Patents

Literature

126 results about "Neodecanoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

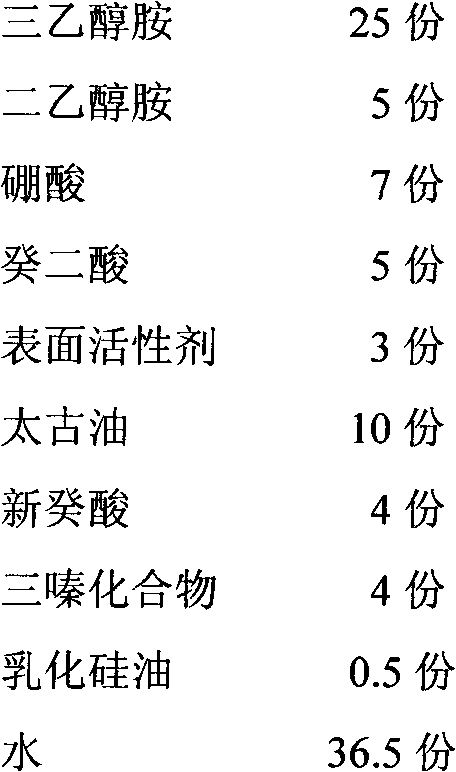

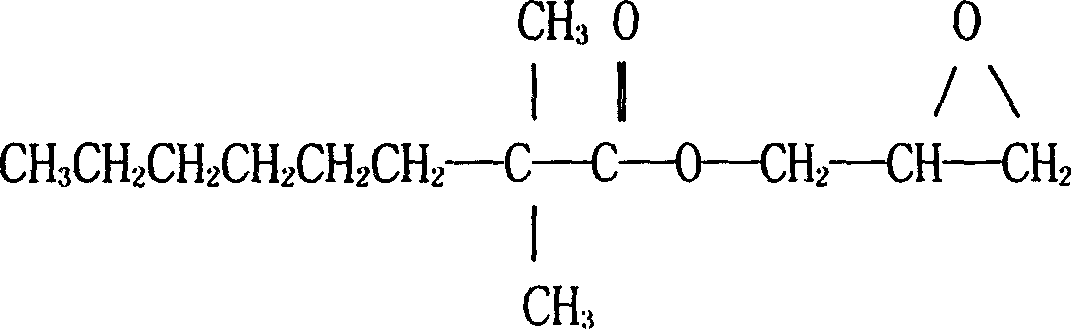

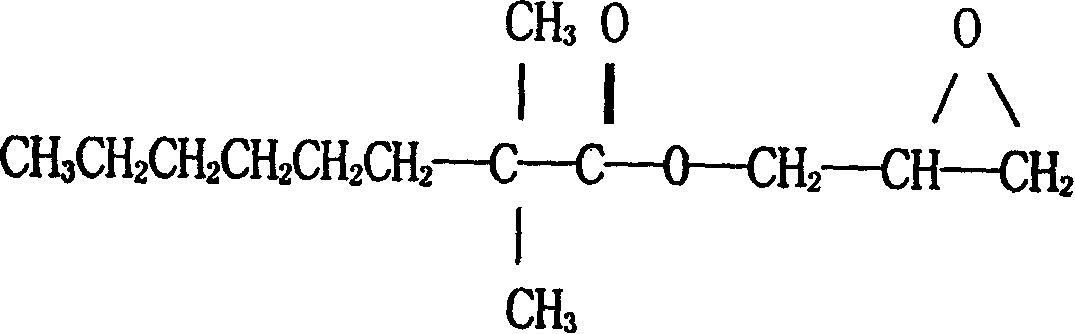

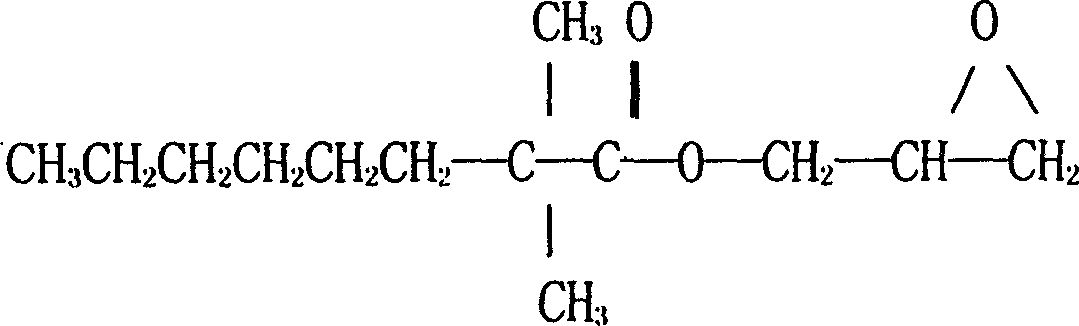

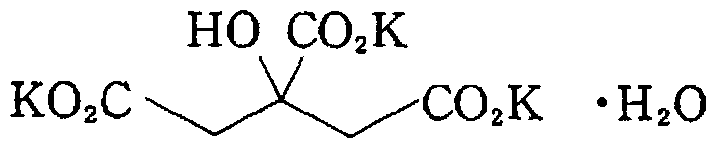

Neodecanoic acid is a mixture of carboxylic acids with the common structural formula C₁₀H₂₀O₂, a molecular weight of 172.26 g/mol, and the CAS number 26896-20-8. Components of the mixture are acids with the common property of a "trialkyl acetic acid" having three alkyl groups at carbon two, including...

Oil soluble hydrogen sulfide scavenger

ActiveUS20150025258A1Fatty acid chemical modificationFatty acids production/refiningParticulatesScavenger

The concentration of hydrogen sulfide in a hydrocarbon can be mitigated by intruding therein a zinc carboxylate oxo complex composition prepared by reacting particulate zinc oxide with a mixture of two or more carboxylic acids wherein the zinc carboxylate oxo complex composition is soluble in hydrocarbons. Useful acids useful include acetic acid, oleic acid, isobutyric acid, lineoleic acid, cekanoic acid, and neodecanoic acid.

Owner:BAKER HUGHES INC

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

Adjustment method for molecular weight distribution of rare-earth isoprene rubber

The invention relates to an adjustment method for the molecular weight distribution of a rare-earth isoprene rubber; an isoprene monomer comprises 5-20g / 100mL of hexane in concentration; a ratio of the mole number of Nd of a rare-earth catalyst to the gram of the isoprene monomer is 1*10<-7>-1*10<-6>:1, wherein the rare-earth catalyst contains a component A, i.e. neodymium naphthenate or neodymium neodecanoic acid, a component B, i.e. one or a mixture of diethyl aluminium hydride and aluminium ethyl and a component C, i.e. one of aluminium diisobutyl monochloride or aluminium diethyl monochloride; the molar ratio of A to B to C is 1:5-20:1-5; different polymer molecular weight distribution indexes MW / MN in the range of 1.90-7.80 are obtained by respectively selecting feeding modes of (A+B)+C, (A+C)+B or (C+B)+A; and according to the adjustment method, the content of a cis-1,4 structure is larger than 96.5%, and the Moony viscosity is 80+ / -5 (ML+4100 DEG C).

Owner:PETROCHINA CO LTD

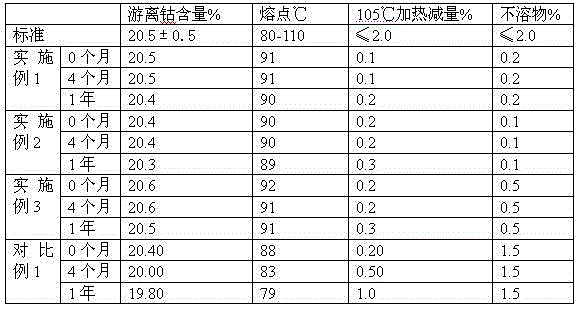

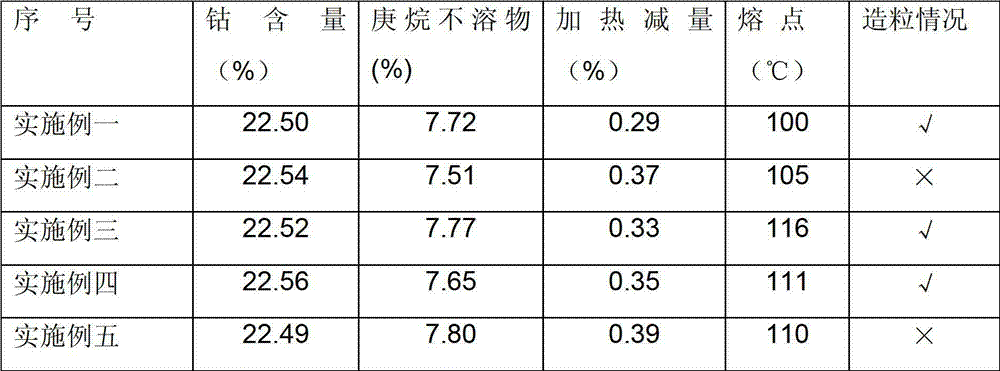

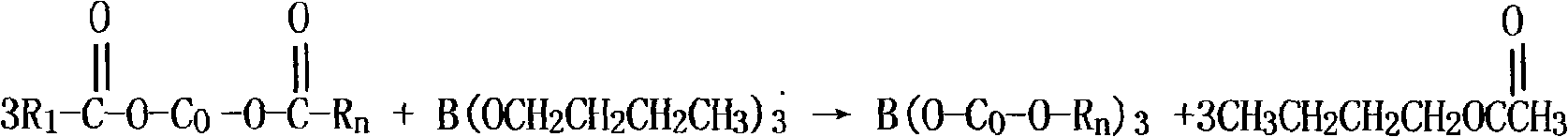

Preparation method of cobalt boracylate

InactiveCN101643480AImprove anti-static performanceFine grainGroup 3/13 element organic compoundsAcetic acidCalcium borate

The invention provides a preparation method of cobalt boracylate, belonging to the field of the preparation of composite material accelerating agent. The preparation method comprises the following steps: mixing neodecanoic acid, isooctyl acid, glacial acetic acid, dimethylbenzene and cobalt hydroxide, carrying out acid-base neutralization reaction, and obtaining an intermediate product after the neutralization reaction is finished; adding tributyl borate into the obtained intermediate product and carrying out boracylate reaction, adding calcium borate as additive simultaneously, and obtaininga reaction product, namely, cobalt boracylate after the boracylate reaction is finished. In the preparation method, the neodecanoic acid, the isooctyl acid, the lower fatty acid glacial acetic acid and the dimethylbenzene are matched and carry out the acid-base neutralization reaction together with the cobalt hydroxide to generate the intermediate product; the reaction velocity can be improved andthe forming of the intermediate product is accelerated due to the effects of the glacial acetic acid and the dimethylbenzene; in addition, in the final boracylate reaction, as the calcium borate as the additive is added together with the tributyl borate, the reaction time is effectively shortened, and the insoluble substance performance and the anti-static property of the cobalt boracylate whichis prepared finally are improved.

