Patents

Literature

71results about How to "Satisfy corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resisting copper alloy materials

ActiveUS20060260721A1Improvement of efficiency durabilityAvoid corrosionFurnace typesWelding/cutting media/materialsMetallurgyHeat resistance

The present invention discloses a heat resistance copper alloy material characterized in that said copper alloy material comprises 0.15 to 0.33 mass percent of Co, 0.041 to 0.089 mass percent of P, 0.02 to 0.25 mass percent of Sn, 0.01 to 0.40 mass percent of Zn and the remaining mass percent of Cu and inevitable impurities, wherein each content of Co, P, Sn and Zn satisfies the relationships 2.4≦([Co]−0.02) / [P]≦5.2 and 0.20≦[Co]+0.5[P]+0.9[Sn]+0.1[Zn]≦0.54, wherein [Co], [P], [Sn] and [Zn] are said mass percents of Co, P, Sn and Zn content, respectively; and said copper alloy material is a pipe, plate, bar, wire or worked material obtained by working said pipe, plate, bar or wire material into predetermined shapes.

Owner:MITSUBISHI SHINDOH CO LTD

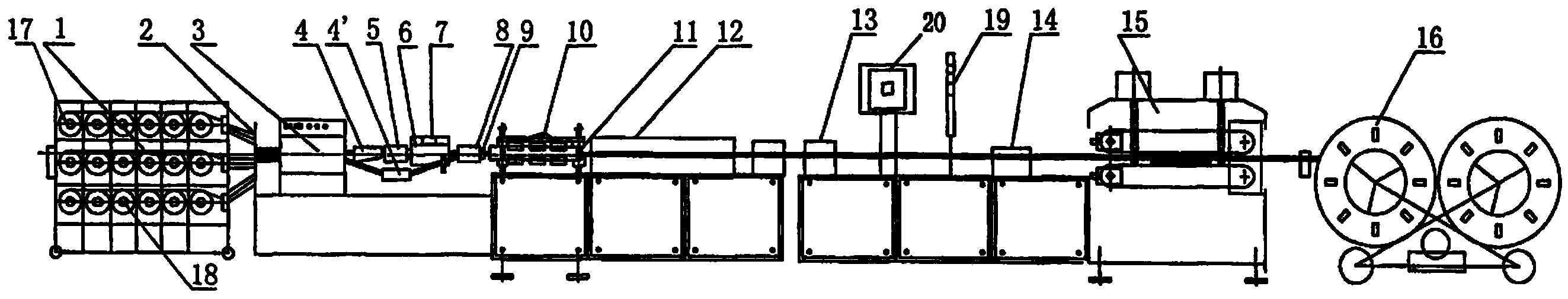

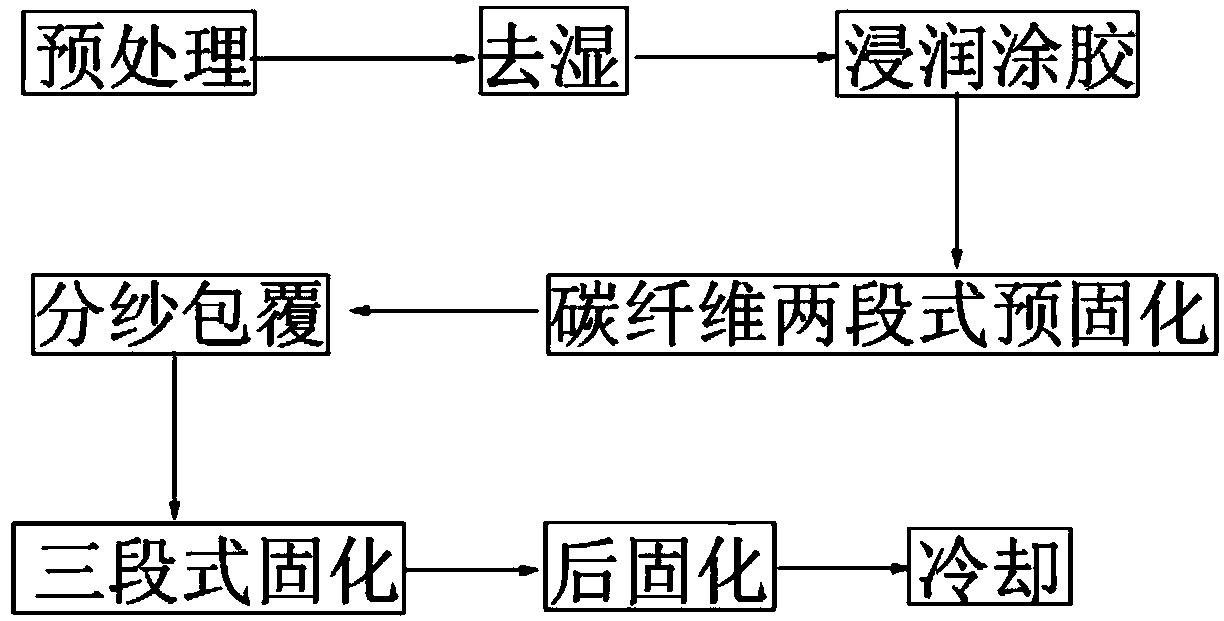

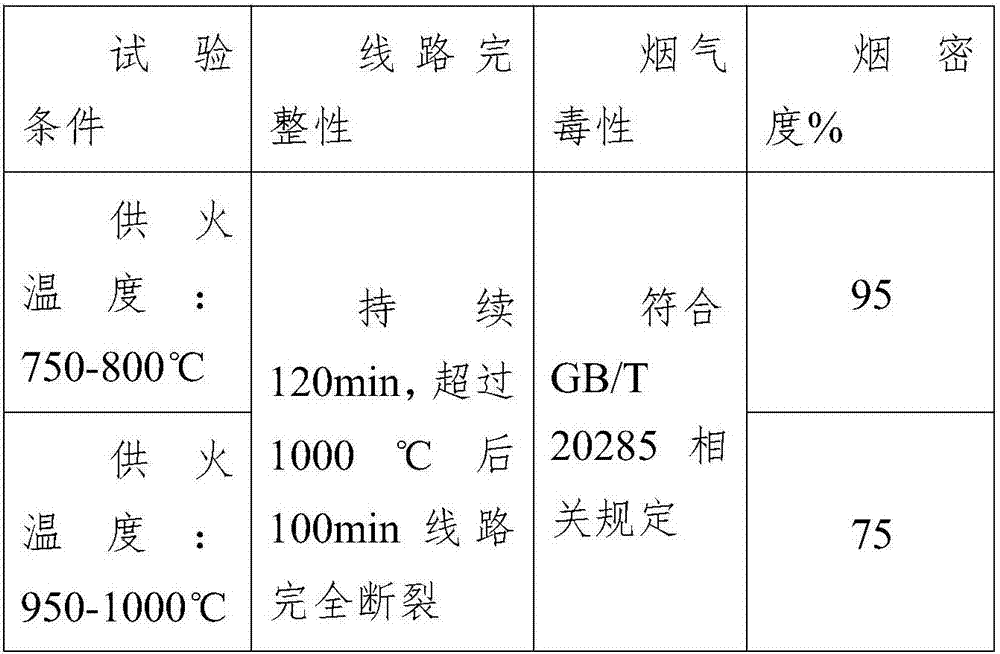

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

Large-diameter seamless steel tube for high-pressure gas cylinders and manufacturing method thereof

The invention belongs to the technical field of metallurgy, and provides a large-diameter seamless steel tube for high-pressure gas cylinders and a manufacturing method thereof. The large-diameter seamless steel tube for high-pressure gas cylinders comprises the following chemical components in percentage by mass: 0.30-0.60% of C, 0.20-0.50% of Si, 0.20-0.60% of Mn, at most 0.010% of P, at most 0.010% of S, 0.90-1.70% of Cr, 2.50-3.50% of Ni, 0.25-0.55% of Mo, 0.05-0.25% of V and the balance of Fe. The manufacturing method adopts spongy iron and scrap steel as raw materials for steelmaking. The large-diameter seamless steel tube has the advantages of high heat stability, high strength, impact toughness, stable enduring plasticity, high heat resistance, excellent corrosion resistance and excellent fatigue resistance, and the yield strength is not lower than 1000 MPa.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Heat resistance copper alloy materials

ActiveUS7608157B2Improvement of efficiency durabilityAvoid corrosionFurnace typesWelding/cutting media/materialsHeat resistanceImpurity

Owner:MITSUBISHI SHINDOH CO LTD

Fe-Ni alloy pipe stock and method for manufacturing the same

ActiveUS20070175547A1Improve mechanical propertiesEasy to manufactureMetal rolling arrangementsChemical compositionAlloy

An Fe—Ni alloy pipe stock having a chemical composition comprising, by mass %, C≦0.04%, Si≦0.50%, Mn: 0.01 to 6.0%, P≦0.03%, S≦0.01%, Cr: 20 to 30%, Ni: 30 to 45%, Mo: 0 to 10%, W: 0 to 20%, with Mo(%)+0.5W(%): more than 1.5% to not more than 10%, Cu: 0.01 to 1.5%, Al≦0.01% and N: 0.0005 to 0.20%, and the balance substantially being Fe, with 1440−6000P−100S−2000C≧1300, Ni+10(Mo+0.5W)+100N≦120, (Ni−35)+10(N−0.1)−2(Cr−25)−5(Mo+0.5W−3)+8≧0, can be manufactured into a seamless pipe by use of a Mannesmann piercing and rolling mill because of its excellent inner surface properties. The resulting seamless pipe has excellent mechanical properties and moreover has excellent corrosion resistance in a sour gas environment, and thus, the Fe—Ni alloy pipe stock can be used as a pipe stock for oil country tubular goods and line pipes and further as a pipe stock for various structural members of nuclear power plants and chemical industrial plants.

Owner:NIPPON STEEL CORP

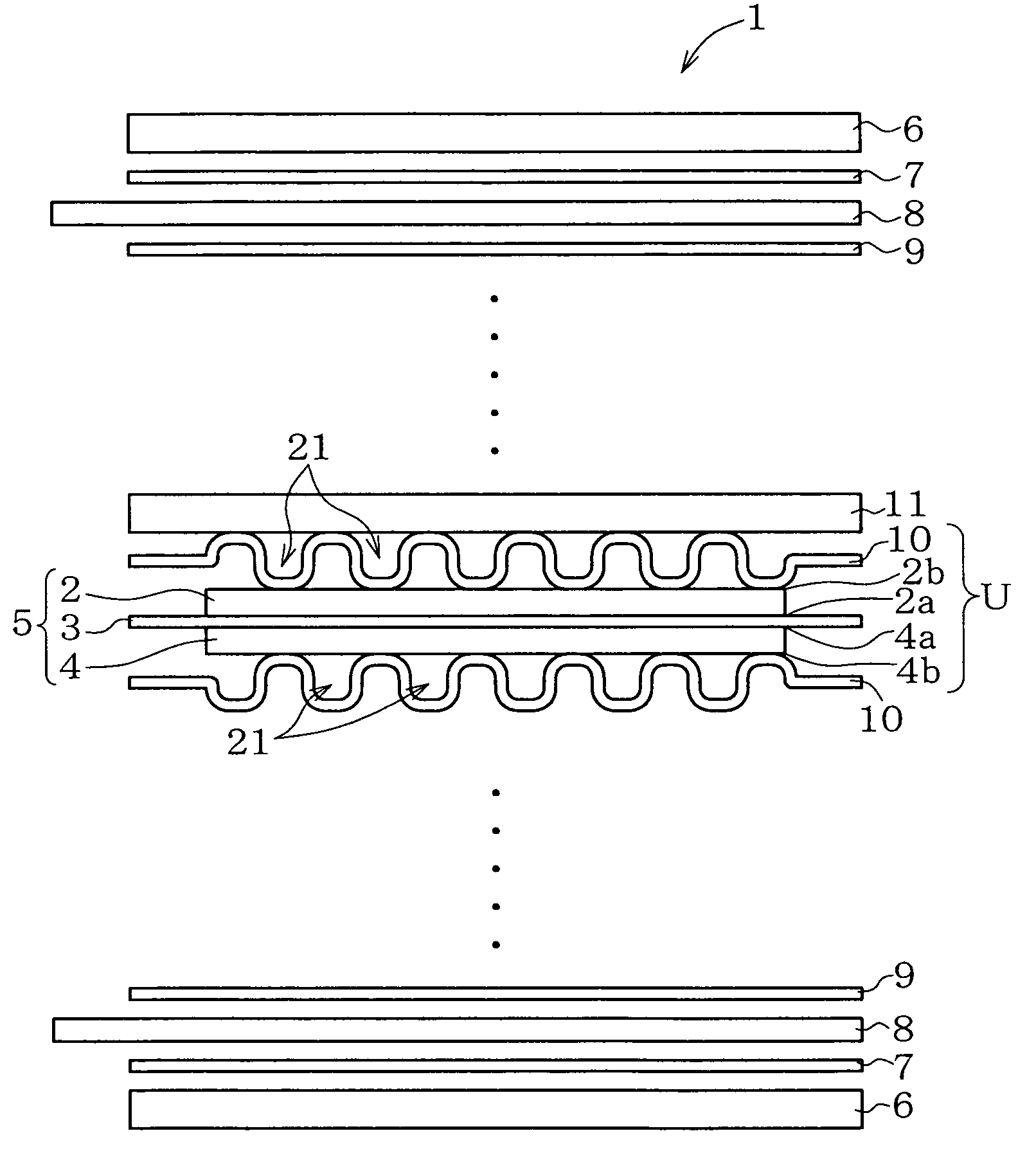

Aluminum alloy clad material

InactiveUS20110027610A1Small thicknessReduce weightWelding/cutting media/materialsCoatingsFilling materialsImpurity

Disclosed is an aluminum alloy clad material which includes a core material; a sacrificial anode material on one surface of the core material; and a filler material on the other surface of the core material and composed of an Al—Si alloy, in which the core material contains 0.3 to 2.0 percent by mass of Mn, 0.15 to 1.6 percent by mass of Si, 0.1 to 1.0 percent by mass of Cu, and 0.1 to 1.0 percent by mass of Mg, with the remainder including Al and inevitable impurities, the sacrificial anode material contains 7.0 to 12.0 percent by mass of Zn, 0.3 to 1.8 percent by mass of Mn, and 0.3 to 1.2 percent by mass of Si, with the remainder including Al and inevitable impurities, and has a thickness of 10 to 30 μm. The sacrificial anode material shows resistance to both local corrosion and general corrosion.

Owner:KOBE STEEL LTD

Chromate-Free Surface Treated Metal Material with Excellent Corrosion Resistance, Heat Resistance, Fingermark Resistance, Conductivity, Coatability, and Blackening Resistance at the Time of Working

InactiveUS20090110921A1Satisfy corrosion resistanceLayered productsMetallic material coating processesAdditive ingredientPhosphoric acid

The present invention provides a metal material given a chrome-free surface treatment satisfying all of the requirements of corrosion resistance, heat resistance, fingermark resistance, conductivity, coatability, and blackening resistance at the time of working, which was difficult to achieve with conventional chromate-free technology. The chromate-free surface treated metal material of the present invention is comprised of a metal material on the surface of which is coated and dried an aqueous metal surface treatment agent comprising an organic silicon compound (W), obtained by blending a silane coupling agent (A) containing one amino group in its molecule and a silane coupling agent (B) containing one glycidyl group in its molecule in a solid weight ratio [(A) / (B)] of 0.5 to 1.7, at least one type of fluorocompound (X) selected from fluorotitanic acid or fluorozirconic acid, phosphoric acid (Y), and a vanadium compound (Z) so as to form a composite coating containing the different ingredients.

