Patents

Literature

79results about How to "Good dynamic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

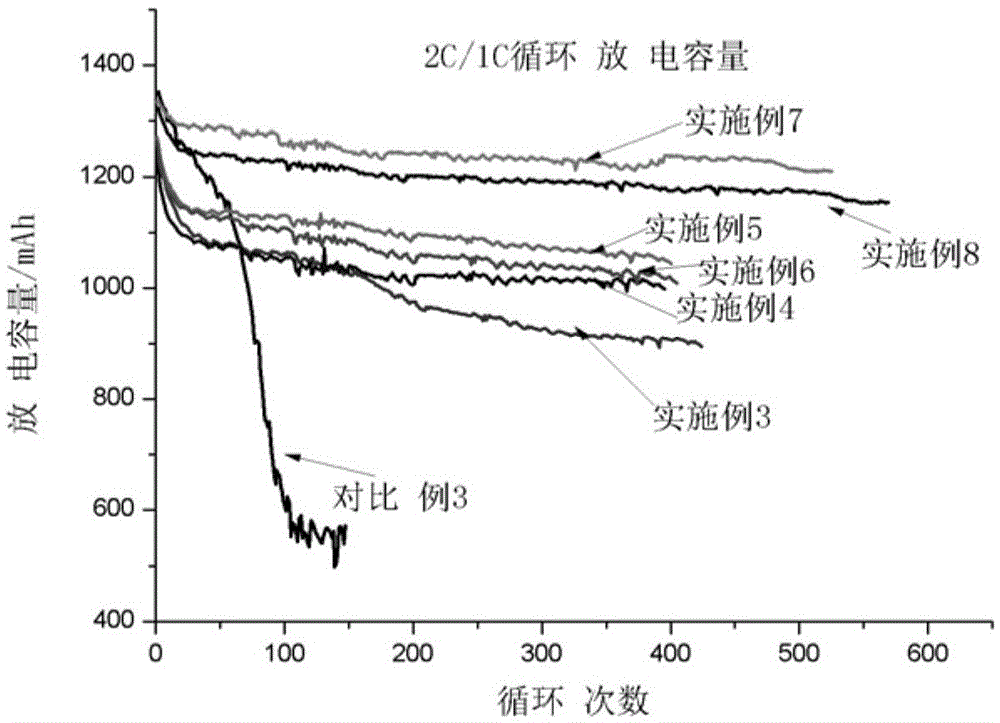

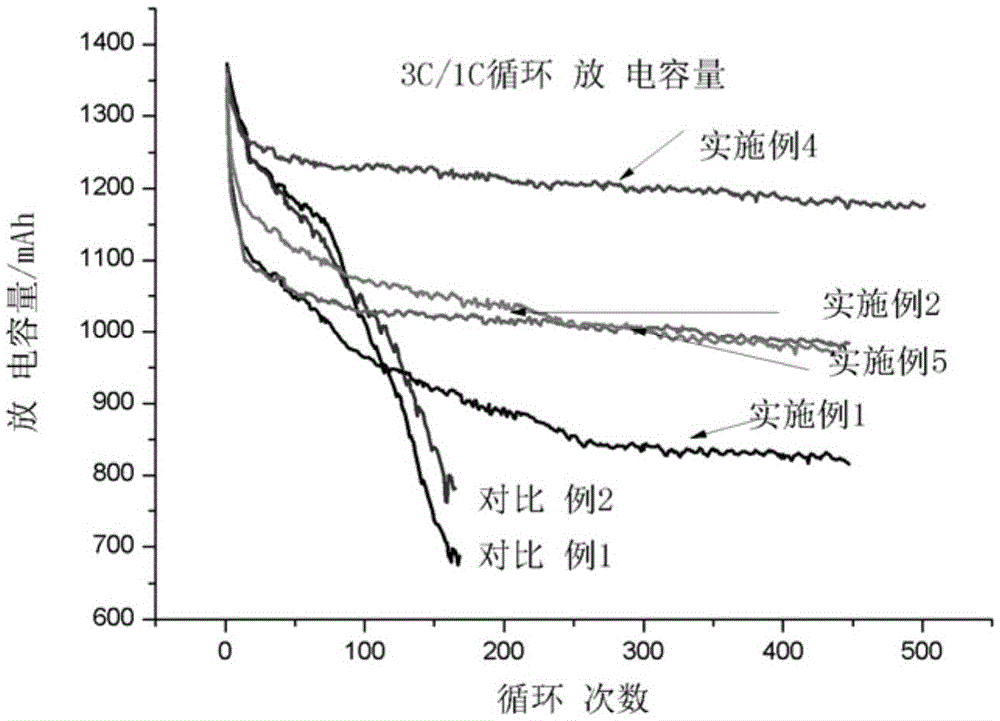

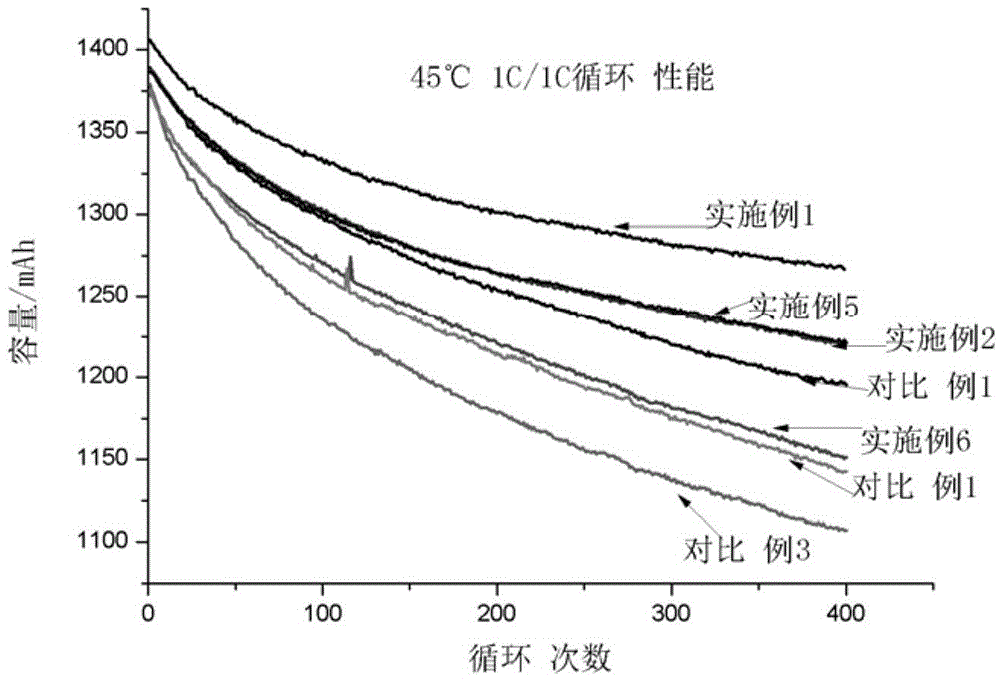

Electrolyte of rapid-charging lithium ion battery

InactiveCN105552439AImprove dynamic performanceGood film formingSecondary cellsElectrolytesOrganic solventBoiling point

The invention relates to technical field of a lithium ion battery, in particular to an electrolyte of a rapid-charging lithium ion battery. The electrolyte comprises a solvent, a lithium salt and an additive, wherein the solvent contains more than two mixtures of linear carbonic ester with a low boiling point, linear carboxylic ester, fluorobenzene and hydrofluoroether, and the additive comprises a first additive for negative electrode film forming, a second additive for improving the cycle performance of the battery and a third additive for improving the high-temperature performance of the battery. Compared with the prior art, the organic solvent and the three additives are used in a combination way to generate a synergistic effect, the rapid charging demand of a high-potential, high-compaction-density and more than 2C rapid-charging system battery with a voltage of 4.35V and negative electrode compaction density of over 1.6g / cm<3> can be met, and meanwhile, the electrolyte has favorable cycle performance and high- and low-temperature performance.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