Owner:大连爱柏斯化工股份有限公司

Metal paste and film formation method using the same

InactiveUS20050127332A1Increasing the thicknessLower resistanceConductive materialNon-conductive material with dispersed conductive material2-Ethylhexanoic acidColloidal particle

Owner:TANAKA PRECIOUS METAL IND

Total-synthesis water-base metal cutting fluid and preparation method

The invention discloses a total-synthesis water-base metal cutting fluid and a preparation method. The cutting fluid is composed of triethanolamine, monoethanolamine, a special amine, an antirust agent, ethylene oxide-propylene oxide block copolymer PN30, neodecanoic acid, a quaternary amine cationic surfactant chlorine salt and hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, and the balance water. The preparation method comprises: adding triethanolamine, monoethanolamine, the special amine, the antirust agent and water into a reaction tank according to a ratio and stirring; adding ethylene oxide-propylene oxide block copolymer PN30 and neodecanoic acid according to a ratio into the mixture in the reaction tank, and stirring; and finally adding the quaternary amine cationic surfactant chlorine salt and hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine into the reaction tank and stirring, so as to obtain the cutting fluid. The cutting fluid has advantages of a total-synthesis type cutting fluid, is excellent in performances and does not contain nitrites and other compositions harmful to human body. By utilizing the method for preparing the cutting fluid, the preparation process is simple and operation is convenient.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

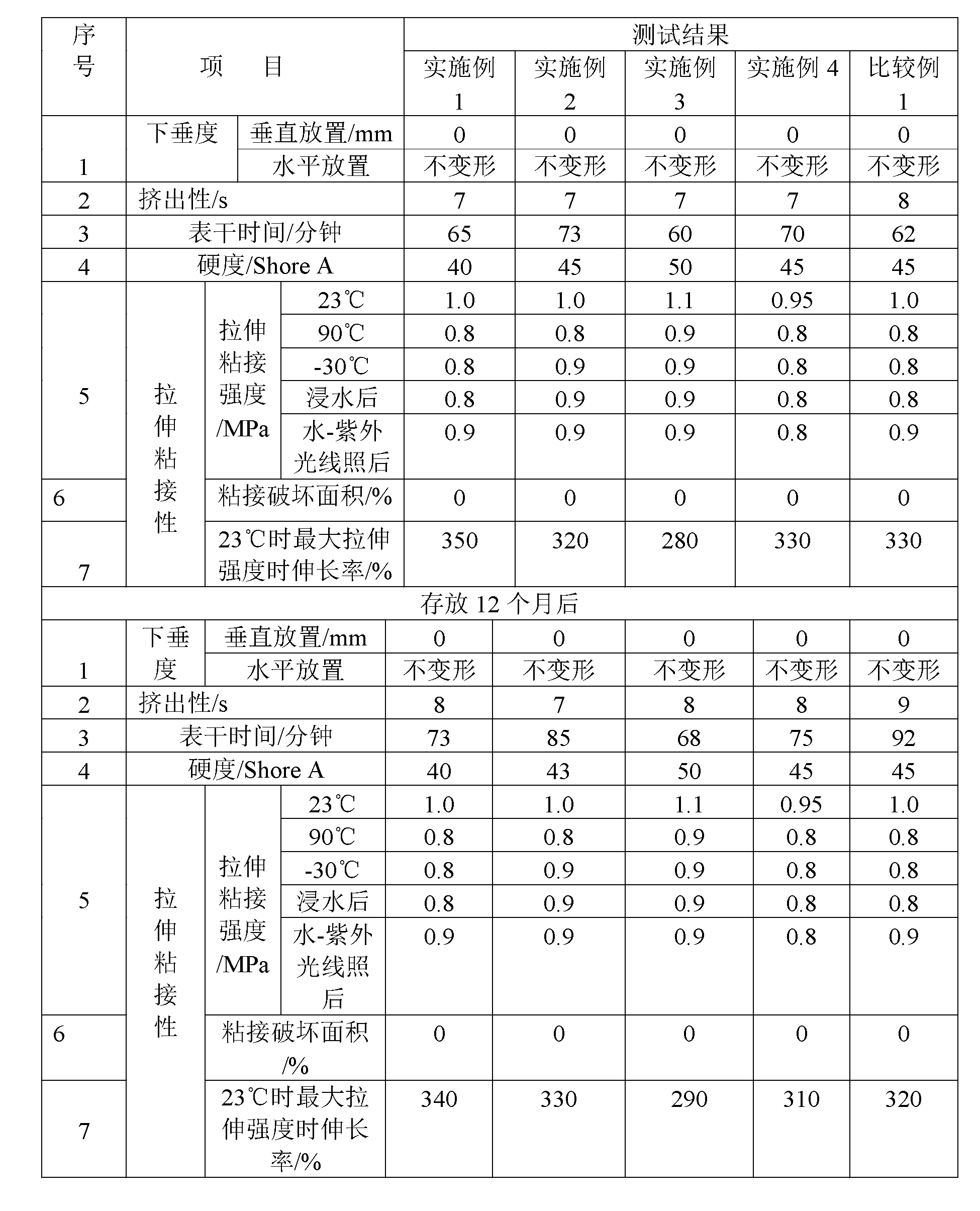

Environment-friendly organosilicone sealant and manufacturing method thereof

InactiveCN103013430AEnvironmentally friendly and healthyReduce dosageNon-macromolecular adhesive additivesOmegaSealant

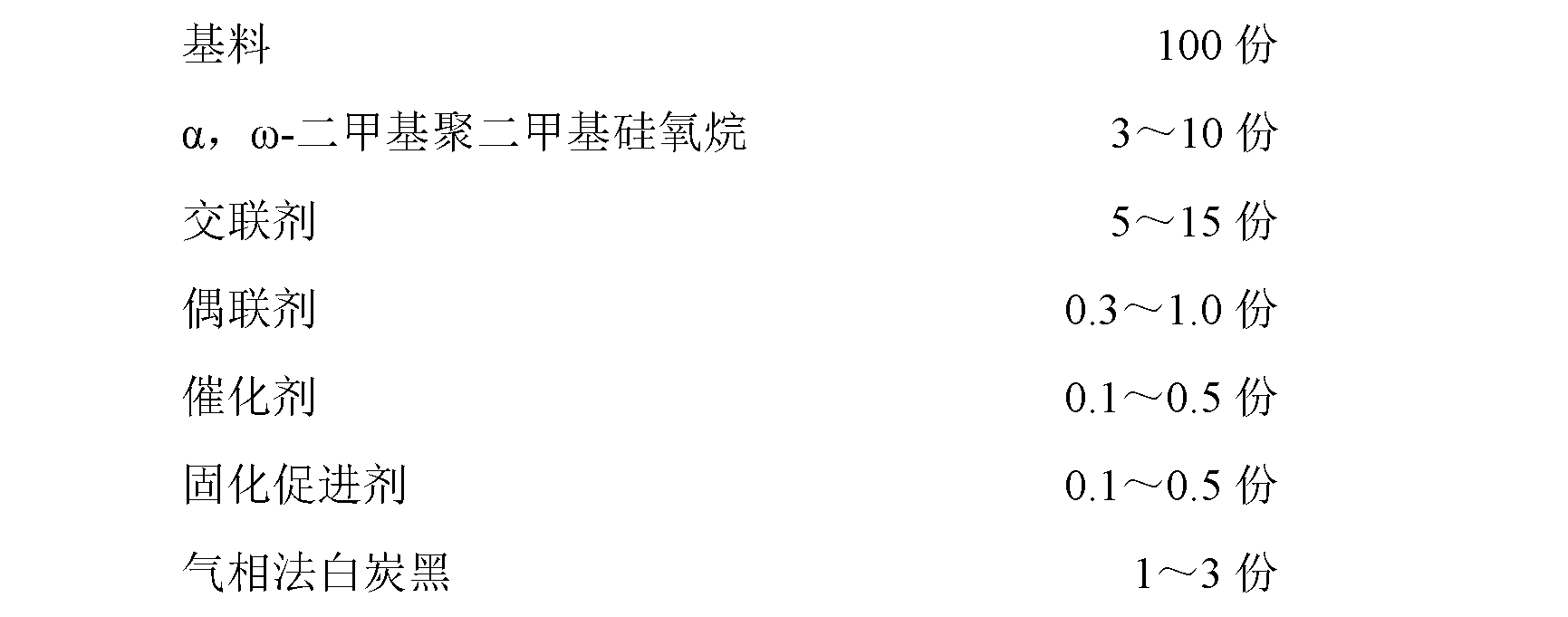

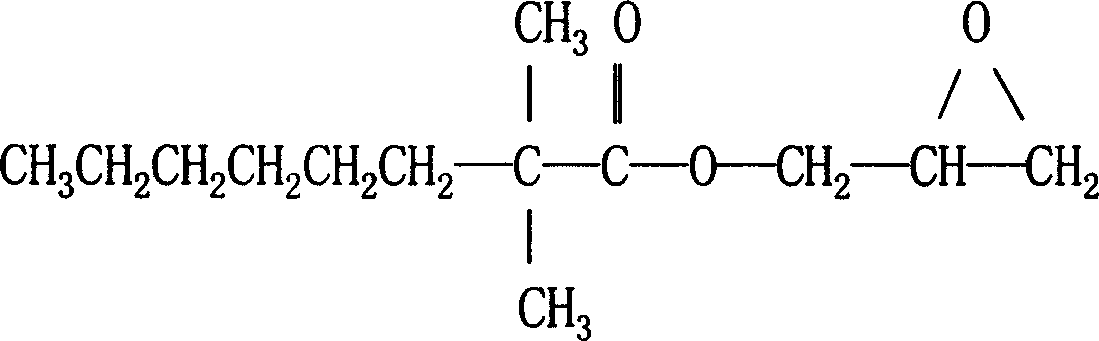

The invention discloses an environment-friendly organosilicone sealant which is characterized in that 100 parts by mass of alpha,omega-dyhydroxyl polydimethylsiloxane and 50-150 parts by mass of packing are added into a vacuum kneader for dehydration and blending for 120-240min at 120-170 DEG C and at the vacuum degree of 0.06-0.099MPa, and a base stock is obtained. 100 parts by mass of base stock, 3-10 parts by mass of alpha,omega-dimethyl polydimethylsiloxane, 5-15 parts by mass of cross-linking agent, 0.3-1.0 parts by mass of coupling agent, 0.1-0.5 parts by mass of dimethylbis [(1-oxoneodecyl) oxy] stannane, neodecanoic acid zinc and organic bismuth, 0.1-0.5 parts by mass of curing accelerator and 1-3 parts by mass of fumed silica are added into a dispersion machine for vacuum mixing for 20-4040 at a room temperature and at the vacuum degree of 0.06-0.099MPa, and the environment-friendly organosilicone sealant is obtained. Various performances of the environment-friendly organosilicone sealant meet requirements of building sealants, and can be widely applied to the field of buildings.

Owner:CHENGDU GUIBAO SCI & TECH

Liquefied dicyandiamide and its preparing process

Liquefacient dicyandiamide and its preparation method. The method comprises: adding 100 parts of dicyandiamide, 300-600 parts of dehydrated neodecanoic acid glyceride, 50-200 parts of solvent, 0.5-1 par of 2-ethyl-4-methylimidazol or 2-methylimidazol into a reactor; mixing and heating, reacting for 12-14hours at 140degree Cí½150degree C ; vacuumizing and removing the solvent, obtaining viscous liquid. When the liquefacient dicyandiamide is used with ethoxyline resin, the weight ratio of liquefacient dicyandiamide to ethoxyline resin is 30-50í†100. Liquefacient dicyandiamide of the invention could be dissolved in ethoxyline resin, has an ability of solidifying ethoxyline resin with high mechanical strength.