Owner:NIPPON STEEL CORP

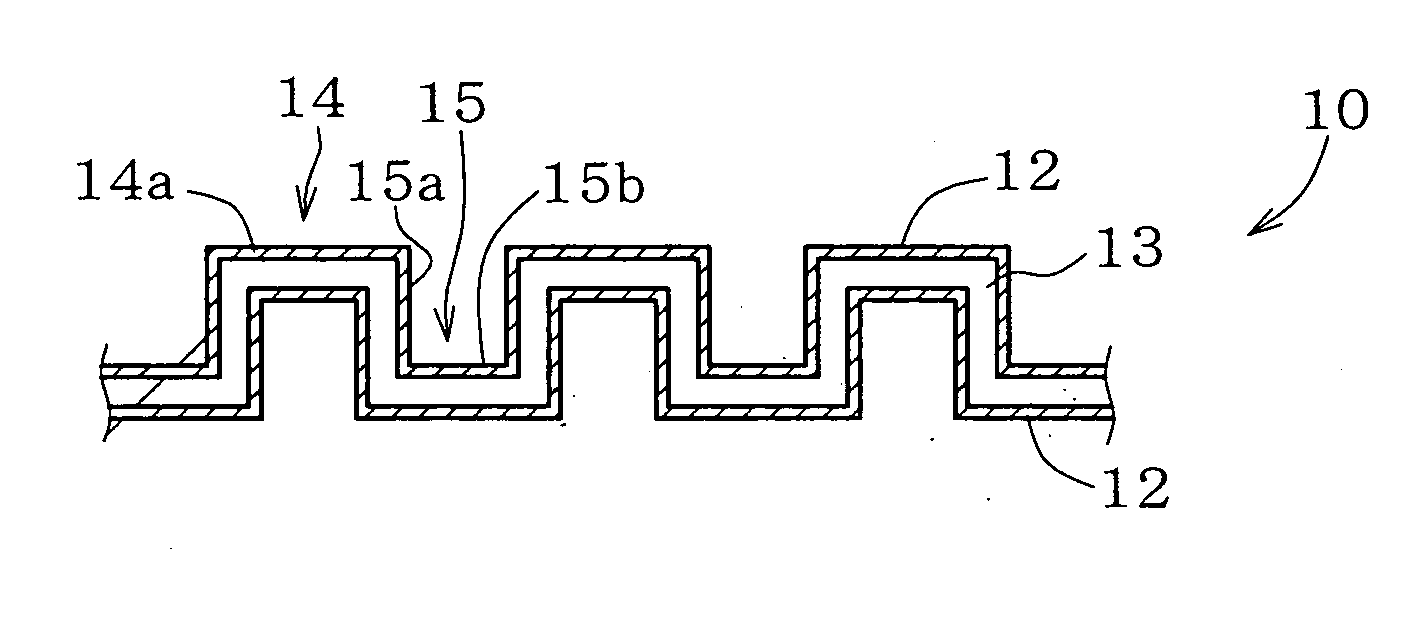

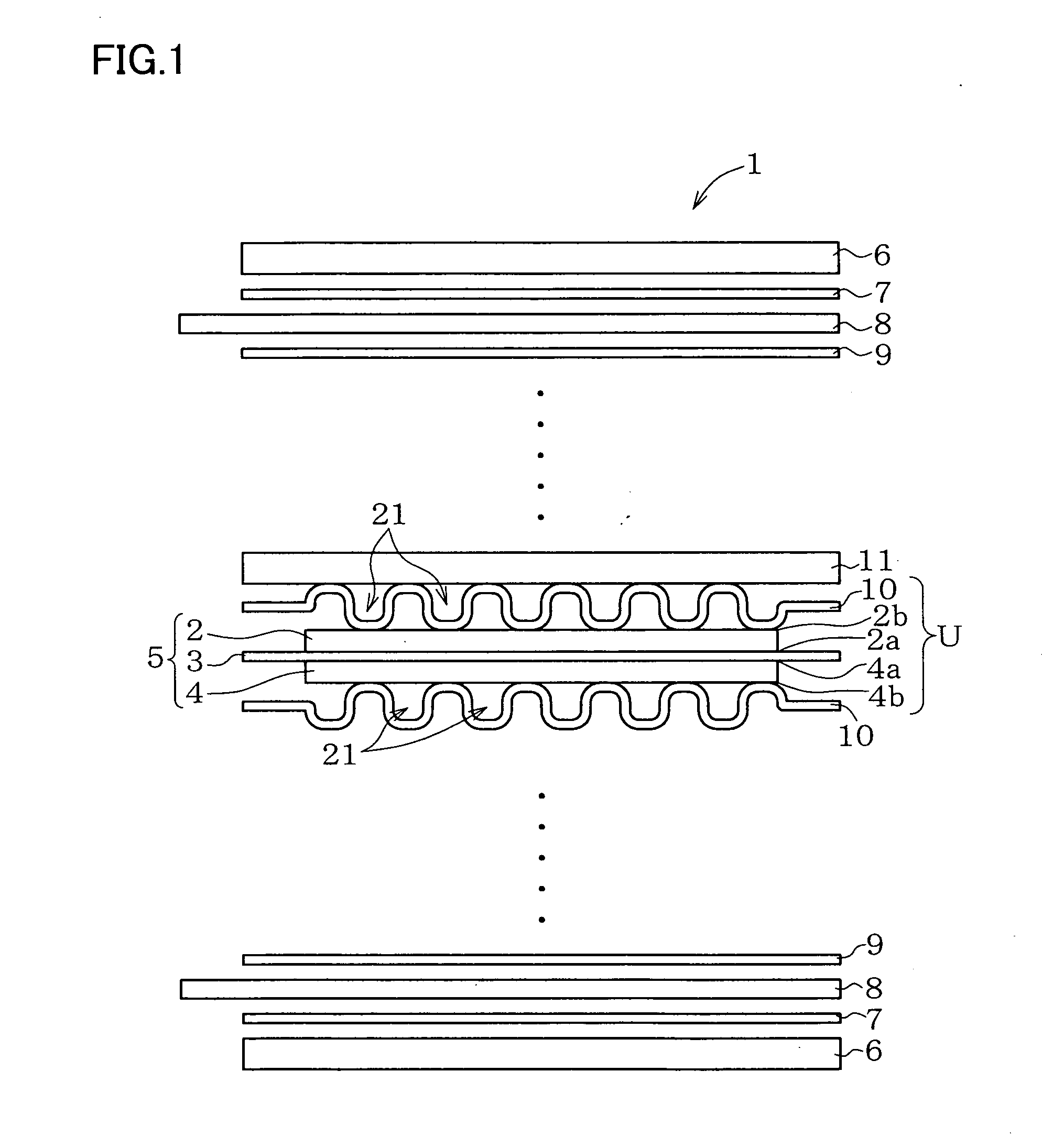

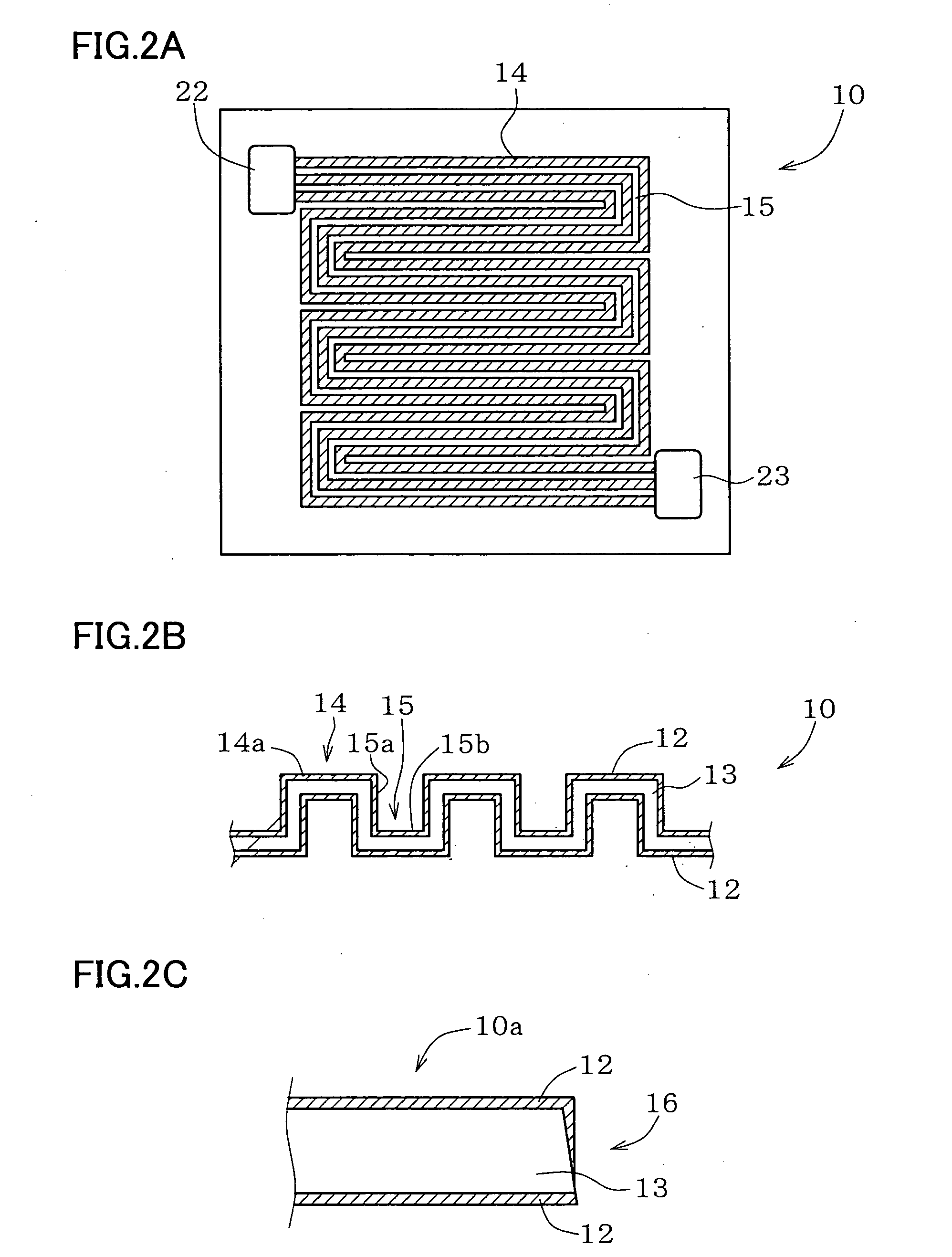

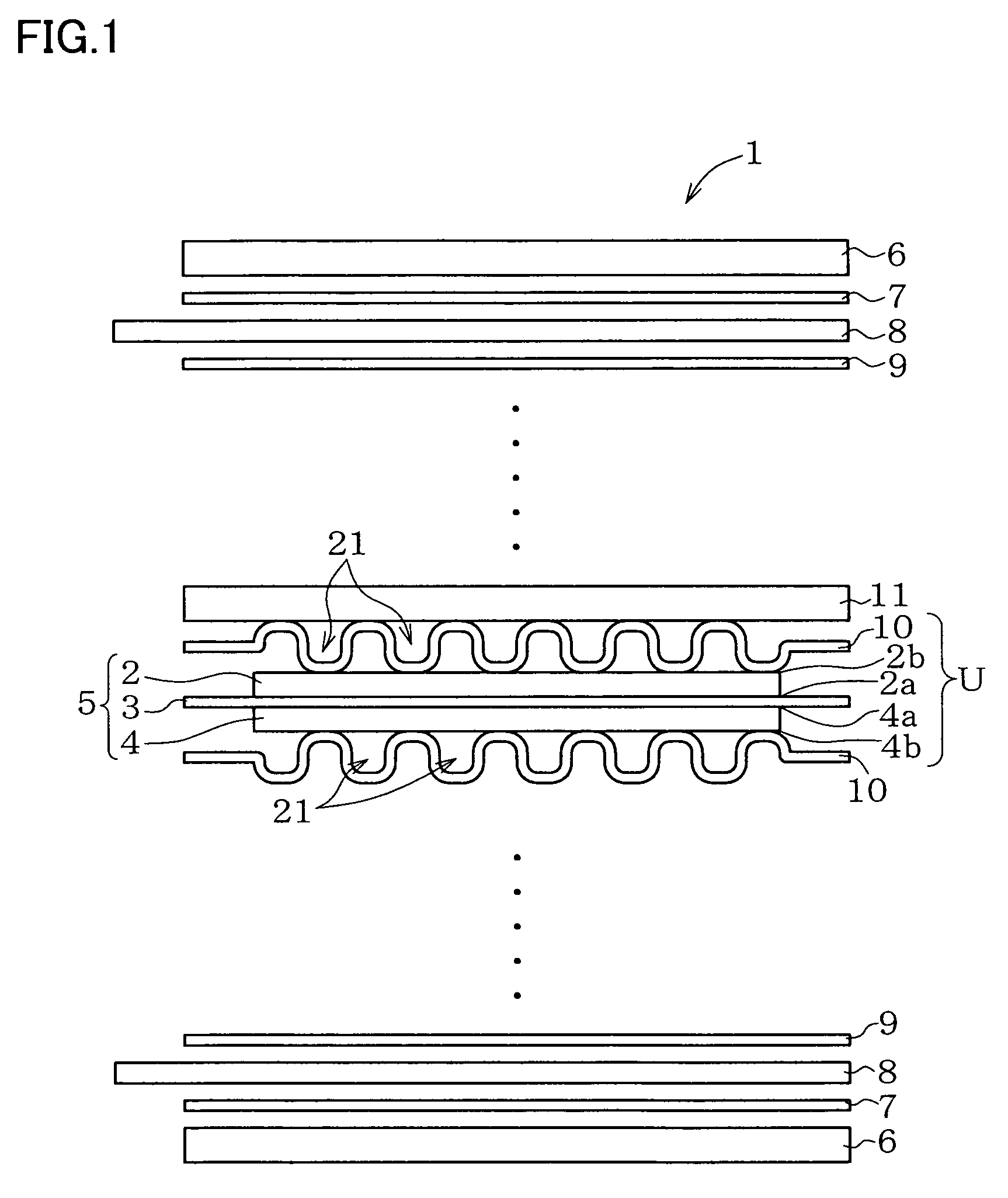

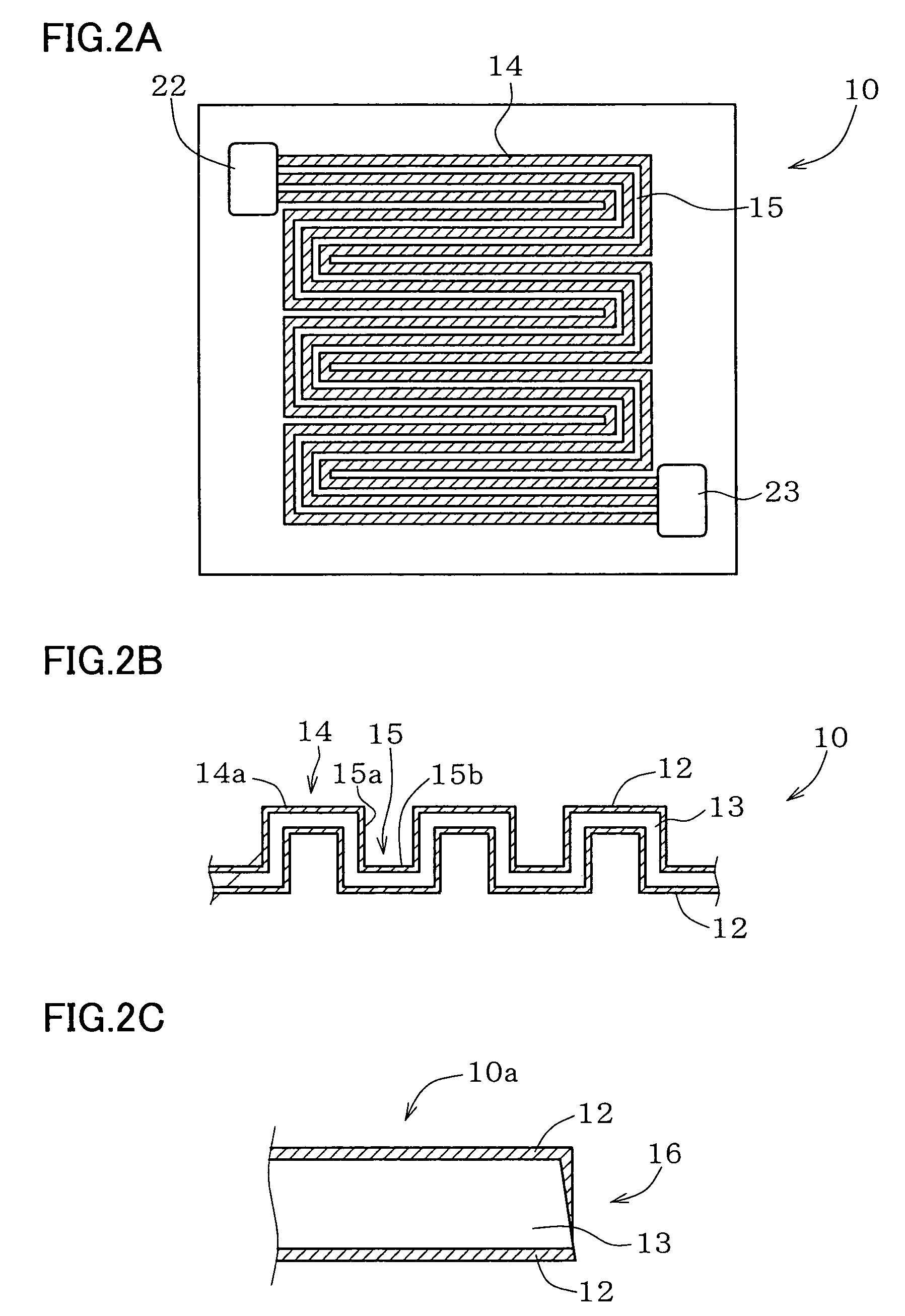

Metal component for fuel cell and method of manufacturing the same, austenitic stainless steel for polymer electrolyte fuel cell and metal component for fuel cell material and method of manufacturing the same , corrosion-resistant conductive component and method of manufacturing the same, and fuel cell

InactiveUS20060159971A1Satisfy corrosion resistanceSimple processFinal product manufactureFuel cell auxillariesFuel cellsAustenite

An Au plated film 12 is formed on the surface of a plate-formed metal base 13 composed of a metal less noble than Au, and the product is cut along a planned cutting line 18 reflecting a contour of a desired component, to thereby form a separator 10. Thus-formed separator 10 has the Au plated film 12 formed on the main surface 10a thereof, and has a cutting plane 16 formed as an end face 16 stretched up to the main surface 10a. The metal base 13 exposes in a part of the cutting plane 16, in a width of the exposed region of 1 mm or less. This is successful in providing a metal component for fuel cell which is satisfactory in the corrosion resistance and allows easy fabrication at low costs, a method of manufacturing the same, and also in providing a fuel cell having thus-fabricated metal component for fuel cell.

