Patents

Literature

50results about How to "Achieve leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

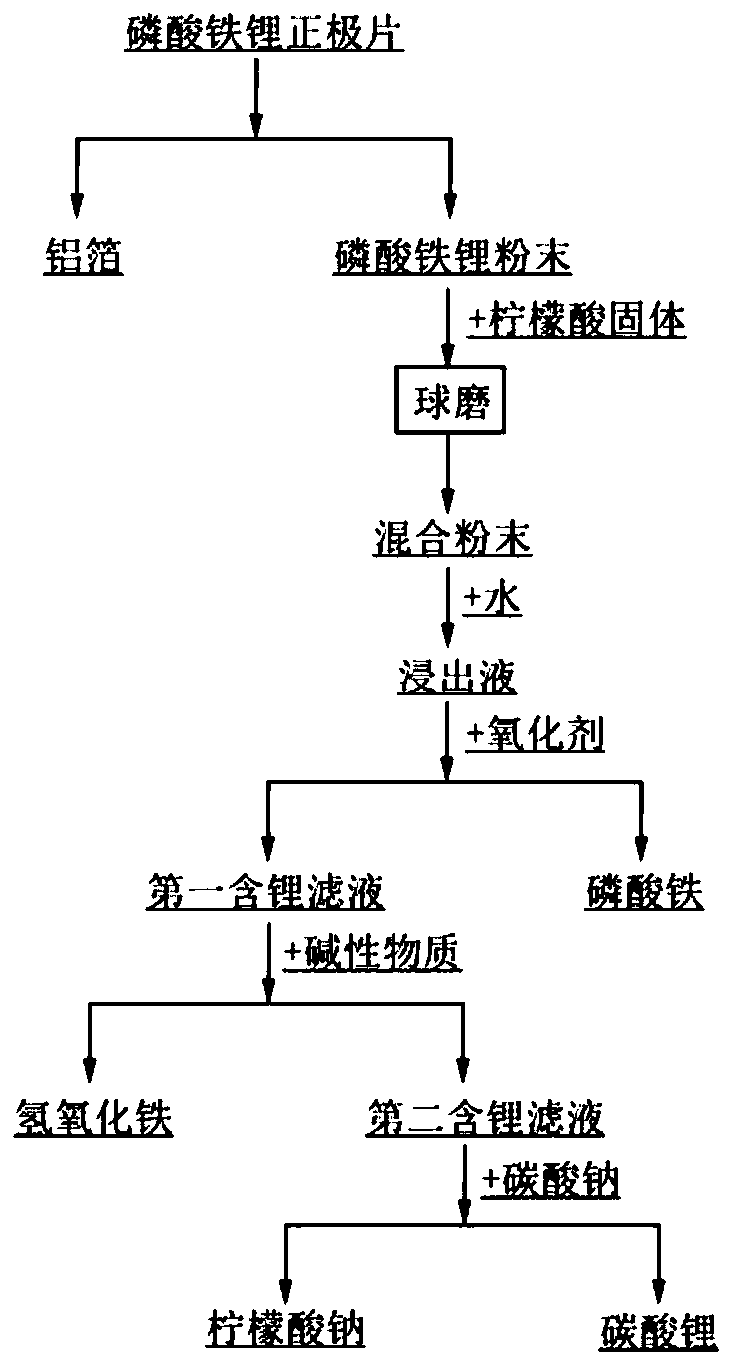

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN111370800AAchieve leachingReduce dosageWaste accumulators reclaimingProcess efficiency improvementOrganic acidLithium iron phosphate

The invention discloses a waste lithium iron phosphate positive electrode material recovery method, which comprises: S1, taking a waste lithium iron phosphate positive electrode material, carrying outpretreatment to obtain lithium iron phosphate powder, mixing the lithium iron phosphate powder and a solid grinding aid, and carrying out ball milling to obtain mixed powder; and S2, leaching the mixed powder with water to obtain a leaching solution containing valuable metal ions, wherein the grinding aid is an organic acid, and the acid radical ions in the organic acid can form soluble complexeswith iron and lithium respectively. According to the scheme, the problems that in the prior art, the using amount of acid and alkali is too large, the yield of salt-containing wastewater is too large, and secondary pollution is likely to be generated can be well solved.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Method for selectively leaching scandium and sodium from bayer red mud

ActiveCN106086436AAchieve leachingAchieve separationProcess efficiency improvementRed mudIon exchange

The invention mainly belongs to the technical field of pyrogenic process-hydrometallurgy and particularly relates to a method for selectively leaching scandium and sodium from bayer red mud. By the adoption of the method, the scandium, a rare and expensive metallic element, and sodium high in content can be leached from the red mud, and separation of the scandium and the iron element in the red mud can also be achieved. According to the method, based on the occurrence form of the scandium in the red mud, the bayer red mud is evenly mixed with concentrated sulfuric acid, after low-temperature sulphating is conducted, medium-temperature calcinating is conducted, and escaping sulfur trioxide and sulfur dioxide or sulfuric acid are recycled during sulphating and medium-temperature calcinating; and after sulfate impurities are decomposed, a washing liquor rich in the scandium and the sodium and low in iron content is obtained through water leaching. The washing liquor, prepared through the method, rich in the scandium and the sodium and low in iron content provides absolute advantages for the follow-up steps of ion exchange and solvent extraction and re-extraction; and after solid-liquid separation, the obtained leaching residues high in iron content and low in sodium content can be used as a building material or a raw material of blast furnace iron making. Besides, the sulfuric acid used as the reagent in the method can be recycled and reused, and therefore no new pollution is generated.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing manganese sulfate by manganese oxide ore

The invention provides a method for preparing manganese sulfate from manganese oxide ore. The method comprises the following processing steps: a, adding manganese oxide ore, ferrous sulfate or sulfur and water into a reactor; b, allowing for reaction; c, performing solid-liquid separation and slag washing to obtain iron concentrate and ready-to-use filtrate; d, removing impurities from the filtrate to get manganese sulfate solution. The extraction rate of manganese can exceed 85 percent. The manganese sulfate preparing method of the invention has the advantages of environment friendliness, short course and high manganese recovery, and can not only overcome problems of long course, low recovery, high cost, environmental pollution, etc. of traditional methods and significantly improve the recovery and extraction rate of manganese, but also utilize low grade manganese ore (iron-manganese ore in particular) and transform slag into products. The invention has prominent technological progress and outstanding substantial characteristics, and can produce excellent social and economic benefits.

Owner:汪云华 +1

Method for leaching nickel and molybdenum from amorphous nickel-molybdenum sulfide mineral by oxidative conversion

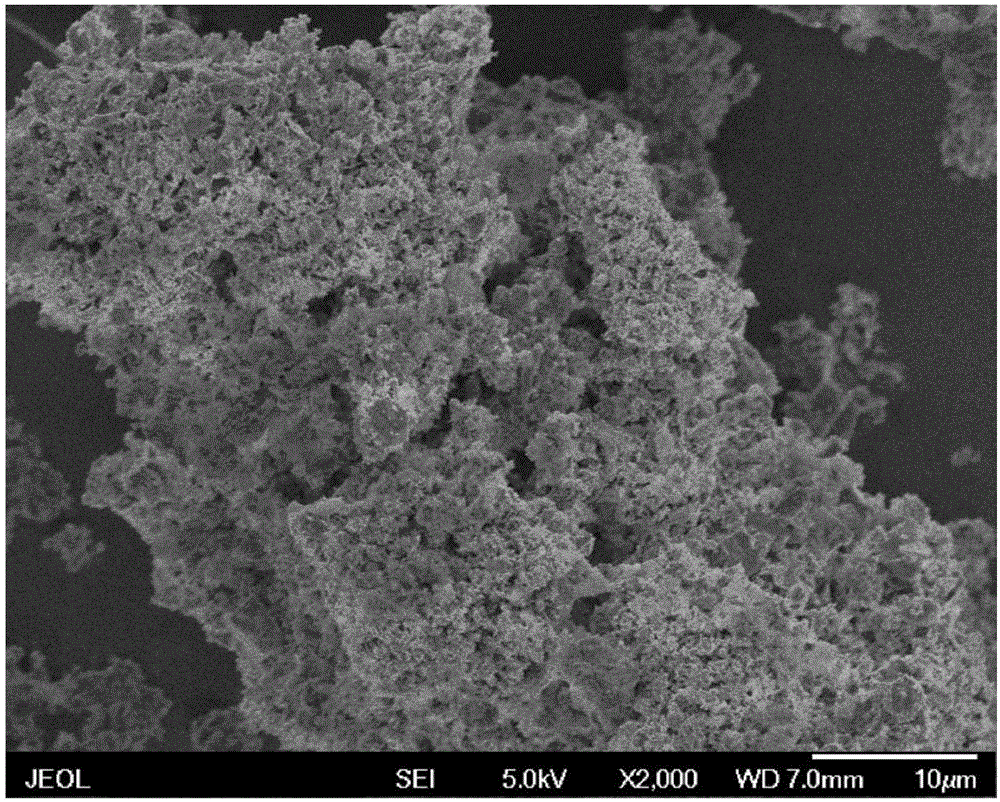

InactiveCN103966432ALarge specific surface areaAchieve leachingProcess efficiency improvementChemical industryOxygen

The invention belongs to the field of metallurgical chemical industry, and particularly relates to a method for leaching nickel and molybdenum from an amorphous nickel-molybdenum sulfide mineral by oxidative conversion. According to the technical scheme, the method comprises the following steps: mixing the amorphous nickel-molybdenum sulfide mineral which is finely ground with water to prepare pulp; adding the pulp into a pressure kettle, introducing industrial oxygen, and performing temperature rising reaction under the pressure of 0.8-2.0 MPa and at the temperature of 110-200 DEG C; converting the nickel and the molybdenum into sulfates, dissolving the sulfates into a solution, and filtering the pulp to obtain a leachate containing nickel sulfate and molybdenum sulfate acyl. The characteristics of large specific surface area and high activity of the amorphous nickel-molybdenum sulfide mineral are fully utilized; under the condition that acid is not added, colloidal sulfide is directly converted into sulfuric acid and sulfate in an oxidative manner, so that the nickel and the molybdenum can be leached, the process flow is short, conventional roasting is not needed, harmful smoke pollution is avoided, the process is clean, the consumption of reagents is low, and the leaching rate of metal is high.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Acidophilic iron-oxidizing composite microbial agent and preparation method thereof

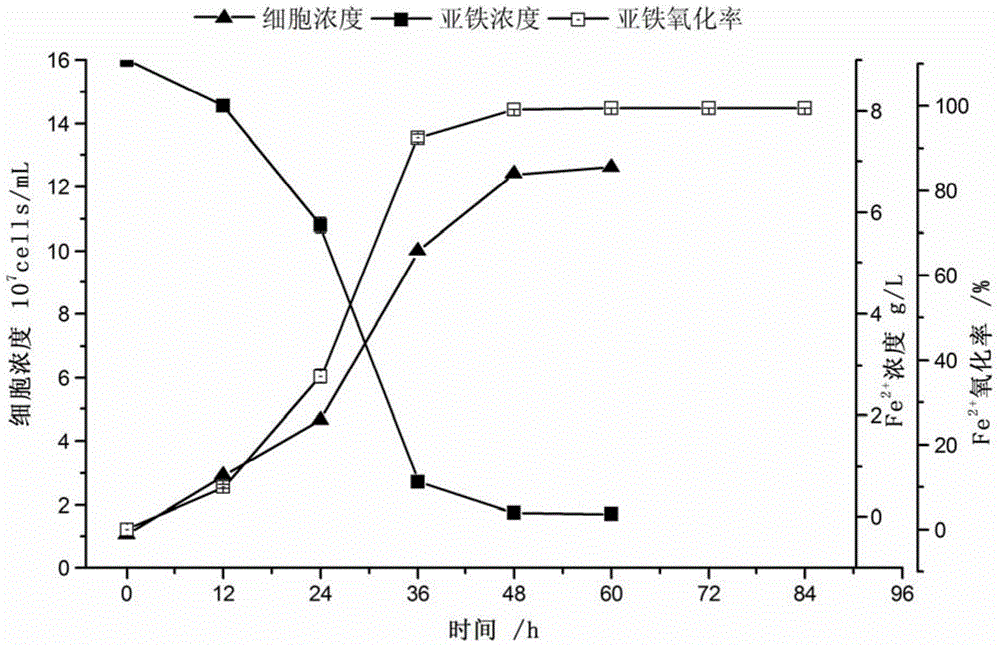

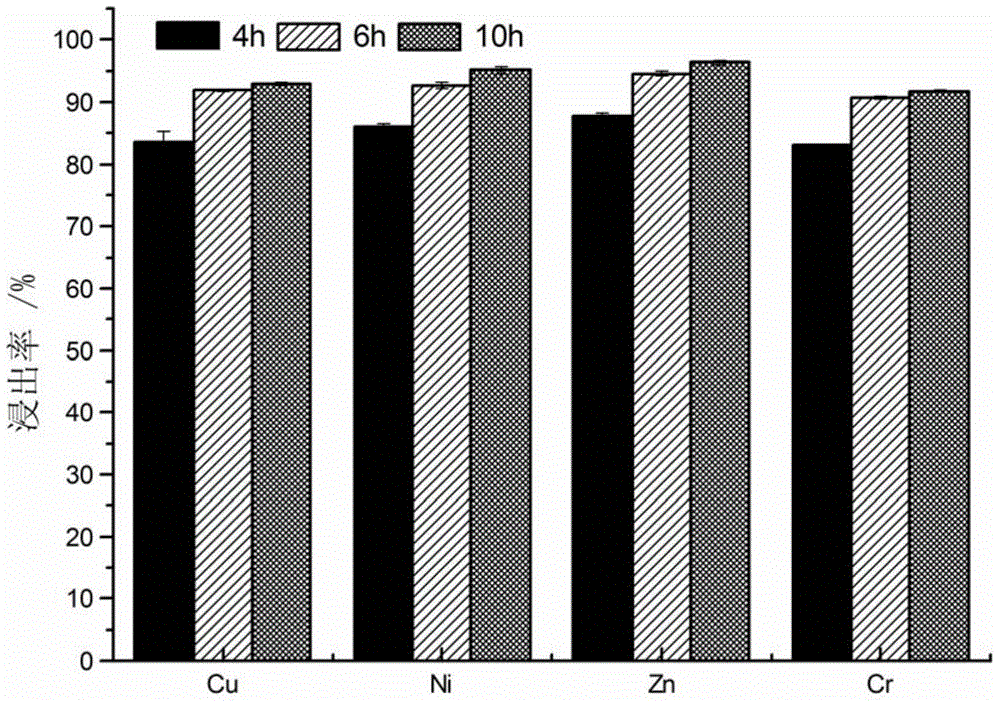

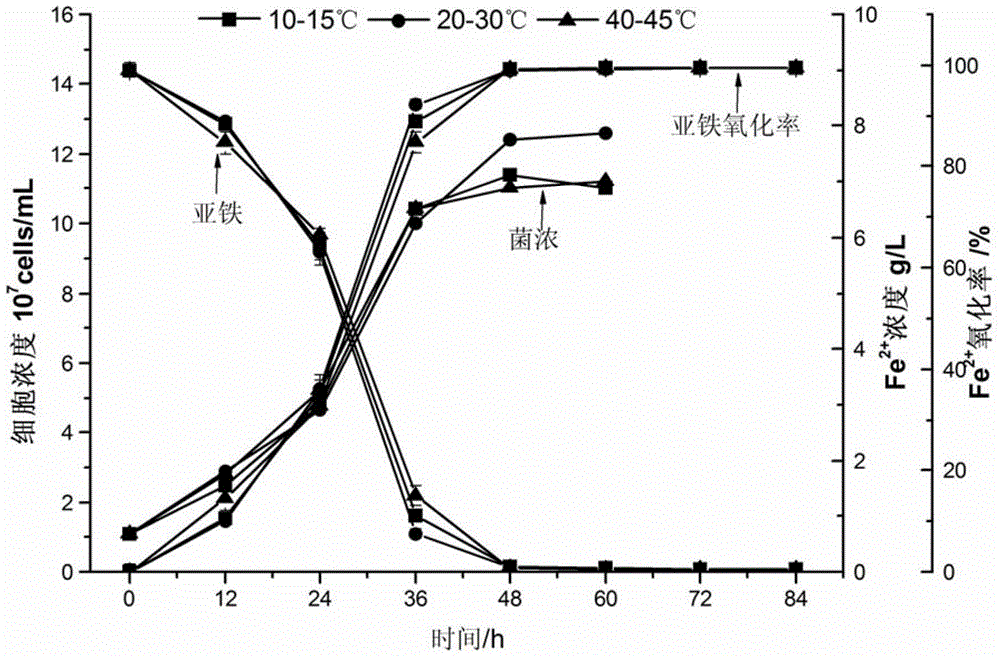

ActiveCN104862250AAchieve leachingAchieve recyclingBacteriaMicroorganism based processesSludgeMicrobial agent