Owner:北京科化新材料科技有限公司

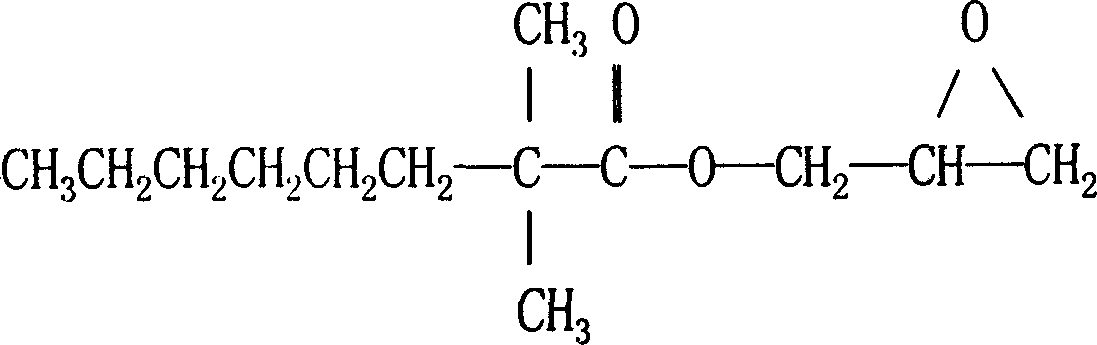

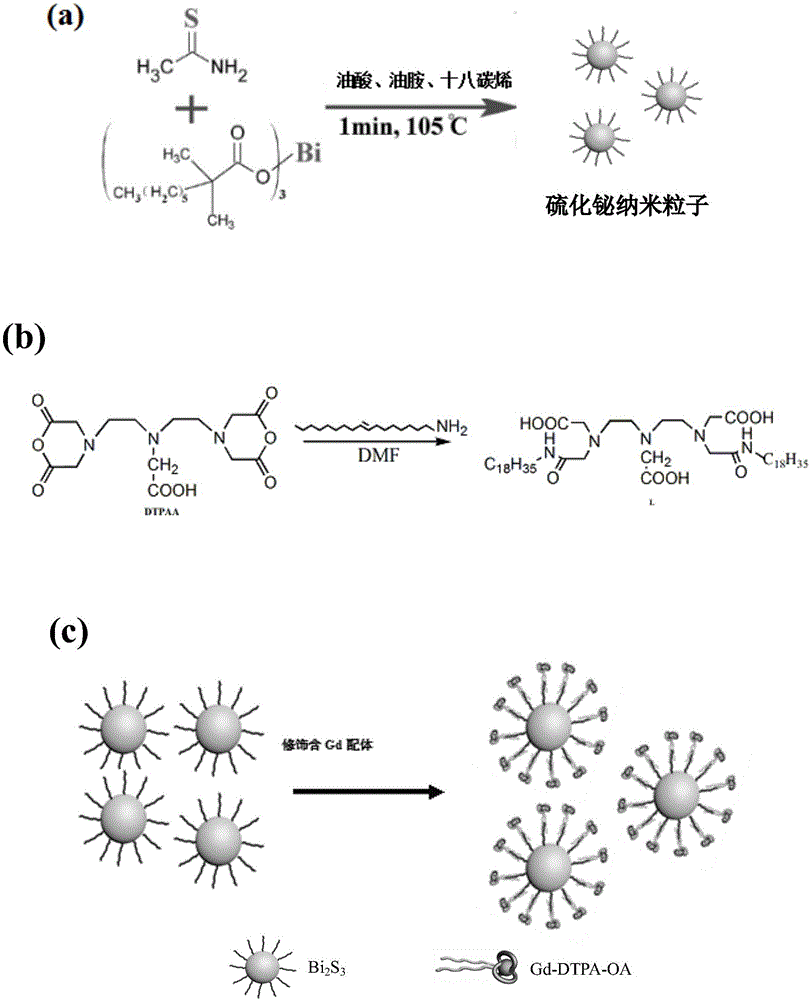

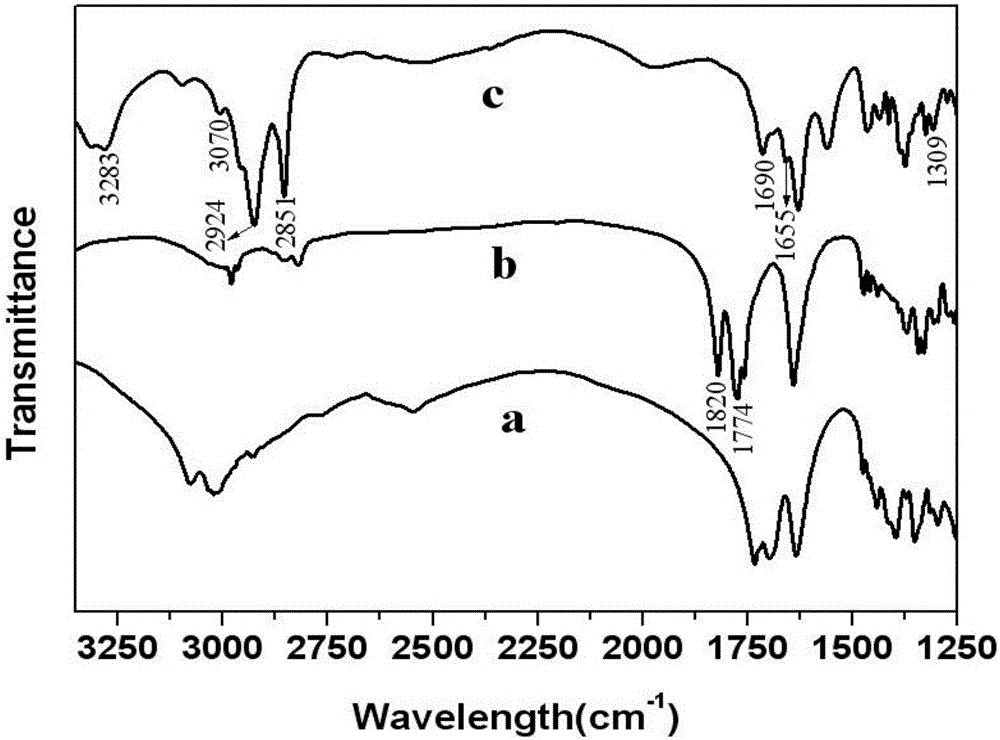

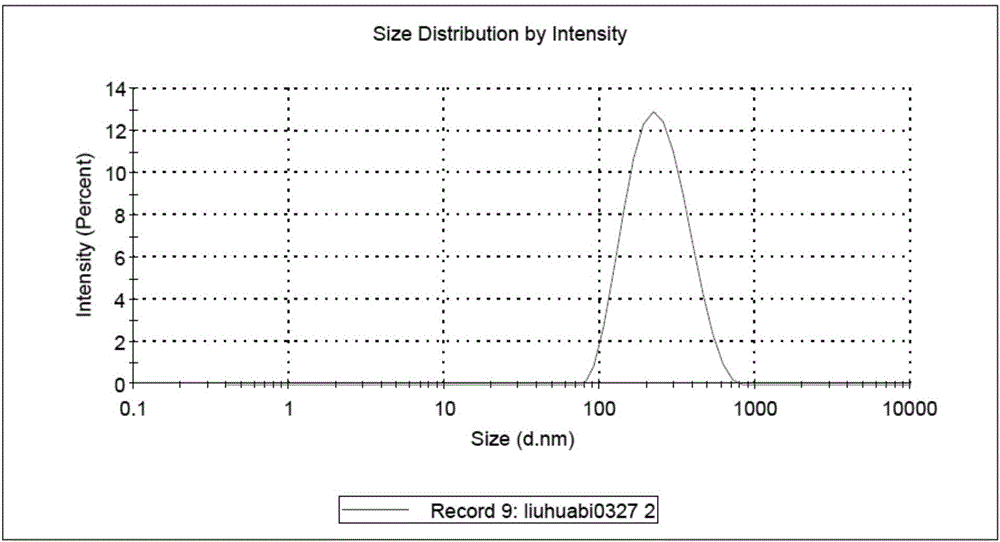

Preparation method of gadolinium-modified bismuth sulfide nanometer diagnosing agent

InactiveCN106390145APhotothermal therapy achievedMake up for deficienciesEnergy modified materialsX-ray constrast preparationsBismuth sulfideDiethylenetriamine

The invention discloses a preparation method of a gadolinium-modified bismuth sulfide nanometer diagnosing agent used for MRI (magnetic resonance imaging) and CT (computerized tomography) double-mode imaging instruction. According to the preparation method, oleic acid, oleylamine, 1-octadecene, neodecanoic acid bismuth and thioacetamide are used as raw materials to composite bismuth sulfide, diethylenetriamine pentaacetic acid bicycle-anhydride and bismuth trichloride are used to prepare a Dd-DTPA-OA ligand, and then the Dd-DTPA-OA ligand is modified by the bismuth sulfide to obtain a gadolinium-modified bismuth sulfide nanometer material. The preparation method of the gadolinium-modified bismuth sulfide nanometer diagnosing agent has the advantages that a research background of an existing medical contrast agent is combined, a CT / MRI double-mode contrast agent preparation is simplified, and the preparation method is simple in preparation, highly controllable, high in efficiency, easy for industrialized production and the like.

Owner:HUBEI UNIV OF TECH

Peroxided neodecanoic acid isopropyl phenyl ester and method for preparing peroxided neodecanoic acid isopropyl phenyl ester through phase transfer catalyst

InactiveCN105693584AImprove product qualityHigh yieldOrganic compound preparationPeroxy compound preparationPtru catalystPotassium hydroxide

The invention relates to the technical field of initiators, in particular to peroxided neodecanoic acid isopropyl phenyl ester and a method for preparing the peroxided neodecanoic acid isopropyl phenyl ester through a phase transfer catalyst. The method for preparing the peroxided neodecanoic acid isopropyl phenyl ester comprises the steps that 1, cumyl hydroperoxide and potassium hydroxide are subjected to a reaction; 2, the phase transfer catalyst is added; 3, neodecanoyl chloride is added dropwisely; 4, standing is performed for layering, and mother solution separation is performed; 5 washing is performed. The phase transfer catalyst is added in the process of preparing the peroxided neodecanoic acid isopropyl phenyl ester, a mother solution is layered more easily, and mother solution separation is more easily achieved; furthermore, after the phase transfer catalyst is added, the quality of the obtained peroxided neodecanoic acid isopropyl phenyl ester is better; in addition, the yield of the peroxided neodecanoic acid isopropyl phenyl ester is improved, and the technology for preparing the peroxided neodecanoic acid isopropyl phenyl ester is high in efficiency and yield.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

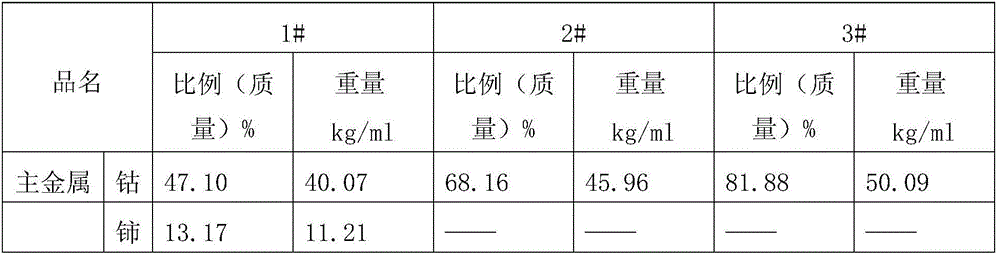

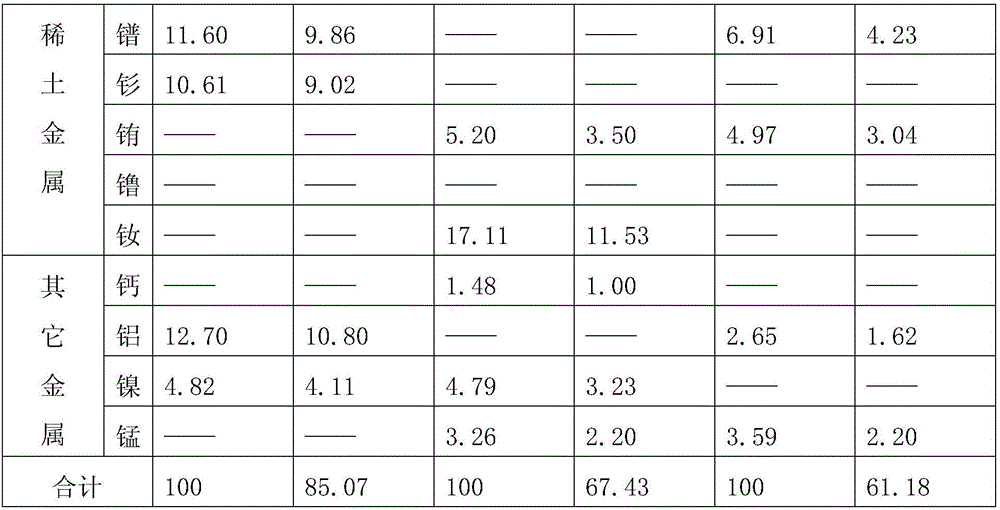

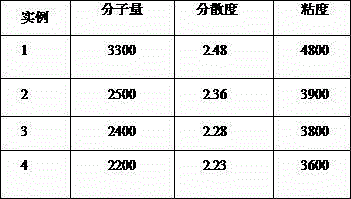

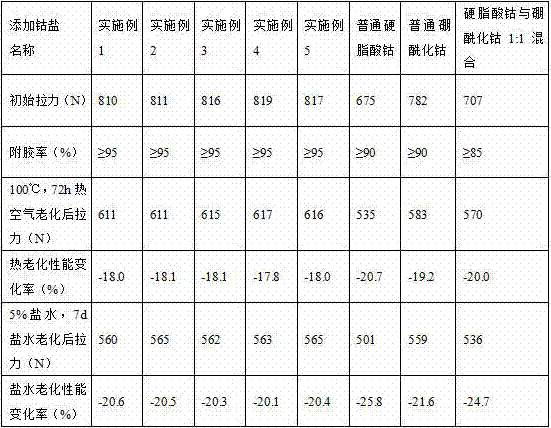

Direct adding type high-performance cobalt salt adhesion promoting agent and preparation method thereof