Owner:DAIDO STEEL CO LTD

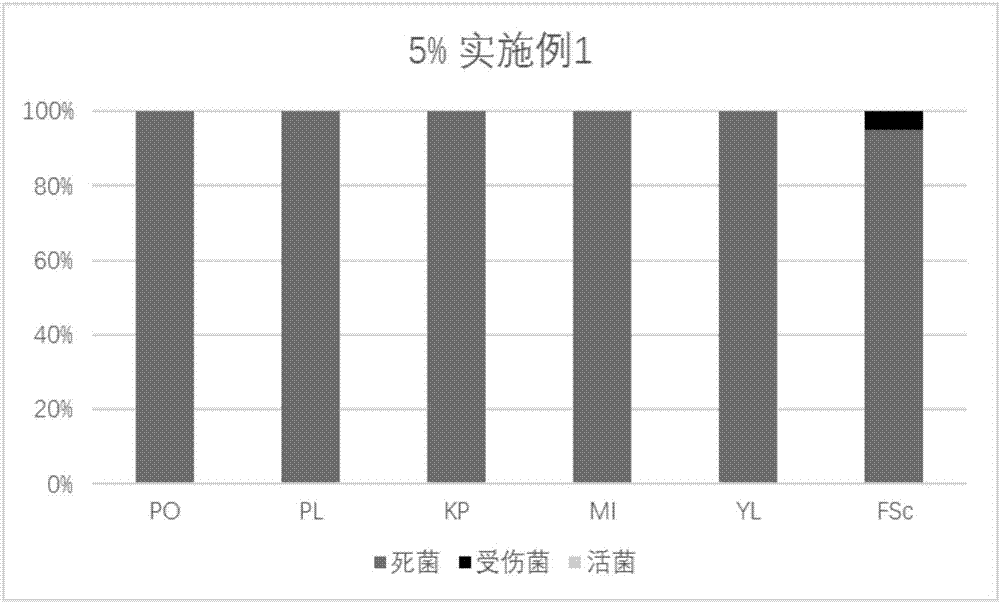

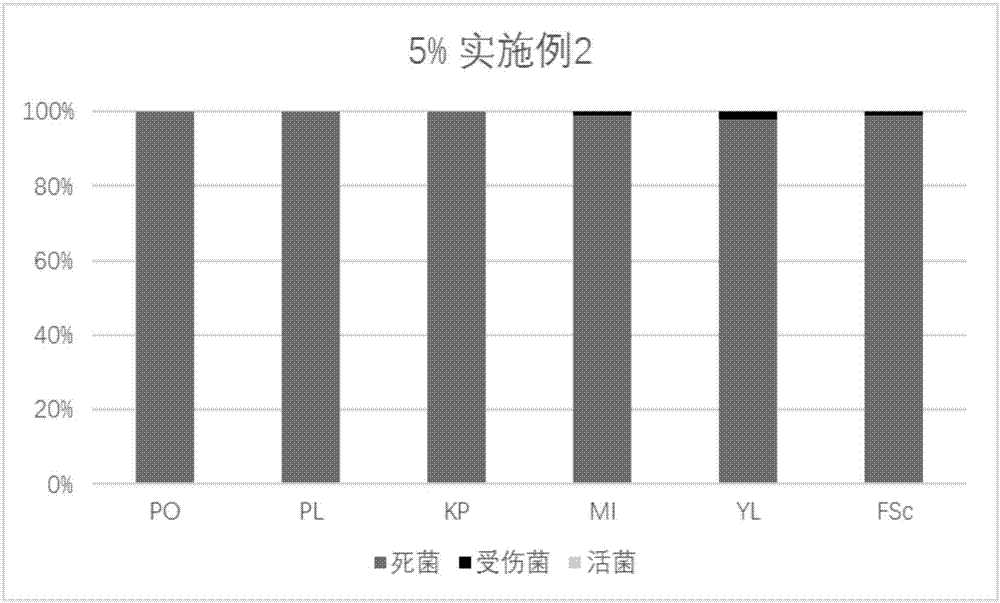

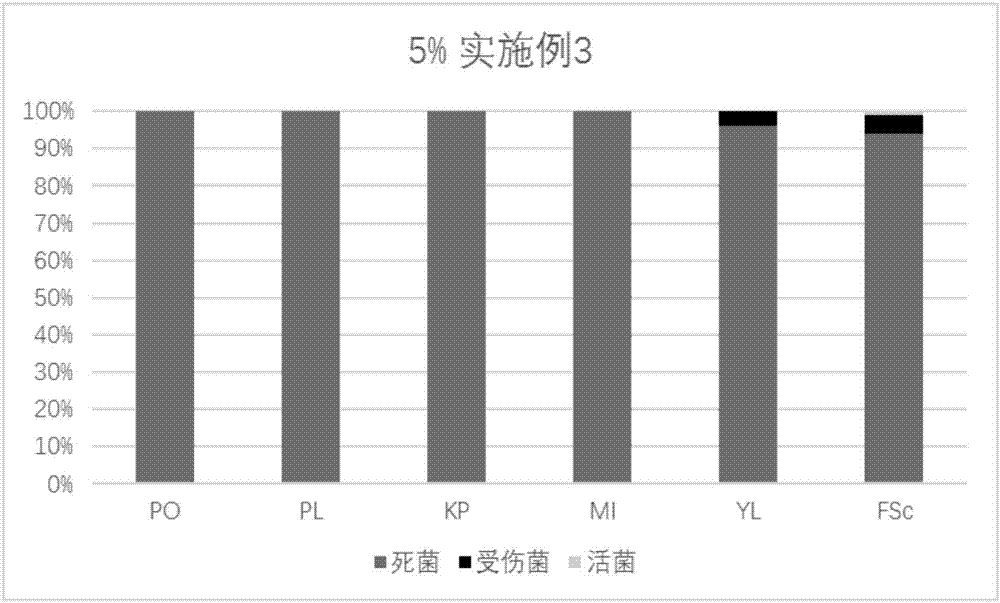

Composite fungicide and metal cutting fluid with same and preparation method of composite fungicide

ActiveCN107125249AImprove the bactericidal effectOvercoming the problem of poor sterilization effectBiocideDead animal preservationKetoneLubrication

The invention provides a composite fungicide and metal cutting fluid with the same and a preparation method of the composite fungicide. The composite fungicide comprises 1,2-benzisothiazole-3-ketone, epsilon-polylysine and water-soluble organic amino. In the composite fungicide provided by the invention, the three components, namely the 1,2-benzisothiazole-3-ketone, the epsilon-polylysine and the water-soluble organic amino are synergistic, so that the sterilization effect of the composite fungicide is improved; and the metal cutting fluid with the composite fungicide is good in sterilization effect, remarkable in biological stability, high in security and wide in application prospect, meets on-site process requirements such as lubrication, cooling, emulsion stability and corrosion resistance, and meets ideas of green chemicals.

Owner:QUAKER CHEM CHINA

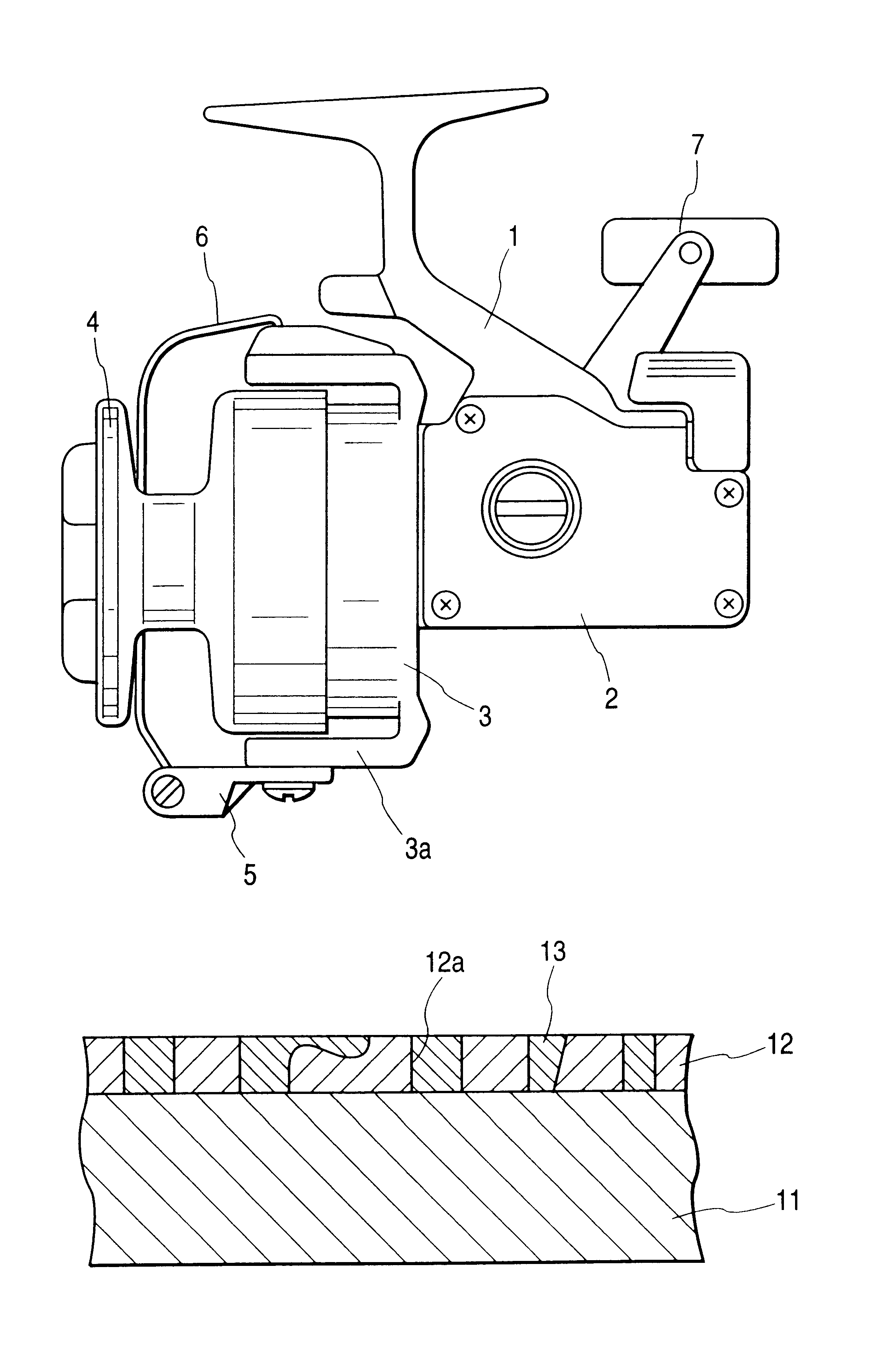

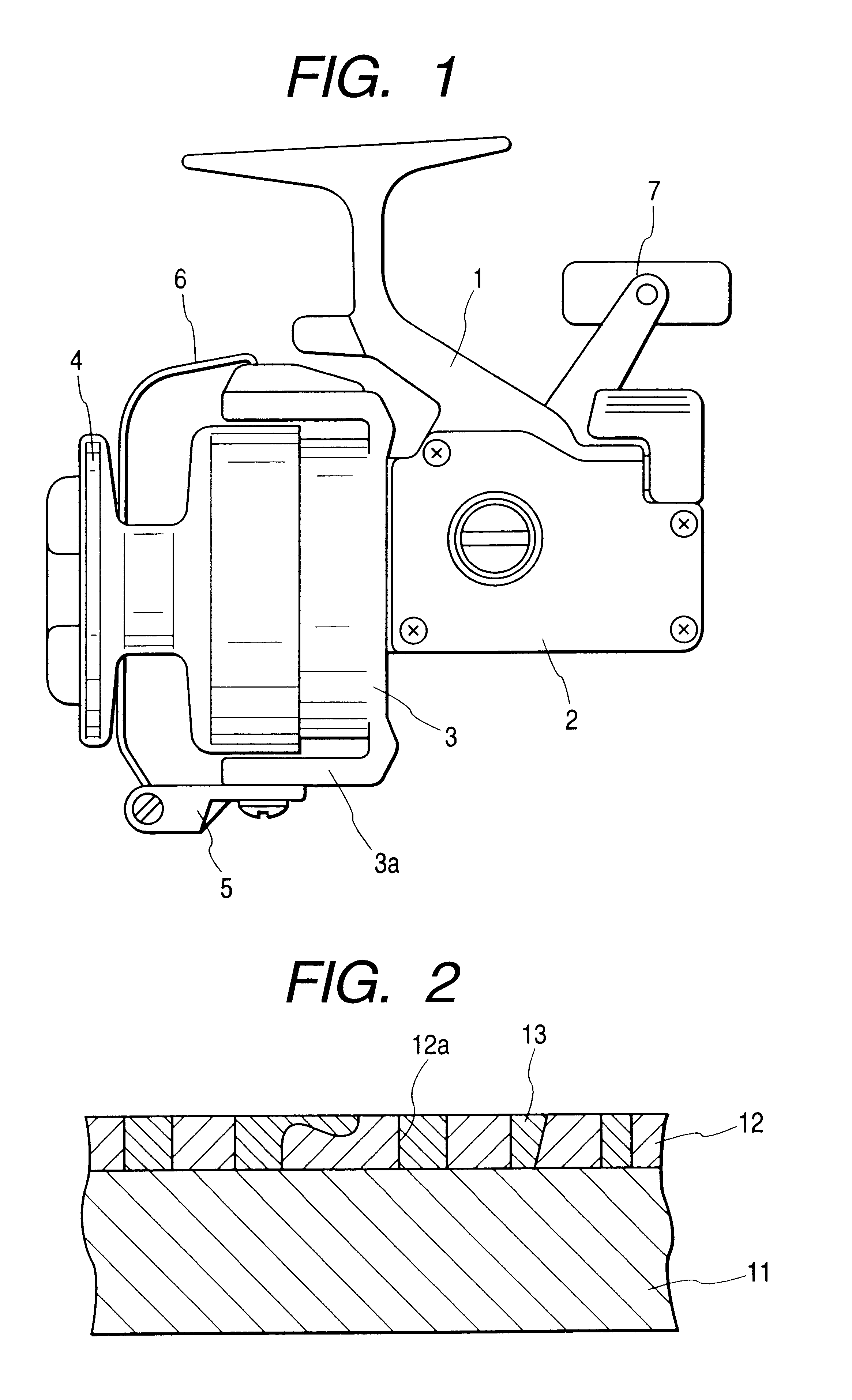

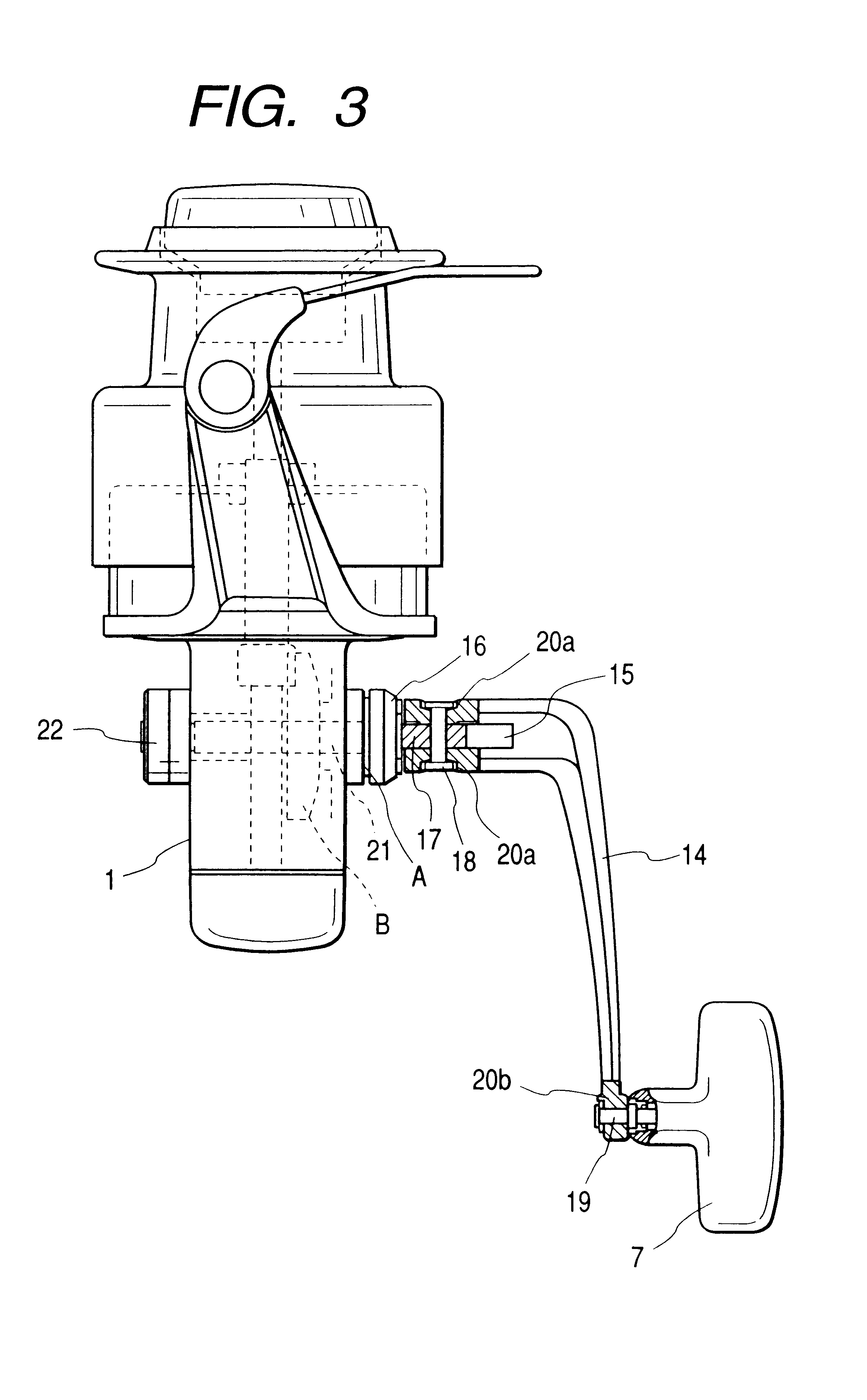

Component member of fishing reel

A component member of a fishing reel incorporating a body constituted by a Mg alloy; and a corrosion prevented layer formed on the body by a high-voltage anodization process or a body constituted by a Mg alloy; a corrosion prevented layer formed on the body by a high-voltage anodization process or conversion treatment; and a sealing layer which is formed on the corrosion prevented layer by an impregnating process and which is free from any change in the dimension thereof.

