lot of occasions with high flame retardant level and performance requirements, and is widely applicable to capacitor shells, load break switches, motor shells, terminal boards, coil skeletons, plugs and circuit connectors, telephone distribution boxes and other low voltage electrical apparatuses.

Owner:NANNING UNIV

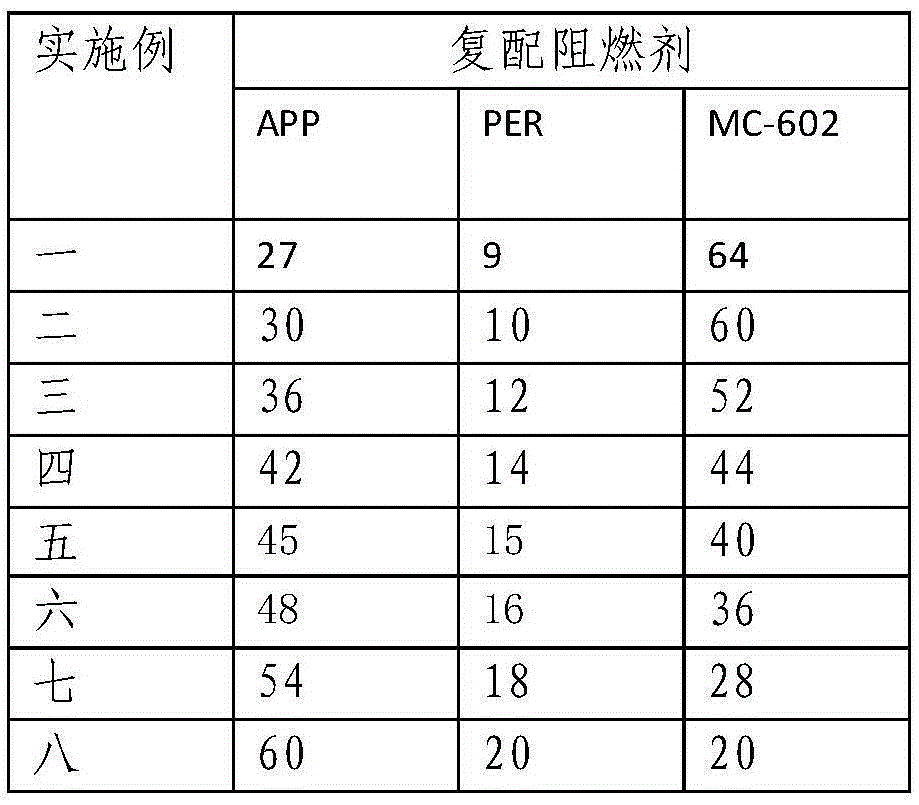

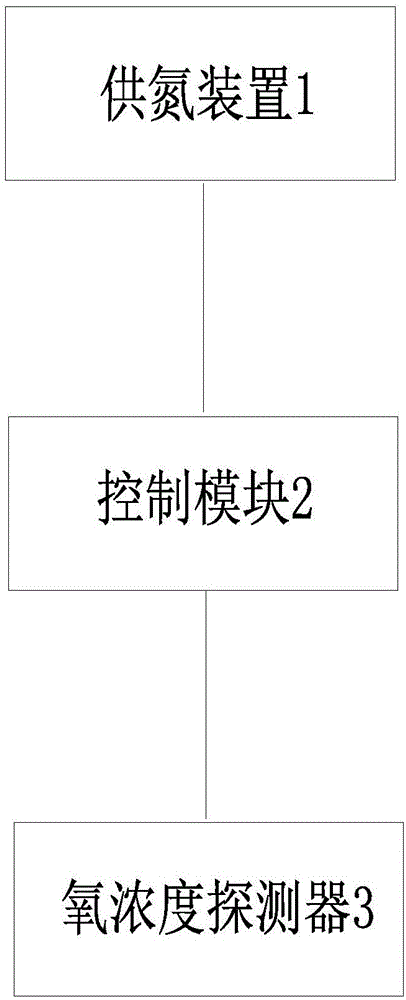

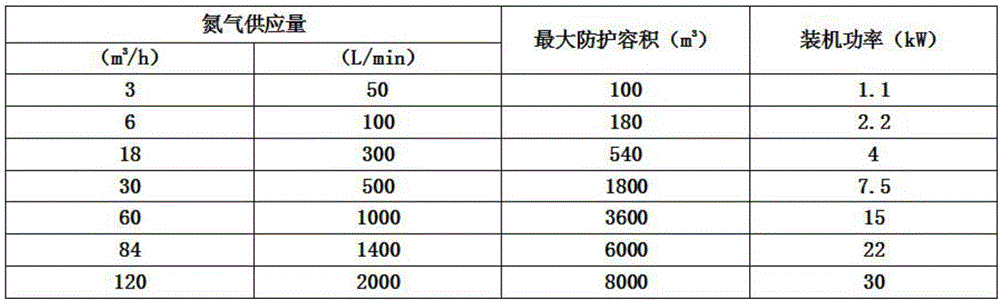

Nitrogen injection and oxygen control active fire prevention system and using method thereof

InactiveCN106492370AEffective protectionEnsure safetyFire rescueBoring toolsLower limitComputer module

The invention discloses a nitrogen injection and oxygen control active fire prevention system. The nitrogen injection and oxygen control active fire prevention system comprises a nitrogen supply device, a control module and at least one fire prevention protective space; the nitrogen supply device introduces nitrogen into the fire prevention protective space; and the control module comprises a main controller, an oxygen concentration upper limit module, an oxygen concentration lower limit module, an alarming controller and an alarming device. The using method of the nitrogen injection and oxygen control active fire prevention system includes the following steps that firstly, a threshold is set; secondly, nitrogen is input; thirdly, the concentration value of oxygen in the fire prevention protective space is detected; and fourthly, the oxygen concentration value is judged. The nitrogen injection and oxygen control active fire prevention system accurately achieves the condition of guaranteeing safety in real time, plays an active fire prevention effect and guarantees the safety of the environment, personnel and property.

Owner:EASTEX XIAMEN FIRETEC

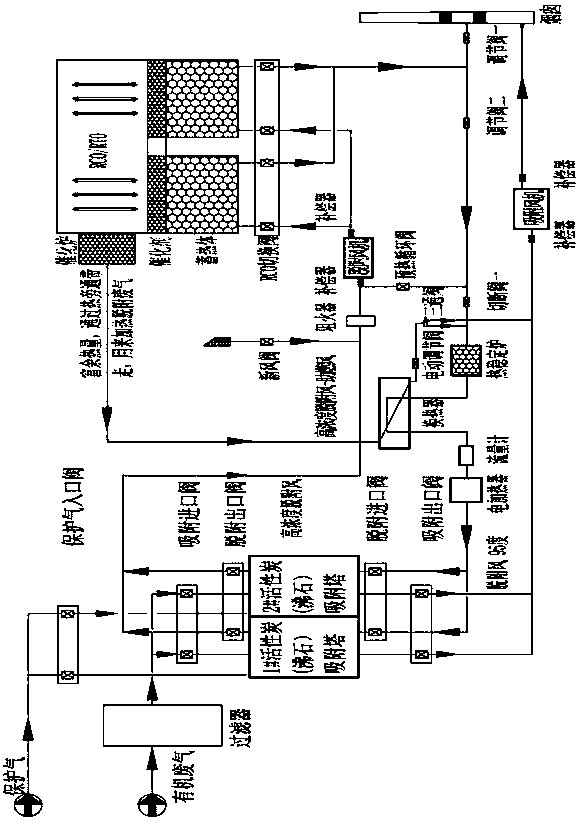

Activated carbon adsorption and desorption process

InactiveCN109589744AReasonable designDisperse in timeGas treatmentDispersed particle separationActivated carbonDesorption

The invention discloses an activated carbon adsorption and desorption process. The activated carbon adsorption and desorption process is characterized by utilizing an activated carbon adsorption and RCO desorption process, the problems that an existing activated carbon adsorption and desorption process is high in energy consumption and ignition risk, and the service life of activated carbon is short are well solved. According to the activated carbon adsorption and desorption process, a flow field of waste gas in an adsorption bed in an activated carbon adsorption tank is uniform, the flow speed is reasonably designed, and heat generated in the process that organic matters in the waste gas are changed from a gas state into a liquid stage during adsorption can be timely dissipated, so that the danger caused due to the heating of the activated carbon bed along the continuous accumulation of phase change heat of the organic matters adsorbed by activated carbon is avoided.

