Flame-throwing nozzle of engine

A flame nozzle and engine technology, applied in the direction of engine ignition, spark plugs, spark plugs, etc., can solve the problems of incomplete combustion of mixed gas, slow combustion speed, and consumption of oxygen molecules, so as to improve ignition and combustion efficiency, reduce fuel waste, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

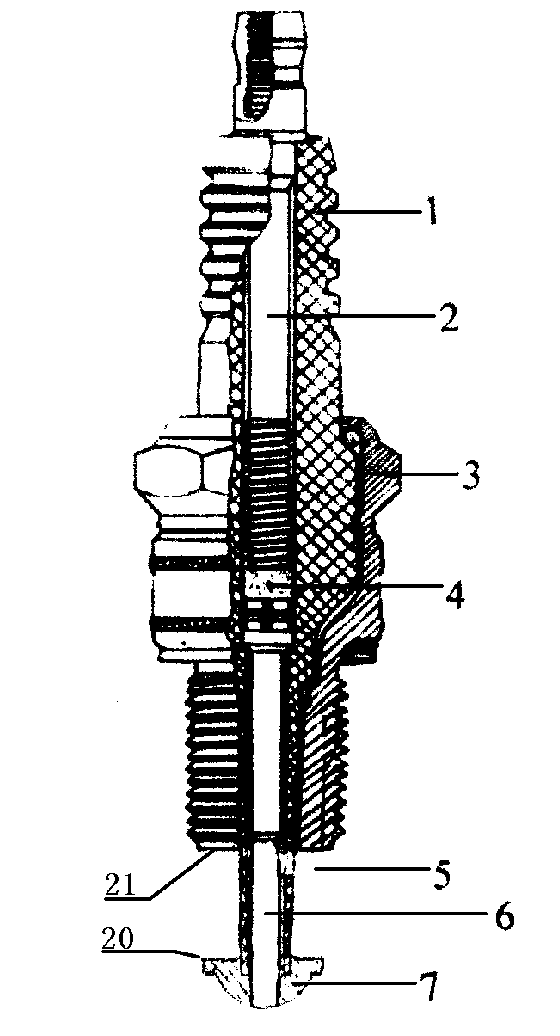

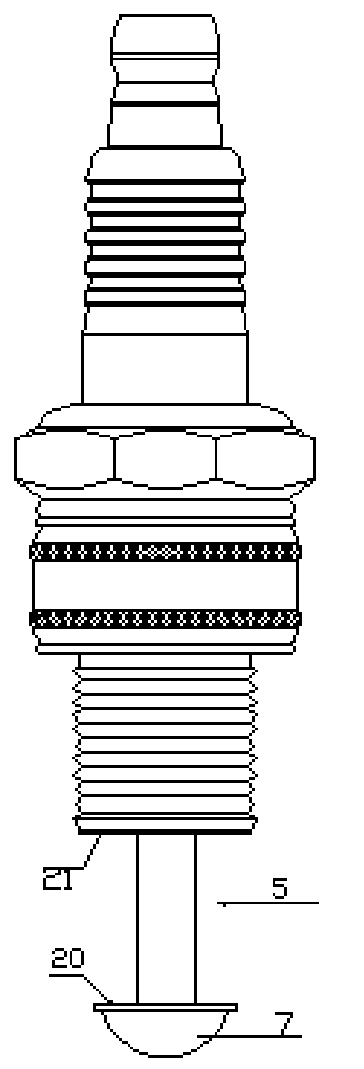

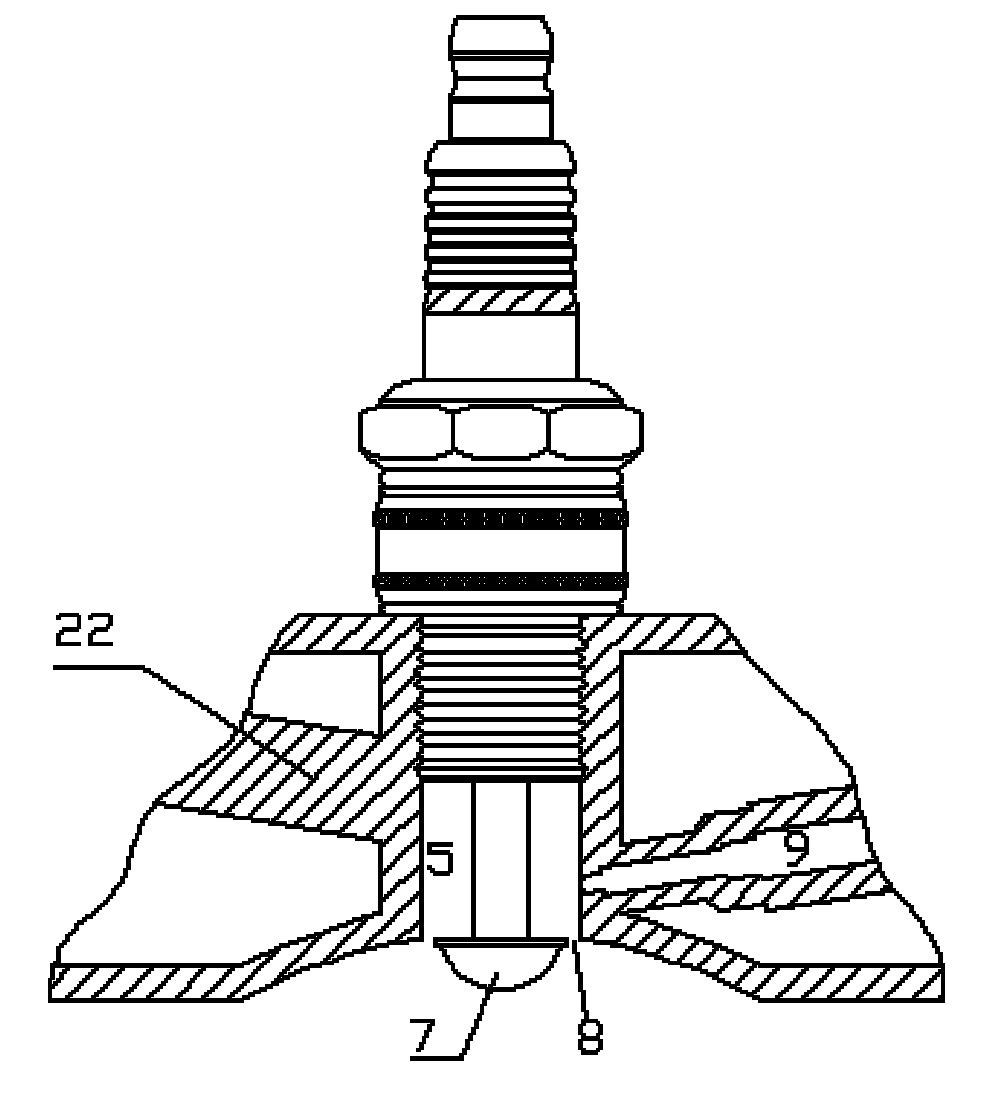

[0031] combine figure 1 , figure 2 The flame nozzle in the figure includes a shell 3, a porcelain insulator 1 is housed in the shell 3, a double-headed screw 2 with a wiring nut is arranged in the porcelain insulator 1, a conductor glass sealant 4 and a center electrode 6 with one end protruding from the porcelain insulator 1, The flame spray cap 7 welded to the end of the center electrode 6, wherein the flame spray cap 7 is a hemispherical structure, and the vertical distance between the hemispherical plane 20 and the end face 21 of the shell 3 is greater than 8 mm. Wherein the center electrode 6 protrudes from the porcelain insulator 1 at the part welded with the flame cap 7 , and the other parts of the center electrode 6 are wrapped by the porcelain insulator 1 . Flame cap 7 can be combined with the hemispherical shape shown in the figure and a platform, also can be a hemispherical, can also be shapes such as triangular, as long as the flame cap made of it has sharp point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com