The invention discloses an acidophilic iron-oxidizing composite microbial agent which comprises the following communities: a ferroplasma acidiphilum-containing strain, an acidithiobacillus ferrivorans-containing strain, an acidithiobacillus ferrooxidans-containing strain, a leptospirillum ferriphilum-containing strain and a sulfobacillus acidophilus-containing strain, wherein a preparation method of the composite microbial agent comprises the following steps: the aforementioned five strains are placed in a specific basic iron salt / nutrient-containing culture medium, and are subjected to the temperature gradient compounding culture, tolerance mixed-heavy-metal gradient pressure type domestication, temperature cycling gradient type domestication, ferrous oxidation activity improvement and tolerance high-iron domestication, so as to obtain the acidophilic iron-oxidizing composite microbial agent. According to the invention, the acidophilic iron-oxidizing composite microbial agent is simple in formulation, economical, adaptable, versatile and efficient, and can be used for the efficient extraction of heavy metals in electroplating sludge.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

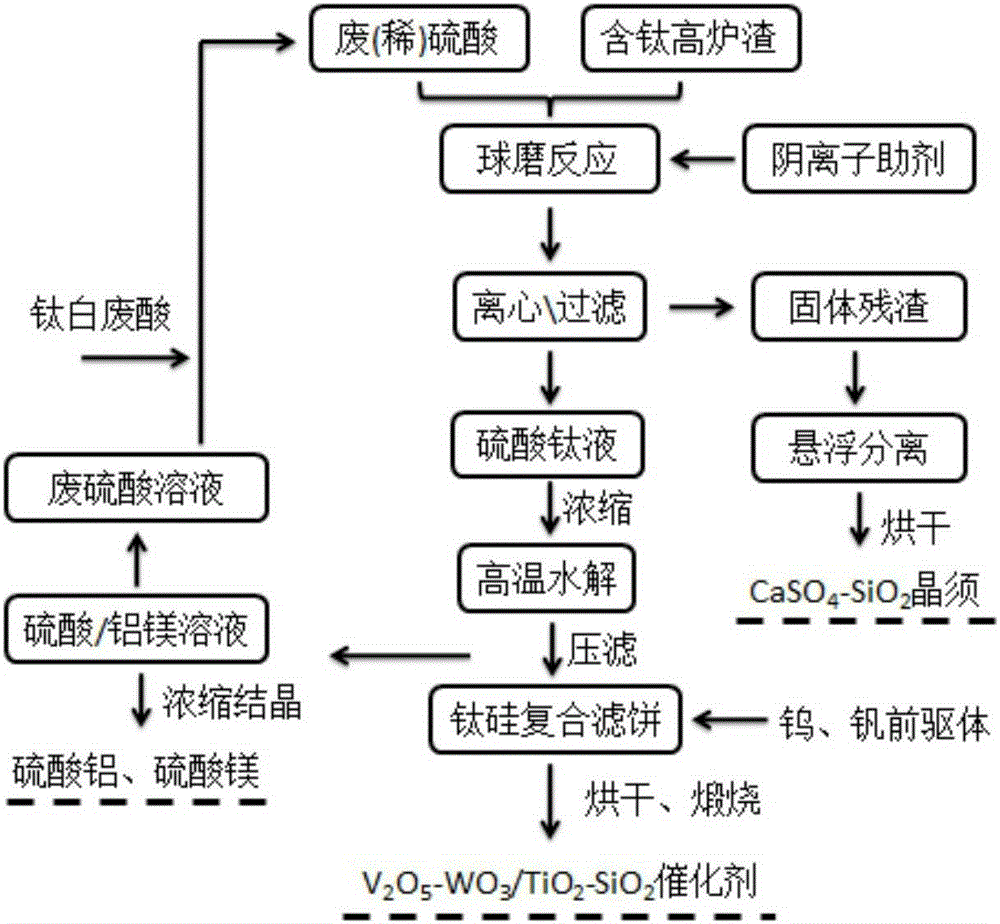

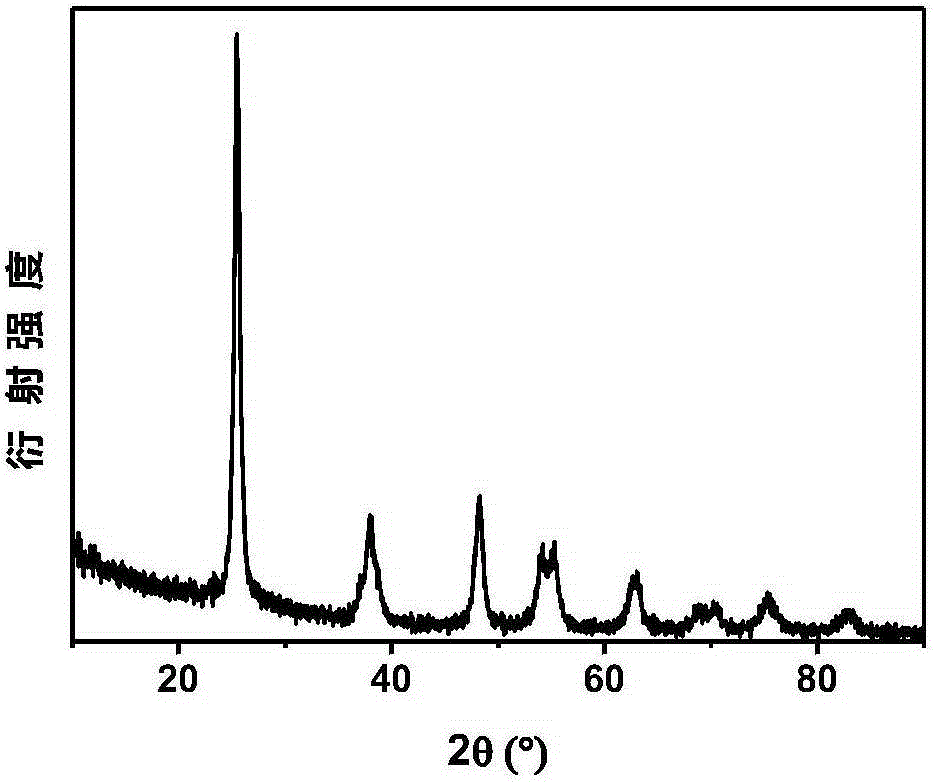

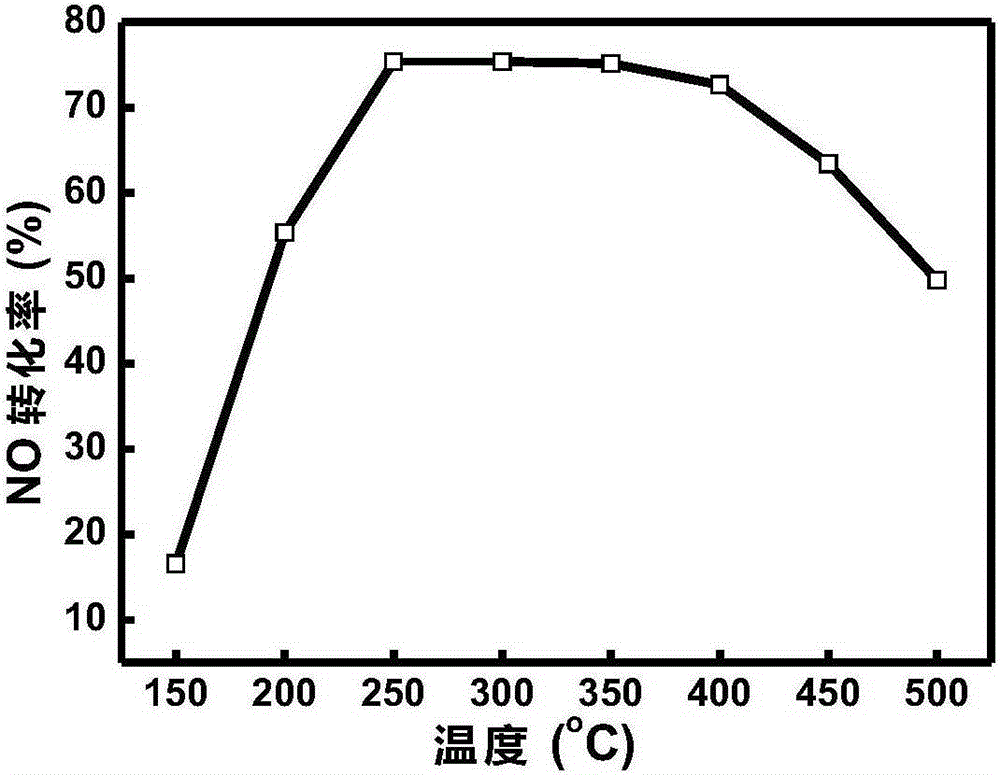

Treating and using method for titanium-containing blast furnace slag

InactiveCN105217664AReduce manufacturing costRelieve stressPhysical/chemical process catalystsChemical industrySilicic acidSlag

The invention belongs to the field of solid waste resource utilization. The treating and using method for titanium-containing blast furnace slag provided by the invention comprises: adding titanium-containing blast furnace slag into waste dilute sulfuric acid to be leached and separating the mixture to obtain a filter residue and a leaching liquid; after controlling the normal concentration of TiO2 in the leaching liquid through reduction vaporization, further carrying out oxidative hydrolysis reaction; filtering, washing and drying the hydrolyzed product to obtain a metatitanic acid-silicic acid compound; further loading tungsten on the product; and calcining the product to obtain titanium tungsten silicon powder; carrying out simple suspended separation and drying and roasting on the ball-milled filter residue to obtain a calcium sulfate-SiO2 composite whisker material; and crystallizing and separating the hydrolyzed liquid to obtain an aluminum sulfate chemical. The method not only realizes effective use of titanium, silicon, calcium and aluminum of blast furnace slag, and solves the problem that a titanium product extracted from the blast furnace slag is hard to separate and purify and the product quality is hard to reach the standard, but also greatly lowers the titanium-extracting cost, reduces the energy consumption, and realizes high value utilization of calcium and silicon.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

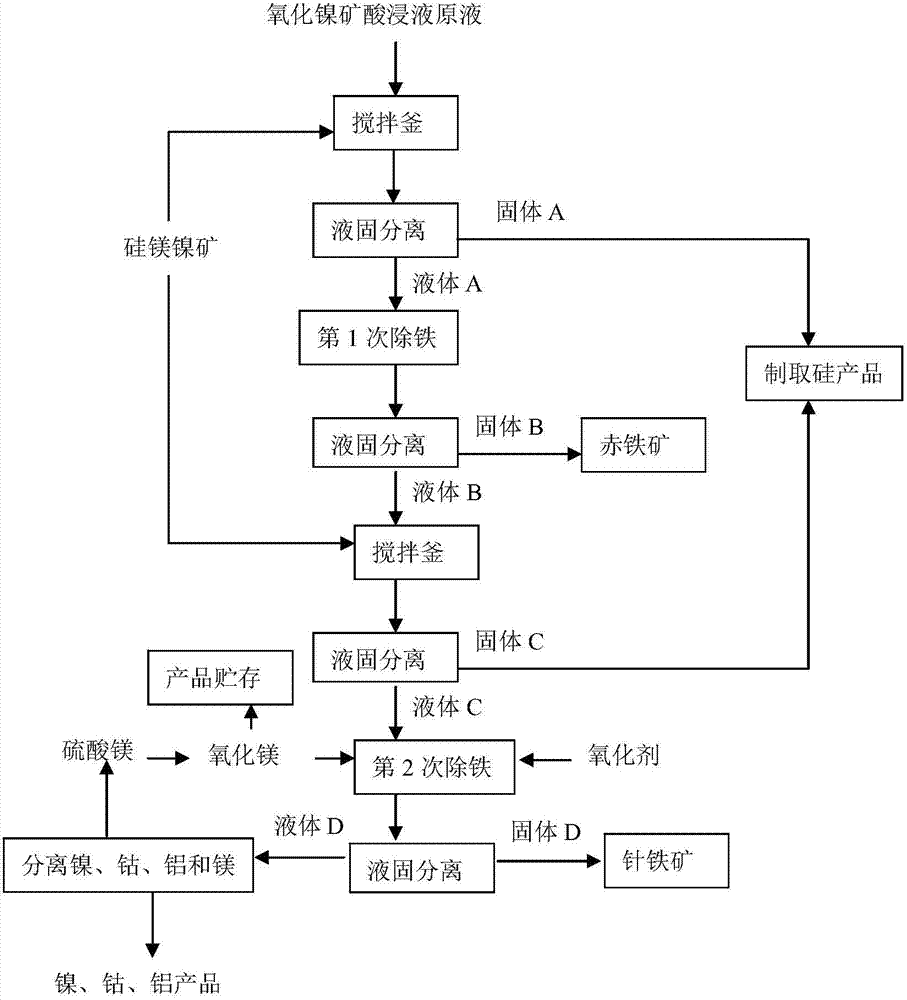

Nickel oxide ore acid leaching solution two-step iron removal method

ActiveCN104120259ADeposit completelyAvoid interferenceProcess efficiency improvementDissolutionCobalt

The invention discloses a nickel oxide ore acid leaching solution two-step iron removal method. The method comprises the following steps: adding garnierite ore pulp into a nickel oxide ore acid leaching solution, stirring and reacting until the dissolution is completed and the pH value of the solution is more than or equal to 1.6, performing liquid-solid separation, raising the temperature of obtained liquid to 130-170 DEG C, stirring and reacting for 1-3 hours, performing liquid-solid separation, and drying a solid to obtain a hematite product; adding the garnierite ore pulp into the collected liquid for the second time, stirring and reacting until the dissolution is completed and the pH value of the solution is about 2, performing liquid-solid separation, and adding magnesium oxide and an oxidizing agent into the obtained liquid, or only adding the oxidizing agent; stirring and reacting for 0.5-4 hours, performing liquid-solid separation, and drying the solid to obtain a goethite product. By adopting the method disclosed by the invention, complete iron removal can be achieved under a relatively mild condition; hematite and goethite which can be directly sold can be obtained; meanwhile, residual acid in the acid leaching solution and acid released in the iron deposition process are recycled; loss of nickel, cobalt, aluminum and magnesium in the leaching solution can not be generated.

Owner:GUANGXI NORMAL UNIV

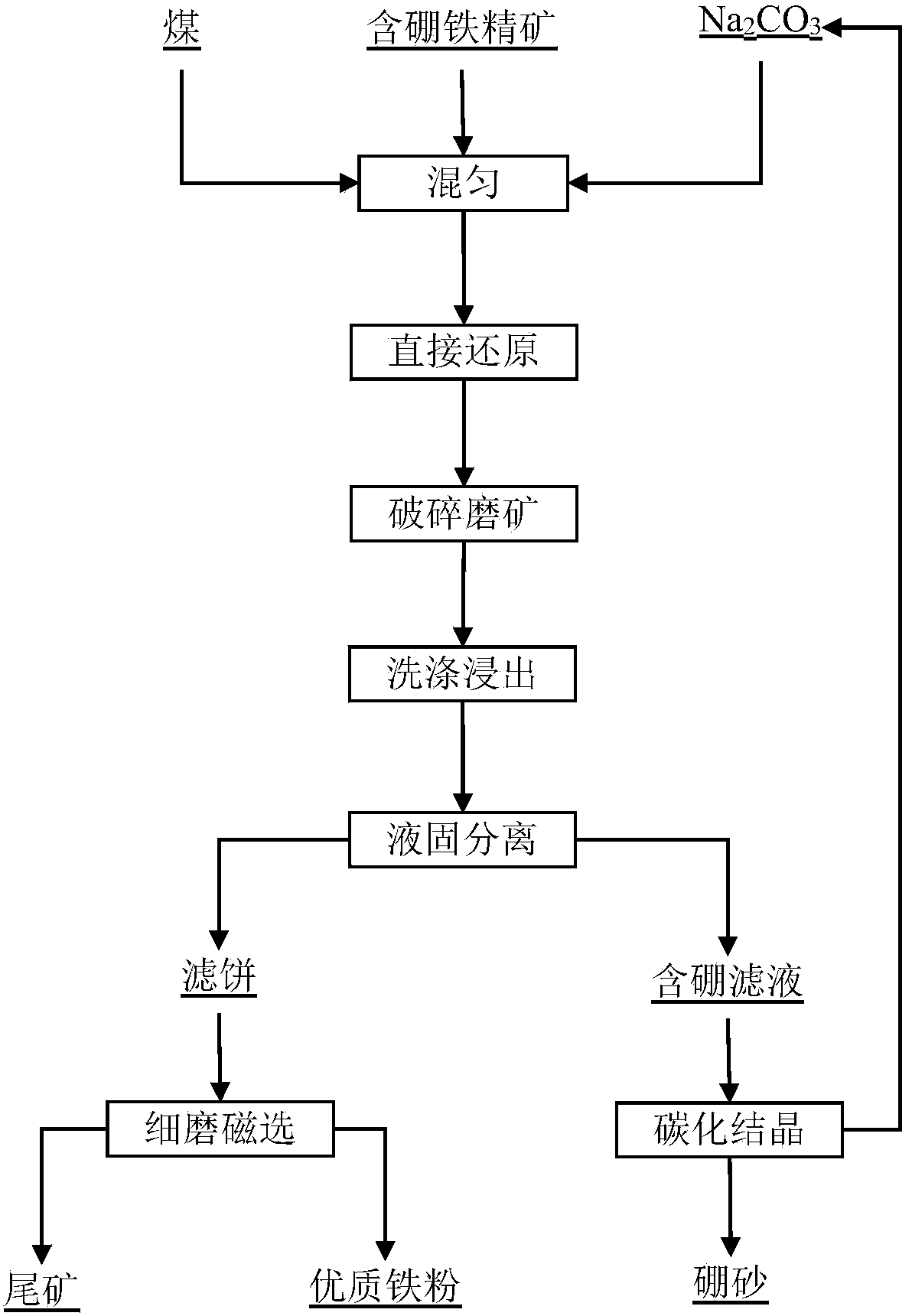

Method for extracting high-quality iron powder and borax from paigeite

ActiveCN103952537AShort processReduce energy consumptionMagnetic separationBoratesPowder metallurgyIron reduction

