Patents

Literature

38results about How to "Satisfy flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

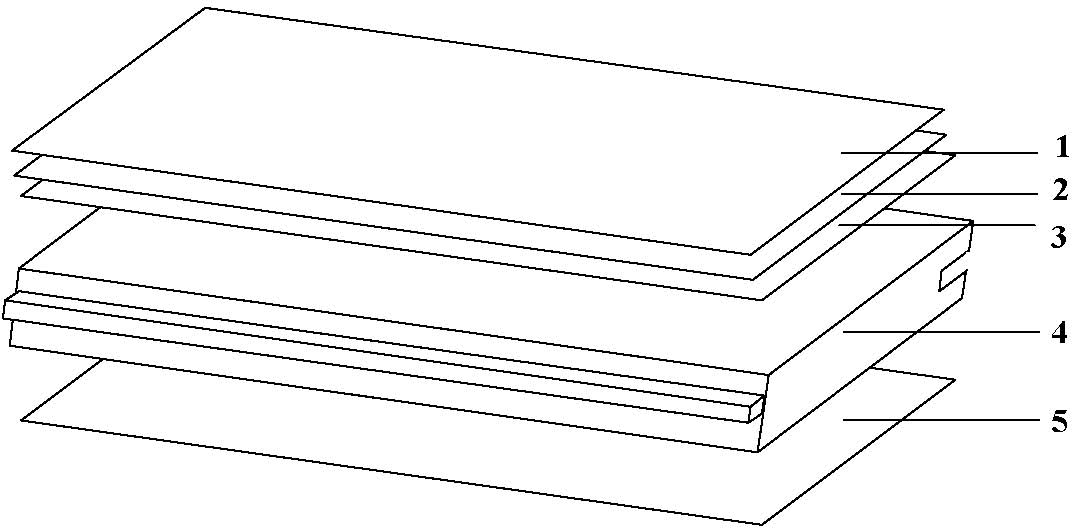

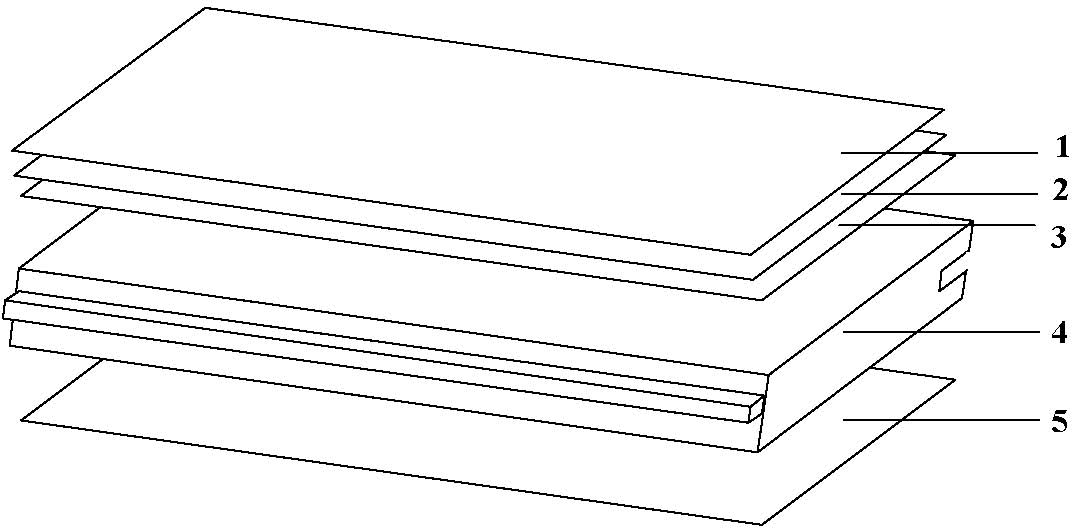

Wear-resisting anti-flaming poplar solid flooring and preparation method thereof

The invention provides a wear-resisting anti-flaming poplar solid flooring which is mainly composed of a modified solid flooring billet layer, and a preparation method of the wear-resisting anti-flaming poplar solid flooring; the wear-resisting anti-flaming poplar solid flooring sequentially comprises a balance moisture-proof layer, the modified solid flooring billet layer, a color blending layer, an ultrathin natural veneer decoration layer and a wear-resisting layer from bottom to top. The method comprises the steps of preparing a composite modified impregnation liquid and performing technologies of vacuum pressurization dipping treatment, drying, assembling and pressing and the like on woods. A composite modification processing technique of the invention enables the strength of poplar to be increased, the stability of the poplar to be enhanced, and enables the poplar to have properties of wear resistance, flame retardant, mildew prevention and anticorrosion and the like, so that the utilization value of artificial poplar is improved greatly. The method is simple and easy; and the wear-resisting anti-flaming poplar solid flooring processed by the method has the advantages of scratch resistance, wear resistance, flame retardant, mildew prevention, anticorrosion, easiness in maintenance, natural textures, comfort, environmental protection and high cost performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Preparation method of halogen-free CEM-1 copper-clad plate with high peeling strength

ActiveCN106739376AIncrease crosslink densityReduce dosagePaper coatingLaminationBisphenol AChemistry

The invention belongs to the technical field of copper-clad plate production, and especially relates to a preparation method of a halogen-free CEM-1 copper-clad plate with a high peeling strength. Phosphor containing epoxy resin and bisphenol A type epoxy resin are taken as the main resin; phosphor containing linear phenolic resin is taken as the curing agent, polyfunctional epoxy resin is used to enhance the heatproof performance; a certain ratio of aluminum hydroxide is added to increase the electric tracking resistant index of the copper-clad plate; a nitrogen and phosphor containing fire retardant is added, and through the synergistic effect between nitrogen and phosphor, the fireproof performance of the copper-clad plate is enhanced and can reach the FV0 grade. By processing the surface of used filling material and controlling the particle size, the filling material can be evenly dispersed into resin glue to obtain uniform glue dipped sheets, the toughness of sheets is improved, the obtained copper-clad plate can reach the environment protection requirements and does not contain any halogen, the contents of chlorine and bromine are low, the peeling strength is high, the characteristic of resisting tracking caused by electric leakage is excellent, and CTI>=600V.

Owner:SHANDONG JINBAO ELECTRONICS

Resin composition, molded product, and method for producing the resin composition

A biodegradable resin composition comprising at least one biodegradable organic polymeric compound, a flame retardant additive containing a phosphorous compound, and a hydrolysis inhibitor capable of inhibiting the hydrolysis of at least one organic polymeric compound. As an aliphatic polyester resin, use is made of polylactic acid, polycaprolactone, polyhydroxybutyric acid, polyhydroxyvaleric acid, polyethylene succinate, polybutylene succinate, polybutylene adipate, polymalic acid, microbially synthesized polyester or a copolymer containing at least one of these. As a polysaccharide, use is made of cellulose, starch, chitin, chitosan, dextran, a derivative of any of these or a copolymer containing at least one of these.

Owner:SONY CORP

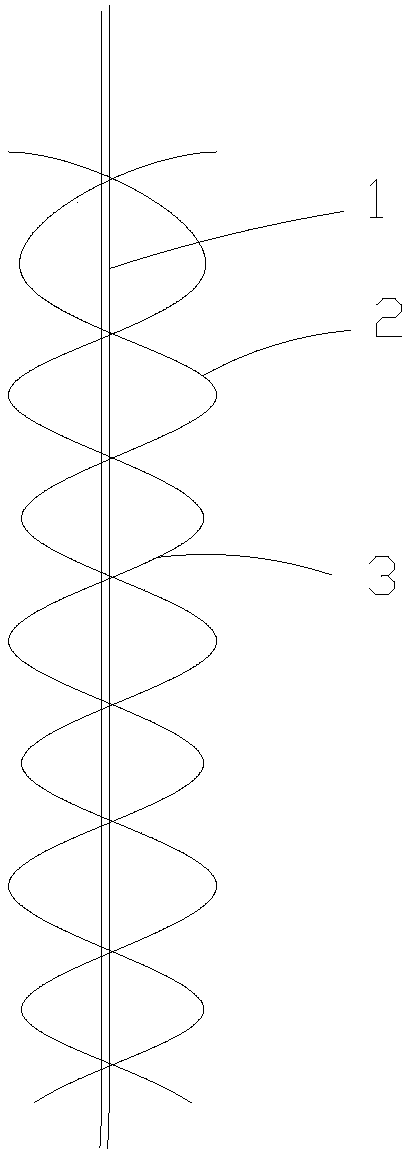

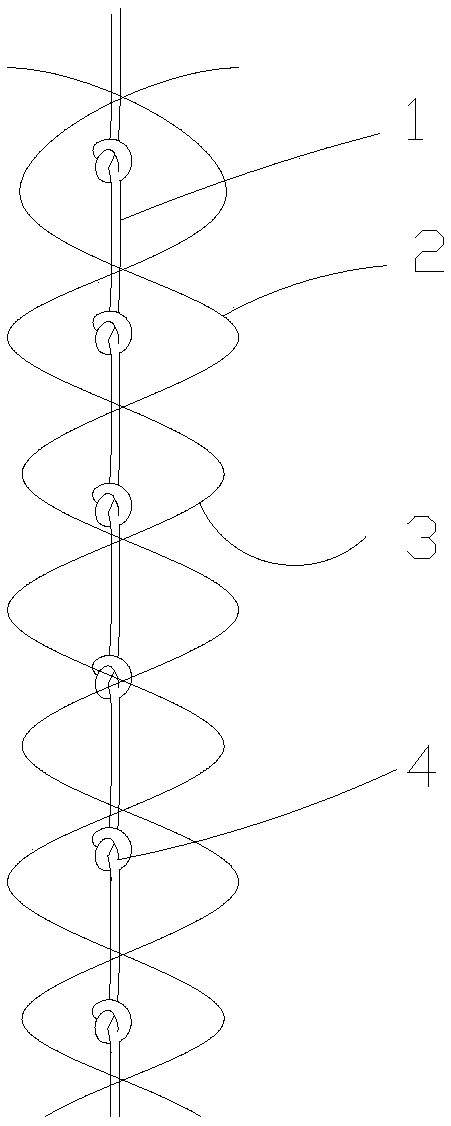

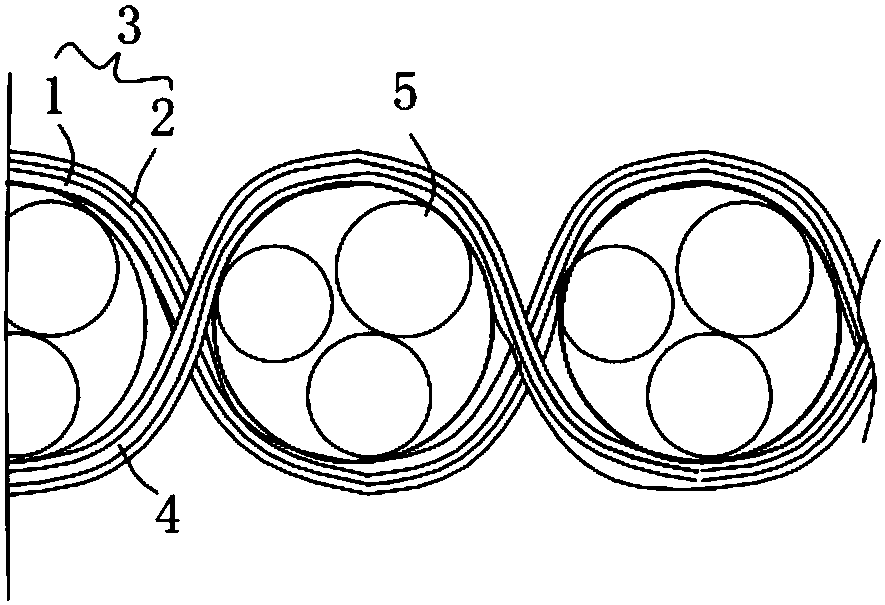

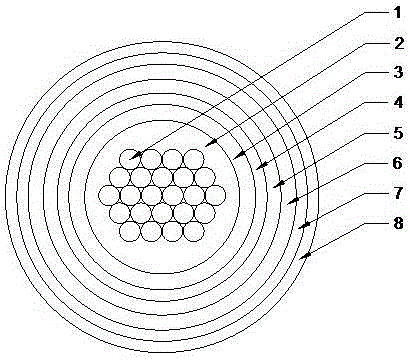

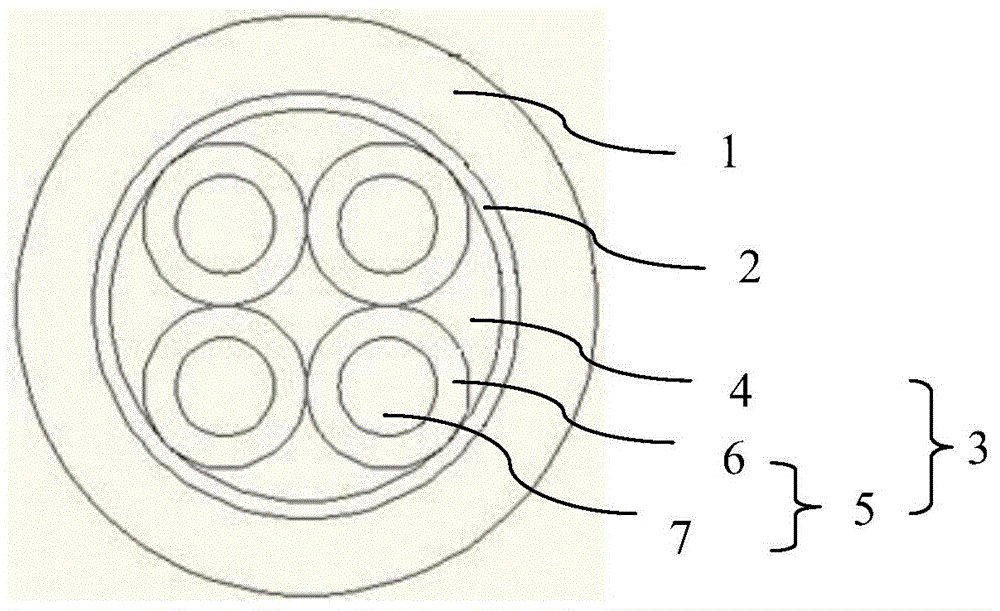

Wrapped yarn based fabric for flame-retarding clothes and production method thereof