The invention discloses a direct adding type high-performance cobalt salt adhesion promoting agent and a preparation method thereof. The adhesion promoting agent comprises neodecanoate and boroacylate; the neocaprate is prepared from 18%-25% of a mixed metal, 44%-50% of neodecanoic acid, 18%-20% of neopentanoic acid and 12%-13% of propionic acid; the boroacylate is prepared from 16%-21% of a mixed metal, 33%-35% of neodecanoic acid, 9%-10% of neopentanoic acid, 17%-20% of propionic acid and 18%-21% of tributyl borate, wherein according to the mass percentage, the mixed metal comprises 46%-84% of cobalt, 10%-36% of rare earth elements, and 6%-18% of other metals. The product releases active metal ions and active bivalent cobalt ions under vulcanizing conditions to form a 'synergistic catalytic' effect, the catalytic ability of single cobalt ions is increased in multiples, the product amount is reduced by half, the residual amount of cobalt in rubber products can be reduced by about 60%, the residual amount of organic acid radicals can be reduced by about 40%, and the adhesion level and other physical indicators all can reach or exceed the same level with use of an original cobalt salt adhesion promoting agent, so that improvement of the aging performance of the rubber products and increase of the service life of the rubber products are facilitated, and the purpose of low cobalt formation of the direct adding type cobalt salt adhesion promoting agent is achieved.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

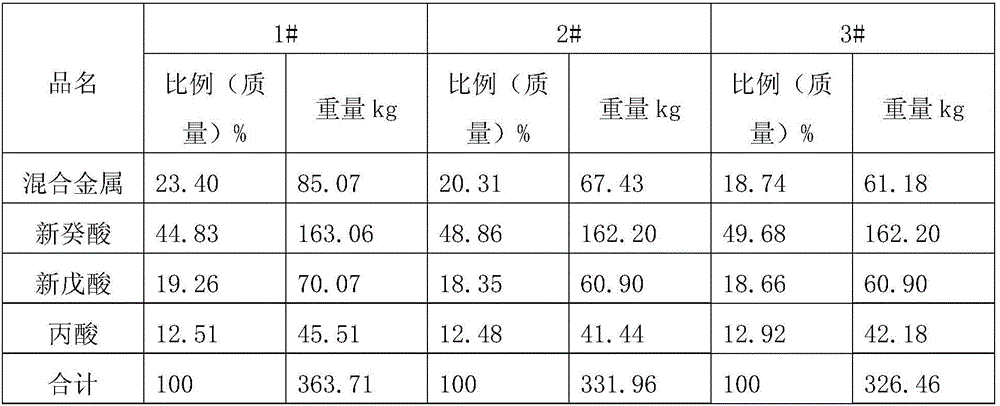

Preparation method of high-solid acrylic polyurethane coating

The invention provides a preparation method of a high-solid acrylic polyurethane coating. According to the invention, acrylic acid is adopted as a monomer; a tert-amyl peroxide is adopted as an initiator; and with a chain transfer agent and glycidyl neodecanoate, high-solid-content low-viscosity hydroxy acrylic resin is prepared. An optimal process comprises the following points: a reaction temperature is 140 DEG C; a monomer dosing time is 4.5h; the amount of the tert-amyl peroxide initiator is 2.5% of the total amount of the monomer; the amount of the chain transfer agent is 3% of the total amount of the monomer; xylene and butyl acetate are adopted as a synthetic solvent; the addition amount of glycidyl neodecanoate is 20% of the total amount of the monomer. The synthesized high-solid acrylic resin is adopted as a base material; polyurethane is prepared according to that the ratio of isocyanato content in isocyanate to hydroxy content in an N-3390 curing agent from Germany is 5:1; polyurethane is added into the base material, such that a high-solid acrylic polyurethane automotive finish paint is obtained. The method is environment-friendly, and has a low preparation cost.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

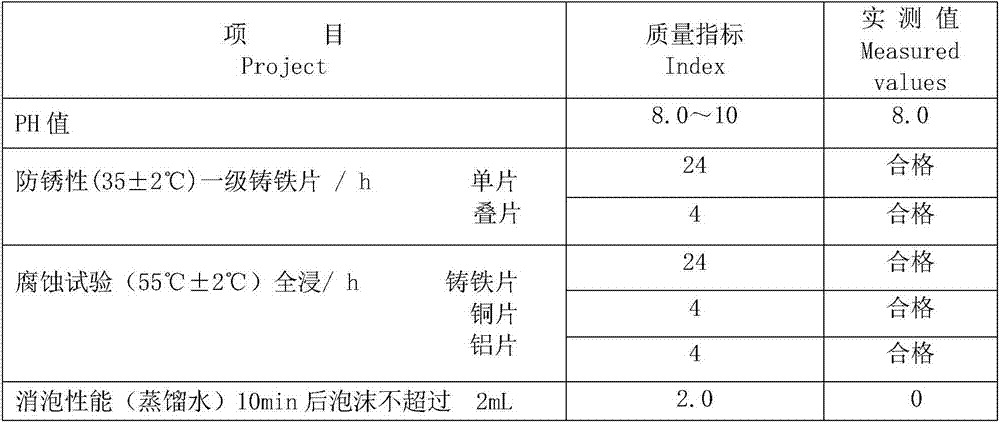

Finishing solution and preparation method thereof

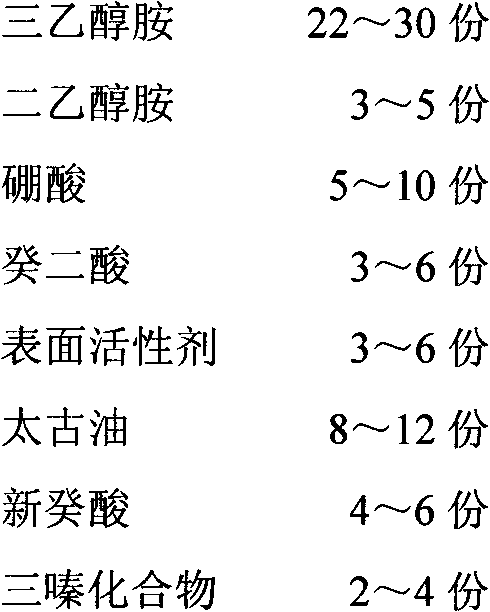

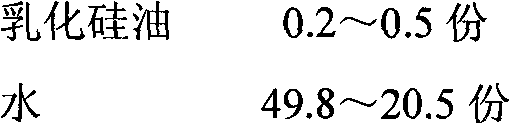

InactiveCN102876438AImprove the lubrication effectReduce contact partsLubricant compositionWorking environmentBoric acid

The invention relates to a finishing solution and a preparation method thereof. The finishing solution consists of the following components in part by weight: 22 to 30 parts of triethanolamine, 3 to 5 parts of diethanol amine, 5 to 10 parts of boric acid, 3 to 6 parts of sebacic acid, 3 to 6 parts of surfactant, 8 to 12 parts of sulfonated caster oil, 4 to 6 parts of neodecanoic acid, 2 to 4 parts of triazine compound, 0.2 to 0.5 part of emulsified silicone oil and 49.8 to 20.5 parts of water. The finishing solution has a good lubricating effect, can effectively remove rust and oxide skin on the surface of a metal piece to make the metal piece bright like before, has a good antirust effect, eliminates an anti-rust process flow, has a good defoaming capacity, and avoids foam overflow to avoid influencing work environment.

Owner:XIAOGAN JIANGYAN CHEM

Preparation method for high-stability cobalt neocaprate mixed salt

ActiveCN104788718ADelay agingReduce material wire corrosionNon-macromolecular adhesive additivesPropionatePropanoic acid

The invention relates to a preparation method for high-stability cobalt neocaprate mixed salt. The preparation method is characterized by comprising the following steps: 1 salt forming reaction, to be specific, adopting a mixed acid of cobalt hydroxide, propanoic acid and neodecanoic acid as a raw material, reacting for greater than or equal to 2 hours at the temperature of 150-190 DEG C to generate a mixed salt of cobalt propionate and cobalt neocaprate; 2 acid replacement reaction, to be specific, adding isocaprylic acid and stearic acid into the reaction system in the step 1, reacting through controlling the temperature to be 190-200 DEG C and the time to be greater than or equal to 1 hour for replacement of the propanoic acid; 3 finished product preparation, to be specific, in the reaction system in the step 2, controlling the temperature to be 200-210 DEG C, and adding cobalt hydroxide as an auxiliary agent, so as to prepare the high-stability cobalt neocaprate mixed salt. The prepared product has better bonding performance, higher ageing resistance and good stability.

Owner:JIANGYIN SANLIANG CHEM

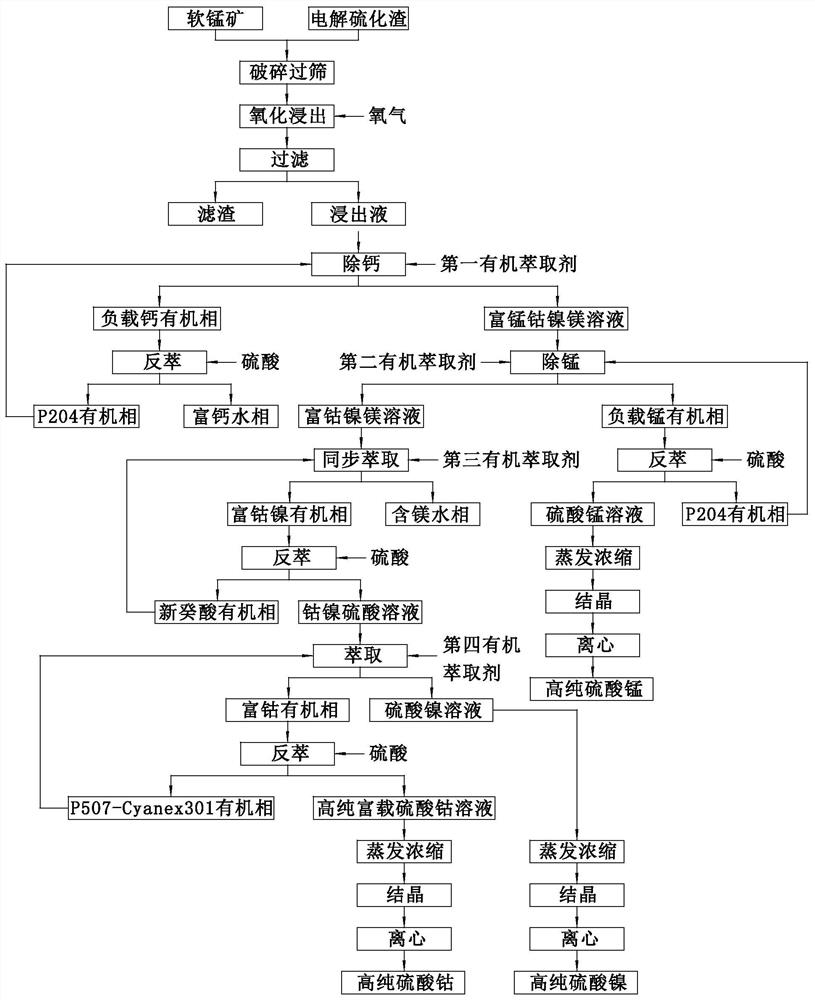

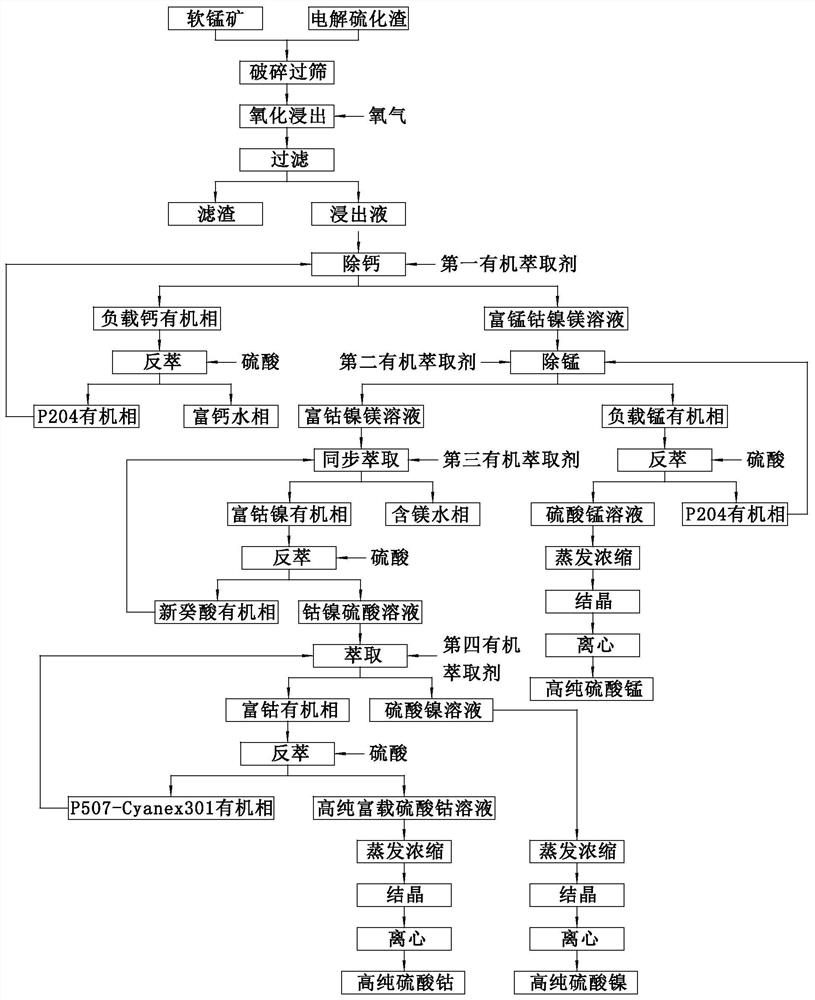

Method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag

PendingCN112662877AAchieve leachingSimple processCobalt sulfatesNickel sulfatesManganese sulfideSulfate