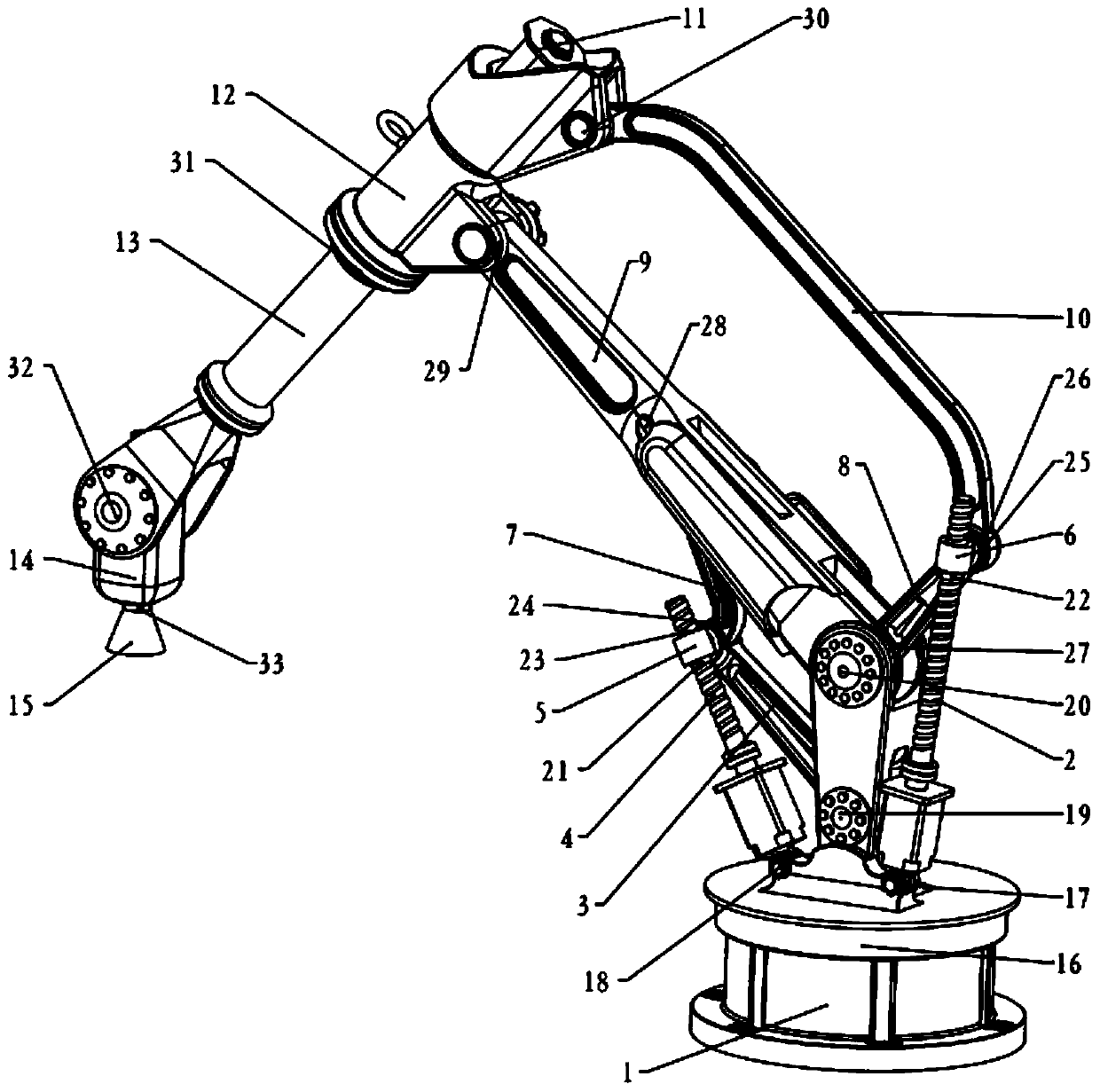

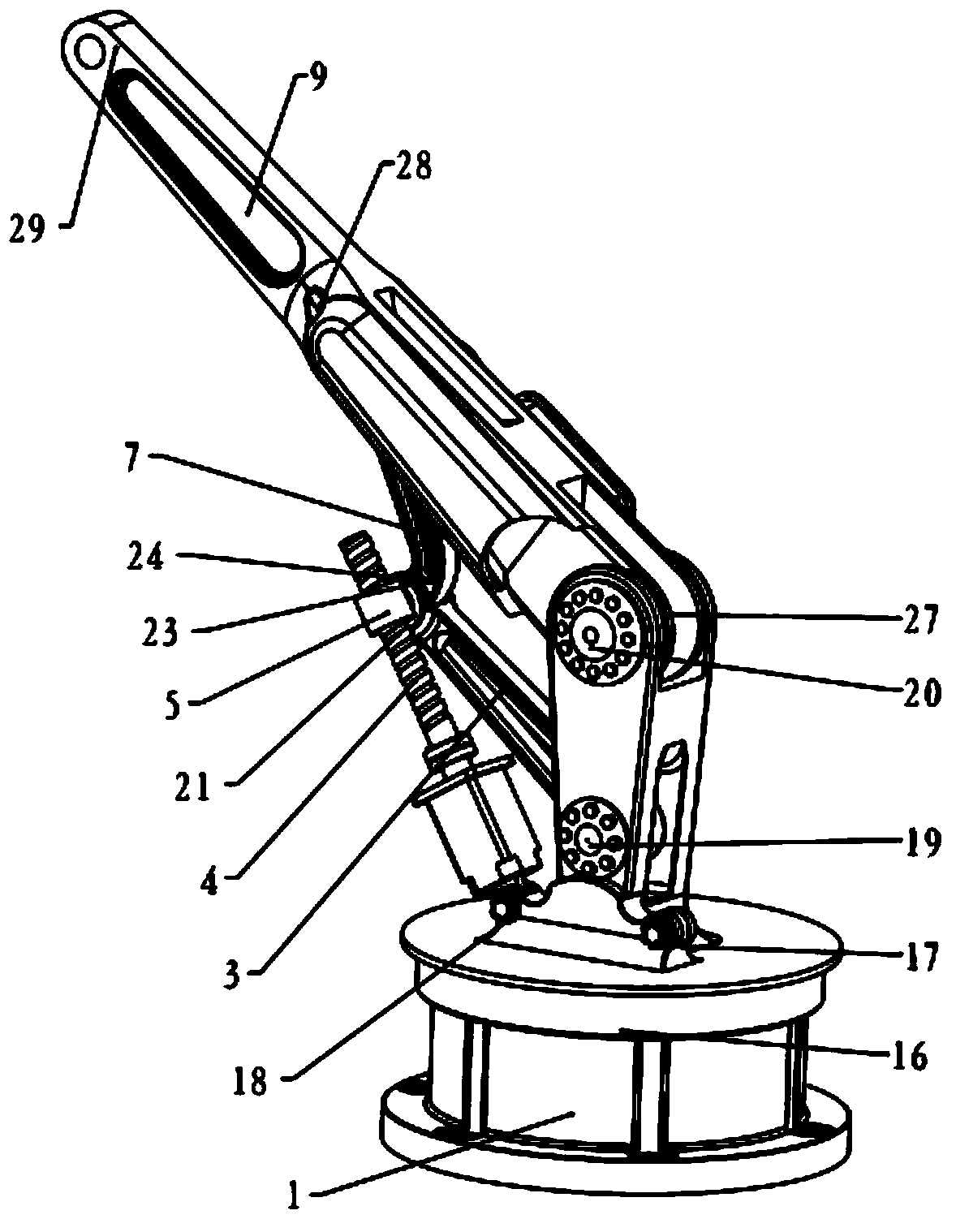

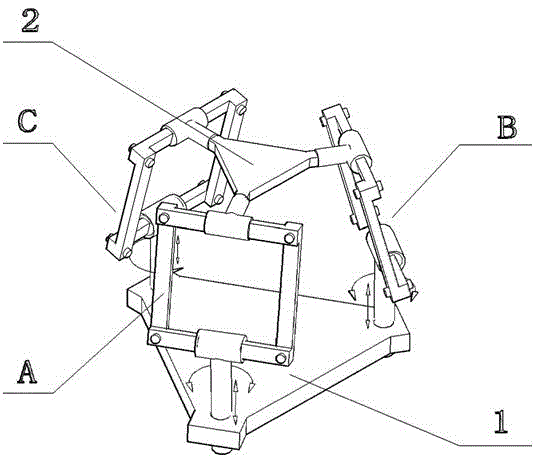

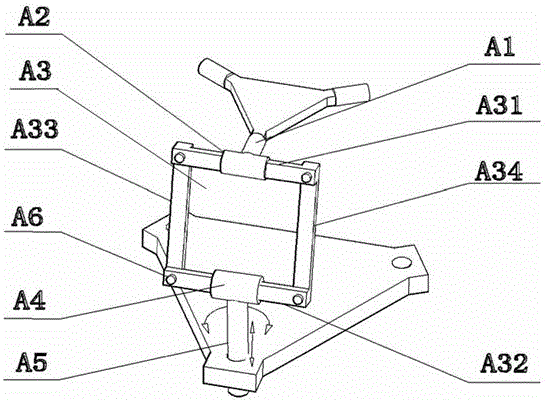

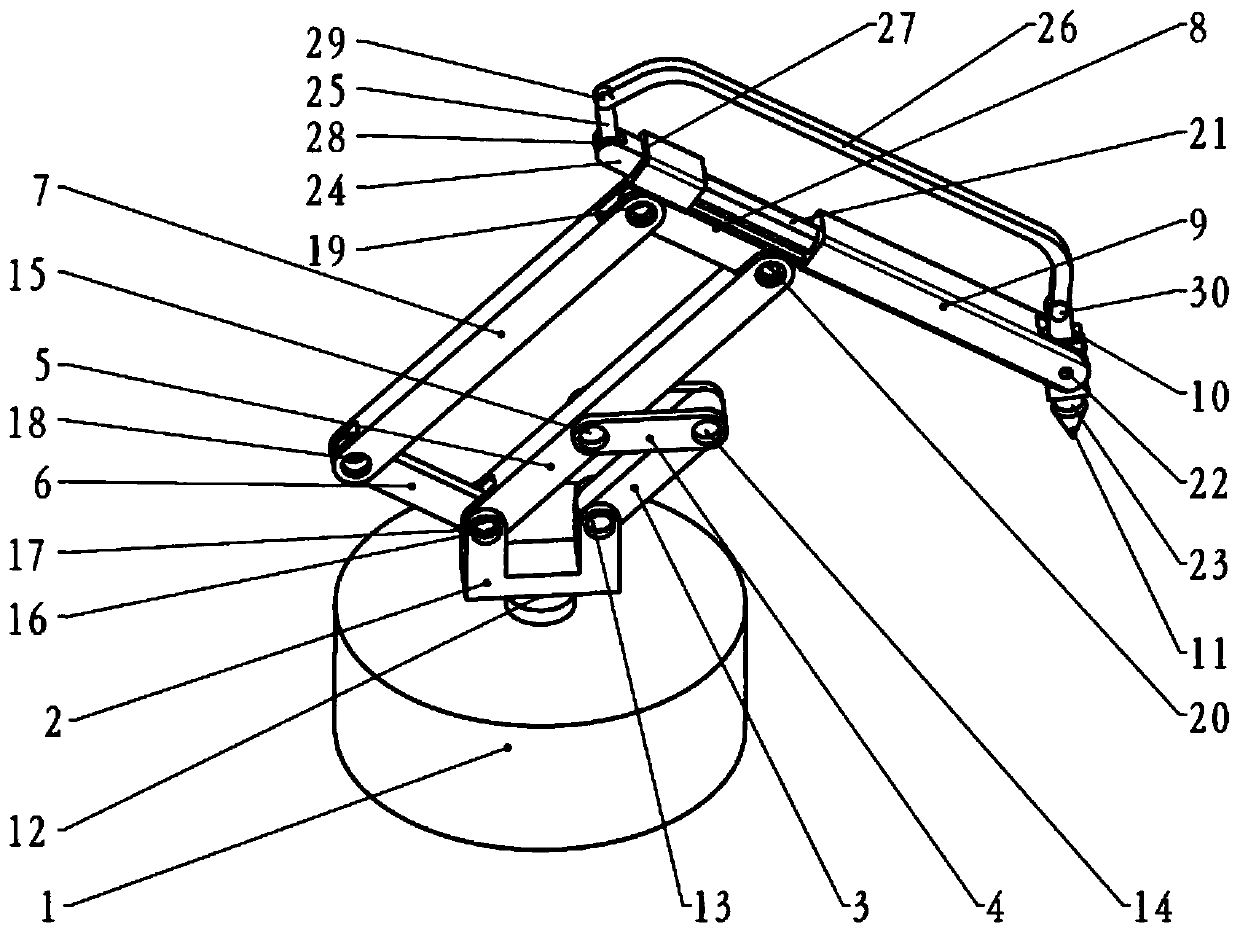

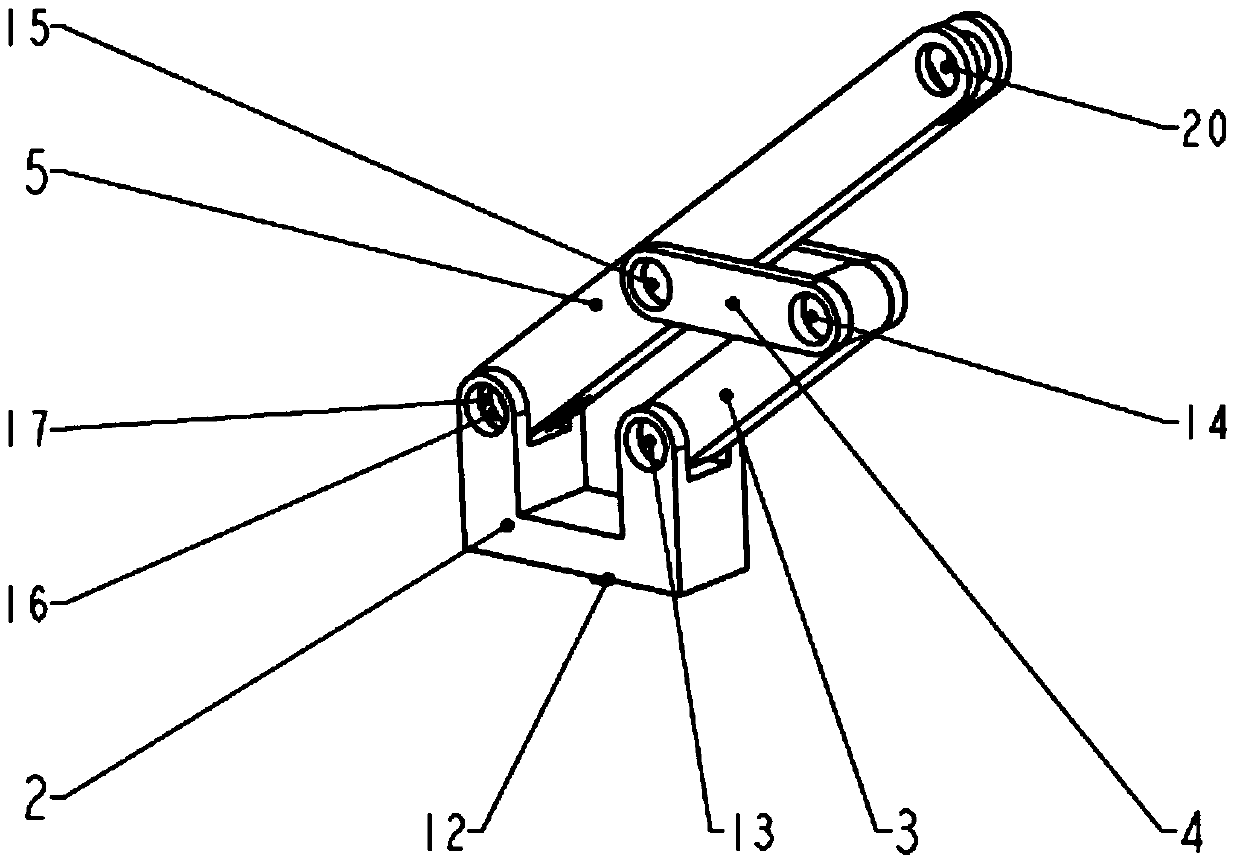

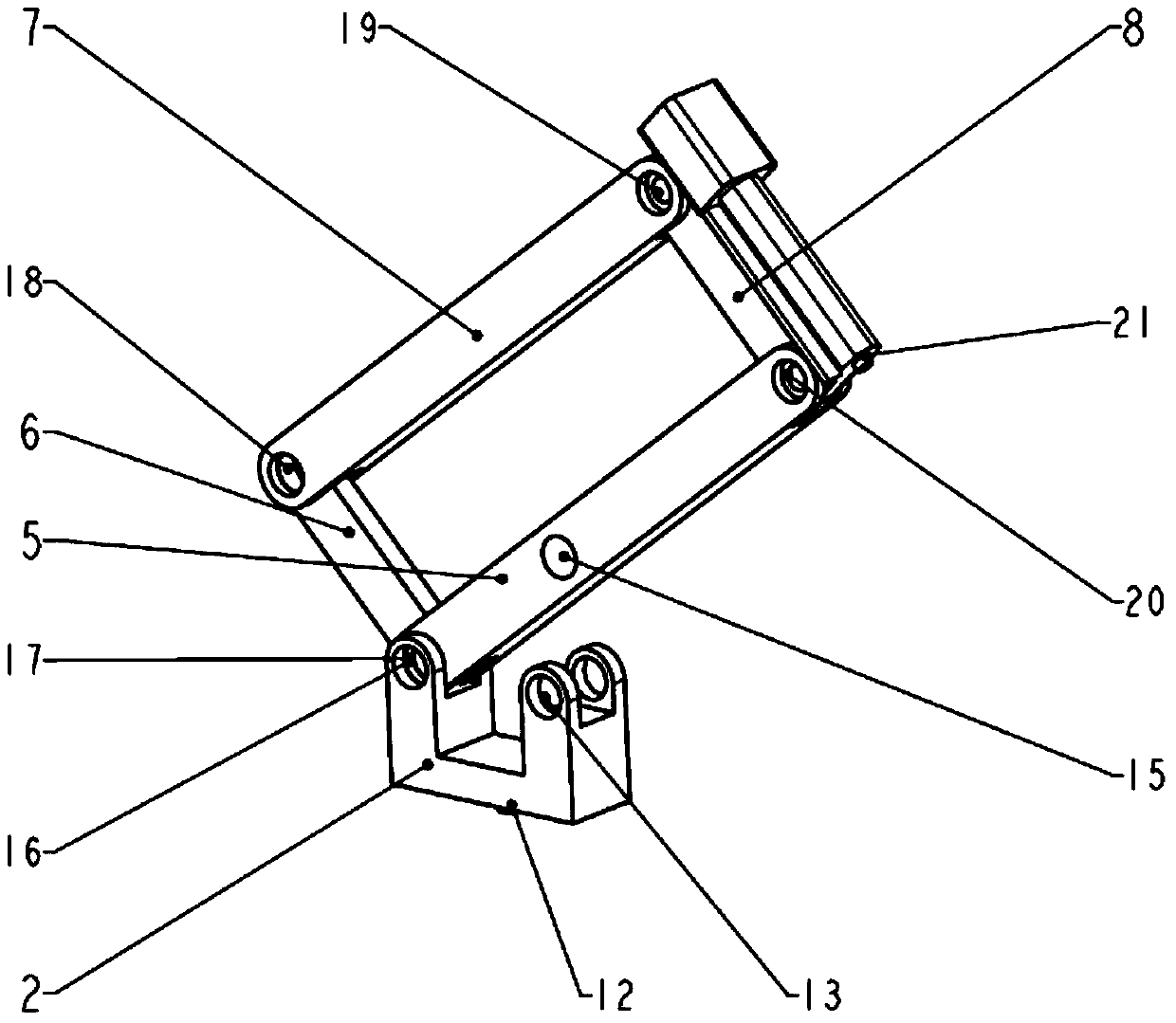

Six-freedom-degree industrial robot with ball screw pair transmission

InactiveCN103737577ARealize two-dimensional translationRealize three-degree-of-freedom attitude adjustmentProgramme-controlled manipulatorBall screw driveDrive motor

The invention relates to a six-freedom-degree industrial robot with ball screw pair transmission. Waist whole circle rotating is achieved through a waist swing mechanism, a shoulder swing mechanism and an elbow swing mechanism form a two-freedom-degree parallel mechanism to achieve two-dimensional horizontal moving, and ball screws are driven by motors arranged on a swing platform respectively. Three mutual-orthometric rotating shafts connected through a front arm rotating mechanism, a wrist swing mechanism and a tool clamping base swing mechanism are driven independently by three motors respectively, and three-freedom-degree gesture adjusting of an executing tail end tool is achieved. The advantage of the large working space of a serial mechanism is kept, ball screw transmission is used, the rigidness of the mechanism is guaranteed, the positions of the driving motors are lowered, good dynamic characteristics are obtained, bearing capacity is large, high-speed or superspeed operation can be easily achieved, and the six-freedom-degree industrial robot has the advantages that side gaps do not exist, rigidness is high, micro-motion feeding can be conveniently achieved, accumulated errors are small, motion accuracy is high, positive and athwart kinematics solving is convenient, and control is convenient.

Owner:GUANGXI UNIV

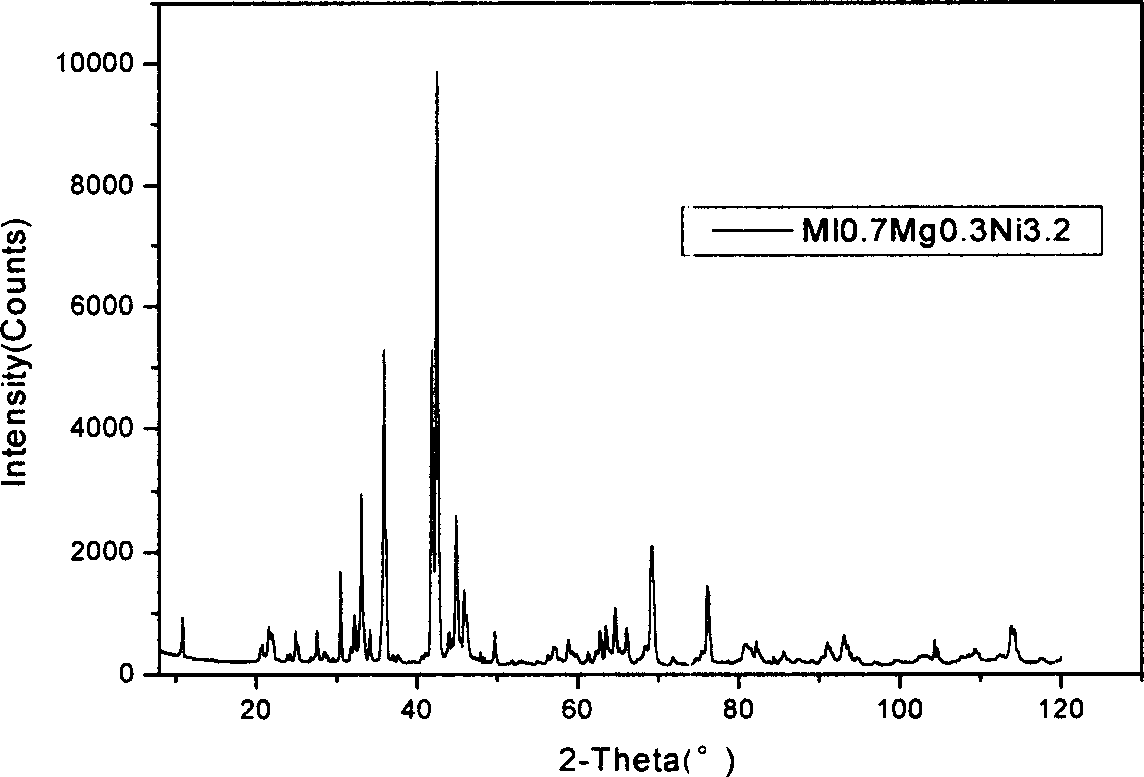

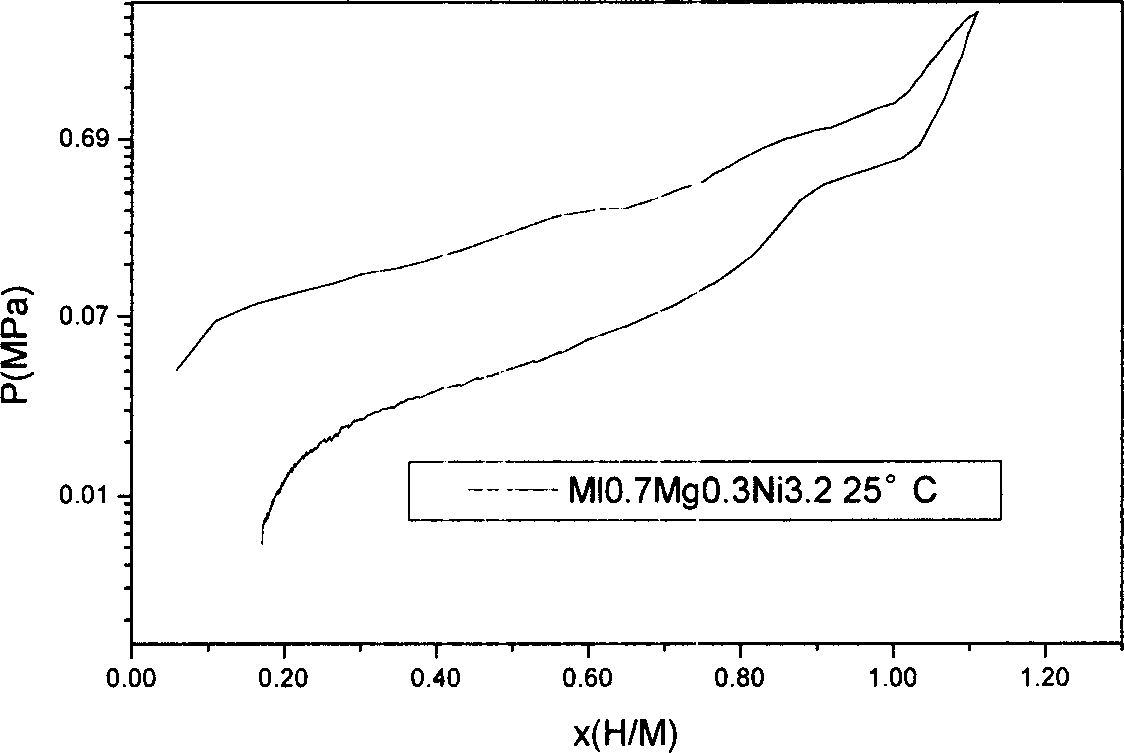

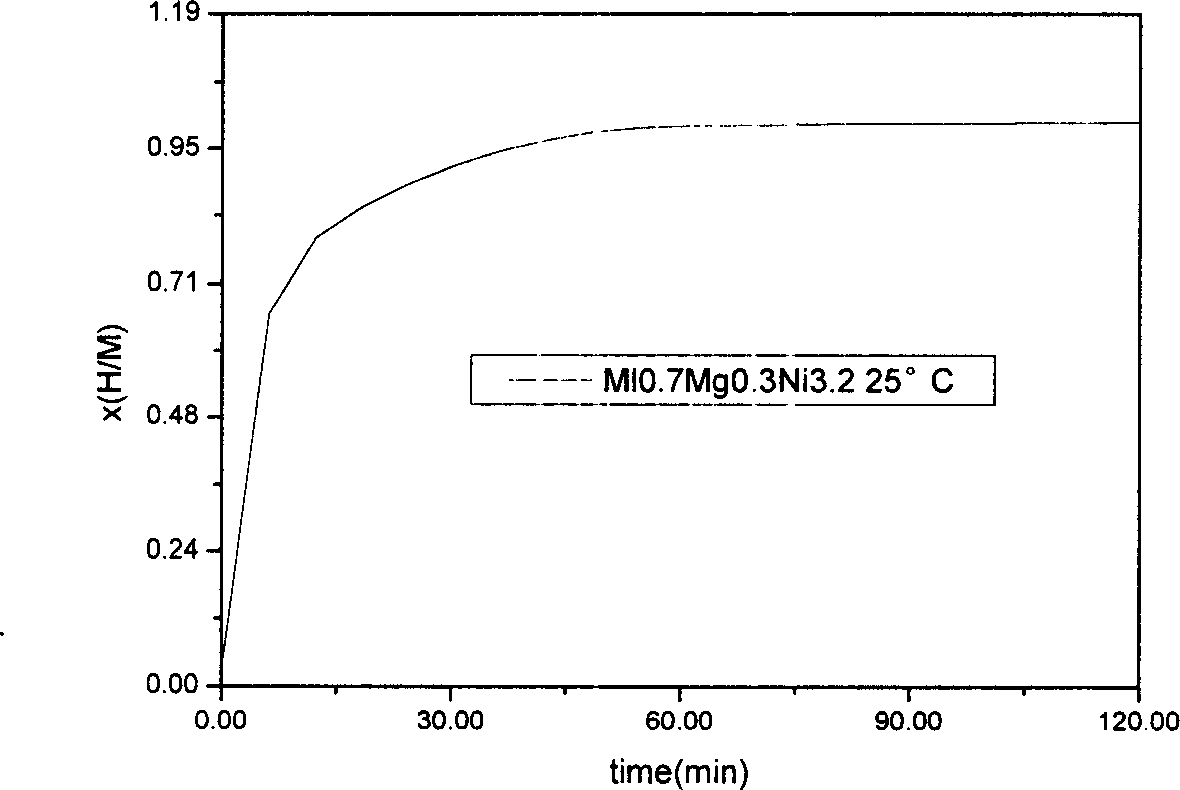

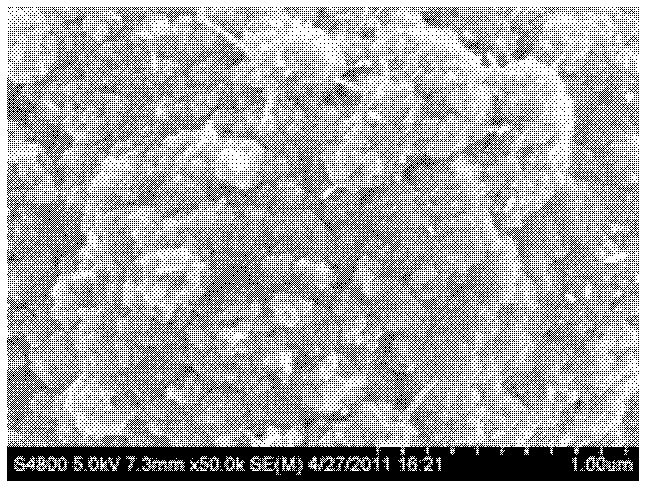

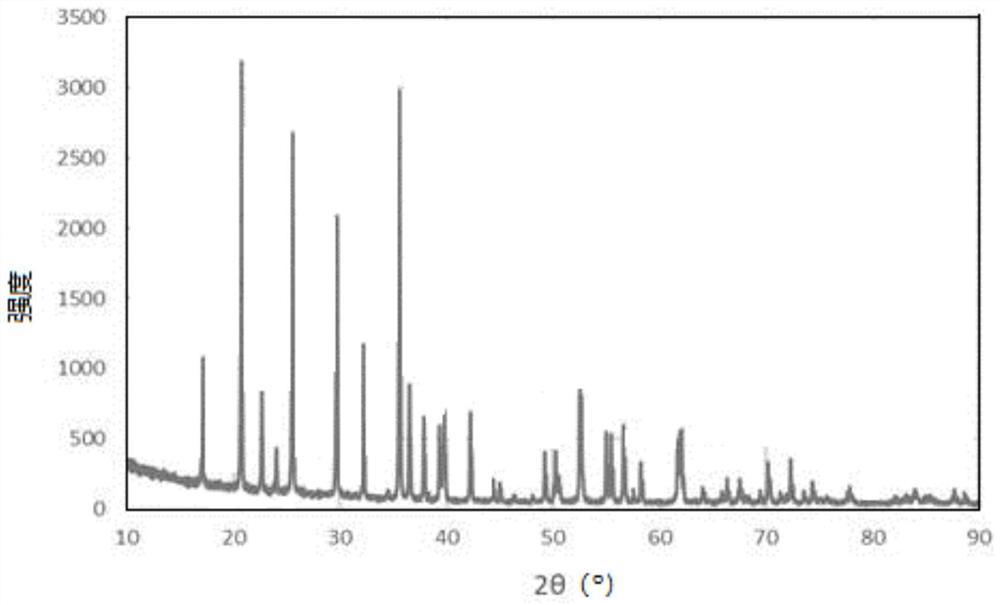

Nano crystal multiphase mixed rare earth-magnesium system hydrogen-storing alloy and its preparation method