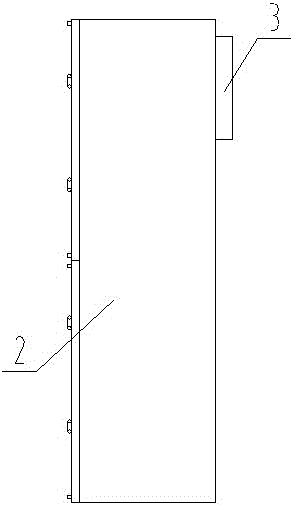

The invention discloses a wrapped yarn based fabric for flame-retarding clothes and a production method thereof. A tissue structure of the fabric is a jacquard tissue; the fabric is formed by interweaving weft yarns and warp yarns (5) made of flame-retarding polyester yarns, wherein the weft yarns are composed of core yarns (1), first wrapped yarns (2) and second wrapped yarns (3); the first wrapped yarns (2) and the second wrapped yarns (3) are spirally wound outside the core yarns (1) in opposite directions; the core yarns (1) are viscose fibers with the fineness of 20S / 2 to 100S; the firstwrapped yarns (2) and the second wrapped yarns (3) are made of the flame-retarding polyester yarns; the linear density of the first wrapped yarns (2) and the second wrapped yarns (3) is 83.3dtex and 166.6dtex respectively; the linear density of the warp yarns (5) is 83.3dtex and the twist degree is 600T / m. The fabric for the clothes, disclosed by the invention, has the advantages of flame-retarding performance and comfort; the flame-retarding capability is not reduced after the fabric is used for long time.

Owner:ZHEJIANG DUNNU UNITED IND

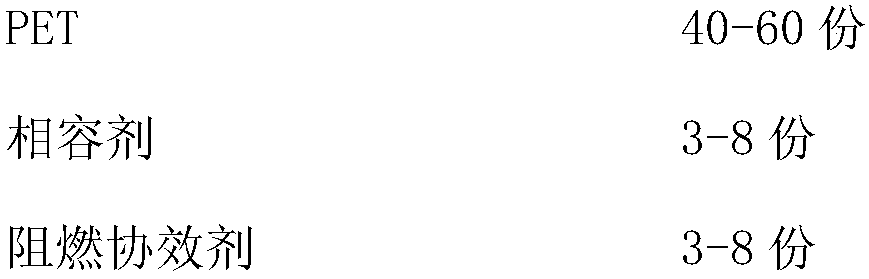

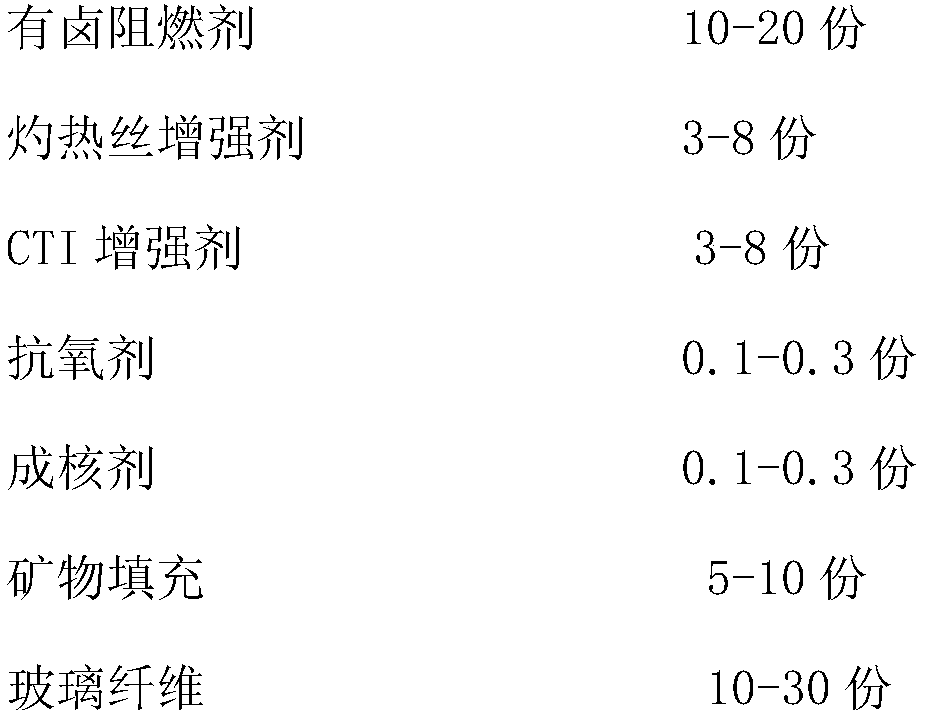

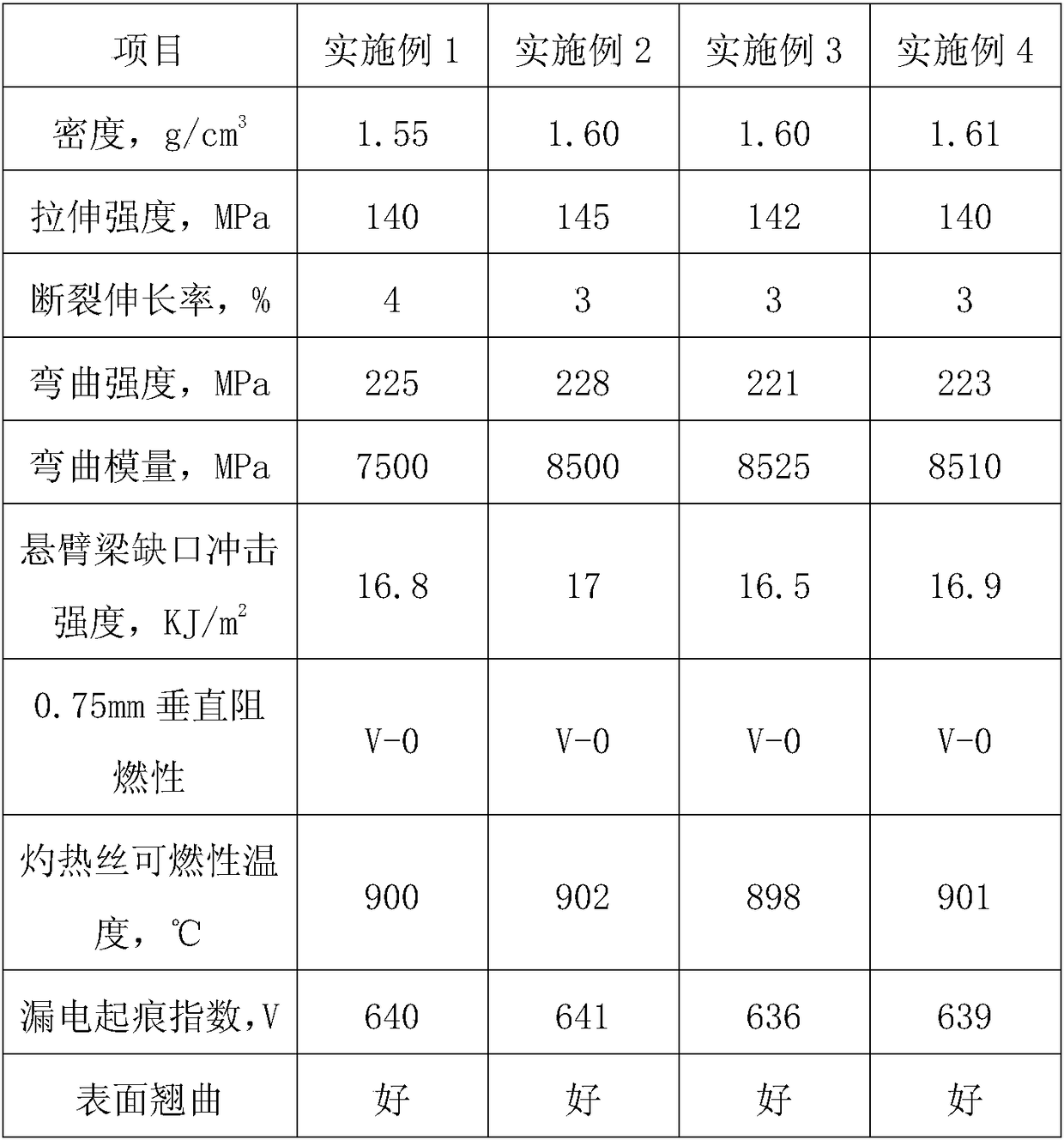

High-GWIT high-CTI thin-wall flame-retardant glass-fiber reinforced low-warpage PET composite material and preparation method thereof

InactiveCN108164935AGood synergySatisfy flame retardancyPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a high-glow-wire ignition temperature (GWIT) high-comparative tracking index (CTI) thin-wall flame-retardant glass-fiber reinforced low-warpage polyethylene terephthalate (PET)composite material and a preparation method thereof. The high-GWIT high-CTI thin-wall flame-retardant glass-fiber reinforced low-warpage PET material comprises the following raw materials in parts byweight: 40-60 parts of PET, 3-8 parts of a compatilizer, 3-8 parts of a flame-retardant synergist, 10-20 parts of a halogen-containing flame retardant, 3-8 parts of a glow-wire reinforcing agent, 3-8parts of a CTI enhancer, 0.1-0.3 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 5-10 parts of a mineral filler and 10-30 parts of glass fibers. According to the high-GWIT high-CTI flame-retardant glass-fiber reinforced low-warpage PET composite material, the GWIT of and the CTI of a glowing filament of the material are notably improved in the premise of not influencing the mechanicalproperties of the material and meeting the flame retardance; and with the addition of the nucleating agent and the mineral filler, the warping problem of a product is solved, the molding cycle of theproduct is reduced, and the formula cost is also reduced.

Owner:NANJING HONGRUI PLASTIC PROD

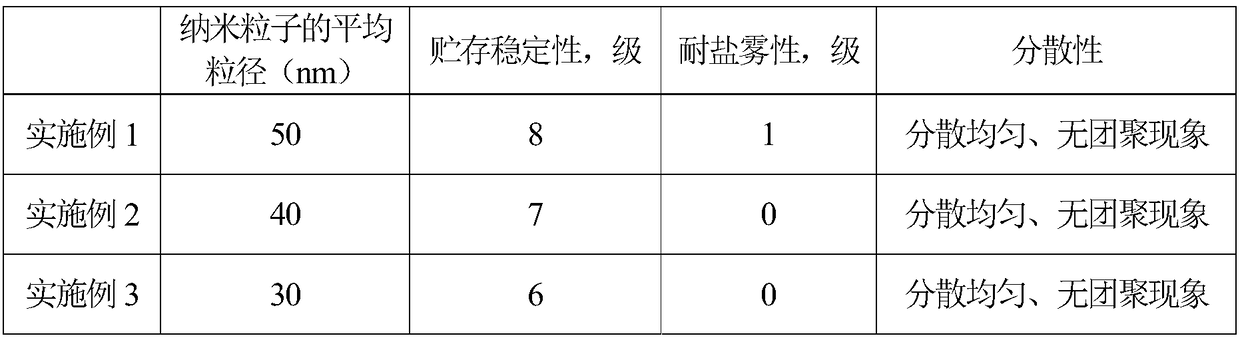

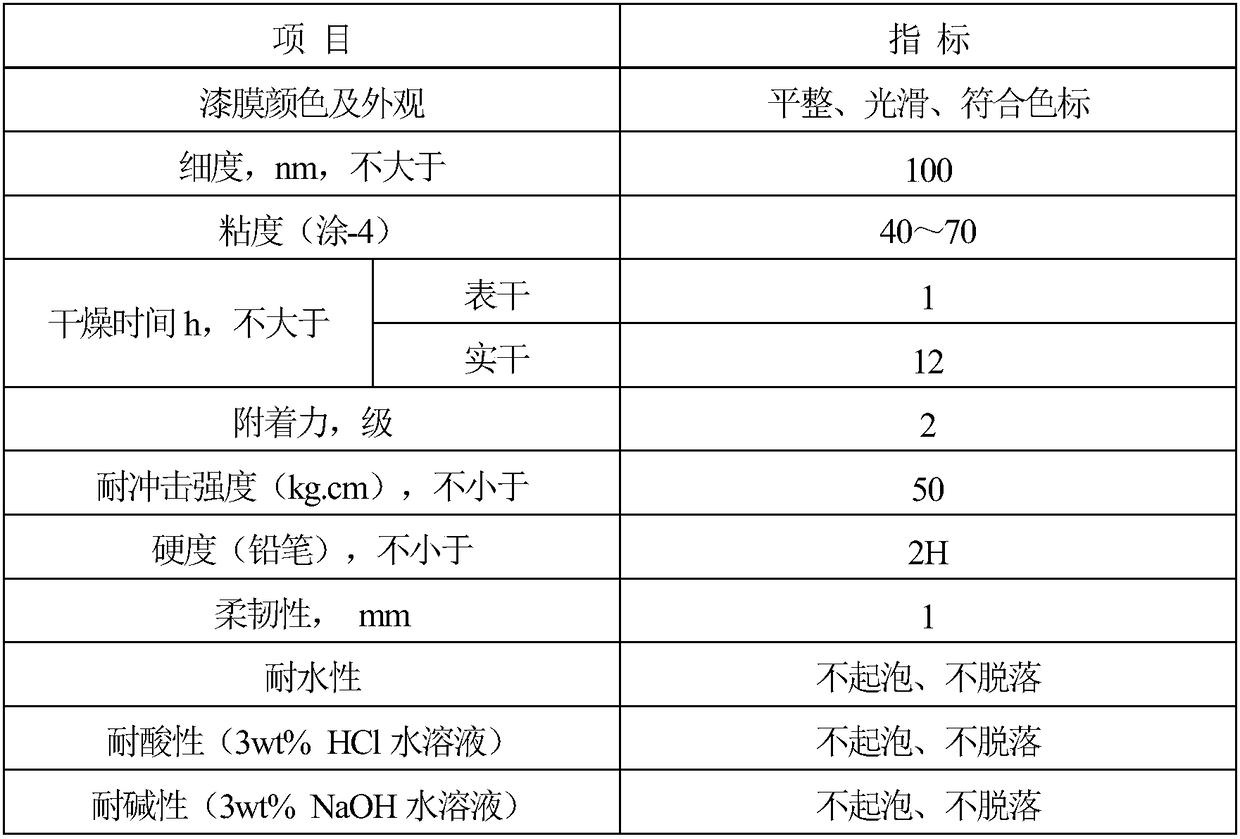

Anti-ultraviolet nanometer polyurethane wood surface coating and preparation method thereof

