Integrated terminal box of a rotary dynamoelectric machine

A technology for rotating electrical machines and junction boxes, applied in electrical components, electromechanical devices, electrical components, etc., can solve problems such as reducing the compactness of the drive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

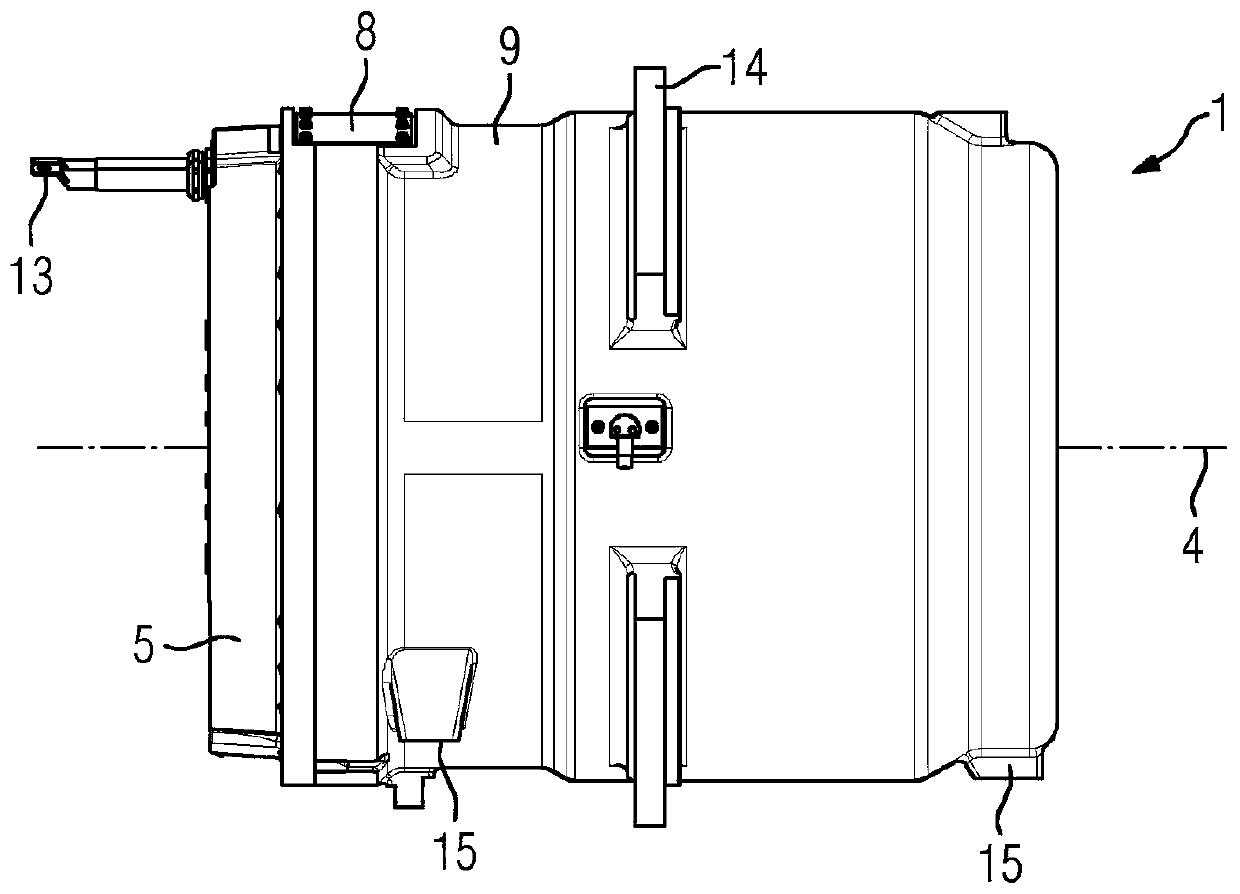

[0030] figure 1 A side view of the electric machine 1 is shown, the external connecting lines 13 of which protrude parallel to the axis 4 through the bearing shield 5 into the electric machine 1 . Viewed in the circumferential direction, the flange element 14 is located section by section in the middle region of the housing 9 of the electric machine 1 , by means of which the machine 1 is arranged and positioned in the installation space of the vehicle or machine tool provided for this purpose. . Optional further fastening points 15 can allow additional fastening points in a correspondingly formed installation space.