Owner:德州奥深节能环保技术有限公司

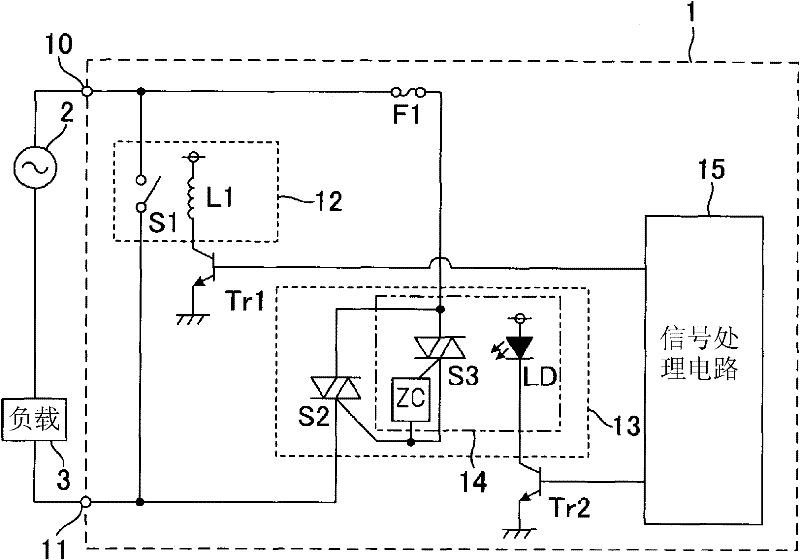

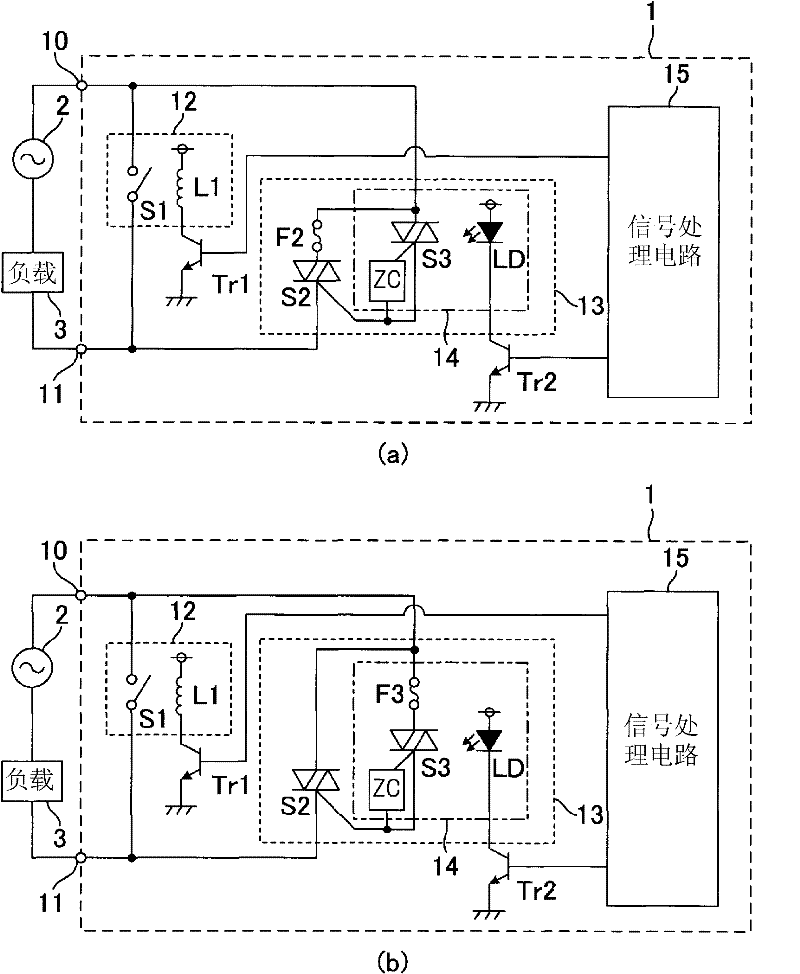

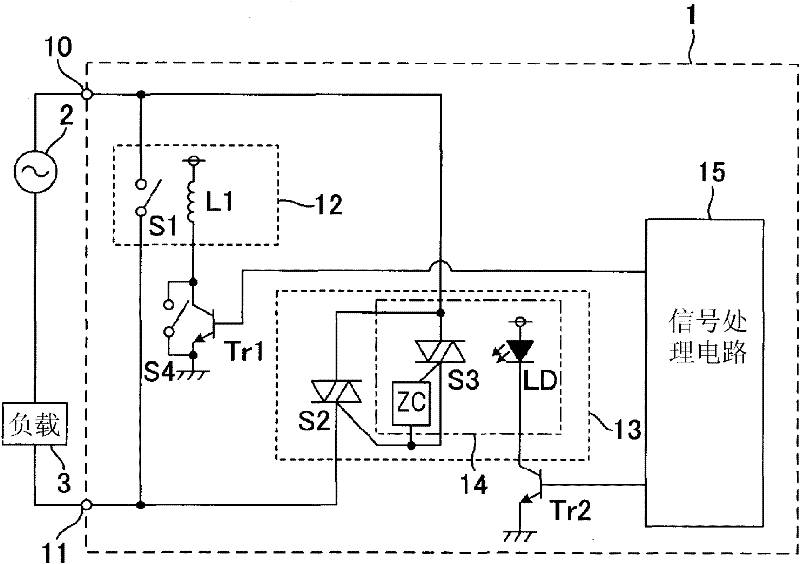

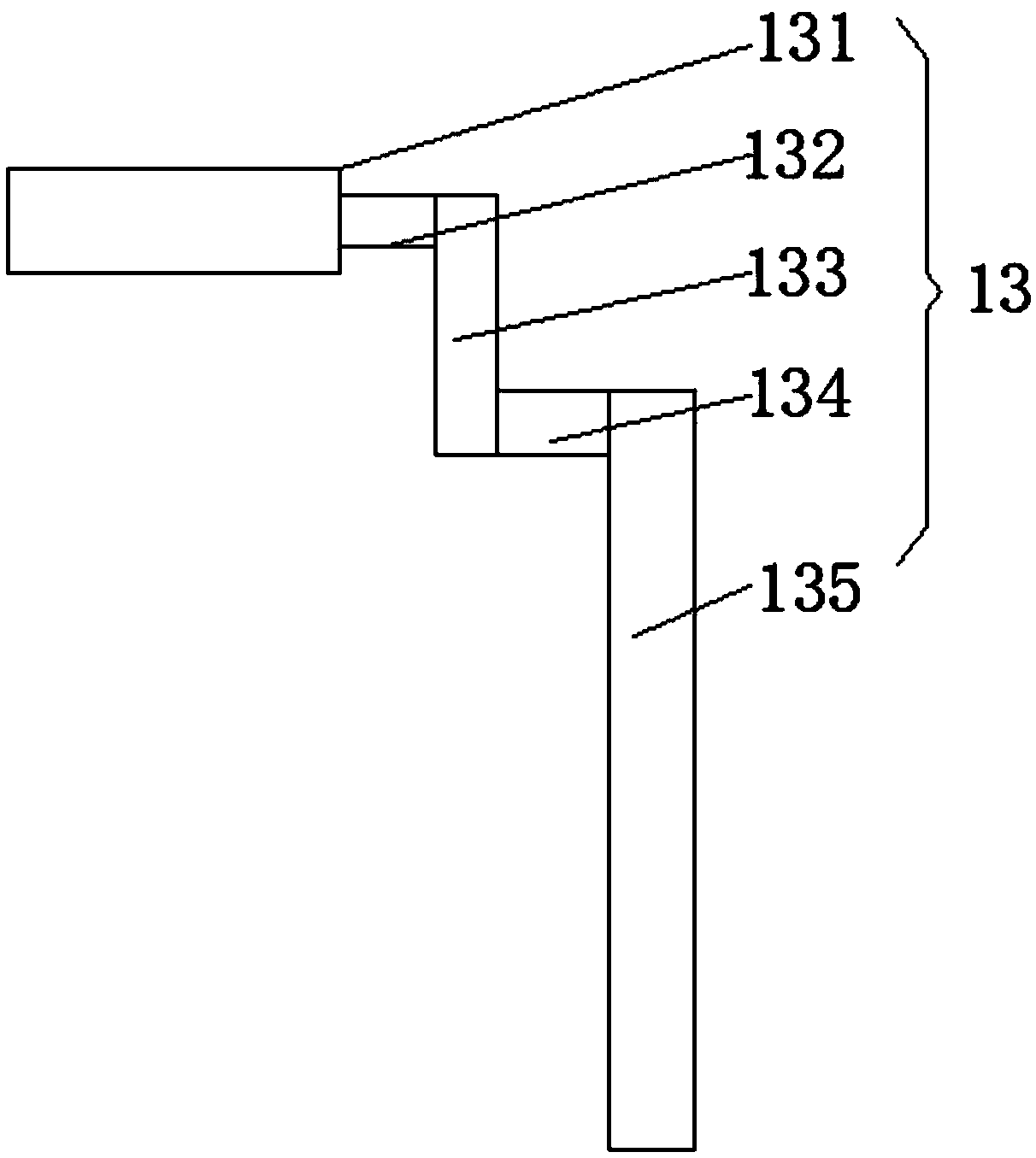

Hybrid relay

Provided is a hybrid relay wherein a semiconductor switch can be prevented from reaching a high temperature. The hybrid relay comprises a mechanical contact switch (12) the contact of which is opened / closed by a driving unit, and a semiconductor switch (13) that is connected in parallel with the mechanical contact switch (12). The hybrid relay also has a first power feeding comprising the mechanical contact switch (12) and a second power feeding path comprising the semiconductor switch (13) connected in parallel, as power feeding paths for supplying power to a load from a power supply. The hybrid relay also comprises a thermal fuse (F1), for example, as a safety circuit section for opening the power feeding path when the temperature of the semiconductor switch becomes equal to or more than a prescribed temperature.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Preparation method of multi-functional liquid glue

ActiveCN102199411AHigh ignition pointIncrease stickinessMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholAntiseptic Agent

The invention discloses a preparation method of multi-functional liquid glue. The preparation method comprises: adding 5 parts by weight of deionized water and 10 to 15 parts by weight of polyvinyl alcohol into a reaction vessel under room temperature; heating the materials to a temperature of 90 DEG C; after the materials are completely dissolved, adding 20 to 25 parts by weight of butyl acetate and 15 to 20 parts by weight of glycerin; leaving the materials to react for 1 hour with preserved temperature; cooling the materials to room temperature; adding 8 to 15 parts by weight of ethanol,15 to 20 parts by weight of polyvinyl acetate, a proper amount of an antiseptic agent and a proper amount of an antifoaming agent; leaving the material to de-foam by standing. The technology of the invention is simple. Once the component proportions, the temperatures, and the reaction times are controlled accurately, the preparation can be successful. During the whole process, no wasting is caused, and no pollution is generated. The production process remains in a clean condition. The produced liquid glue is a single-component liquid glue which is easy to use and is multi-purposed. The liquid glue has strong viscosity and can be widely applied for gluing papers, card boards, fabrics, cork, leather, wood materials, ceramics, colored glaze, cards, plastics, and the like.