The invention discloses a method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel: taking a solution rich in cobalt, nickel and magnesium, and adding a third organic extractant formed by mixing saponified neodecanoic acid with sulfonated kerosene for extraction to obtain an organic phase rich in the cobalt and the nickel and a magnesium-contained aqueous phase; (6) cobalt removal: taking the organic phase rich in the cobalt and the nickel, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, and adding a fourth organic extractant formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution; and (7) preparation of the high-purity nickel sulfate. The method has the advantages that the method is simple and feasible, leaching of nickel sulfate can be realized, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions with precipitation of fluorine ions can be avoided.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

Preparation method for cobalt boroacylate with low melting point

ActiveCN103113416ALow melting pointSmall dispersionCobalt organic compoundsGroup 3/13 element organic compoundsCalcium boratePropanoic acid

The invention discloses a preparation method for cobalt boroacylate with a low melting point. The preparation method comprises the following steps of: carrying out a neutralization reaction, namely, mixing neodecanoic acid, propionic acid, valeric acid, stearic acid, rosin, dimethylbenzene and cobalt hydroxide to carry out acid-base neutralization reaction so as to obtain an intermediate product after the neutralization reaction is completed; carrying out boro-acylation reaction, namely, adding tributyl borate to the obtained intermediate product to carry out boro-acylation reaction, adding the calcium borate as an additive, wherein the reaction product obtained by the boro-acylation reaction is cobalt boroacylate. The cobalt boroacylate prepared by the preparation method disclosed by the invention is low in melting point and good in dispersion; and moreover, high-concern substances mentioned by the REACH (REGULATION concerning the Registration, Evaluation,Authorization and Restriction of Chemicals) are avoided, and a green passport is provided for the exportation of products.

Owner:大连爱柏斯化工股份有限公司

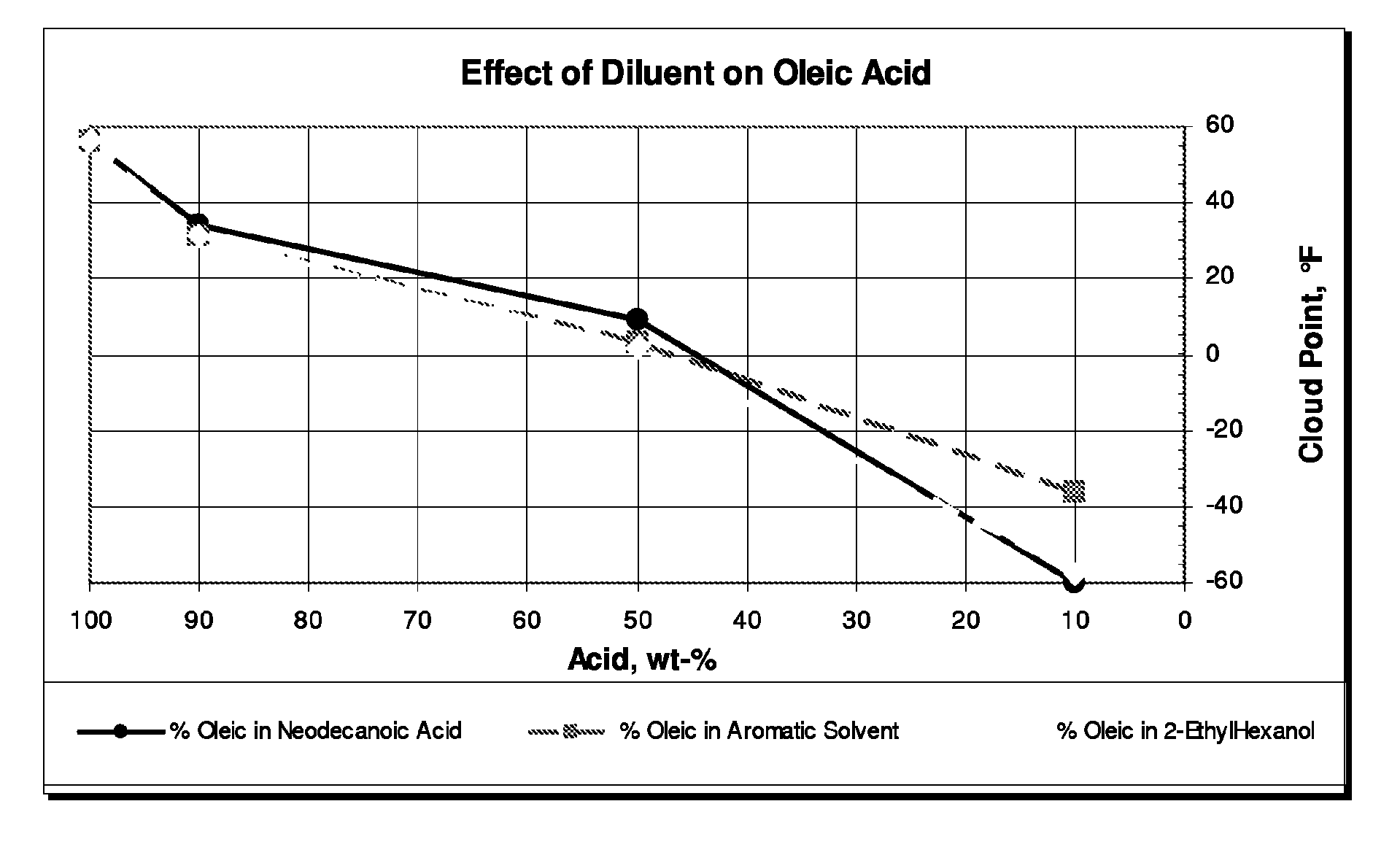

Branched carboxylic acids as fuel lubricity additives

ActiveUS7867295B2Improve the lubrication effectLiquid carbonaceous fuelsFuel additivesPivalic acidIsostearic acid