The invention belongs to the field of metallurgy of steel and iron and processing of mineral resources and specifically relates to a method for extracting high-quality iron powder and borax from paigeite. The method provided by the invention comprises the following steps: (1) mixing boron-containing iron concentrate, solid Na2CO3 and coal together to obtain a mixture; (2) roasting the mixture under a reducing atmosphere at the temperature of 950-1150 DEG C to obtain a roasted product; (3) crushing and grinding the roasted product and then, leaching, washing and filtering ore slurry to obtain an alkaline filtrate and an iron-containing filter cake; (4) performing desilication, CO2 carbonization, filtration and crystallization on the alkaline filtrate to obtain qualified borax and simultaneously realize recycling of reaction medium Na2CO3; (5) performing magnetic separation, grinding and secondary magnetic separation on the obtained filter cake to obtain high-quality reducing iron powder (TFe is more than 98.5%) which can be used as an iron-based raw material for powder metallurgy. According to the method provided by the invention, by adding a large amount of Na2CO3, the leaching of boron minerals is simultaneously realized during iron reduction, the process flow is shortened and the energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

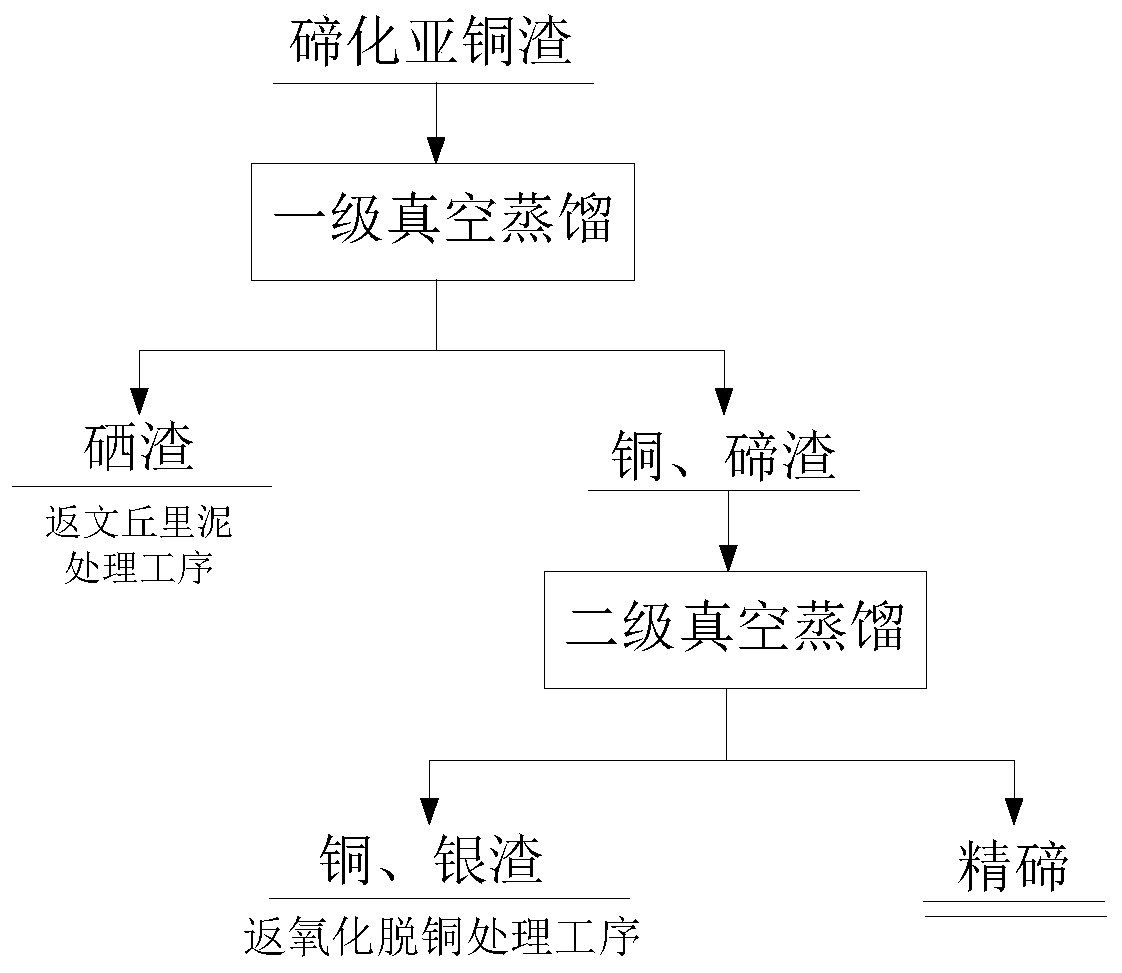

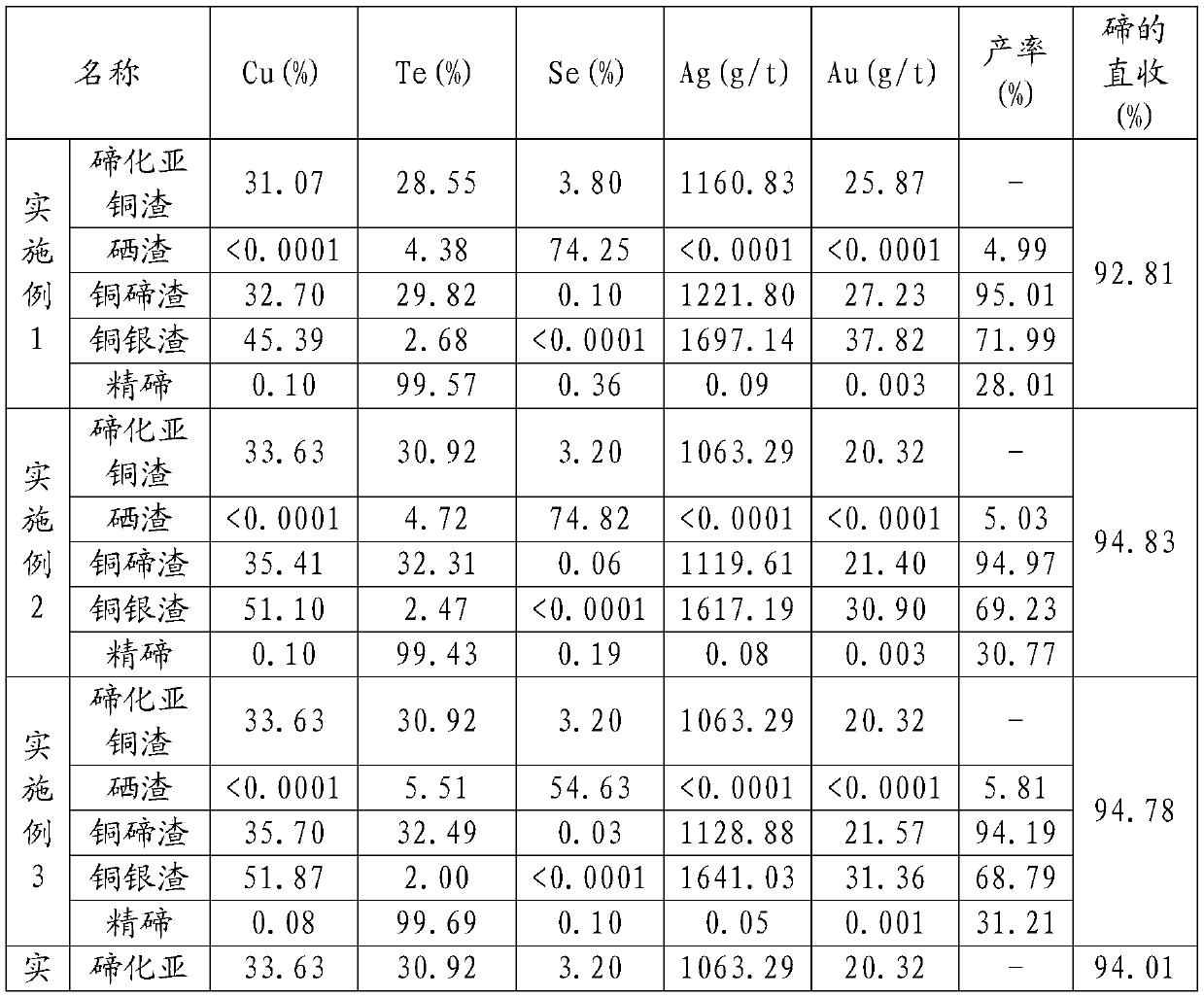

Method for separating and purifying tellurium from cuprous telluride slag through vacuum distillation

InactiveCN110144458AAchieve leachingStable in natureRotary drum furnacesProcess efficiency improvementSlagTe element

The invention discloses a method for separating and purifying tellurium from cuprous telluride slag through vacuum distillation. The method comprises the following steps of S1, placing the cuprous telluride slag in a vacuum distillation furnace, and performing vacuum distillation at the vacuum degree of 10-150 Pa to obtain selenium slag and copper-tellurium slag, wherein the vacuum distillation temperature is 390 DEG C-470 DEG C, and the time is 1-4 h; and S2, placing the copper-tellurium slag obtained in the S1 in the vacuum distillation furnace, and performing vacuum distillation at the vacuum degree of 10-150 Pa again to obtain refined tellurium products and copper-silver slag, where the secondary vacuum distillation temperature is 890 DEG C-950 DEG C, and the time is 1-4 h. According to the method, the problems of low direct recovery, long process flow and the like in the current cuprous telluride slag treatment process can be solved, and the short-process and high-value recovery of valuable elements in the cuprous telluride slag is achieved.

Owner:ZIJIN MINING GROUP +2

New method for extracting nickel from enriched ore of nickel sulfide

This invention discloses a novel method for extracting nickel from nickel sulfide concentrate. The method overcomes the problems of long extraction time, low nickel recovery rate and serious pollution faced by the traditional methods. The method comprises: (1) placing nickel sulfide concentrate and pyrolusite at a certain weight ratio into a reactor; (2) adding certain volume and concentration of H2SO4 solution at a certain temperature, and reacting. Nickel sulfide concentrate is leached to form nickel sulfate, and manganese dioxide is leached to form manganese sulfate. The method has such advantages as short reaction time and high nickel recovery rate. The method can choose nickel sulfide concentrate and pyrolusite at different weight ratios, and adopt different parameters and temperatures to realize multiple reactions.

Owner:KUNMING INST OF PRECIOUS METALS

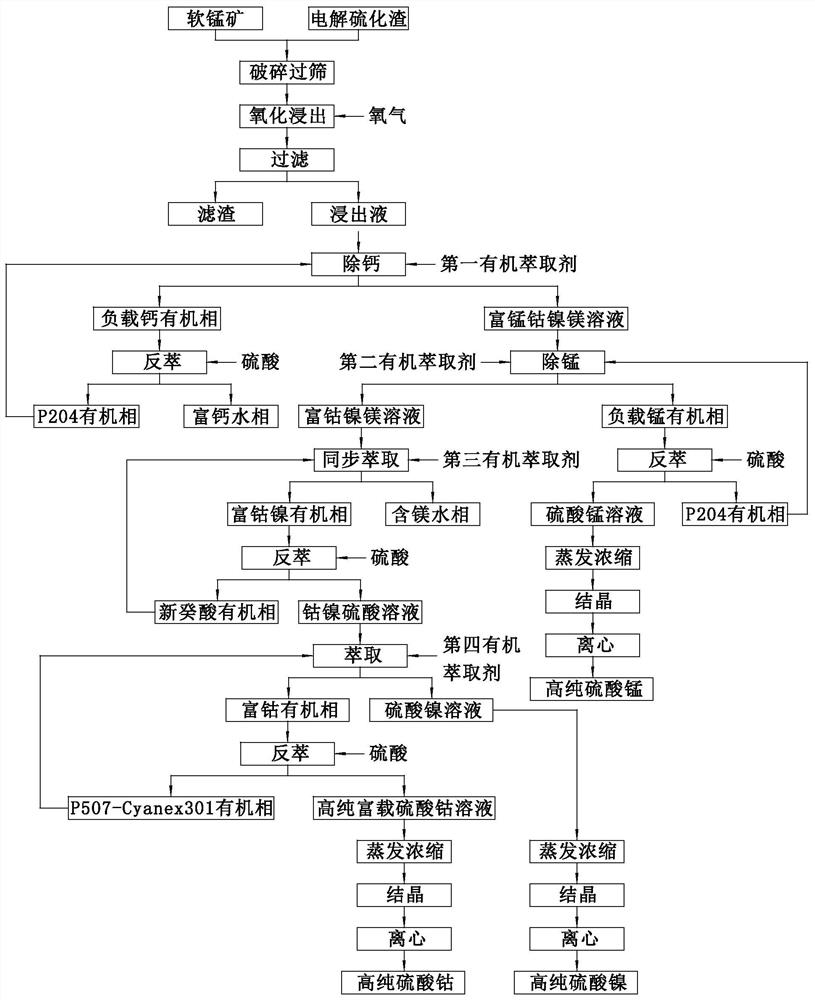

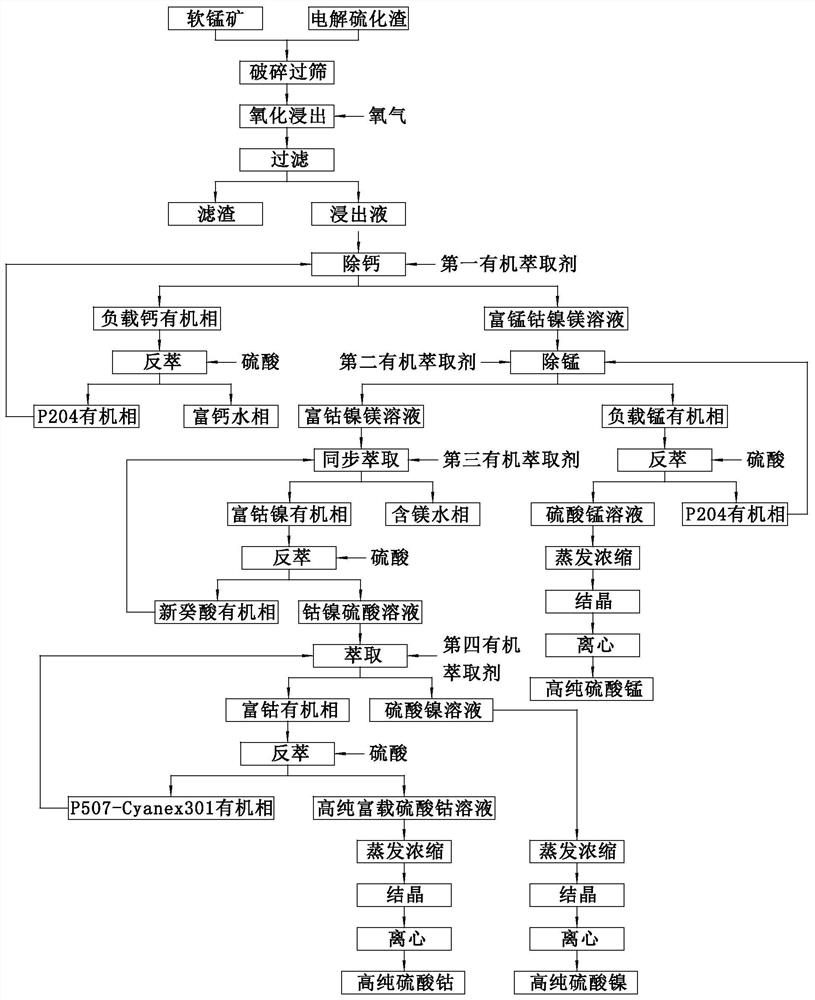

Method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag

PendingCN112662877AAchieve leachingSimple processCobalt sulfatesNickel sulfatesManganese sulfideSulfate