Owner:JIANGSU XINGDA STATIONERY GRP

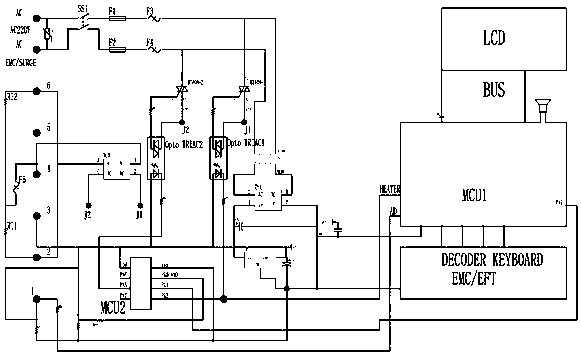

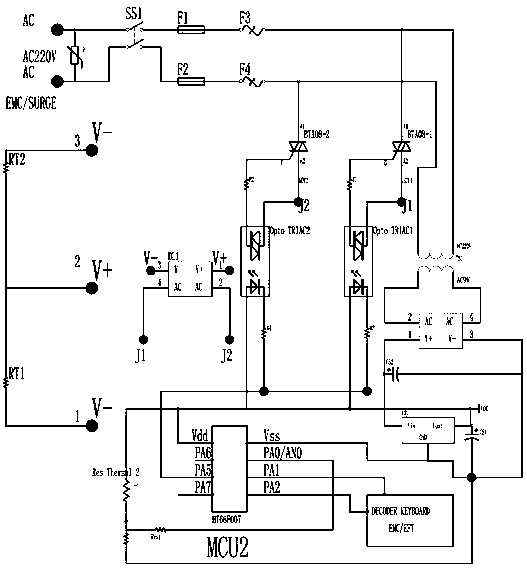

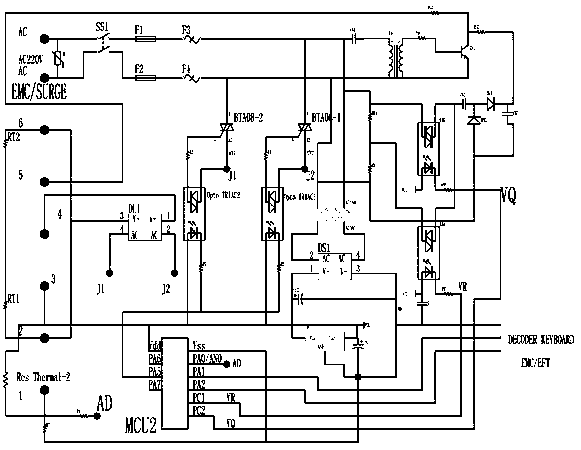

Temperature control method for electric heating pad

ActiveCN108966372AWon't catch fireOhmic-resistance heating detailsTemperature control using electric meansTemperature controlElectricity

The invention relates to a temperature control method for an electric heating pad, and belongs to the technical field of electric heating control. The method comprises 1) setting a constant temperature value and a fixed time; 2) measuring the real-time temperature value of the electric heating pad and comparing the same with the constant temperature value; 3) when the real-time temperature value is less than the constant temperature value, continuously powering the electric heating pad the fixed time by using a pulse signal having a first duty cycle of 100%; 4) when the fixed time expires, pulse-powering the electric heating pad by a pulse signal having a second duty cycle less than 100%; 5)when the real-time temperature value is greater than or equal to the constant temperature value, stopping powering the electric heating pad; and 6) when the real-time temperature measurement and / or the temperature fuse of the electric heating pad fail(s), pulse-powering the electric heating pad by the pulse signal having the second duty cycle. The method, even if the temperature sensor and the temperature fuse of the existing electric heating pad fail, can maintain the temperature of the electric heating pad at a temperature not over than a safe maximum temperature, so as to thoroughly ensure that the electric heating pad does not catch fire.

Owner:滁州国康医疗仪器有限公司

Machining method for electrical cabinet body

InactiveCN106755764AGood hardness uniformityImprove red hardnessFurnace typesQuenching agentsWater basedHardness

The invention relates to a machining method for an electrical cabinet body. The machining method for the electrical cabinet body comprises the following steps that (1) the electrical cabinet body is quenched, specifically, the electrical cabinet body is separately or integrally placed in quenching liquid to be quenched, and the mass percent of the quenching liquid is 20%-25%; (2) the electrical cabinet body is heated, specifically, after being quenched and tempered, the electrical cabinet body is separately or integrally placed in a heating furnace to be heated to the temperature of 800-830 DEG C for the first time, and heat preservation is conducted for 2-4 hours; then the electric cabinet body is heated to the temperature of 850-880 DEG C, and heat preservation is conducted for 2-4 hours; and finally, the electrical cabinet body is heated to the temperature of 900-1000 DEG C and stands to be cooled; and (3) the electrical cabinet body is tempered, specifically, after being cooled to the temperature of 500-550 DEG C, the electrical cabinet body is conveyed into a tempering furnace and air-cooled to the temperature of 200-250 DEG C, the electrical cabinet body is tempered to the temperature of 500-550 DEG C at the moment, and heat preservation is conducted for 2-4 hours. According to the machining method for the electrical cabinet body, operation is easy, cleanliness is guaranteed, smoke and odor are avoided, ignition is avoided, and the good structure and performance can be obtained after quenching and tempering; and practice indicates that after quenching in PQL water-based quenching media and tempering, the hardness uniformity, red hardness and service life of a mold are better compared with the hardness uniformity, red hardness and service life of a mold subjected to quenching through quenching oil.

Owner:YANGZHOU HUADONG POWER MACHINE

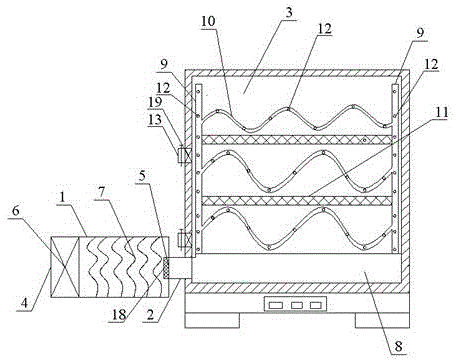

Pork drying machine

InactiveCN106689331AIncrease the number of rootsAvoid cloggingMeat/fish preservation by heatingMeat/fish preservation by dryingWater depletionAgricultural engineering

The invention discloses a pork drying machine. The pork drying machine comprises a heater, wherein the heater is connected with a drying box through a heating transporting pipe; a wind inlet and a wind outlet are separately formed in two ends of the heater; a wind sucking fan is arranged at the wind inlet; at least two heating wires are arranged between the wind outlet and the wind sucking fan; the drying box comprises a hot wind chamber; at least two layers of meat laying frames are arranged above the hot wind chamber; the hot wind chamber is connected with hot wind heating pipes; the hot wind heating pipes are vertically arranged on the inner walls of the drying box; sub hot wind heating pipes are arranged on the hot wind heating pipes, and the sub hot wind heating pipes are distributed on the inner walls of the drying box in a sinusoidal manner; wing outlets are formed in the hot wind heating pipes and the sub hot wind heating pipes; wind releasing holes are formed in the side wall of the drying box; a wind releasing fan is arranged on each wind releasing hole; observation windows are also formed in the drying box; a temperature sensor and a humidity sensor are arranged on each observation window; and a controller is also arranged on the drying box. According to the pork drying machine disclosed by the invention, temperature is easy to control, the drying efficiency is high, the water depletion of pork is uniform, and the labor intensity is low.