Owner:DAIWA SEIKO CORPORATION

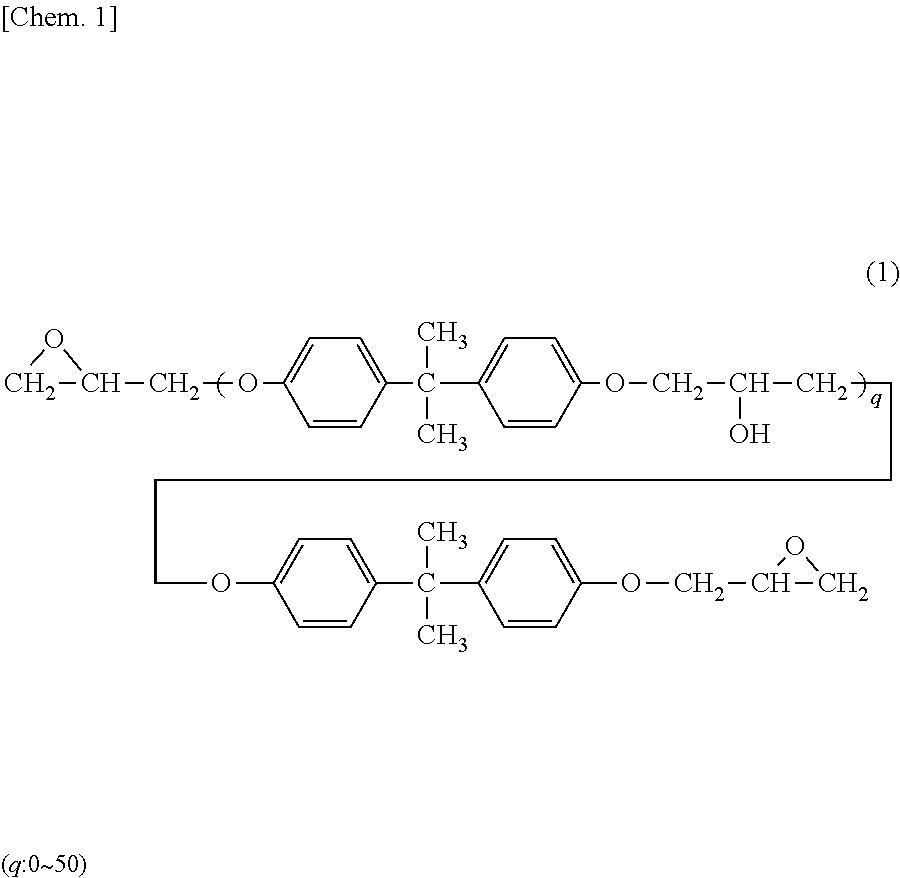

Hot-dip galvanized steel sheet and method for producing the same

ActiveUS20130273389A1Improve conductivitySolve the lack of corrosion resistanceHot-dipping/immersion processesPolyurea/polyurethane coatingsHot-dip galvanizationSilane coupling

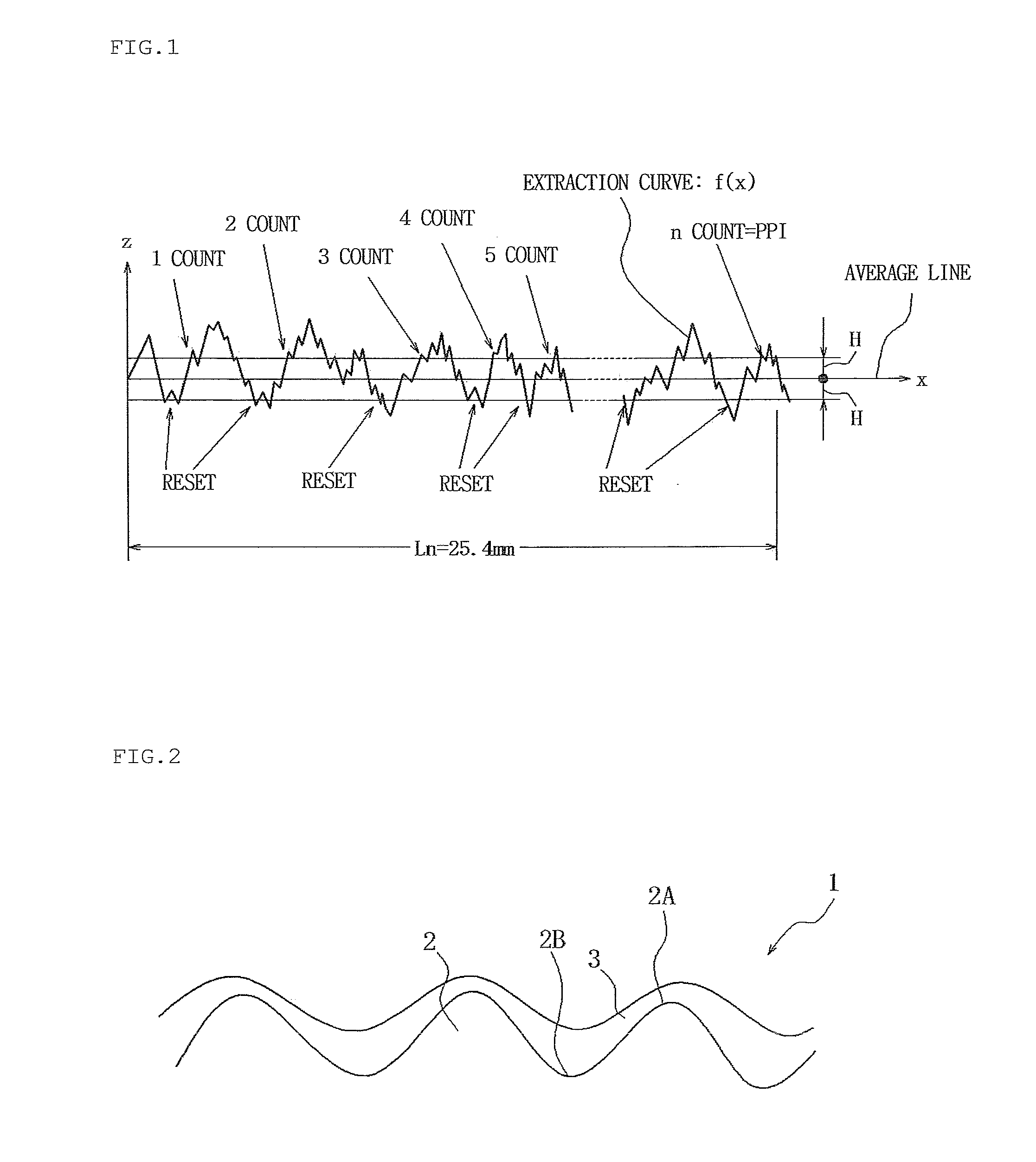

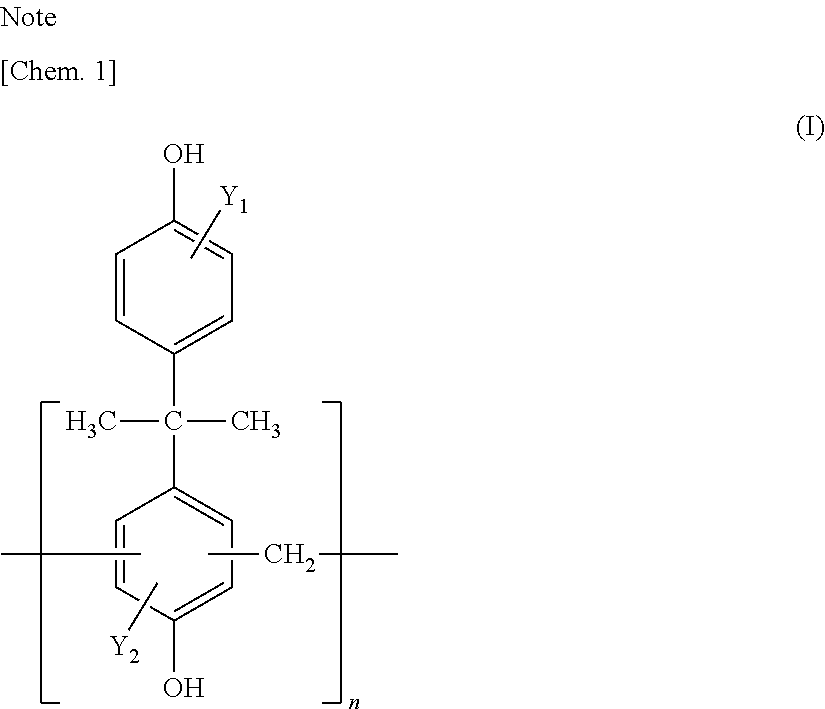

A method of producing a hot-dip galvanized steel sheet includes applying, to a hot-dip galvanized steel sheet having a Ra of 0.5 to 2.0 μm and a PPI of 150 or more, a predetermined surface treatment agent, i.e., a surface treatment agent containing a specified resin compound, a specified urethane resin having cationy, a specified silane coupling agent having a functional group, a specified organic Ti chelate compound, and a tetravalent vanadyl compound at a specified ratio; and drying the surface treatment agent at a ultimate sheet temperature of 50° C. to 180° C. to form a surface treatment coating film with a coating weight of 0.2 to 1.0 g / m2 on the surface of the steel sheet.

Owner:JFE STEEL CORP

Three-dimensional greening light-weight nutrient soil column and preparation method thereof

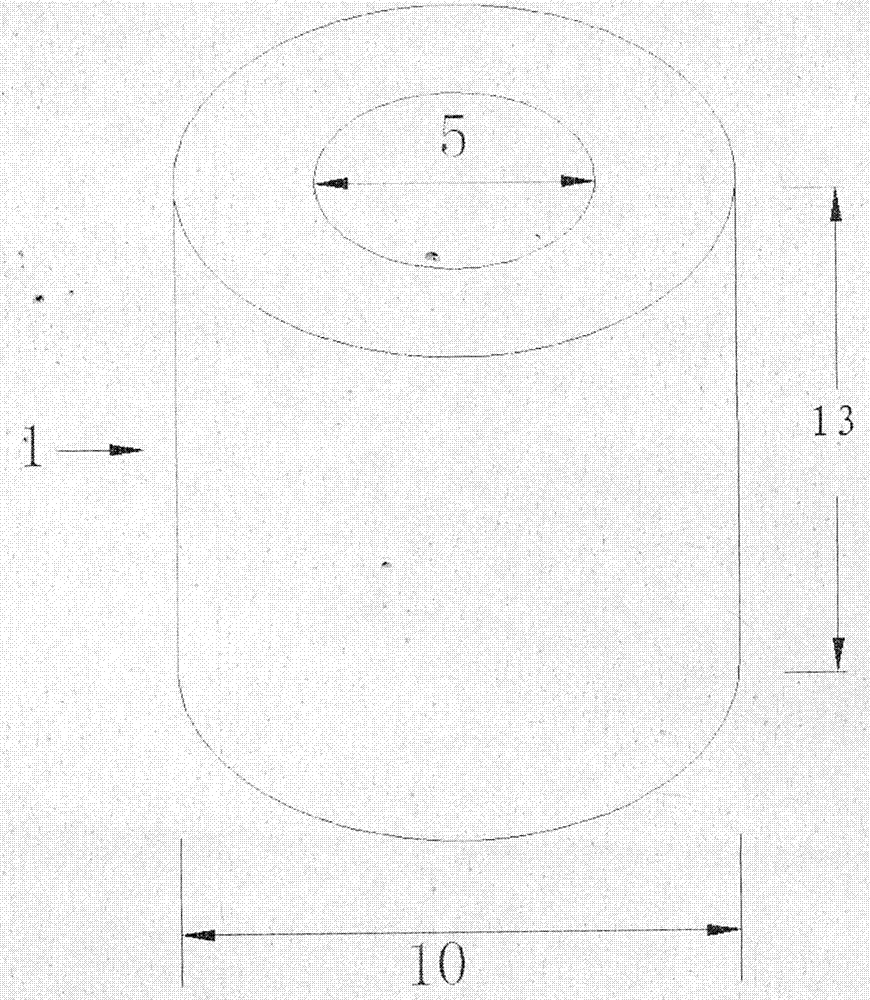

InactiveCN103688788AReduce weightCorrosion resistantCultivating equipmentsFertilizer mixturesAdditive ingredientPotassium

The invention relates to the technical field of soil column processing, in particular to a three-dimensional greening light-weight nutrient soil column and a preparation method thereof. The three-dimensional greening light-weight nutrient soil column comprises a soil column (1), wherein the soil column (1) is a cylindrical hollow soil column. The three-dimensional greening light-weight nutrient soil column is characterized in that the soil column (1) is formed by mixing, stirring and compressing water, substrates and bonding agents, the weight ratio of the water to the substrates is (1-2):(48-49), and the volume ratio of the bonding agents to the substrates is 2:8. The substrates of the soil column are formed by mixing saw dust, grass carbon, perlite, loess and organic fertilizers, various kinds of mineral nutrient ingredients required by plant growth are realized, nutrient elements such as nitrogen, phosphorus and potassium in atmosphere can also be absorbed, the self nutrition is realized, the one-step and concentrated completion requirements of work such as cultivation, fertilization and maintenance are met, and the soil column has the characteristics of light weight, good water retention and fertilizer retention performance, durable modeling, corrosion resistance and the like, and meets indoor and outdoor three-dimensional greening requirements. The invention also provides the preparation method of the three-dimensional greening light-weight nutrient soil column, and the preparation method has the advantages that the operation is simple, and the popularization is easy.

