Negative pole piece as well as preparation method and application thereof

A technology of negative electrode sheet and electrode layer, applied in the field of negative electrode sheet and its preparation, can solve the problems of reducing battery power performance, affecting battery cycle performance, and high cost of PTC coating, so as to improve thermal stability and electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

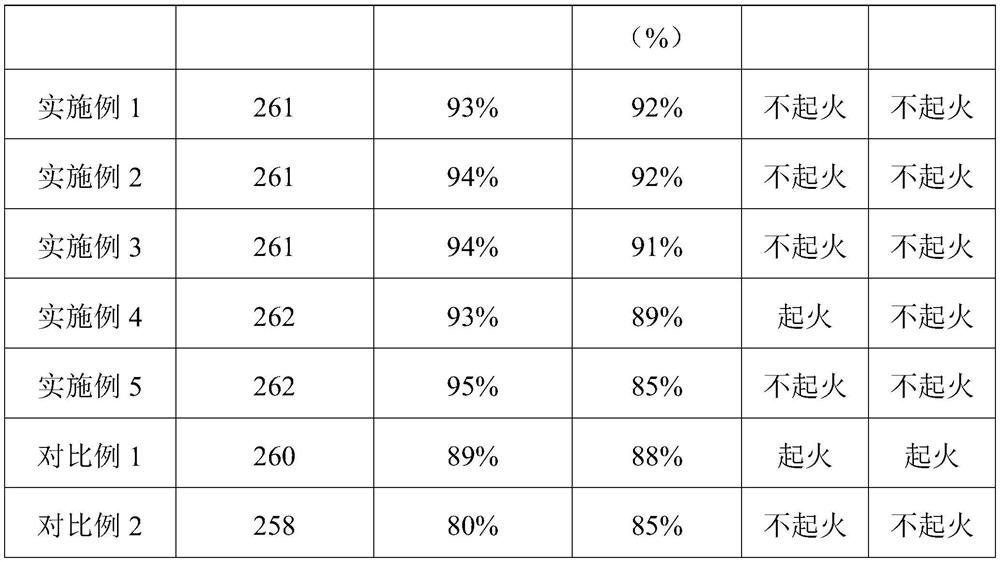

Embodiment 1

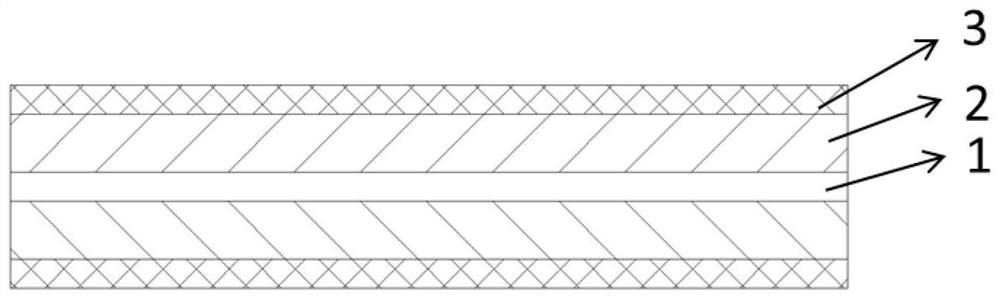

[0049] This embodiment provides a negative electrode sheet, which includes a current collector 1, an electrode layer 2, and a safety coating 3 that are sequentially stacked; the safety coating 3 includes lithium titanate, aluminum oxide, carbon black and polyvinylidene fluoride;

[0050] Wherein, the thickness of the security coating 3 is 3 μm, the median particle size of lithium titanate is 1 μm, and the median particle size of aluminum oxide is 350 nm;

[0051] In the safety coating 3, the mass proportion of lithium titanate is 77%, the mass proportion of aluminum oxide is 15%, the mass proportion of carbon black is 5%, and the mass proportion of polyvinylidene fluoride is 3%. .

[0052] The preparation method of the negative electrode sheet is as follows:

[0053] Mix artificial graphite, conductive carbon black (SP), styrene-butadiene rubber (SBR) and sodium carboxymethyl cellulose (CMC) in a mass ratio of 95:1:2.5:1.5, add deionized water, and prepare negative electrode...

Embodiment 2

[0056] This embodiment provides a negative electrode sheet, which includes a current collector, an electrode layer, and a safety coating layered in sequence; the safety coating includes lithium titanate, boehmite, carbon nanotubes, and polyacrylic acid ;

[0057] Among them, the thickness of the safety coating is 5 μm, the median particle size of lithium titanate is 2 μm, and the median particle size of aluminum oxide is 580 nm;

[0058] In the safety coating, the mass proportion of lithium titanate is 80%, the mass proportion of boehmite is 12%, the mass proportion of carbon black is 3%, and the mass proportion of polyacrylic acid is 5%.

[0059] The preparation method of the negative electrode sheet is as follows:

[0060] Mix natural graphite, conductive carbon black (SP), styrene-butadiene rubber (SBR) and sodium carboxymethyl cellulose (CMC) in a mass ratio of 95:1.5:2:1.5, add deionized water, and prepare negative electrode slurry The negative electrode slurry is coate...

Embodiment 3

[0063] This embodiment provides a negative electrode sheet, which includes a current collector, an electrode layer, and a safety coating layered in sequence; the safety coating includes lithium titanate, aluminum oxide, carbon black, and polybias vinyl fluoride;

[0064] Among them, the thickness of the safety coating is 2 μm, the median particle size of lithium titanate is 0.5 μm, and the median particle size of aluminum oxide is 100 nm;

[0065] In the safety coating, the mass proportion of lithium titanate is 72%, the mass proportion of aluminum oxide is 20%, the mass proportion of carbon black is 4%, and the mass proportion of polyvinylidene fluoride is 4%.

[0066] The preparation method of the negative electrode sheet is as follows:

[0067] Artificial graphite, conductive carbon black (SP), and polyacrylic acid are mixed in a mass ratio of 97:1:2, and deionized water is added to prepare negative electrode slurry, and the negative electrode slurry is coated on both side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com