Outdoor yacht leather and preparation method thereof

A yacht and outdoor technology, applied in the field of synthetic leather, can solve the problems of low aging resistance, high price, unqualified PVC leather environmental protection, etc., and achieve the effect of anti-mildew and antibacterial properties, good aging resistance, and meeting environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

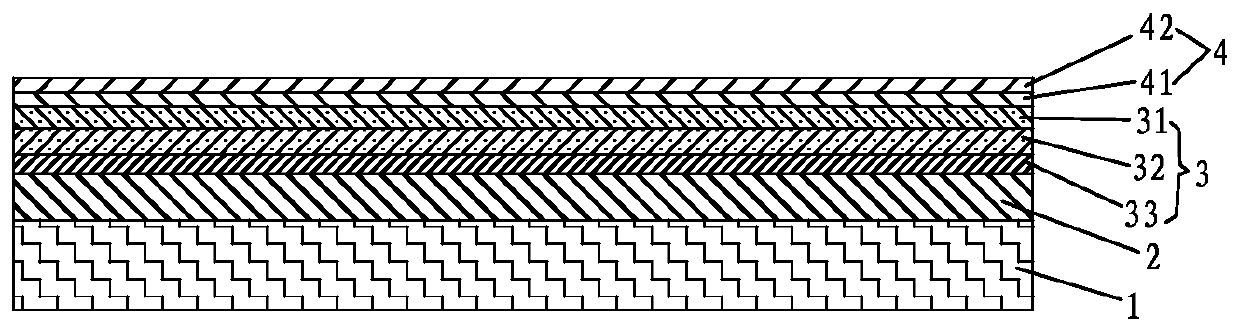

[0039] Such as figure 1 As shown, the synthetic leather for outdoor yachts provided by this embodiment includes a base fabric layer 1, a wet PU bottom layer 2, a dry PU surface layer 3 and a surface treatment layer 4 arranged in sequence, and the dry PU surface layer 3 includes sequentially formed The first dry process PU surface layer 31, the second dry process PU surface layer 32 and the third dry process PU surface layer 33 between the wet process PU bottom layer 2 and the surface treatment layer 4, the first dry process PU surface layer 31 is located at Between the second dry process PU surface layer 32 and the surface treatment layer 4, the third dry process PU surface layer 33 is located between the wet process PU bottom layer 2 and the second dry process PU surface layer 32, and the surface treatment layer 4 includes the The first treatment layer 41 and the second treatment layer 42 on the first dry process PU surface layer 31 , the first treatment layer 41 is located b...

Embodiment 2

[0050] In the outdoor yacht leather provided in this embodiment, the raw material formula of the wet-process PU bottom layer is shown in Table 1, and the raw material formula of the first dry-process PU surface layer, the second dry-process PU surface layer, and the third dry-process PU surface layer As shown in Table 2, the raw material formulations of the first treatment layer and the second treatment layer are shown in Table 3.

[0051] Others are the same as embodiment 1.

Embodiment 3

[0053] In the outdoor yacht leather provided in this embodiment, the raw material formula of the wet-process PU bottom layer is shown in Table 1, and the raw material formula of the first dry-process PU surface layer, the second dry-process PU surface layer, and the third dry-process PU surface layer As shown in Table 2, the raw material formulations of the first treatment layer and the second treatment layer are shown in Table 3.

[0054] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com