InactiveCN108129968AUniform and stable dispersionSimple compositionFireproof paintsAnti-corrosive paintsUltravioletMaterials science

The invention belongs to the field of nanometer materials, and specifically provides an anti-ultraviolet nanometer polyurethane wood surface coating and a preparation method thereof. The coating comprises the following components with contents in parts by weight: 100 parts of polyurethane resin, 15 to 20 parts of a nanocomposite mother liquor, 6 to 8 parts of a composite corrosion inhibitor, 0.5 to 1.0 part of an organic corrosion inhibitor, 1 to 3 parts of an anti-ultraviolet pigment, 1 to 3 parts of a flame-retardant filler, 6 to 8 parts of isocyanate and 5 to 10 parts of an organic solvent.The preparation method comprises the following steps: weighing the polyurethane resin, the nanocomposite mother liquor, the composite corrosion inhibitor, the organic corrosion inhibitor, the anti-ultraviolet pigment, the flame-retardant filler, the isocyanate and the organic solvent, carrying out mixing in proportion, carrying out dispersion, and carrying out grinding until a particle size is 100 nm or below so as to prepare the anti-ultraviolet nanometer polyurethane wood surface coating. The coating provided by the invention has rapid drying speed and high strength and toughness, has shielding effect to electromagnetic wave, is insusceptible to aging, and can meet the requirements of flame retardancy, ultraviolet resistance and aging resistance.

Owner:大连保税区百克经贸有限公司

Insulating flame-retardant pressure-sensitive adhesive applied to power battery, adhesive tape and preparation method of insulating flame-retardant pressure-sensitive adhesive

InactiveCN112126384AMeet safety requirementsStable and excellent insulationNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateElectrolytic agent

The invention relates to the technical field of special adhesive tapes for new energy batteries, in particular to an insulating flame-retardant pressure-sensitive adhesive applied to a power battery,an adhesive tape and a preparation method of the adhesive tape. The pressure-sensitive adhesive comprises the following components in parts by weight: 15-20 parts of 2-ethylhexyl acrylate, 10-15 partsof butyl acrylate, 7-10 parts of methyl acrylate, 5-7 parts of isobornyl acrylate, 5-7 parts of acrylic acid, 0.3-0.6 part of an initiator, 20-40 parts of ceramic powder, 0.3-0.6 part of aziridine and 40-71 parts of a solvent.Compared with an existing adhesive tape for a power battery, the pressure-sensitive adhesive tape has excellent insulation, flame retardancy and electrolyte resistance; andthe change of the bonding strength of the pressure-sensitive adhesive tape is extremely small in high-temperature and electrolyte environments, so that the safety requirement of the existing power battery can be well met.

Owner:广东安利华新材料科技有限公司

Polyester fabric foamed flame-retardant coating adhesive

InactiveCN105507004AMeet the new demands of finishingMeet the technical requirements of foam finishingHeat resistant fibresPolyesterPhosphate

The invention relates to a polyester fabric foamed flame-retardant coating adhesive which comprises 100 parts of matrix emulsion composed of 20-50 parts of vinyl acetate polymer and 50-80 parts of ethylene-vinyl acetate copolymer resin, 10-23 parts of tri(2, 3-dibromopropyl) isocyanuric acid ester, 5-8 parts of tri(isopropyl chloride) phosphate, 1-3 parts of associative waterborne polyurethane emulsion, 5-10 parts of polyacrylate emulsion, 2-4 parts of fumed silica, 0.5-1.0 part of organic silicone emulsion and 0.5-2 parts of straight chain alcohol sulfate. The polyester fabric foamed flame-retardant coating adhesive has the advantages that a composite foamed flame-retardant coating adhesive system which has good flame-retardant effect is provided, and washing durability and mechanical resistance of the flame-retardant coating adhesive on fabric are improved.

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

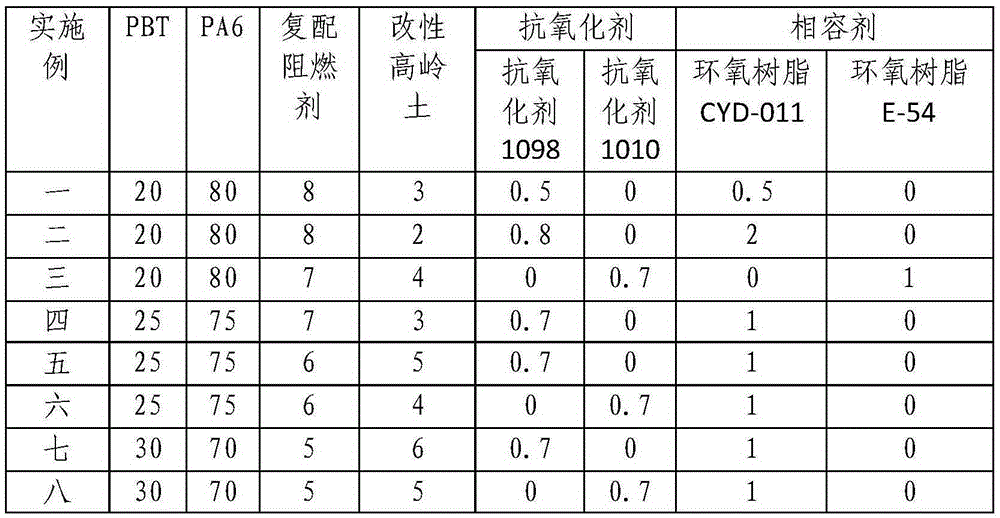

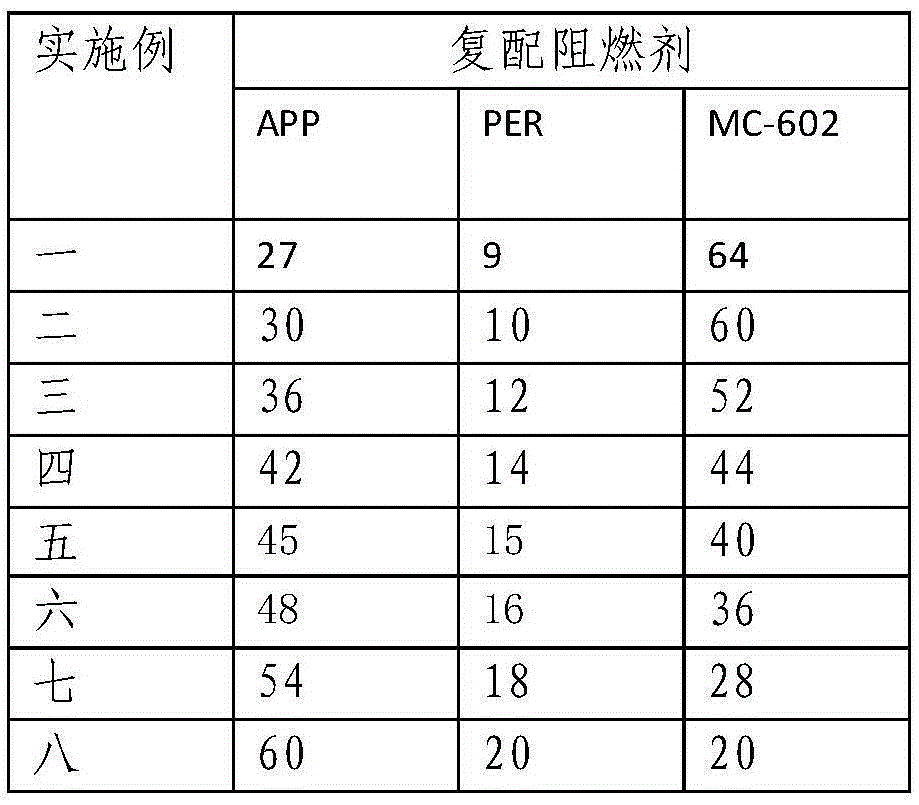

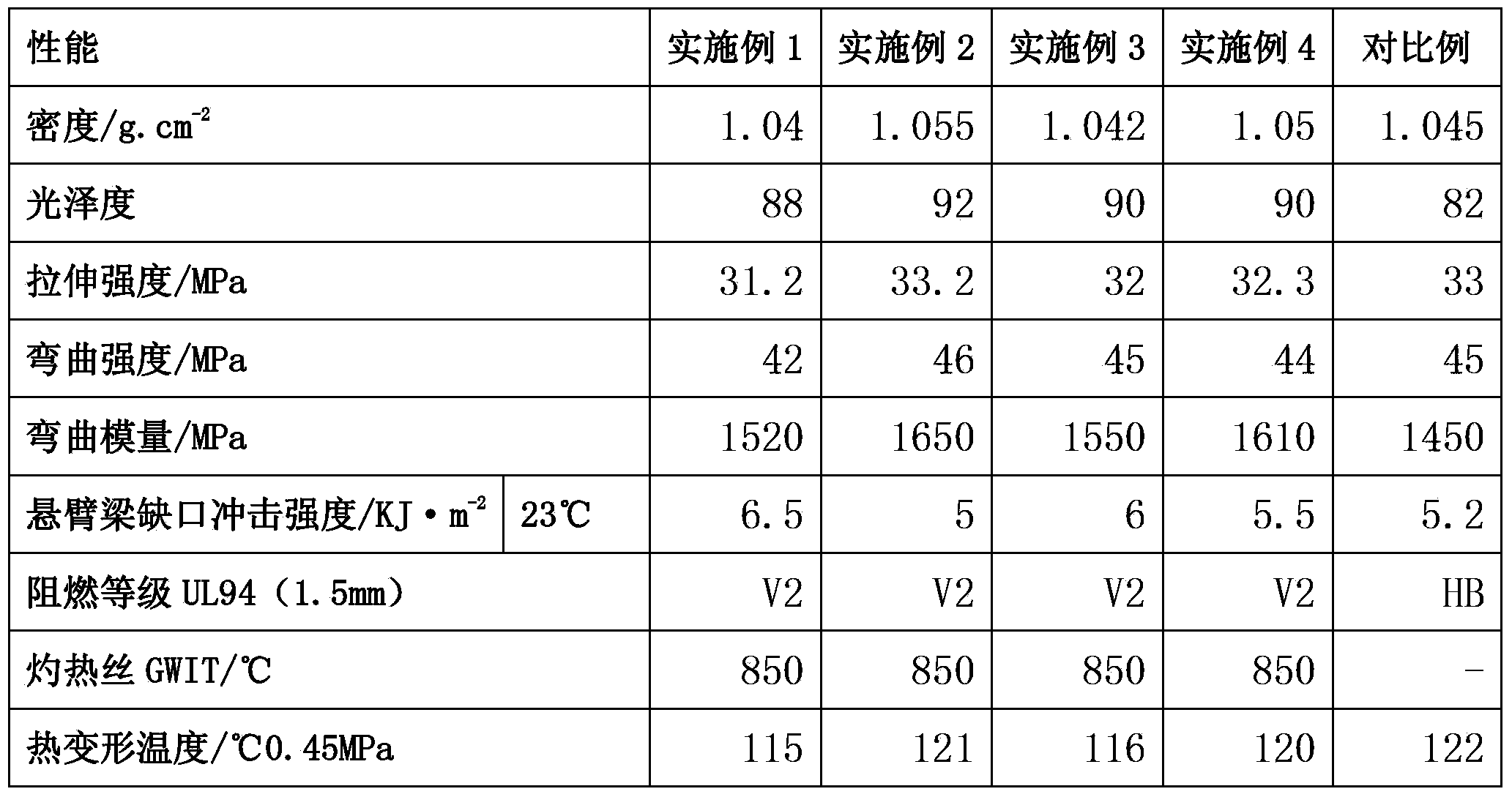

Novel nylon 6-polybutylene terephthalate flame retardant alloy material and preparation method thereof

Belonging to the technical field of high polymer materials, the invention provides a novel nylon 6-polybutylene terephthalate flame retardant alloy material and a preparation method thereof. According to the invention, an appropriate formula process is adopted, and a unique compound flame retardant is employed for cooperation to prepare the environment-friendly high-performance flame retardant PA6-PBT alloy material, compared with general PBT / PA6 flame retardant materials, the alloy material has obvious advantages in the aspects of rigidity, toughness, heat resistance, flame resistance and dimensional stability, and is easy for molding processing. Also, the added modified kaolin is well compatible with all polymers, the alloy material can stably pass the UL94-V0 flame retardant grade, can stably pass 850DEG C glowing filaments without fire breakout, also can satisfy a lot of occasions with high flame retardant level and performance requirements, and is widely applicable to capacitor shells, load break switches, motor shells, terminal boards, coil skeletons, plugs and circuit connectors, telephone distribution boxes and other low voltage electrical apparatuses.

