High density anti-compression optical fiber bundle optical cable for data center

A high-density, optical fiber bundle technology, used in the field of optical cables, can solve the problems of poor cold resistance, poor mechanical properties, and inapplicability of the outer sheath, and achieve the effect of light optical cable weight, wear resistance, and small outer diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

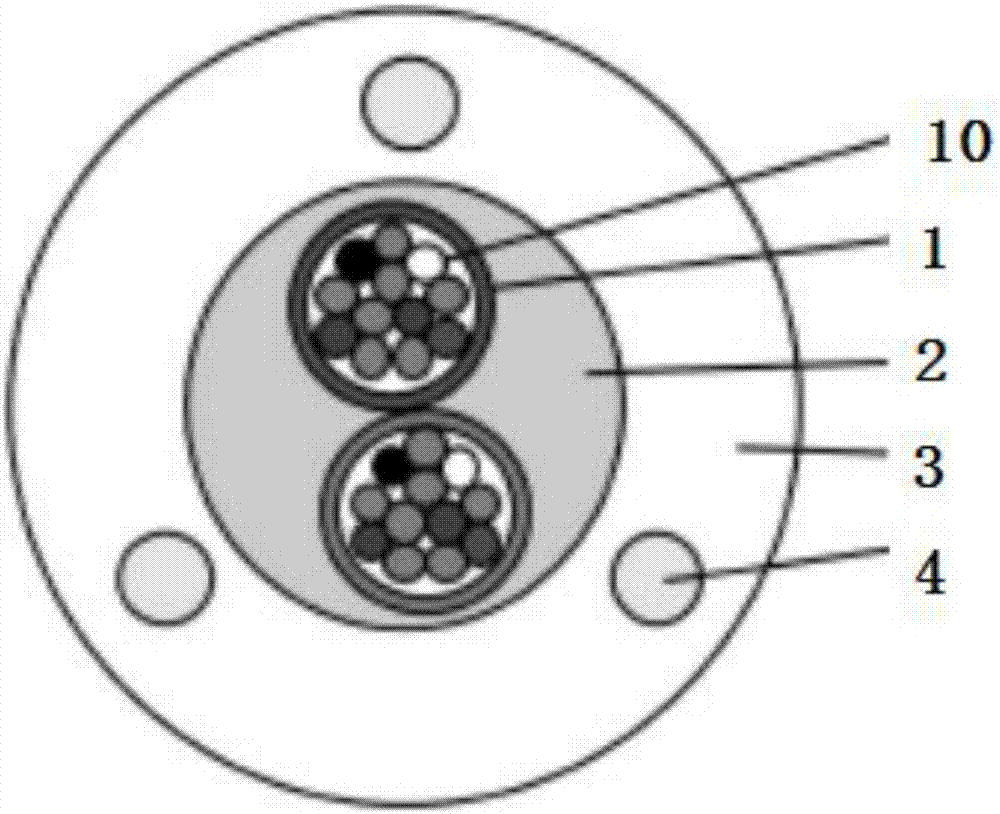

[0025] Embodiment 1 discloses a high-density compression-resistant optical fiber bundle cable for data centers, which includes: a micro-bundle tube optical fiber 1, a number of optical fibers 10 are arranged in the micro-bundle tube fiber 1, and are coated on the micro-bundle tube The aramid fiber layer 2 on the outside of the optical fiber 1, and the sheath layer 3 coated on the outside of the aramid fiber layer 2, and the three non-metallic strength members 4 are embedded in the sheath layer 3, and the three non-metal strength members 4 are composed of triangle.

[0026] The angle between the three non-metallic reinforcements is 120°, and the stability of the equilateral triangle ensures the beauty and good mechanical properties of the optical cable section; the outer diameter of the optical cable is 5.0±0.2mm; the thickness of the sheath layer 1.1±0.1mm, the thinnest point is not less than 0.9mm, each of the non-metallic reinforcements is embedded in the middle of the sheat...

Embodiment 2

[0032] The structure in Example 2 is as in Example 1. In parts by weight, the formula of the sheath layer includes: 30 parts of polyurethane, 30 parts of polyvinyl chloride, 8 parts of polyoxyalkylene modified polymethylsiloxane, 25 parts of nitrile rubber, 1.5 parts of dibutoxyethyl adipate, 1 part of trioctyl phosphate, 1.5 parts of modified carbon fiber, 2 parts of ammonium polyphosphate, 0.5 parts of zinc oxide, and 0.5 parts of accelerator DM. Wherein, the length of the modified carbon fiber is 1-10 μm, and the particle size of the zinc oxide is 600 mesh.

[0033] The modified carbon fiber is prepared through the following steps: take 2% of the aluminate coupling agent equivalent to the weight of the carbon fiber, add it to the DMF solution, heat to 80°C until the aluminate coupling agent is completely dissolved, and the aluminate coupling agent The mass ratio of the coupling agent to the DMF solution is 1:20; then the carbon fiber is added to the DMF solution, and centri...

Embodiment 3

[0039] In this embodiment, in parts by weight, the formula of the sheath layer includes: 20 parts of polyurethane, 35 parts of polyvinyl chloride, 12 parts of polyoxyalkylene modified polymethylsiloxane, 25 parts of nitrile rubber, 2 parts of dibutoxyethyl adipate, 1 part of trioctyl phosphate, 0.5 parts of modified carbon nanotubes, 3.5 parts of magnesium hydroxide, 0.4 parts of calcium carbonate, and 0.6 parts of accelerator DM. Wherein, the length of the modified carbon nanotube is 1-10 μm, and the particle size of the calcium carbonate is 800 mesh.

[0040] The modified carbon nanotubes are prepared through the following steps: take an aluminate coupling agent equivalent to 2% of the weight of the carbon nanotubes, add it to the DMF solution, and heat it to 80 ° C until the aluminate coupling agent is completely dissolved. The mass ratio of aluminate coupling agent to DMF solution is 1:20; then carbon nanotubes are added to the DMF solution, and centrifuged at 80°C for 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com