Method for preparing high-performance composite cobalt boroacylate

A cobalt boroacylate and composite technology, which is applied in the field of preparation of cobalt boroacylate, can solve the problems of difficulty in controlling the degree of boroacylation, poor dispersion of cobalt boroacylate, and irregular substitution, so as to increase the cobalt content and Reactivity, controllable acyl carbon content, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

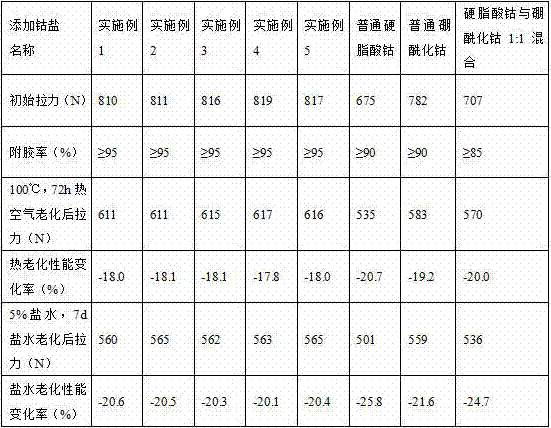

Examples

Embodiment 1

[0046]In a 500ml three-neck flask equipped with a moisture collector, a back distillation condenser, and a vacuum pump, respectively add 50g of propionic acid and 66g of cobalt hydroxide, control the reaction temperature at 100-150°C, and the reaction time for 2 hours, release the waste water, and then Add 60g of neodecanoic acid and 100g of stearic acid, control the reaction temperature at 150-190°C, and the reaction time is 2 hours, release waste water, then add 55g of tributyl borate and stir, control the heating temperature at 190-195°C and keep it warm for 1 hour , steam the butyl propionate, control the temperature at 180-190°C, and discharge the material after half an hour. Cobalt content of the reaction product: 23%, melting point: 125°C, appearance is blue-purple solid.

Embodiment 2

[0048] In a 1000ml three-necked flask equipped with a moisture collector, a back distillation condenser, and a vacuum pump, add 74g of propionic acid and 93g of cobalt hydroxide respectively, control the reaction temperature at 120-170°C, and the reaction time for 2.5 hours, release the waste water, and then Add 84 g of neodecanoic acid and 134 g of stearic acid, control the reaction temperature at 170-190 ° C, and react for 1.5 hours, release waste water, then add 75 g of tributyl borate and stir, control the heating temperature at 190-195 ° C and keep warm for reaction 1 hour, distilled butyl propionate, the temperature was controlled at 180°C~190°C, and the material was discharged after half an hour. Cobalt content of the reaction product: 22.5%, melting point: 122°C, appearance is blue-purple solid.

Embodiment 3

[0050] In a 500ml three-neck flask equipped with a moisture collector, a back distillation condenser, and a vacuum pump, respectively add 52g of propionic acid and 66g of cobalt hydroxide, control the reaction temperature at 100-150°C, and the reaction time for 2 hours, release the waste water, and then Add 62g of neodecanoic acid and 62g of stearic acid, control the reaction temperature at 150-190°C, and react for 3 hours, release waste water, then add 50g of tributyl borate and stir, control the heating temperature at 190-195°C and keep it warm for 1 hour , steam the butyl propionate, control the temperature at 180-190°C, and discharge the material after half an hour. The reaction product contains 24% cobalt, melting point: 125°C, and appears as a rich blue-purple solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com