High-strength composite board structure and mounting method thereof

A composite board, high-strength technology, applied in the direction of building structure, floor, covering/lining, etc., can solve the problems of harming human health, high water absorption rate of inorganic board, easy to burn, etc., to reduce residual deformation and residual stress, The effect of increasing the bearing area and increasing the foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

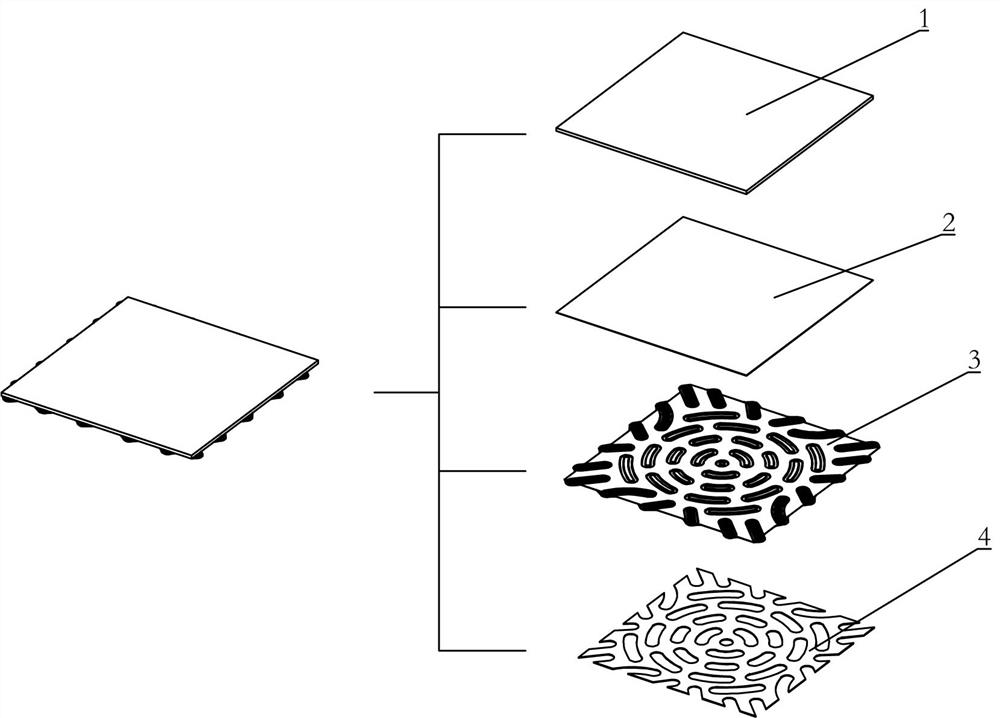

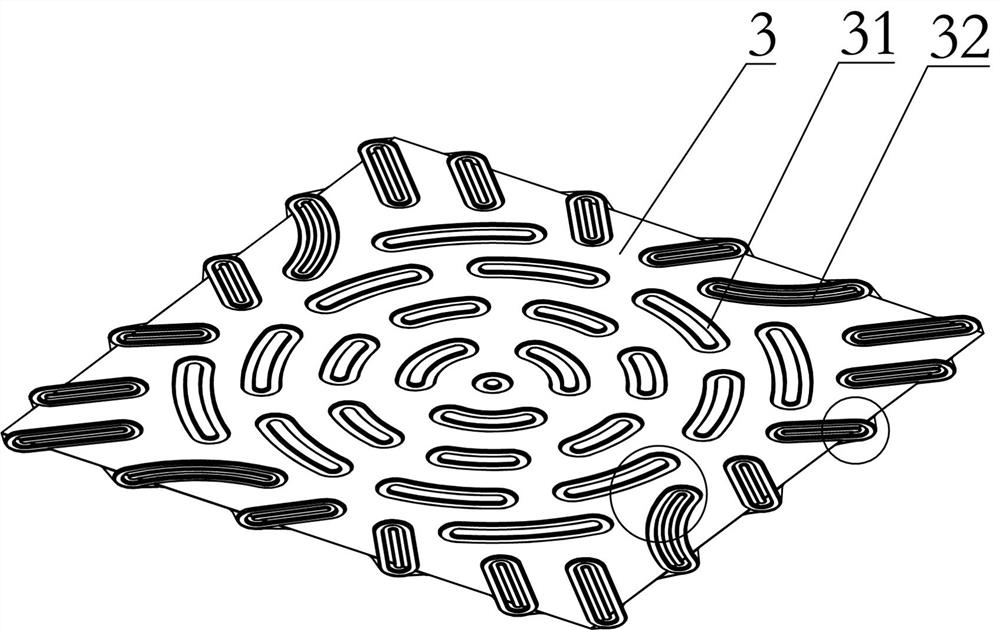

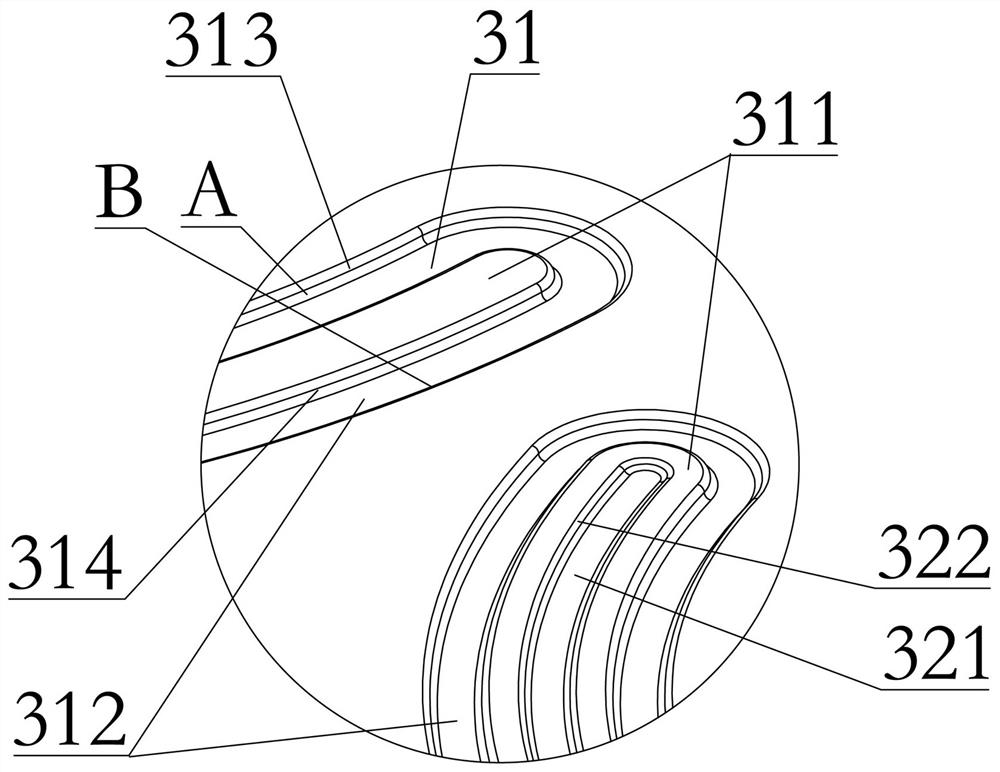

[0035] Embodiment one: if Figure 1-3 As shown, it is only one embodiment of the present invention, a high-strength composite panel structure, including a decorative panel part 1, a metal sheet part 3 located at the bottom of the decorative panel part 1, and used to connect the decorative panel part 1 and the adhesive layer 2 of the sheet metal part 3, the foam pad 4 at the bottom of the sheet metal part 3, and the sheet metal part 3 is provided with a first bearing part 31 located in the middle of the sheet metal part 3 , and the second load-bearing portion 32 located around the edge of the thin metal piece 3 , and the clamping portion 33 located around the thin metal piece 3 for connecting adjacent composite panels.

[0036] In the present invention, the sheet metal part 3 is formed by a stretching process, and the shape of the sheet metal part 3 is not limited to a rectangle, and may also be an equilateral triangle and a positive even-numbered polygon with sides not less th...

Embodiment 2

[0041] Embodiment two: if figure 2 and 4 As shown, it is only one of the embodiments of the present invention. On the basis of the first embodiment, the snap-in part 33 includes lap buckles located around the sheet metal part 3, and is connected with the edge of the sheet metal part 3 for lapping. Steps that connect to the buckle arc transition.

[0042] The first is the structure of the lap buckle. The lap buckle includes a second composite surface 331, a fourth annular section 333 for connecting the second composite surface 331 and the first supporting surface 312, and a fourth annular section 333 for connecting the second composite surface 331 and the first support surface 312. The fifth annular section 332 of the second support surface 321, the sixth annular section 334 for connecting the step and the first support surface 312, the height of the second composite surface 331 is lower than the height of the first composite surface 311, the second composite surface The hei...

Embodiment 3

[0045] Embodiment three: as figure 1 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, a high-strength composite panel structure can be directly used for the kitchen and other areas with Class A fire protection requirements. The composite board formed by compounding with the decorative panel part 1 meets the Class A fire protection requirements; when used in areas without Class A fire protection requirements, the metal sheet part 3 with the foam pad 4 can be used.

[0046] It should be noted that the thin metal plate 3 and the foam pad 4 are integrally formed by molding and foaming. The specific process is that the metal plate is first stretched and formed, and then put into a molding and foaming mold, injected with foaming material, and passed through the molding mold. Foam molding. The sheet metal part 3 and the foam pad 4 adopt a molded integral molding process, which avoids the use of the adhesive layer 2 for secondary com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com