The invention discloses a method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel: taking a solution rich in cobalt, nickel and magnesium, and adding a third organic extractant formed by mixing saponified neodecanoic acid with sulfonated kerosene for extraction to obtain an organic phase rich in the cobalt and the nickel and a magnesium-contained aqueous phase; (6) cobalt removal: taking the organic phase rich in the cobalt and the nickel, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, and adding a fourth organic extractant formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution; and (7) preparation of the high-purity nickel sulfate. The method has the advantages that the method is simple and feasible, leaching of nickel sulfate can be realized, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions with precipitation of fluorine ions can be avoided.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

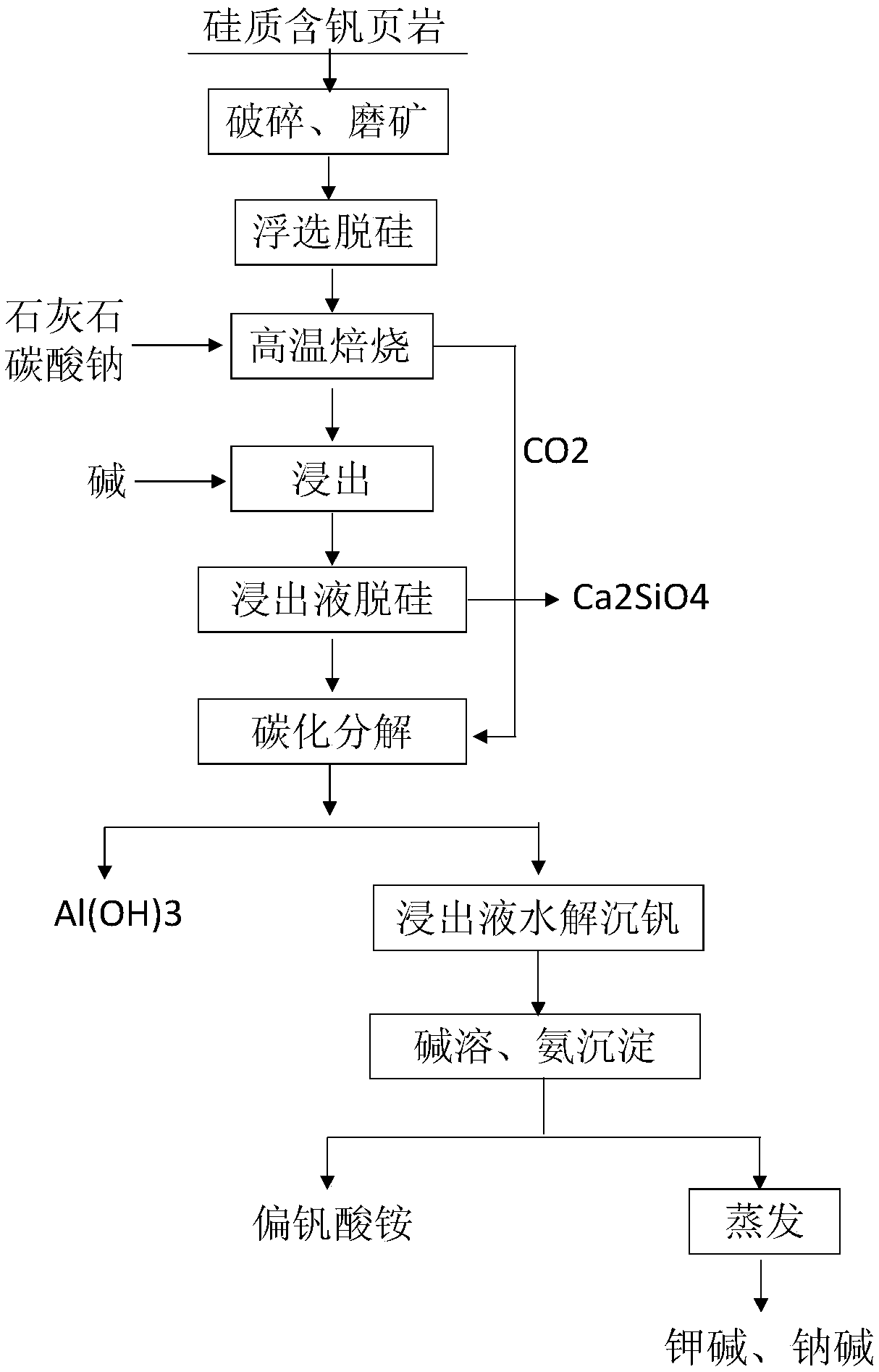

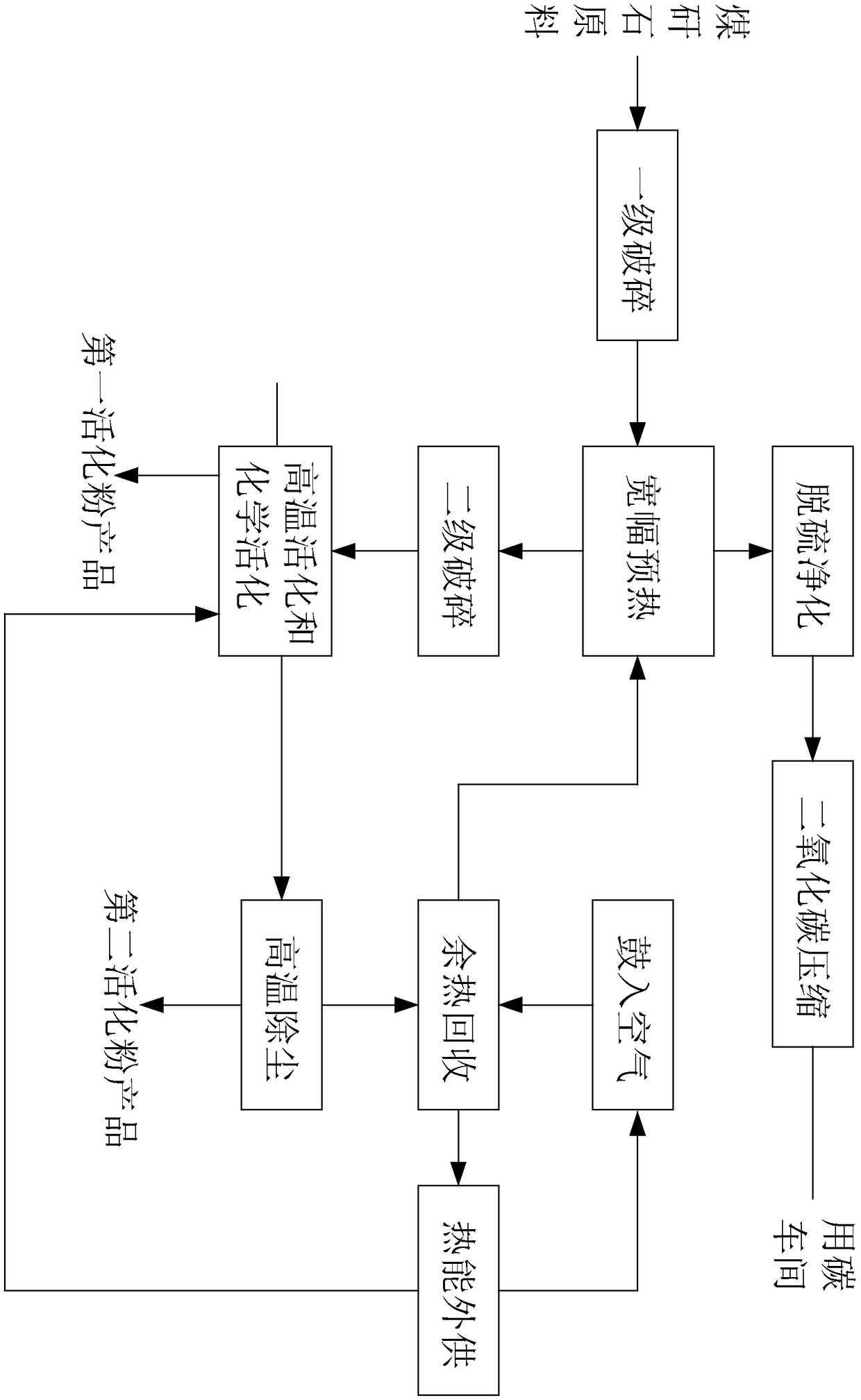

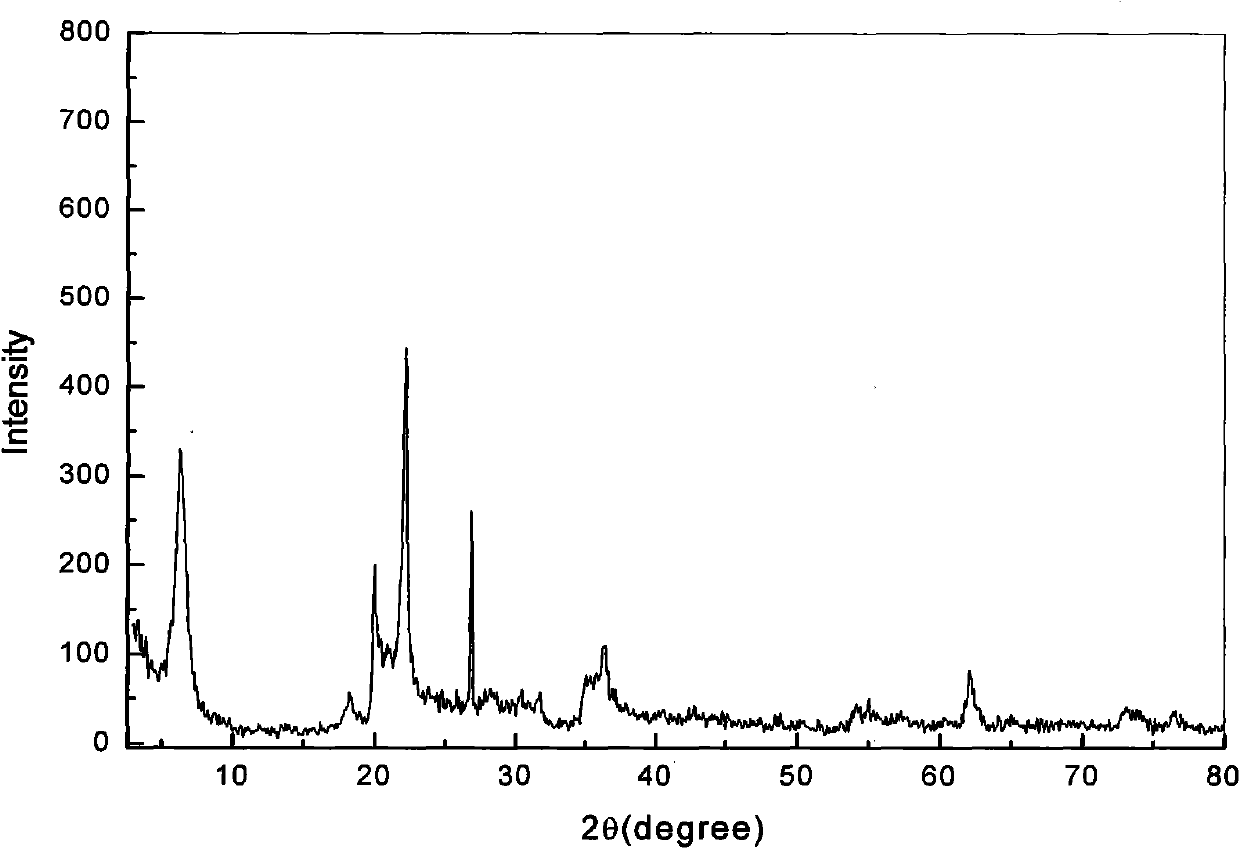

Beneficiation-metallurgy combination process with function of comprehensive recovery for vanadium, aluminum, potassium and silicon in vanadium-containing siliceous shale

ActiveCN107586947ARaise the gradeReduce manufacturing costAlkaline-earth metal silicatesProcess efficiency improvementCarbonizationPotassium

The invention relates to the field of beneficiation and metallurgy with a function of comprehensively recovering valuable components such as vanadium, aluminum, potassium and silicon from the vanadium-containing siliceous shale as a raw material. The process comprises steps as follows: the low-grade vanadium-containing siliceous shale is taken as the raw material, firstly, the vanadium-containingsiliceous shale is desiliconized with a flotation method, vanadium ore concentrate is uniformly mixed with excessive limestone and sodium carbonate, a mixture is subjected to high-temperature roastingin a rotary kiln, and products such as potassium aluminate, potassium ferrite, calcium metavanadate, calcium orthosilicate, carbon dioxide and the like are obtained; the sintered products are dissolved in a dilute alkaline solution, after a dissolution solution is desiliconized and purified, carbon dioxide gas produced by the rotary kiln is introduced into a closed container for carbonization reaction, Al(OH)3 precipitates are separated out, a dealumination solution is subjected to hydrolytic precipitation under the acidic condition, coarse vanadium is obtained and dissolved with alkali, ammonium chloride is added, ammonium metavanadate is obtained, a final solution is a potassium-rich and sodium-rich solution and evaporated step by step, and potash and soda are obtained. According to theinvention, the problem of environmental pollution produced by stockpiling of stone coal leaching residues is solved completely.

Owner:CENT SOUTH UNIV

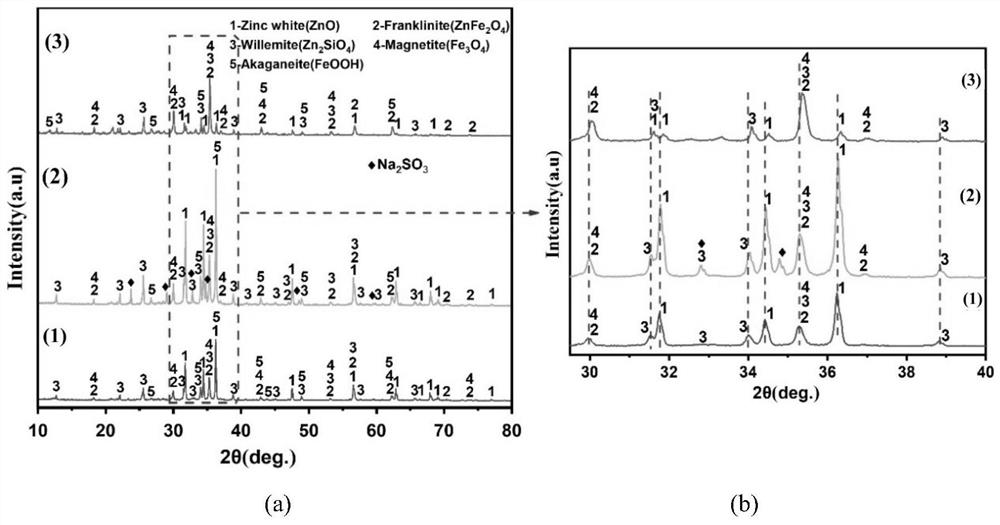

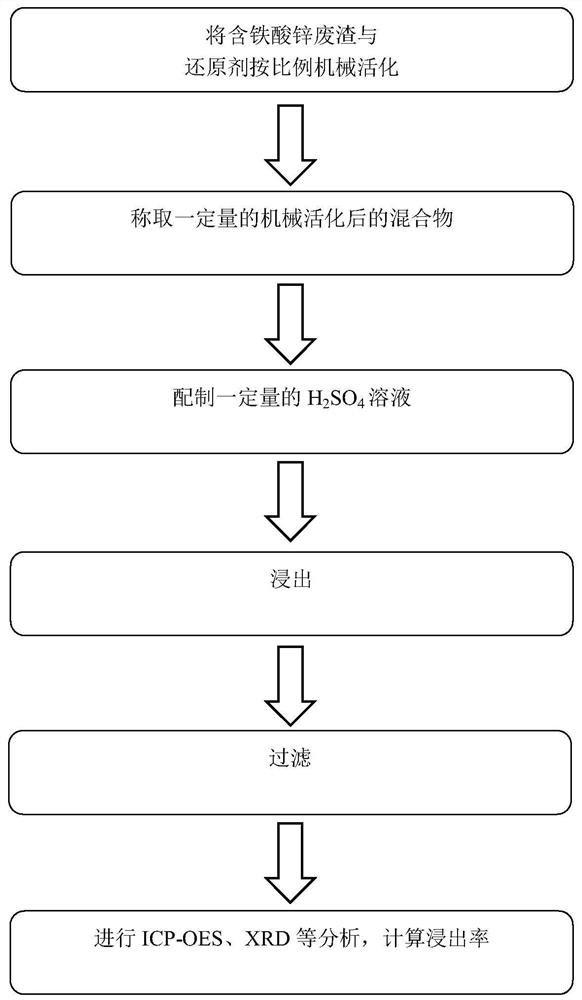

Method for selectively leaching zinc in zinc ferrite-containing waste residues through mechanical activation and directional reduction

ActiveCN113249592AReduce concentrationLow leaching rateProcess efficiency improvementSmelting processHydrometallurgy

The invention discloses a method for selectively leaching zinc in zinc ferrite-containing waste residues through mechanical activation and directional reduction. According to the method, zinc ferrite lattices in the waste residues are subjected to distortion and defects through mechanical activation, the zinc ferrite is directionally reduced into ZnO which is easy to dissolve in acid and Fe3O4 which is not easy to dissolve in acid, the zinc enters a solution, and the iron is left in the residues. By means of the method, zinc leaching is selectively achieved, hazardous waste is reduced, the zinc smelting time is shortened, the zinc smelting cost is reduced, Zn < 2 + > is leached to the maximum extent under the low acid concentration, iron is left in the residues in the form of ferroferric oxide, and therefore the problem of jarosite slag in the zinc hydrometallurgy process is solved from the source.