Owner:NANNING UNIV

Halogen-free flame retardant highlight polypropylene and preparation method thereof

The invention relates to the technical field of thermoplastic high polymer material modification and discloses halogen-free flame retardant highlight polypropylene applied to household appliances, electronics and the like. The halogen-free flame retardant highlight polypropylene comprises the following materials: polypropylene, a nucleating agent, a halogen-free flame retardant, a superfine barium sulphate filling agent, an antioxidant and a processing aid. The invention also discloses a preparation method of the halogen-free flame retardant highlight polypropylene. The invention aims at providing high-glossiness, halogen-free and flame retardant modified polypropylene which can be applied to a bread maker, a water dispenser, a shell of an electric appliance and the like.

Owner:广东波斯科技股份有限公司

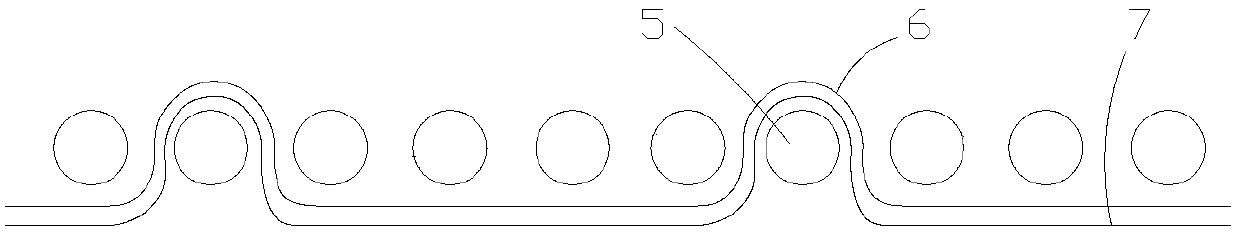

Anti-static, radiation-proof, flame-retardant and high-breathability fabric and preparation method thereof

ActiveCN108385242AMeet anti-staticMeet radiation protectioFibre typesWoven fabricsPolyesterPolymer science

The invention discloses an anti-static, radiation-proof, flame-retardant and high-breathability fabric and a preparation method thereof. The anti-static, radiation-proof, flame-retardant and high-breathability fabric is formed by clamping breathable cores through warp clusters and weft clusters, wherein every warp cluster is composed of 1-3 calcium alginate flame-retardant fiber filaments 1, 3-5 silver fiber filaments 2, and 1-2 polyester fiber filaments; every weft cluster is composed of 2-4 flame-retardant acrylic fiber filaments 4, 1-3 stainless steel fiber filaments, and 1-2 polyester fiber filaments; every breathable core is composed of 2-4 bamboo fiber filaments or carbon fiber filaments; the cross seams of the warp clusters and the weft clusters on both sides of the breathable coresare coated with antistatic agent. The anti-static, radiation-proof, flame-retardant and high-breathability fabric meets the requirements on anti-static, radiation-proof, flame-retardant and high-permeability properties as well as meets the functional requirements to achieve high comfort level, and meanwhile ensures stability of the antistatic agent to achieve good anti-static, radiation-proof, flame-retardant and high-breathability properties and ensure high integral comfort performance.

Owner:上海沙驰服饰有限公司

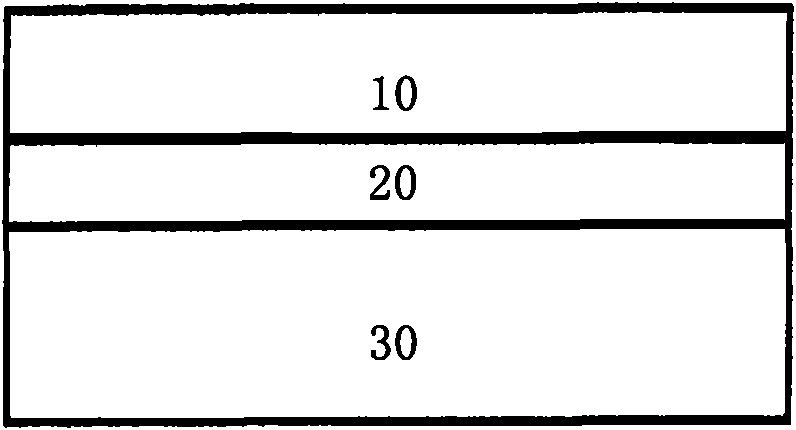

Environmentally-friendly flame-retardant floor leather and production method thereof

The invention discloses an environmentally-friendly flame-retardant floor leather and a production method thereof. The floor leather successively comprises a cloth base layer, a flame-retardant layerand a non-slip wear-resistant layer. The flame-retardant layer comprises the following raw materials by mass: 43.92-53.68% of polyvinyl chloride, 26.02-31.80% of dioctyl phthalate, 2.20-2.68% of dioctyl sebacate, 4.12-5.04% of tin methyl sulfonate, 5.50-6.72% of a fire retardant, 3.19-3.89% of a smoke suppressor, 3.78-4.62% of a PVC processing aid and 1.28-1.56% of a flavoring agent. The production method comprises the following concrete production steps: (1) mixing the raw materials of the flame-retardant layer; (2) carrying out extrusion molding to complete the preparation of the flame-retardant layer; (3) during extrusion molding of a semi-finished floor leather product in the step (2), spreading a layer of colored-spot quartz sand on one surface of the semi-finished floor leather product, blowing hot air with a hot-air blower to realize fusing and then carrying out embossing and cooling molding so as to complete the preparation of the non-slip wear-resistant layer; and (4) laminating the other surface of the semi-finished floor leather product obtained in the step (3) with the composite cloth base layer so as to obtain a floor leather product. According to the invention, the flame retardant properties of the floor leather are allowed to accord with standard requirements prescribed in JT / T1095-2016 through the improvement of the formula of the flame-retardant layer.

Owner:浙江通达塑业有限公司

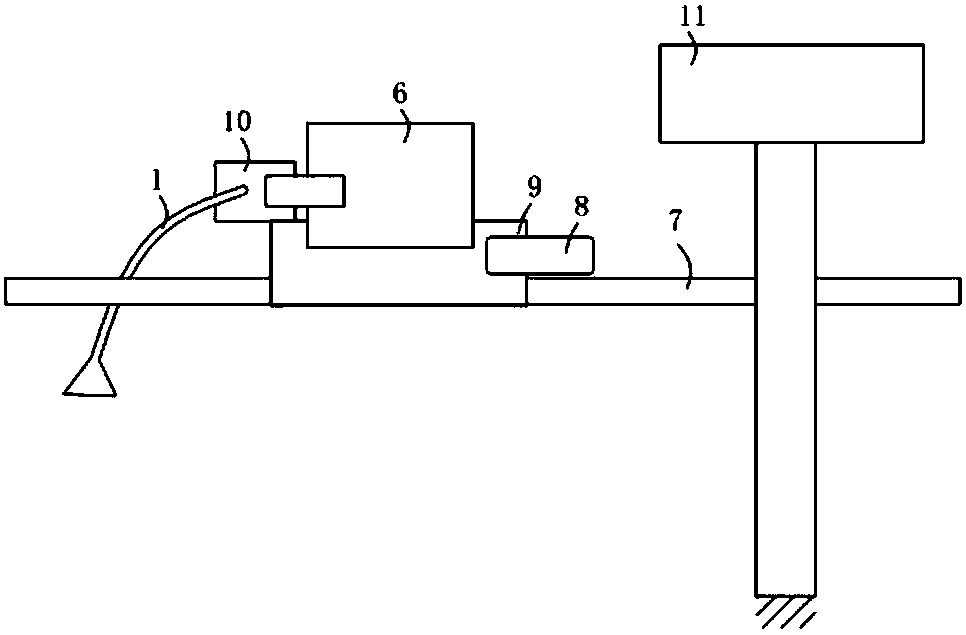

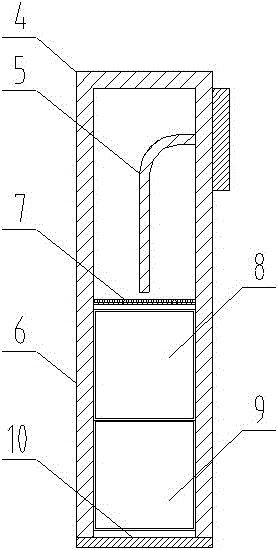

Silencing electrostatic air purification device for ship

ActiveCN105730667AReduce noiseSatisfy flame retardancyAuxillariesVessel ventillation/heating/coolingNoise controlEngineering

The invention provides a silencing electrostatic air purification device for a ship. The silencing electrostatic air purification device for the ship comprises device door plates, a shell frame, an adjustable air inflow grid, a silencing bend, a sheet type silencer, a pipeline silencer, a metal filter screen, an ionization region, an adsorption region, a fixed air outflow grid and an electric control box. Compared with the prior art, the silencing electrostatic air purification device has the beneficial effects that the air noise control technology and the air purification technology are integrated and designed; the manner that the pipeline silencer, the sheet type silencer and the silencing bend are adopted and an air layer is additionally arranged in a silencing material is adopted for conducting effective treatment on noise of all frequency bands, and the silencing material has a good sound absorption effect on medium-frequency noise and high-frequency noise and has the beneficial effects of being fireproof, resistant to inflaming and free of dust; and the high-voltage electrostatic technology is adopted, all the return air of an air conditioner is subjected to purification treatment in a concentrated manner, the purification treatment efficiency of the device is improved, and on the basis that the noise and the air quality of a cabin are effectively controlled, the occupation of general resources of the overwater ship is greatly reduced, and the workload of seamen is reduced.

