Composite fungicide and metal cutting fluid with same and preparation method of composite fungicide

A technology of metal cutting fluid and composite fungicide, which is applied in the fields of botanical equipment and methods, biocides, additives, etc., can solve problems such as complex formula systems, and achieve broad application prospects, high safety, and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

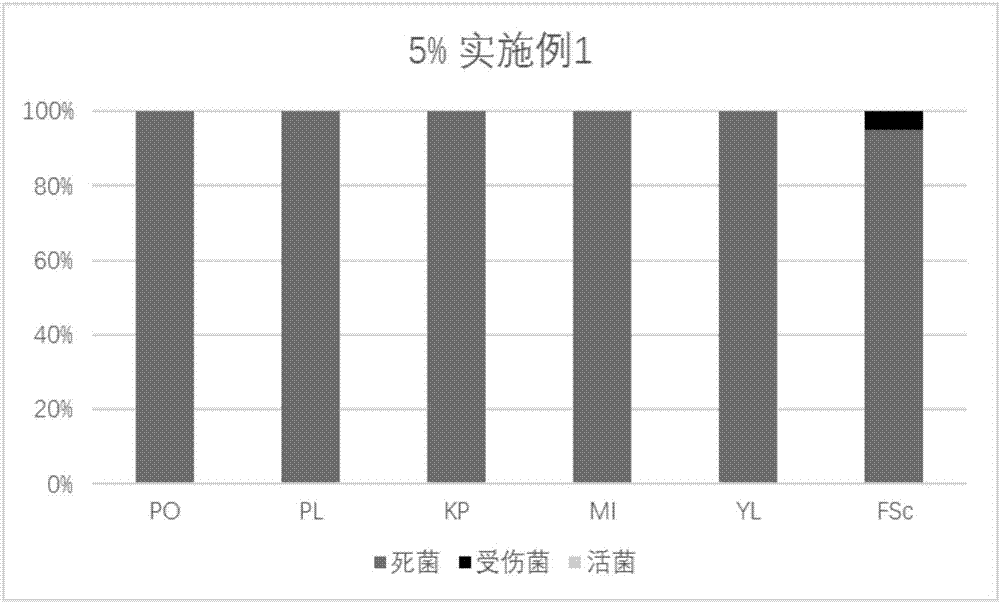

Embodiment 1

[0054] In this example, the compound fungicide includes 1,2-benzisothiazol-3-one, ε-polylysine and water-soluble organic amine, wherein 1,2-benzisothiazol-3-one The mass ratio of ε-polylysine to ε-polylysine is 2:1, and the mass ratio of water-soluble organic amine to ε-polylysine is 3:1.

[0055] The compound bactericide of this example is used in metal cutting fluid, and the metal cutting fluid is to add and stir the following various raw material components one by one at a temperature of 45°C: 37% of base oil, 13% of synthetic ester, organic acid 10%, 10% organic amine, 2% emulsifier, 11% water, 7% antirust agent, 7% coupling agent, 3% compound bactericide, and mix uniformly to prepare metal cutting fluid.

[0056] The base oil is mineral oil, the synthetic ester is trimethylolpropane oleate and polyricinoleic acid, the organic acid is a mixture of oleic acid, ricinoleic acid and tall oilic acid, and the water-soluble organic The amine is triethanolamine, and the organic a...