Owner:SOUTHWEAT UNIV OF SCI & TECH

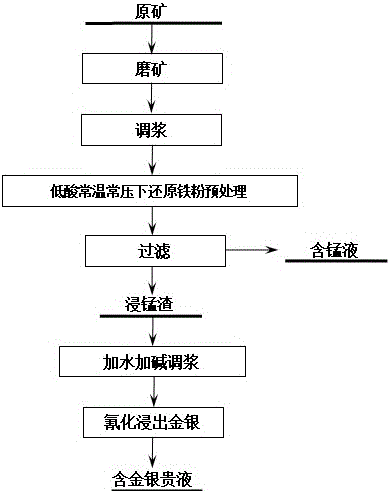

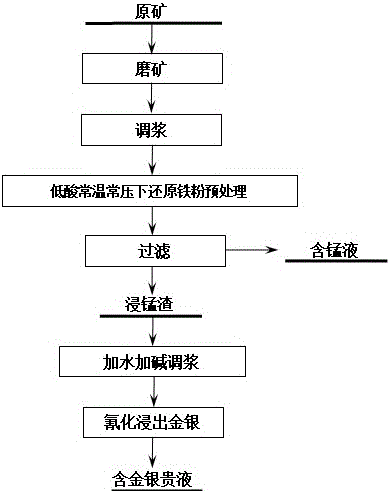

Method for leaching gold and silver out of kustelite wrapped by manganese under normal pressure and temperature

The invention discloses a method for leaching gold and silver out of kustelite wrapped by manganese under normal pressure and temperature. The method includes the steps that raw ore grinding is performed; pretreatment is performed through sulfuric acid and reduced iron powder; filtering is carried out; and manganese-leaching slag obtained through filtering is subjected to cyanide leaching to obtain the gold and silver. Compared with existing methods for leaching the gold and silver out of the kustelite wrapped by the manganese, the method achieves pretreatment of the kustelite wrapped by the manganese under low acid concentration and normal pressure and temperature, the gold and silver leaching rate is substantially increased, and the method is applicable to the kustelite wrapped by the manganese.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

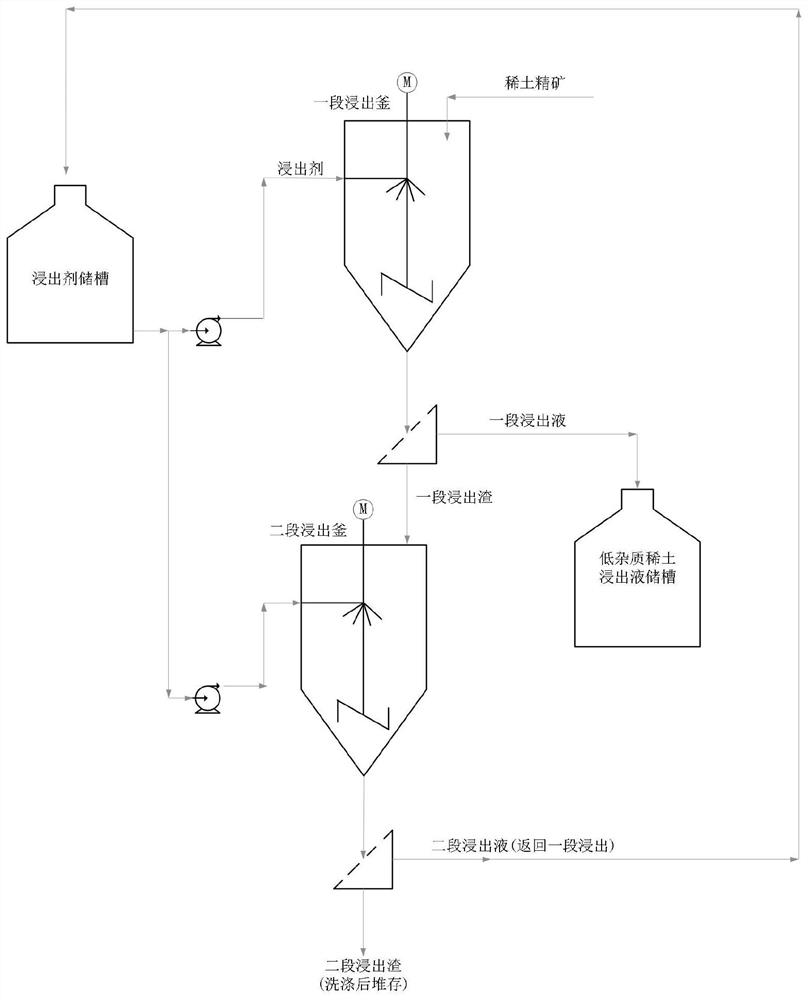

Leaching-purifying method for rare earth concentrate

ActiveCN113699389AIncreased solubility selectivityImprove separation characteristicsProcess efficiency improvementPregnant leach solutionNonferrous metal

The invention relates to a leaching-purifying method for rare earth concentrate, and belongs to the field of non-ferrous metallurgy. According to the method, a leaching process is adjusted, and a two-stage reverse feeding countercurrent process is adopted, namely, in first-stage leaching, rare earth concentrate slurry is used as a base solution, and a leaching agent is added into the base solution, so that low-impurity rare earth leaching liquid is obtained; in second-stage leaching, first-stage leaching residues serve as raw materials, after a certain number of seed crystals are added, a leaching agent hydrochloric acid is added into the first-stage leaching residues, so that the leaching residues low in rare earth content and an acid leaching solution high in impurity content are obtained, and the acid leaching solution is returned to the first-stage leaching for use; and by means of the leaching process, separation of impurities can be achieved, and rare earth resources can be fully utilized. The method has the advantages of being simple in process, low in cost, high in impurity removal rate, high in rare earth recovery rate and the like, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

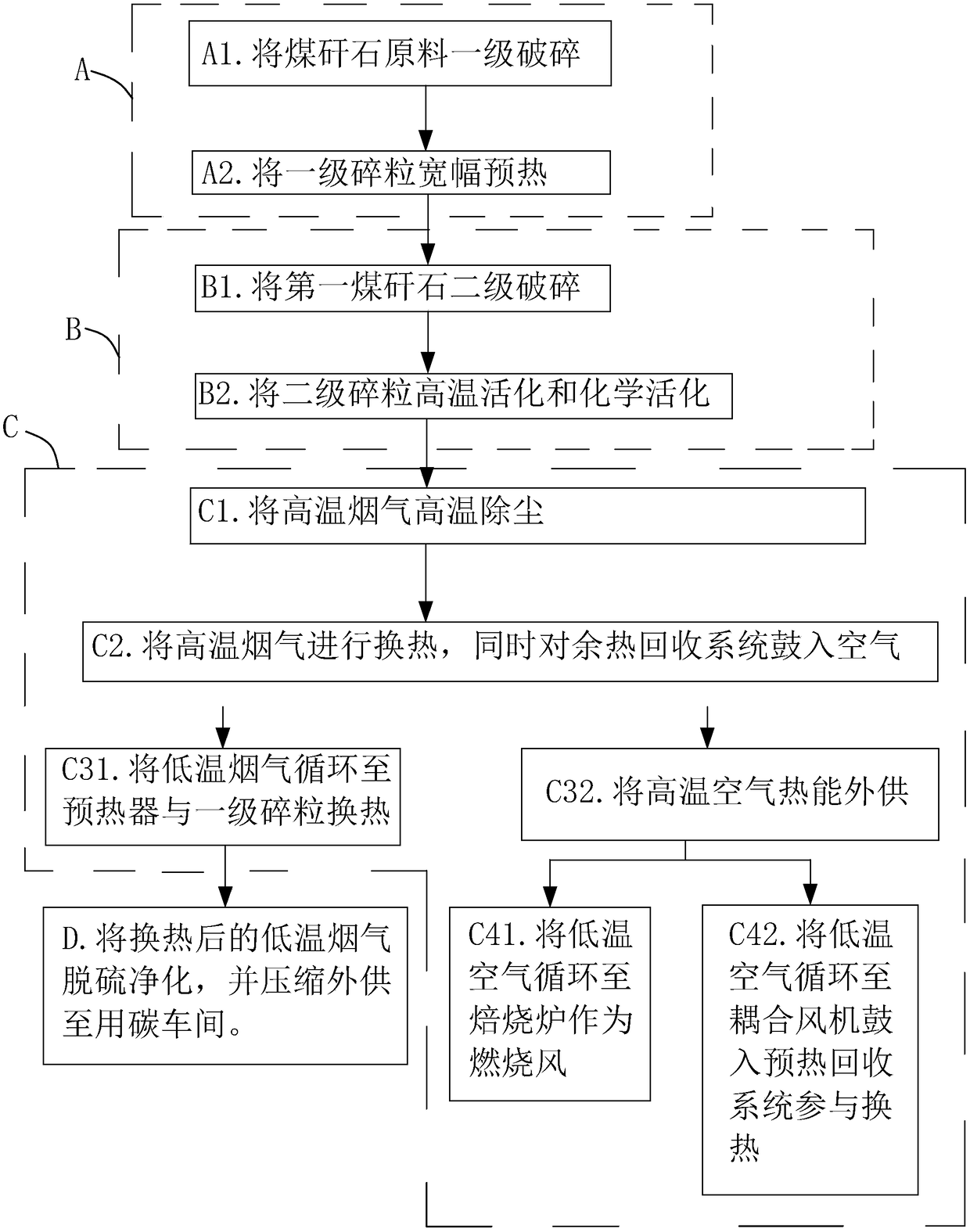

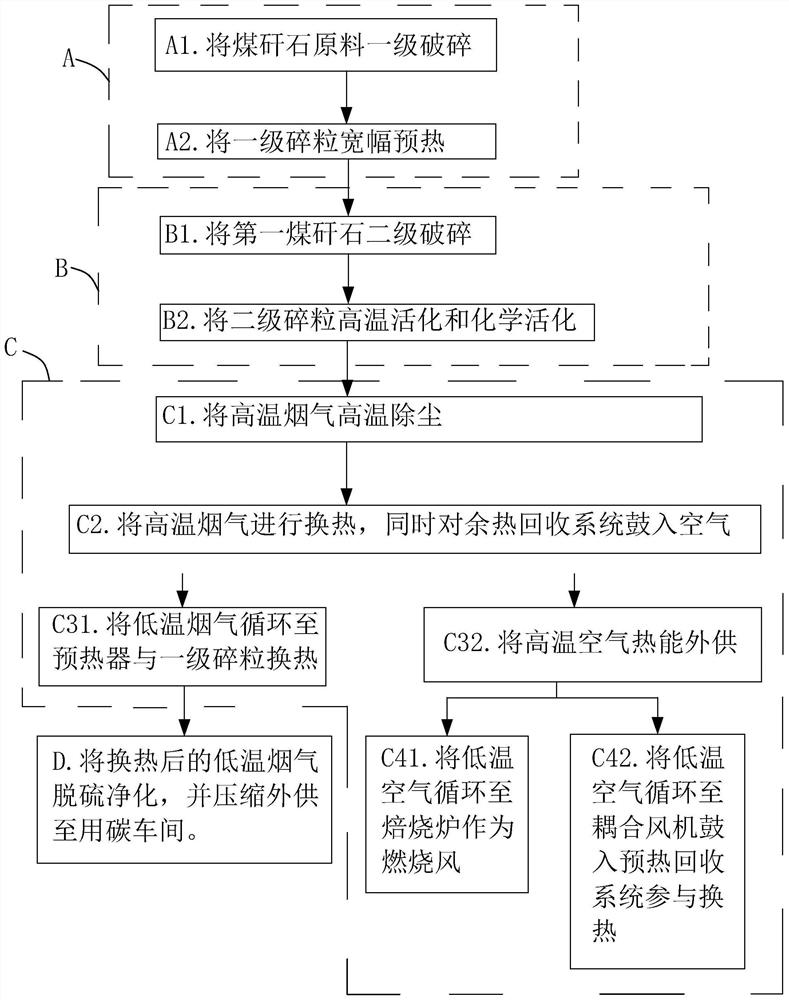

High-efficiency coupling, polygeneration and low-nitrogen coal gangue activation process

ActiveCN109200963AChange crystal formAchieve leachingProcess control/regulationHeat treatmentsThermal energyFlue gas

A high-efficiency coupling, polygeneration and low-nitrogen coal gangue activation process includes the following process steps: A. a coal gangue raw material is subjected to wide preheating to obtainfirst coal gangue having a water content of less than 0.8%; B. the first coal gangue is subjected to field effect low nitrogen roasting to obtain a first activated powder product and a high temperature flue gas; C. the high temperature flue gas is subjected to residual heat coupling adjustment to obtain a second activated powder product, a low temperature flue gas recycled to the step A to participate in the wide preheating and low temperature air recycled to the step B to participate in the field effect low nitrogen roasting. The process adopts the combination of mechanical, high temperatureand chemical three activation modes, the activation effect almost reaches the limit, the activation is no longer a single roasting process, the thermal energy in the flue gas is fully utilized, and the coupling adjustment form is designed, the material itself is preheated for drying, combustion air is preheated, and external heat is supplied.

Owner:辽宁盛达环保科技发展有限公司

Leaching method of zinc sulfide concentrates

ActiveCN109022770AStrong hydrolysis-oxidationImprove leaching rateProcess efficiency improvementSlagManganese

The invention relates to a leaching method of zinc sulfide concentrates, and belongs to the field of wet metallurgy. Water, an oxidizing agent, the zinc sulfide concentrates, additives and a dispersing agent are added in a high-temperature and high-pressure reaction kettle to obtain a reaction system; under the condition of tightness, the reaction system in the high-temperature and high-pressure reaction kettle is heated and pressurized to reach a supercritical state, is reacted by 10-60 min to obtain a reaction product system, and is cooled to reach the room temperature; the solid / liquid-phase separation is performed to obtain zinc-contained leaching liquid and iron-contained oxide leaching slag; the additives are sulfur-contained additives or nitrogen-contained additives; the temperaturein the supercritical state is 380-500 DEG C; and the pressure is 22.5-40 Mpa. The zinc sulfide concentrates are leached by using supercritical water; and high zinc leaching rate and the deposition ofsuch metal as iron, copper and manganese can be realized at the same time.