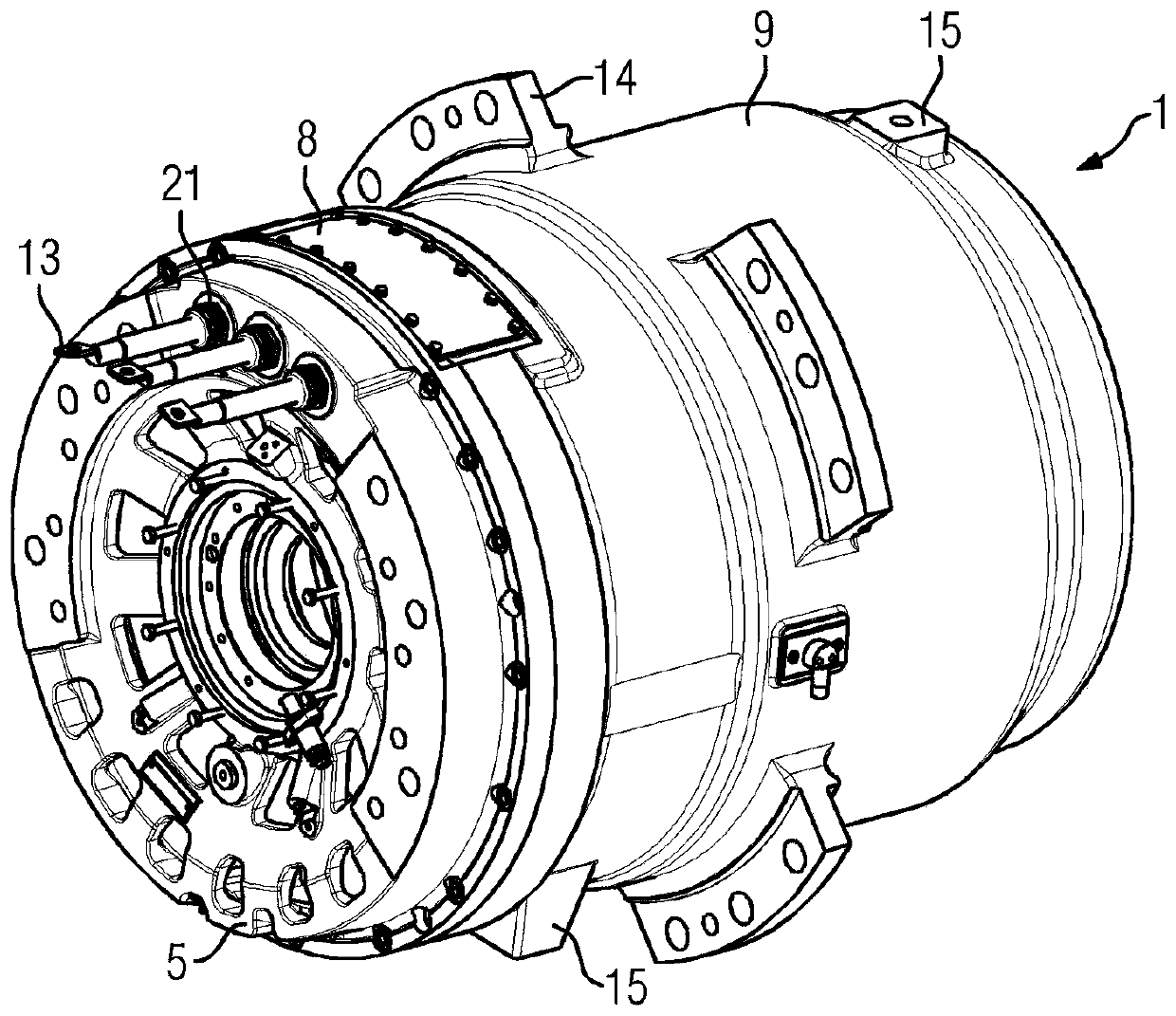

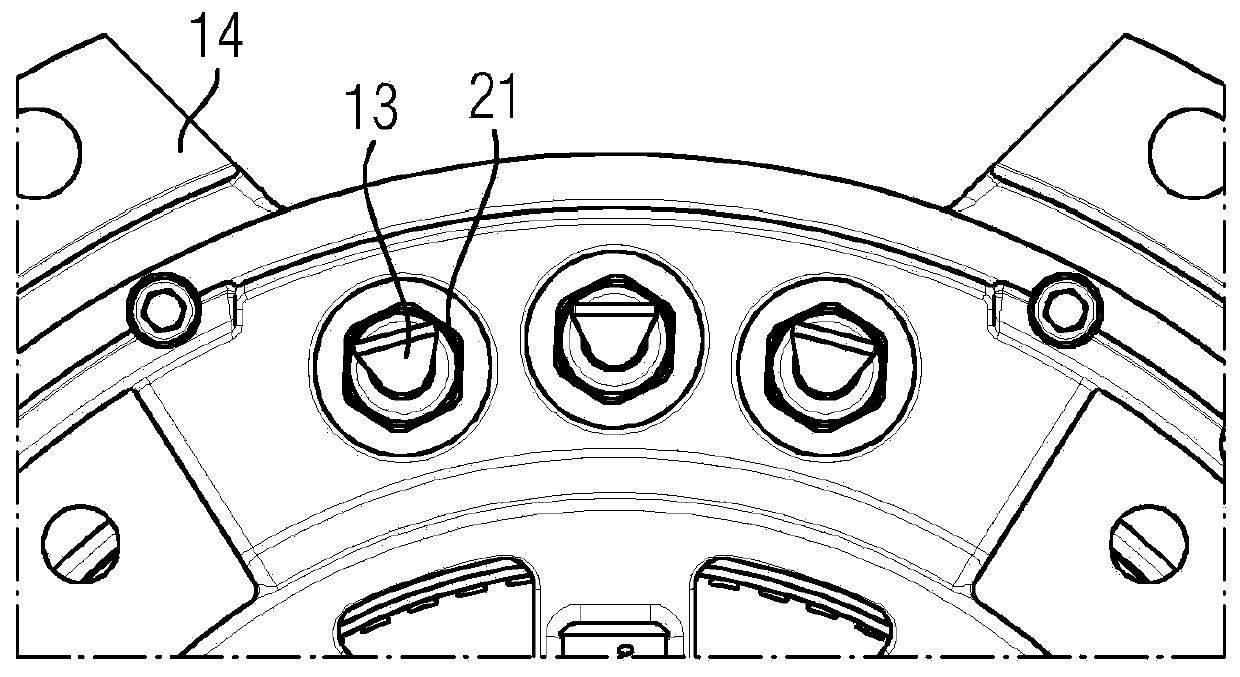

[0031] figure 2 A perspective view of the electric machine 1 is shown, wherein this view shows the inner cover 8 of the terminal box 23 which is not yet visible in this view. In this case, the external connecting wires 13 (three in this case) run through the bearing cap 5 to one connecting wire for each electrical phase.

[0032] Optionally, a plurality of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com