Blocks free of mortar and composite thermal insulating wall and masonry method thereof

A composite insulation and mortar-free technology, applied in insulation, walls, buildings, etc., can solve the problems of easy fire, high thermal conductivity and self-insulation, and easy falling off of organic insulation materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

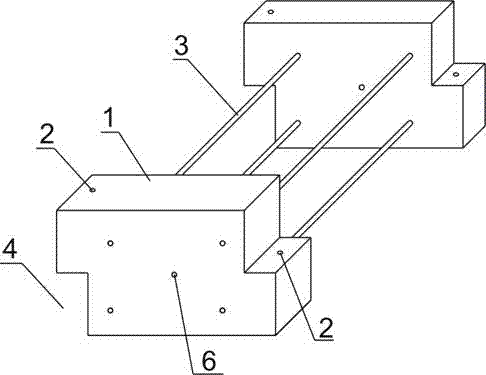

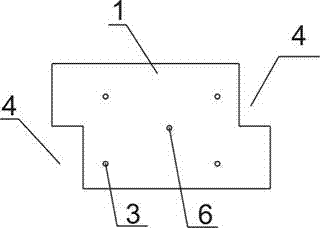

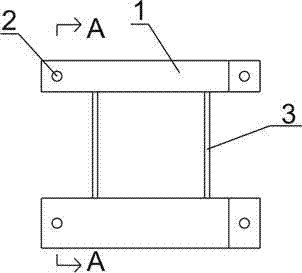

[0028] A mortar-free block brick, such as Figure 1~4 As shown, it includes two square bricks 1 (solid) with the same structure and set in front and back facing each other. The brick 1 is a concrete brick 1. A horizontal ventilation hole 6 is reserved in the center from front to back, and an L-shaped notch 4 is respectively inwardly opened at two opposite corners of the brick 1. The lengths of the two L-shaped notches 4 are equal, and the lengths of the two L-shaped notches 4 The width is equal and equal to the width of the brick 1, and the sum of the heights of the two L-shaped notches 4 is equal to the height of the brick 1; on the bumps corresponding to the two L-shaped notches 4, vertical holes are respectively reserved from top to bottom. Anchor holes 2; four round steel bridging rods 3 are evenly fixed between the upper, lower, left, and right positions of the air hole 6 on the two bricks 1 .

Embodiment 2

[0030] A kind of composite insulation wall comprising the free mortar block brick described in embodiment 1, such as Figure 5~6 As shown, the composite thermal insulation wall includes several "rows and columns" stacked mortar-free block bricks. The front row of bricks 1 of the mortar-free block bricks forms the front row of walls, and the rear row of bricks 1 of the mortar-free block bricks is formed. Anchor pieces 7 are inserted through the anchor holes 2 of the front and back rows of wall heads from top to bottom, and inorganic thermal insulation material 5 (foamed concrete) is poured between the front and back two rows of wall heads; among them, two adjacent The mortar-free block bricks are stacked through the L-shaped gap 4 of one of the mortar-free block bricks and the protrusion of the other mortar-free block brick.

[0031] The masonry method of the composite thermal insulation wall: before masonry, lay a layer of mortar on the ground first, then stack the lowest laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com