Owner:刘芳

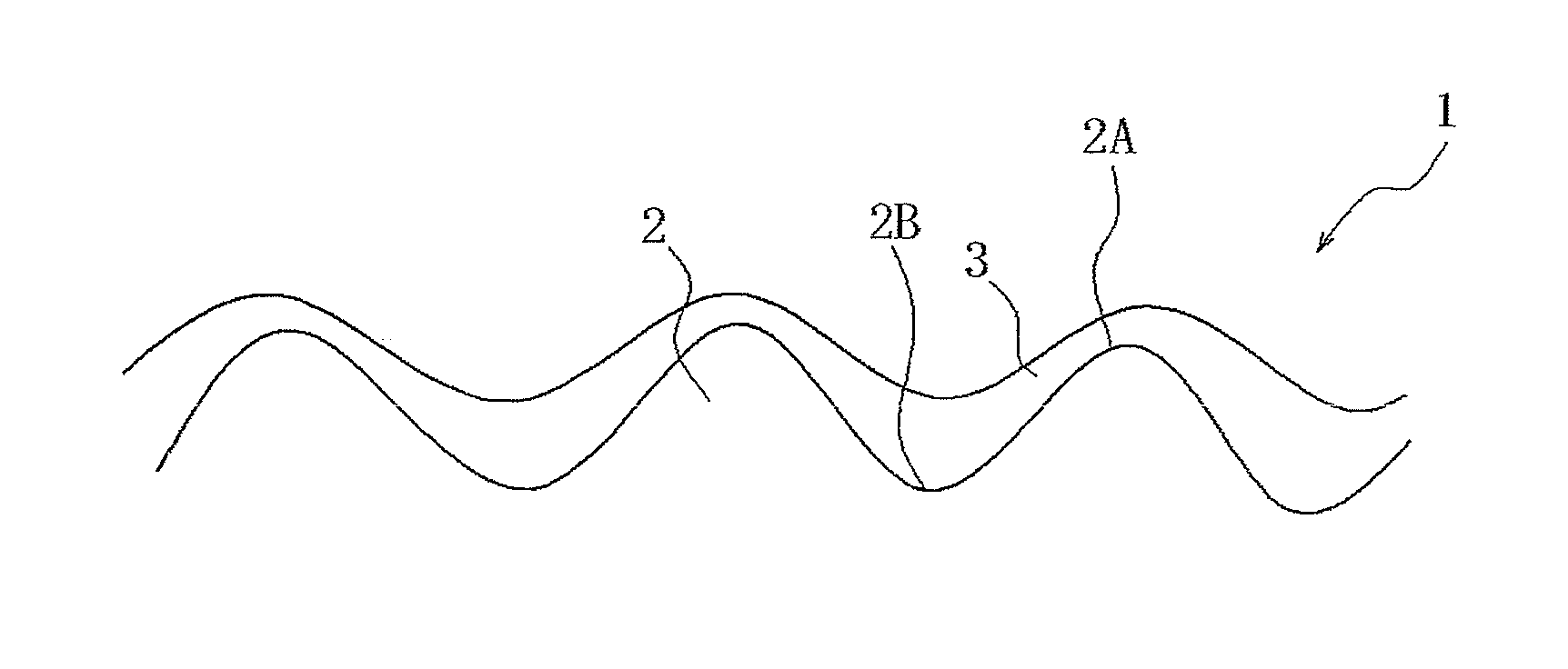

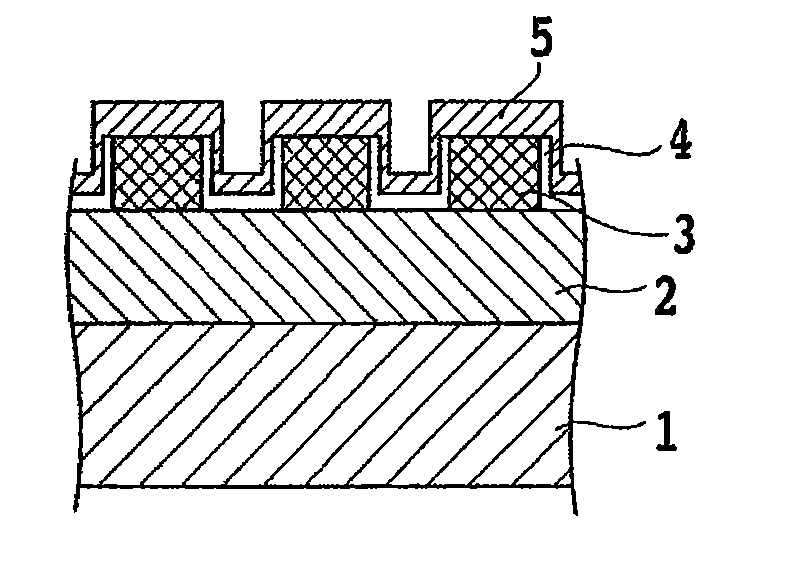

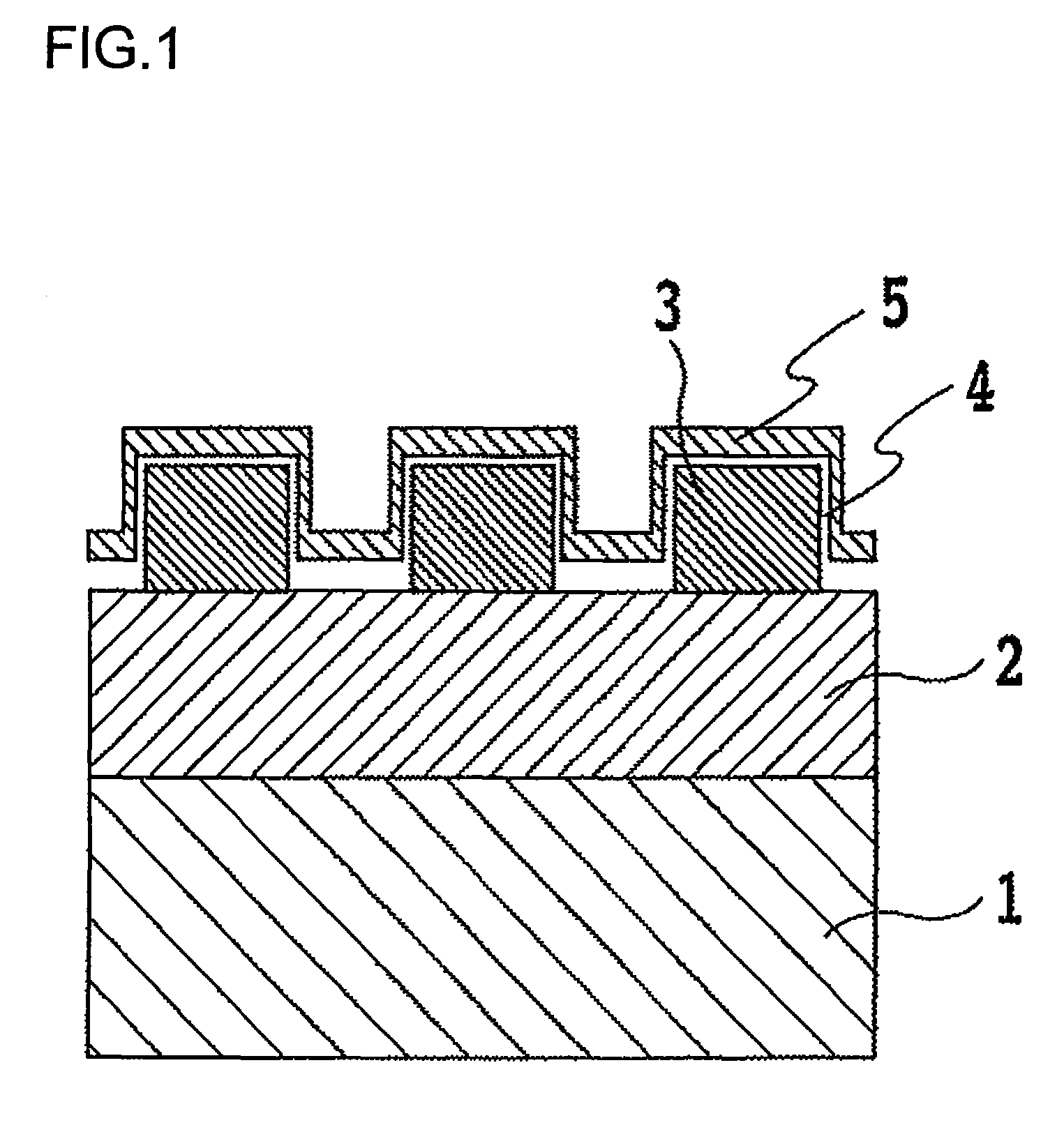

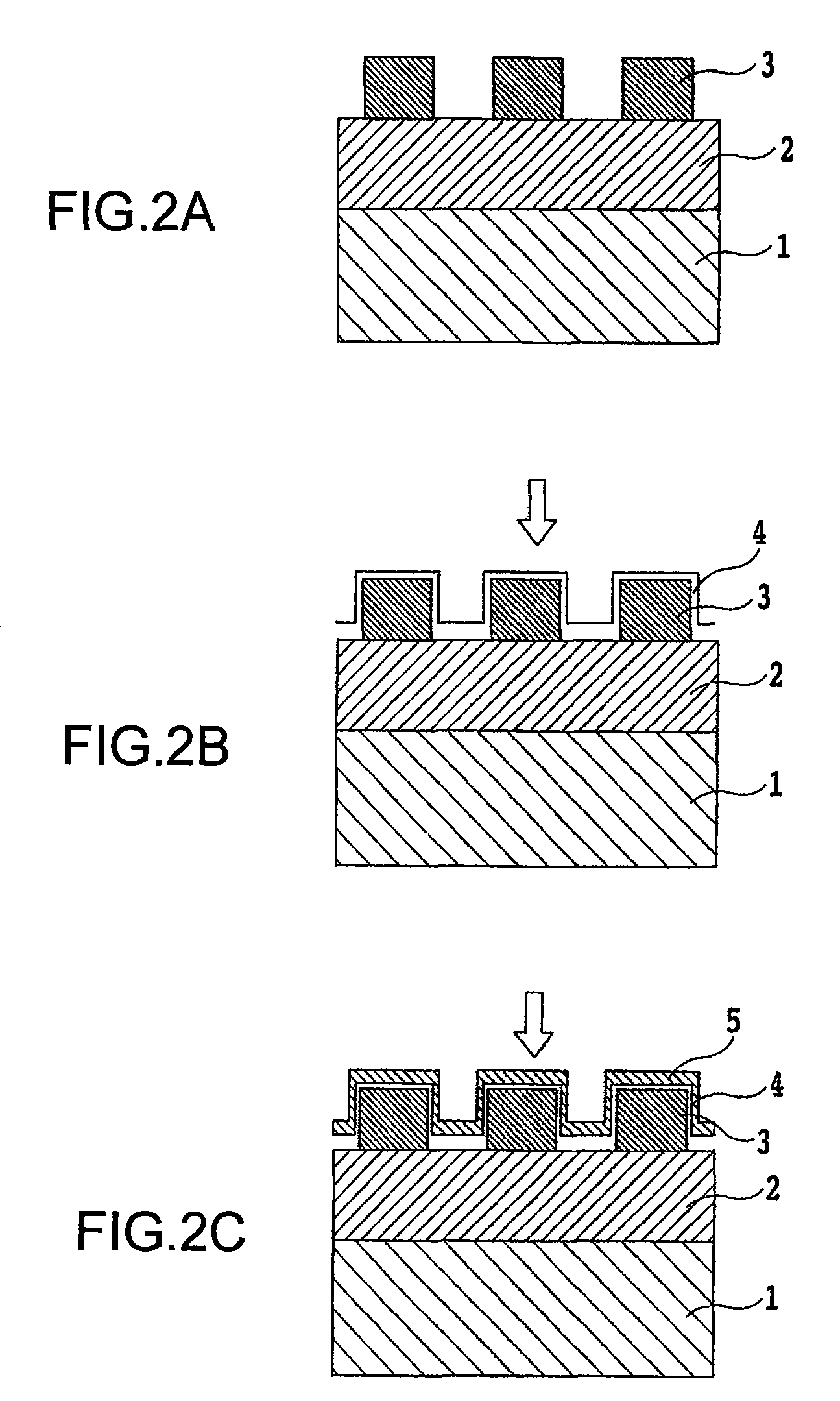

Magnetic recording medium and a method of manufacturing the same

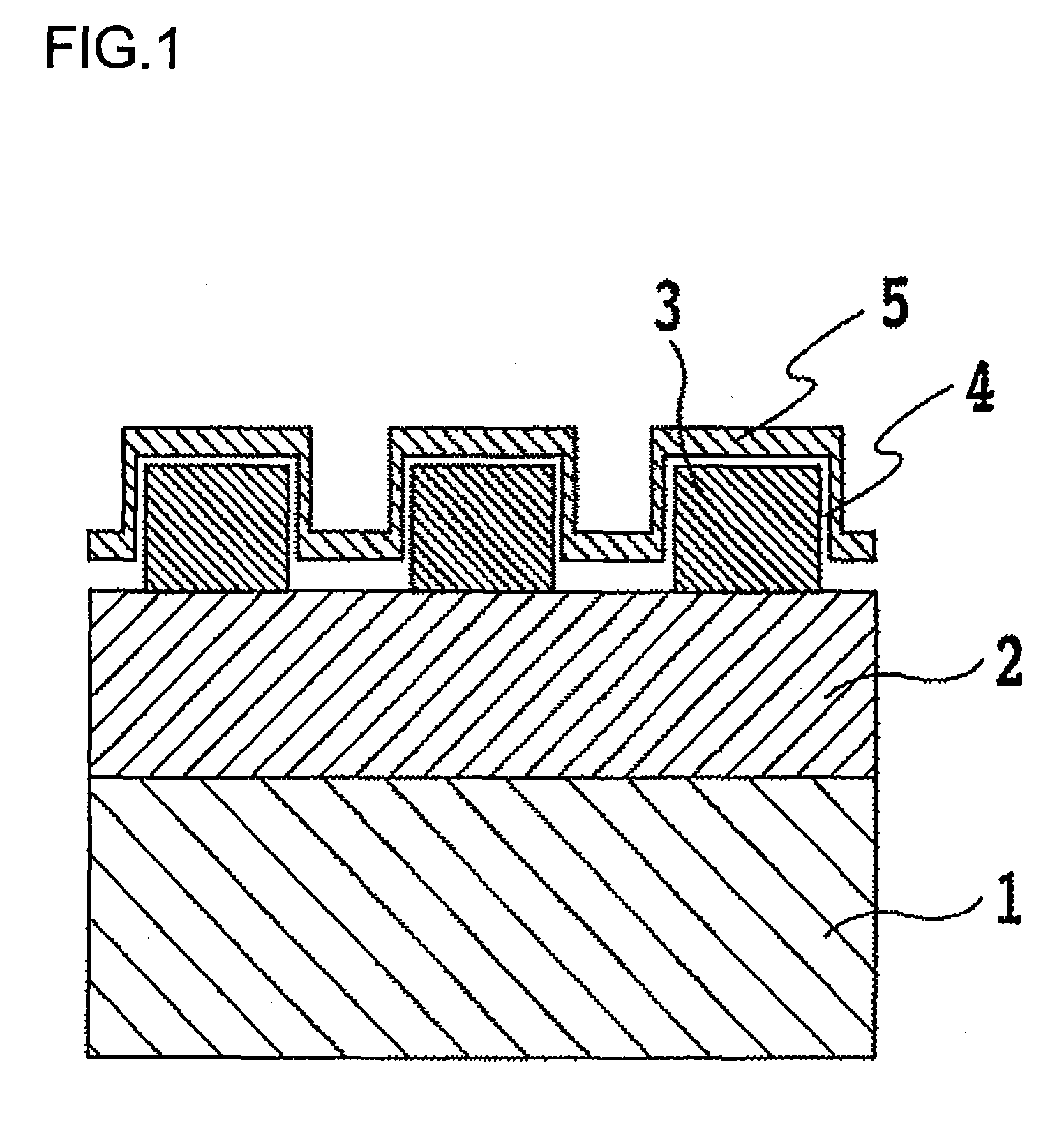

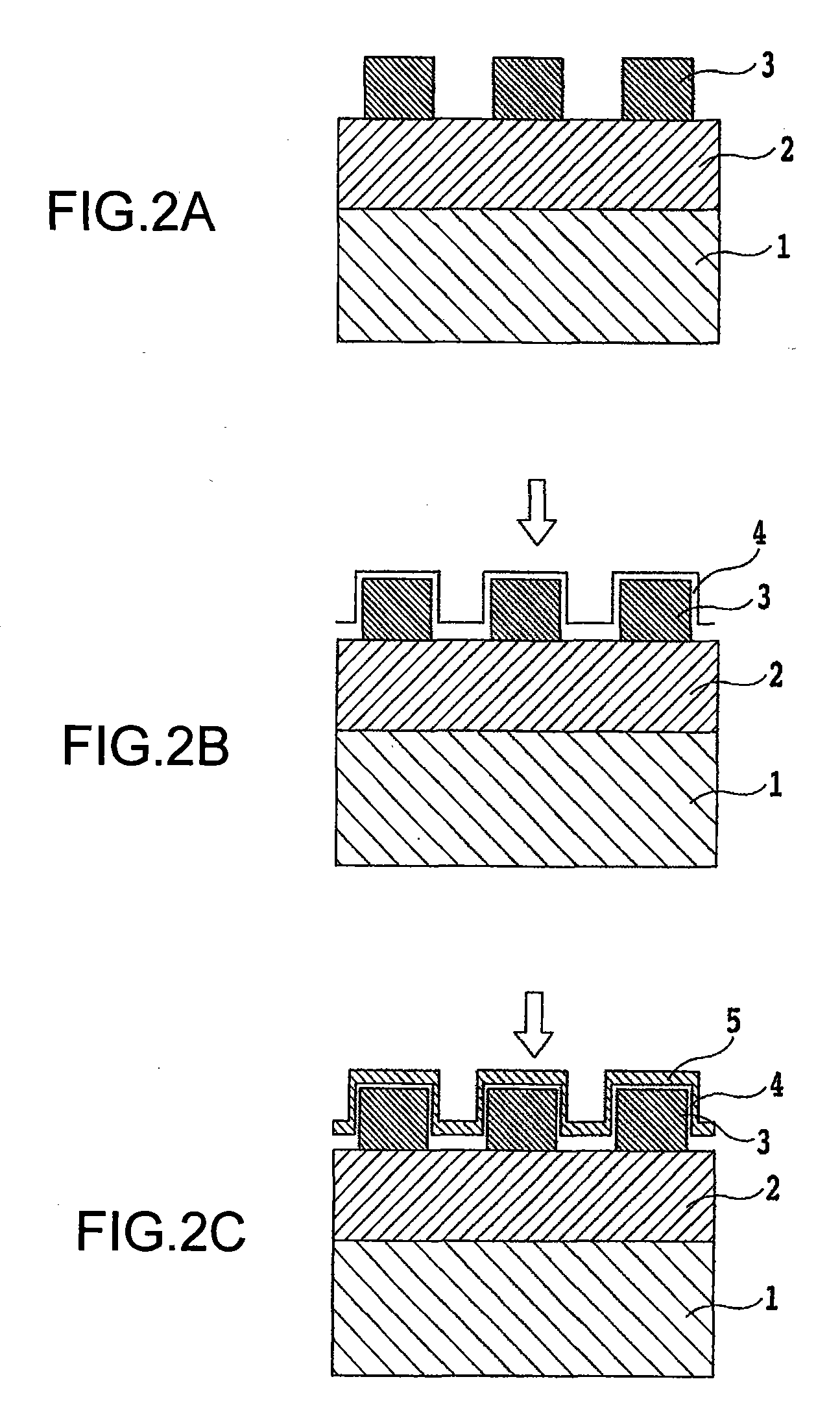

ActiveUS20080187779A1Satisfy corrosion resistanceReduce resistanceProtective coatings for layersVacuum evaporation coatingEngineeringRecording layer

A magnetic recording medium and a method of manufacturing a magnetic recording medium are provided, in which degradation of wear resistance against a magnetic head and performances of the medium is restrained, and metal dissolving out of the magnetic recording layer and degradation of corrosion resistance due to low coverage of a protective layer are suppressed. The method of manufacturing provides a magnetic recording medium having a convex portion of a magnetic recording layer for recording information and a concave portion without a recording function on a disk substrate. An ALD protective layer is formed on the magnetic recording medium using an ALD method. The magnetic recording medium has a convex portion of a magnetic recording layer for recording information and a concave portion without a recording function on a disk substrate, and has a protective layer formed by an ALD method on the concavo-convex pattern.

