Liquefied dicyandiamide and its preparing process

A technology of dicyandiamide and chemical formula, applied in the field of liquefied dicyandiamide and its preparation, can solve the problems of poor miscibility of epoxy resins and complicated processes, and achieve long-term storage stability and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

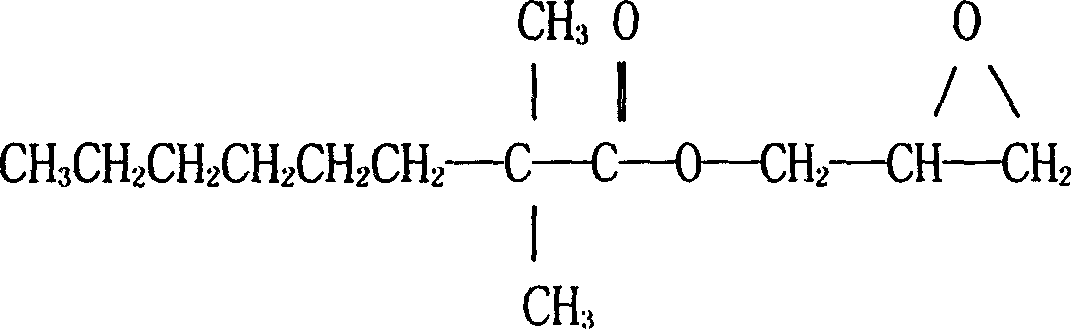

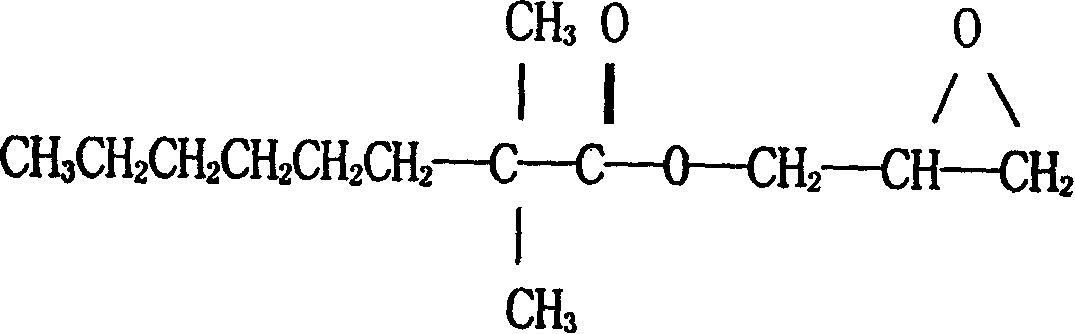

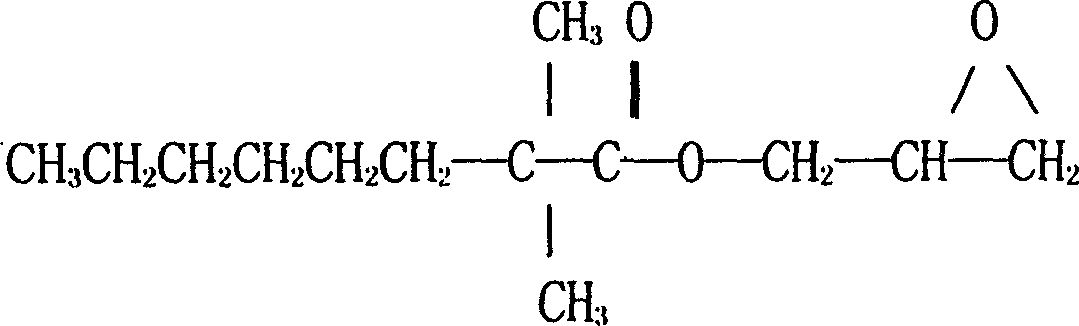

Image

Examples

Embodiment 1

[0032] In a 250ml there-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 34 grams of dicyandiamide, 0.34 grams of 2-ethyl-4-methylimidazole, 60 grams of ethylene glycol monomethyl ether and 91 gram of glycidyl neodecanoate, start the stirrer, start to heat up, keep the temperature at 140°C to 150°C, react for 12 hours, vacuumize and remove the solvent for about 10 minutes. A milky white viscous liquid was obtained. See Tables 1 and 2 for properties.

Embodiment 2

[0034] In a 50ml there-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 34 grams of dicyandiamide, 0.34 grams of 2-ethyl-4-methylimidazole, 80 grams of ethylene glycol monomethyl ether and 137 gram of glycidyl neodecanoate, start the stirrer, start to heat up, keep the temperature at 140°C to 150°C, react for 12 hours, vacuumize and remove the solvent for about 10 minutes. A viscous, pale milky white product was obtained. See Tables 1 and 2 for properties.

Embodiment 3

[0036] In a 250ml there-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 34 grams of dicyandiamide, 0.34 grams of 2-ethyl-4-methylimidazole, 100 grams of ethylene glycol monomethyl ether and 182 grams of glycidyl neodecanoate, start the stirrer, start to heat up, keep the temperature at 140 ℃ ~ 150 ℃, react for 14 hours, vacuumize and remove the solvent, the time is about 10 minutes. A viscous, light orange-red product was obtained. See Tables 1 and 2 for properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com