InactiveCN1443861AHigh hydrogen storage capacityImprove cycle stabilityCell electrodesNickel accumulatorsRare earthShielding gas

The present invention relates to a nano crystal multi-phase mixed rear earth-magnesium system hydrogen-storing alloy and its preparation method. The preparation method of said alloy includes the following steps: smelting, homogenizing annealing, etc. and its smelting process is placing the La-enriched mixed rare earth, metal magnesium and metal nickel into an induction smelting furnace crucible according to a certain proportion, evacuating, charging protective gas, regulating power and temp. to melt metal, heat-insulating and fully stirring, injecting the molten metal into water-cooling ingotmould, cooling and discharging. Said alloy has anique components and multi-phase nano crystal structuer, and has good circulation stability.

Owner:SOUTH CHINA UNIV OF TECH

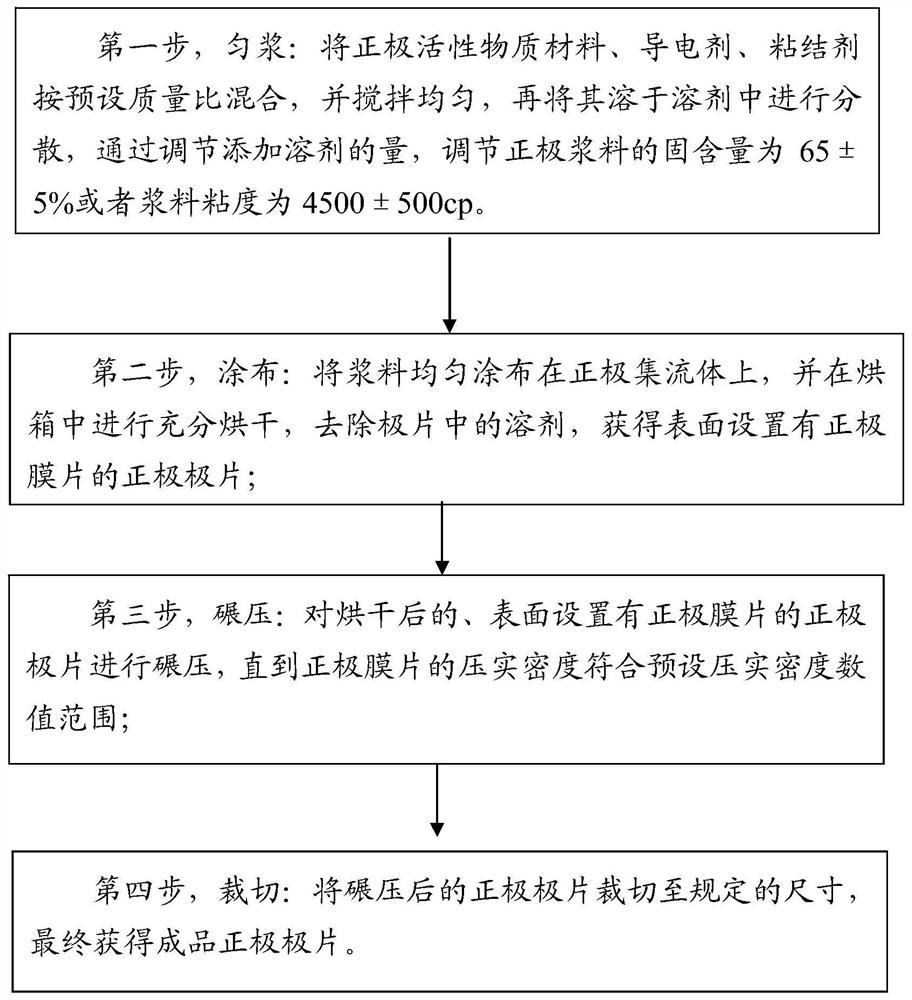

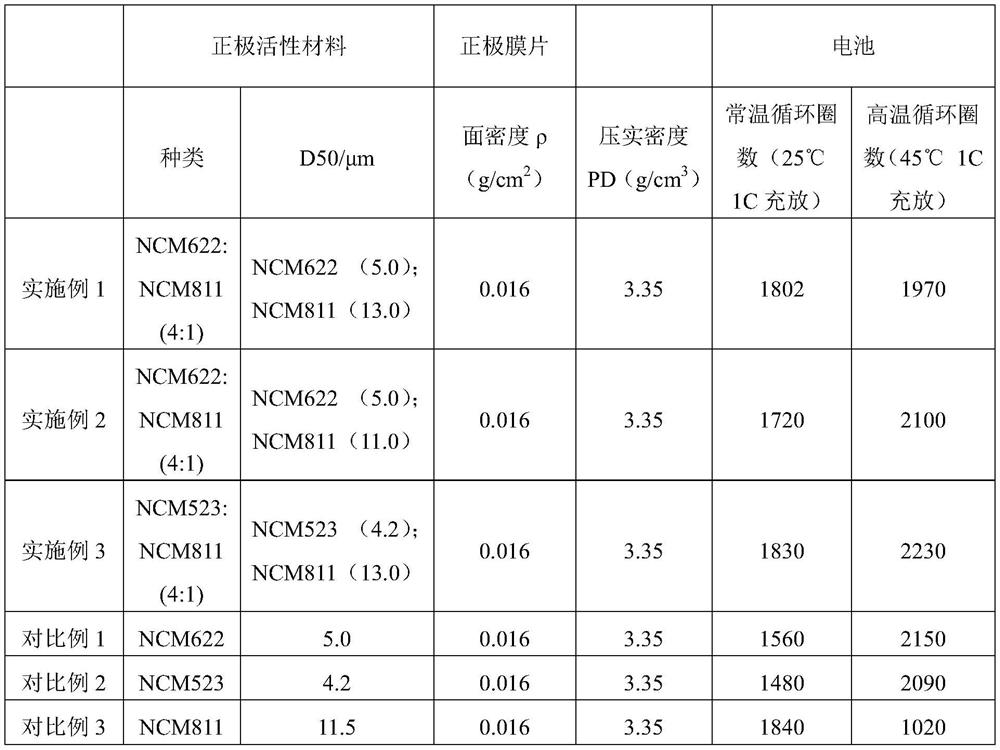

Positive pole piece and preparation method thereof and lithium ion secondary battery

PendingCN111640912AImprove thermal stabilityGood dynamic performanceSecondary cellsPositive electrodesSingle crystalPole piece

The invention discloses a positive pole piece which comprises a positive pole current collector and a positive pole diaphragm arranged on at least one surface of the positive pole current collector, and the positive pole diaphragm comprises a positive pole active substance; the positive electrode active substance comprises at least two lithium nickel cobalt manganese oxides LiNixCoyMn1-x-yO2 withdifferent morphologies and average particle sizes D50, wherein one type is primary particle single crystal LiNixCoyMn1-x-yO2, and the other type is secondary particle polycrystalline LiNixCoyMn1-x-yO2; the weight ratio [omega] of the single crystal to the polycrystalline LiNixCoyMn1-x-yO2 satisfies the relational expression: 0.1<=[omega]<=9. By adjusting the ratio of the primary particle single crystal to the secondary particle polycrystalline material and the nickel content, the positive pole piece can have better thermal stability and excellent dynamic performance, so that the lithium ion secondary battery based on the positive pole piece has the characteristics of long cycle life at normal temperature and high temperature.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

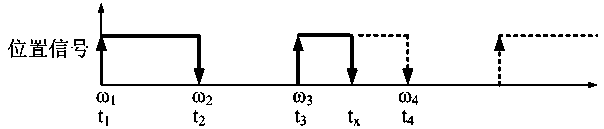

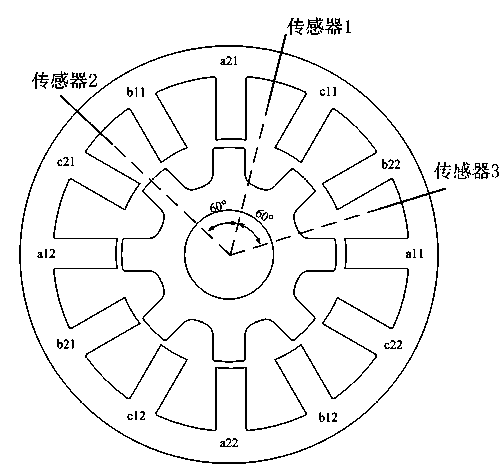

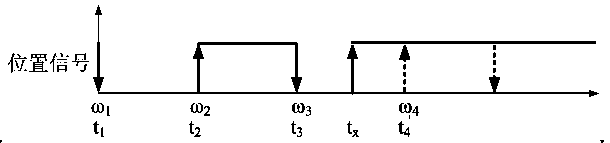

Fault diagnosis method with fault-tolerant control of switch reluctance motor position sensors

ActiveCN103439655AGood speedGood dynamic performanceDynamo-electric machine testingElectronic commutatorsDiagnosis methodsPosition sensor

The invention discloses a fault diagnosis method with fault-tolerant control of switch reluctance motor position sensors. The fault diagnosis method includes diagnosis and fault-tolerant control on faults of several position sensors and diagnosis and control over fault recovery of the several position sensors. The fault diagnosis method can timely diagnose faults of a position sensor of each phase, switch control algorithms and enable operation states of a switch reluctance motor to be free from influences of the faults of the position sensors, and namely normal operation can continue to remain when the faults of the position sensors happen; when the position sensors recover, whether signals are normal is judged first, if the signals are normal, diagnosis faults recover, original algorithms are switched back, therefore, fault-tolerant capacity of the switch reluctance motor is effectively improved, and great significances are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

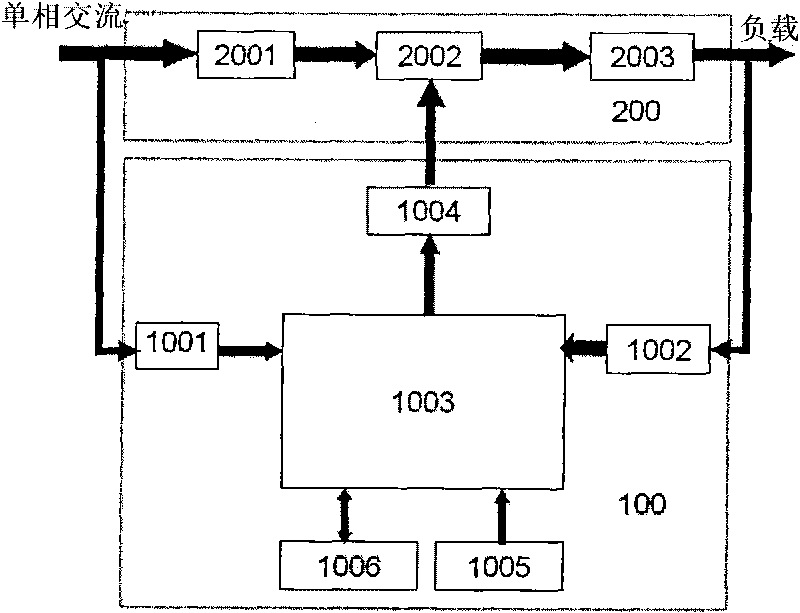

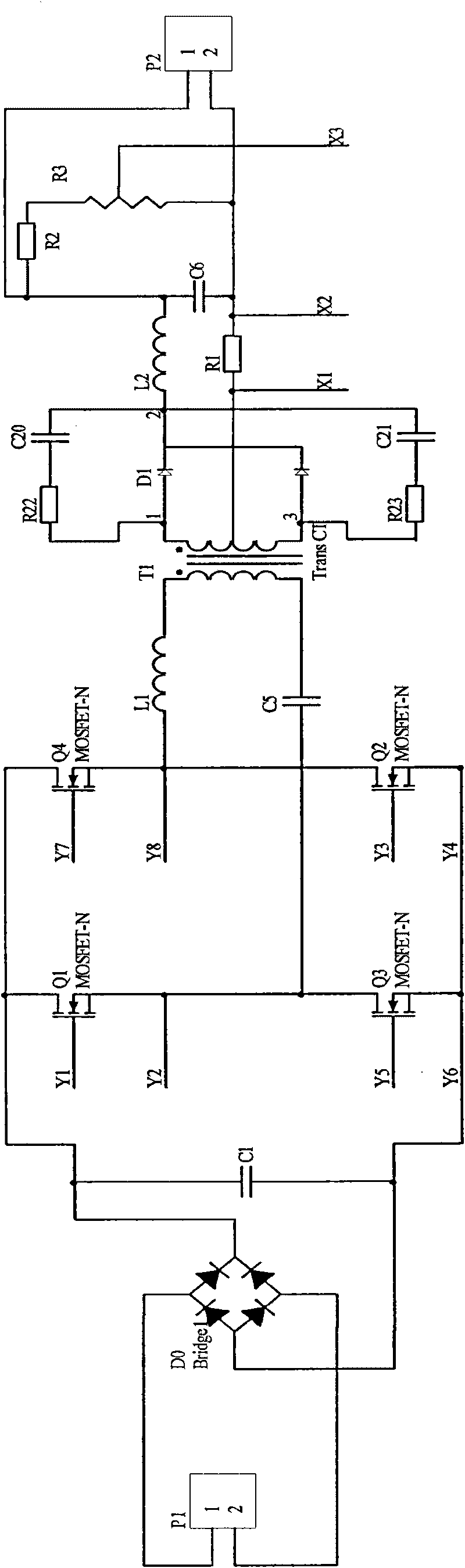

Intelligent dimming driver for networking-type high-power packaged LEDs

ActiveCN101697653AGood dynamic performanceImprove consistencyAc-dc conversion without reversalEfficient power electronics conversionSingle phaseSoft switch

The invention provides an intelligent dimming driver for networking-type high-power packaged LEDs, which comprises a power adjusting system and a digital control system, wherein the power adjusting system is formed by sequentially connecting a single-phase rectifying filtering module, a resonant soft switch inverting module and a transforming and rectifying module which are switched in a single-phase alternating current input power; and the digital control system is formed by connecting an abnormity detection protection module, a sampling detection module, an ARM micro-processor system, a high-frequency driving module, a parameter setting module and a serial bus communication module mutually. The intelligent dimming driver for the networking-type high-power packaged LEDs can automatically match constant current, constant voltage and variable property driving output according to the working property of the high-power packaged LEDs so as to realize remote networking and intelligent dimming.

