A method for leaching and removing sodium in coal by using hydrostatic pressure

A static pressure, sodium element technology, applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of insufficient sodium removal effect, high energy consumption, and difficulty, and achieve expanded utilization scale, high removal efficiency, and applicable wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

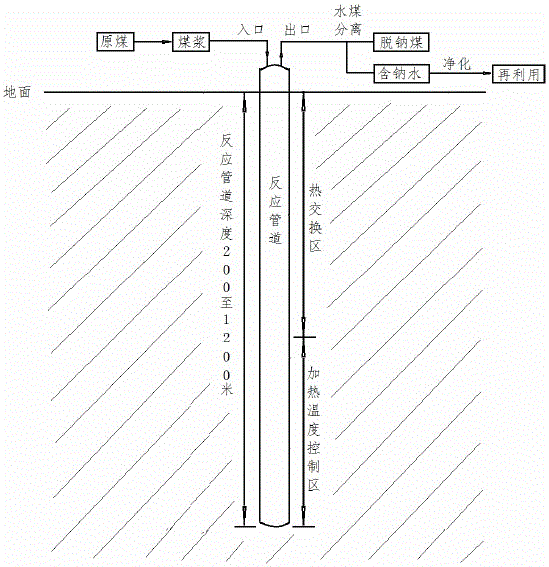

[0021] see figure 1 , The characteristics of the high-sodium coal raw coal in the present embodiment are shown in Table 1.

[0022] Table 1. Analysis results of raw coal ash components of high-sodium coal

[0023] Ash component Na 2 o K 2 o CaO MgO Fe 2 o 3 SiO 2 al 2 o 3 TiO 2 SO 2 content(%) 6.55 0.30 30.84 6.95 8.51 13.5 6.35 0.32 19.5

[0024] The percentages in Table 1 are all mass percentages. From the analysis results of the coal ash composition in Table 1, the Na in the coal ash 2 The O content is 6.55%, the CaO content is 30.84%, and the MgO content is about 6.95%, all of which are much higher than the common coal types in the world, while the acidic oxide SiO 2 Content about 13.5%, Al 2 o 3 The content is only 6.35%. Slagging index calculated according to its coal ash composition R s and dust index R f They are 1.21 and 17.26 respectively, which belong to coal with moderate slagging and serious ash acc...

Embodiment 2

[0038] In this embodiment, the method for leaching and removing sodium in coal by using hydrostatic pressure is as follows.

[0039] A. Applicable coal type is coal ash with sodium content greater than 1.5% (w / w, expressed as Na 2 O meter) of coal.

[0040]B. Apply high temperature and high pressure to the coal slurry, so that the coal slurry undergoes hydrothermal reaction underground. The concentration of coal in the coal slurry can be 30-70% (w / w). Coal slurry can be obtained by dry grinding followed by mixing with water, directly by wet grinding technology, or a combination of dry and wet grinding.

[0041] C. The underground reaction pipeline is one or more reaction pipelines perpendicular to the ground or at a certain angle to the ground. It can be constructed by using the existing local mines. The outer wall of the pipeline is rock or supported by underground rock. The technical requirements for pipeline materials The high pressure resistance performance requirement ...

Embodiment 3

[0051] In this embodiment, the method of using hydrostatic pressure to realize the leaching and removal of sodium in coal is suitable for coal ash with a sodium content greater than 1.5% (w / w, expressed as Na 2 In this method, the raw coal is first ground to a particle size below 0.2mm, and mixed with water to make a coal slurry with a concentration of 30% to 70% (w / w); then the coal slurry is transported to the reaction pipeline , and the residence time of the coal slurry in the reaction pipeline is 5 to 30 minutes, the reaction pipeline is located underground, the distance between the bottom of the reaction pipeline and the ground is 200 to 1200 meters, and the static pressure generated by the water in the coal slurry is utilized , instead of the energy consumption required to provide continuous high pressure for the reaction, the temperature of the coal slurry in the reaction pipeline is controlled to increase with the increase of the depth of the reaction pipeline. The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com