Lightweight class-A fireproof composite board core and manufacturing method thereof

A composite board, lightweight technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of composite board core material pulverization, composite board core material peeling, hidden safety hazards, etc., to maintain integrity and improve insulation Effects of improving thermal performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

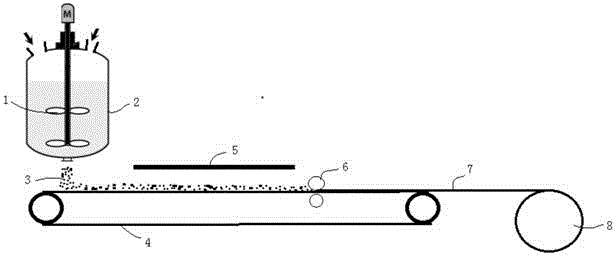

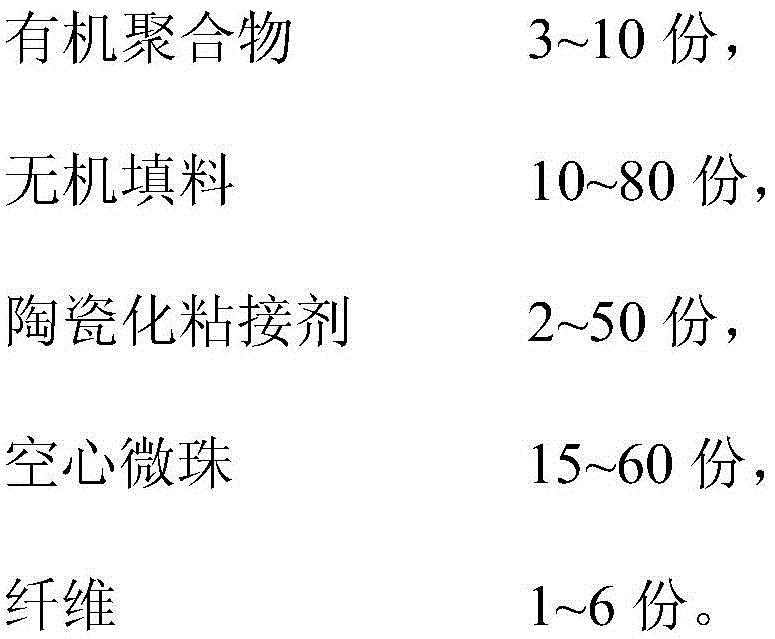

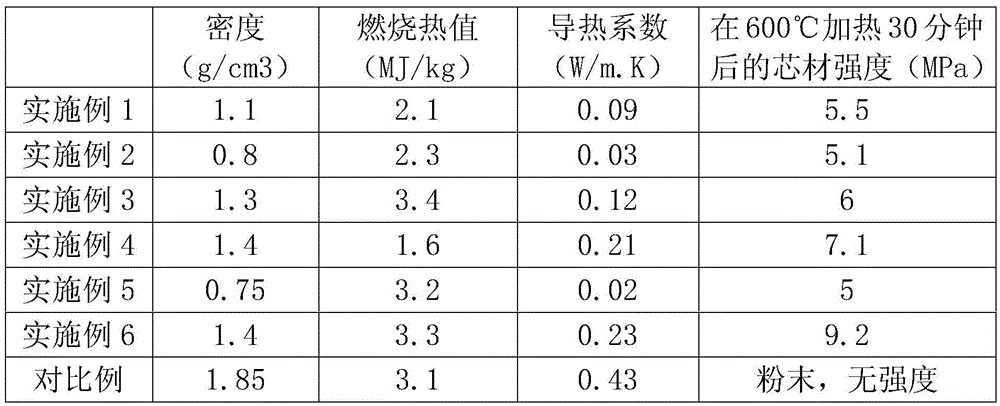

[0033] 15 parts of solid content is 50% EVA emulsion (comprising EVA and water in the EVA emulsion) and 30 parts of water, drop in the stainless steel container 2 that stirrer 1 is housed, stir, then 40 parts of hollow glass microspheres, 30 parts of magnesium hydroxide, 20 parts of sodium silicate and 2.5 parts of chopped glass fiber were put into the container 2 containing the EVA emulsion, and vigorously stirred to disperse the components evenly to form a paste 3 . Then spread the paste 3 evenly on the conveyor belt 4, send it into the infrared oven 5 for heating, and evaporate the water quickly, and the completely dried paste is compacted by the pressure roller 6 and the thickness of the product is controlled to form a sheet material 7, roll the rolled sheet 7 with a winder 8 to obtain a lightweight fireproof composite board core material, the preparation process is as follows figure 1 shown. Wherein, the bulk density of the hollow glass microspheres is 0.9g / cm 3 .

Embodiment 2

[0035] Put 12 parts of acrylic copolymer emulsion with a solid content of 50% and 80 parts of pulp with a concentration of 4% into a stainless steel container equipped with a stirrer and stir evenly, then add 55 parts of fly ash hollow microspheres, 10 parts of boric acid Add zinc, 15 parts of phosphate glass powder, 6 parts of aluminum hydroxide, and 4.8 parts of talc powder into the container, and stir vigorously to disperse the components evenly and obtain a paste. Spread the paste evenly on the conveyor belt, heat it in an infrared oven, and quickly evaporate the water. The completely dried paste is compacted by a pressure roller and the thickness of the product is controlled to form a sheet, and the roller is pressed well. The sheet material can be rolled to obtain a lightweight fireproof composite board core material. Wherein, the bulk density of the fly ash hollow microspheres is 0.2g / cm 3 .

Embodiment 3

[0037] Put 20 parts of polyurethane emulsion with a solid content of 50% and 30 parts of water into a container equipped with a stirrer, stir evenly, then mix 20 parts of hollow ceramic microspheres, 30 parts of low-temperature glass powder, 10 parts of perlite powder, 10 parts of 1 part of aluminum hydroxide, 3 parts of polyvinyl alcohol fiber, 5 parts of clay and 2 parts of silicon dioxide are put into a container, and vigorously stirred to disperse the components evenly and obtain a paste. Spread the paste evenly on the conveyor belt, heat it in an infrared oven, and quickly evaporate the water. The completely dried paste is compacted by a pressure roller and the thickness of the product is controlled to form a sheet, and the roller is pressed well. The sheet material can be rolled to obtain a lightweight fireproof composite board core material. Wherein, the bulk density of the hollow ceramic microspheres is 1.5g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com