Owner:SOUTH CHINA UNIV OF TECH

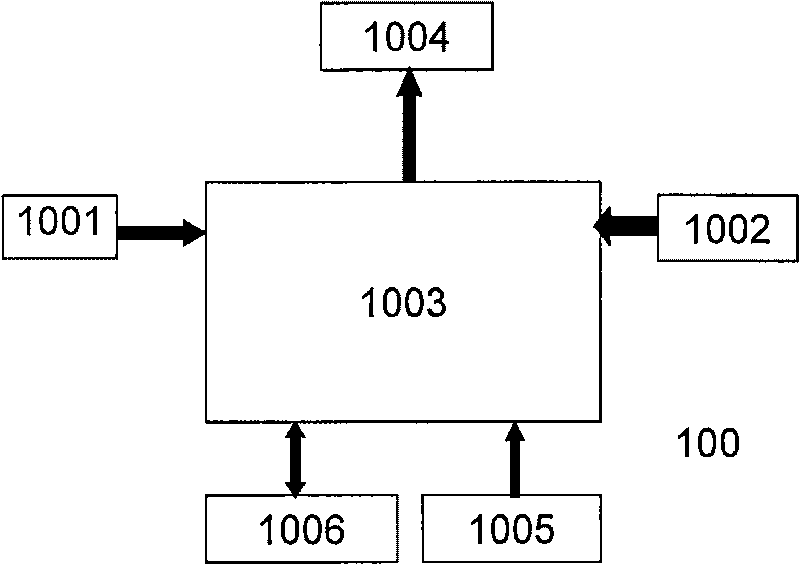

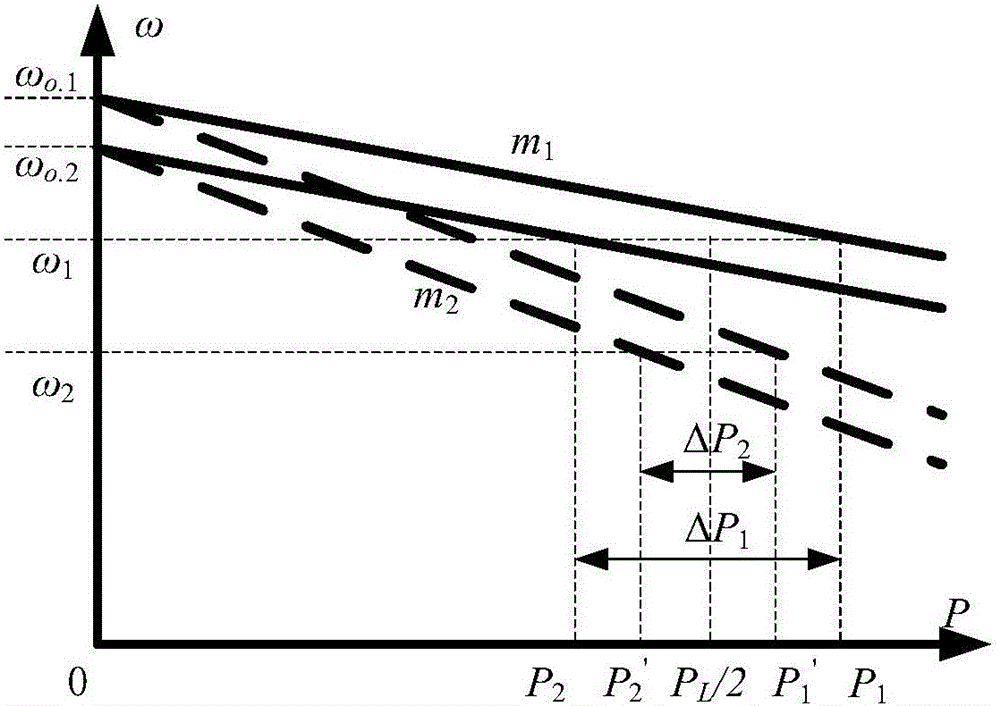

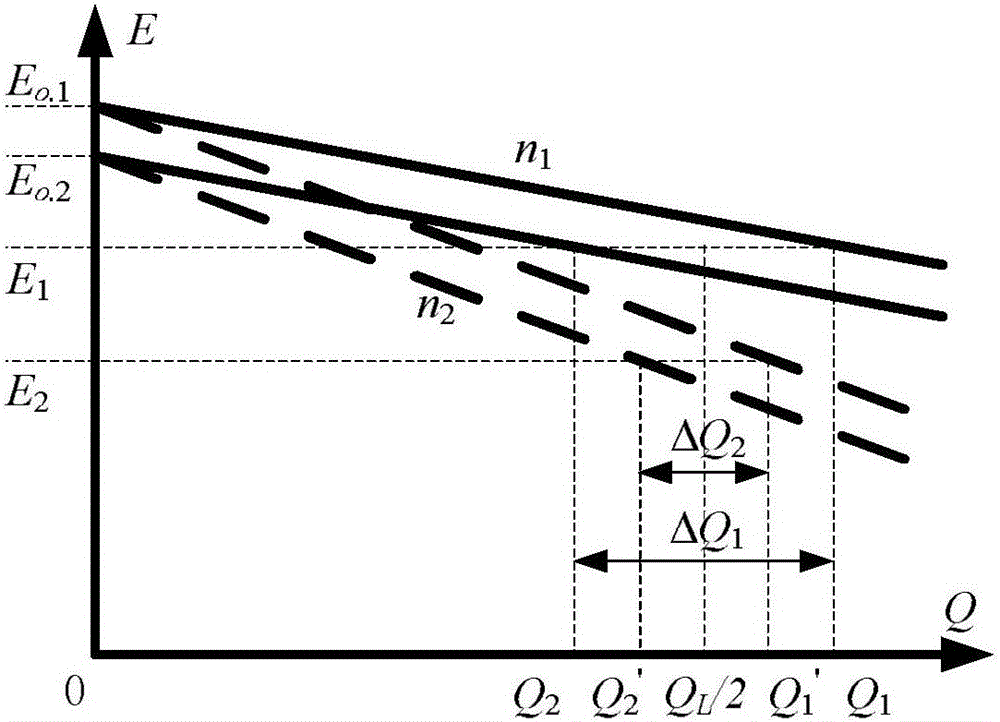

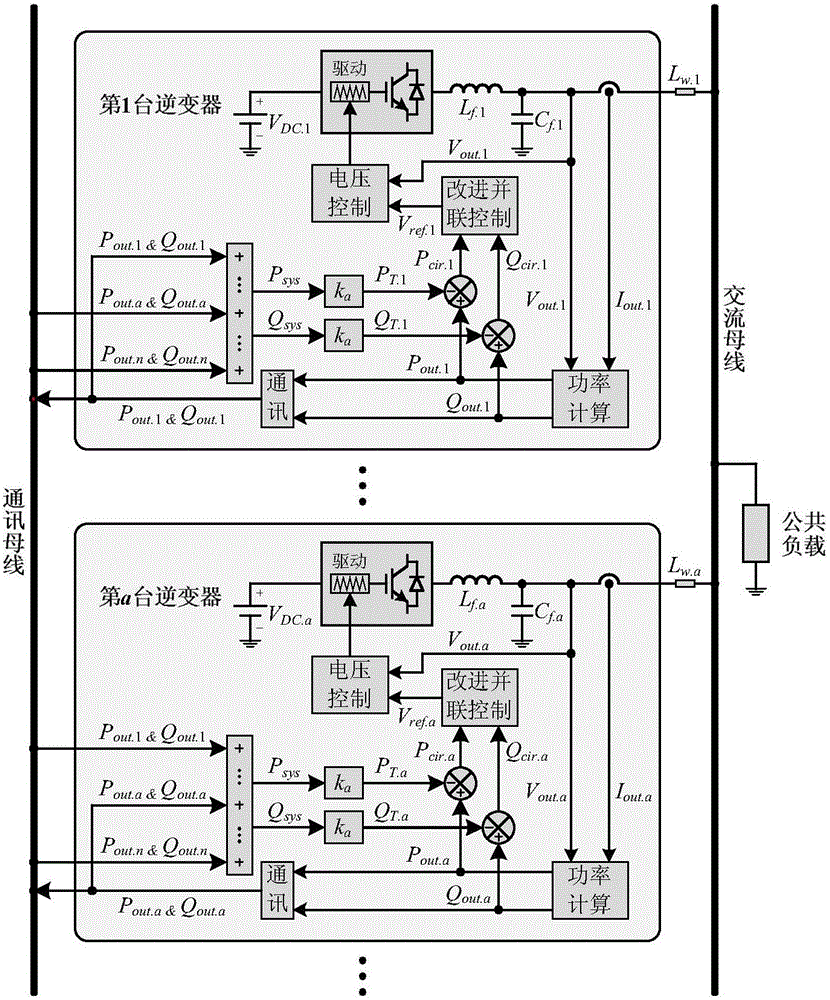

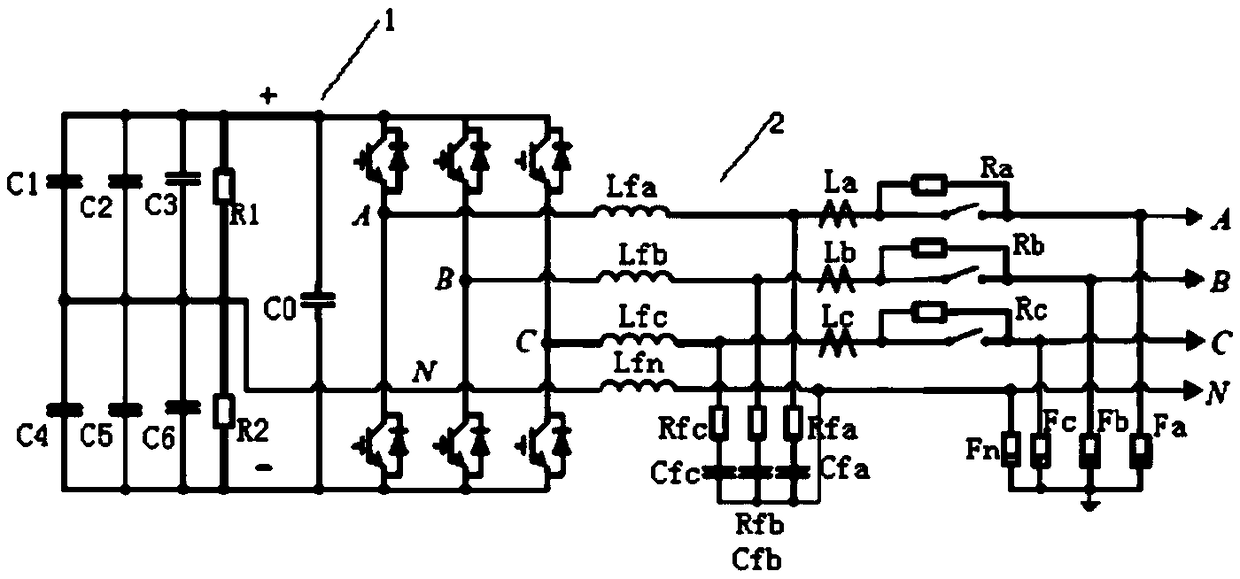

Circulation power theory-based distributed parallel control method applied to miniature power grid system island mode

ActiveCN105790310AIncrease redundancyImprove reliabilitySingle network parallel feeding arrangementsIslandingControl system

The present invention provides a circulation power theory-based distributed parallel control method applied to a miniature power grid system island mode. The method is characterized in that a distributed power generation and energy storage unit in a miniature power grid system is connected with an AC bus via an inverter and operates in a parallel mode in the island mode, and by taking a communication network as the basis in a parallel operation mode, the controllers of the inverter units in the miniature power grid system form a whole control system. According to the method of the present invention, the circulation active power and the circulation reactive power of an inverter parallel system in the parallel operation mode of the miniature power grid system can be restrained effectively, the situation that the parallel system has the optimal dynamic performance and transient response capability is guaranteed, the reliability of the system is improved, at the same time, the steady-state errors of the frequencies and the amplitudes of the output voltages of the inverter units are eliminated, and the inverter units share the public load power evenly according to the occupied proportions of the respective power capacities of the inverter units in the parallel system, so that the method has a very strong practicality.

Owner:ZHEJIANG UNIV

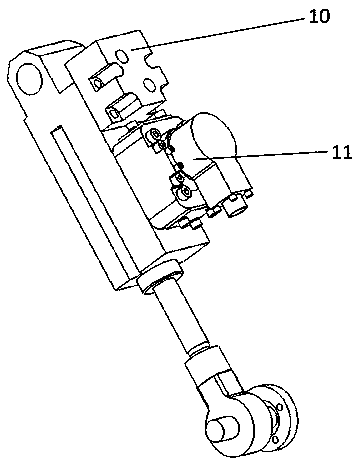

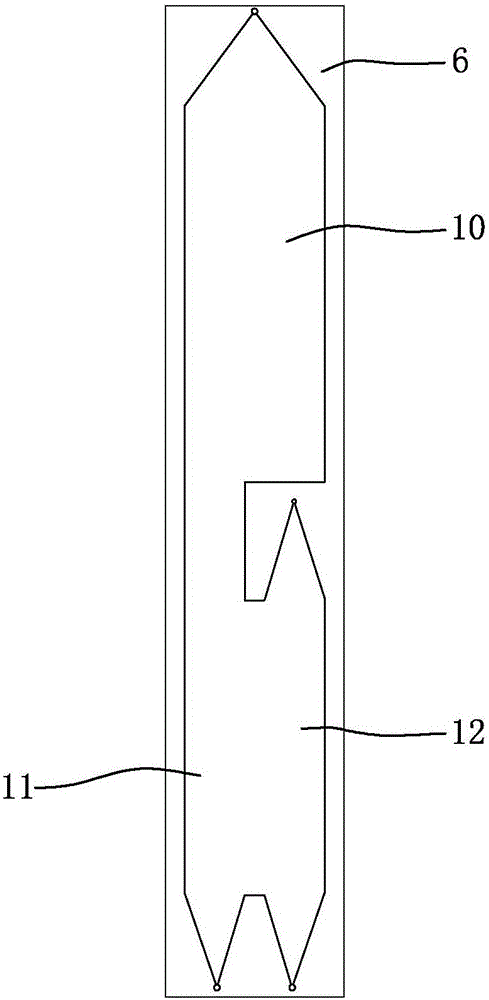

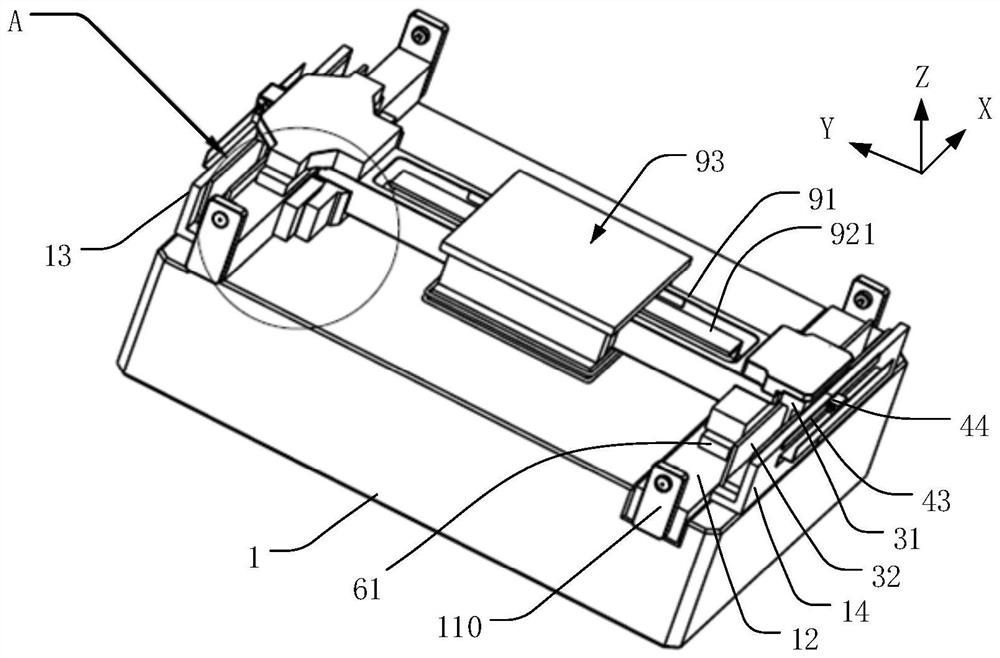

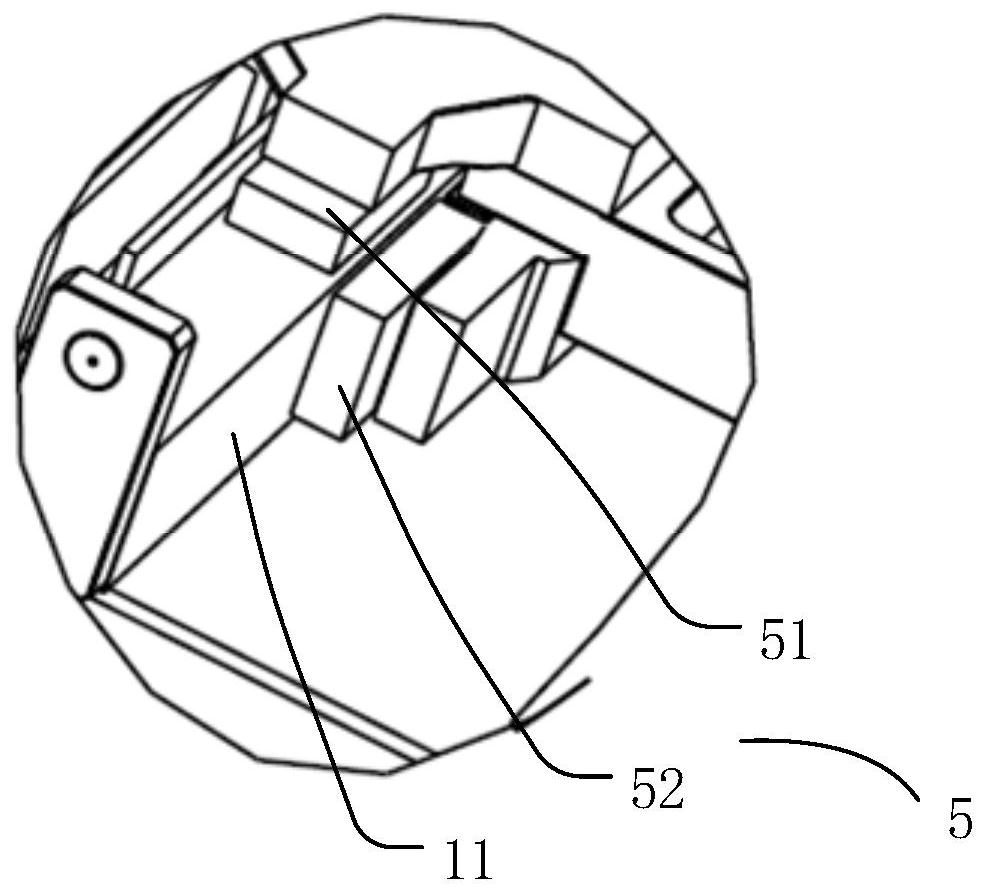

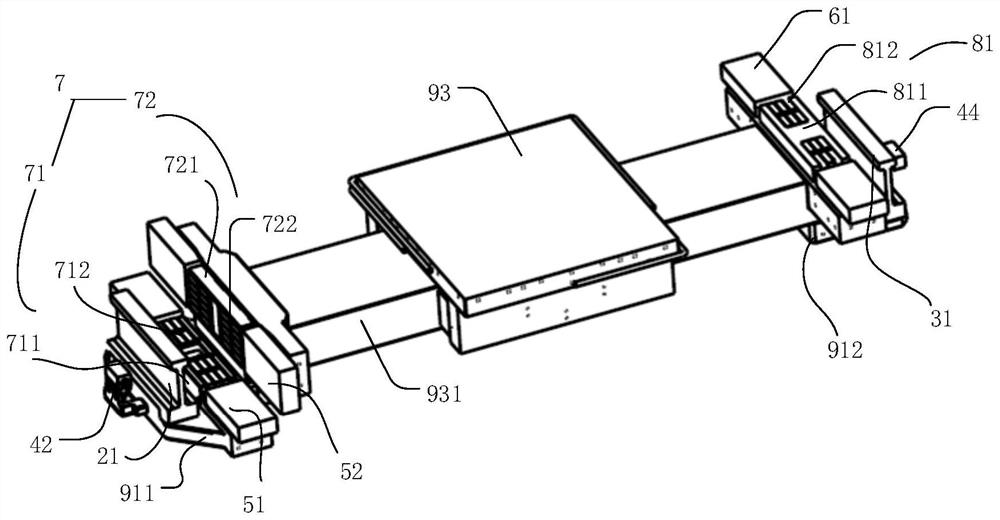

A leg structure of a wheel-foot integrate robot is disclosed

PendingCN109018058AHigh control precisionGood dynamic performanceVehiclesControl parametersEngineering

The invention relates to a leg structure of a wheel-foot integrated robot, which comprises a yaw mechanism, a thigh, a lower leg and a foot end of the robot. The whole leg has three sets of identicalhydraulic cylinders controlled by servo valves, the leg swing can be realized, the forward and backward movement of the thighs and calves, The direction of the wheels can be adjusted arbitrarily, andthere is a separate power source at the foot of the robot. A stepping drive machine is used to integrate the driving and control. According to the feedback of the motor motion parameters and real-timestate, the control parameters are adjusted at any time to make the motor reach the preset torque or speed. When traveling on a flat section of the road, the foot motor can be used alone to drive thewheels to rotate, so as to make the movement faster and save energy; When a user moves on a bumpy stretch of road, hydraulic actuators can be used to help the robot get over obstacles.