Owner:FUJI ELECTRIC CO LTD

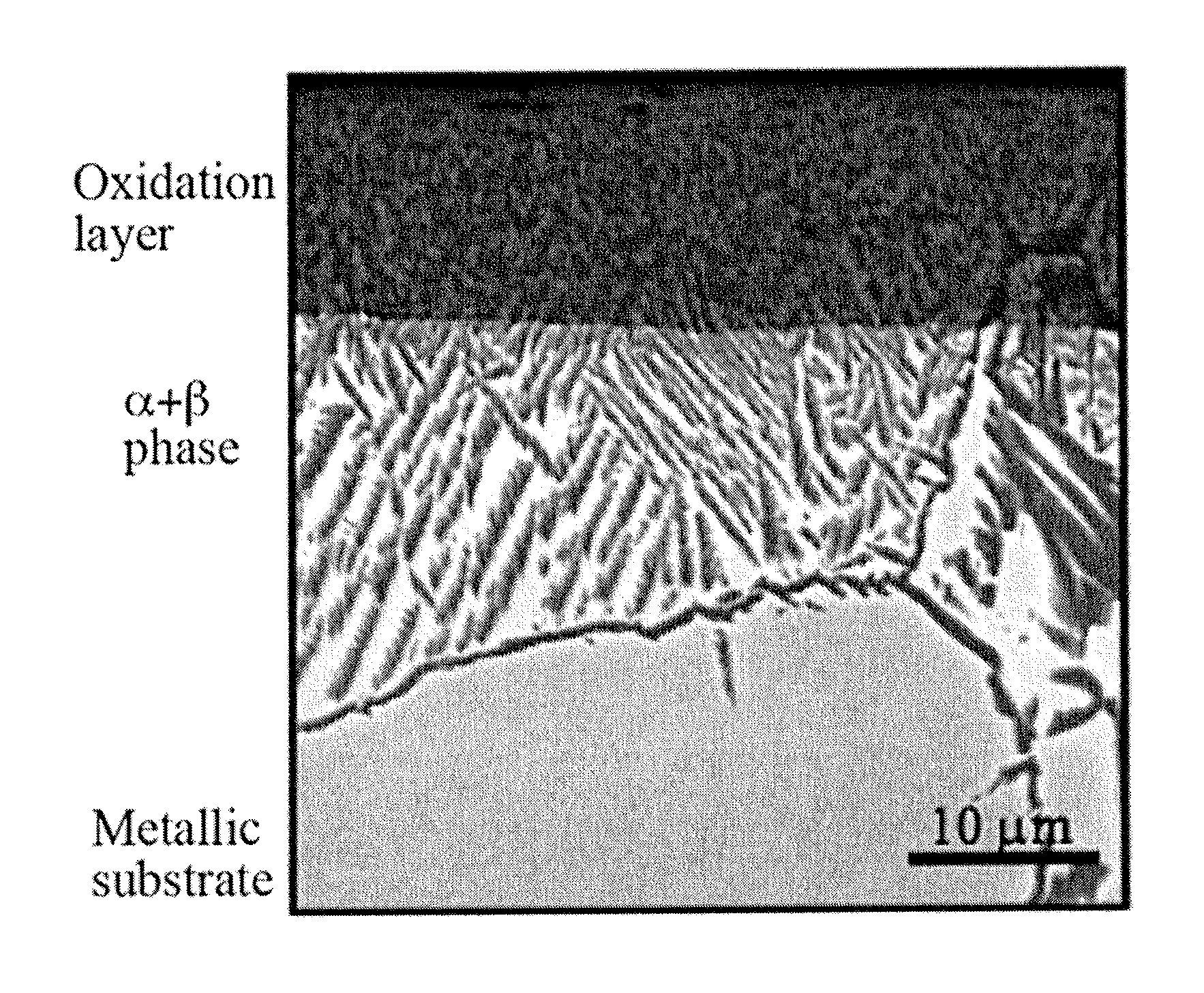

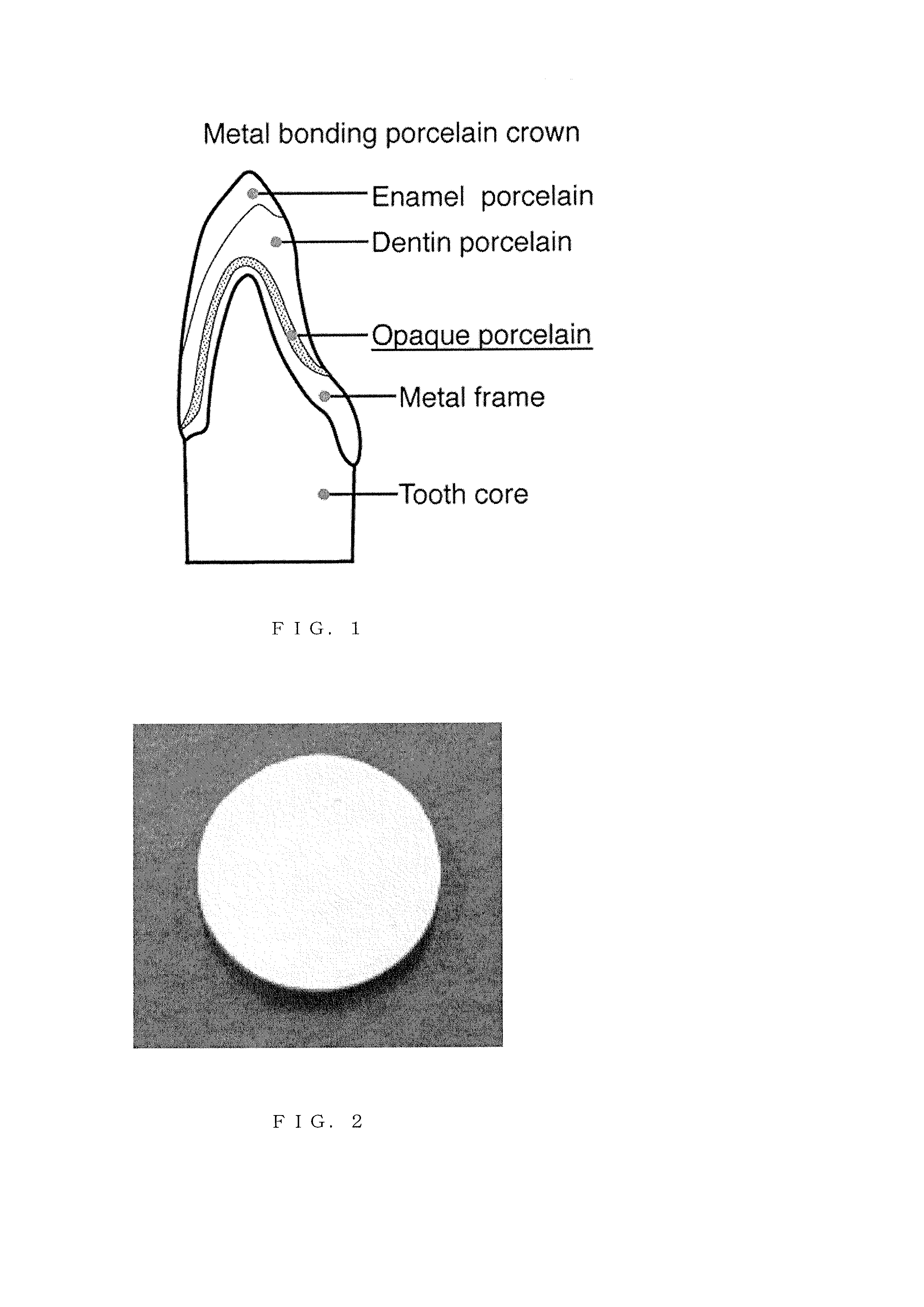

Composite material for dental prosthesis and method for manufacturing the same

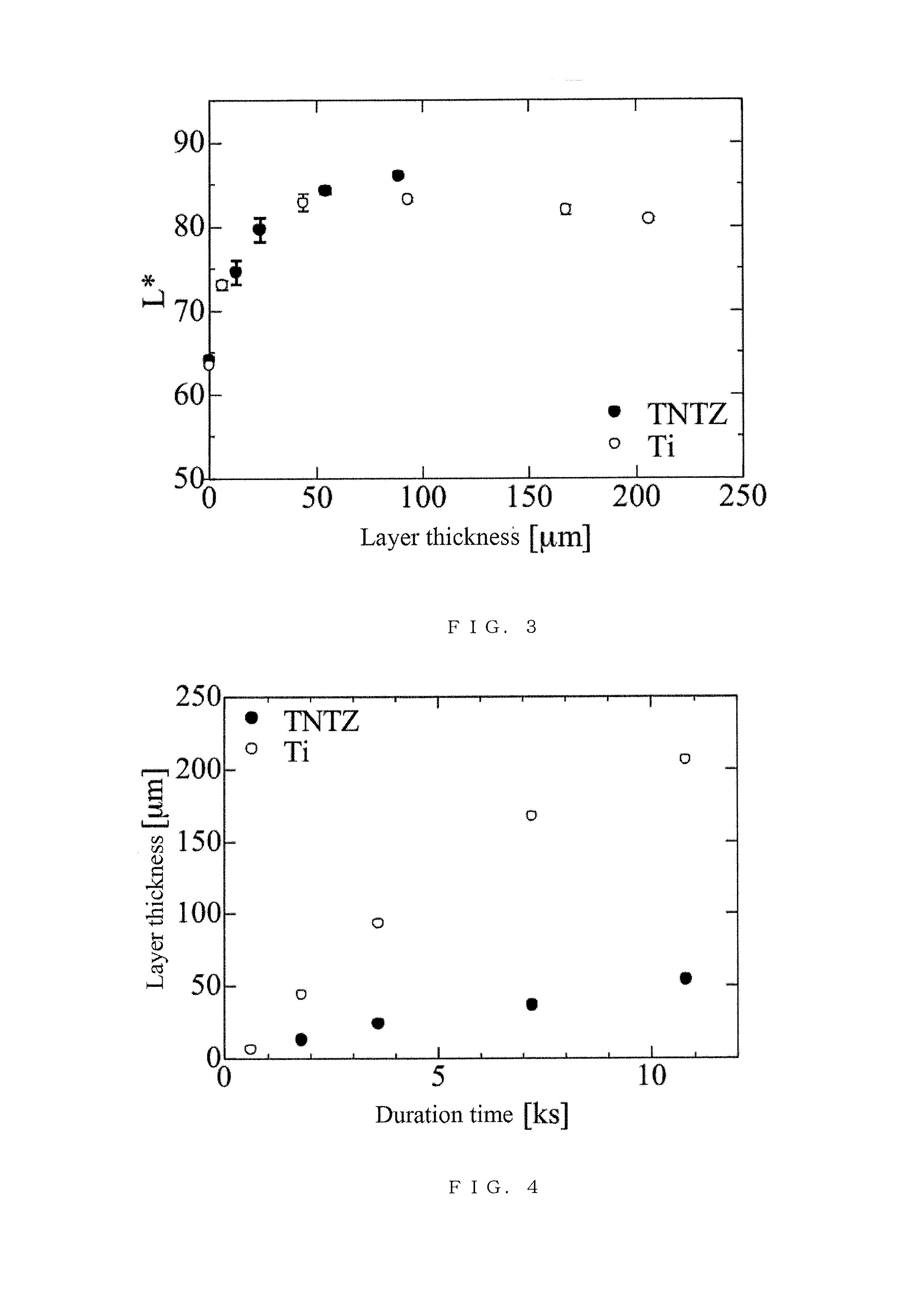

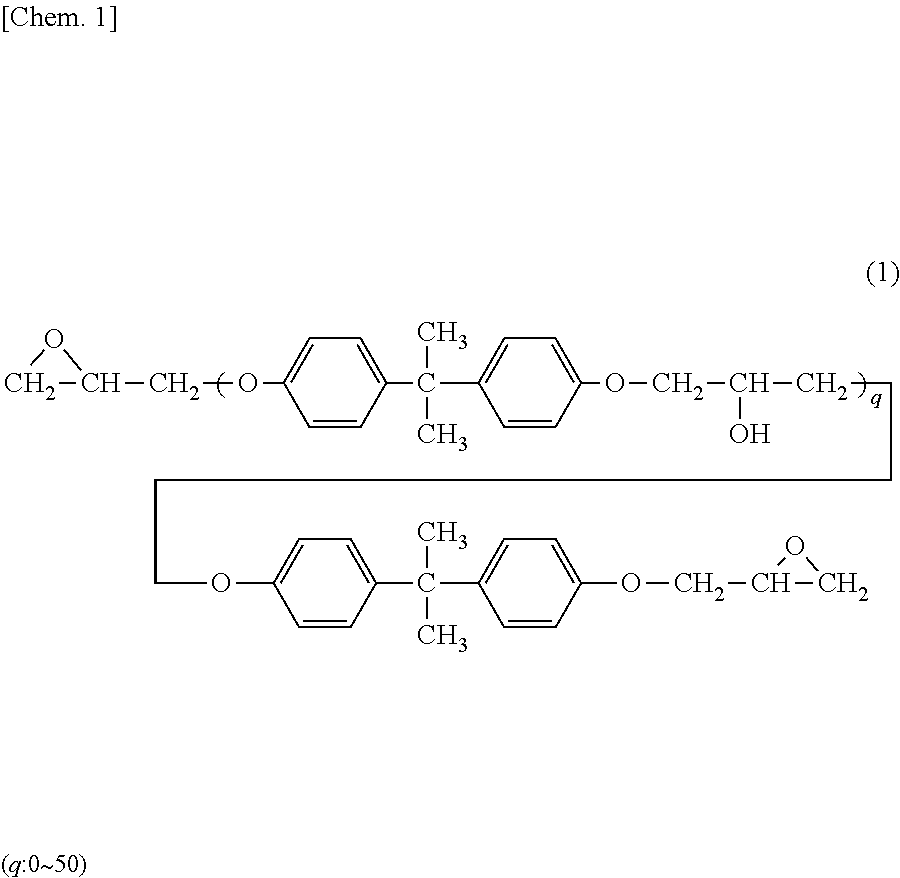

InactiveUS20130180627A1Improve aesthetic qualityMaintain strengthSolid state diffusion coatingMetal layered productsOxide compositeTitanium

Disclosed is a metal-metal oxide composite material for dental prosthesis, which has a white surface with good aesthetic quality and includes a titanium or titanium alloy substrate; and an oxidation layer present on a surface of the substrate. The metal-metal oxide composite material is manufactured by subjecting the substrate to a heat treatment at a temperature of around 1000° C. in an oxygen-containing atmosphere to form the oxidation layer on the surface of the substrate with good adhesion.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY

Aluminum alloy clad material

InactiveUS8668993B2Satisfy corrosion resistanceAvoid pittingWelding/cutting media/materialsCoatingsFilling materialsImpurity

Disclosed is an aluminum alloy clad material which includes a core material; a sacrificial anode material on one surface of the core material; and a filler material on the other surface of the core material and composed of an Al—Si alloy, in which the core material contains 0.3 to 2.0 percent by mass of Mn, 0.15 to 1.6 percent by mass of Si, 0.1 to 1.0 percent by mass of Cu, and 0.1 to 1.0 percent by mass of Mg, with the remainder including Al and inevitable impurities, the sacrificial anode material contains 7.0 to 12.0 percent by mass of Zn, 0.3 to 1.8 percent by mass of Mn, and 0.3 to 1.2 percent by mass of Si, with the remainder including Al and inevitable impurities, and has a thickness of 10 to 30 μm. The sacrificial anode material shows resistance to both local corrosion and general corrosion.

Owner:KOBE STEEL LTD

Zinc-based metal coated steel sheet

ActiveUS20130302637A1Improve adhesionImprove corrosion resistancePretreated surfacesAnti-corrosive paintsHydrogenEmulsion

A surface treatment liquid contains a resin emulsion that contains a cationic urethane resin emulsion and / or a nonionic acrylic resin emulsion, a tetraalkoxysilane, at least one silane coupling agent (c) that contains at least one reactive functional group selected from active hydrogen-containing amino group, an epoxy group, a mercapto group, and a methacryloxy group, a chelating agent (d), a vanadic acid compound (e), a titanium compound (f), and water in a specific ratio. The surface treatment liquid has a pH of 3 to 6. The surface treatment liquid is applied to a surface of a zinc-based metal coated steel sheet and dried by heating to form a first layer. Next, a surface treatment liquid containing an organic resin is applied to a surface of the first layer and dried by heating to form a second layer.

Owner:JFE STEEL CORP

Zinc-based metal coated steel sheet

ActiveUS9127366B2Improve corrosion resistanceInhibit progressPretreated surfacesAnti-corrosive paintsPolymer scienceMeth-

Owner:JFE STEEL CORP

Nickel- based alloy with excellent corrosion resistance in inorganic-acid-containing supercritical water environment

A Ni based alloy with a composition including Cr: from more than 43% to 50% or less, Mo: 0.1% to 2%, Mg: 0.001% to 0.05%, N: 0.001% to 0.04%, Mn: 0.05% to 0.5%, and where necessary also including either one, or both, of Fe: 0.05% to 1.0% and Si: 0.01% to 0.1%, and the remainder as Ni and unavoidable impurities, in which the quantity of C amongst the unavoidable impurities is restricted to 0.05% or less. It has excellent corrosion resistance relative to supercritical water environments containing inorganic acids. Also provided is a member for a supercritical water process reaction apparatus comprises the Ni based alloy.

Owner:MITSUBISHI MATERIALS CORP

Novel aluminum alloy material and production process thereof

The invention relates to the technical field of aluminum alloy production, in particular to a novel aluminum alloy material and a production process thereof. The novel aluminum alloy material comprises, by mass percentage, 0.05-0.22 wt% of nickel, 0.8-1.6 wt% of chromium, 0.024-0.032 wt% of manganese, 0.78-1.5 wt% of magnesium, 0.66-1.65 wt% of silicon, 0.45-1.2 wt% of iron, 3.5-5.8 wt% of copper, 4.8-6.5 wt% of zinc, and the balance aluminum and other inevitable impurities. The mechanical property and mechanics property of the novel aluminum alloy material are excellent, and the surface of an aluminum alloy profile can be effectively protected against scratches; and in addition, the process is simple and reasonable, and the production efficiency is high.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

Fe-Ni alloy pipe stock and method for manufacturing the same

ActiveUS8784581B2Improve mechanical propertiesEasy to manufactureFurnace typesRollsAlloyMechanical property

An Fe—Ni alloy pipe stock containing, by mass %, C≦0.04%, Si≦0.50%, Mn: 0.01 to 6.0%, P≦0.03%, S≦0.01%, Cr: 20 to 30%, Ni: 30 to 45%, Mo: 0 to 10%, W: 0 to 20%, with Mo(%)+0.5W(%): more than 1.5% to not more than 10%, Cu: 0.01 to 1.5%, Al≦0.01% and N: 0.0005 to 0.20%, and the balance being Fe, with 1440−6000P−100S−2000C≧1300, Ni+10(Mo+0.5W)+100N≦120, (Ni−35)+10(N−0.1)−2(Cr−25)−5(Mo+0.5W−3)+8≧0, can be manufactured into a seamless pipe by use of a Mannesmann piercing and rolling mill because of its excellent inner surface properties. The resulting seamless pipe has excellent mechanical properties and moreover has excellent corrosion resistance in a sour gas environment.