Owner:CHINA SHIP DEV & DESIGN CENT

Halogen-free flame-retardant resin and preparation method thereof

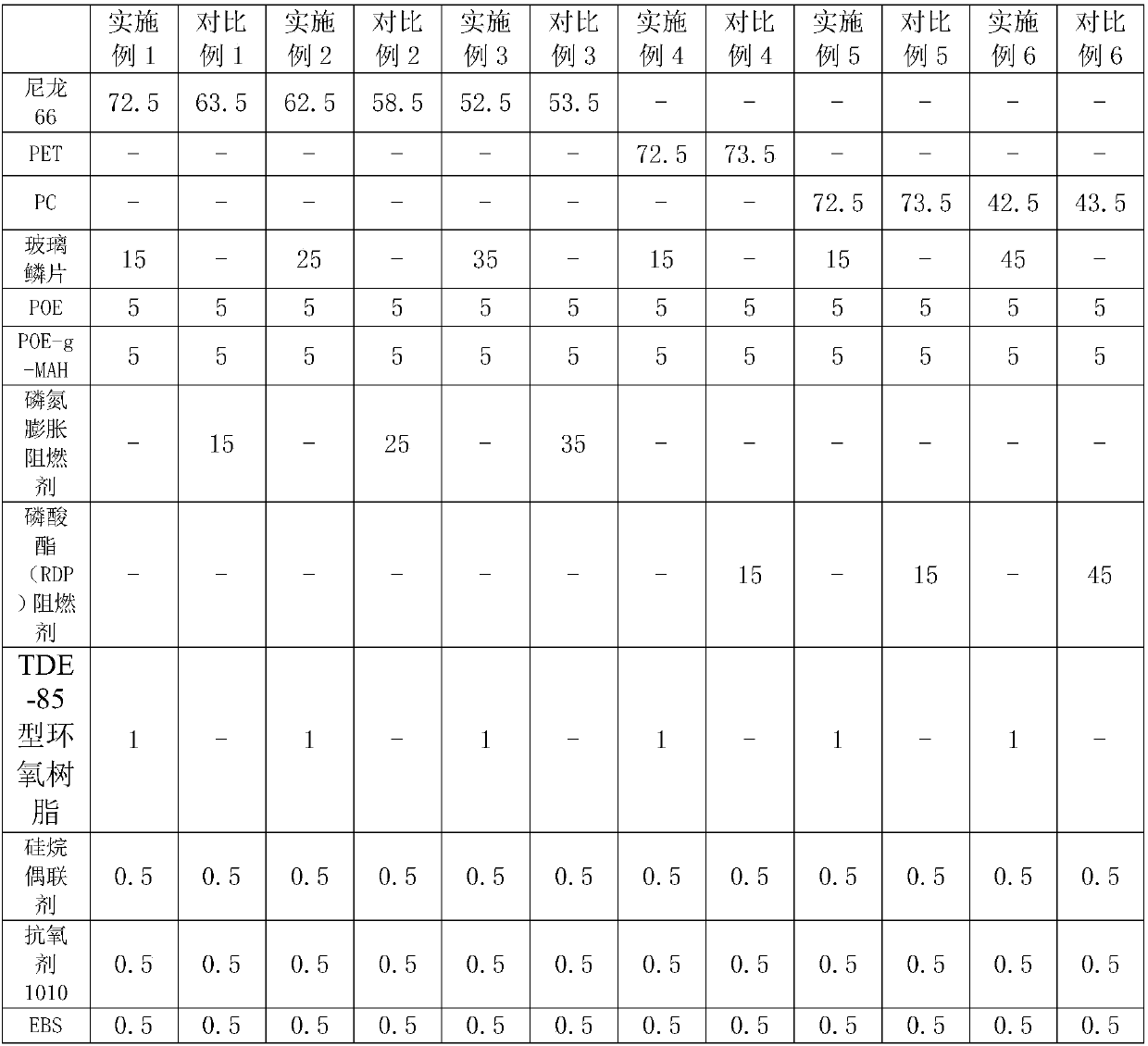

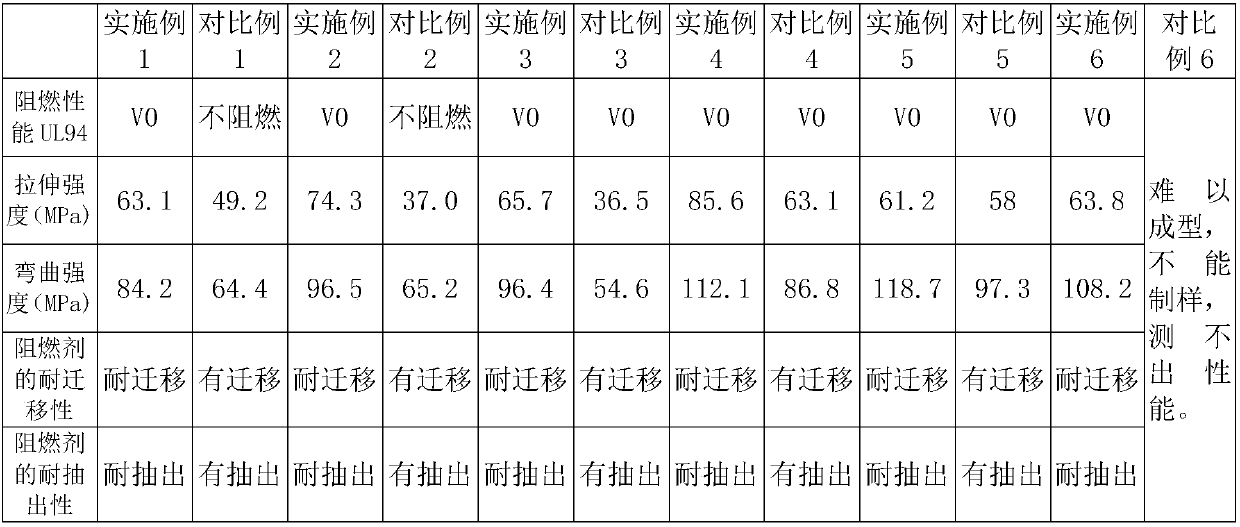

The invention provides a halogen-free flame-retardant resin and a preparation method thereof. The halogen-free flame-retardant resin comprises the following components in percentage by weight: 50-80%of a thermoplastic substrate resin, 15-35% of glass flakes, 5-10% of a thickening agent, 5-10% of a compatilizer, 0.5-5% of an epoxy resin, 0.2-1% of a coupling agent, 0.2-1% of an antioxidant and 0.2-1% of a lubricant. According to the technical scheme of the invention, the glass flakes in plastic form a labyrinth structure, a plastic material is filled with the glass flakes, very good flame retardancy is achieved, very good barrier properties and mechanical properties can be achieved, the halogen-free flame-retardant resin is applied to barrier packaging materials or containers, and high requirements of automobile plastic fuel tank materials on strength, flame retardancy and gas barrier properties are met.

Owner:SHENZHEN POLYTECHNIC

Inorganic particle composite polyurethane synthetic leather and preparation method and application thereof

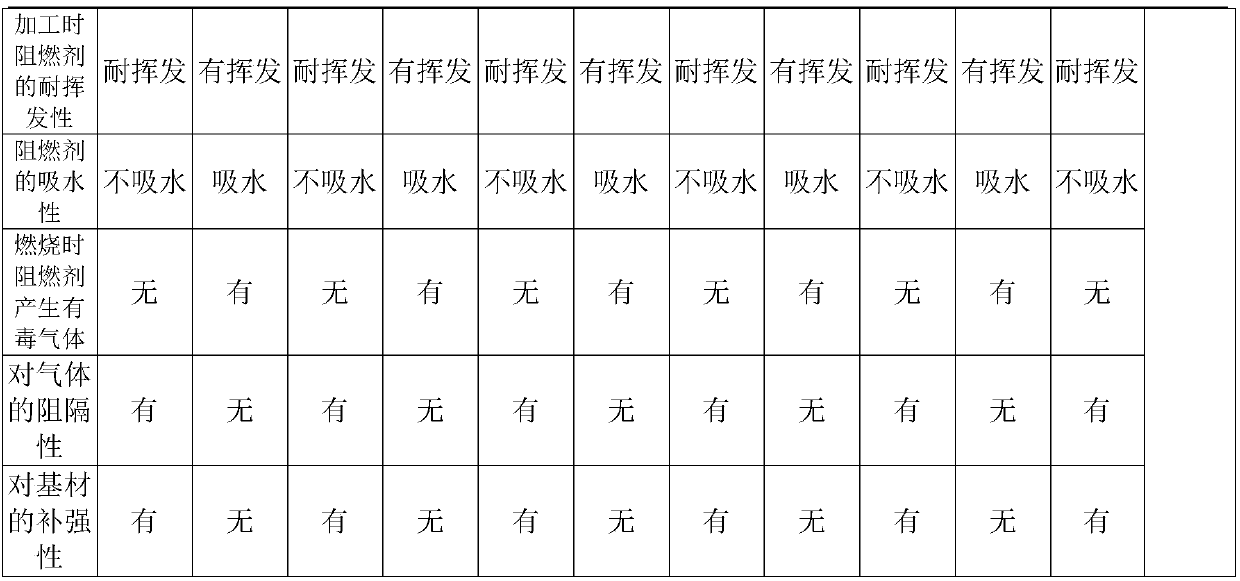

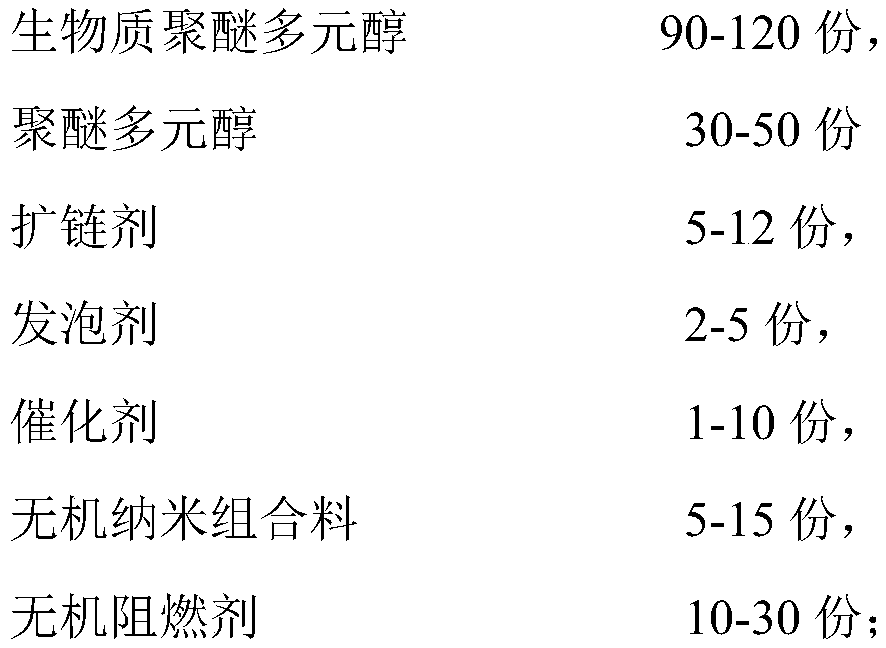

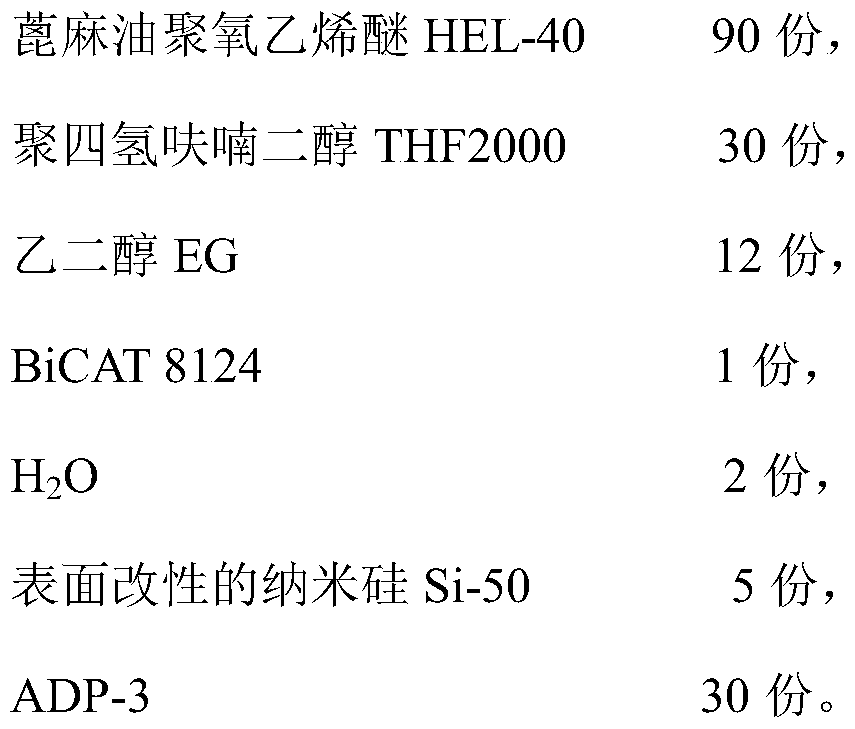

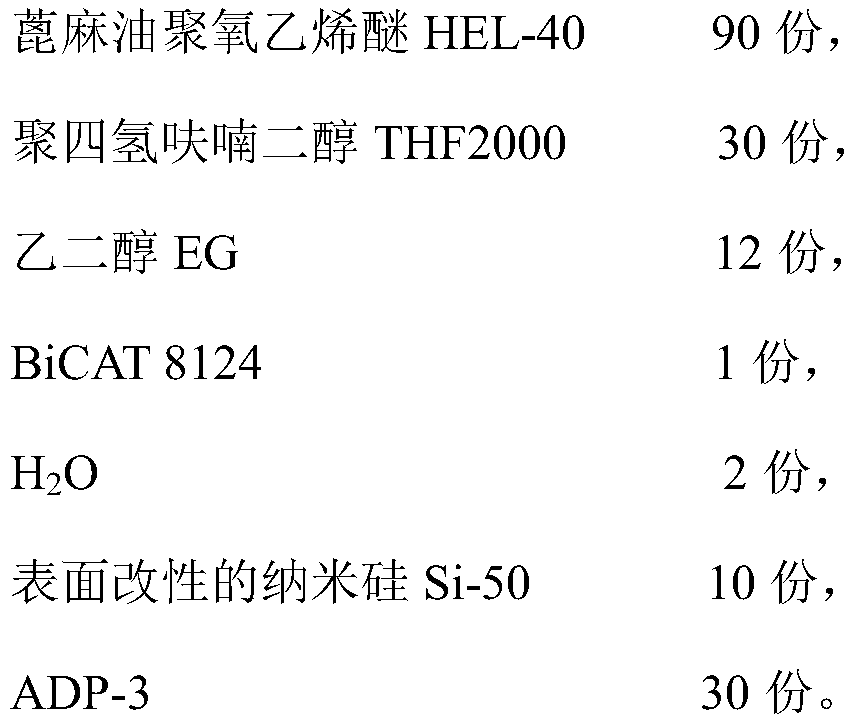

InactiveCN110656506ASolve the problem of high VOC contentSatisfy flame retardancyVehicle componentsRoad vehiclesPtru catalystPolyol

The invention discloses inorganic particle composite polyurethane synthetic leather and a preparation method and application thereof. The inorganic particle composite polyurethane synthetic leather isprepared from a composite material A and a composite material B according to a mass ratio of 100:(40-80) through solvent-free reaction. The composite material A is prepared from, by mass, 90-120 parts of biomass polyether polyol, 30-50 parts of polyether polyol, 5-12 parts of a chain extender, 2-5 parts of a foaming agent, 1-10 parts of a catalyst, 5-15 parts of an inorganic nano composite material and 10-30 parts of an inorganic flame retardant. The composite material B refers to cyanate ester organics. Organic solvent consumption is avoided in a manufacturing process, and the prepared inorganic particle composite polyurethane synthetic leather has excellent flame retardation and mechanical properties, high resistance to light and heat and long service life and has evident economic and environment-friendly advantages in application to automotive interior decorative materials.

Owner:ANHUI ANLI MATERIAL TECH

Dyeable permanent antistatic flame-retardant polyolefin material as well as preparation method and application thereof

The invention discloses a dyeable permanent antistatic flame-retardant polyolefin material and a preparation method thereof. The dyeable permanent antistatic flame-retardant polyolefin material comprises a polyolefin matrix, a flame retardant, a compatilizer and an antistatic agent, and the antistatic agent comprises a permanent antistatic agent and a nonionic antistatic agent. The polyolefin material has dyeable, permanent antistatic and flame-retardant properties, can meet the requirements of MT181-1988 standard mining pipes, and can also meet the requirements of standardized mines.