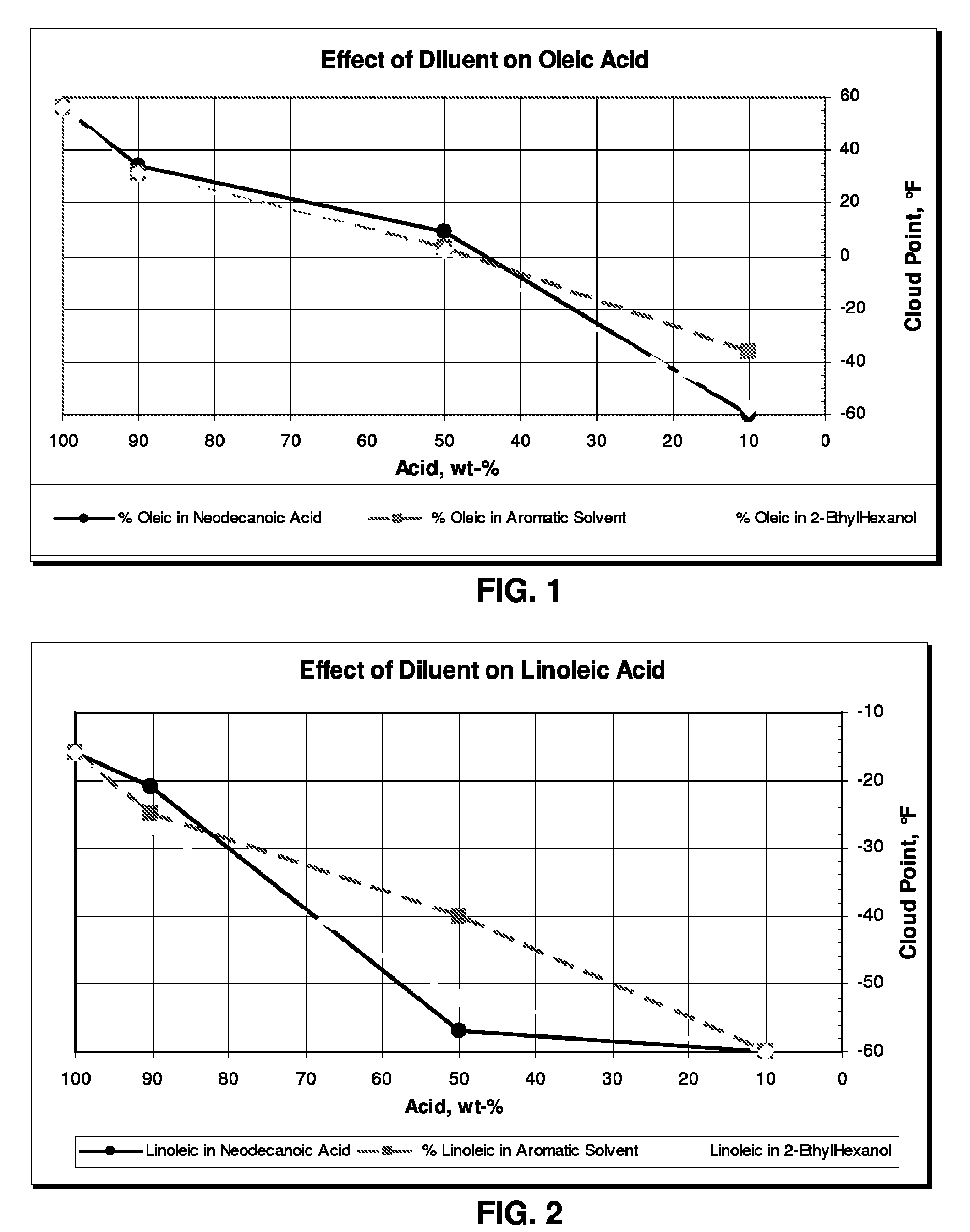

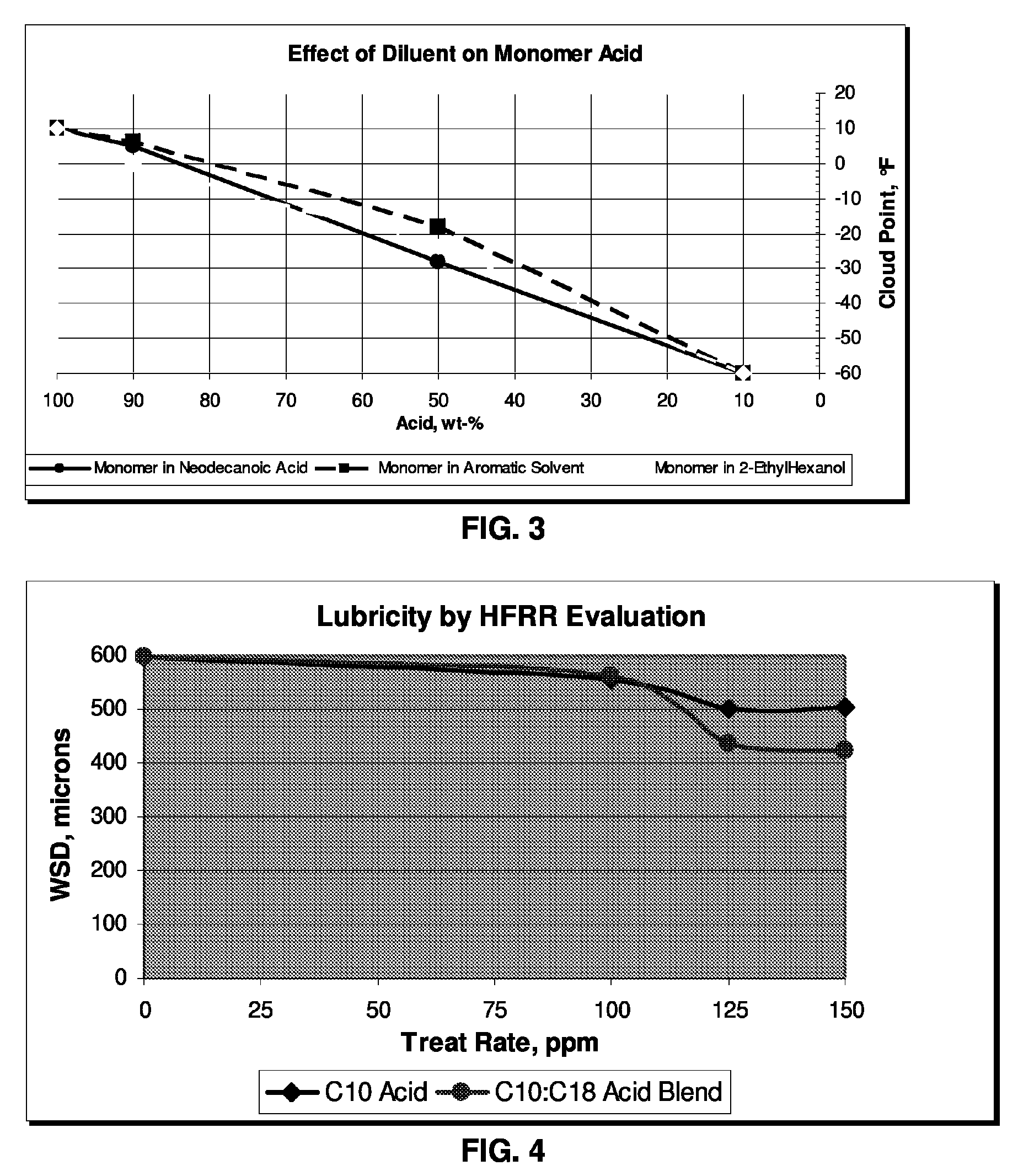

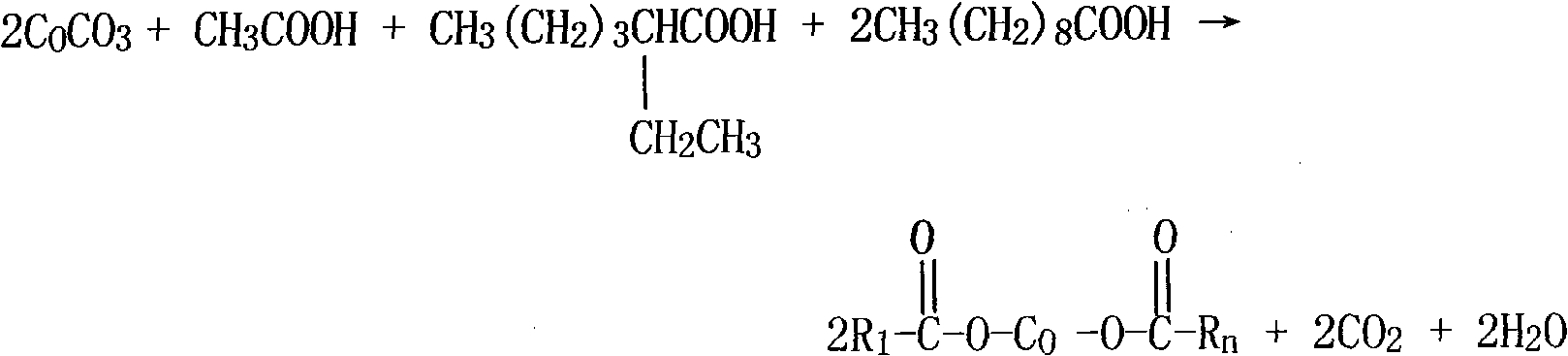

Certain branched carboxylic acids may serve as improved lubricity additive compositions in distillate fuels, and in particular for cold weather applications. Suitable branched carboxylic acids may include, but are not necessarily limited to, isostearic acid, neodecanoic acid, isononanoic acid, neononanoic acid, neoundecanoic acid, isovaleric acid, pivalic acid, and the like and mixtures thereof. The branched carboxylic acids may be used alone or together with straight chain carboxylic acids, and optionally with an aromatic solvent.

Owner:BAKER HUGHES HLDG LLC

Method for synthesizing cobalt neocaprate through water solvent

InactiveCN101805253ALow costEnsure stabilityCarboxylic acid salt preparationPropanoic acidReaction temperature

The invention relates to a method for synthesizing cobalt neocaprate through a water solvent, which relates to a processing aid used in rubber product production. The method is characterized by comprising the following steps: adding 40 to 45 parts by mass of basic cobaltous carbonate, 13 to 15 parts by mass of propionic acid, 16 to 20 parts by mass of neopentanoic acid and 65 to 67 parts by mass of neodecanoic acid into 90 to 100 parts by mass of solvent water, stirring and simultaneously carrying out a reflow reaction, wherein the reflow reaction temperature is 120 to 130 DEG C, and the reflow reaction time is 4 to 8 hours; obtaining a mixed salt of propionic acid-neopentanoic acid-cobalt neocaprate after the reaction is finished; and finally removing the solvent water and the unreacted organic acid through a distillation method to obtain the cobalt neocaprate. Water is used for replacing organic solvents with larger toxicity, such as toluene, dimethylbenzene and the like in the preparation process, and the basic cobaltous carbonate is used for replacing cobalt hydroxide, thereby not only the production process is green and environment-friendly, but also the production cost is greatly lowered, the stability of Co (II) is effectively kept, the product quality is enhanced, and the method has higher economic benefit and social benefit.

Owner:镇江迈特化工新材料有限责任公司

Process for preparing cobalt boracylate by hybrid reaction of cobaltous carbonate and organic carboxyl acid

InactiveCN101348505ALong-term stabilityPrevent rustCobalt organic compoundsGroup 3/13 element organic compoundsOrganic synthesisReaction temperature

The invention provides a process for preparing a carboxyl cobalt-boron complex by the mixing reaction of cobalt carbonate and an organic carboxylic acid, belonging to the organic synthesis technical field. Cobalt carbonate is taken as a material, and the invention is characterized in that the preparation process comprises the following steps that: (1) cobalt carbonate, glacial acetic acid, neodecanoic acid and isooctanoic acid are taken as materials and put in a normal pressure sealing reactor, the reaction temperature is controlled to be between 100 and 110 DEG C, and the reaction time is no less than 3h; (2) tributyl borate is added in the reaction system, the reaction temperature is controlled to be between 160 and 180 DEG C, the reaction time is no less than 2h, and the carboxyl cobalt-boron complex and the side product of butyl acetate are generated; (3) the temperature is controlled to be between 175 and 185 DEG C, and active carbon and resin acid are added to obtain the refined product. In the invention, cobalt carbonate is used to replace cobaltous hydroxide, the carboxyl cobalt-boron complex is added with adhesion agent and activated calcium carbonate with amphoteric compound, thereby effective balancing ph in the system, making the product effectively prevent corrosion of metal, enhancing adhesion level and improving thermal oxygen resistant, heat resistant and steam ageing resistant performances.

Owner:逯大成

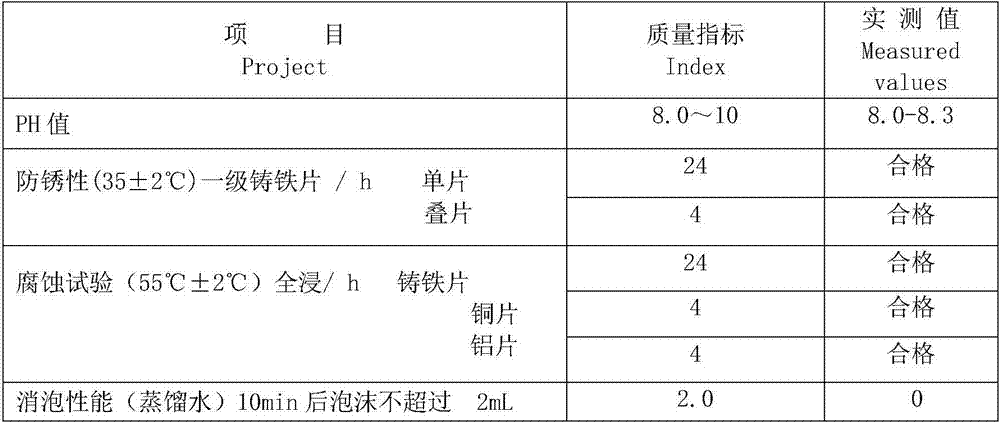

Aerolite cutting fluid with low PH value, its preparation and application

ActiveCN107151578AImprove protectionImprove the finishLubricant compositionPhosphateBenzisothiazolone

The invention discloses an aerolite cutting fluid with low PH value and its preparation method, and belongs to the domain of the cutting fluid. The cutting fluid is prepared from, by weight ratio, trimethylolpropane trioleate, tall oil, triethanolamine, neodecanoic acid, phosphate, benzisothiazolone, hard water resisting agent, tribasic acid, benzotriazole, castor oil polyoxyethylene ether, trihydroxy hexahydro-s-triazine, and 2, 6-bismethylmorpholine; the allowance is water. The aerolite is extremely sensitive to alkalinity; the cutting solution has low PH value due to its special preparation method and composition, and the PH value is ranged from 8.0 to 8.3; the cutting fluid is free from corrosion to the aerolite and magnalium zinc alloy which are extremely easy to corrode; moreover, the class 2 and class 7 aluminum alloys in the aerolite are big in hardness and not easy to process. The cutting solution has excellent lubricating performance and can be used for cutting during the process conveniently; the surface smoothness is high.

Owner:辽宁泰克诺美科技有限公司

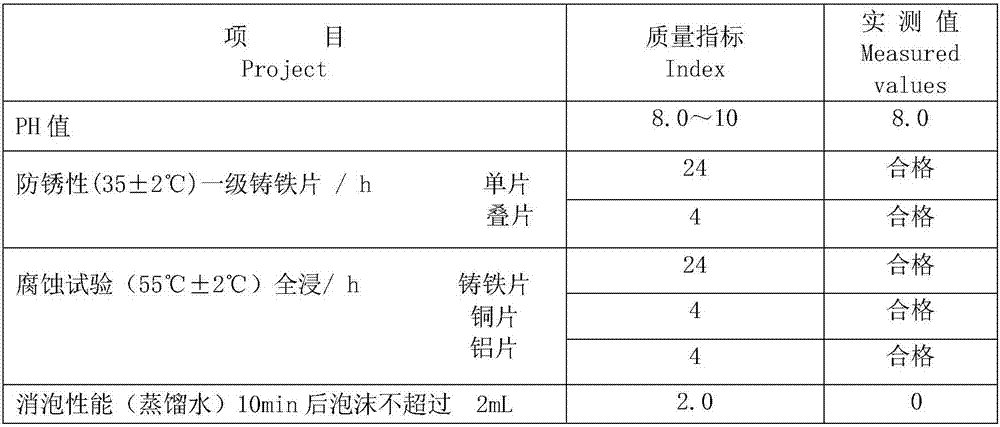

Finishing liquid for hot-galvanized plate and preparation method for finishing liquid

ActiveCN104194908AGood anti-rust functionImprove rust resistanceLubricant compositionSodium metasilicateTricarboxylic acid

The invention relates to finishing liquid for a hot-galvanized plate and a preparation method for the finishing liquid. The finishing liquid comprises a component I and a component II, wherein the component I comprises following ingredients in parts by weight: 23-33 parts of water, 5-8 parts of dibasic acid, 8-12 parts of tricarboxylic acid and 54-57 parts of triethanolamine; the component II comprises following ingredients in parts by weight: 47-68 parts of water, 4-8 parts of sodium carbonate, 3-5 parts of potassium hydroxide, 2-4 parts of disodium ethylenediamine tetraacetate, 6-10 parts of sodium metasilicate pentahydrate, 8-12 parts of reverse block polyether, 6-8 parts of neodecanoic acid and 3-6 parts of sodium benzoate. The finishing liquid has relatively good rust-proof and lubricating effects, has excellent wetting and cleaning properties and relatively high cleaning ability, and can lubricate and repair the surface of a roll; the finished galvanized plate is smooth in surface, and defects of finishing spots and coating moire can be effectively eliminated or reduced; the finishing liquid has good foam-inhibiting and defoaming functions, so that liquid can be avoided from remaining on the surfaces of the roll and a steel plate and the foam can be avoided from overflowing around to affect the working environment.