Owner:贵州省福泉市安运腌制食品有限责任公司

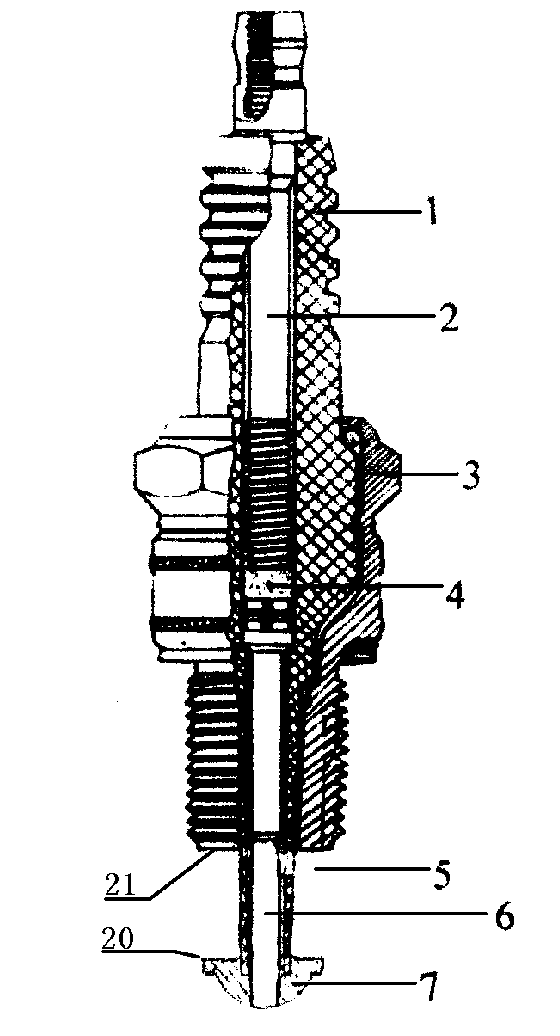

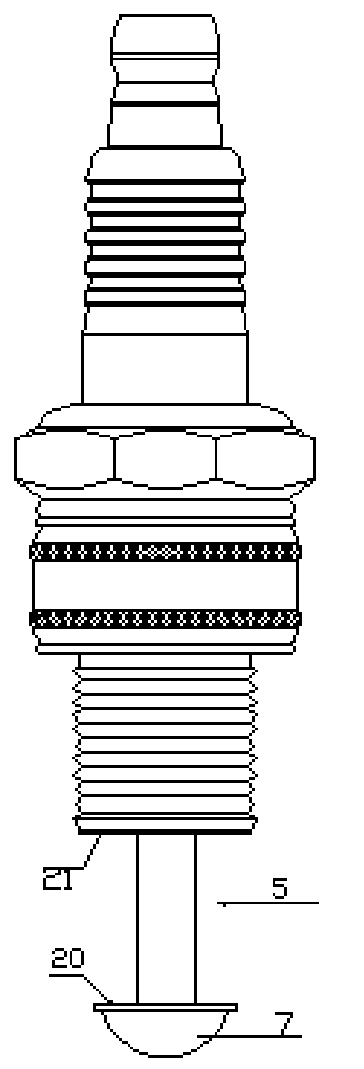

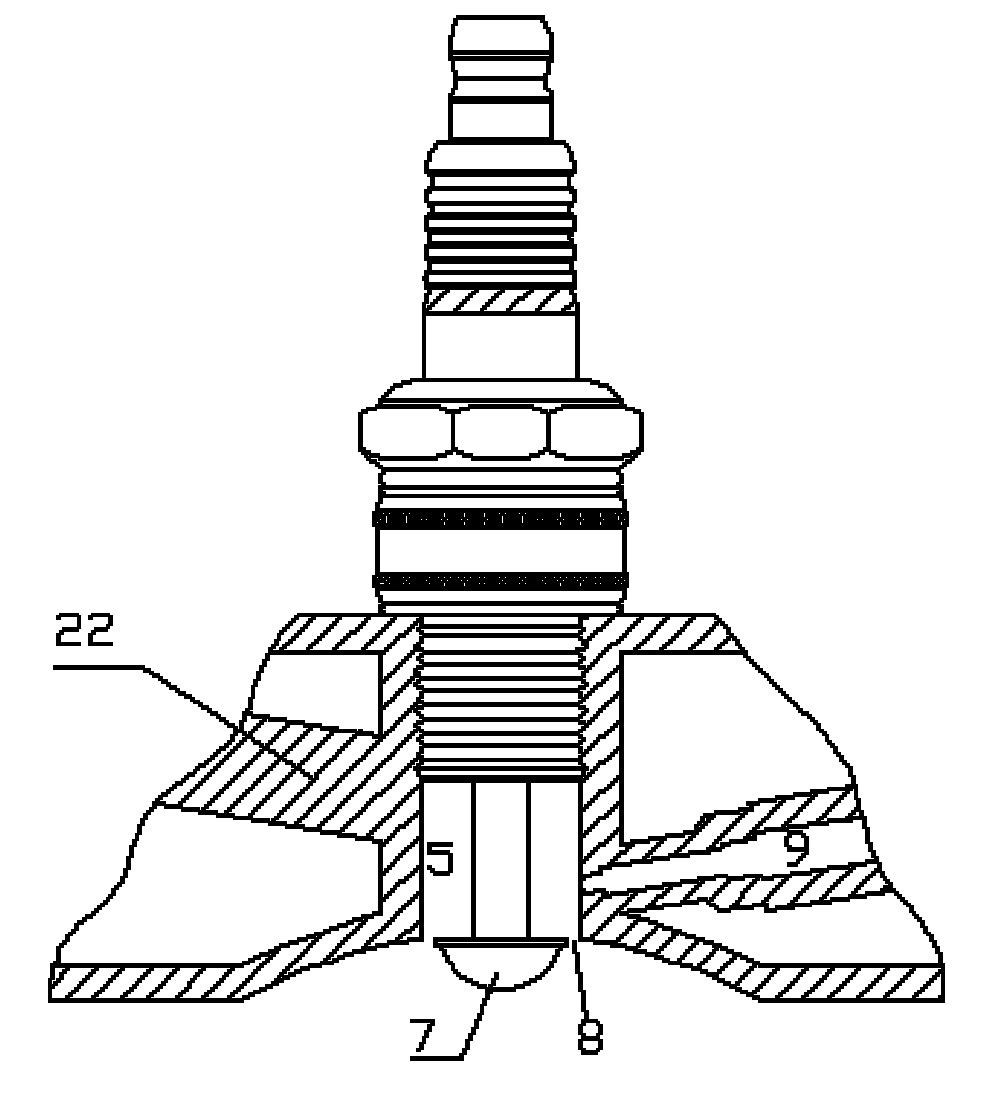

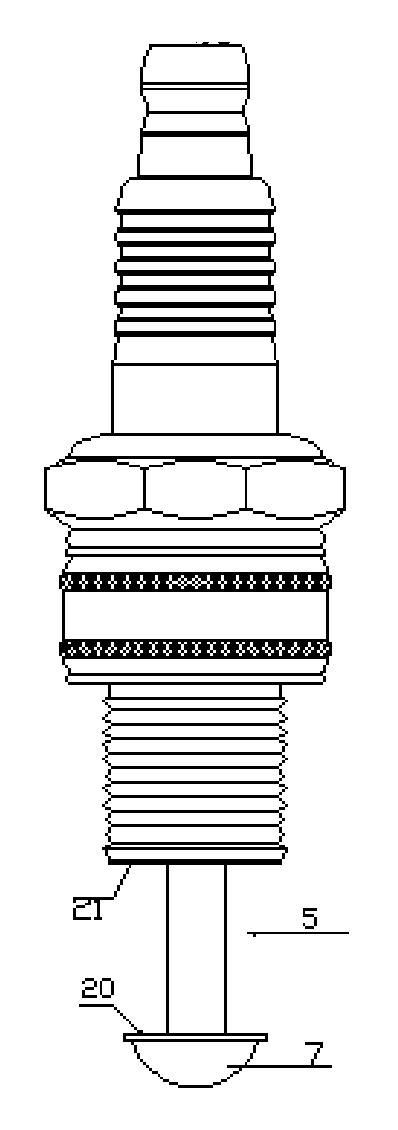

Flame-throwing nozzle of engine

InactiveCN101789563AIgnite effectiveReduce wasteSparking plugsIgnition sparking plugsSealantHeat capacity

The invention discloses a flame-throwing nozzle of an engine, which comprises a housing, wherein a porcelain insulator is arranged in the housing, a double-headed screw stem with a wiring screw cap, a conductor glass sealant, a central electrode with one end extending out of the porcelain insulator and a flame-throwing cap which is welded with the end part of the central electrode are arranged inthe porcelain insulator, the flame-throwing cap comprises a plane, the sharp edge of the plane forms a circle, the vertical distance between the plane and the end surface of the housing is greater than 8mm, an ignition gap formed by the flame-throwing cap and an engine cylinder cover is annular, and a heat capacity flame-throwing cavity is formed by the flame-throwing cap and the engine cylinder cover. The flame-throwing nozzle of the engine has the functions of electric spark ignition, flame throwing, heating for supporting combustion and the like and can realize the reliable, uniform and rapid completion of the whole combustion process. The flame-throwing nozzle of the engine can fundamentally eliminate the basic conditions of exhaust pollution of a vehicle, simultaneously greatly reduce the oil consumption, improve a variety of performances of the vehicle and prolong the service life of the engine.