Owner:NIPPON STEEL CORP

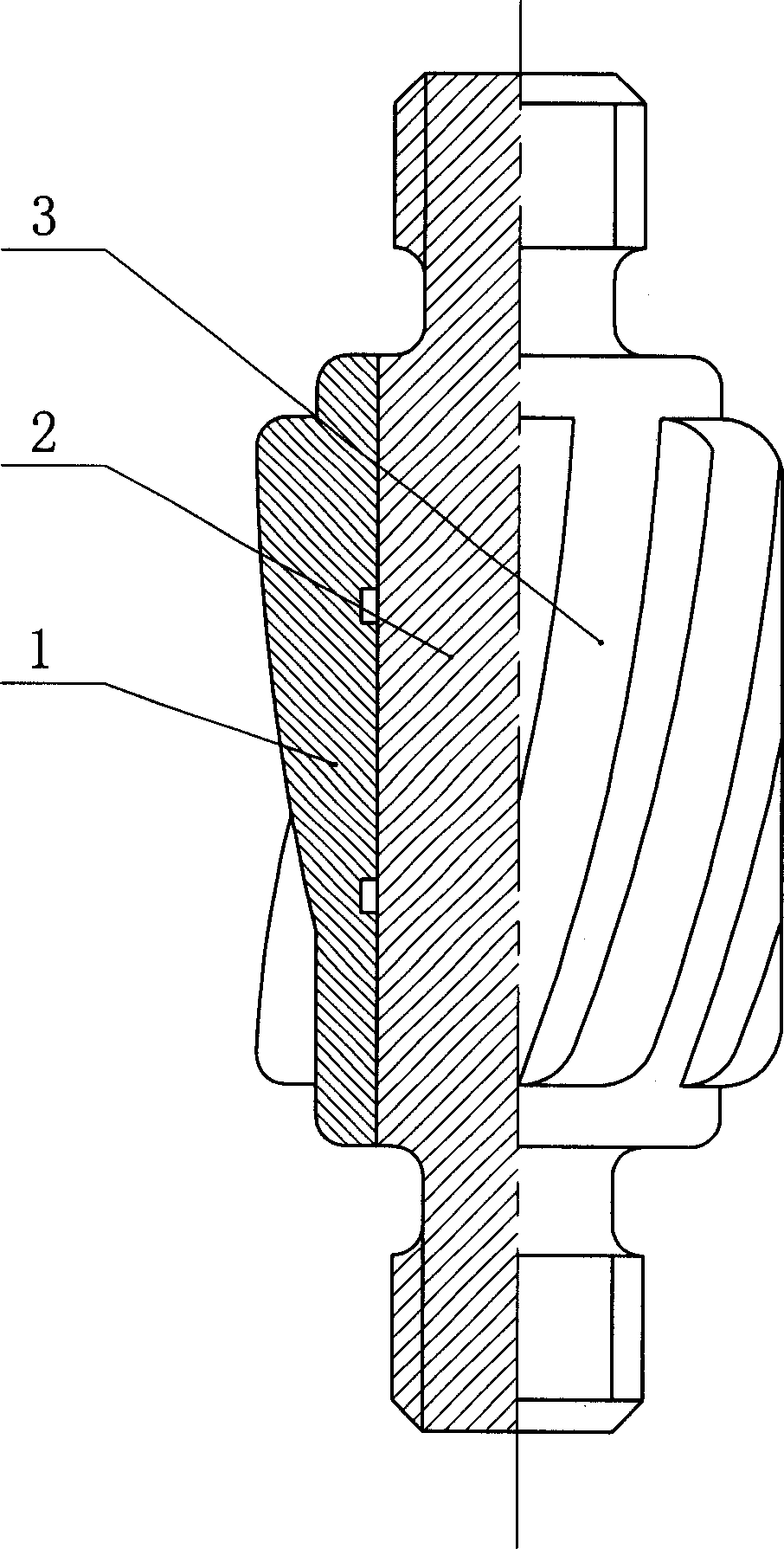

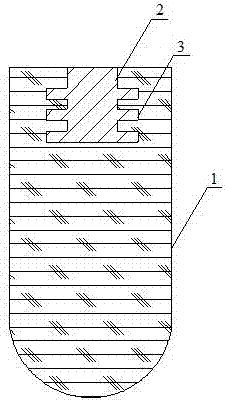

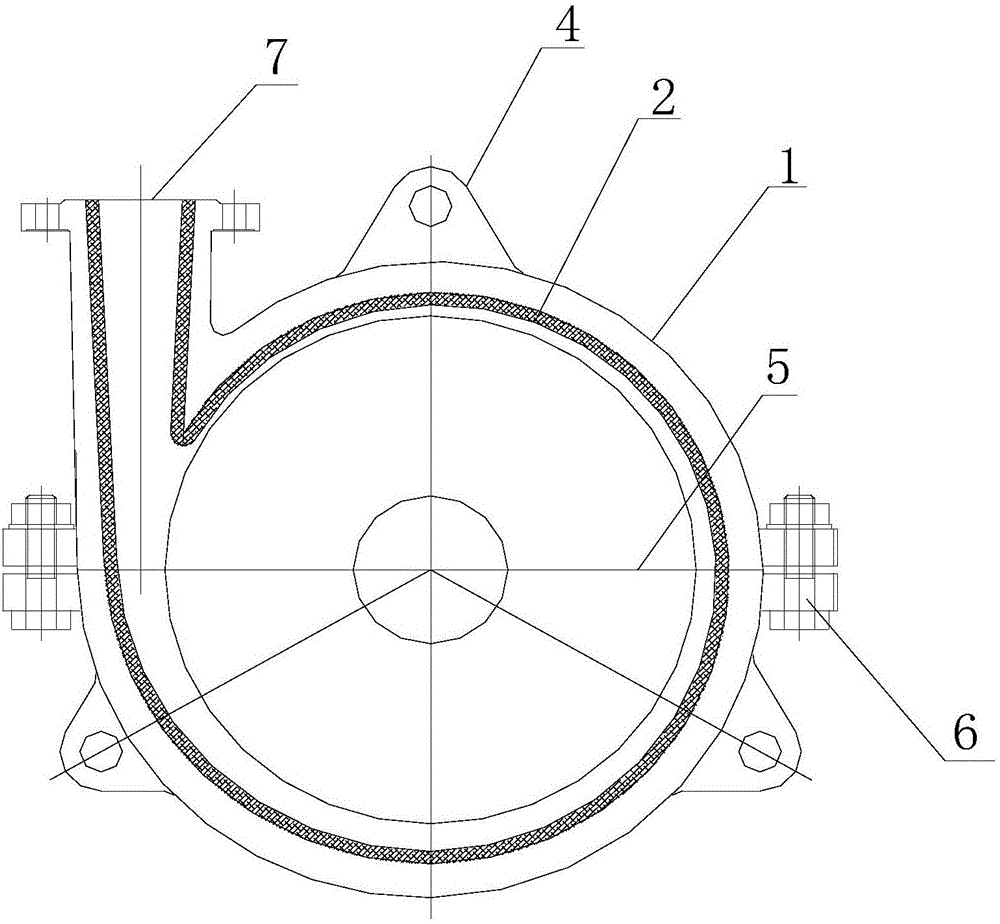

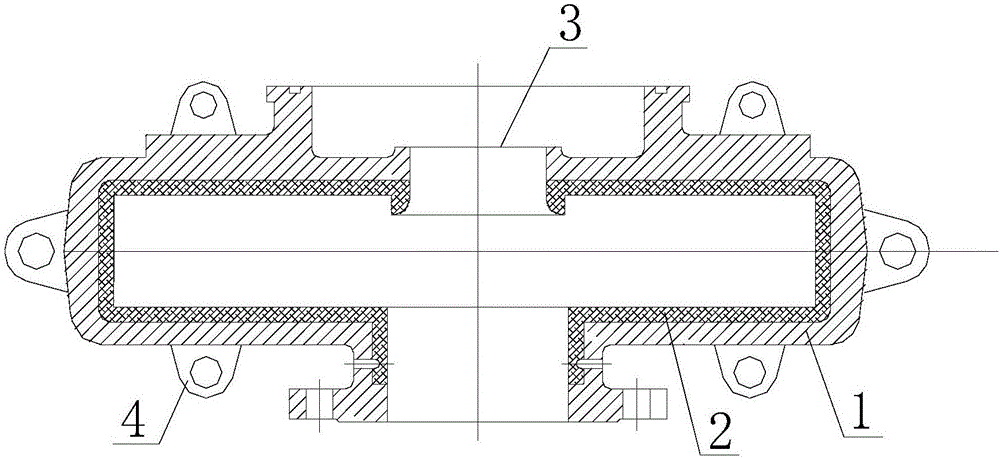

Centralizer and its manufacturing method

InactiveCN1755062AGood processing performanceUnique wear-resistantDrilling rodsCeramic shaping apparatusCeramicSilicon nitride

The invention discloses a stabilizer and making method for supplying an uneasy abrasive, long lifespan, long replacing period, high product efficient stabilizer, which comprises the following parts: stable block (1), short rob (2) and diagonal pilot channel (3), wherein the stable block (1) is encased around the peripheral short rob (2); several diagonal pilot channels (3) are set around the stable block (1) and each channel forms a certain critical angle to the stable block (1); the stable block (1) is made of silicon nitride ceramics material which comprises the following peculiar advantages: abrasion-proof, corrosion-resisting, high temperature-resistant and light quality. The making method of the stabilizer comprises the following steps: loading the silicon nitride ceramics power in the preparing stabilizer mould; compressing the mould by 1800kg / cm2 pressure to form a pattern; finishing the stabilizer by agglomeration in 1100-1300 Deg.C. The making method contains simple process and low cost, which can be applied in the domain of oil exploitation.

Owner:王敬东

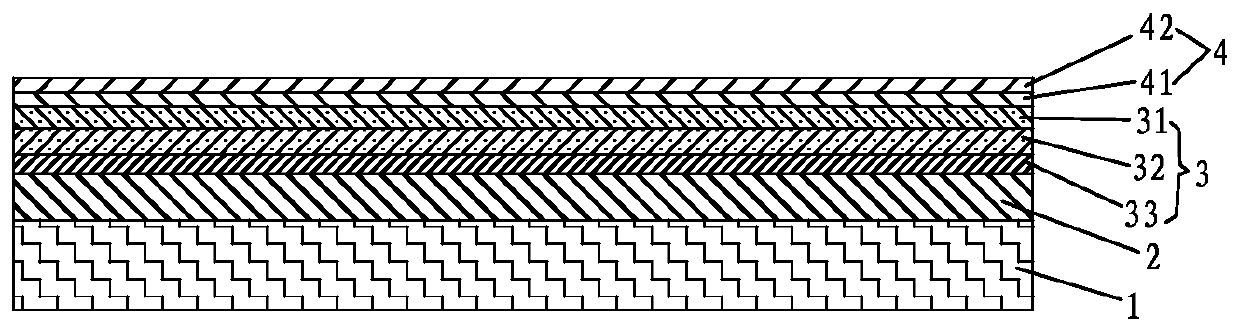

Outdoor yacht leather and preparation method thereof

ActiveCN111058295ASatisfy corrosion resistanceMeet UV resistanceTextiles and paperChemistryComposite material

The invention relates to outdoor yacht leather and a preparation method thereof. The outdoor yacht leather comprises a base fabric layer, a wet-process PU bottom layer, dry-process PU surface layers and a surface treated layer which are sequentially arranged; the dry-process PU surface layers comprise a first dry-process PU surface layer, a second dry-process PU surface layer and a third dry-process PU surface layer which are sequentially formed between the wet-process PU bottom layer and the surface treated layer; the first dry-process PU surface layer is positioned between the second dry-process PU surface layer and the surface treated layer; the third dry-process PU surface layer is positioned between the wet-process PU bottom layer and the second dry-process PU surface layer; the wet-process PU bottom layer is a flame-retardant PU layer; and the first dry-process PU surface layer is an anti-mildew PU layer. The yacht leather disclosed by the invention not only meets requirements ofoutdoor leather for performance of corrosion resistance, ultraviolet resistance, hydrolysis resistance and the like, but also meets requirements of yacht leather for performance of seawater resistance, mildew prevention and bacteria resistance, meanwhile, further meets the environment protection requirement, and also has better ageing resistance than yacht leather made of a PVC material.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

Non-stick electrolyte crust breaking hammer head for producing electrolytic aluminum

InactiveCN107099820ASolve the problem of sticking long bagsAntioxidantWear resistantMetallic materials

The invention provides a non-stick electrolyte crust breaking hammer head for producing electrolytic aluminum. The crust breaking hammer head comprises a hammer body, and the part, contacted with electrolyte, of the hammer body at least in crust breaking is made of any one of a carbon material and silicon carbide bonded silicon nitride. The problem of sticking and lump generation of electrolyte can be completely solved, in addition, a non-metal material is adopted as a matrix and neither a compound coating nor the matrix contains harmful elements influencing the mass of electrolytic aluminum, so that the non-stick electrolyte crust breaking hammer head is high-temperature-resistant and corrosion-resistant, not only can the anti-oxidative, corrosion-resistant and wear-resistant performances of the part, contacted with 920-960DEG C electrolyte, of the lower part of the hammer head be met, but also iron element can be fundamentally prevented from entering molten aluminum.

Owner:李清 +1

Magnetic recording medium and a method of manufacturing the same

ActiveUS8168312B2Reduce resistanceAvoid corrosionProtective coatings for layersVacuum evaporation coatingRecording layerWear resistance

A magnetic recording medium and a method of manufacturing a magnetic recording medium are provided, in which degradation of wear resistance against a magnetic head and performances of the medium is restrained, and metal dissolving out of the magnetic recording layer and degradation of corrosion resistance due to low coverage of a protective layer are suppressed. The method of manufacturing provides a magnetic recording medium having a convex portion of a magnetic recording layer for recording information and a concave portion without a recording function on a disk substrate. An ALD protective layer is formed on the magnetic recording medium using an ALD method. The magnetic recording medium has a convex portion of a magnetic recording layer for recording information and a concave portion without a recording function on a disk substrate, and has a protective layer formed by an ALD method on the concavo-convex pattern.

Owner:FUJI ELECTRIC CO LTD

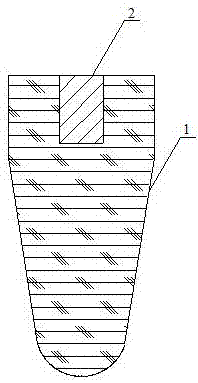

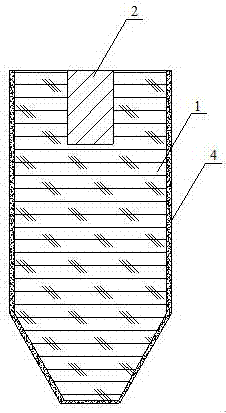

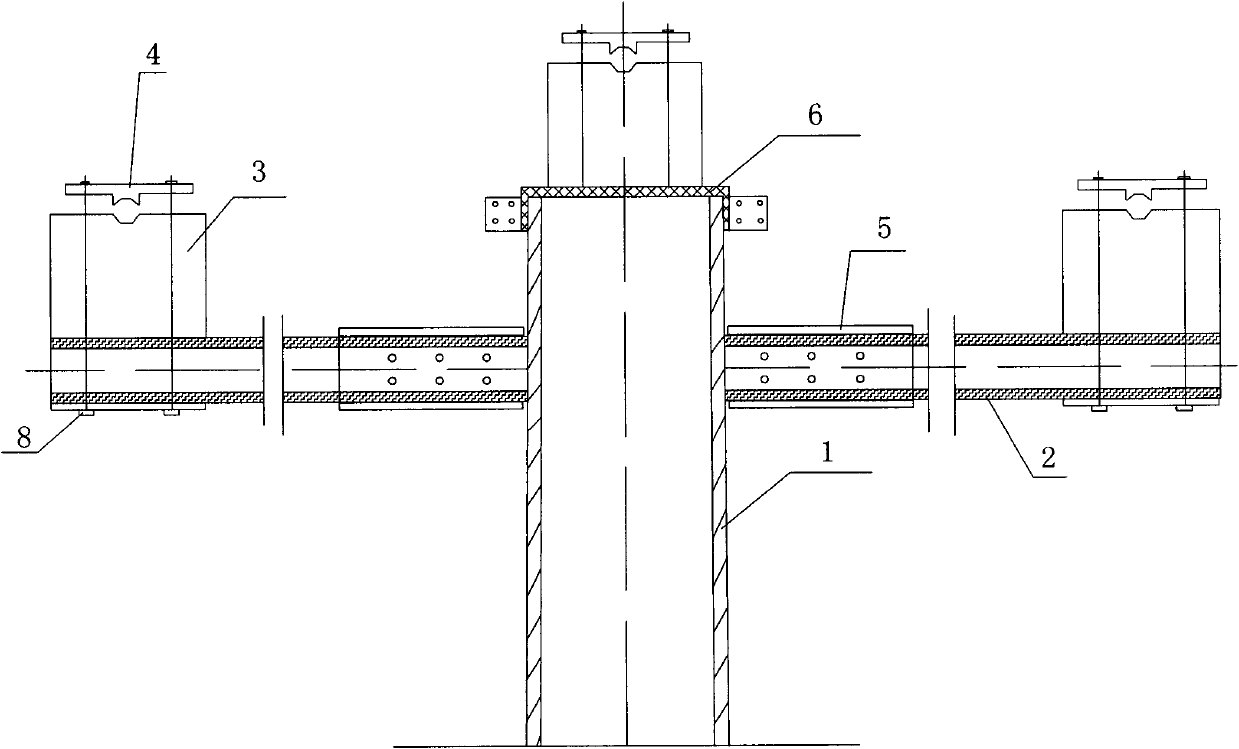

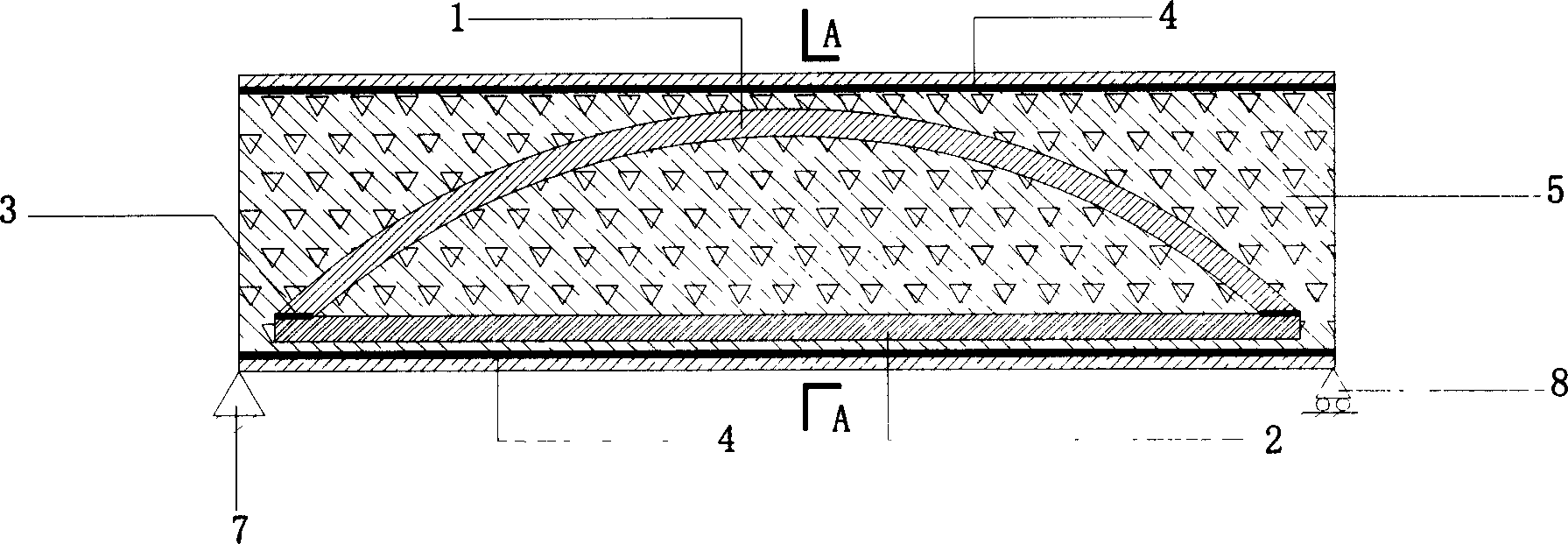

Fiberglass reinforced plastic telegraph pole

The invention provides a fiberglass reinforced plastic telegraph pole. The telegraph pole comprises a pole body, a cross arm, lead wire seats, hardware fittings, a clamp, an end cap and a sleeve, wherein the cross arm is arranged on the upper part of the pole body through the clamp; the end cap is arranged on the top end of the pole body; three lead wire seats and the hardware fittings are fixed at two ends of the cross arm and the end cap respectively through bolts; the sleeve is sleeved on the lower part of the pole body; lead wires are fixed between the lead wire seats and the hardware fittings; the pole body is of a hollow conical structure with a uniformly thickened wall, wall thickness variation delta is between 0.15 and 0.2 percent, the wall thickness variation dmax is the maximum wall thickness of the pole body, namely the wall thickness of the lowest end of the pole body, the wall thickness variation dmin is the minimum wall thickness of the pole body, namely the wall thickness of the top end of the pole body, and l is the bus length of the pole body. By adopting the design with a special variable thickness pole body structure, the materials play the best carrying function, and the manufacture cost is reduced; and in the pole body, the fiberglass reinforced plastic flange at the root of the pole body is integrally molded by adopting a winding method, while the telegraph pole is convenient to assemble with the ground, the mechanical performance requirement is met; and the pole body, the cross arm and the lead wire seats are produced by adopting different materials and molding processes, the designable performance, weight reduction and other function requirements are met while corrosion resistance and electric insulation of the telegraph pole are fulfilled.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

