Anti-static, radiation-proof, flame-retardant and high-breathability fabric and preparation method thereof

An anti-radiation and anti-static technology, which is applied in the fields of anti-radiation, anti-static, high-permeability fabrics and their preparation, and flame retardant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

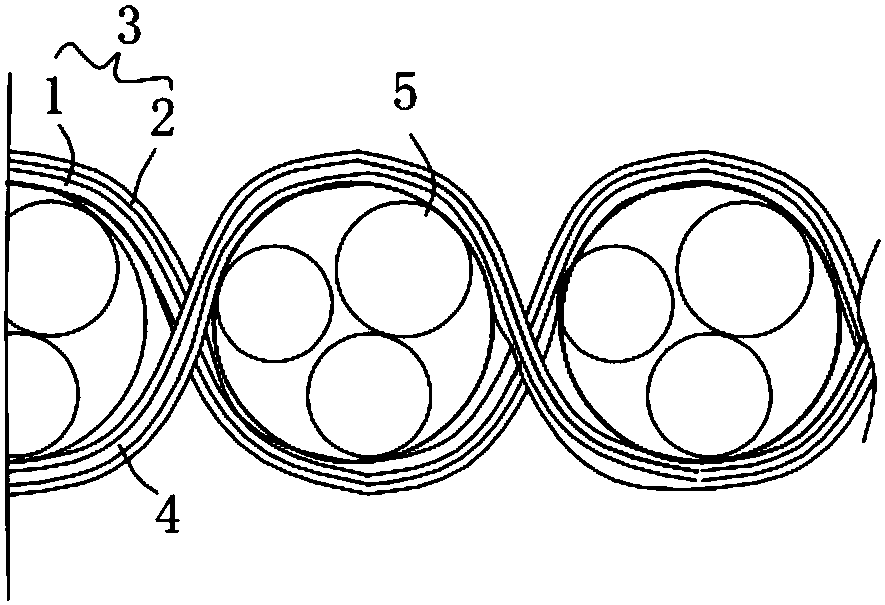

[0047] An anti-static, radiation-proof, flame-retardant, high-permeability fabric, such as figure 1 As shown, it is composed of warp yarn clusters 3 and weft yarn clusters interlacedly sandwiching a breathable core 5, wherein:

[0048] The warp cluster 3 is composed of 1-3 calcium alginate flame-retardant fibers 1, 3-5 silver fibers 2, and 1-2 polyester fibers, which ensures that the fabric has high flame-retardant properties, electrical conductivity, and anti-corrosion properties after it is made. Electrostatic properties and wear resistance;

[0049] The weft cluster 4 is composed of 2-4 flame-retardant acrylic fibers 4, 1-3 stainless steel fiber wires, and 1-2 polyester fibers, which ensures that the fabric has better radiation protection and wear resistance after it is made;

[0050] The air-permeable core 5 is composed of 2-4 bamboo fibers or carbon fibers or bamboo fibers and carbon fibers, and has good electrical conductivity and air permeability;

[0051] An antistat...

Embodiment 2

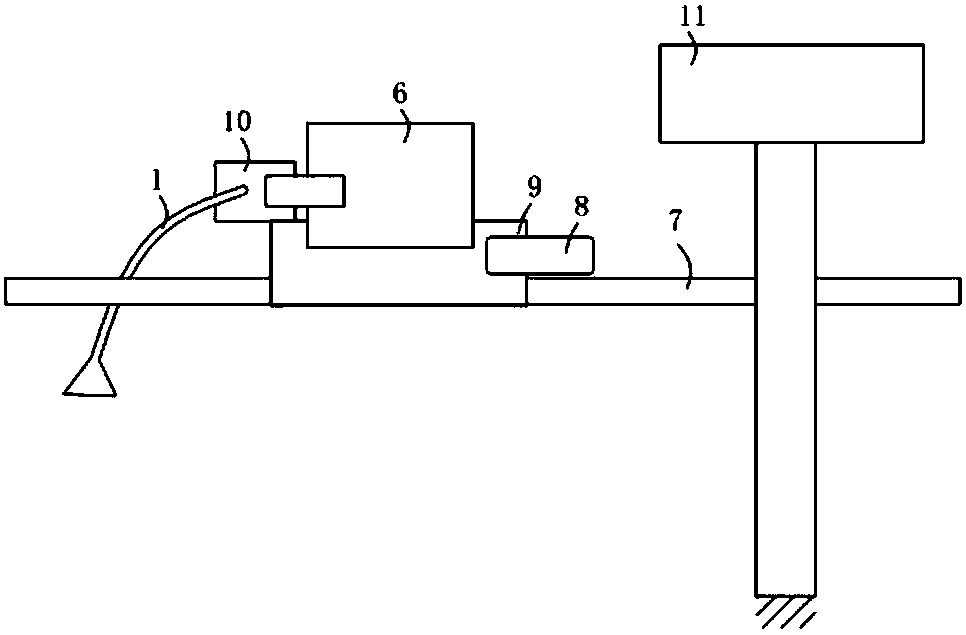

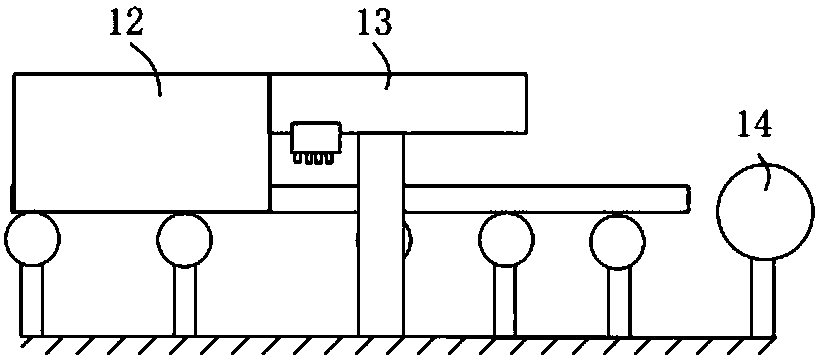

[0060] The difference from Example 1 is that the secondary drying process uses independent drying equipment for drying, and the drying equipment includes sequentially connected drying devices and their transmission equipment, wear-resistant agent spraying and its transmission equipment, and winding The drying device and its transmission equipment carry out secondary drying and automatic transmission of the fabric, the wear-resistant agent spraying and its transmission equipment are used to spray the wear-resistant agent and transmit the fabric at the same time, and the winding device is used to wind the fabric. The overall quality of the prepared fabric is better.

Embodiment 3

[0062] The difference from Examples 1 and 2 is that in this example, the formula of the antistatic agent includes the following components by weight:

[0063] Potassium acetate: 16 parts, industrial white oil: 8 or 11 or 12 parts, polypropylene: 11 or 12 or 13 parts, xylene: 25 parts, p-toluenesulfonic acid: 15 parts, triethanolamine: 13 parts, acetone: 6 Or 7 or 8 parts, dimethyl terephthalate: 21 parts, surfactant: 32 parts, initiator: 4 parts, ethanol: 19 parts, deionized water: 82 parts. The fabric prepared by using this proportioned antistatic agent in combination with the above-mentioned weaving method and preparation method has a more environmentally friendly and durable effect when used.

[0064] A more optimal embodiment is that when the antistatic agent is produced, surfactant, potassium acetate, industrial white oil, polypropylene, xylene, p-toluenesulfonic acid, triethanolamine and 50wt% deionized water are sequentially added to the mixer , stirred at 45°C for hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com