Owner:申阳德

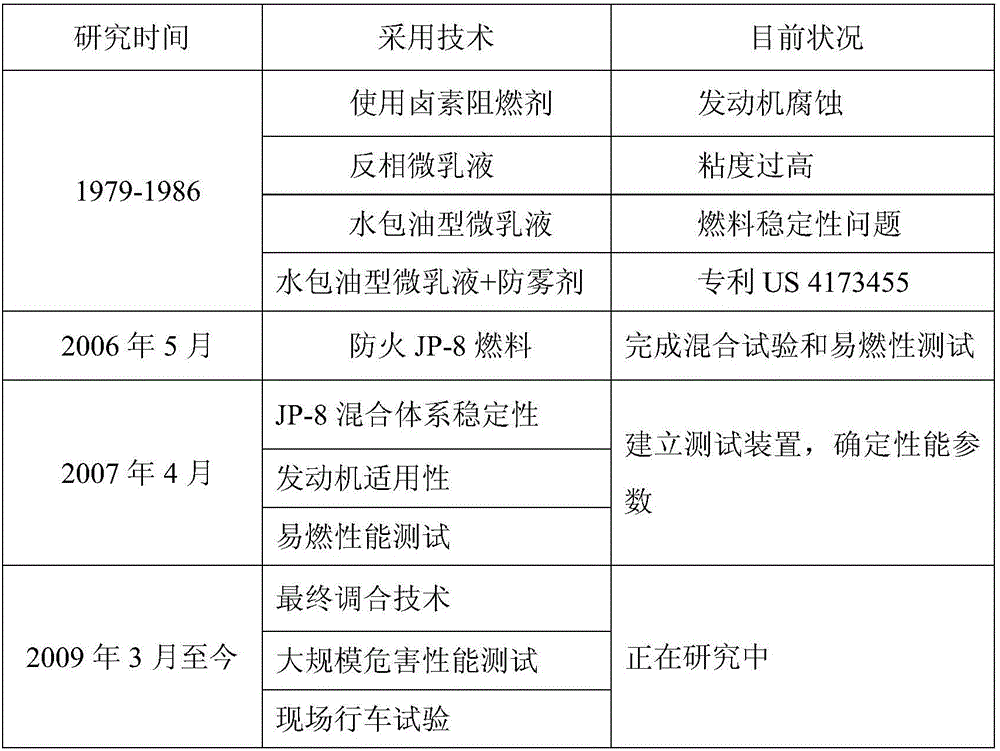

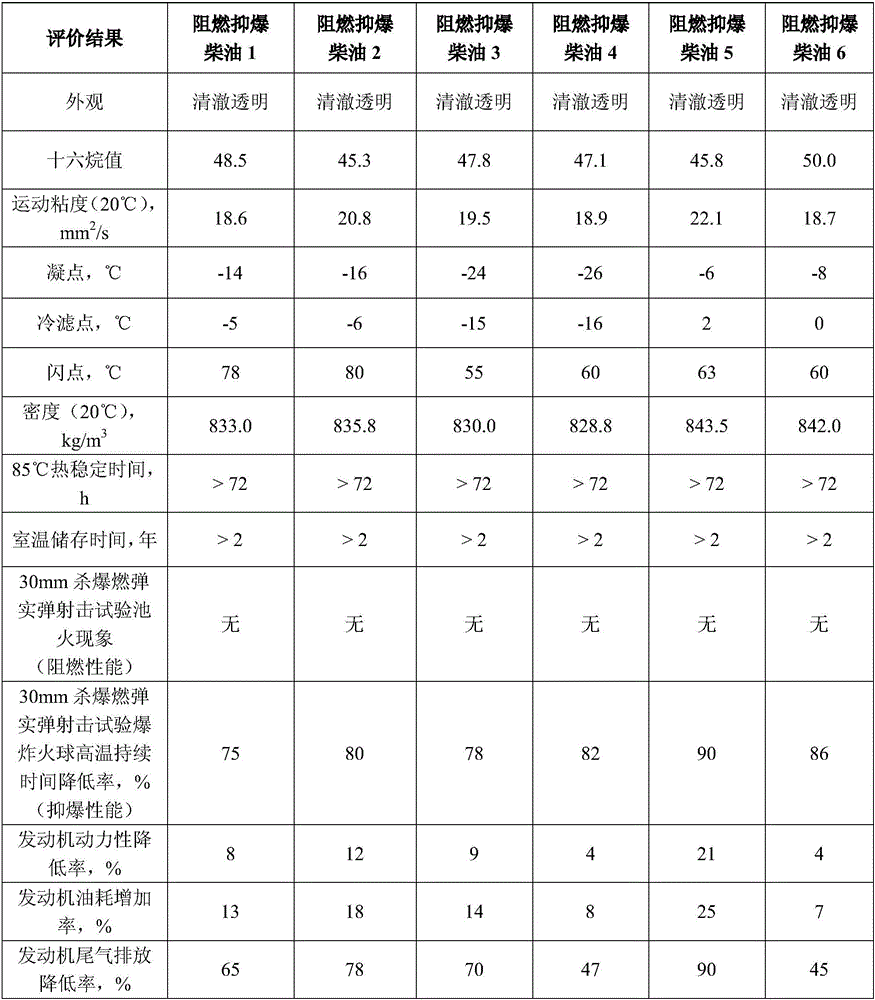

Preparation method of safe diesel oil with flame-retardant explosion suppression function

InactiveCN105733700AClear and transparent appearanceEasy to operateLiquid carbonaceous fuelsFuel additivesDiesel fuelPetroleum engineering

The invention discloses a preparation method of safe diesel oil with a flame-retardant explosion suppression function. In the method, existing diesel oil is added with water, an explosion suppressant, a micro-emulsifier, a co-emulsifier and a functional additive, and the safe diesel oil with the flame-retardant explosion suppression function is prepared through blending by a micro-emulsifying technology. The diesel oil has clear appearance and can be stored for long time; the diesel oil can be normally burnt for use in an engine, but in the case of gunfire strike, the diesel oil is not ignited and has a self-extinguishing function; and meanwhile, the hazard of 'secondary explosion' of diesel oil can be reduced by 70% or over. The invention provides a preparation method of the safe diesel oil with the flame-retardant explosion suppression function. The preparation process has the advantages of simplicity in operation and easiness in implementation, safety and reliability and high efficiency.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

Gauze cooking machine capable of keeping water clean

ActiveCN108796897AEasy to disinfectGood cooking effectLiquid/gas/vapor removalTextile treatment machine arrangementsActivated carbonHeat conducting

The invention provides a gauze cooking machine capable of keeping water clean, and relates to the technical field of gauze cooking machines. The gauze cooking machine capable of keeping water clean comprises a filtering box; an activated carbon board is movably connected in the filtering box, the activated carbon board comprises an activated carbon board body, and sliding blocks are fixedly installed on both sides of the activated carbon board body; a filtering plate is movably connected in the filtering box, the filtering plate comprises a filtering screen, and a sliding frame is fixedly installed on the filtering screen. According to the gauze cooking machine capable of keeping water clean, through the cooperation of a heating wire, a heat conducting plate, a cooking box, a heat insulating plate, a water pump, a connecting pipe, the filtering box and a water pipe, the heating wire performs heating, the heating conducting plate conducts heat to heat water, the cooking box is providedwith the heat insulating plate, the water pump sucks the water in the cooking box into the filtering box through the connecting pipe, impurities in the water are removed after the water passes throughthe filtering box, the water passes through the water pump and then enters the cooking box through the water pipe, so the water in the cooking box circularly passes through the filtering box, the impurities are filtered out, and the disinfecting and cooking effect is better.

Owner:MEDWELL MEDICAL PROD

Grinding operation table

InactiveCN109318119AReduce pollutionSimple structureGrinding carriagesGrinding bedsWorking environmentEngineering

The invention discloses a grinding operation table. The grinding operation table mainly comprises an operation table; a grinding mechanism is arranged at the top of the operation table, a collecting box is arranged on one side of the operation table, and the collecting box comprises a box body, a connecting pipe, a protective net and a collecting box; an opening part is formed in one side of the box body, the connecting pipe is fixed inside the box body, and the bottom of the connecting pipe is connected to the protective net through a hook; a first dust suction opening and a second dust suction opening are formed in the top of the box body, the first dust suction opening and the second dust suction opening are formed in the two sides of the connection pipe, and the first dust suction opening and the second dust suction opening are connected to an external dust collector; and the bottom of the collecting box is movably connected to the bottom of the box body through a sliding rail, anda cabinet door used for taking the collecting box is arranged on one side of the box body. The grinding operation table has the advantages that the structure is simple, the use is safe, and the splashing of sparks during grinding can be effectively prevented; meanwhile, the splashing can be effectively recycled, so that pollution to the working environment is reduced; and due to the buffering performance of the protective net, splashing can not rebound to the body of an operator.