Owner:HARBIN UNIV OF SCI & TECH

Anode of lithium ion battery, preparation method and battery using anode

InactiveCN102339982AGood electrical contactGood dynamic performanceElectrode carriers/collectorsNegative electrodesCyclic stabilityLithium electrode

The invention relates to an anode of a lithium ion battery, a preparation method for the anode and the battery using the anode. A cupric oxide (CuO) thin film is grown in situ on the surface of a current collector Cu foil by a thermal oxidation method for heating in an oxidizing atmosphere, and the current collector Cu foil and the CuO thin film grown in situ on the surface of the current collector Cu foil can be directly used as the anode of the lithium ion battery. A fussy and complex coating process required by the conventional preparation of the anode of the lithium ion battery is not required. The anode has high electrode capacity and high cyclical stability, and solves the problem that the high capacity and high cyclical stability of a commercial lithium ion anode material cannot be achieved at the same time. The preparation method provided by the invention is simple and easy to control, low in environmental requirements, high in electrode specific capacity and cycle performance and applied to the industrial application of the lithium ion battery.

Owner:ZHEJIANG UNIV

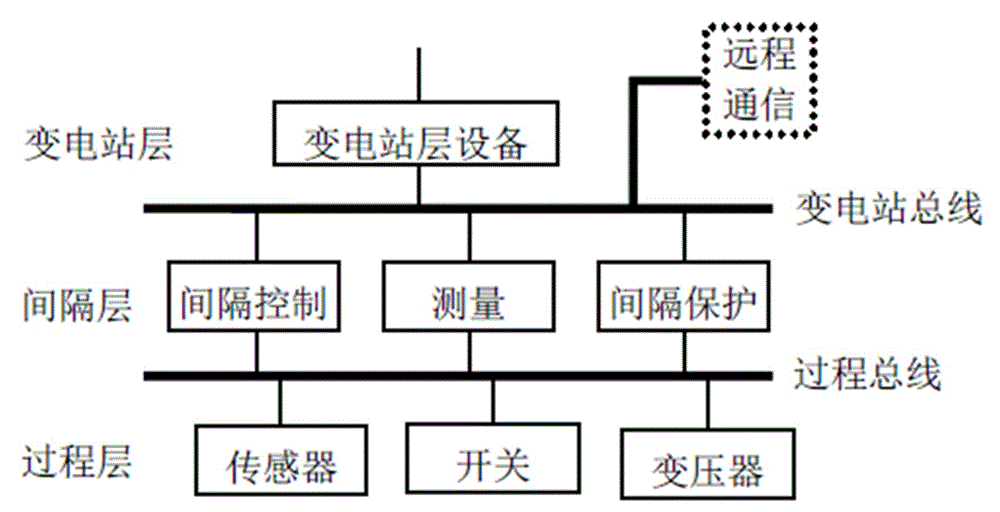

Transformer station automatic system

InactiveCN105071532AGood dynamic performanceStrong anti-interference performanceCircuit arrangementsInformation technology support systemAutomatic controlTransmission line

A transformer station automatic system performs functional combination and optimized design on secondary equipment (including a measuring instrument, a signal system, relay protection, an automatic device, and a telecontrol device) of a transformer station so as to achieve comprehensive automatic functions of the main devices of the transformer station, a power transmission line, and a power distribution line by using advanced computer technology, modern electronic technology and communication technology, and signal processing technology, wherein the comprehensive automatic functions includes automatic monitoring, measurement, automatic control, microcomputer protection, and communication with a control center.

Owner:HENAN XINGZHI PATENT SERVICE CO LTD

REMg3 type hydrogen storage alloy and its preparation method

A hydrogen bearing REMg3 alloy has a molecular formula: RE1.2-xMg3Niy, where RE is rare-earth mixture, x=0-0.4 and y=0-1. Its preparing process includes proportionally loading RE, Mg and Ni in crucible of induction furnace, vacuumizing, filling protective gas, smelting and cooling.

Owner:SOUTH CHINA UNIV OF TECH

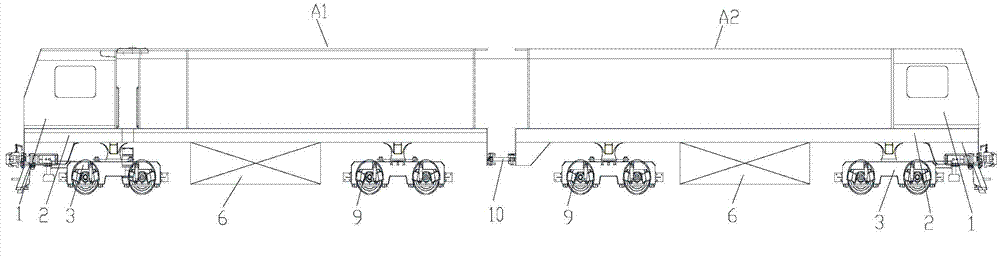

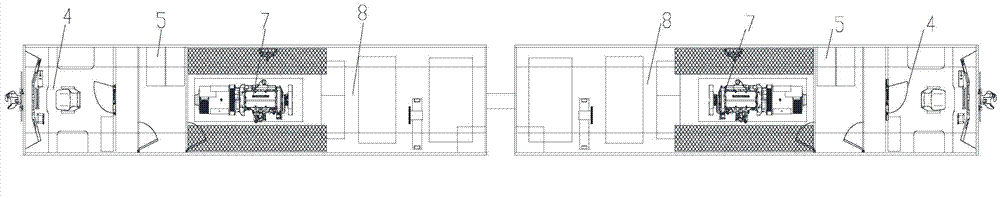

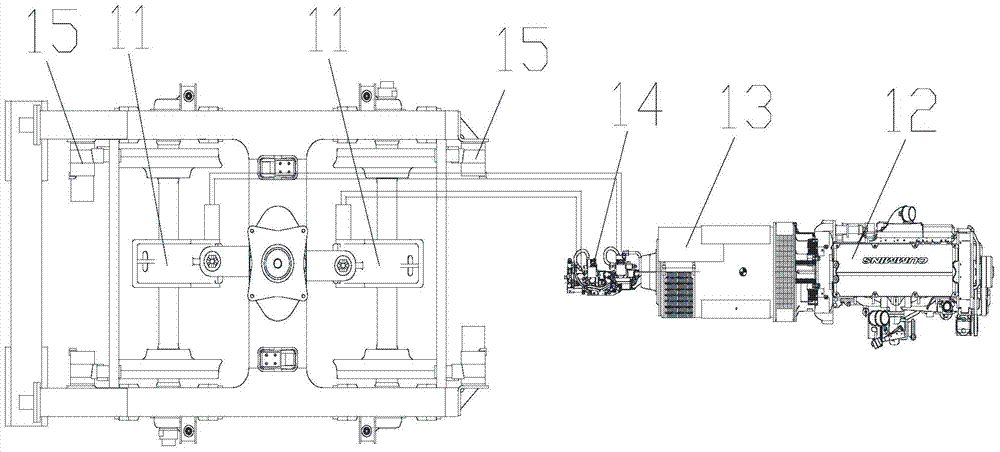

Self-powered metro steel rail grinding wagon

ActiveCN103786734ASmooth rideGood dynamic performanceRailway track constructionLocomotive transmissionsWave shapeEngineering

The invention provides a self-powered metro steel rail grinding wagon. A grinding wagon group comprises a hydraulic transmission grinding wagon A1 and a hydraulic transmission grinding wagon A2 which are connected through an automatic car coupler; a steel rail is subjected to coarse grinding through the hydraulic transmission grinding wagon A1; the steel rail is subjected to fine grinding through the hydraulic transmission grinding wagon A2; the hydraulic transmission grinding wagon A1 and the hydraulic transmission grinding wagon A2 are in the same structures; the motion direction of the hydraulic transmission grinding wagon A1 is forward; the motion direction of the hydraulic transmission grinding wagon A2 is backward. The whole grinding wagon group is in a hydraulic transmission mode, each section of a train is self-powered, the rail head surface of the steel rail can be ground by a grinding motor on a grinding device in the low-constant-speed operating process at the speed of 3-15km / h, and the defects such as wave-shaped steel rail abrasion, excess steel rail edges, saddle-type abrasion, welding depression and scale cracks are eliminated, so that the outline of a rail head operating part is improved.

Owner:BAOJI CSR TIMES ENG MACHINERY

Method for surface modification of AB3 type hydrogen storage alloy

InactiveCN103611930AImprove cycle stabilityGood dynamic performanceAlkaline accumulator electrodesPower batteryIngot

The invention discloses a method for surface modification of AB3 type hydrogen storage alloy. AB3 type parent body alloy is prepared through a vacuum induction melting method, after mechanical pulverization is carried out on alloy ingots, ball milling is conducted for 60-90 minutes at the rotating speed of 250-300 revolutions per minute, the allot ingots are divided into particle powder of 200-300 meshes in a sieved mode, and AB3 type alloy is prepared; the obtained AB3 type alloy and polyaniline are mixed according to the weight percentage, wherein the AB3 type alloy accounts for 96-99%, the polyaniline accounts for 1-4%, the sum of the weight percentage of the AB3 type alloy and the weight percentage of the polyaniline is 100%, ball milling is carried out for 10-30 minutes at the rotating speed of 100-200 revolutions per minute after mixing, and then the AB3 type hydrogen storage alloy undergoing surface modification is obtained. The surface modification is carried out on the AB3 type hydrogen storage alloy serving as power Ni / MH battery negative electrode materials through the method, and an alloy electrode with good cycling stability and excellent dynamics performance is obtained.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

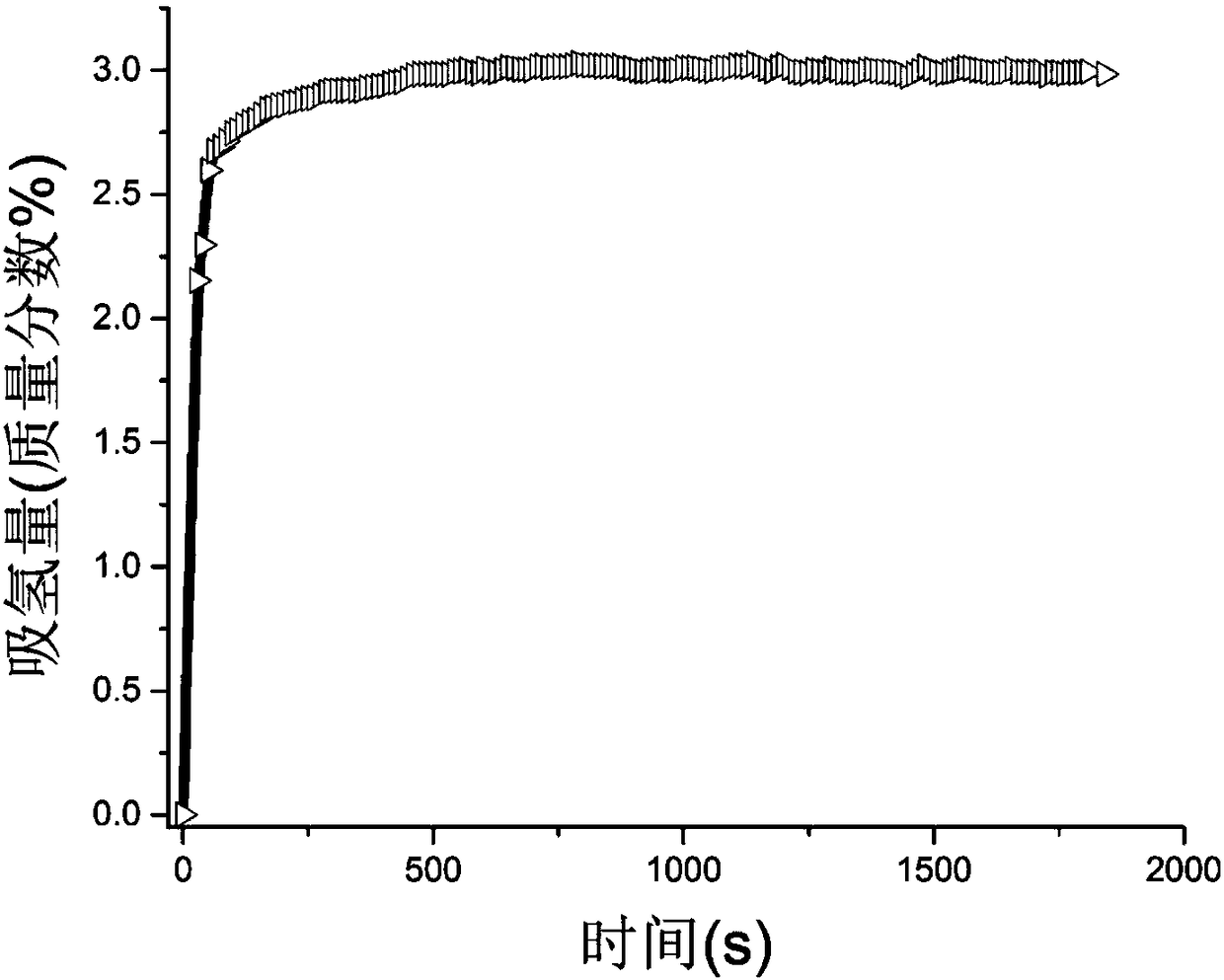

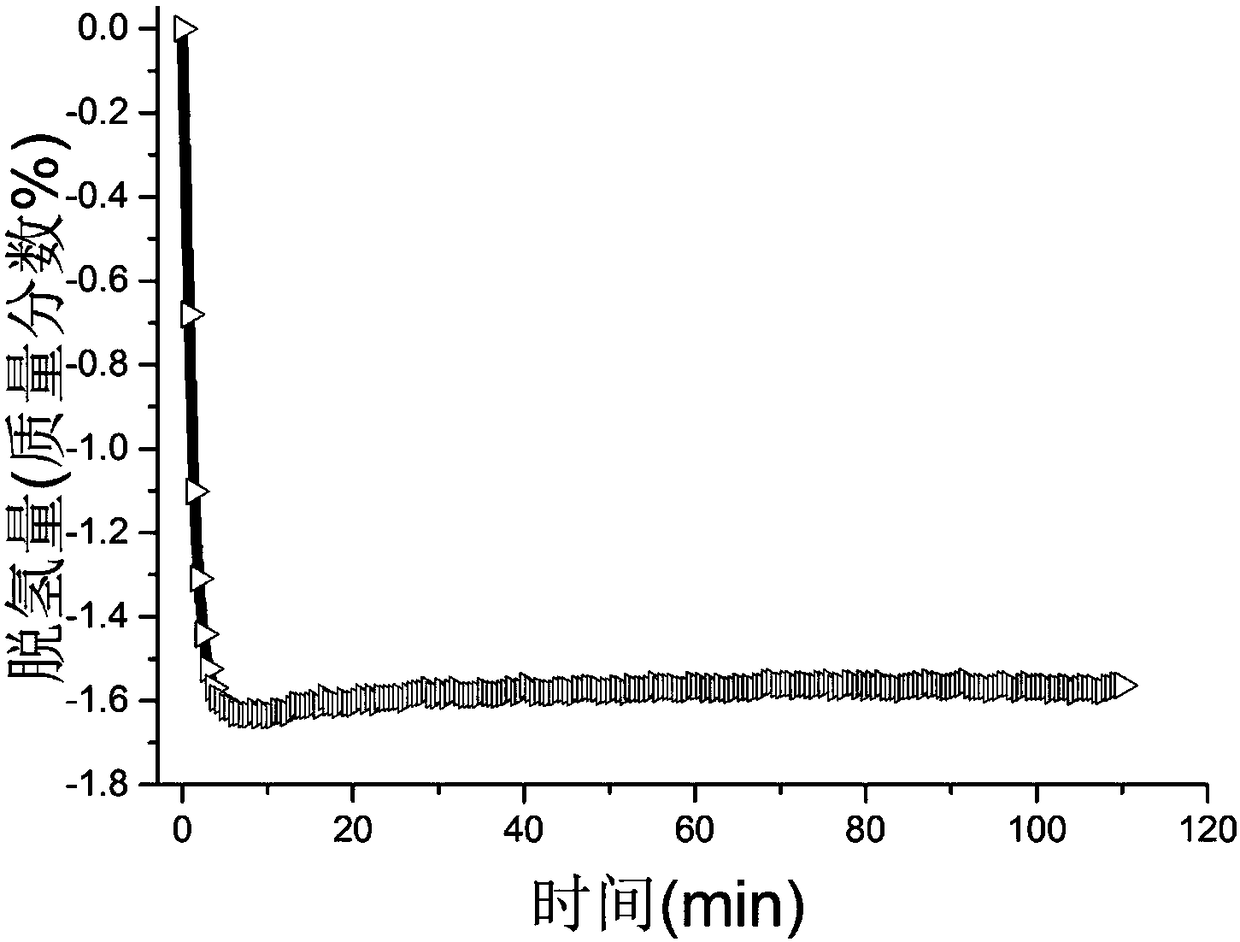

Preparation method of metal oxide composite magnesium hydride hydrogen storage material

PendingCN110980635AAccelerate the rate of hydrogenationSmall particle sizeHydrogenOxide compositeBall mill

The invention belongs to the technical field of hydrogen storage materials, and particularly relates to a preparation method of a metal oxide composite magnesium hydride hydrogen storage material. Themethod comprises the steps that magnesium hydride serves as a base material, metal oxide particles are mixed, the mass percentage content of metal oxide in the mixture is 1%-8%, and the mixture is subjected to hydrogen filling ball milling in a ball mill to obtain the metal oxide composite magnesium hydride hydrogen storage material. By adding the nanoscale metal oxide particles, the hydrogenation speed of the magnesium-based composite powder in the hydrogen charging ball milling process can be increased, and reduction of the particle size of magnesium hydride is facilitated; the nanocrystalline MgH2 is coated with the metal oxide to form a core-shell structure with an excellent synergistic effect, the core-shell structure has a good catalytic effect and remarkable dynamic performance, the hydrogen storage reaction speed can be improved, microcell heat release can be controlled, agglomeration of a hydrogen storage reactant Mg (OH) 2 can be effectively eliminated through the metal oxide, and the hydrogen storage efficiency is improved. Therefore, the purpose of sufficient hydrolysis reaction is achieved.

