An integral oil-impregnated paper high-voltage bushing

A high-voltage bushing, oil-impregnated paper technology, applied in insulators, lead-in/through-type insulators, transformer/inductor components, etc., can solve problems such as fires, oil leakage in transformers, and harsh operating conditions. The effect of reducing the probability of insulation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

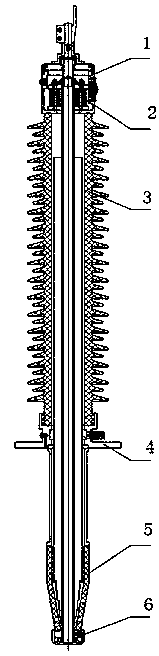

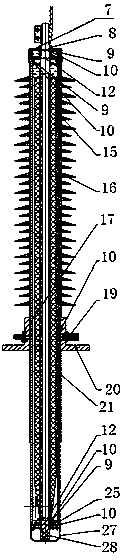

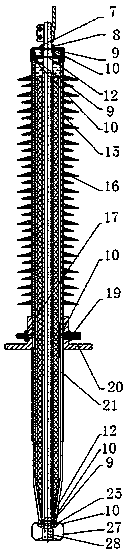

[0018] An integral oil-impregnated paper high-voltage bushing with a voltage level of 145kV and below according to the present invention, see figure 2 , the casing includes a glass fiber reinforced plastic cylinder 15, a conductive rod 12, an expander 7, a mounting flange 20, a base 25 and a pressure equalizing ball 27, and the mounting flange used to connect with the transformer is hermetically set in the middle of the glass fiber reinforced plastic cylinder. The mounting flange is provided with a through hole for leading out the final screen signal of the capacitor core and installing the casing oil extraction device; a silicone rubber umbrella sleeve 16 is injected outside the glass fiber reinforced plastic cylinder at the upper part of the mounting flange, and a glass fiber reinforced plastic tube at the lower part of the mounting flange Semi-conductive paint 21 is sprayed on the outside of the cylinder, and the semi-conductive paint forms an equipotential cylinder with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com