Owner:KUNMING UNIV OF SCI & TECH

Method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag

ActiveCN112662878AAchieve leachingSimple processCobalt sulfatesProcess efficiency improvementManganese sulfidePhysical chemistry

The invention discloses a method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel; (6) cobalt recovery: taking a cobalt-nickel rich organic phase, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, adding a fourth organic extracting agent formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution, separating out the cobalt-rich organic phase, and adding sulfuric acid for reverse extraction to obtain a high-purity cobalt sulfate-rich solution and a P507-Cyanex301 organic phase; and (7) preparation of the high-purity cobalt sulfate. The method has the advantages that the method is simple and feasible, leaching of cobalt sulfate can be achieved, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions through fluorine ion precipitation can be avoided.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

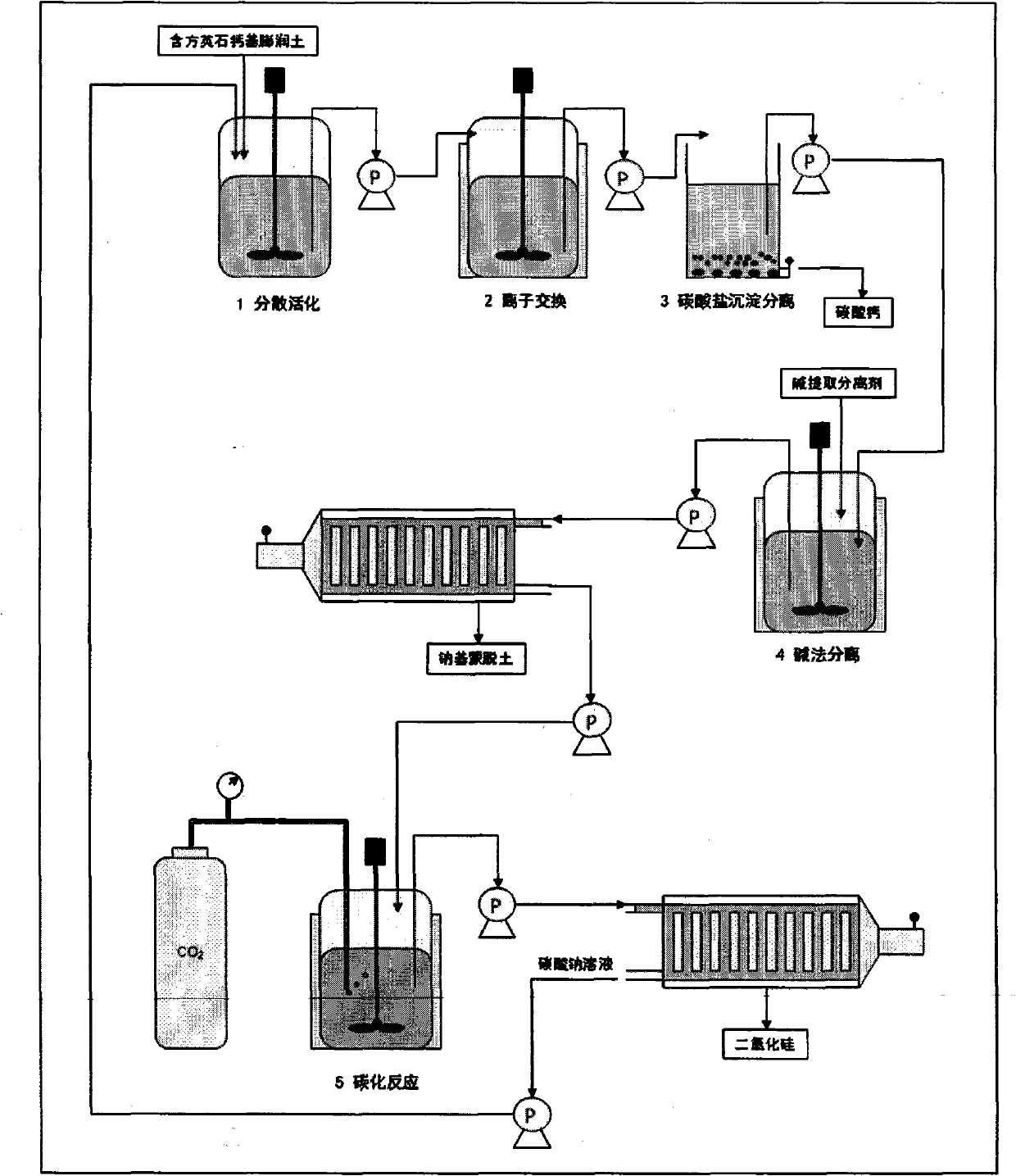

Method for absorbing and fixing carbon dioxide through mineral carbonization

ActiveCN102120588BAchieve leachingImprove the efficiency of hydrolysis to carbonateSilicaSodium BentoniteCo2 absorption

The invention discloses a method for absorbing and fixing carbon dioxide through mineral carbonation, which has the advantages of simple and available process, economy, high ecological benefit and high resource utilization ratio. In the invention, a manner of absorbing and fixing carbon dioxide through mineral carbonation and a manner of deeply processing a calcium bentonite ore containing christobalite impurity are combined, and the carbon dioxide is absorbed and fixed by utilizing the characteristics that the calcium bentonite is easy to form calcium carbonate through ion exchange and is also easy to form a carbon dioxide absorption solution in the process of separating christobalite with an alkaline method so as to realize the favorable ecological benefit, meanwhile, two products of sodium montmorillonoid and silicon dioxide are obtained, therefore the aims of low energy consumption, low cost, development and utilization with high added value and carbon emission reduction of bentonite ore resources rich in christobalite are realized.

Owner:INNER MONGOLIA UNIVERSITY

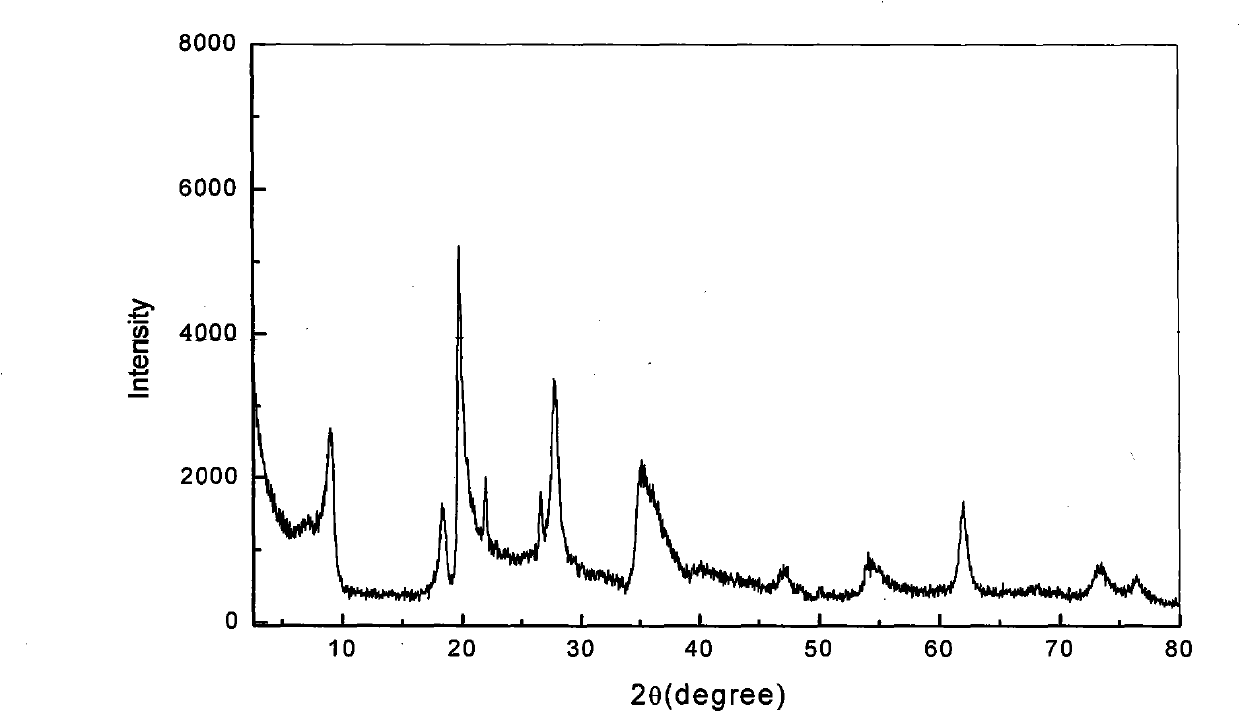

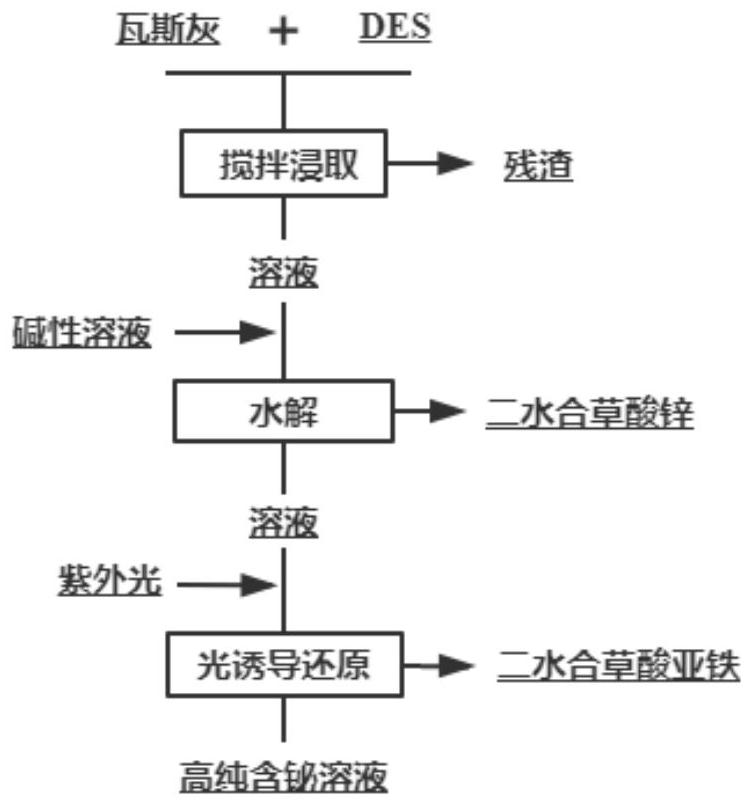

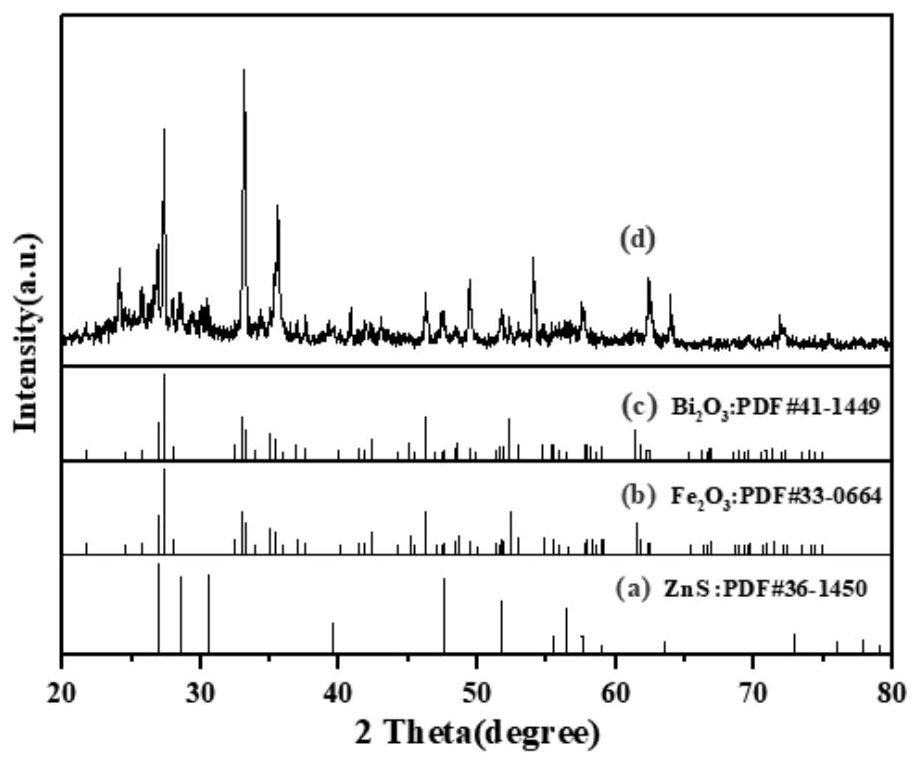

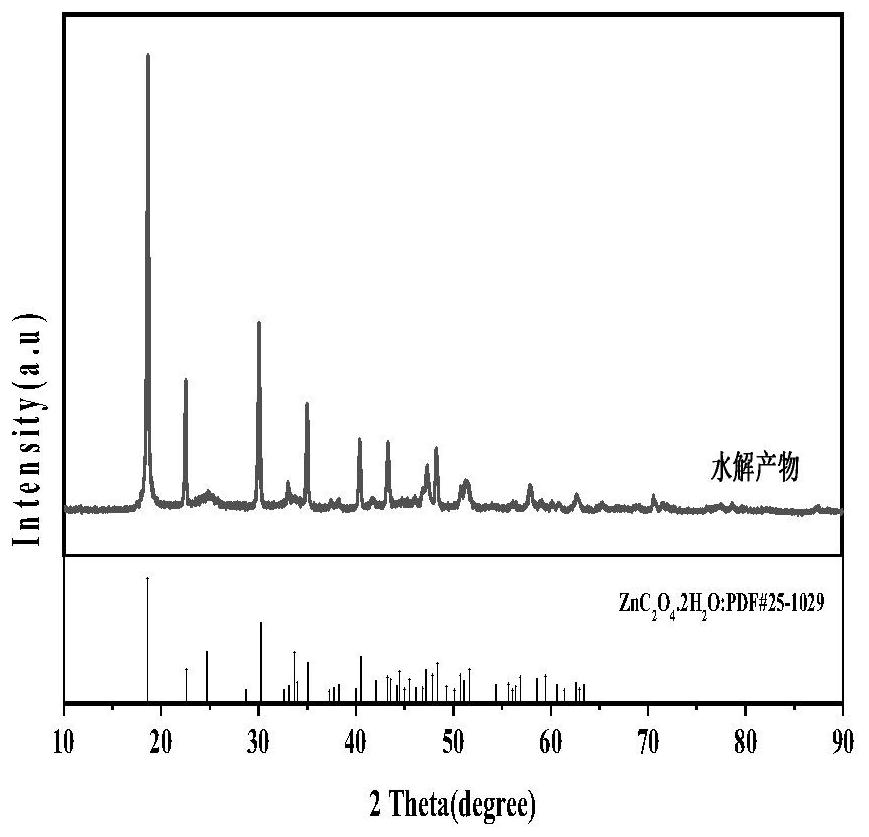

Method for leaching and separating bismuth from blast furnace gas dust or/and mud

PendingCN113293314AHigh selection efficiency of leaching separationImprove economyCarboxylic acid salt preparationProcess efficiency improvementFerric oxalateOXALIC ACID DIHYDRATE

The invention discloses a method for leaching and separating bismuth from blast furnace gas dust or / and mud. The method comprises the following steps: firstly, stirring and leaching blast furnace gas dust or / and mud according to a solid-liquid mass ratio of 1: (1-20) by using an oxalic acid-based eutectic solvent as a leaching agent to obtain a leachate and reaction residues; adjusting the pH value of the leachate by using a NaOH solution, uniformly stirring, standing to form zinc oxalate precipitate, carrying out solid-liquid separation to obtain precipitate and hydrolysate, washing and drying the precipitate to obtain a zinc oxalate byproduct, irradiating the hydrolysate by using an ultraviolet light source to enable an iron element in the hydrolysate to generate light-induced reduction reaction to form ferric oxalate precipitate, and filtering to obtain a ferric oxalate byproduct, wherein the filtrate is a high-purity bismuth-containing solution. According to the method, the high-purity bismuth-containing solution can be selectively separated from the blast furnace gas dust or / and mud so as to be used for producing a bismuth-containing compound with a high additional value, the process is simple, the leaching separation selectivity of the bismuth element is high, and the recycled product and the byproduct are good in economical efficiency.