Owner:江苏苏北能源科技有限公司

Oil soluble hydrogen sulfide scavenger

Owner:BAKER HUGHES HLDG LLC

Cleaning agent for clearing laser carving residue from plastic shell of intelligent mobile terminal and cleaning method

InactiveCN107400566AQuality improvementImprove pass rateNon-ionic surface-active compoundsOrganic detergent compounding agentsGlycerolCleansing Agents

The invention relates to a cleaning agent for clearing laser carving residue from a plastic shell of an intelligent mobile terminal. The cleaning agent is prepared from the following ingredients in percentage by mass: 10 to 30 percent of penetrating agents, 10 to 30 percent of corrosion inhibiters, 1 to 10 percent of surfactants, 1 to 20 percent of organic auxiliary agents, 1 to 10 percent of chelating agents and the balance water; the penetrating agents are one kind of substances or a mixture of more than two kinds of substances in the following substances of diethylene glycol monobutyl ether, diethylene glycol dimethyl ether, proprylene glycol monomethyl ether, glycerol, glycol, isopropanol, diglycol and ethanol; the corrosion inhibiters are one kind of substances or a mixture of more than two kinds of substances in the following substances of benzotriazole, sulfydryl phenylpropyl isothiazole, oleic imidamline, citric acid, tartaric acid, oxalic acid, boric acid, dodecyl succinic anhydride, hexanedioic acid, n-caprylic acid, neodecanoic acid, sebacic acid, dodecandioic acid and gluconic acid. The cleaning agent provided by the invention has the advantages that the residue cleaning speed is high; substrates, protection paint and color paint of the plastic shell of the intelligent mobile terminal cannot be corroded and dissolved; safety and environment protection are realized; the mass cleaning is easy.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Method for preparing high-performance composite cobalt boroacylate

InactiveCN107011369AIncrease the cobalt contentHigh reactivityGroup 3/13 element organic compoundsCarbon numberDispersity

The invention relates to a method for preparing a high-performance composite cobalt boride, which mainly includes a salt-forming reaction, an acid replacement reaction, and a borylation reaction, and the degree of borylation can be achieved by replacing neodecanoic acid with stearic acid and propionic acid. Controlling, the number of carbon groups in the cobalt boroacylate molecule includes 3, 10, and 18 carbons, and the average value is controlled at 10, which improves the dispersion of the cobalt boroacylate product, improves the uniformity of rubber covering the surface of the steel cord, and solves the problem of adhesive adhesion. Practical application problems of dot, line, and surface exposure make the rubber and steel cord adhesion rate reach more than 90%, promote the bonding performance of rubber and steel cord, and prolong the service life of the tire.

Owner:JIANGYIN SANLIANG CHEM

Liquefied dicyandiamide and its preparing process

Liquefacient dicyandiamide and its preparation method. The method comprises: adding 100 parts of dicyandiamide, 300-600 parts of dehydrated neodecanoic acid glyceride, 50-200 parts of solvent, 0.5-1 par of 2-ethyl-4-methylimidazol or 2-methylimidazol into a reactor; mixing and heating, reacting for 12-14hours at 140degree C-150degree C ; vacuumizing and removing the solvent, obtaining viscous liquid. When the liquefacient dicyandiamide is used with ethoxyline resin, the weight ratio of liquefacient dicyandiamide to ethoxyline resin is 30-50:100. Liquefacient dicyandiamide of the invention could be dissolved in ethoxyline resin, has an ability of solidifying ethoxyline resin with high mechanical strength.

Owner:北京科化新材料科技有限公司

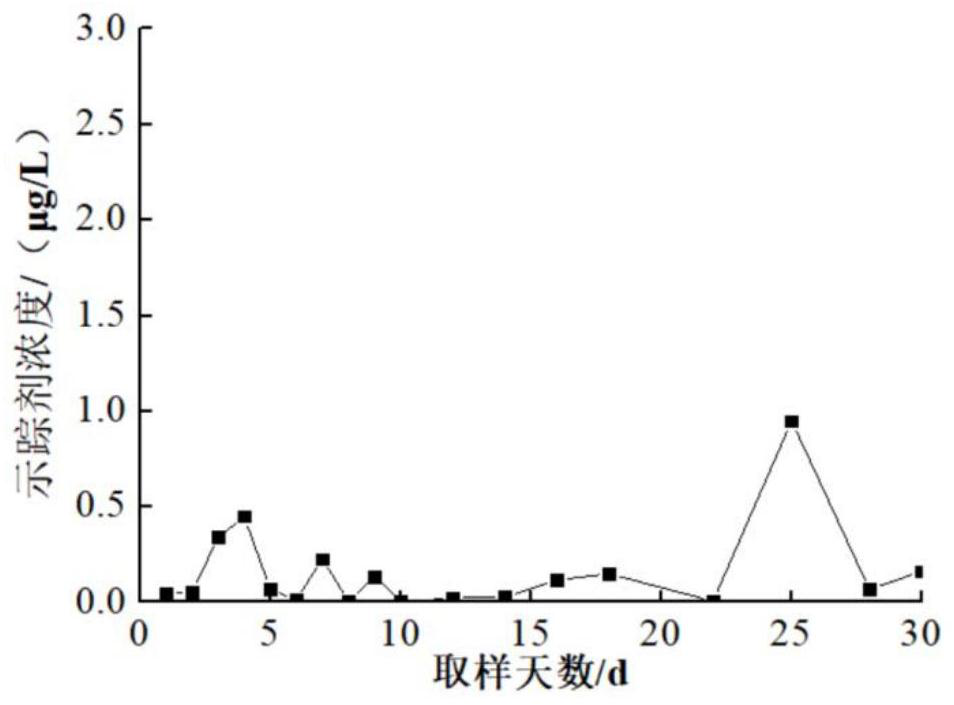

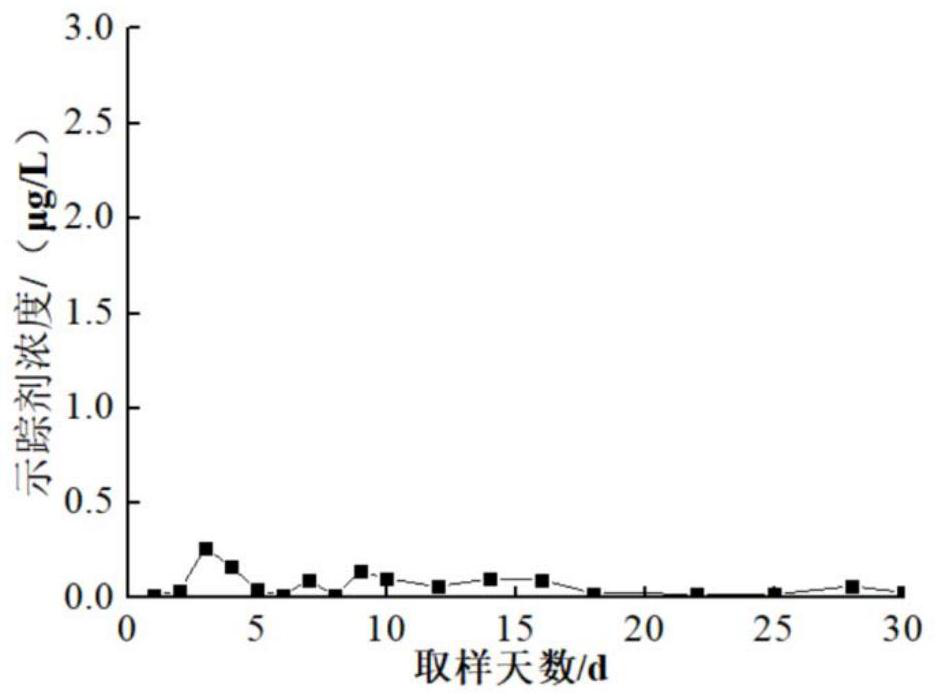

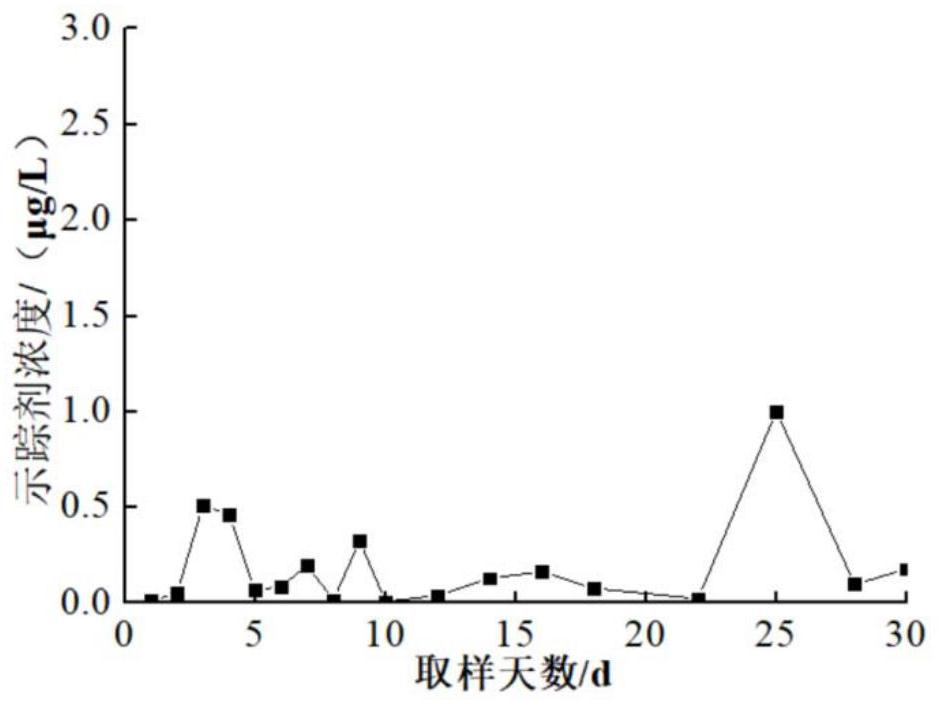

Environment-friendly oil-soluble tracer agent and application thereof

The invention discloses an environment-friendly oil-soluble tracer agent and application thereof. The tracer agent is prepared from the following raw material of, in percentage by weight, 58.4%-73.7%of organic acid rare earth salt, 22%-33% of solvent, 4%-8% of surfactant and 0.3%-0.6% of preservative, wherein the organic acid rare earth salt is at least one of benzoic acid rare earth salt, stearic acid rare earth salt, naphthenic acid rare earth salt and neodecanoic acid rare earth salt. The oil-soluble tracer agent is environment-friendly, multiple in element types, high in flash point, convenient to transport, good in compatibility with crude oil and kerosene and free of precipitation, an inductively coupled plasma mass spectrometer can realize simultaneous detection of multiple rare earth elements, can detect the condition of the oil yield of each section, is high in detection precision which can reach ppt level (10-12kg / L level), and can reduce the usage amount of the oil-solubletracer agent.