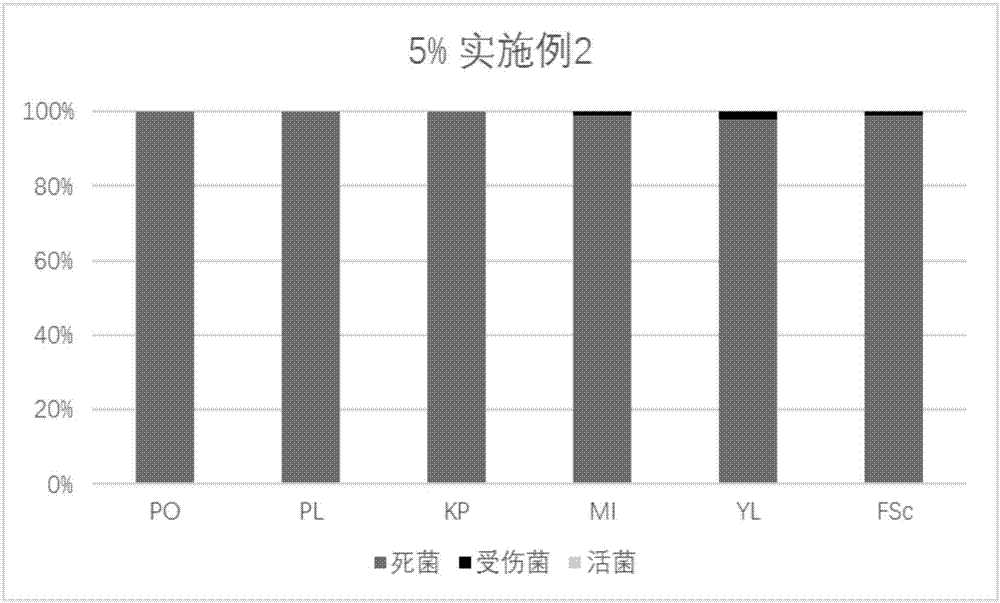

Embodiment 2

[0058] In this example, the compound fungicide includes 1,2-benzisothiazol-3-one, ε-polylysine and water-soluble organic amine, wherein 1,2-benzisothiazol-3-one The mass ratio to ε-polylysine is 3:1, and the mass ratio of water-soluble organic amine to ε-polylysine is 2:1.

[0059] The compound fungicide of this example is used in metal cutting fluid, and the following raw material components are added one by one at a temperature of 20°C and stirred: 42% base oil, 9% synthetic ester, 10% organic acid, 11% organic amine %, 3% emulsifier, 11.5% water, 6% antirust agent, 5% coupling agent, 2.0% compound bactericide, and mix uniformly to prepare metal cutting fluid.

[0060] The base oil is paraffin-based mineral oil, the synthetic ester is isooctyl oleate and polyricinoleic acid, the organic acid is a mixture of oleic acid, ricinoleic acid and tall oilic acid, and the water-soluble organic The amine is diisopropanolamine, and the organic amines in metal cutting fluids other than...

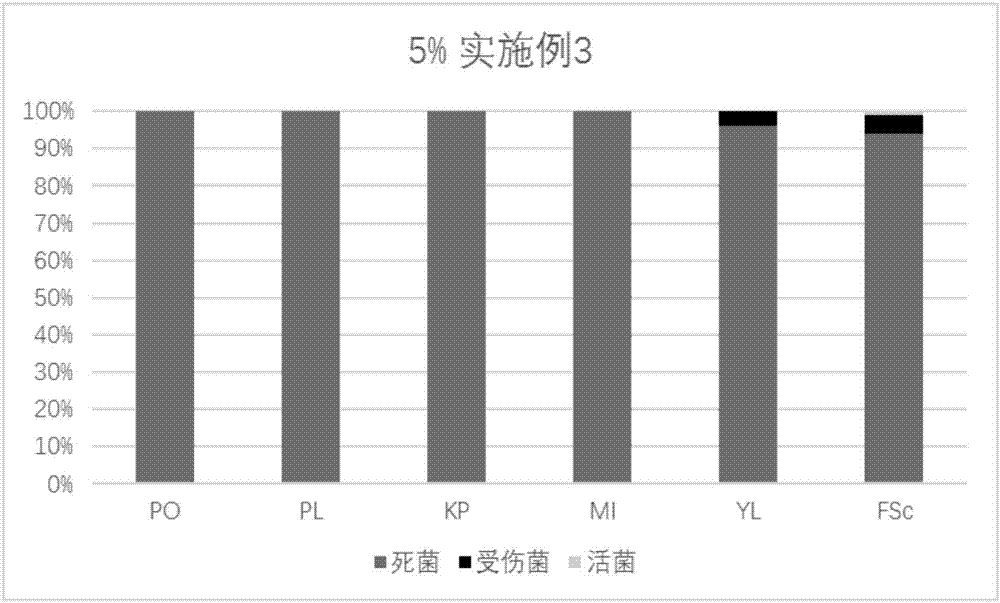

Embodiment 3

[0062] In this example, the compound fungicide includes 1,2-benzisothiazol-3-one, ε-polylysine and water-soluble organic amine, wherein 1,2-benzisothiazol-3-one The mass ratio to ε-polylysine is 4:1, and the mass ratio of water-soluble organic amine to ε-polylysine is 4:1.

[0063] The composite bactericide of this example is used in metal cutting fluid, and the following raw material components are added one by one at a temperature of 55°C and stirred: 44% of base oil, 9% of synthetic ester, 9% of organic acid, 10% of organic amine %, 4% emulsifier, 10.5% water, 5% antirust agent, 6% coupling agent, 2.5% compound bactericide, and mix uniformly to prepare metal cutting fluid.

[0064] The base oil is naphthenic mineral oil, the synthetic ester is isopentyl glycol oleate and polyricinoleic acid, the organic acid is a mixture of neodecanoic acid, oleic acid and talloleic acid, and the water-soluble The non-toxic organic amine is triisopropanolamine, the organic amine in the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com