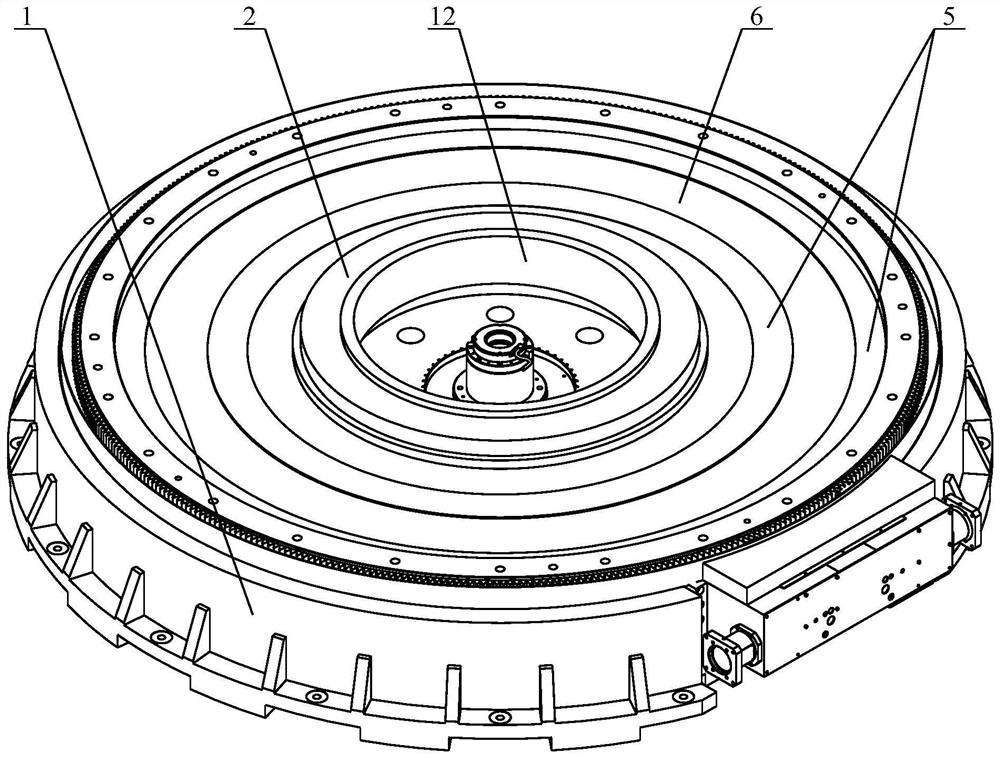

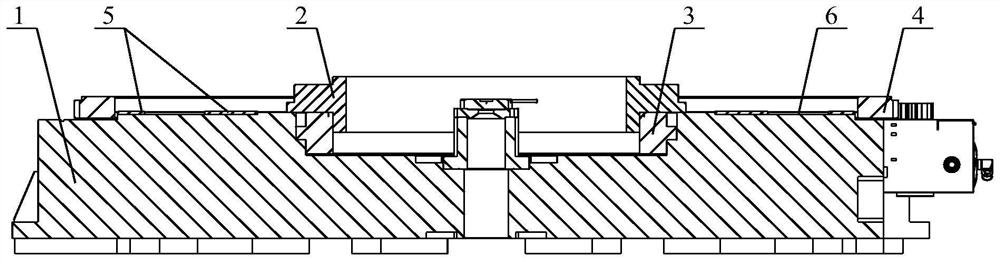

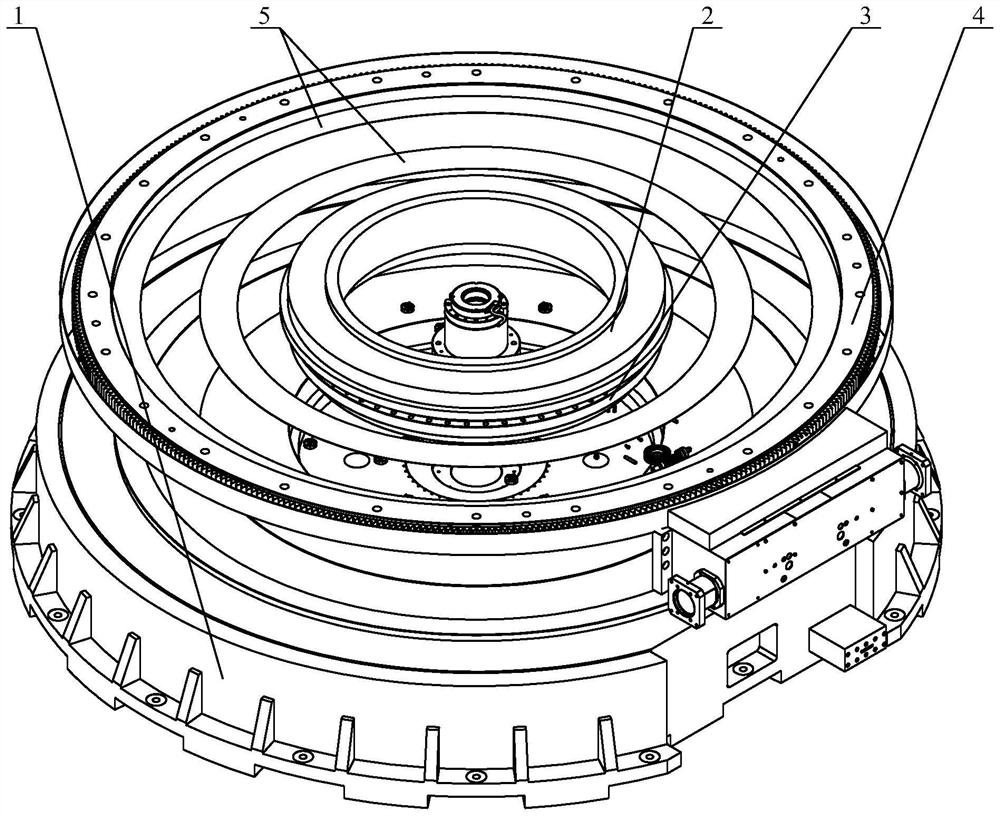

Rotary table bearing device

A technology of rotary table and carrying device, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of decreased machining accuracy, table deformation, etc., to achieve small deformation, prolong service life, avoid jitter and bouncing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0045] The force analysis is carried out on the rotary table designed in the second embodiment of the present invention to detect whether the design of the present invention can meet the load-bearing requirements and ensure that the deformation of the table is extremely small when the load is large.

[0046] Apply a force of 400,000N (40t) within the range of diameter 2293mm to 3800mm on the table surface, and conduct finite element simulation analysis on the strength of the table. The analysis results are shown in Figure 5 .

[0047] Depend on Figure 5 It can be seen from the displayed analysis results that the maximum deformation of the table 1 of the rotary table of the present invention occurs at the outermost edge of the table 1, and the maximum deformation is 0.027mm, which is extremely small and belongs to elastic deformation, and its influence on welding and the use of the turntable can be ignored . It can be seen that the load-bearing device of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com