A method for leaching gold and silver from manganese-coated gold and silver ore under normal temperature and pressure

A gold-silver, atmospheric pressure technology is applied in the field of beneficiation of manganese-coated gold-silver ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

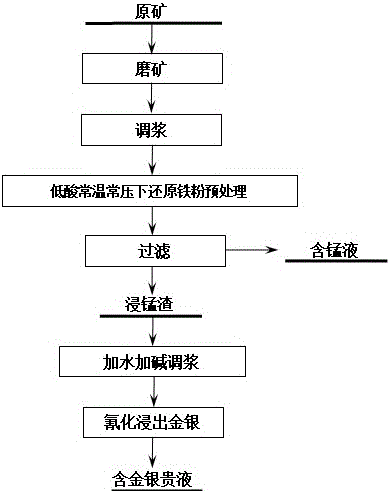

Image

Examples

Embodiment 1

[0027] The original ore is a manganese-silver mine in Yunnan, China.

[0028] S1. Grinding the raw ore to -0.074mm accounts for 80%, adding water to adjust the pulp concentration to 35%;

[0029] S2. Pretreatment: Add 30Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 5%), add 8Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 3 hours to obtain the pretreated raw ore;

[0030] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0031] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 36%, add sodium hydroxide 500g / t, and lime 6Kg / t to adjust the slurry to a pH value of 10, based on ore weight , add sodium cyanide 1000g / t. Stir...

Embodiment 2

[0034] The original ore is a manganese silver mine in Guangxi, China.

[0035] S1. Raw ore is ground to -0.074mm, accounting for 65%, adding water to adjust the pulp concentration to 30%;

[0036] S2. Pretreatment: add 15Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 10%), add 12Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 4.5 hours to obtain pretreated raw ore;

[0037] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0038] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 31%, add lime 8Kg / t to adjust the slurry to a pH value of 11, and add sodium cyanide 1300g / t based on the ore weight t. Stir and leach at normal...

Embodiment 3

[0041] The original ore is a manganese-silver mine in Yunnan, China.

[0042] S1. Grinding the raw ore to -0.074mm accounts for 80%, adding water to adjust the pulp concentration to 30%;

[0043] S2. Pretreatment: add 20Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 10%), add 8Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 3 hours to obtain the pretreated raw ore;

[0044] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0045] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 36%, add sodium hydroxide 500g / t, and lime 6Kg / t to adjust the slurry to a pH value of 10, based on ore weight , add sodium cyanide 1000g / t. Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com