Adhesive agent layer for flexible image display device, laminate body for flexible image display device, and flexible image display device

A technology for image display devices and adhesive layers, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve problems such as hindering the flexibility of organic EL display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

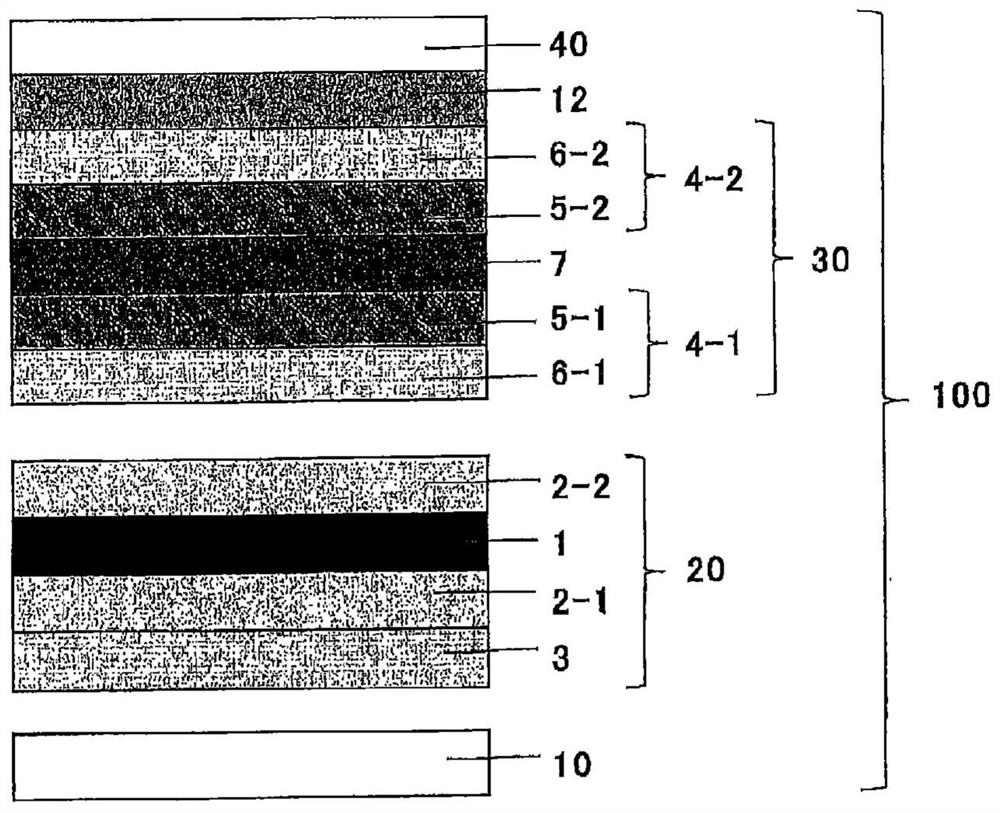

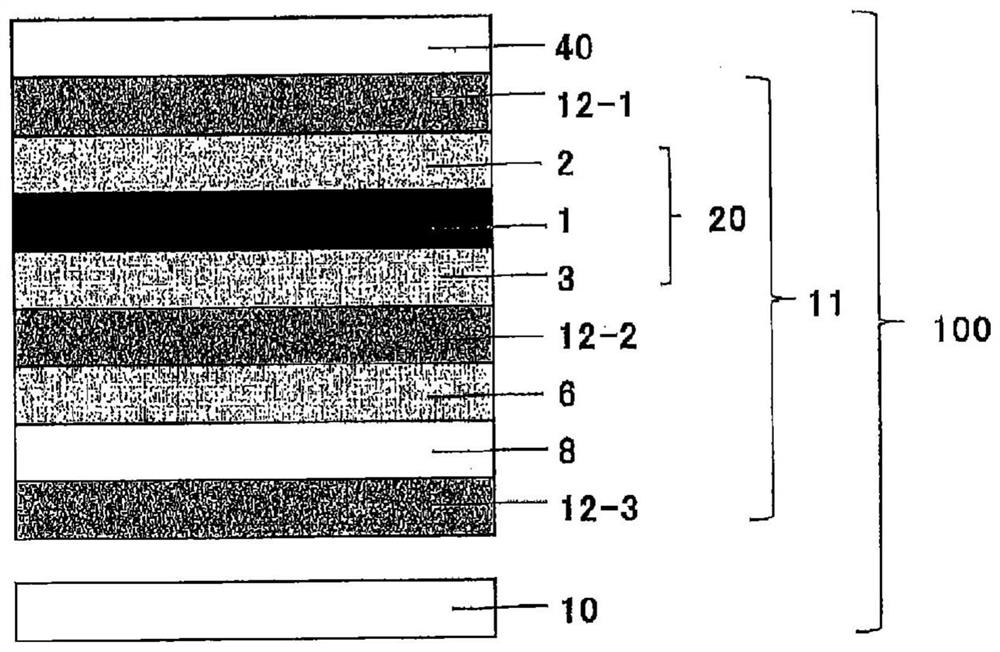

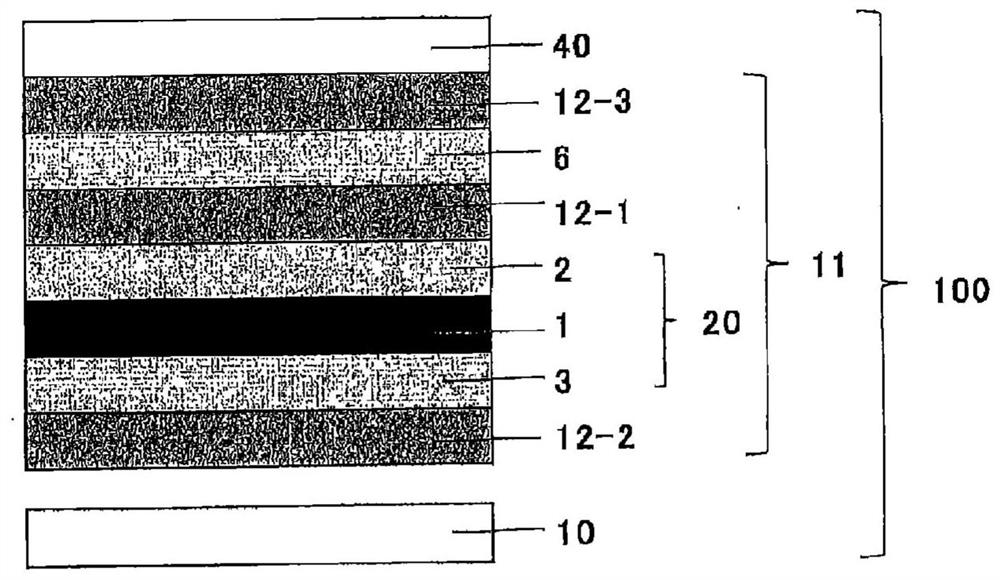

Image

Examples

preparation example Construction

[0150] The preparation method of the above-mentioned adhesive composition is not particularly limited, and a known method can be used. For example, as described above, the solvent-type acrylic adhesive composition is prepared by adding a (meth)acrylic polymer, if necessary, The components (such as the above-mentioned (meth)acrylic oligomer, crosslinking agent, silane coupling agent, solvent, additives, etc.) are mixed to produce. In addition, as described above, the active energy ray-curable acrylic pressure-sensitive adhesive composition is obtained by mixing a monomer mixture or a partial polymer thereof, and optionally added components (such as the above-mentioned photopolymerization initiator, polyfunctional monomer, base) acrylic oligomer, crosslinking agent, silane coupling agent, solvent, additives, etc.)

[0151] The adhesive composition described above preferably has a viscosity suitable for handling and coating. Therefore, the active energy ray-curable acrylic press...

Embodiment 1

[0231]

