Method for recovering rare earth elements in rare earth molten salt electrolytic slag through sub-molten salt method

A technology of molten salt electrolysis and sub-molten salt method, which is applied in the field of rare earth secondary resource recovery and recycling, can solve the problems of low synergistic recovery rate, large energy consumption, secondary pollution, etc., and achieve high activity and high utilization rate , the effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

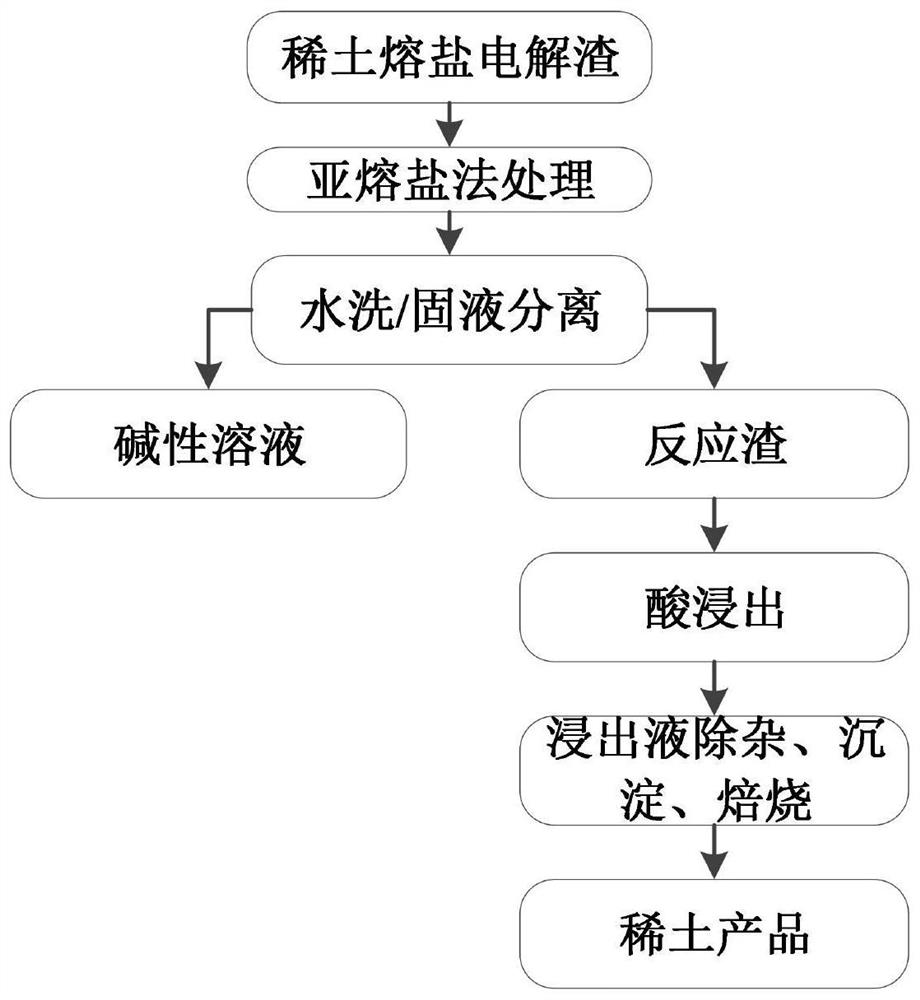

[0029] A method for recovering rare earth elements in rare earth molten salt electrolytic slag by sub-molten salt method, the process flow is as follows figure 1 shown, including the following steps:

[0030] A rare earth molten salt electrolytic slag contains four rare earth elements including Pr, Nd, Sm and Yb, and their contents are 13.07%, 46.83%, 0.29% and 0.14% respectively.

[0031] S1. Take 10 g of the above-mentioned rare earth molten salt electrolytic slag, add a sodium hydroxide sub-molten salt medium prepared from 40 g of sodium hydroxide + 10 g of water, mix evenly, and place it in an autoclave, and react at 180 ° C for 3 hours to obtain The reaction product, the reaction product is washed and filtered by adding 200 mL of water, the filter residue is washed and filtered with 200 mL of water, and repeated 3 times, and the solid-liquid is carried out to obtain an alkaline solution and a sub-molten salt reaction residue;

[0032] S2, adding 4 mol / L hydrochloric acid...

Embodiment 2

[0036] A method for recovering rare earth elements in rare earth molten salt electrolytic slag by sub-molten salt method, the process flow is as follows figure 1shown, including the following steps:

[0037] In the rare earth molten salt electrolytic slag from a rare earth smelter in Ganzhou, rare earth oxides accounted for 77.4%, of which La 2 O 3 , CeO 2 The proportions are 99.61% and 0.25% respectively.

[0038] S1, take 15g of the above-mentioned rare earth molten salt electrolytic slag, add sodium hydroxide+potassium hydroxide sub-molten salt medium configured by 20g sodium hydroxide+20 potassium hydroxide+10g water, mix well, and place in a high-pressure reactor In the process, the reaction was carried out at 200 °C for 4 h to obtain a reaction product, the reaction product was rinsed and filtered with 300 mL of water, and the filtration residue was rinsed and filtered with 300 mL of water, repeated 3 times, and the solid-liquid was carried out to obtain an alkaline s...

Embodiment 3

[0043] A method for recovering rare earth elements in rare earth molten salt electrolytic slag by sub-molten salt method, the process flow is as follows figure 1 shown, including the following steps:

[0044] The rare earth molten salt electrolytic slag from a rare earth smelting plant in Jiangxi has a rare earth oxide content of 38.62%, of which La 2 O 3 , Pr 6 O 11 , Nd 2 O 3 , Gd 2 O 3 The proportions are 15.05%, 12.62%, 64.42% and 4.58% respectively.

[0045] S1, take 10g of above-mentioned rare earth molten salt electrolytic slag, add sodium hydroxide+potassium hydroxide sub-molten salt medium configured by 30g sodium hydroxide+20 peroxy Warner+15g water, mix evenly, and place in a high pressure reactor , react at 200 ° C for 5 h to obtain the reaction product, add 250 mL of water to the reaction product to rinse and filter, add 250 mL of water to the filter residue to rinse and filter, repeat 3 times, and carry out solid-liquid to obtain alkaline solution and sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com