Owner:盐城铭华国际货运代理有限公司

A gauze cooking machine for keeping water clean

ActiveCN108796897BEasy to disinfectGood cooking effectLiquid/gas/vapor removalTextile treatment machine arrangementsActivated carbonProcess engineering

The invention provides a gauze cooking machine capable of keeping water clean, and relates to the technical field of gauze cooking machines. The gauze cooking machine capable of keeping water clean comprises a filtering box; an activated carbon board is movably connected in the filtering box, the activated carbon board comprises an activated carbon board body, and sliding blocks are fixedly installed on both sides of the activated carbon board body; a filtering plate is movably connected in the filtering box, the filtering plate comprises a filtering screen, and a sliding frame is fixedly installed on the filtering screen. According to the gauze cooking machine capable of keeping water clean, through the cooperation of a heating wire, a heat conducting plate, a cooking box, a heat insulating plate, a water pump, a connecting pipe, the filtering box and a water pipe, the heating wire performs heating, the heating conducting plate conducts heat to heat water, the cooking box is providedwith the heat insulating plate, the water pump sucks the water in the cooking box into the filtering box through the connecting pipe, impurities in the water are removed after the water passes throughthe filtering box, the water passes through the water pump and then enters the cooking box through the water pipe, so the water in the cooking box circularly passes through the filtering box, the impurities are filtered out, and the disinfecting and cooking effect is better.

Owner:MEDWELL MEDICAL PROD

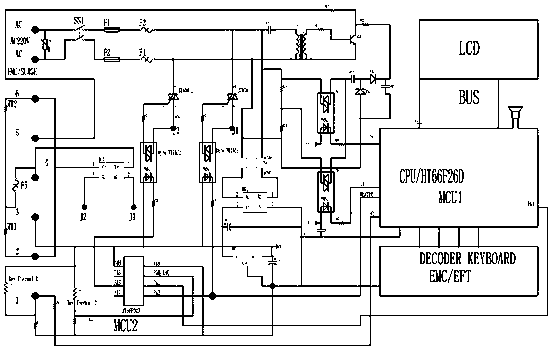

Temperature control device of electric warming pad

PendingCN108762337AWon't catch fireEnsure safetyElectric heatingTemperature control using electric meansTemperature controlSafety control

The invention relates to a temperature control device of an electric warming pad, and belongs to the technical field of electric warming control. The device comprises a power supply for supplying power to heating wires in the electric warming pad, wherein a first electronic switch and a second electronic switch are arranged between the power supply and the heating wires; an and gate is formed between the first electronic switch and the second electronic switch; the device does not comprise a first temperature sensor for measuring and controlling the real-time temperature of the electric warming pad, a first temperature control processor and a temperature fuse. The device further comprises a second temperature control processor which is used for outputting a pulse signal of which the valueis less than 100% of duty ratio in order to control the first electronic switch and the second electronic switch to be alternatively connected and disconnected; the heating wires are used for performing pulse power supplying on the basis of the duty ratio. With the adoption of the device, the double-safety control mechanism including constant temperature control and temperature fuse power-off protection of a conventional electric warming pad is completely removed; the safety of the electric warming pad in use is ensured; and the structure of the electric warming pad is greatly simplified.

Owner:滁州国康医疗仪器有限公司

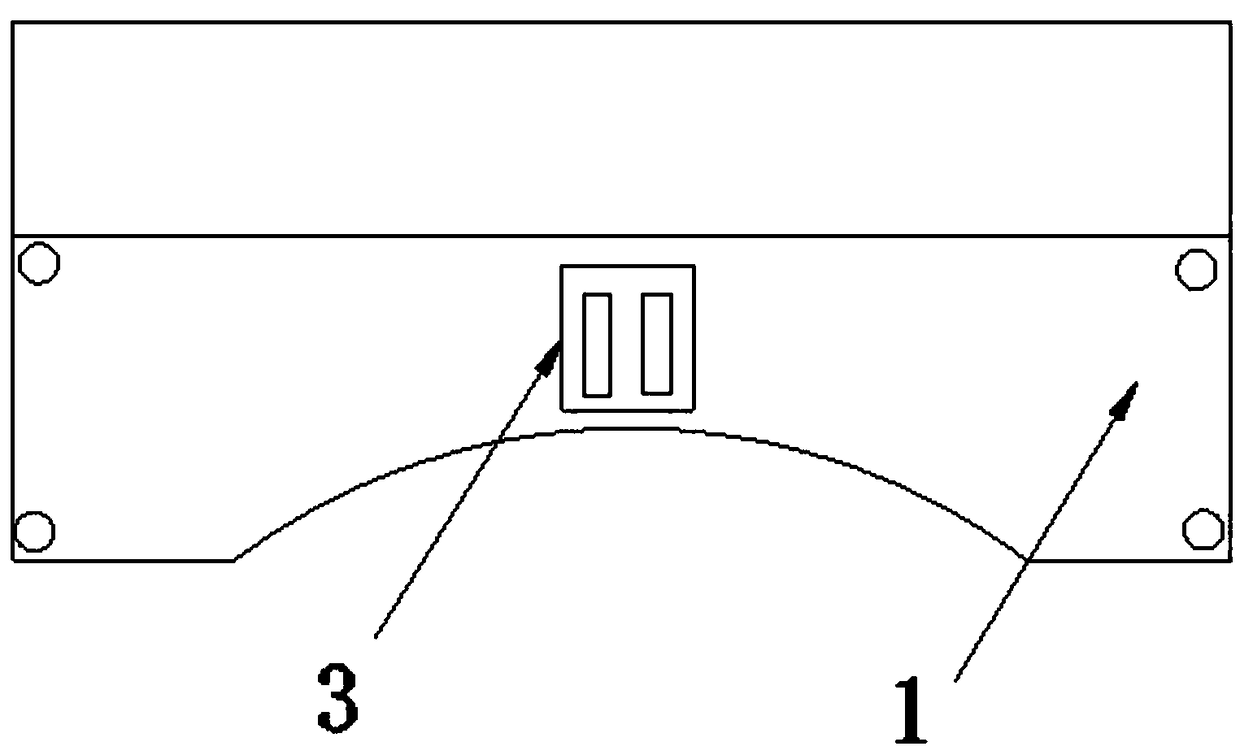

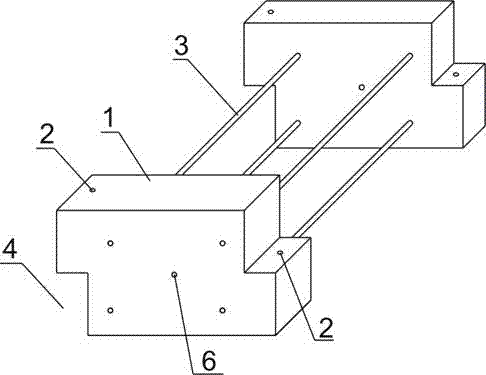

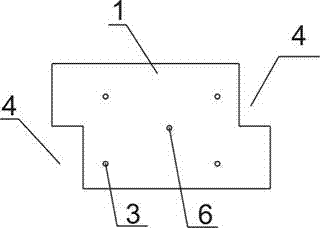

Blocks free of mortar and composite thermal insulating wall and masonry method thereof

InactiveCN107035059AMeet Class A fire protection requirementsWon't catch fireWallsHeat proofingBrickThermal insulation

The invention belongs to the technical field of building, and discloses blocks free of mortar and a composite thermal insulating wall and a masonry method thereof. The blocks free of mortar comprise two square bricks which are arranged at intervals with a same structure and opposite to each other front and back, L-shaped gaps are formed in two diagonal positions, opposite to each other, of the bricks inwards correspondingly, and the lengths of the two L-shaped gaps are equal; the widths of the two L-shaped gaps are equal and are equal to the widths of the bricks, and the sum of the heights of the two L-shaped gaps is equal to the heights of the bricks; and vertical anchor caverns are formed in lugs, corresponding to the two L-shaped gaps up and down, in a reserved mode from top to bottom correspondingly, and a plurality of round steel bridge extension rods are fixedly connected between the two bricks evenly. The composite thermal insulating wall comprises a plurality of blocks free of mortar stacked in multiple lines and multiple rows, anchoring parts are inserted in two rows of the anchor caverns front and back in a penetrating-through mode from top to bottom correspondingly, and inorganic thermal insulation materials are poured between the two rows of wall tops front and back. According to the blocks free of mortar and the composite thermal insulating wall and the masonry method thereof, the inorganic thermal insulation materials are arranged in the composite thermal insulating wall, fire-catching cannot happen, and the same service life as the building can be achieved.

