Method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag

A technology of sulfide slag and electrolytic manganese, applied in the direction of cobalt sulfate, process efficiency improvement, etc., can solve problems such as complicated process, and achieve the effect of simplifying process flow, reducing acid consumption, and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

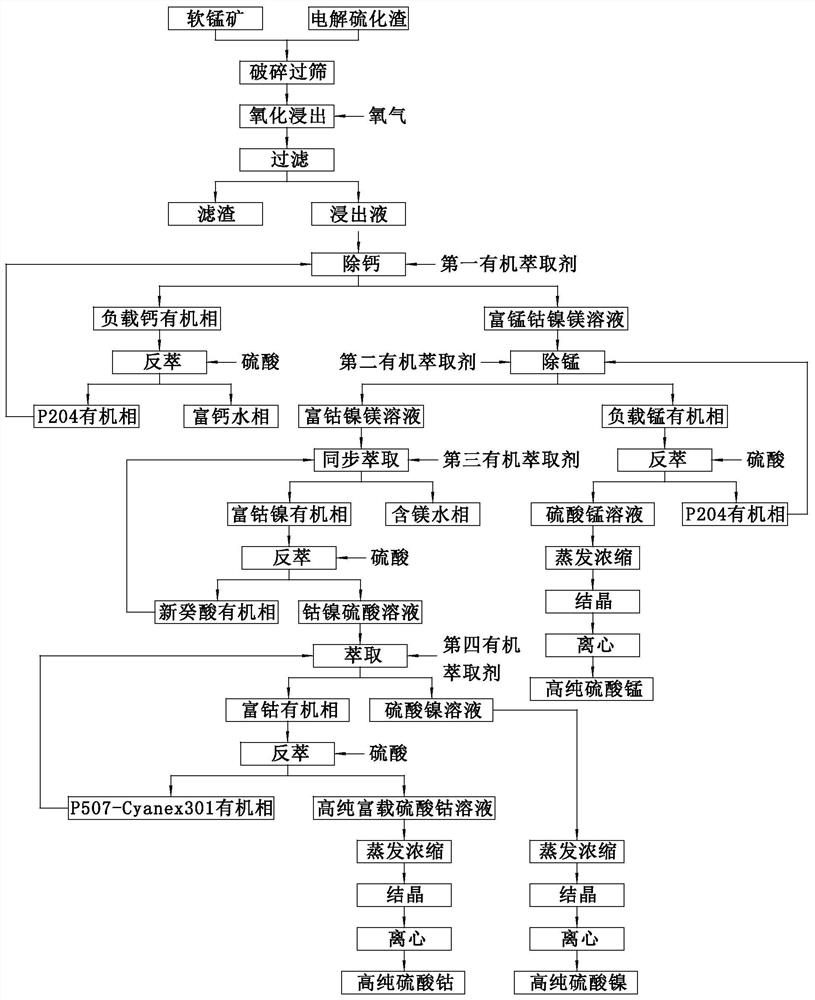

Image

Examples

preparation example Construction

[0043] (7) Preparation of high-purity cobalt sulfate: separate high-purity rich-loaded cobalt sulfate solution, evaporate and concentrate it, crystallize, and centrifuge to obtain high-purity cobalt sulfate.

[0044] The composition detection of the electrolytic manganese sulfide slag adopted in the present invention is as shown in table 1:

[0045] Table 1

[0046] w Mn / %

[0047] According to the above method for preparing high-purity cobalt sulfate, implement the following examples.

Embodiment 1

[0049] Crush and sieve 10g of electrolytic manganese sulfide slag and 17g of pyrolusite to 200 mesh, mix well, add 90g / L sulfuric acid solution according to the liquid-solid ratio of 10:1, feed oxygen 0.1Mpa, heat to 90°C, mechanically stir, and leaching 180min, the measured end point pH=3.0, filter, the leaching solution is adjusted to pH=0.5 with dilute sulfuric acid, and 30% P204+70% sulfonated kerosene is used to remove calcium according to the ratio O / A=1:1, wherein the saponification rate of the extractant is 20 %, extract for 10min, and then separate the liquid in a separating funnel to obtain a manganese-rich cobalt-nickel-magnesium solution after decalcification, then use sodium hydroxide to adjust the pH of the manganese-cobalt-nickel-magnesium solution to 3.5, and use 30% P204+70% sulfonation Kerosene is demanganese-rich manganese-cobalt-nickel-magnesium solution by ratio O / A=2:1, and wherein extractant saponification rate is 40%, extracts 10min, obtains loaded manga...

Embodiment 2

[0051] Crush and sieve 10g of electrolytic manganese sulfide slag and 17g of pyrolusite to 200 mesh, mix well, add 90g / L sulfuric acid solution according to the liquid-solid ratio of 10:1, feed oxygen 0.2Mpa, heat to 90°C, mechanically stir, and leaching 180min, the measured end point pH=3.0, filtered, the leachate was adjusted to pH=1 with dilute sulfuric acid, and 20% P204+80% sulfonated kerosene was used to remove calcium according to the ratio O / A=1:1, wherein the saponification rate of the extractant was 30 %, extract 10min, and then separate liquids in a separating funnel to obtain a calcium-removing manganese-rich cobalt-nickel-magnesium solution, then use dilute sulfuric acid to adjust the pH of the water phase to 4.0, and use 30% P204+70% sulfonated kerosene according to O / A=2.5:1 manganese removal, wherein the saponification rate of the extractant is 30%, extract for 10min, obtain the loaded manganese organic phase, then use 150g / L sulfuric acid to extract the loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com