Owner:青岛大地新能源技术研究院

Method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag

ActiveCN112662878AAchieve leachingSimple processCobalt sulfatesProcess efficiency improvementManganese sulfidePhysical chemistry

The invention discloses a method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel; (6) cobalt recovery: taking a cobalt-nickel rich organic phase, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, adding a fourth organic extracting agent formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution, separating out the cobalt-rich organic phase, and adding sulfuric acid for reverse extraction to obtain a high-purity cobalt sulfate-rich solution and a P507-Cyanex301 organic phase; and (7) preparation of the high-purity cobalt sulfate. The method has the advantages that the method is simple and feasible, leaching of cobalt sulfate can be achieved, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions through fluorine ion precipitation can be avoided.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

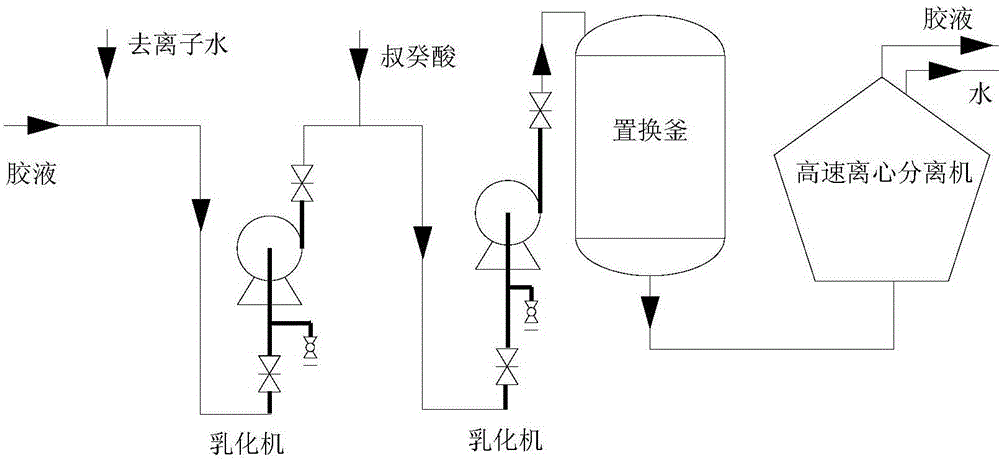

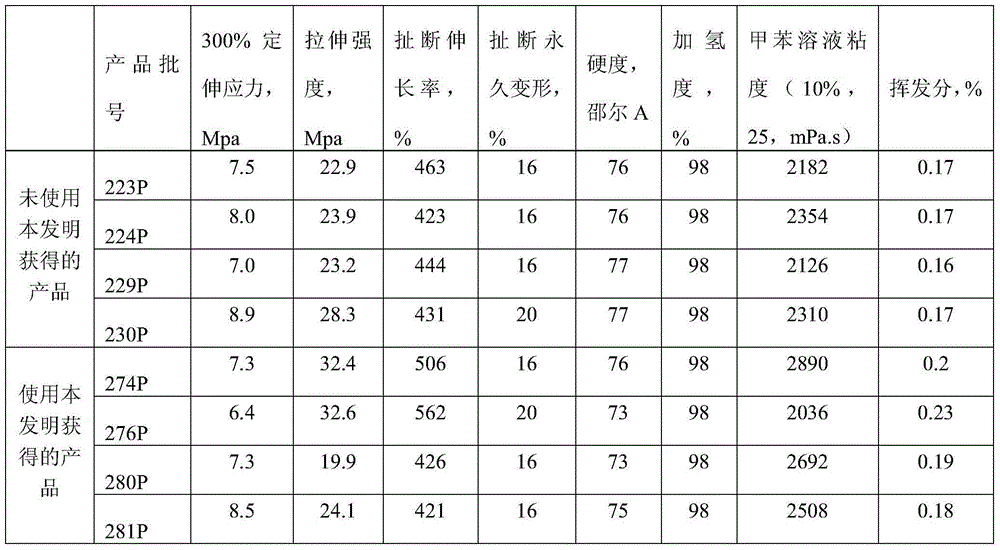

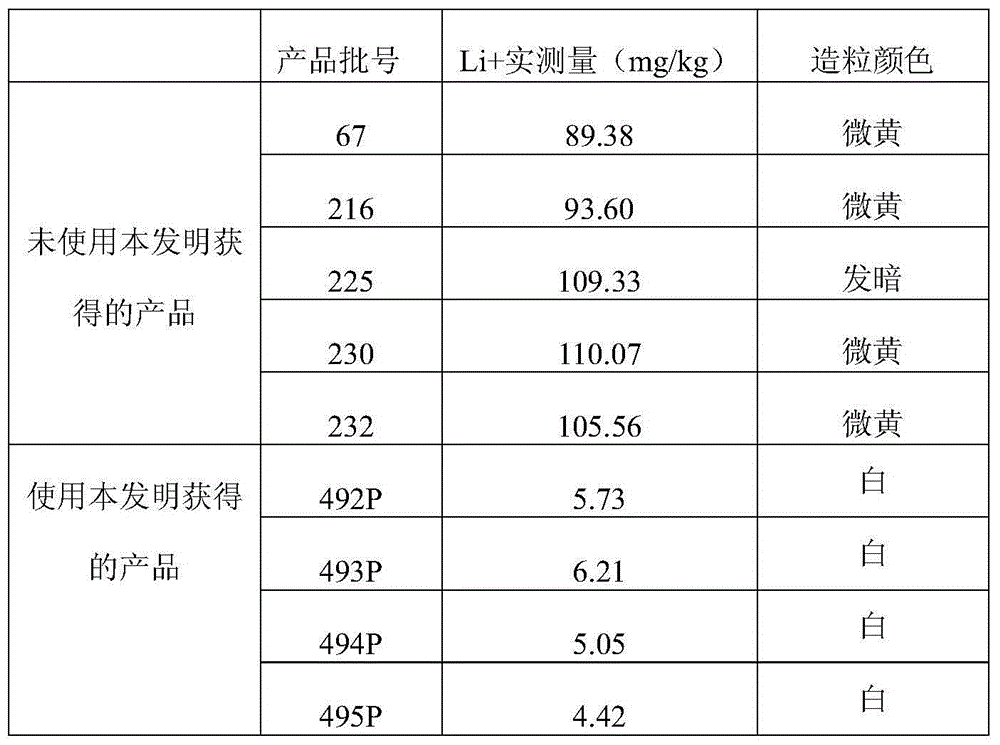

Process for industrialized continuous removal of alkaline impurities in SEBS rubber liquid or SBS rubber liquid

The invention relates to a process for industrialized continuous removal of alkaline impurities in an SEBS rubber liquid or an SBS rubber liquid. An emulsifying machine for emulsifying deionized water with a rubber liquid and an emulsifying machine for emulsifying neodecanoic acid with the rubber liquid are in series operation, and thereafter, a high-speed centrifugal separator is used for separating the emulsified water and the emulsified rubber liquid, moreover, the high-speed centrifugal separator operates in a continuous feeding mode, and lithium ions and other alkaline impurities in the SEBS rubber liquid or the SBS rubber liquid are continuously and effectively removed; the process is simple and efficient, and is suitable for industrialized production for removal of the alkaline impurities in the SEBS rubber liquid or the SBS rubber liquid.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of neodymium neodecanoic acid

ActiveCN103613496AIncrease concentrationQuality improvementOrganic compound preparationCarboxylic acid salt preparationImpuritySaponification

The invention relates to the technical field of neodymium carboxylate and provides a preparation method of neodymium neodecanoic acid. The preparation method has the advantages of safety, environmental friendliness, low consumption, time-saving property and low production cost, and the neodymium neodecanoic acid is prepared under the conditions of low temperature and normal pressure. The preparation method comprises the following steps: (1) dissolving neodymium oxide; (2) precipitating; (3) performing saponification; (4) extracting; (5) removing impurities; (6) canning.

Owner:福建聚创新材料科技有限公司

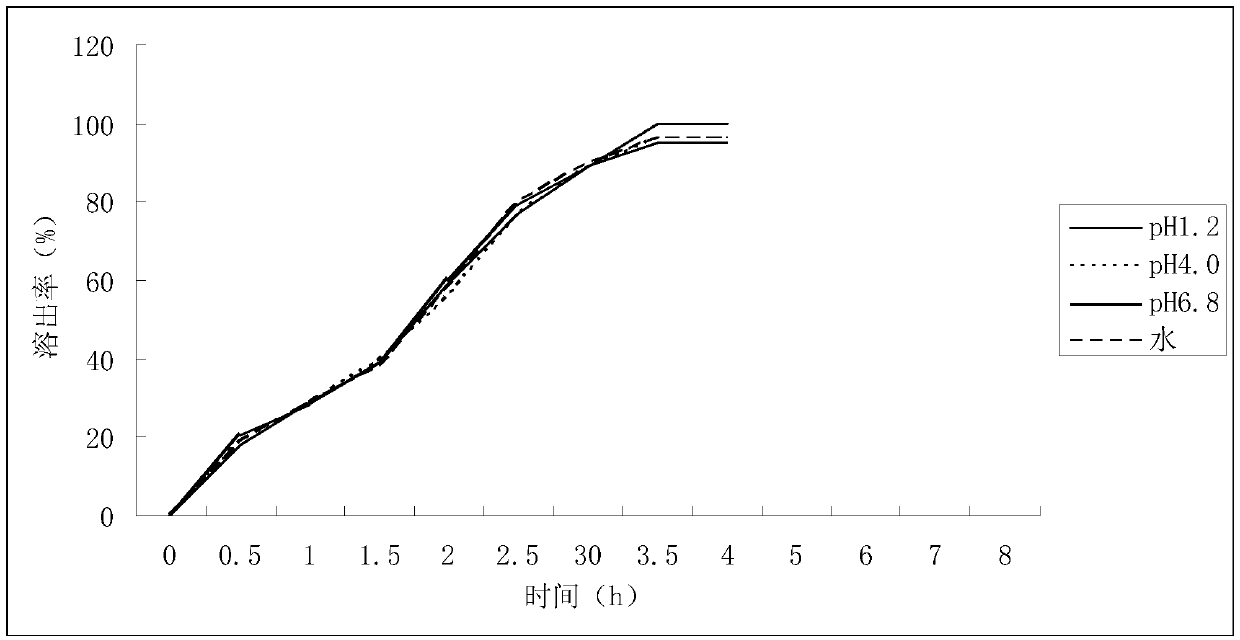

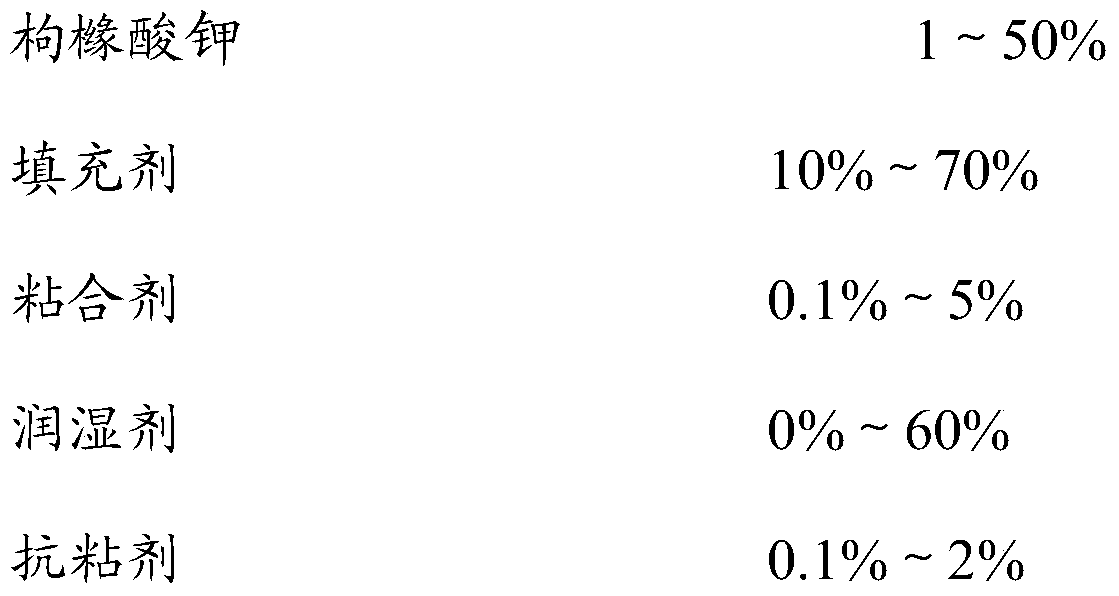

Novel potassium citrate sustained release tablet and preparation method thereof

InactiveCN104739794AImprove drug stabilityImprove bioavailabilityOrganic active ingredientsPharmaceutical delivery mechanismMonoglycerideGLYCERYL PALMITATE

The invention provides a novel potassium citrate sustained release tablet and a preparation method thereof, the preparation method comprises the steps of crushing, weighing raw materials, granulating, mixing and tabletting. The potassium citrate sustained release tablet comprises the following components: potassium citrate, a lipid material (monoglyceride stearate, glycerol distearates, glyceryl behenate, glyceryl palmitate-stearate, glycerol trilaurate, neodecanoic acid glyceride, stearic acid, palmitic acid, beeswax), lactose and microcrystalline cellulose. The potassium citrate sustained release tablet is prepared by the components by weight percentage: 1-50% of potassium citrate, 10-50% of lipid material, 10-70% of filler, 0-60% of wetting agent, 0.1-5% of adhesive and 0.1-2% of antitackiness agent. The potassium citrate sustained release tablet has the advantages of the quality is good, medicine release is alleviated, and biology utilization degree is increased.

Owner:GUANGZHOU PHARMACEUTICAL INDUSTRIAL RESEARCH INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com