Owner:HUANGHUAI UNIV

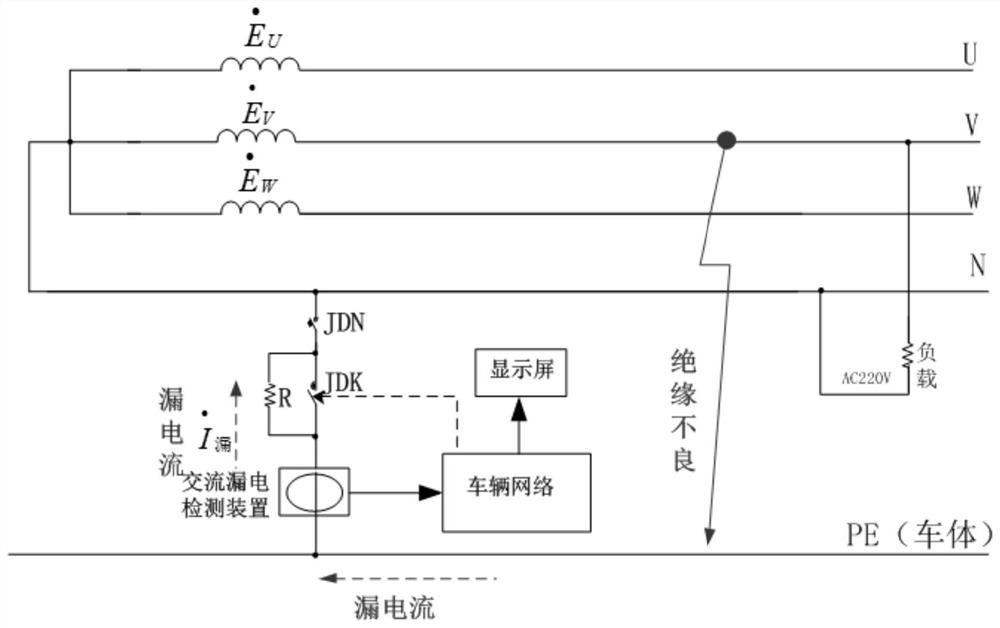

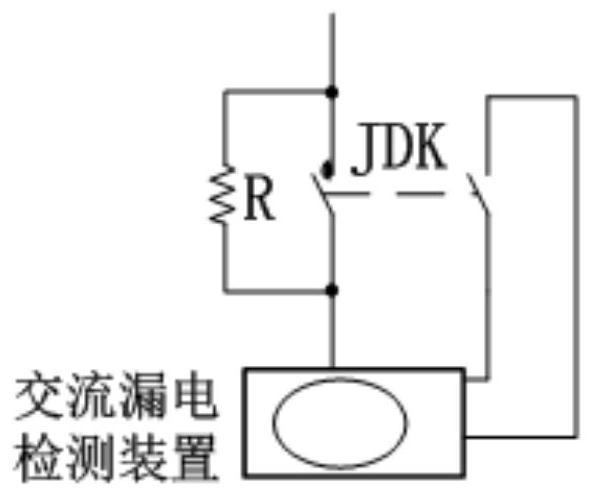

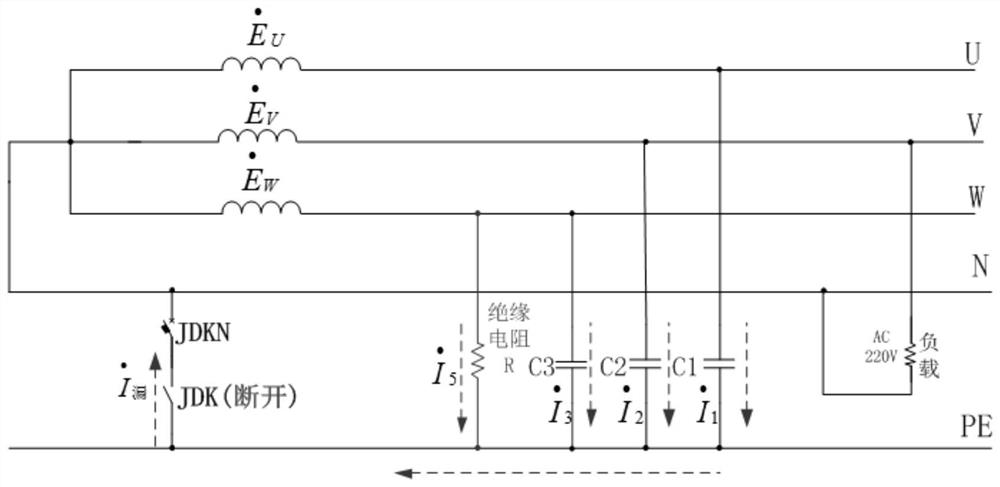

Alternating current leakage detection system and method supporting power supply mode conversion, and vehicle

PendingCN114563733AReduce design costReduce the impactRailway vehiclesShort-circuit testingContactorAutomotive engineering

The invention provides an alternating current leakage detection system and method supporting power supply mode conversion and a vehicle, the system comprises an alternating current insulation detection device, a leakage current contactor, a leakage detection resistor, a circuit breaker and a controller, and the circuit breaker, the leakage current contactor and the alternating current leakage point detection device are sequentially connected in series and are connected between a neutral line and the vehicle; the leakage detection resistor is connected in parallel with the leakage current contactor; the alternating current insulation detection device is used for detecting a vehicle leakage current value and sending an early warning / alarm signal to the controller, and the controller is used for controlling the leakage current contactor to be switched on or switched off according to a vehicle state, so that a vehicle auxiliary power supply mode is a TT mode or an IT power supply mode; an isolation transformer does not need to be added, and the vehicle design cost is reduced; when an electric leakage fault occurs, an IT power supply mode is automatically converted, a fault load power supply does not need to be cut off, the influence on the operation order is reduced, and the vehicle availability is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Method and equipment for treating waste gas of hot press

ActiveCN102284220BImprove processing efficiencyWon't catch fireUsing liquid separation agentSewageWater spray

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

An integral oil-impregnated paper high-voltage bushing

ActiveCN103456473BReduced probability of insulation failureWon't catch fireTransformers/inductances coils/windings/connectionsLead-in/lead-through insulatorsTransformerShock resistance

The invention discloses an integral type oil-paper high-voltage bushing which comprises a glass reinforced plastic cylinder, a conducting rod, an expander, a mounting flange, a base and a voltage-sharing ball, wherein the mounting flange for being connected with a transformer is hermetically arranged in the middle position of the glass reinforced plastic cylinder in a sleeving manner; a silicone rubber umbrella cover is cast on the outer side of the glass reinforced plastic cylinder at a position above the mounting flange, and semi-conductive paint is sprayed on the outer side of the glass reinforced plastic cylinder at a position below the mounting flange and forms an isoelectric cylinder which has the same diameter as the flange; the base is hermetically arranged at the bottom of the glass reinforced plastic cylinder; the conducting rod is inserted in the glass reinforced plastic cylinder and integrated with the mounting flange, the glass reinforced plastic cylinder and the base; the expander is arranged at the top of the glass reinforced plastic cylinder, and the voltage-sharing ball is arranged at the bottom of the glass reinforced plastic cylinder. The integral type oil-paper high-voltage bushing is simple in structure; oil in the bushing is completely isolated from that in the transformer; the probability of failure of the product is greatly reduced; the transformer can be effectively prevented from catching fire and burning; the product has a light weight; the mounting is convenient; the shock resistance and bending resistance are good; maintenance is basically avoided.

Owner:JIANGSU ZHIDA ELECTRIC

Preparation method of multi-functional liquid glue

ActiveCN102199411BHigh ignition pointIncrease stickinessMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholAntiseptic Agent

The invention discloses a preparation method of multi-functional liquid glue. The preparation method comprises: adding 5 parts by weight of deionized water and 10 to 15 parts by weight of polyvinyl alcohol into a reaction vessel under room temperature; heating the materials to a temperature of 90 DEG C; after the materials are completely dissolved, adding 20 to 25 parts by weight of butyl acetate and 15 to 20 parts by weight of glycerin; leaving the materials to react for 1 hour with preserved temperature; cooling the materials to room temperature; adding 8 to 15 parts by weight of ethanol,15 to 20 parts by weight of polyvinyl acetate, a proper amount of an antiseptic agent and a proper amount of an antifoaming agent; leaving the material to de-foam by standing. The technology of the invention is simple. Once the component proportions, the temperatures, and the reaction times are controlled accurately, the preparation can be successful. During the whole process, no wasting is caused, and no pollution is generated. The production process remains in a clean condition. The produced liquid glue is a single-component liquid glue which is easy to use and is multi-purposed. The liquid glue has strong viscosity and can be widely applied for gluing papers, card boards, fabrics, cork, leather, wood materials, ceramics, colored glaze, cards, plastics, and the like.

