Novel nylon 6-polybutylene terephthalate flame retardant alloy material and preparation method thereof

A technology of polybutylene terephthalate and alloy materials, which is applied in the field of kaolin modified nylon 6-polybutylene terephthalate alloy materials and its preparation, can solve the problem of large flame retardant addition, Problems such as poor comprehensive properties of alloy materials and poor flame retardant properties, etc., to achieve the effect of easy forming and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of kaolin reinforced nylon 6-polybutylene terephthalate alloy material and preparation method thereof provided by the invention are as follows:

[0027] 1. Raw material preparation:

[0028] Polybutylene terephthalate (PBT);

[0029] Modified nylon 6 (PA6);

[0030] Compatibilizer: one of epoxy resin CYD-011 and epoxy resin E-54, epoxy resin CYD-011 is selected in this embodiment;

[0031] Compound flame retardant: 20kg of ammonium polyphosphate (APP), 5kg of pentaerythritol (PER) and 30kg of compound melamine cyanuric acid (MC-602);

[0032] Antioxidant: one of antioxidant 1098 (N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine), antioxidant 1010, this The embodiment selects antioxidant 1098;

[0033] Modified kaolin, its modification method is:

[0034] 1) First prepare kaolin and 18mol / L urea solution into a suspension with a mass ratio of 1:10, then put it in a water bath, keep the temperature at a constant temperature when th...

Embodiment 2 Embodiment 8

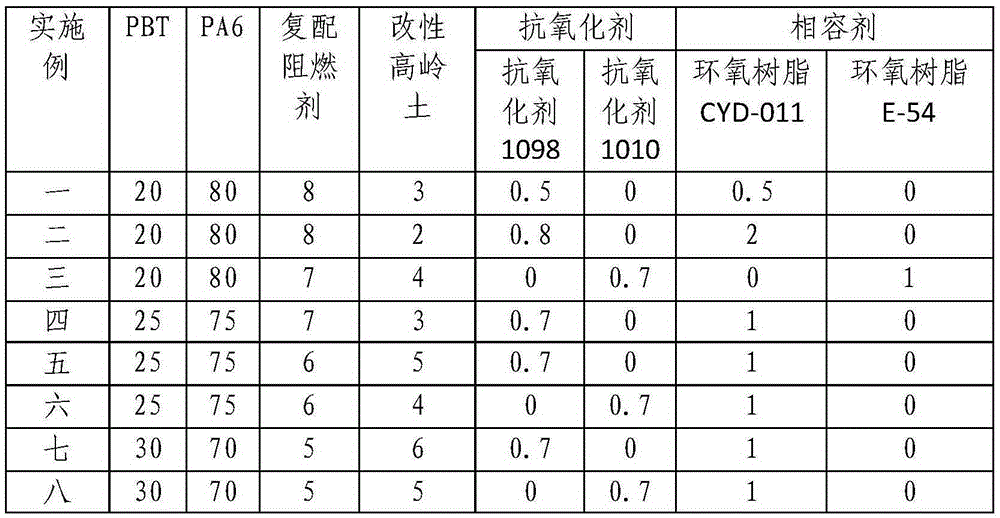

[0044] The raw materials and dosage used in Examples 2 to 8 are different from those in Examples. The modification method of modified kaolin and the preparation method of kaolin-reinforced nylon 6-polybutylene terephthalate alloy material are the same as in Example 1. The raw materials and consumption of embodiment two~embodiment eight are as follows table 1:

[0045] Table 1

[0046]

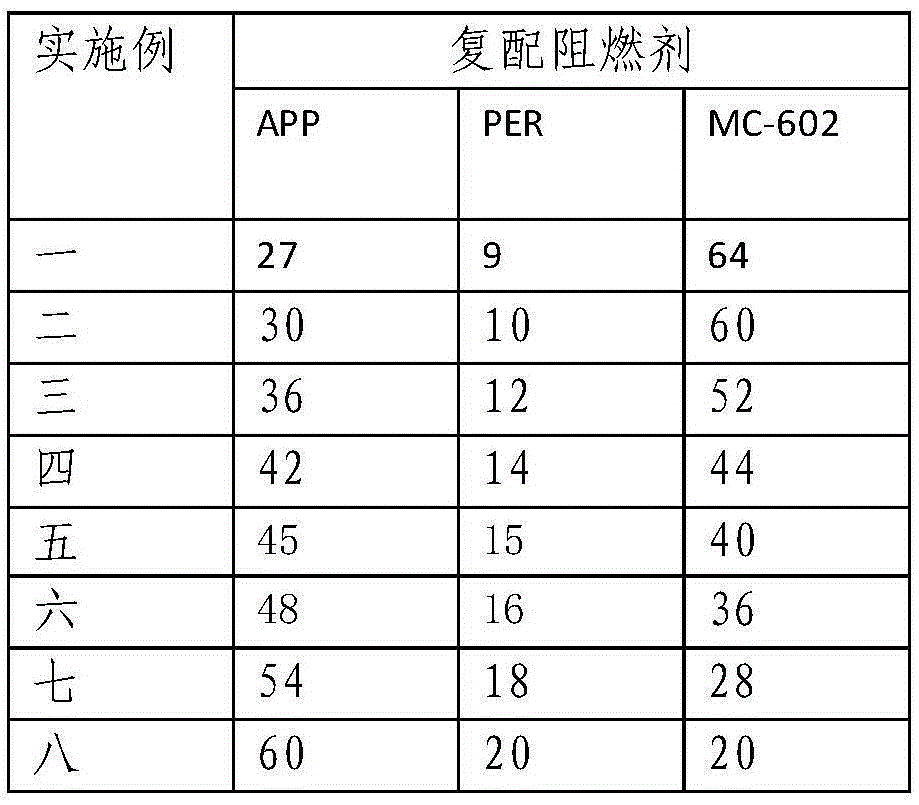

[0047] The formula of the compound flame retardant is as follows:

[0048] Table 2

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com