Owner:SHANDONG DONGHONG PIPE IND

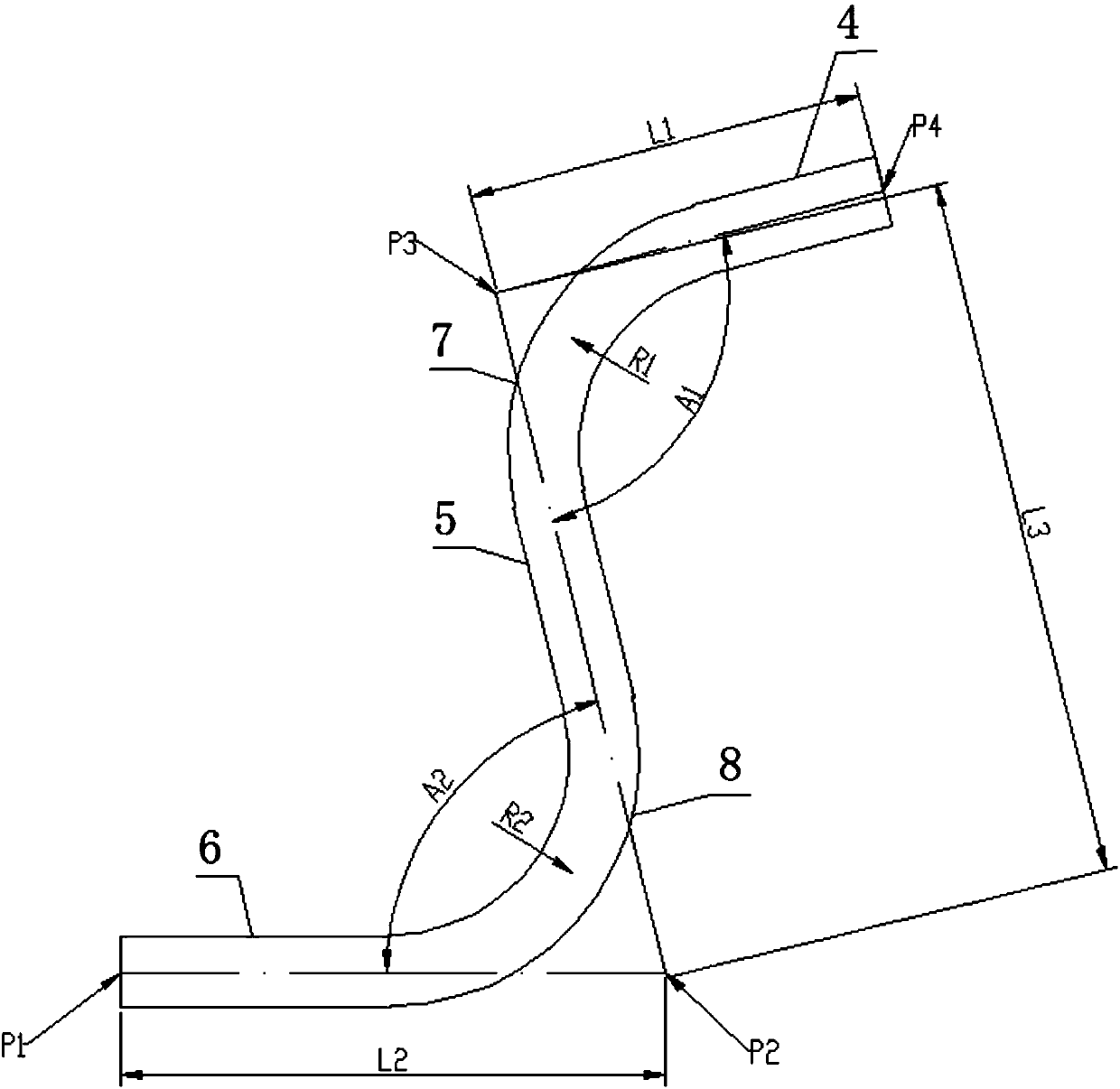

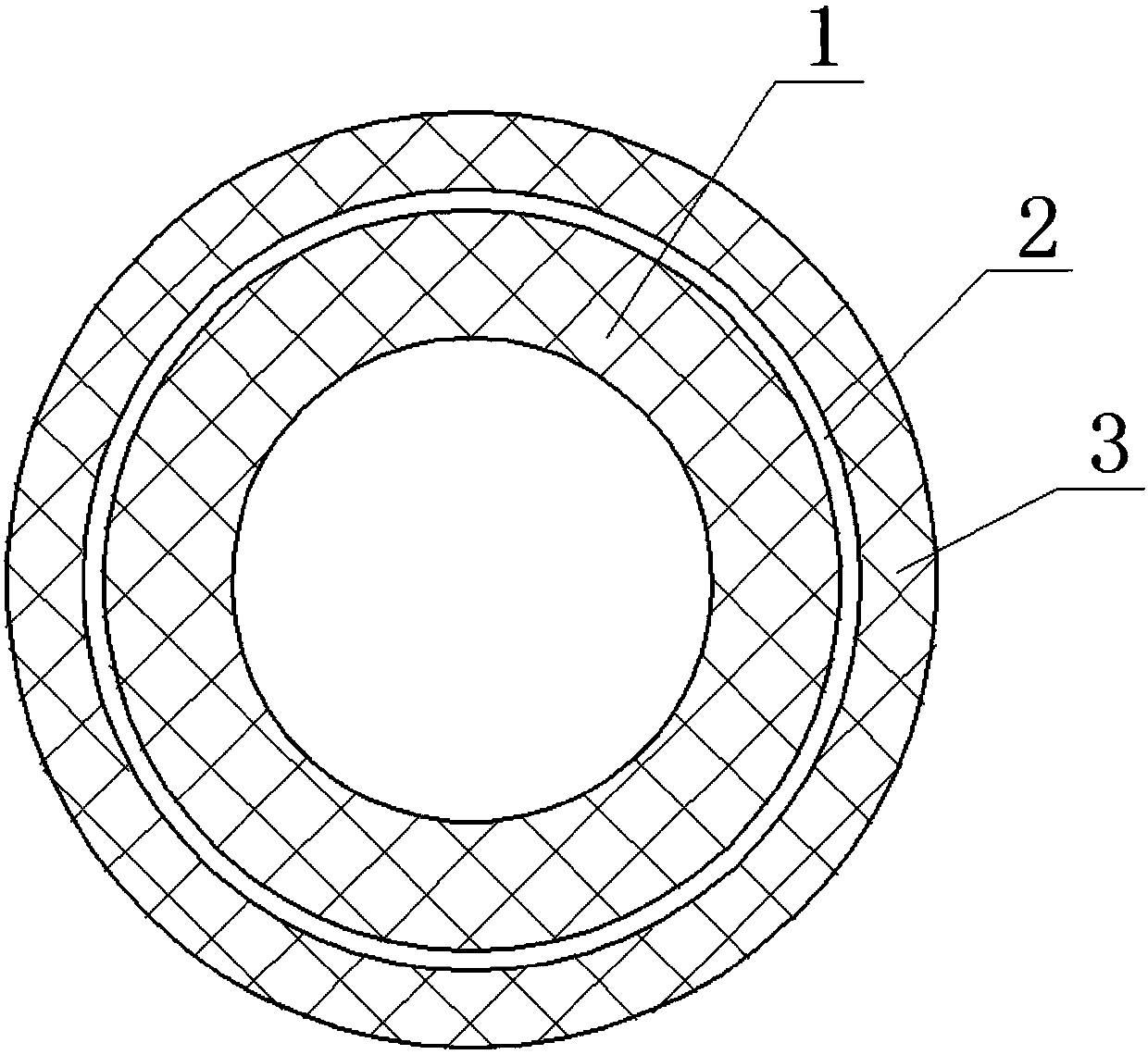

Special-shaped insulation wear-resistant sand spraying rubber flexible pipe

PendingCN107859794AAvoid Axial Twist ProblemsMeet insulationFlexible pipesPipe protection against damage/wearPolyesterWeather resistance

The invention discloses a special-shaped insulation wear-resistant sand spraying rubber flexible pipe. The flexible pipe is composed of an inner rubber layer, a reinforcing layer and an outer rubber layer; the inner rubber layer and the outer rubber layer are made of rubber with good insulation, wear resistance, weather resistance and low-temperature soft performance; the reinforcing layer is madeof fiber materials such as aramid fibers, polyester and vinylon by using winding, knitting or weaving process; the special-shaped sand spraying rubber flexible pipe comprises a first straight pipe section, a second straight pipe section, a third straight pipe section, a first arc section which connects the first straight pipe section and the second straight pipe section and a second arc section which connects the second straight pipe section and the third straight pipe section; the first straight pipe section and the second straight pipe section are correspondingly tangent to the first arc section; and the second straight pipe section and the third straight pipe section are correspondingly tangent to the second arc section. According to the special-shaped insulation wear-resistant sand spraying rubber flexible pipe, the axial twisting force caused by the straight pipe state is effectively avoided, and the rigid pulling force of a rubber pipe and a joint is relieved; and meanwhile, theinstallation direction of the rubber pipe is identified, the installation operation is standardized, and the operation failure rate is effectively reduced.

Owner:NANJING ORIENTLEADER TECH CO LTD

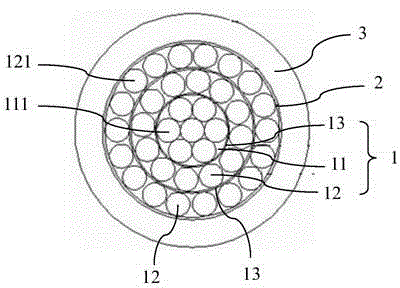

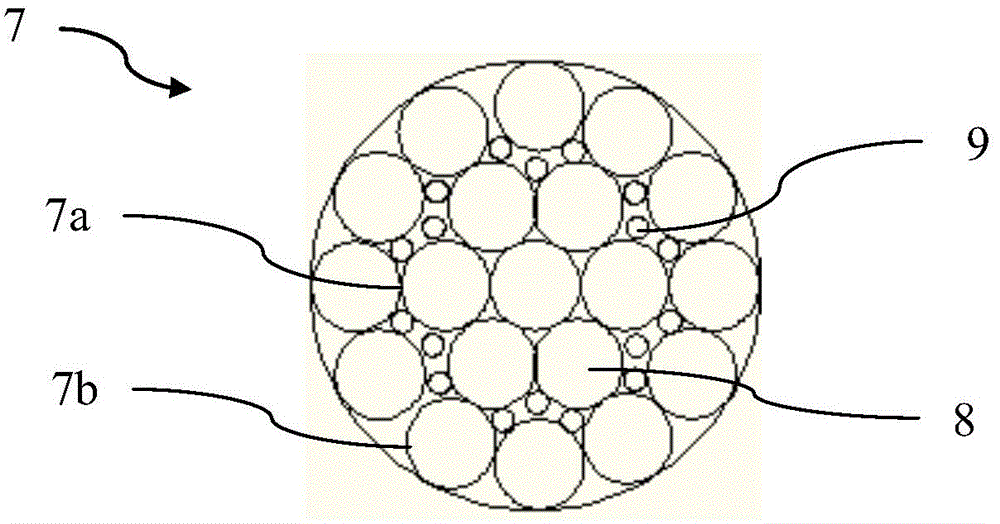

Small cross section super flexible waterproof cable and preparation method thereof

InactiveCN105810317AGood flexibilityIncrease the flexibilityNon-insulated conductorsClimate change adaptationElectrical conductorWater layer

The invention discloses a small cross section super flexible waterproof cable and a preparation method thereof. The small cross section super flexible waterproof cable comprises a cable inner core, an external water resistance layer and an insulating layer, wherein the external water resistance layer and the insulating layer sequentially cover the cable inner core from inside to outside. The cable inner core is formed by sequentially stacking and coating a number of conductor layers. Each conductor layer comprises a first conductor layer and a number of second conductor layers which sequentially cover the first conductor layer. An internal water resistance layer is arranged between two adjacent conductor layers. The cross section area of the cable inner core is more than 10mm<2>. According to the invention, an internal water resistance layer is wrapped between two adjacent conductor layers; the conductor layers can be fixed and are prevented from loosening; water infiltrating into the cable can be absorbed; the internal water resistance layers which absorb water can expand more than twice their size; radial seepage of the cable can be effectively prevented; vertical seepage of the cable can be absorbed; and conductor oxidizing is prevented.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

Environmentally-friendly acid-and alkali-resistant wire

InactiveCN106710696ASuit one's needsSatisfy flame retardancyInsulated cablesInsulated conductorsElastomerInsulation layer

The invention discloses an environmentally-friendly acid-and alkali-resistant wire. The environmentally-friendly acid-and alkali-resistant wire comprises seven outer protective layers and one kind of conductors; the seven outer protective layers include a galvanized annealed copper strip shielding layer, a nitrile insulation layer, a silver plated copper strip armor layer, a nickel strip shielding layer, an aluminum strip shielding layer, a chlorosulfonated ethylene-propylene polymer sheath layer and a rubber insulation layer which are distributed from inside to outside sequentially; the conductors are silver-plated annealed nickel conductors; and 24 silver-plated annealed nickel conductors are adopted. The raw materials in parts by weight of the rubber insulation layer include chlorinated polyethylene rubber, flame retardant, ethylene-vinyl acetate copolymer elastomer, barium sulfate, microcrystalline wax, carbon black, DOS, high-activity magnesium oxide, antimony oxide, DCP, TAIC, coupling agent and antioxidant. The environmentally-friendly acid-and alkali-resistant wire of the invention has the advantages of high acid and alkali resistance, environmental friendliness, inflame retardant performance, high temperature resistance and low temperature resistance, and can satisfy the needs of special cables such as acid and alkali resistant cables. According to the environmentally-friendly acid-and alkali-resistant wire of the invention, magnesium hydroxide or aluminum hydroxide is adopted to make the fire retardant, and therefore, requirements of a material system for flame retardant performance, low smoke zero and halogen-free performance can be satisfied.