Owner:世能氢电科技有限公司 +1

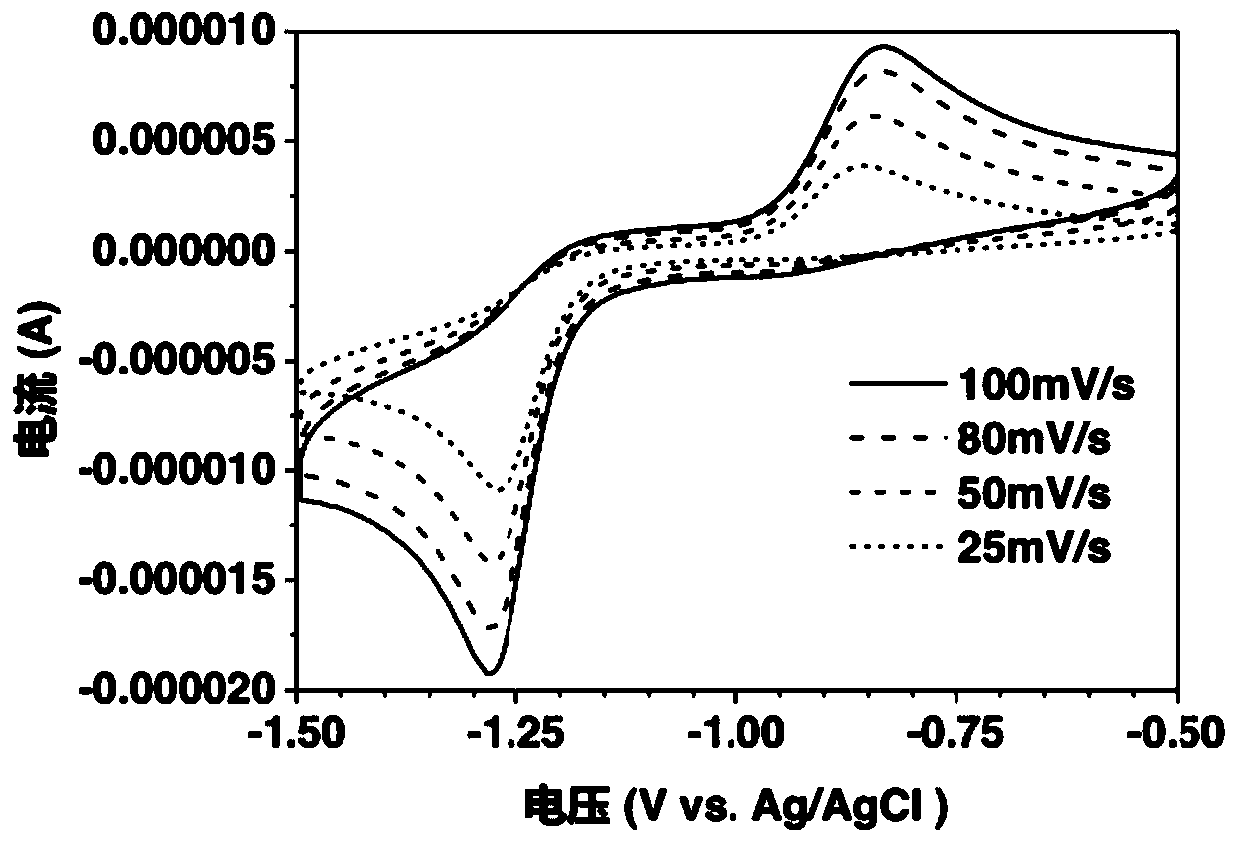

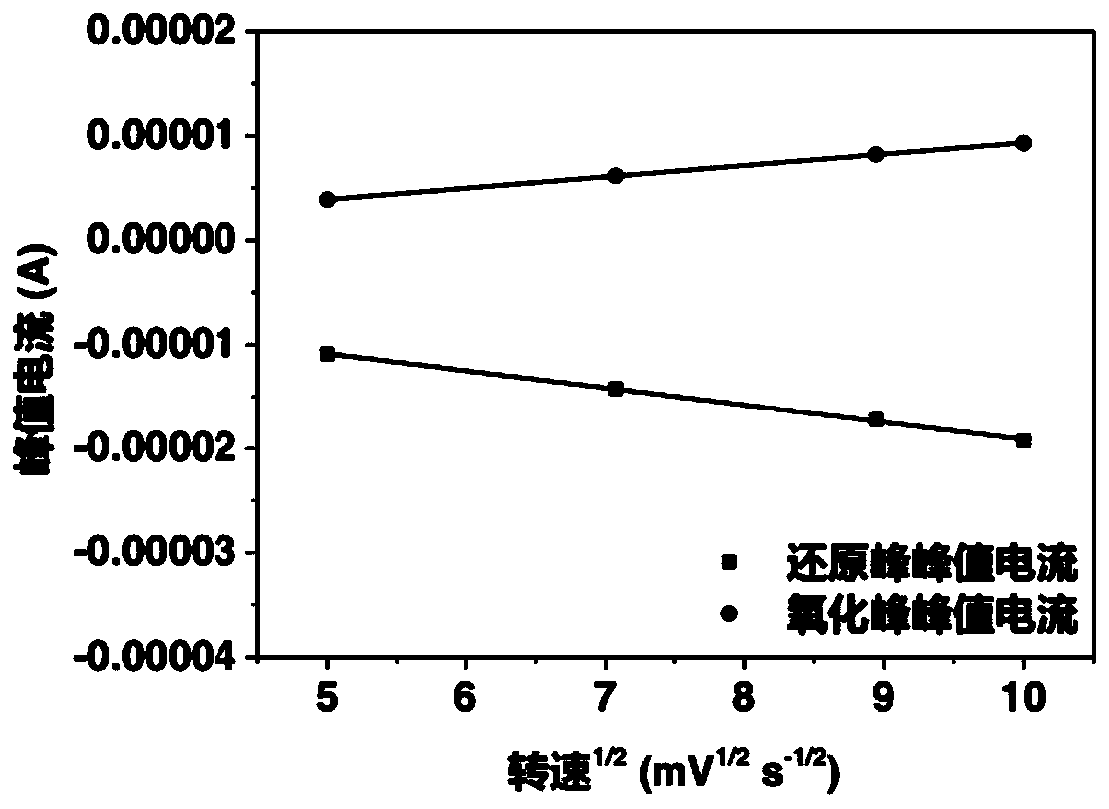

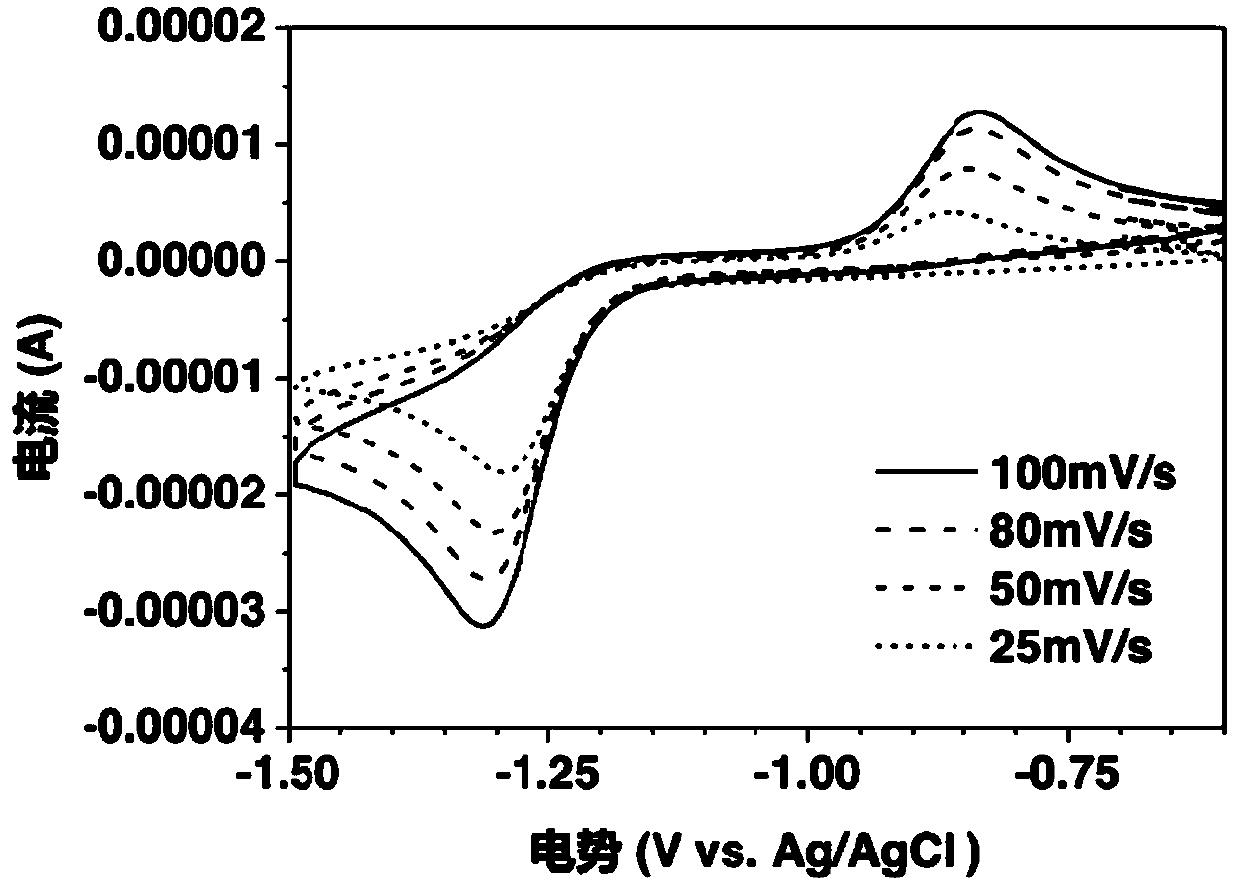

Pteridine aqueous organic redox flow battery

ActiveCN110265694ALow costSource is cheap and plentifulRegenerative fuel cellsPotassiumMetal electrodes

The invention discloses a pteridine aqueous organic redox flow battery. According to the pteridine aqueous organic redox flow battery, organic molecules containing a pteridine structure is taken as a negative electrode; potassium ferrocyanide, TEMPO or benzoquinone potassium sulfonate is taken as a positive electrode; one or a mixture of more of an acid solution, an alkali solution and a salt water solution is taken as an electrolyte; a perfluorosulfonic acid-polytetrafluoroethylene copolymer membrane is taken as an ion exchange diaphragm; two copper plates serve as a current collector of the battery; a graphite plate with a flow channel is used as a flow field plate of the positive electrode and the negative electrode; a carbon paper, graphite felt or a metal electrode serves as an electrode of the battery; and the pteridine aqueous organic redox flow battery has the advantages of power energy design flexibility, low cost, large-scale assembly and application and the like, and is very suitable for large-scale energy storage application.

Owner:XI AN JIAOTONG UNIV

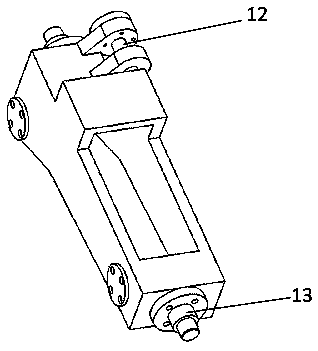

Parallel mechanism with three branching chains and six degrees of freedom

ActiveCN104400780AReduce complexity and qualityGood dynamic performanceProgramme-controlled manipulatorKinematic chainSix degrees of freedom

The invention discloses a parallel mechanism with three branching chains and six degrees of freedom. The parallel mechanism comprises a static platform, a dynamic platform and three moving branching chains, wherein the three moving branching chains are uniformly distributed and connected between the static platform and the dynamic platform. The parallel mechanism is characterized in that each moving branching chain comprises a cylinder pair, a parallelogram-shaped moving chain, an upper link rotating pair, a lower link rotating pair and a dynamic platform rotating pair, wherein the axes of the upper link moving pair and the lower link moving pair are parallel to each other; the axis of the dynamic platform rotating pair passes through a central point of the dynamic platform; the cylinder pair is connected with the static platform, and the axis of the cylinder pair is vertical to the static platform; the cylinder pair can move and up and down along the axis and rotate around the axis to drive the parallel mechanism; the axes of the upper link rotating pair and the lower link rotating pair are respectively positioned at an upper link and a lower link of the parallelogram-shaped moving chain, and are also overlapped with the axes of the upper link and the lower link, respectively; the parallelogram-shaped moving chain comprises a parallelogram and four parallelogram-shaped rotating pair, wherein the parallelogram is composed of four links; the four parallelogram-shaped rotating pairs are of the same structure.

Owner:HEBEI UNIV OF TECH

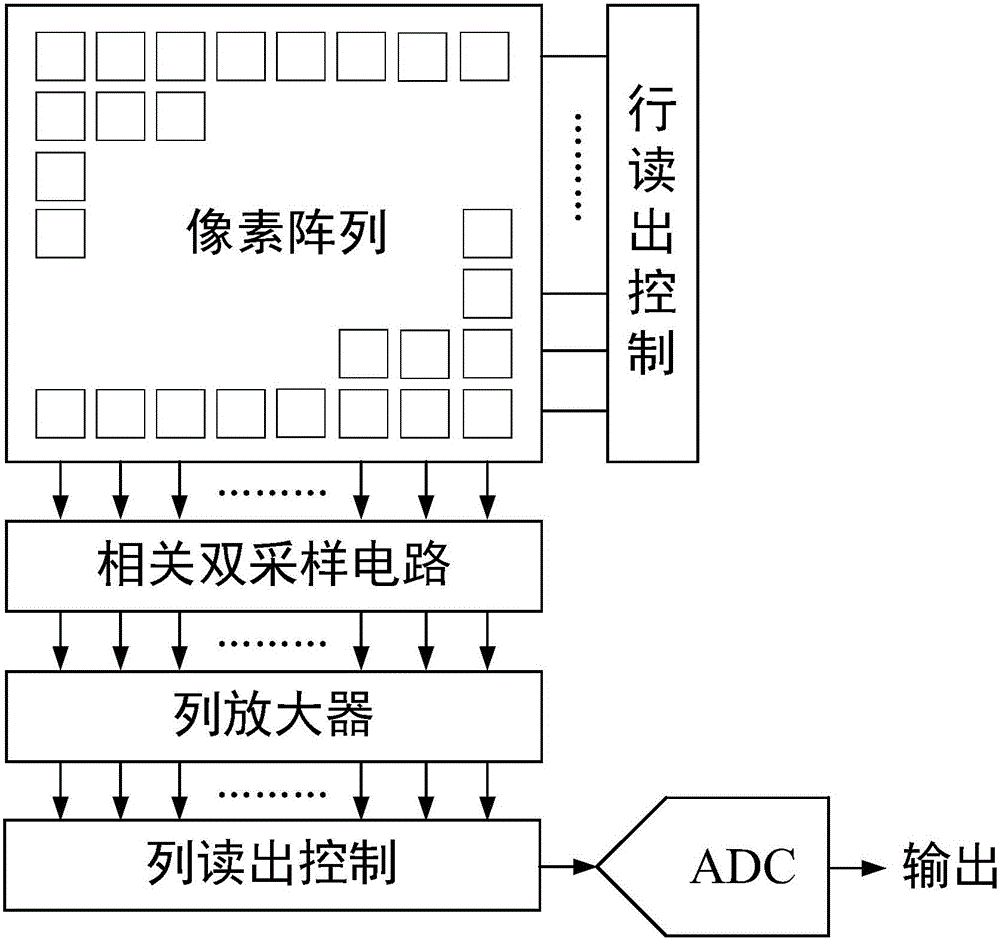

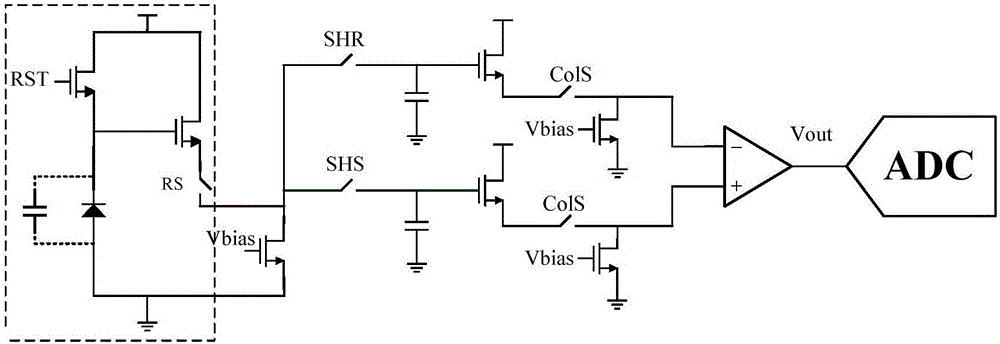

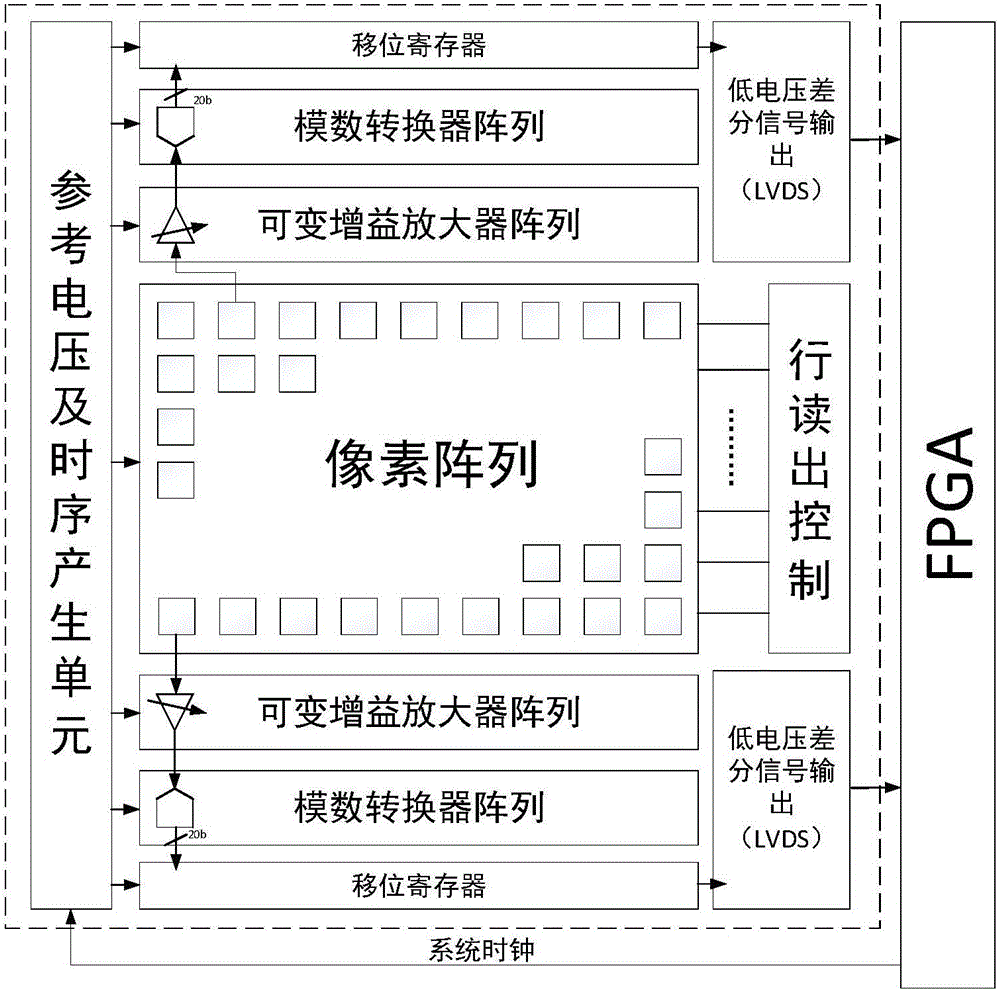

Digital correction method for array analog to digital converter of high-performance CMOS image sensor

ActiveCN106027924AReduce Mismatch ProblemsGood dynamic performanceTelevision system detailsColor television detailsCMOSImage sensor

The invention belongs to the field of semiconductor image sensing, and specifically relates to a digital correction method for an array analog to digital converter of a high-performance CMOS image sensor. The invention provides an algorithm based on a multi-way collaborative digital correction technology. In particular, for the features that the number of the ADCs in the array ADC of the CIS is high, the area of a single ADC is very small and capacitance mismatch is high, according to the algorithm, an analog to digital converter array which is applied to the CIS and is realized by matching with the algorithm fully is designed. A low working voltage of 1.8V is employed in the integral design. The pixel voltage of the image sensor passes through a variable gain amplifier (VGA), then is directly sent to the analog to the digital converter (ADC) array for conversion, and then is sent to a digital correction engine for calculation. The array analog to digital converter applied to the CMOS image sensor is taken as an integral system. The mismatch problem due to the fact that the area of the single analog to digital converter of the array analog to digital converter is small is reduced to a great extent. According to the multi-way collaborative digital correction technology of the array analog to digital converter applied to the CMOS image sensor provided by the invention, the integral performance of the array analog to digital converter can be effectively improved.

