Aerolite cutting fluid with low PH value, its preparation and application

A cutting fluid, aluminum alloy technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of easy corruption, restricting the development of national industries, and high cost of use, achieving excellent lubricity and extreme pressure, excellent protection, prolonged The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

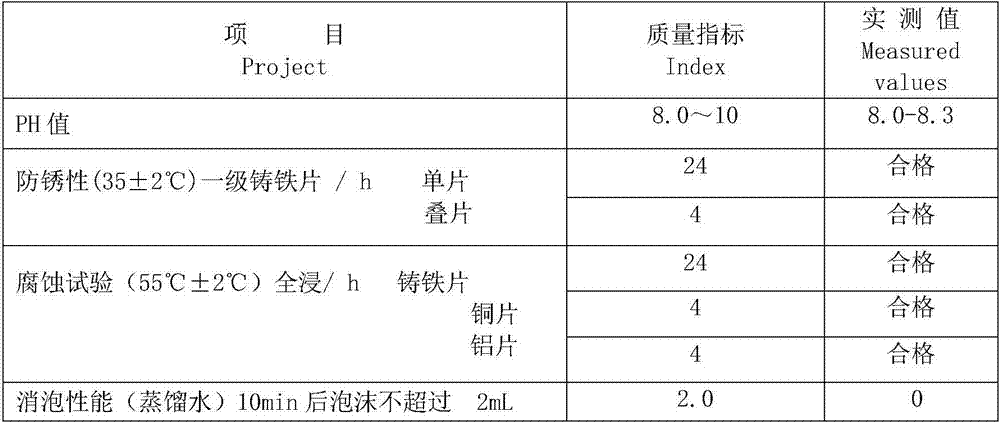

Embodiment 1

[0029] This example provides a low pH aviation aluminum alloy cutting fluid, which is composed of the following raw materials: Trimethylolpropane trioleate 10%, tall oil 8%, triethanolamine 18%, neodecanoic acid 5.5% , phosphate ester 1.2%, benzisothiazolinone 1%, anti-hard water agent EDTA 0.5%, tribasic acid 4.5%, benzotriazole 1%, castor oil polyoxyethylene ether 6%, trihydroxyhexahydro 1% of s-triazine, 0.7% of 2,6-dimethylmorpholine, and the balance is water.

[0030] The preparation method is a step-by-step method.

[0031] Specifically, it includes the following steps:

[0032] a. Put tall oil and triethanolamine in the required amount of cutting fluid into the reaction kettle, add 20%-25% of the water in the required amount of cutting fluid, start stirring and start the reaction, and control the temperature at 60-70°C , the reaction time is 2-3 hours;

[0033] b. The neodecanoic acid is added to the reaction kettle in step a according to the required formulation amo...

Embodiment 2

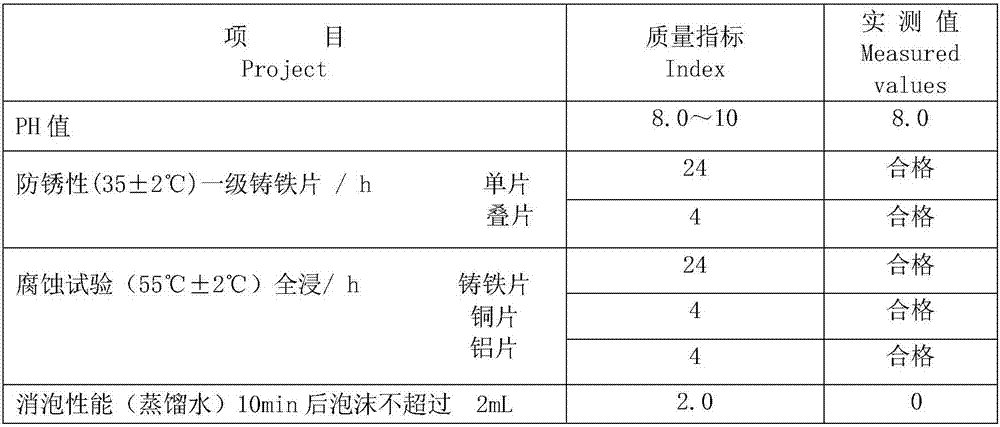

[0042] This example provides a low pH aviation aluminum alloy cutting fluid, which is composed of the following raw materials: Trimethylolpropane trioleate 5%, tall oil 5%, triethanolamine 12%, neodecanoic acid 4% , phosphate ester 0.7%, benzisothiazolinone 1.5%, anti-hard water agent EDTA 0.5%, tribasic acid 4%, benzotriazole 1%, castor oil polyoxyethylene ether 4%, trihydroxyhexahydro S-triazine 0.5%, 2,6-dimethylmorpholine 0.3%, and the balance is water.

[0043] The preparation method is a step-by-step method.

[0044] Specifically, it includes the following steps:

[0045] a. Put tall oil and triethanolamine in the required amount of cutting fluid into the reaction kettle, add 20%-25% of the water in the required amount of cutting fluid, start stirring and start the reaction, and control the temperature at 60-70°C , the reaction time is 2-3 hours;

[0046] b. The neodecanoic acid is added to the reaction kettle in step a according to the required formulation amount of ...

Embodiment 3

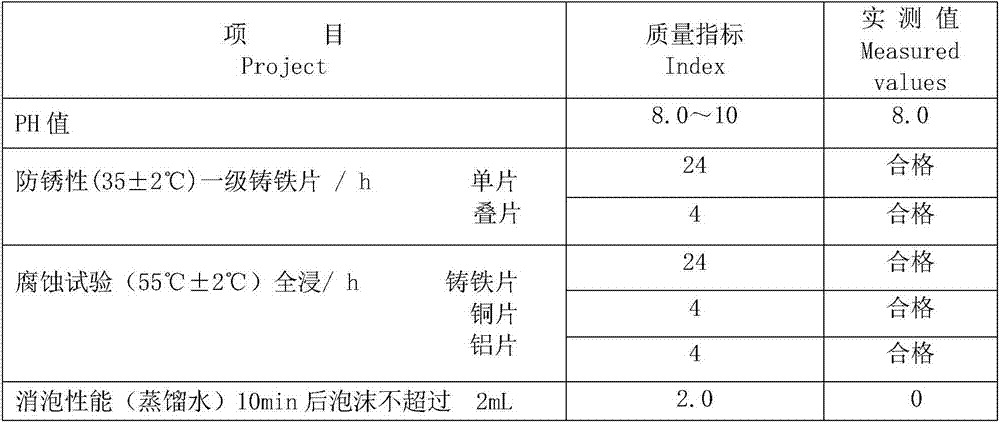

[0055] This example provides a low pH aviation aluminum alloy cutting fluid, which is composed of the following raw materials: trimethylolpropane trioleate 8%, tall oil 4%, triethanolamine 12%, neodecanoic acid 4% , phosphate ester 0.7%, benzisothiazolinone 1.5%, anti-hard water agent EDTA 0.5%, tribasic acid 4.5%, benzotriazole 1%, castor oil polyoxyethylene ether 5%, trihydroxyhexahydro S-triazine 0.5%, 2,6-dimethylmorpholine 0.3%, and the balance is water.

[0056] The preparation method is a step-by-step method.

[0057] Specifically, it includes the following steps:

[0058] a. Put tall oil and triethanolamine in the required amount of cutting fluid into the reaction kettle, add 20%-25% of the water in the required amount of cutting fluid, start stirring and start the reaction, and control the temperature at 60-70°C , the reaction time is 2-3 hours;

[0059] b. The neodecanoic acid is added to the reaction kettle in step a according to the required formulation amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com