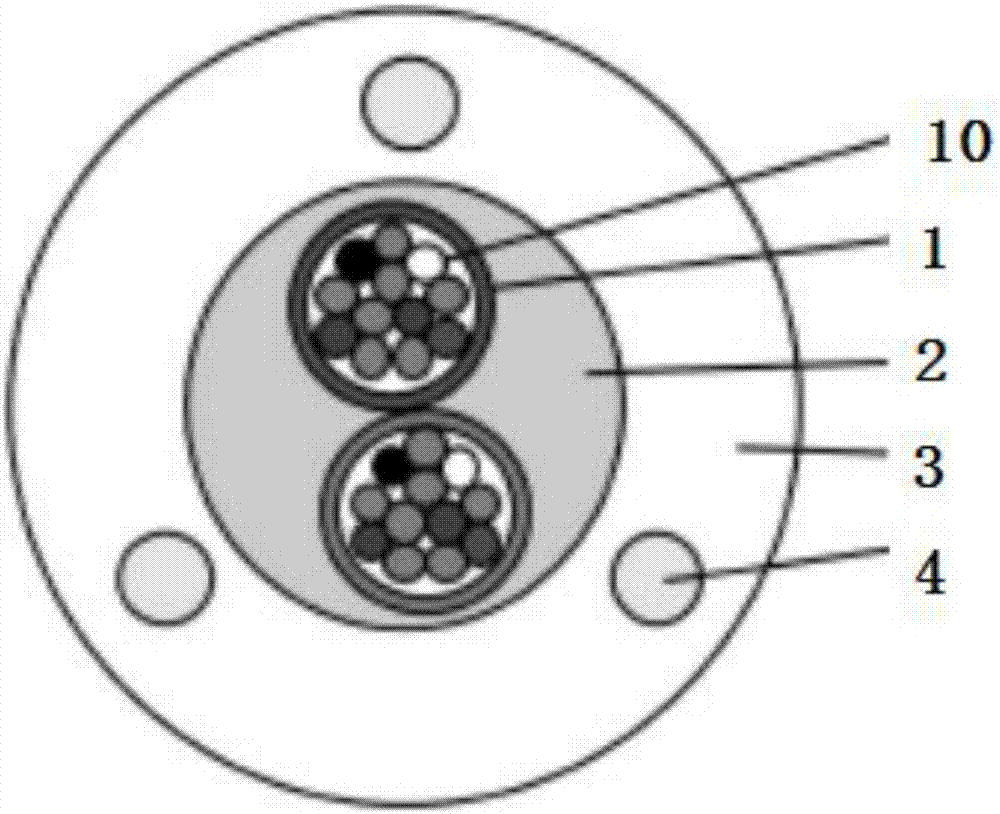

High density anti-compression optical fiber bundle optical cable for data center

PendingCN107884891AMeet the anti-lateral pressureSatisfy bending resistanceFibre mechanical structuresClimate change adaptationHigh densityPhosphate

The invention discloses a high density anti-compression optical fiber bundle optical cable for a data center. The optical fiber herein includes a micro-beam optical fiber, an aramid fiber layer whichcoats outside the micro-beam optical fiber, and a sheath layer which coats outside the aramid fiber layer. The sheath layer is embedded with three non-metal reinforcing members therein. The three non-metal reinforcing members constitute a triangle. The material of the sheath layer is composed of the following components by weight: polyurethane of 20-40 parts, polyvinyl choride of 25-45 parts, polyoxyalkylene modified polymethyl siloxane of 5-15 parts, chemigum of 20-30 parts, dibutoxyethyl adipate of 0.5-2 parts, trioctyl phosphate of 0.4-1 parts, modified filling material of 0.5-2 parts, a fire retardant of 2-4 parts, an activator of 0.2-0.6 parts, and a promoter of 0.5-1 parts. According to the invention, the optical fiber uses a center tubular structure, can ensure the moulding processof the optical fiber free from impact, and can also meet higher mechanical and environmental performances of the optical fiber.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

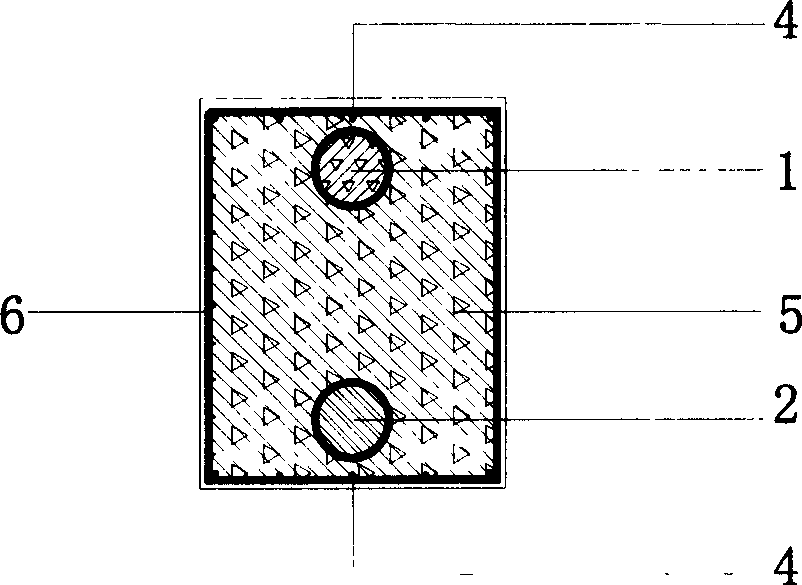

Breathing type photovoltaic connecting box for building integrated photovoltaic (BIPV) photovoltaic assembly

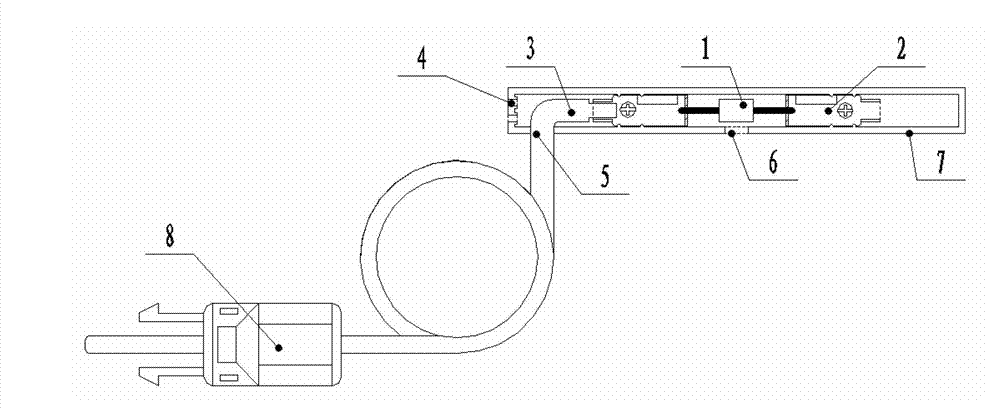

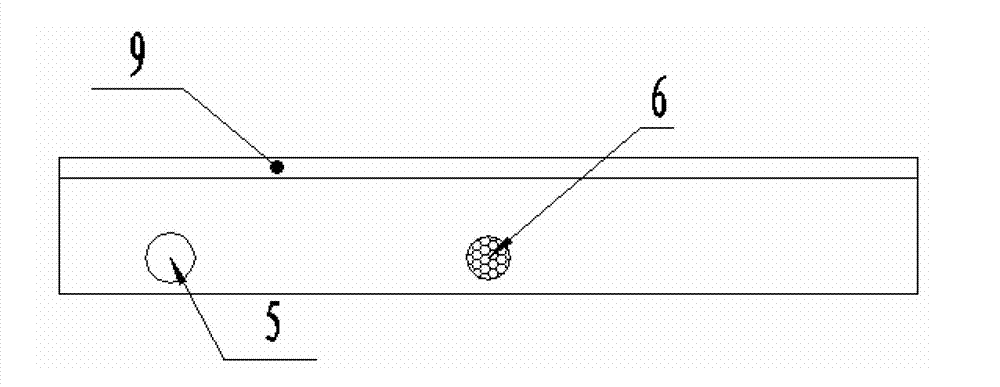

ActiveCN103035764AImprove insulation performanceImprove water resistanceClimate change adaptationPhotovoltaicsCapillary TubingAtmospheric pressure

The invention relates to a breathing type photovoltaic connecting box for a building integrated photovoltaic (BIPV) photovoltaic assembly. The breathing type photovoltaic connecting box comprises a casing and is characterized in that at least one breathing hole directly contacted with the external air is positioned on the surface of the casing (7), a breathing film (6) is covered on each breathing hole to enable air to pass through freely and prevent liquid from passing through, at least one capillary tube access hole (4) is arranged on the surface of the casing close to the inside of the photovoltaic assembly, a capillary tube is arranged on each capillary tube access hole (4), one end of the capillary tube extends into the photovoltaic assembly, the other end of the capillary tube extends into the casing (7), and pressure of the two ends can be balanced. By means of the connecting box, the BIPV photovoltaic assembly and the inside of the breathing type photovoltaic connecting box can form microcirculation similar to the microcirculation principle in the bodies of living beings. Thus, pressure of a hollow layer in the BIPV photovoltaic assembly can be changed, and safety of the hollow layer of the BIPV photovoltaic assembly is improved when the BIPV photovoltaic assembly is applied to buildings.

Owner:宁夏银星能源光伏发电设备制造有限公司

High-technology ceramic pump body used for pump and manufacturing method thereof

InactiveCN106337831AWon't fall offWon't leakPump componentsCeramic shaping apparatusCeramic metalCorrosion

The invention provides a high-technology ceramic pump body used for a centrifugal pump and a manufacturing method thereof. The high-technology ceramic pump body is mainly composed of a ceramic lining and a metal shell, wherein the ceramic lining is formed by combining two semicircular ceramic pieces and is provided with a feeding inlet and a discharging outlet; the metal shell is also composed of two semicircular metal pieces, the structure of the metal shell is matched with ceramic, and the ceramic and metal are bonded with high-temperature glue; and two semicircular parts are connected through bolts, the connection surface is subjected to flexible sealing, and the integrated pump body is formed. The manufacturing method of the high-technology ceramic pump body comprises the steps of ceramic lining manufacturing, ceramic-metal assembly assembling and forming machining. Compared with existing stainless steel and macromolecular pump bodies, the ceramic pump body can simultaneously meet the requirements for corrosion resistance, abrasion resistance, high-temperature resistance, good sealing performance, safety and reliability, and the life of the pump shell is prolonged by 5-10 times. Compared with pump shells inlaid with ceramic blocks, the ceramic of the pump shell of the high-technology ceramic pump body is not disengaged, leakage does not occur, and the reliability is improved.

Owner:HEFEI JINGCHUANG CERAMIC EQUIP TECH +1

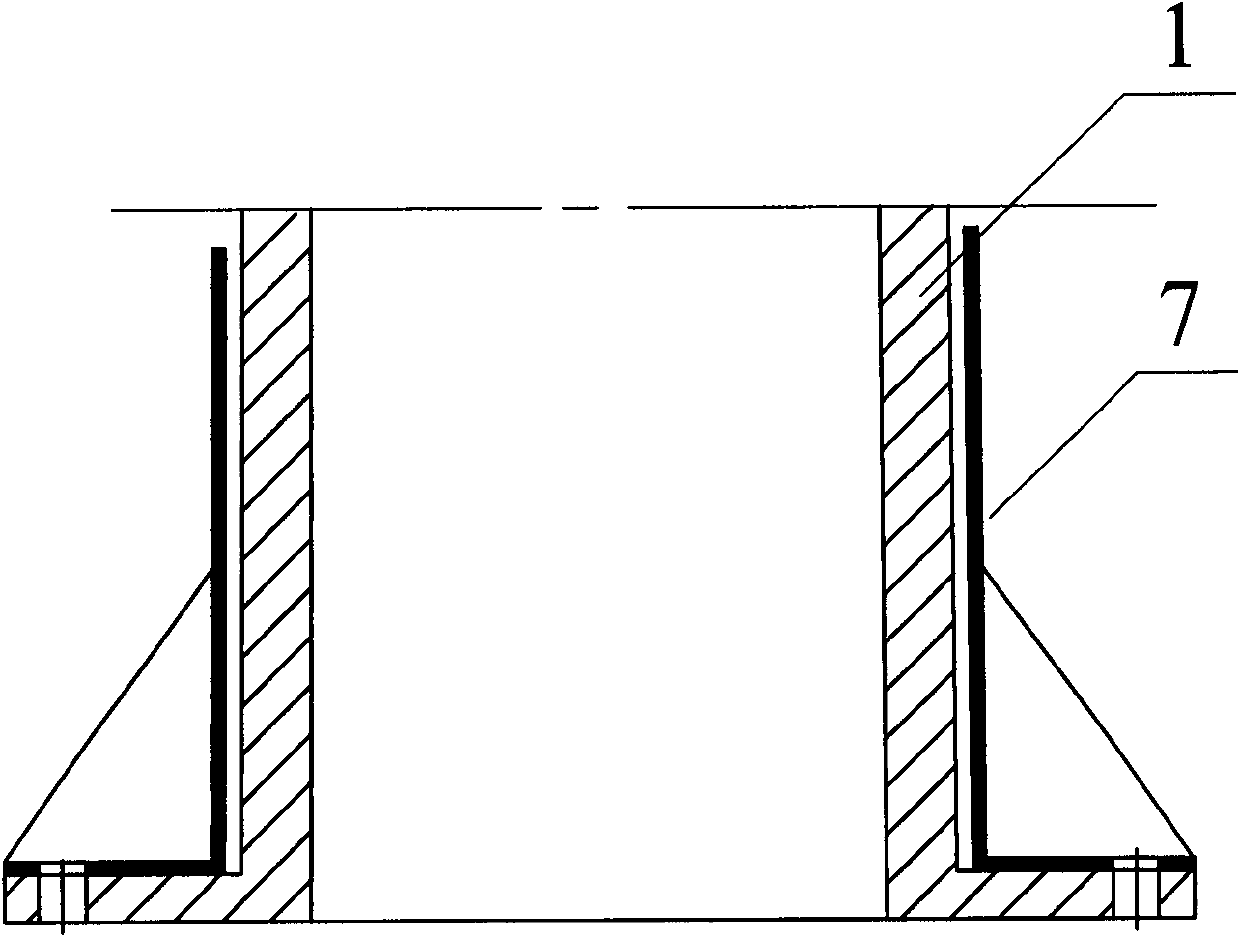

Steel arch concrete simply supported beam

InactiveCN1587573ASatisfy fire resistanceSatisfy corrosion resistanceGirdersJoistsSteel barMaterials science

The steel arch concrete simply supported beam consists of steel skeleton or steel pipe concrete, high strength steel bar or wire cable, longitudinal steel rib, concrete and hoop rib. The inside steel skeleton or steel pipe concrete has two ends connected to high strength steel bar or wire cable to constitute the key stress part of the steel arch concrete simply supported beam; and the outside of the steel arch concrete simply supported beam has longitudinal steel rib and hoop rib configured and concreted deposited. The steel arch concrete simply supported beam has raised bearing capacity and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Metal component for fuel cell and method of manufacturing the same, austenitic stainless steel for polymer electrolyte fuel cell and metal component for fuel cell material and method of manufacturing the same, corrosion-resistant conductive component and method of manufacturing the same, and fuel cell

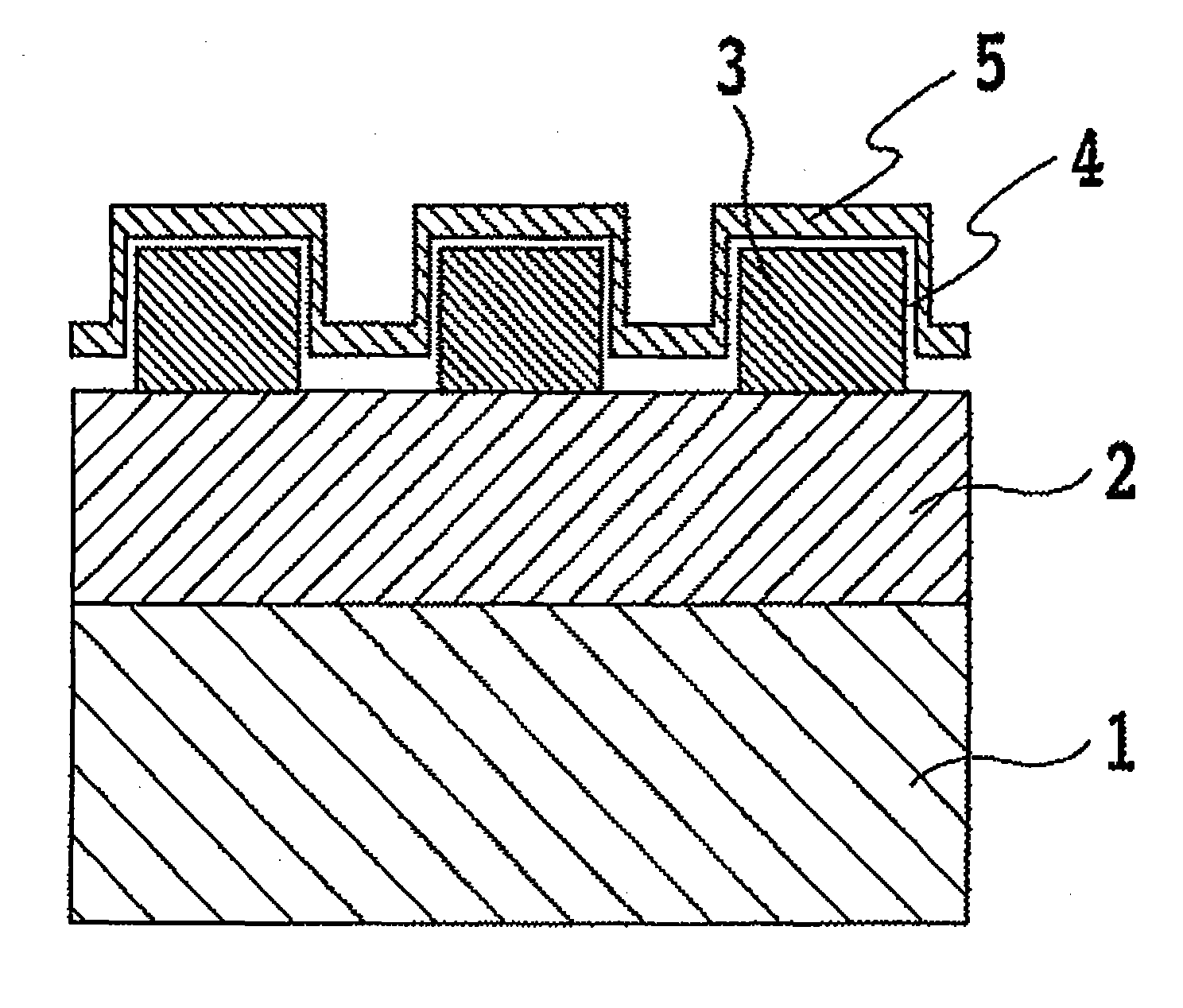

InactiveUS7597987B2Satisfy corrosion resistanceSimple processFinal product manufactureFuel cell auxillariesFuel cellsAustenite

An Au plated film 12 is formed on the surface of a plate-formed metal base 13 composed of a metal less noble than Au, and the product is cut along a planned cutting line 18 reflecting a contour of a desired component, to thereby form a separator 10. Thus-formed separator 10 has the Au plated film 12 formed on the main surface 10a thereof, and has a cutting plane 16 formed as an end face 16 stretched up to the main surface 10a. The metal base 13 exposes in a part of the cutting plane 16, in a width of the exposed region of 1 mm or less. This is successful in providing a metal component for fuel cell which is satisfactory in the corrosion resistance and allows easy fabrication at low costs, a method of manufacturing the same, and also in providing a fuel cell having thus-fabricated metal component for fuel cell.

Owner:DAIDO STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com