Owner:JILIN UNIV

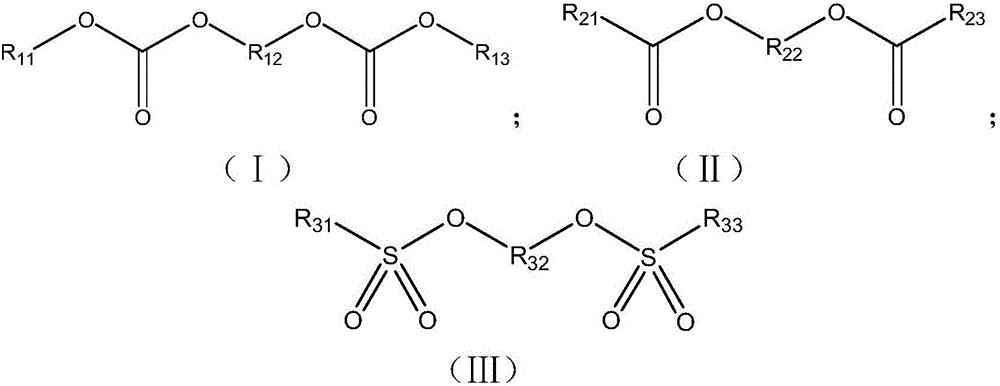

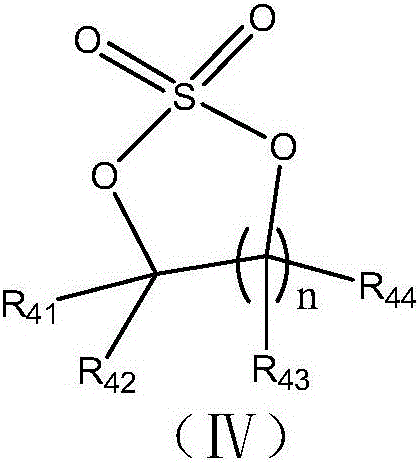

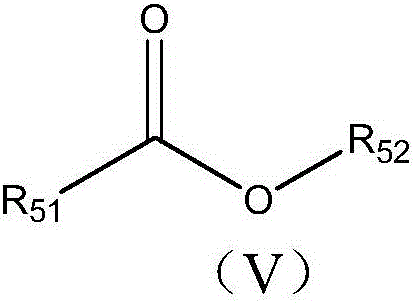

Electrolyte and lithium-ion battery comprising same

ActiveCN106025356AInhibition of persistent responseImprove high-rate charging performanceSecondary cellsOrganic electrolytesPolyesterHigh temperature storage

The invention relates to the technical field of lithium-ion batteries, in particular to an electrolyte and a lithium-ion battery comprising the same. An organic solvent contains linear or branched chain carboxylic ester; an additive contains a di-polyester compound and a cyclic sulfate compound; and the di-polyester compound comprises a carbonic ester dipolymer, a carboxylic ester dipolymer and a sultone dipolymer. The linear or branched chain carboxylic ester with a low solidifying point, low viscosity and a high dielectric coefficient is adopted as the solvent for improving the high-rate charging performance of the lithium-ion battery. The cycle performance and the charging performance of the battery can be improved by cyclic sulfate lactone added to the electrolyte; continuous oxidation reaction of the linear or branched chain carboxylic ester on a positive electrode under high voltage can be inhibited by the di-polyester compound added to the electrolyte; and high-temperature storage performance deterioration of the battery caused by cyclic sulfate is effectively improved.

Owner:NINGDE AMPEREX TECH

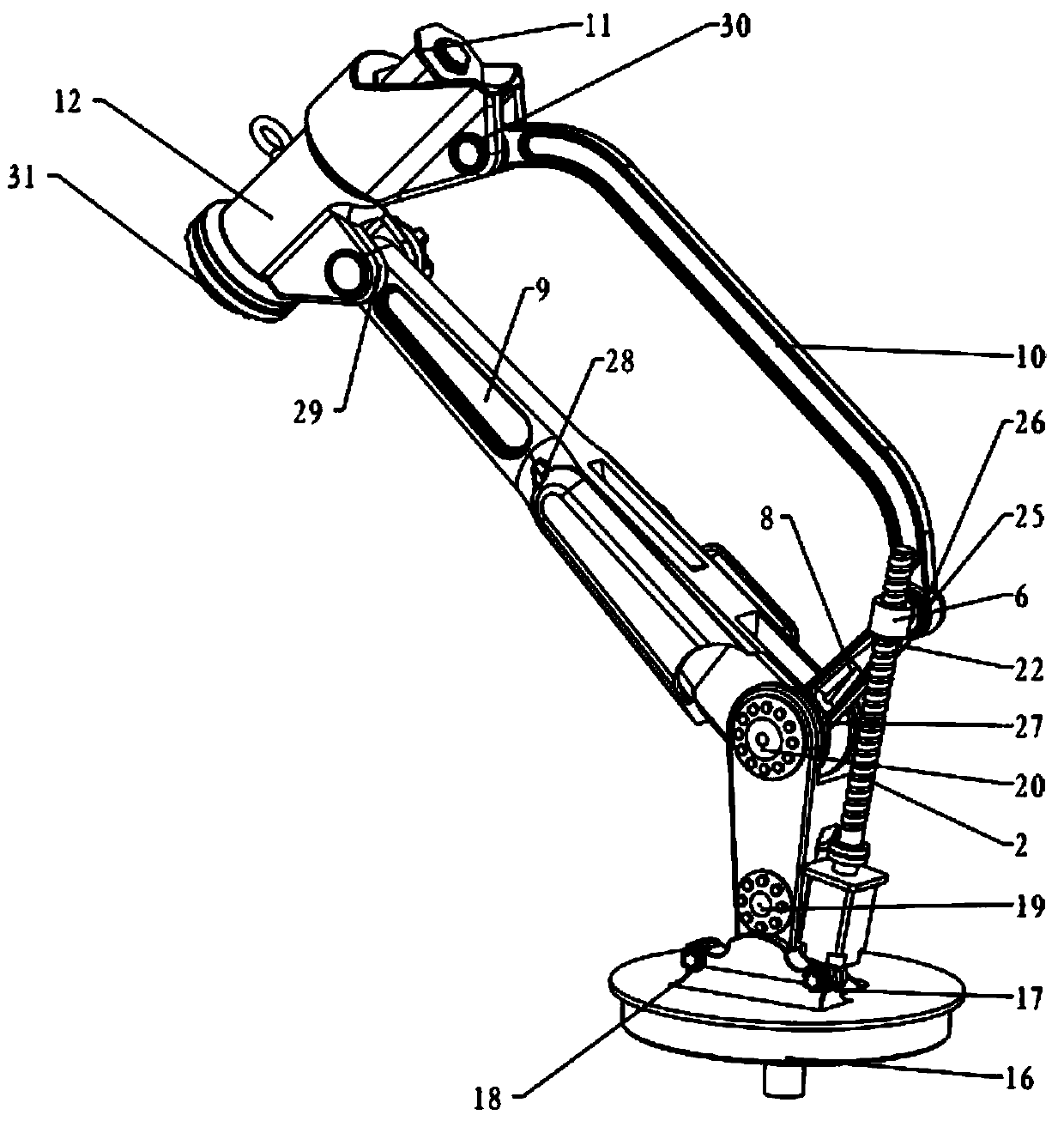

High-precision advanced welding robot mechanism with six degrees of freedom

InactiveCN103737582ARealize three-degree-of-freedom attitude adjustmentIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesSix degrees of freedomWorking space

The invention relates to a high-precision advanced welding robot mechanism with six degrees of freedom. The high-precision advanced welding robot mechanism comprises a waist rotary mechanism, a shoulder swing mechanism, an elbow rotary mechanism, a forearm twisting mechanism, a wrist rotary mechanism, a welding gun clamping seat rotary mechanism, a machine base and a rotary platform. The two-dimensional translation of a plane is achieved through a mechanism formed by the shoulder swing mechanism and the elbow rotary mechanism, and a forearm execution tail end welding gun clamping seat is sent to a preset area. The position of an execution tail end within a space range is adjusted through the whole circle rotation of the rotary platform, and large work space is obtained. A welding gun posture is adjusted through the three-dimensional rotation of the forearm twisting mechanism, the wrist rotary mechanism and the welding gun clamping seat rotary mechanism. The high-precision advanced welding robot mechanism can flexibly and conveniently send a welding gun to different space points to work, good dynamics performance is obtained, the bearing loads of shoulder joints are reduced, and the excellent characteristics of high precision, high reliability and convenient maintenance are achieved.

Owner:GUANGXI UNIV

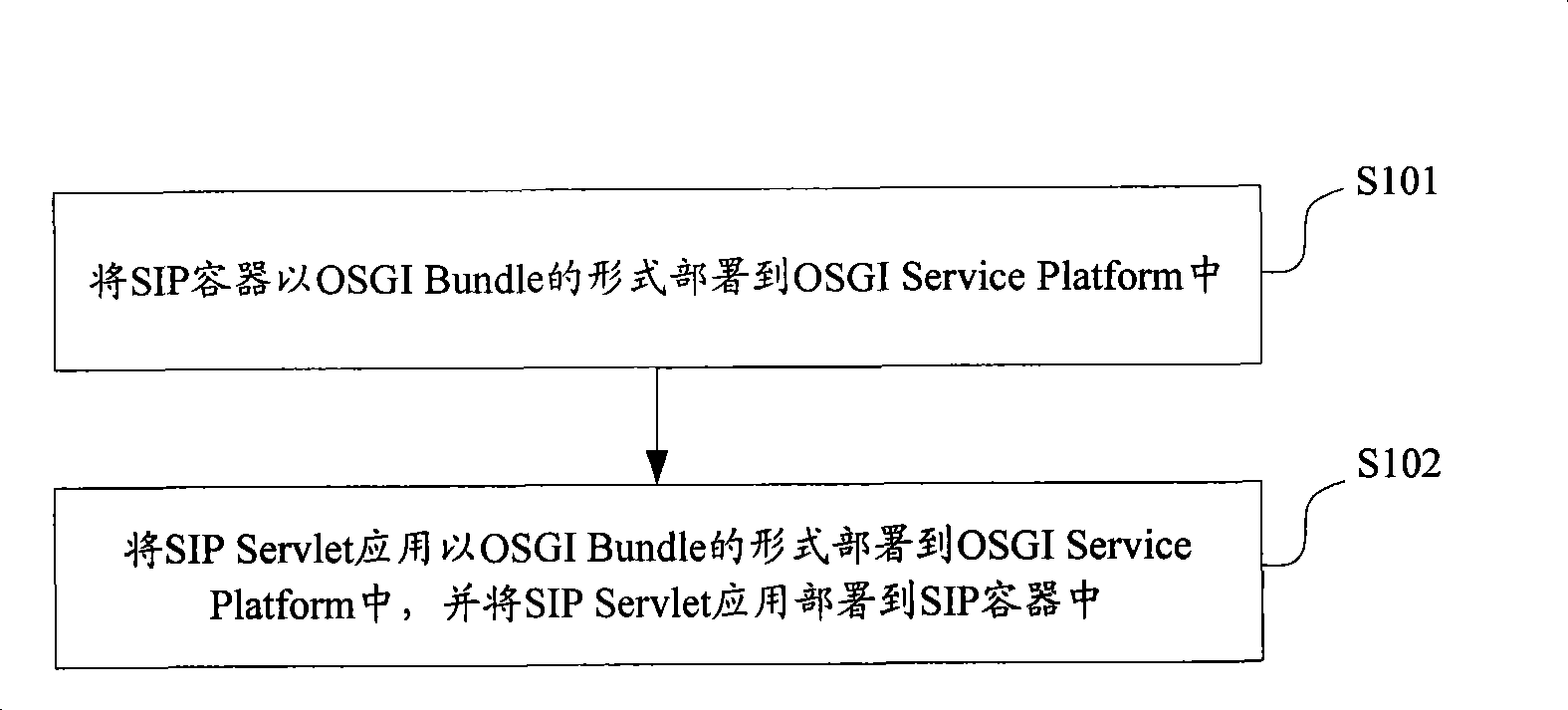

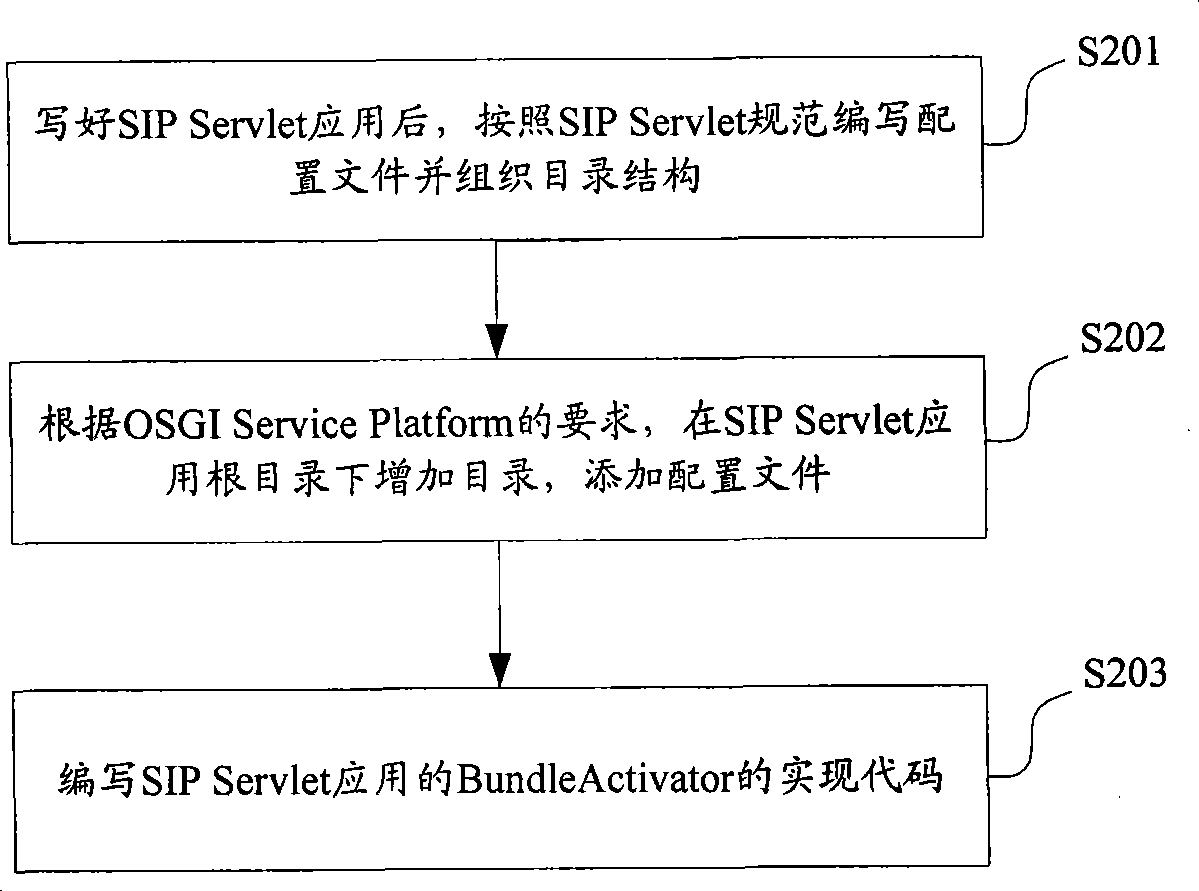

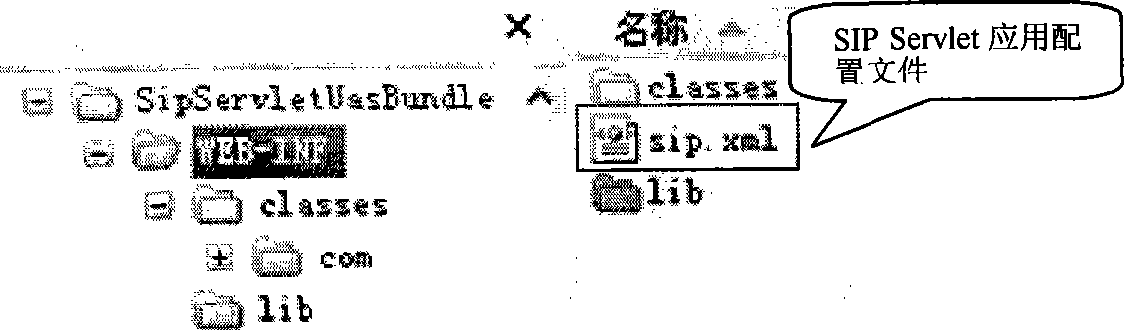

Method for deploying SIP Servlet application, managing SIP Servlet application and system thereof

ActiveCN101459740AGood dynamic performanceImprove dynamic performanceInterconnection arrangementsProgram loading/initiatingOperating system