Owner:JIANGSU XINGDA STATIONERY GRP

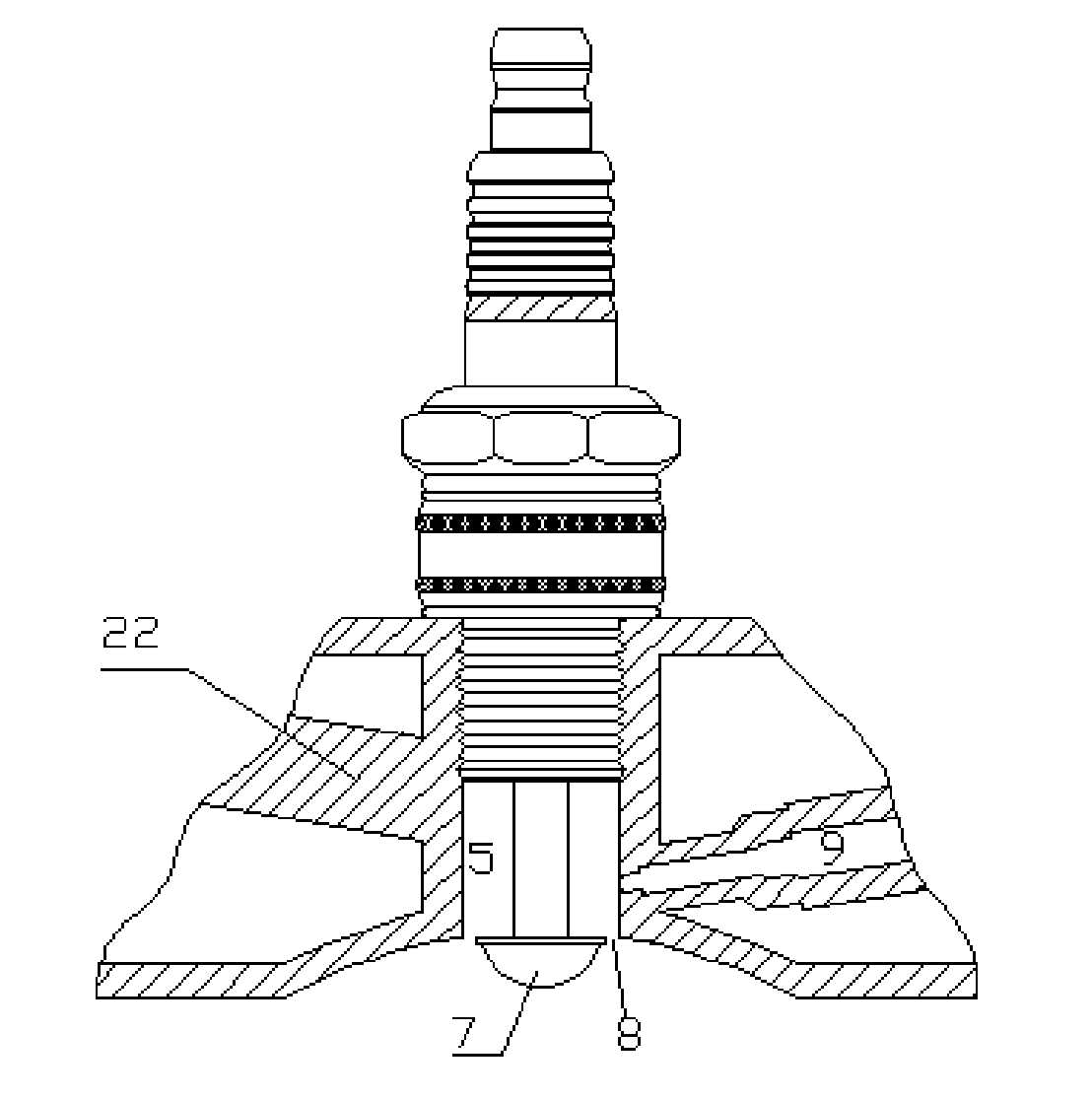

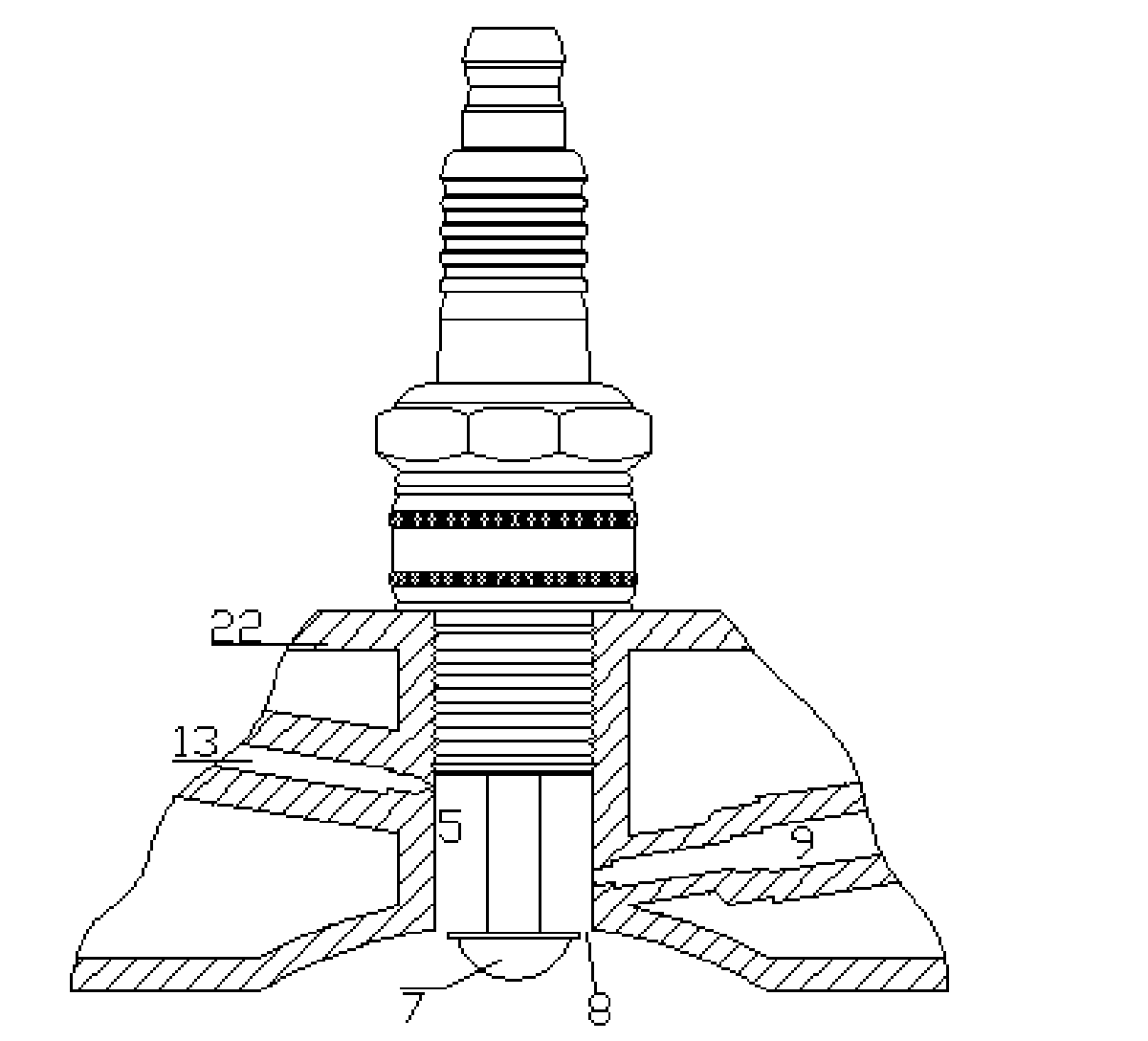

Direct injection system in engine cavity

InactiveCN101787924AReduce exhaust pollutionReduce fuel wasteInternal combustion piston enginesAutomotive engineeringEngineering

The invention discloses a direct injection system in an engine cavity, which comprises an engine cylinder cover, a flame-throwing nozzle and a fuel spray nozzle, wherein the flame-throwing nozzle mainly comprises a housing, a porcelain insulator, a double-headed screw stem, a conductor glass sealant, a central electrode and a flame-throwing cap, a heat capacity flame-throwing cavity is formed by the flame-throwing cap and the engine cylinder cover, an annular ignition gap is formed by the flame-throwing cap at the end part of the heat capacity flame-throwing cavity and the engine cylinder cover, and at least one spray nozzle is arranged on the wall of the heat capacity flame-throwing cavity. One spray nozzle on the wall of the heat capacity flame-throwing cavity is the fuel spray nozzle, and another spray nozzle can be a gas spray nozzle. The direct injection system in the engine cavity has the functions of ignition, flame throwing, heating for supporting combustion and the like and can realize the reliable, uniform and rapid completion of the whole combustion process; and the addition of high pressure air can lead the combustion of an engine to be more complete. The direct injection system in the engine cavity can change the combustion way of the engine and greatly optimize and upgrade the performances of the engine.

Owner:申阳德

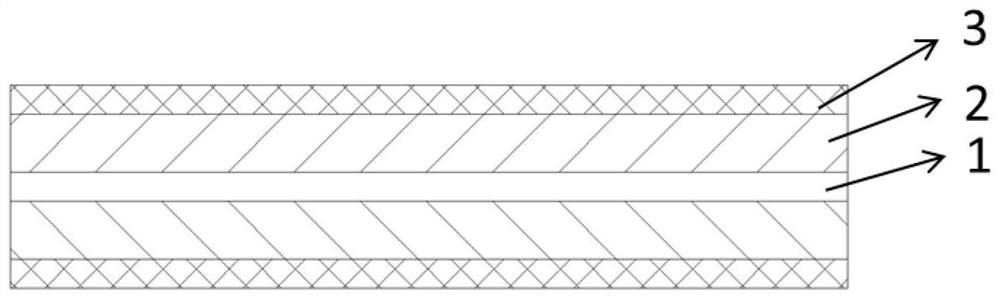

Negative pole piece as well as preparation method and application thereof

PendingCN114122318AImprove thermal stabilityImprove electrochemical performanceNegative electrodesNon-aqueous electrolyte accumulator electrodesElectrical batteryHeat stability

The invention provides a negative pole piece as well as a preparation method and application thereof. The negative pole piece comprises a current collector, an electrode layer and a safety coating which are sequentially stacked; the safety coating comprises lithium titanate, a conductive agent and a binder. The safe coating is arranged on the surface of the electrode layer of the negative electrode plate, and lithium titanate can be used as a safe material and an active substance at the same time through the synergistic effect of lithium titanate and the conductive agent, so that the thermal stability of the negative electrode plate of the lithium ion battery is improved, and other electrochemical properties such as rate capability and cycle performance are also improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com