Owner:XIANGTAN UNIV

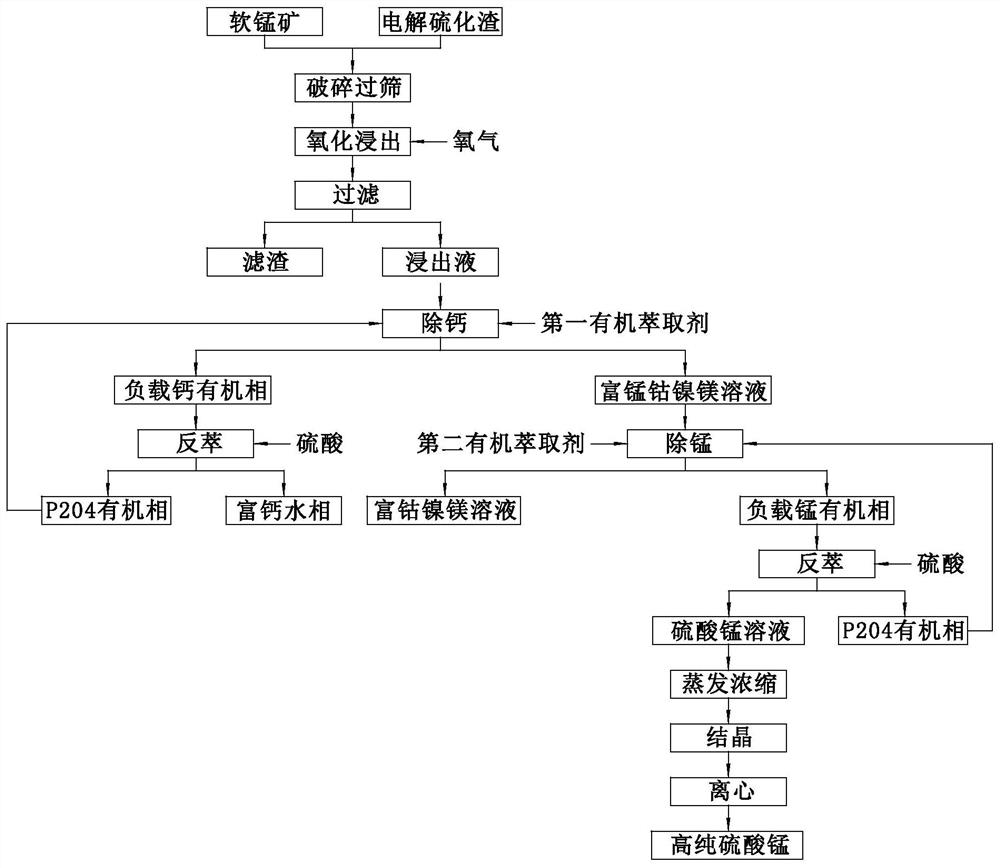

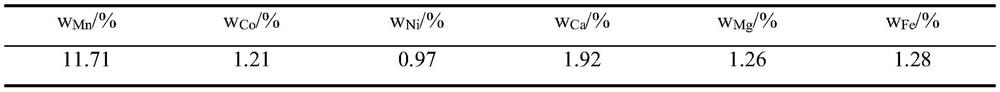

A method for preparing high-purity manganese sulfate from electrolytic manganese sulfide slag

ActiveCN112575208BAchieve leachingSimple processProcess efficiency improvementManganese sulphateManganese sulfide

The invention discloses a method for preparing high-purity manganese sulfate from electrolytic manganese sulfide slag, which is carried out according to the following steps: (1) crushing and sieving; (2) oxidation leaching; (3) decalcification: adding saponified P204 to the leaching solution Extraction with the first organic extractant formed by mixing with sulfonated kerosene to obtain a calcium-loaded organic phase and manganese-cobalt-rich nickel-magnesium solution; (4) Manganese recovery: take manganese-rich cobalt-nickel-magnesium solution, add saponified P204 and sulfonated kerosene Extraction with the second organic extractant formed by mixing to obtain a manganese-loaded organic phase and a cobalt-rich nickel-magnesium solution; take the manganese-loaded organic phase, add sulfuric acid for back extraction, and obtain a P204 organic phase and manganese sulfate solution; (5) High-purity manganese sulfate preparation. The invention has the advantages of being simple and feasible, capable of realizing the leaching of manganese sulfide, avoiding the generation of hydrogen sulfide gas, using the iron-precipitating process and using the fluoride ion precipitation method for removing calcium and magnesium ions.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

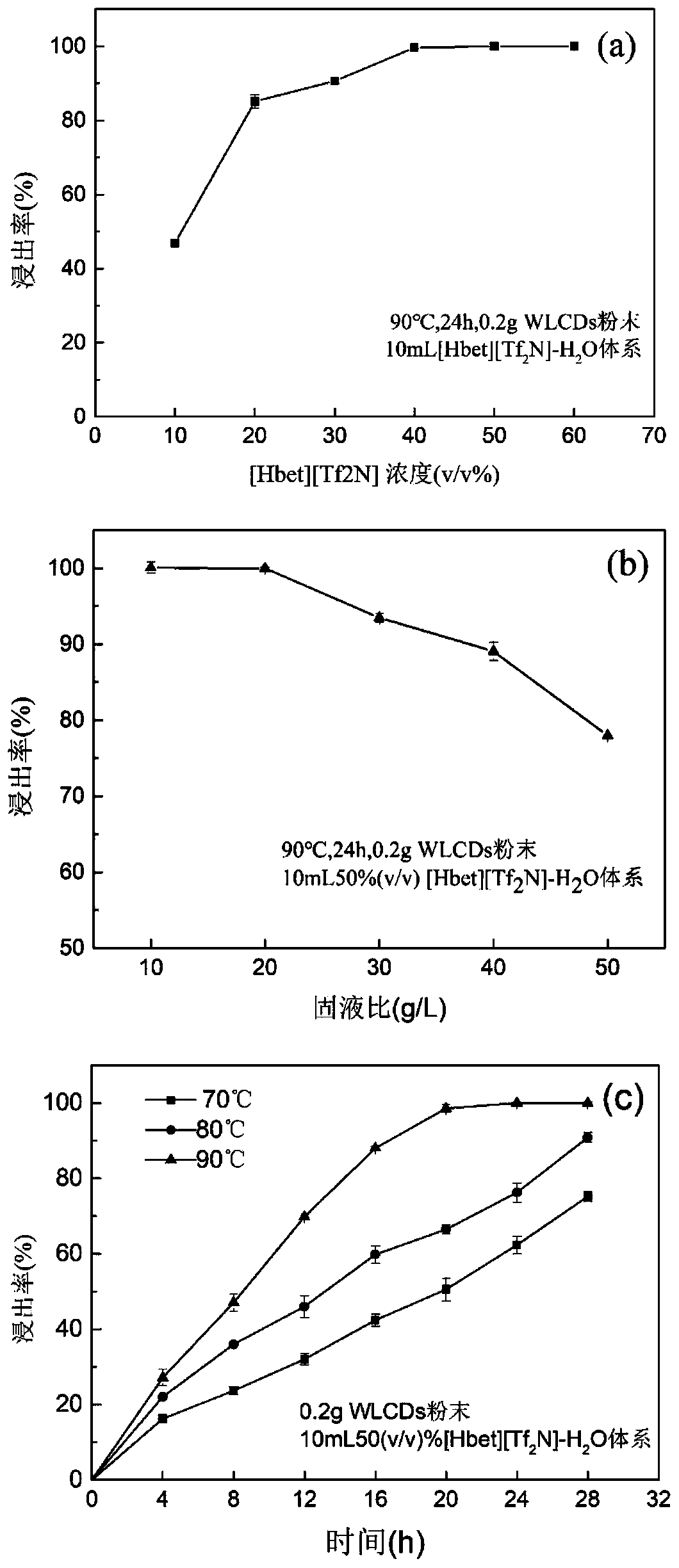

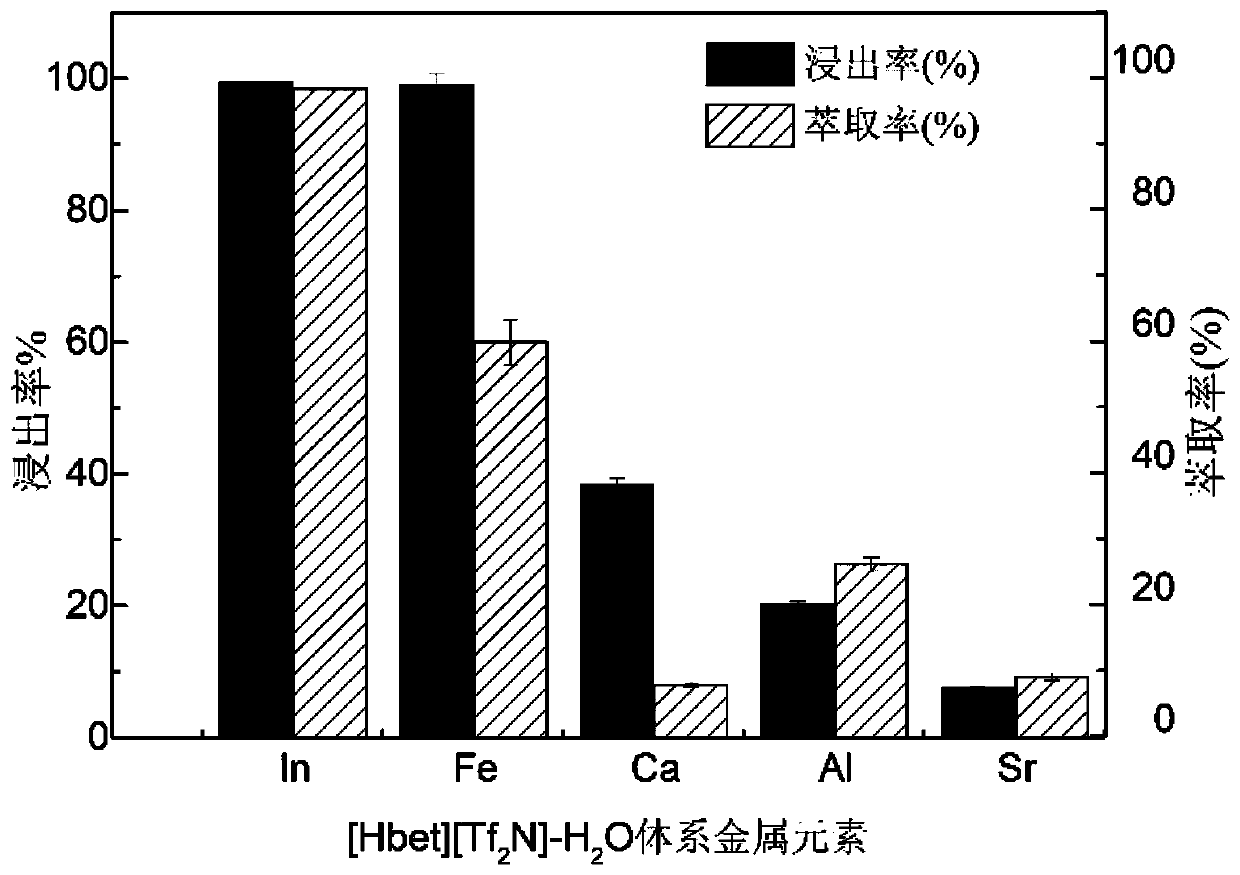

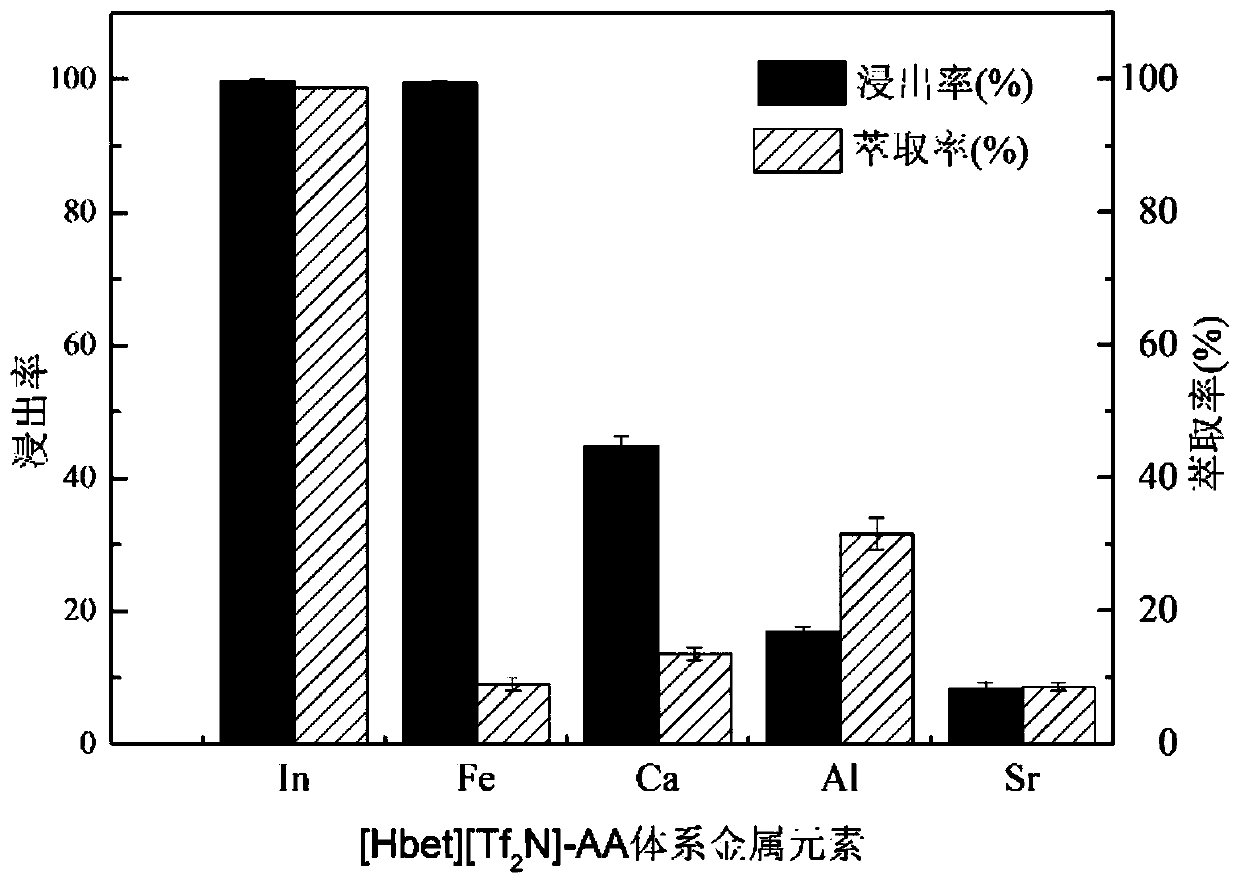

Method for recycling indium in waste liquid crystal display

ActiveCN110055422AHigh leaching separation efficiencyAchieve leachingProcess efficiency improvementOXALIC ACID DIHYDRATEOxalate

The invention belongs to the field of national scarce resource recycling, and discloses a method for recycling indium in a waste liquid crystal display. The method for recycling the indium in the waste liquid crystal display comprises the following steps of (1) crushing the waste liquid crystal display into glass powder, and carrying out high-temperature leaching reaction in an acidic ionic liquidsystem; (2) carrying out solid-liquid separation on the reaction product obtained in the step (1), cooling and layering a leaching agent, and extracting to obtain an ion liquid organic phase containing the indium; and (3) reacting the ion liquid organic phase containing the indium obtained in the step (2) and an oxalic acid solution, fully vibrating, centrifugally layering to obtain an indium-containing oxalic acid solution on the upper layer and ionic liquid on the lower layer, and separating to obtain an oxalic acid-containing solution. According to the method for recycling the indium in the waste liquid crystal display provided by the invention, an acid leaching and extracting integration process is effectively realized, a process flow is simplified, the indium leaching separation efficiency is high, and the environment pollution is reduced; and meanwhile, the ionic liquid can be recycled, so that the usage amount of a chemical agent is reduced, and a new method is provided for waste treatment and recycle.

Owner:SOUTH CHINA UNIV OF TECH

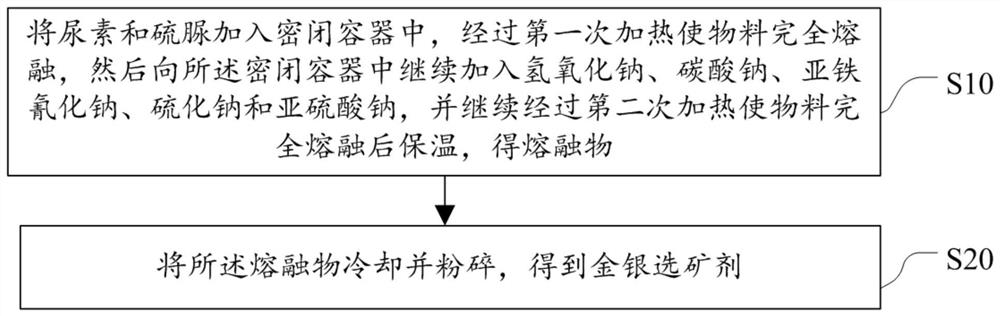

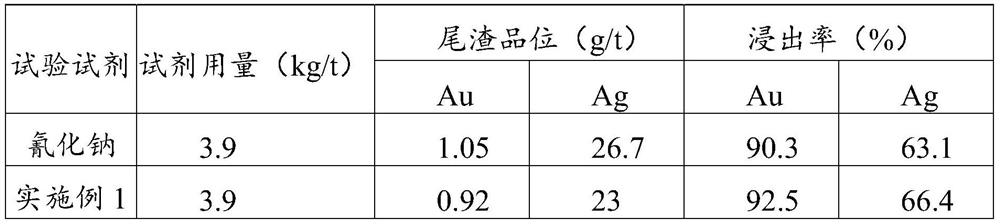

Gold and silver beneficiation agent, and preparation method and application thereof

The invention discloses a gold and silver beneficiation agent and a preparation method and application thereof, and relates to the technical field of mineral flotation. The gold and silver beneficiation agent comprises the following components: sodium ferrocyanide, urea, thiourea, sodium hydroxide, sodium carbonate, sodium sulfide and sodium sulfite. According to the gold and silver beneficiationagent, during beneficiation, active components in the gold and silver beneficiation agent and gold or silver in ore form a complex compound, so that the gold or the silver enters a solution from the ore, gold or silver leaching is achieved, and the gold and silver beneficiation agent has the advantages of being non-toxic, convenient to produce and low in cost, when the gold and silver beneficiation agent is used for gold and silver beneficiation, the cost is reduced, and the toxicity is lower.

