Fiberglass reinforced plastic telegraph pole

A technology of utility poles and glass fiber reinforced plastics, applied in the field of utility poles, can solve problems such as mechanical analysis and molding process that have not yet been discovered, and achieve the effects of meeting mechanical performance requirements, simple structure, and reduced load-bearing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

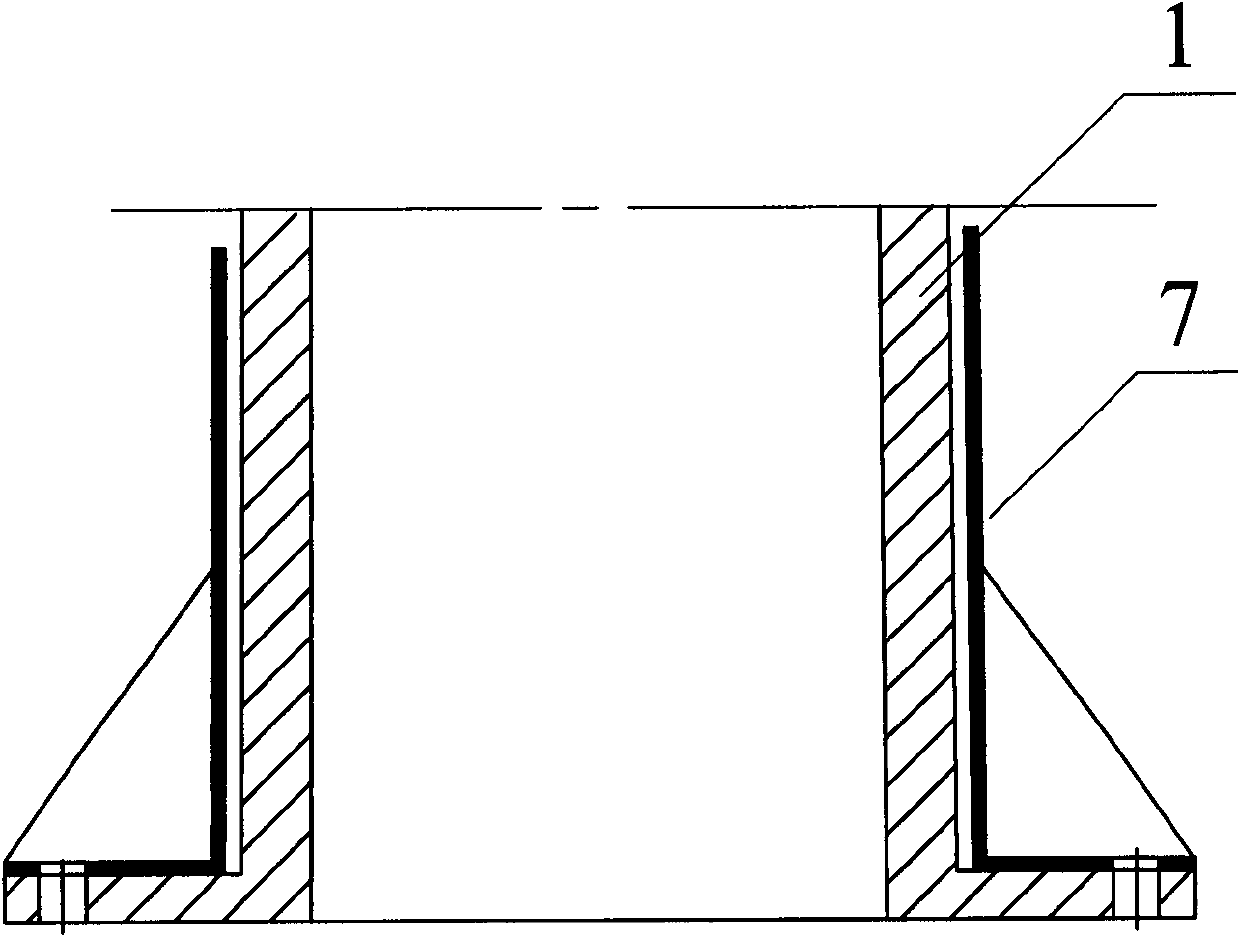

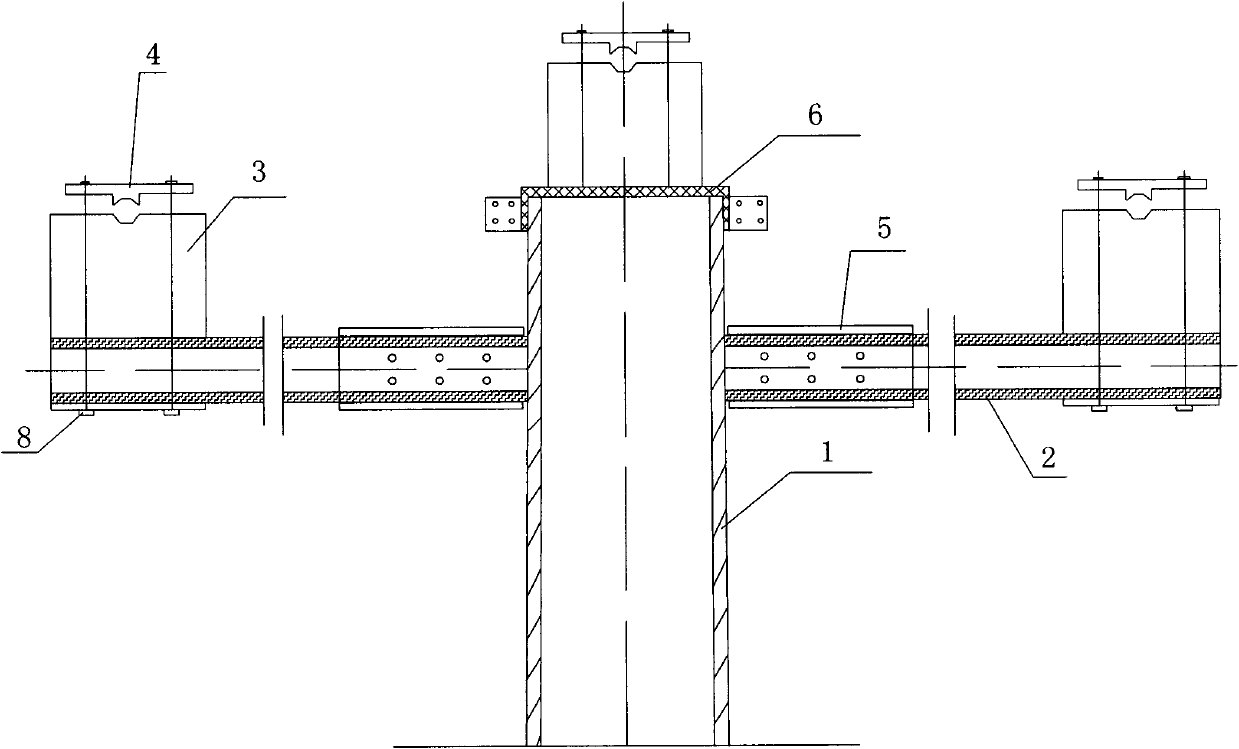

[0039] The invention as figure 2 , 3 As shown, it includes rod body 1, cross arm 2, wire seat 3, fittings 4, clamp 5, end cap 6 and sleeve 7, cross arm 2 is installed on the upper part of rod body 1 through clamp 5, and end cap is installed on the top of rod body 1 6. Three sets of wire holders 3 and fittings 4 are respectively fixed on the two ends of the cross arm 2 and the end cap 6 with screws 8, the lower part of the rod body 1 is fitted with the sleeve 7, and the wires are fixed between the wire holder 3 and the fittings 4.

[0040] 1. Rod body

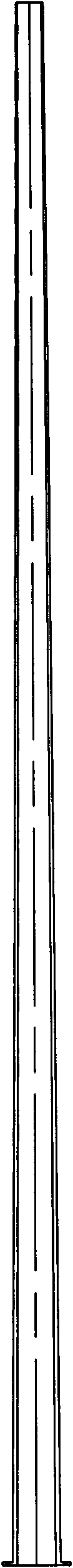

[0041] The force characteristic of the rod body is that the force on the top of the rod body is the smallest, and the closer to the root of the rod body, the more serious the force is. Therefore, according to its stress characteristics, the rod body is designed in the form of a hollow tapered uniform variable thickness, that is, the thickness at the root of the rod body is the largest, and gradually decreases toward the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com