Owner:SHANGHAI LUSHENYUAN IND & TRADE CO LTD

High-performance flame-retardant reinforced hydrolysis-resistant PBT (polybutylene terephthalate) material and preparation method thereof

InactiveCN103525030AReduce carboxyl end contentImprove hydrolysis resistanceGlass fiberPolyethylene terephthalate

The invention discloses a high-performance flame-retardant reinforced hydrolysis-resistant PBT (polybutylene terephthalate) material and a preparation method thereof. The high-performance flame-retardant reinforced hydrolysis-resistant PBT material comprises the following components in percentage by mass: 45-60% of PBT, 5-10% of flame retardant, 1-10% of antimony trioxide, 20-35% of glass fiber, 0.2-1.5% of coupling agent, 0.1-2% of chain extender, 0.2-0.5% of antioxidant, 0.5-5% of toughener and 0.3-1% of lubrication dispersing agent. According to the invention, on the basis of performing glass fiber reinforced flame retardance on the PBT material, a proper amount of chain extender is added, thus greatly reducing the terminal carboxyl content of the PBT, and enhancing the hydrolysis resistance, compatibility and toughening and reinforcing performance of the PBT. The preparation method provided by the invention adopts a secondary extrusion process, and the PBT material meeting flame-retardant and hydrolysis-resistant requirements and having excellent comprehensive performance can be obtained; and the preparation process is simple and easy to operate.

Owner:QINGDAO XINZHAN PLASTIC

Composite material and preparing method thereof

InactiveCN106242451AHas the function of thermal insulationSatisfy water absorptionAbsorption rateCoal

The invention discloses a composite material and a preparing method thereof. The composite material is prepared from, by weight, 100 parts of coal ash, 50-75 parts of rubber particles, 45-60 parts of sand, 10-30 parts of kaolin, 1-5 parts of magnesium oxide and the balance water. The requirement for water absorption rate, inflame retarding rate and strength can be met, and heat insulation can also be achieved; besides, the preparing method is simple and environment-friendly, and has high economic and social value.

Owner:张春辉

Composite waterproof cable and preparation method thereof

InactiveCN105810338AHas a service lifeReach radialClimate change adaptationInsulated cablesElectrical conductorInsulation layer

The invention discloses a composite waterproof cable and a preparation method thereof. The composite waterproof cable comprises a cable inner core, an isolation layer and a sheath layer, wherein the isolation layer and the sheath layer successively cover the cable inner core from the inside out. The cable inner core is formed by twisting a number of insulation core wires. Water blocking filling layers are arranged in twisting voids of a number of insulation core wires. Each insulation core wires comprises a conductor group and an insulation layer which covers the conductor group. Each conductor group is formed by tow-twisting a number of copper wires and a number of water blocking wires, wherein the filament diameter of each water blocking wire before water swelling is less than or equal to the filament diameter of each copper wire, and the filament diameter of each copper wire is less than 0.2mm. According to the invention, water blocking ropes are arranged in twisting voids of a number of insulation core wires; the water blocking ropes can block radial seepage of the cable and can absorb vertical seepage of the cable; and radial and longitudinal full range stereo waterproof effect of the cable is realized.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

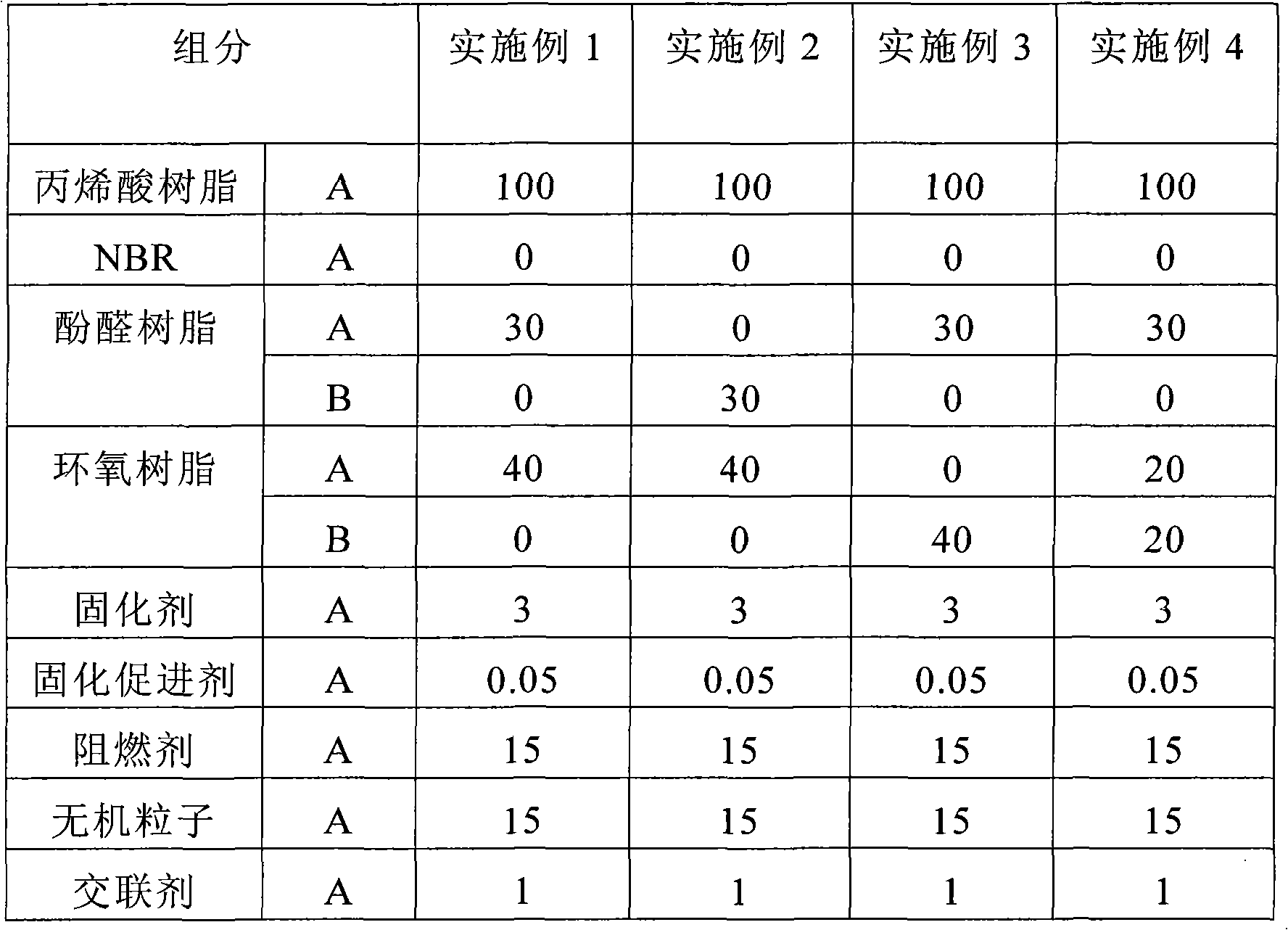

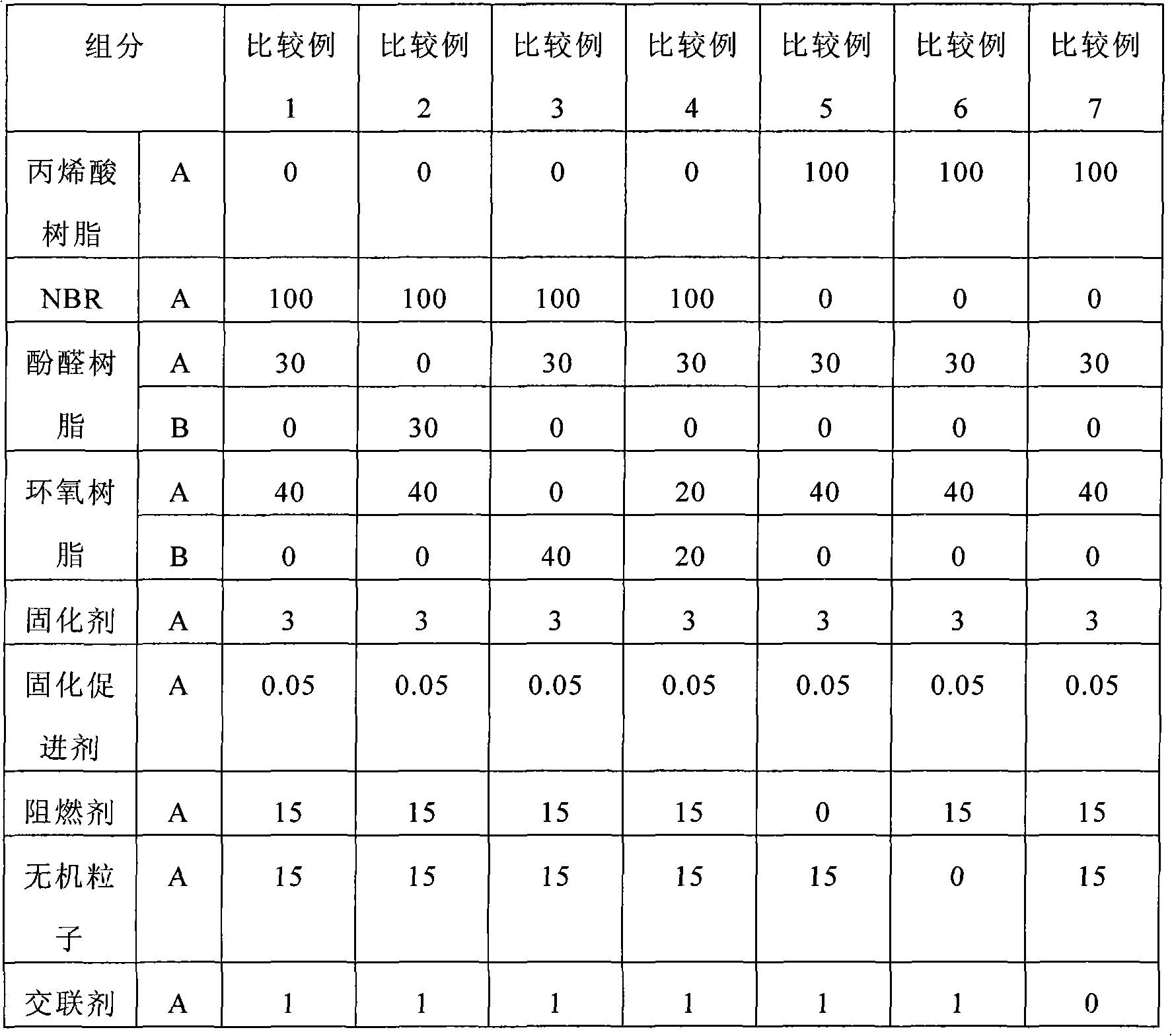

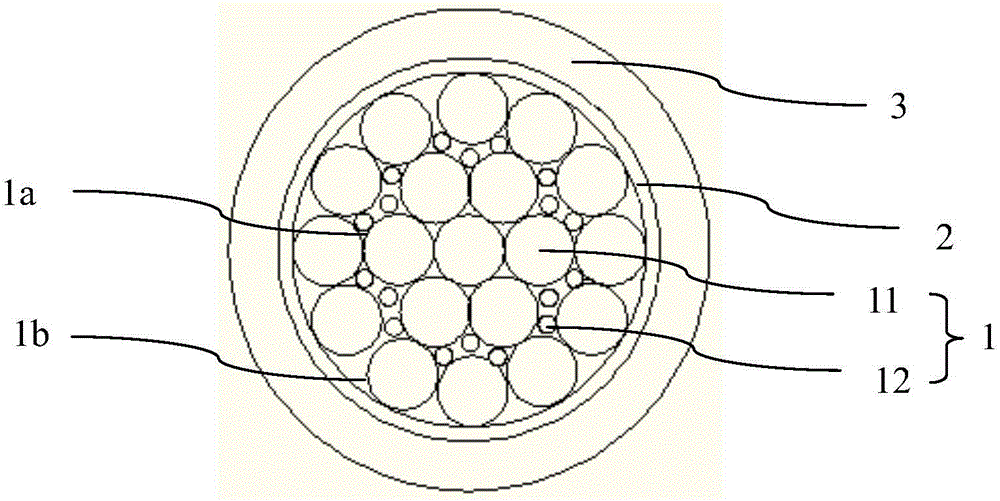

Adhesive composition for halogen-free coverlay film and coverlay film coated by the same

InactiveCN101987947ASatisfy flame retardancySatisfy the adhesive strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAcrylic resin

The present invention generally relates to an adhesive composition for halogen-free coverlay film and a coverlay film coated by the same. More particularly, the invention relates to the adhesive composition for the halogen-free coverlay film and the coverlay film coated by the same. The adhesive composition has undeteriorated binding strength and heat resistance in a humidity condition in which the covering film is covered through replacing NBR (nitrile butadiene rubber) which is commonly used as the adhesive for cover binding by the acrylic acid copolymer that contains hydroxy and carboxyl. Thus the adhesive composition for the halogen-free coverlay film comprises the following components: (1) acrylic resin which contains hydroxy and carboxyl and has a weight average molar mass of 300,000-800,000 and a viscosity of 800-10,000cP in 25 DEG C; (2) phenolic resin; (3) multifunctional epoxide resin; (4) solidifying agent; (5) solidifying promoting agent; (6) flame retardant based on non-halogen; (7) inorganic particles and (8) cross linker.

Owner:TORAY ADVANCED MATERIALS KOREA

Phenolic foam building material

InactiveCN107601962ASatisfy water absorptionSatisfy flame retardancyCeramicwareEnvironmental resistanceCellulose

The invention provides a phenolic foam building material which is prepared from the following materials in parts by weight: 20-25 parts of coal ash powder, 20-25 parts of rubber particles, 2.5 parts of resin, 1.6 parts of dispersing agent, 10-20 parts of quick lime, 3-7 parts of carbon cellulose, 10-15 parts of kaoline, 1 part of magnesium oxide, 6-10 parts of phenolic foam and the balance of water. The building material disclosed by the invention not only can meet the requirements of water absorption, flammasbility and strength, but also has a heat insulation effect; and the preparation method is simple, is strong in operability, is green and environment-friendly and has great economical and social values.