[0232] A monomer mixture containing 59 parts by weight of lauryl acrylate (LA), 40 parts by weight of 2-ethylhexyl acrylate (2EHA), and 1 part by weight of 4-hydroxybutyl acrylate (4HBA), 2 , 2-dimethoxy-1,2-diphenylethan-1-one (trade name "IRGACURE 651", manufactured by BASF Japan Co., Ltd.) and 1-hydroxycyclohexyl phenyl ketone (trade name "IRGACURE 184 ", manufactured by BASF Japan Co., Ltd.) were put into a four-neck flask in an amount of 0.05 parts by weight, and photopolymerized by irradiating ultraviolet rays in a nitrogen atmosphere until the viscosity (BH viscometer No. 5 rotor, 10 rpm, temperature 30°C) reached about 15 Pa s, thereby obtaining a partially polymerized monomer slime (partial polymer of monomer components).

[0233]

[0234] In 100 parts by weight of the partially polymerized monomer viscous obtained, 5 parts by weight of N-vinylpyrrolidone and 1,6-hexanediol diacrylate (trade name "A-HD-N ", manufactured by Shin-Nakamura Chemical Co., Ltd...

Embodiment 2~3、 comparative example 1~5

[0238] In the preparation of the prepolymer of Example 1, the monomer mixture (type, composition) of the prepolymer was changed as shown in Table 2, and in the preparation of the acrylic adhesive composition, additional The monomer (type, compounding amount) was changed as shown in Table 2, except that, the preparation of the prepolymer and the preparation of the acrylic adhesive composition were carried out in the same manner as in Example 1, and then, the Adhesive layer.

[0239] It should be noted that, in Comparative Examples 2 and 3, as shown in Table 2, the compounding amount of 1,6-hexanediol diacrylate was changed to 0.3 parts by weight, and 2, The amount of 2-dimethoxy-1,2-diphenylethan-1-one (trade name "IRGACURE 651", manufactured by BASF Japan Co., Ltd., additional initiator) was changed to 0.6 parts by weight.

[0240] After producing an optical layered body using each member produced by the following method, an optical layered body with an adhesive layer was pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com