Steel arch concrete simply supported beam

A concrete-filled steel tube and concrete technology, which is applied to joists, girders, trusses, etc., can solve the problems of material waste and large amount of steel, and achieve the effect of meeting engineering requirements, improving bearing capacity, and reducing the amount of steel and concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

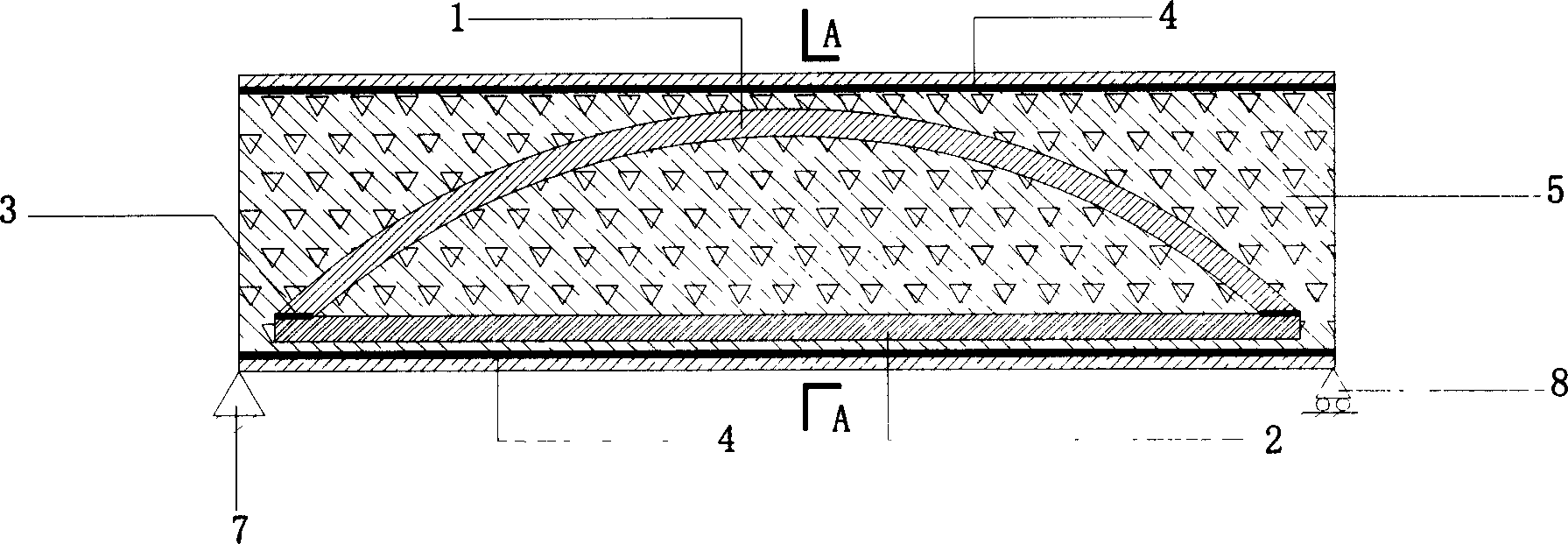

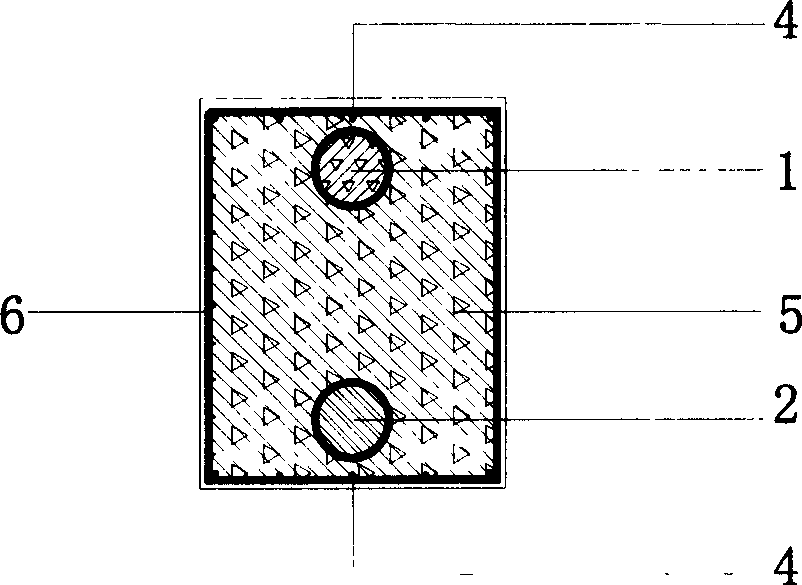

[0012] Such as figure 1 , 2 As shown, the steel arch concrete simply supported beam supported by fixed support 7 and sliding support 8 is mainly composed of steel frame (or concrete filled steel tube) 1, high-strength steel bar (or high-strength steel wire bundle) 2, longitudinal steel bar 4, concrete 5, stirrup 6 composition. The two ends of the internal steel frame (or steel tube concrete) 1 are connected with high-strength steel bars (or high-strength steel wire bundles) 2 through connectors 3;

[0013] The main part of the steel arch concrete simply supported beam, that is, the tie rod arch (or cable arch) composed of high-strength steel bar (or high-strength steel wire bundle)-steel bone (or steel tube concrete), can be constructed according to the height and span requirements of the building and structural analysis. The obtained load is subjected to finite element analysis, and the corresponding detailed design is carried out according to the analysis results; then, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com