Owner:湖北安耀红旗电缆股份有限公司

A kind of environment-friendly fireproof material for electric equipment and preparation method thereof

ActiveCN106497339BExcellent Melt Flow RateHigh flame retardant efficiencyFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Single-core flexible waterproof cable and production method thereof

InactiveCN105810333AUnaffected by physicsDoes not affect electrical performanceClimate change adaptationInsulated cablesElectrical conductorInsulation layer

The invention discloses a single-core flexible waterproof cable and a production method thereof. The single core flexible waterproof cable comprises a conductor, a water-blocking layer, and an insulation layer. The water-blocking layer and the insulation layer are sequentially, from inside to outside, disposed on the outer part of the conductor in a wrapped manner. The conductor is formed by intertwisting a plurality of copper wires and a plurality of water-blocking filaments, and the cross section of the conductor is smaller than 10mm2. The diameter of the single filament before the water swelling of the water-blocking filaments is smaller than or equal to the diameter of the single filament of the copper wires, and the diameter of the single filament of the copper filaments is smaller than 0.18mm. The radial and vertical all-directional three-dimensional waterproof effect can be achieved by adopting the waterproof filaments in the conductor, the water-blocking tape disposed on the outer side of the conductor, and the insulation waterproof function of the insulation layer.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

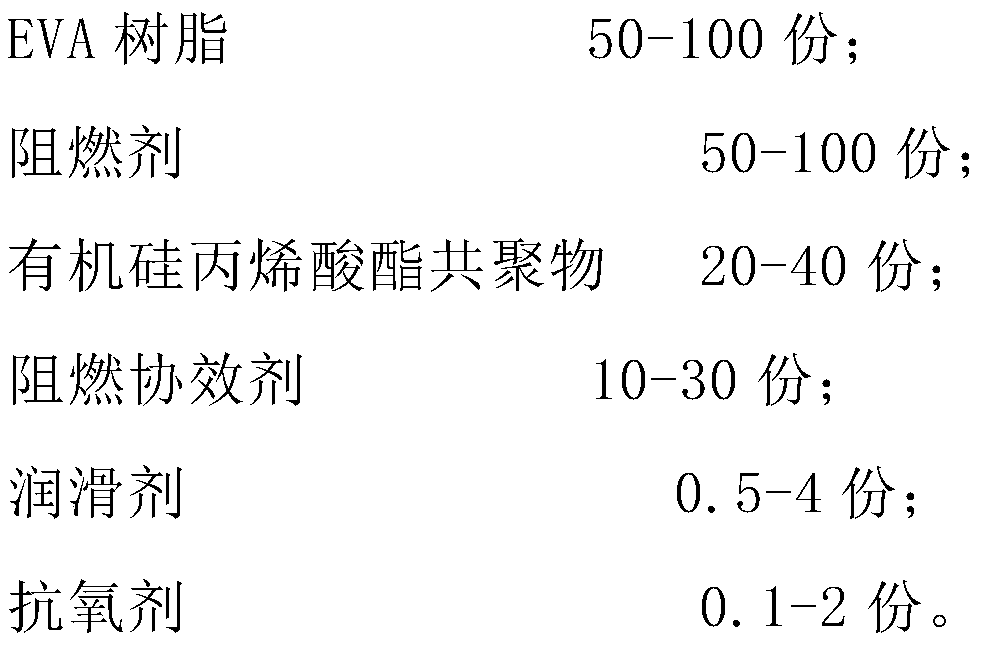

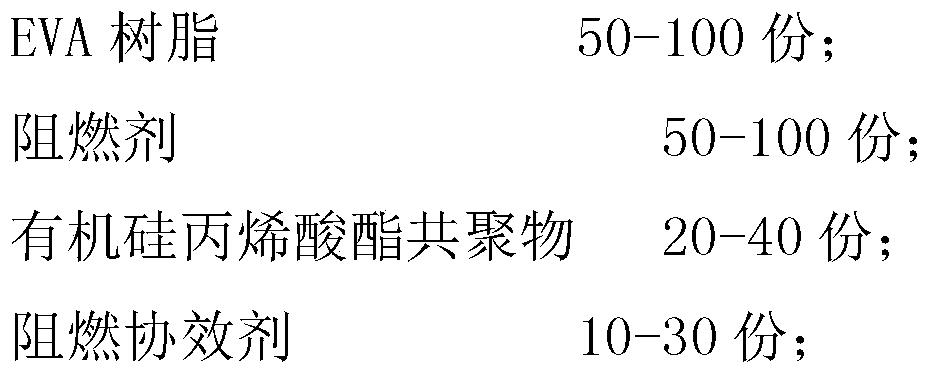

Special constant-temperature constant-humidity flame-retardant halogen-free cable material used for five cables and not prone to discoloring, and preparation method thereof

InactiveCN111040291AProcess environmental protectionSatisfy flame retardancyPlastic/resin/waxes insulatorsHeat resistancePhysical chemistry

The invention discloses a special constant-temperature constant-humidity flame-retardant halogen-free cable material used for five cables and not prone to discoloring. The cable material is characterized by comprising the following components in parts by weight: 50-100 parts of EVA resin, 50 to 100 parts of a flame retardant, 20 to 40 parts of an organosilicon acrylate copolymer, 10 to 30 parts ofa flame retardant synergist, 0.5 to 4 parts of a lubricant and 0.1-2 parts of antioxidant. The invention also discloses a preparation method of the cable material. According to the cable material inthe invention, common materials of traditional cable materials are improved, and the problems that the common materials are large in mechanical property loss and prone to yellowing and discoloring indamp and heat resistance tests at a temperature of 85 DEG C and a relative humidity of 85% are mainly solved, so the cable material meets various requirements for environmental protection, flame retardance and damp-heat resistance.

Owner:上海至正新材料有限公司

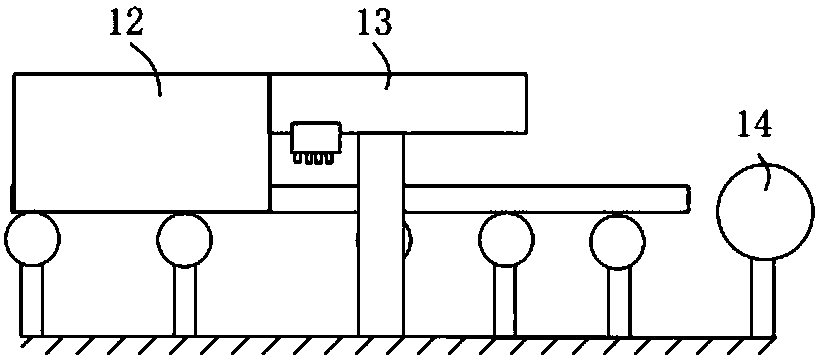

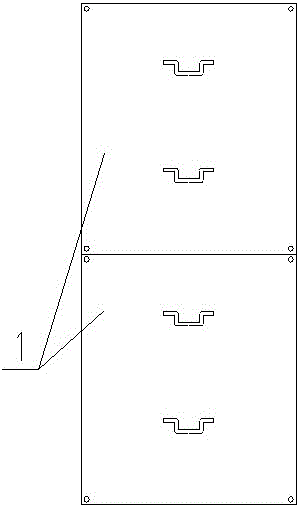

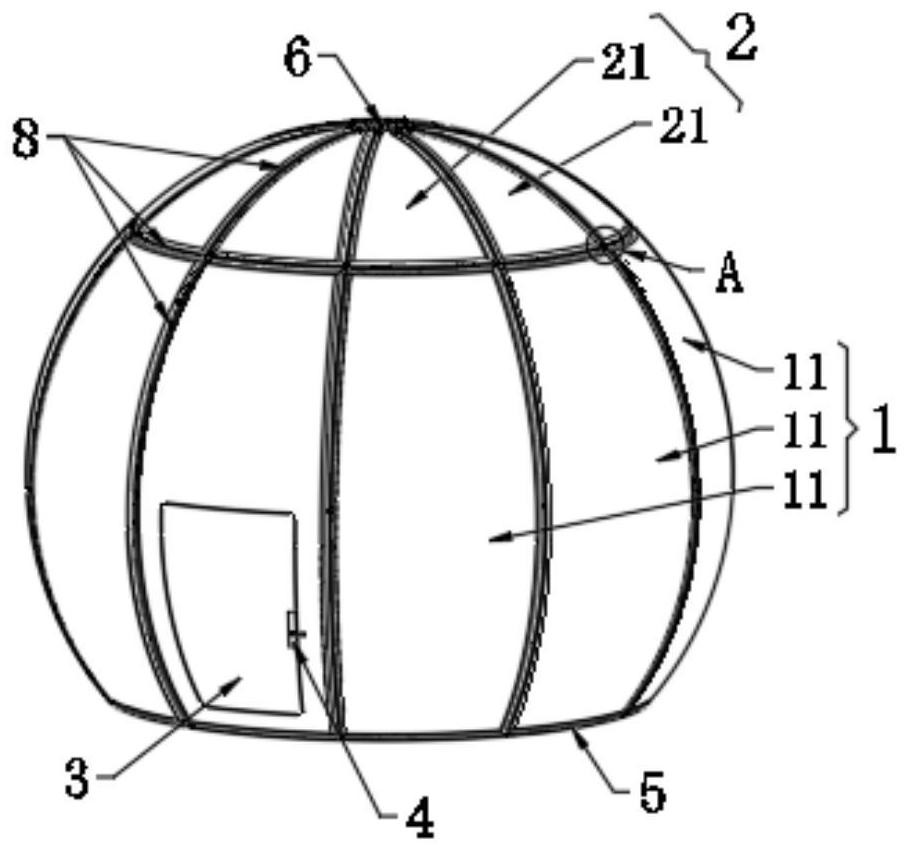

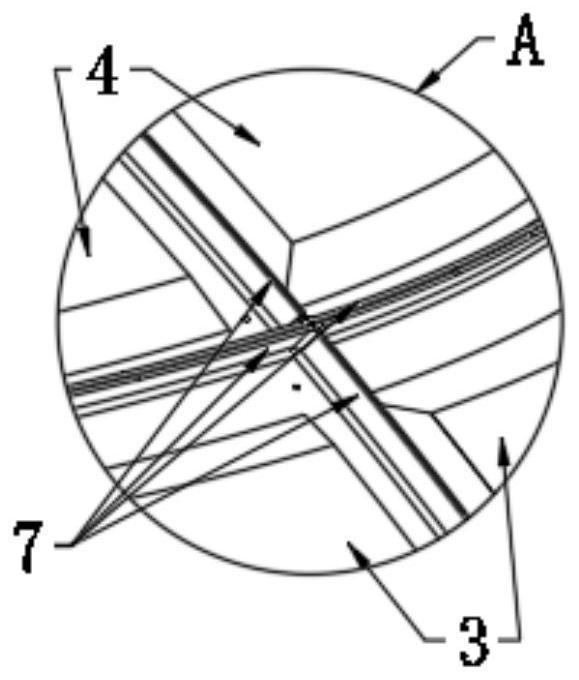

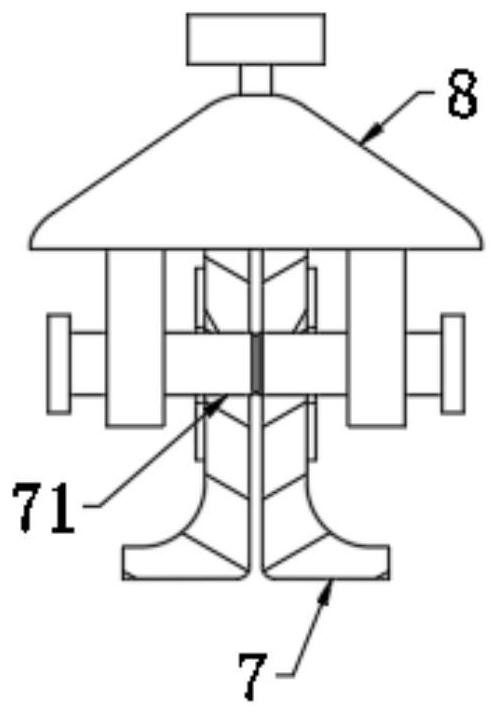

Dome-screen simulation cabin structure and preparation method thereof

PendingCN113658480AReduce weightImprove shadingCosmonautic condition simulationsSimulatorsDriver/operatorStructural engineering

The invention belongs to the technical field of dome-screen simulation cabins, and particularly relates to a dome-screen simulation cabin structure and a preparation method thereof. The dome-screen simulation cabin structure comprises a belly cabin and a top cabin. The belly cabin comprises a plurality of web plates distributed in a circle, the top cabin comprises a plurality of top plates distributed in a circle, and flanged plates are fixedly installed on the two sides and the top of each web plate and the periphery of each top plate; every two adjacent web plates, every two adjacent top plates and the sides, close to each other, of the top plates and the web plates are connected together through two corresponding flanged plates, and two assembly holes are formed in each flanged plate. The dome-screen simulation cabin structure has the advantages of being attractive, light in weight, good in sealing performance, easy to fix, maintain and replace, low in cost, short in development period, capable of being used for manufacturing various driver simulation cabins and the like; traditional fasteners are replaced with fastening mechanisms, the connection fastening performance can be ensured, and meanwhile, compared with a traditional fastener installation mode, the installation mode of the dome-screen simulation cabin structure is faster and more convenient; repeated utilization can be achieved, and the use cost is reduced.

Owner:北京蓝科盈晟航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com