Owner:陆云骏

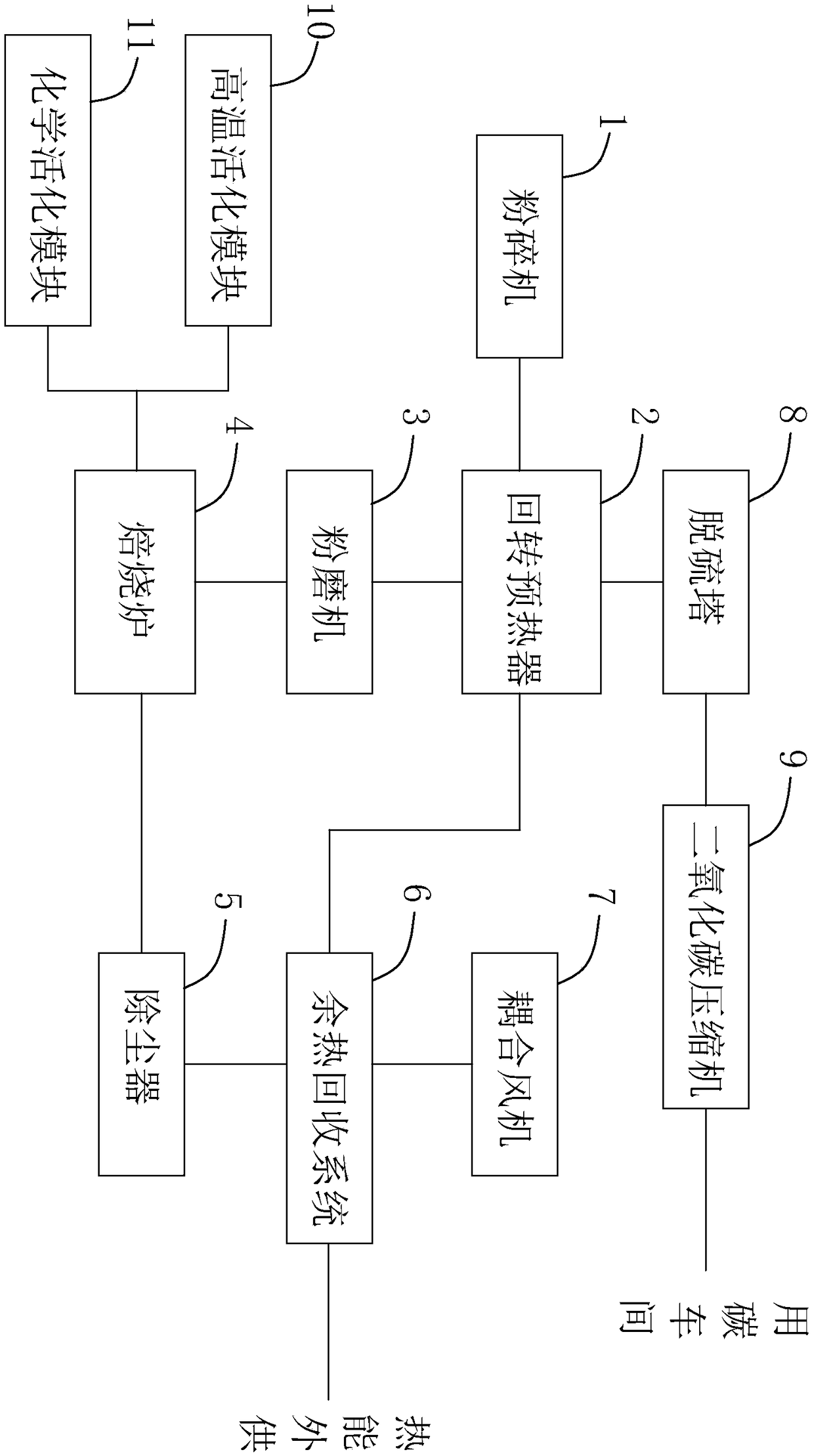

Waste storage battery dismantling processing technology

InactiveCN110656246AAchieve leachingWill not polluteWaste accumulators reclaimingProcess efficiency improvementAqueous sodium hydroxideEnvironmental engineering

The invention discloses a waste storage battery dismantling processing technology which comprises the following steps: soaking a waste storage battery in sodium hydroxide aqueous solution, dischargingfor 1-2 h, then, fixing and dismantling the discharged waste storage battery shell to obtain an anode electrode grid plate, anode mud and a cathode electrode grid plate, processing the anode electrode grid plate, anode mud and the cathode electrode grid plate separately, and under the alkaline condition, taking 10% aqueous hydrogen peroxide solution as a strong oxidant to recycle arsenic and leadelements in anode mud under the pressurizing and warming condition. The waste storage battery dismantling processing technology does not belong to the wet process and the pyrogenic process of traditional lead anode mud treatment, avoid arsenic secondary pollution, and solves the technical problem about arsenic secondary pollution existing in the wet process and the pyrogenic process of traditional lead anode mud treatment when the storage battery anode mud contains multiple valuable metals including lead, bismuth, copper, arsenic and precious metal.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

New method for extracting nickel from enriched ore of nickel sulfide

This invention discloses a novel method for extracting nickel from nickel sulfide concentrate. The method overcomes the problems of long extraction time, low nickel recovery rate and serious pollution faced by the traditional methods. The method comprises: (1) placing nickel sulfide concentrate and pyrolusite at a certain weight ratio into a reactor; (2) adding certain volume and concentration of H2SO4 solution at a certain temperature, and reacting. Nickel sulfide concentrate is leached to form nickel sulfate, and manganese dioxide is leached to form manganese sulfate. The method has such advantages as short reaction time and high nickel recovery rate. The method can choose nickel sulfide concentrate and pyrolusite at different weight ratios, and adopt different parameters and temperatures to realize multiple reactions.

Owner:KUNMING INST OF PRECIOUS METALS

High-efficiency coupling, polygeneration, and low-nitrogen coal gangue activation process

ActiveCN109200963BChange crystal formAchieve leachingProcess control/regulationHeat treatmentsThermodynamicsLow nitrogen

A high-efficiency coupling, polygeneration and low-nitrogen coal gangue activation process includes the following process steps: A. a coal gangue raw material is subjected to wide preheating to obtainfirst coal gangue having a water content of less than 0.8%; B. the first coal gangue is subjected to field effect low nitrogen roasting to obtain a first activated powder product and a high temperature flue gas; C. the high temperature flue gas is subjected to residual heat coupling adjustment to obtain a second activated powder product, a low temperature flue gas recycled to the step A to participate in the wide preheating and low temperature air recycled to the step B to participate in the field effect low nitrogen roasting. The process adopts the combination of mechanical, high temperatureand chemical three activation modes, the activation effect almost reaches the limit, the activation is no longer a single roasting process, the thermal energy in the flue gas is fully utilized, and the coupling adjustment form is designed, the material itself is preheated for drying, combustion air is preheated, and external heat is supplied.

Owner:辽宁盛达环保科技发展有限公司

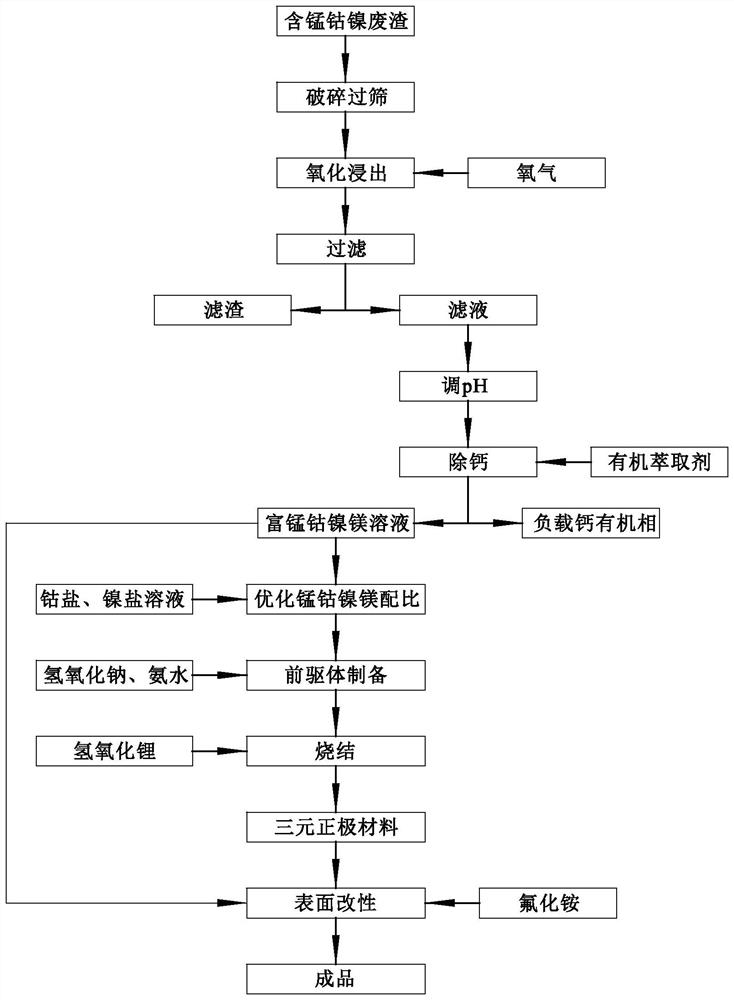

A method for preparing ternary positive electrode material using manganese-cobalt-nickel waste residue

ActiveCN113611857BAchieve leachingSimple processSecondary cellsPositive electrodesManganeseElectro conductivity

The invention discloses a method for preparing a ternary positive electrode material by utilizing manganese-cobalt-nickel waste residue, which is carried out according to the following steps: (1) crushing and sieving; (2) oxidative leaching; (3) calcium removal; (4) optimization of manganese-cobalt-nickel Magnesium ratio; (5) Preparation of magnesium ion-doped manganese-cobalt-nickel ternary cathode material precursor; (6) Preparation of ternary cathode material; (7) Surface modification: The ternary cathode material is dispersed in water, According to a certain mass ratio, the manganese-rich cobalt-nickel-magnesium solution and ammonium fluoride after decalcification in step (3) are used as modifiers to modify the surface of the ternary cathode material. The method is simple and feasible, can realize leaching of manganese-cobalt-nickel-magnesium waste residue, filter and remove impurities from the filtrate, directly prepare magnesium ion-doped manganese-cobalt-nickel ternary positive electrode material precursor, and prepare ternary positive electrode material, which can not only realize The comprehensive utilization of waste residue can also improve the ionic conductivity of the product, inhibit the increase of electrochemical impedance, and improve the cycle performance.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

A method for leaching gold and silver from manganese-coated gold and silver ore under normal temperature and pressure

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

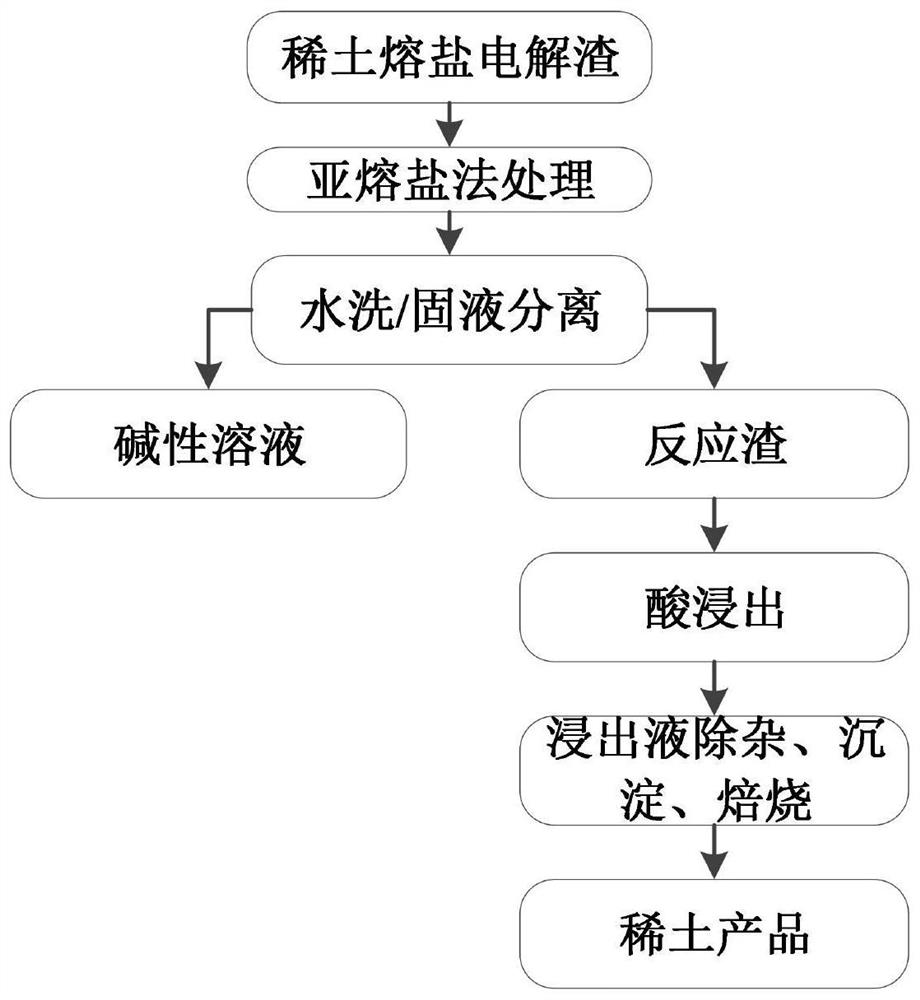

Method for recovering rare earth elements in rare earth molten salt electrolytic slag through sub-molten salt method

The invention belongs to the technical field of rare earth secondary resource recovery and recycling, and provides a method for recovering rare earth elements in rare earth molten salt electrolytic slag through a sub-molten salt method, which comprises the following steps: S1, treating the rare earth molten salt electrolytic slag through the sub-molten salt method to obtain an alkaline solution and reaction slag; s2, the reaction residues are subjected to acid leaching, and a leaching solution is obtained; s3, performing impurity removal and precipitation on the leachate to obtain rare earth salt precipitation; and S4, roasting the rare earth salt precipitate to obtain the rare earth oxide. Aiming at the technical problems existing in the chemical recovery process of the rare earth elements in the rare earth molten salt electrolytic slag, the rare earth elements in the rare earth molten salt electrolytic slag are recovered by the sub-molten salt method by utilizing the high chemical reactivity of the sub-molten salt medium, and the method has the advantages of high operability, simple process, low cost, low reaction temperature, no secondary pollution and the like; and efficient recycling of rare earth elements in the rare earth molten salt electrolytic slag is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

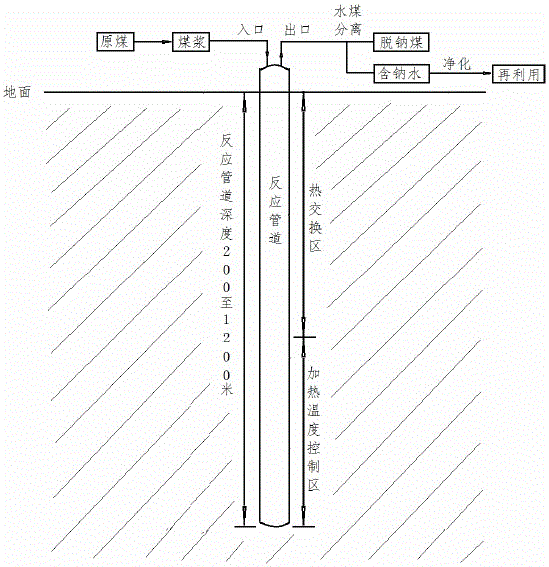

A method for leaching and removing sodium in coal by using hydrostatic pressure

ActiveCN104178237BAchieve leachingConducive to expanding the scale of utilizationSolid fuelsOrganic structureChemical structure

The invention provides a method for leaching and removing sodium in high-sodium coal by utilizing the high-temperature and high-pressure environment generated by hydrostatic pressure and underground heating technology. In this method, the coal is ground to a certain particle size range, so that the coal slurry formed can meet the requirements of being pumped; the coal slurry is pumped from the ground inlet into the underground reaction pipeline of a certain depth, flows in the pipeline at a certain speed, and then flows from the ground inlet into the underground reaction pipeline of a certain depth. The ground outlet is pumped out; through the underground heating temperature control system, the temperature of different positions of the reaction pipeline is controlled to be below the boiling point of the water corresponding to the pressure of the position. Using the pressure of the coal slurry itself and the high temperature provided by the underground heating, the physical and chemical structure of the coal changes during the stay in the underground reaction pipeline. The water-soluble sodium and organic sodium in the coal are released from the internal structure of the coal and dissolve in the process. water, which is then further removed. This technology will provide a low-energy-consumption, water-saving and high-efficiency technical approach for the processing and utilization of high-sodium coal.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com