Universal rolling wheel device for pipeline support

A technology of pipe supports and rollers, which is applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc. It can solve the problems of affecting friction, excessive contact stress, and poor fixation, and achieves small friction, Good carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

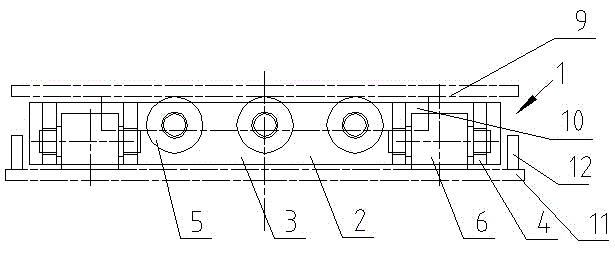

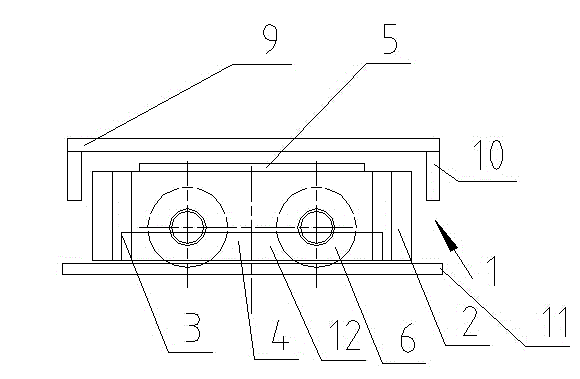

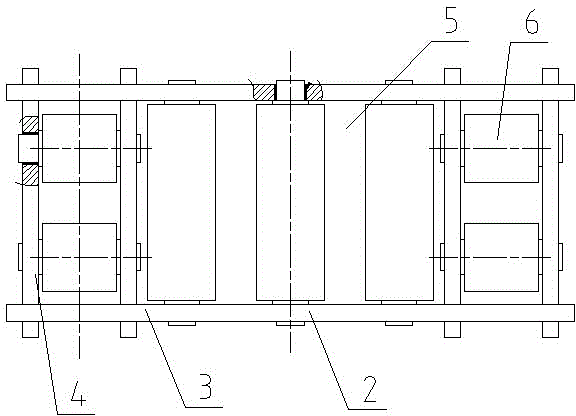

[0017] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a rolling device 1, and the rolling device 1 includes a rectangular frame 2, and the rectangular frame 2 includes front and rear panels 3 arranged transversely, and two ends of the front and rear panels 3 are symmetrically connected with two A side plate 4 arranged vertically, the two ends of the front and rear panels 3 are respectively provided with two sets of first draw-in slots 7 with lower openings, and the two ends of the side plate 4 are respectively provided with the second draw-in slots 8 with upper openings. 4 The second card slot 8 through the upper opening is engaged in the first card slot 7 corresponding to the lower opening of the front and rear panels 3,

[0018] The middle part of the front and rear panels 3 is equipped with three longitudinal rollers 5 through the first bearing, and two transverse rollers 6 are connected between the two longitudinally arranged side plates 4 at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com