Owner:XFUSION DIGITAL TECH CO LTD

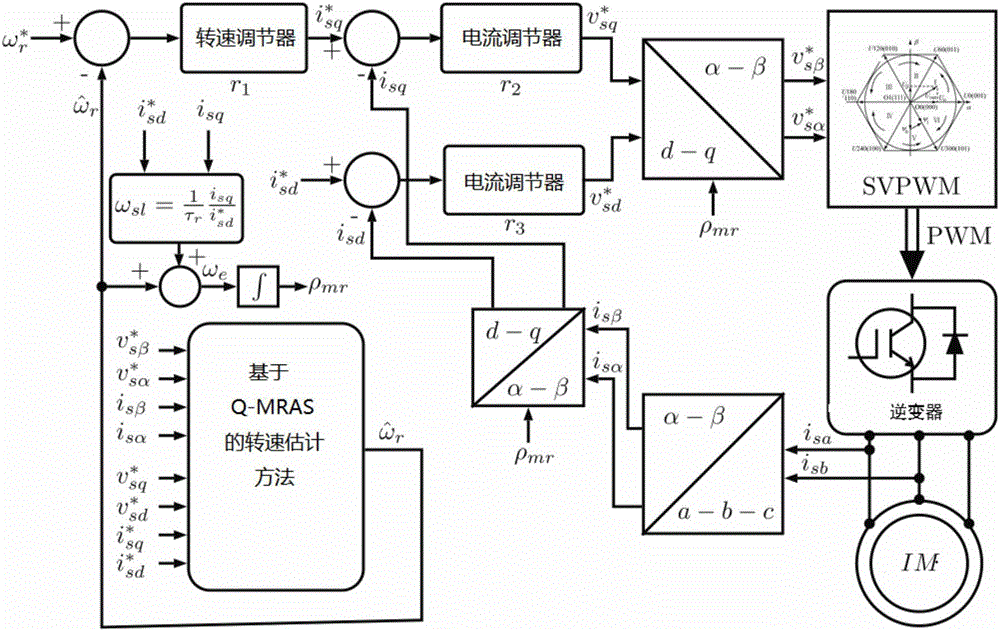

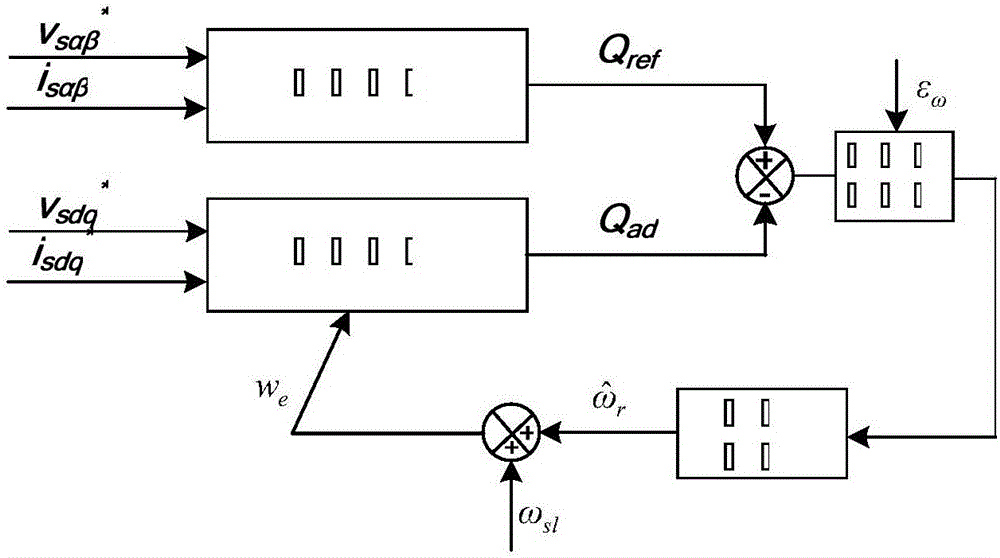

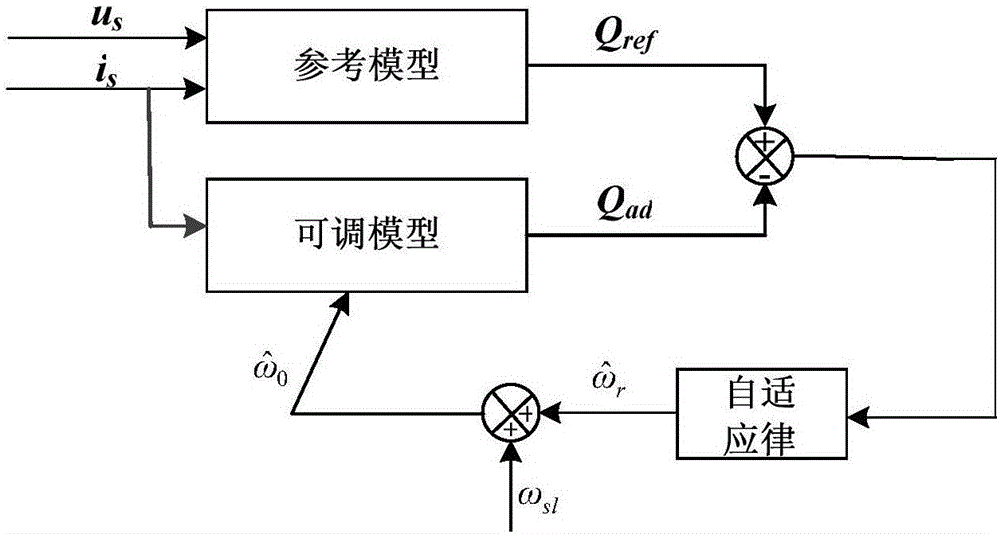

Asynchronous motor speed sensorless control method based on improved Q-MRAS

InactiveCN107181438AGood dynamic performanceStrong load capacityElectronic commutation motor controlVector control systemsStatorVoltage

The invention provides an asynchronous motor speed sensorless control method based on an improved Q-MRAS. The method includes the steps of rotational speed control: obtaining a given value of a stator current q-axis component, calculating a rotational speed difference frequency, and obtaining a rotational speed difference angular speed and a flux linkage phase of a motor; coordinate transformation: obtaining a stator current under dq-axis by coordinate transformation; current control: obtaining a given value of a stator voltage dq-axis component, modulating space vectors, and performing space vector modulation according to the stator voltage given value to output a drive pulse; and a speed sensorless method: obtaining an estimated motor rotational speed through an appropriately designed reference model and adjustable model based on a Q-MRAS structure. The beneficial effects of the method of the invention are that a rotational speed identification system based on the improved Q-MRAS well fits to the actual rotational speed no matter under a starting process, a state switching process or a low speed condition, the dynamic tracking performance is high, meanwhile the problem of high dependency of a traditional Q-MRAS method on motor parameters is solved, and the identification accuracy and loading capacity are high.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system

ActiveCN106486687AStrong oxidation abilityImprove performanceFinal product manufactureRegenerative fuel cellsChemistryCathode

The invention discloses a photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system. A groove-shaped cavity is formed in a reaction cavity body and is sealed by conductive glass, the front portion of the cavity is a reaction chamber, the rear portion is provided with a cathode chamber and an anode chamber arranged side by side and communicated mutually, a photocatalyst layer is arranged in the reaction chamber, a cathode catalyst layer is arranged in the cathode chamber, an anode photocatalyst layer is arranged in the anode chamber, and the photocatalyst layer, the cathode catalyst layer and the anode photocatalyst layer are supported on the conductive glass. The system integrates photocatalytic hydrogen peroxide generation and simultaneous power generation of organic matter from photocatalytic fuel cell disposal, is simple in structure and low in cost and has the advantages of being free of membranes, large in specific surface area, high in mass transfer efficiency, accurate in flow control, short in contact time, easy to enlarge, uniform in lighting, small in optical path loss and the like, and the performance is effectively improved. The organic matter in water can be utilized to generate power, environmental pollution can be controlled, and meanwhile electric energy can be also obtained.

Owner:CHONGQING UNIV

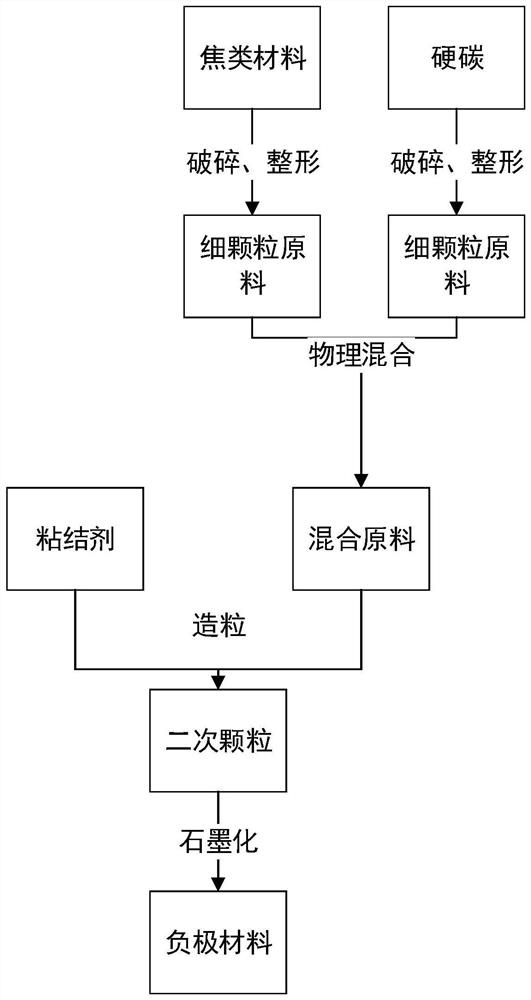

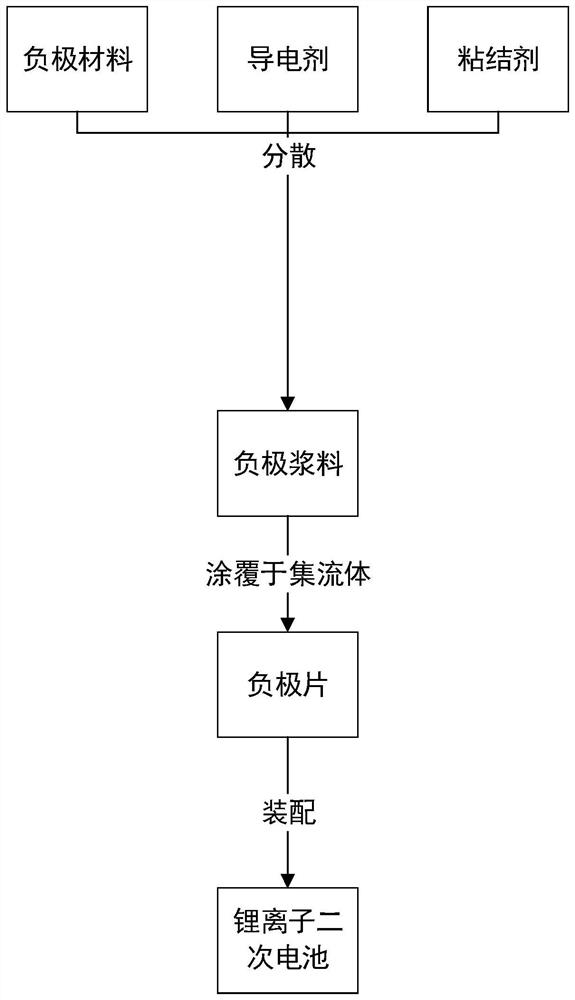

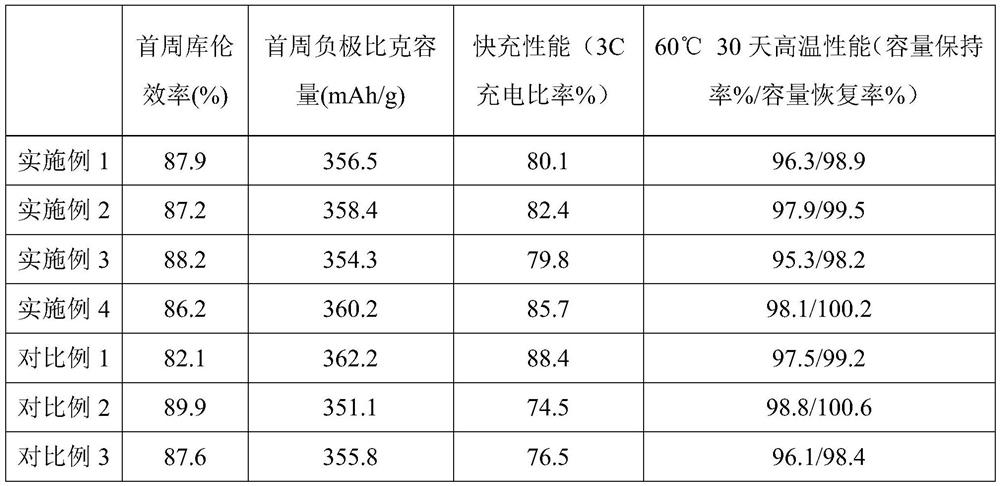

Negative electrode material and preparation method thereof, negative plate and lithium ion battery

PendingCN111620332AImprove high temperature performanceIncrease gram capacityCarbon compoundsNegative electrodesPhysical chemistryGraphite

The invention provides a negative electrode material and a preparation method thereof, a negative plate and a lithium ion battery. The method comprises the following steps: (1) mixing a coke materialand hard carbon, adding a carbon-containing binder, and granulating to obtain a granulated product; and (2) graphitizing the granulated product to obtain the negative electrode material. The negativeelectrode material obtained by the method disclosed by the invention is high in energy density and excellent in quick charging performance and high-temperature performance.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

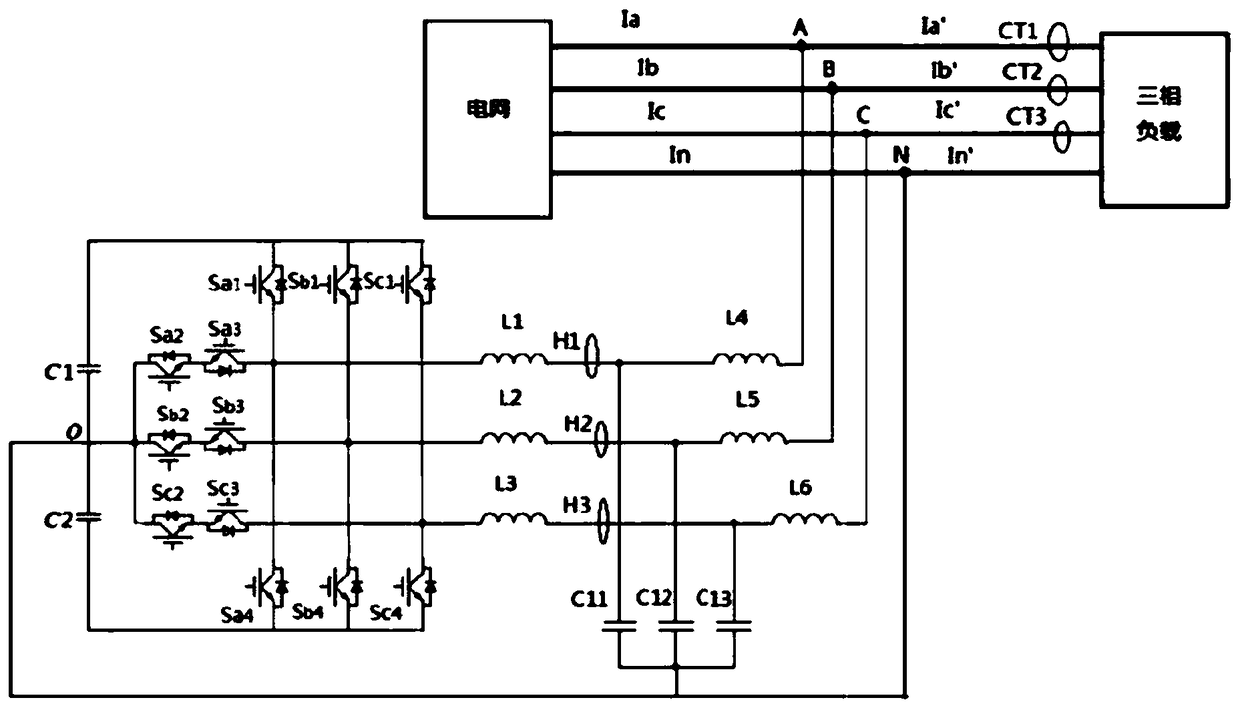

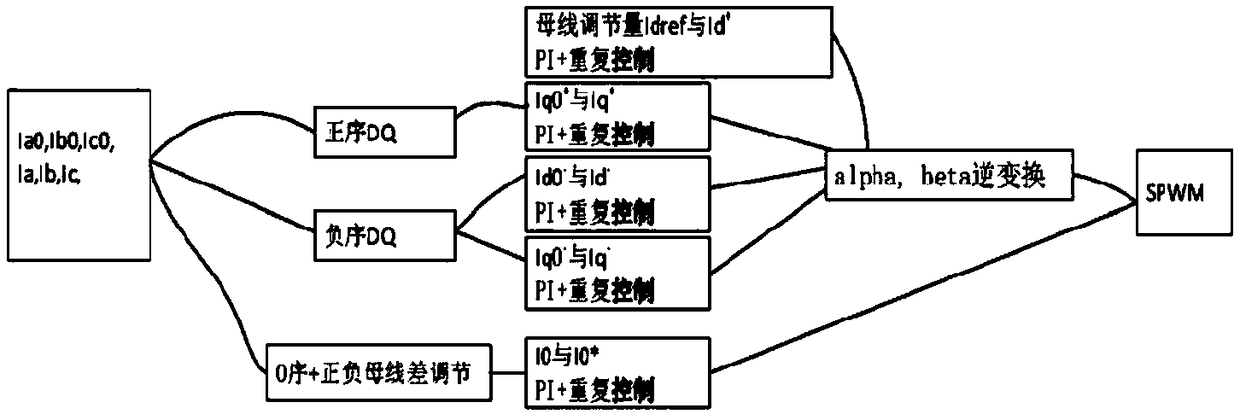

Three-phase load unbalance intelligent adjusting device and method

InactiveCN109494770AGood dynamic performanceImprove dynamic performancePolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionSelf adaptiveCapacitance

The invention discloses a three-phase load unbalance intelligent adjusting device and method, and the device comprises a DC side capacitor module, a main power module, a filtering module and a controlcircuit. The DC side capacitor module is connected with the main power module, the main power module is connected with the filtering module, and the filtering module is connected with the control circuit. The DC side capacitor module is formed by the series and parallel connection of multiple sets of capacitors. The main power module uses an IGBT, and an AC output side is connected with the filtering module. The device of the invention can realize accurate three-phase unbalanced processing and reactive power compensation, the response speed is less than 5ms, the power loss is less than 3%, the dynamic performance is good, and the device has the active balance intelligent adaptive control and parallel connection control mechanism. Moreover, on the basis of ensuring good governance effects,with simple topology and advanced control algorithms, the dynamic performance of the equipment is improved, and the volume and cost of the equipment are reduced.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

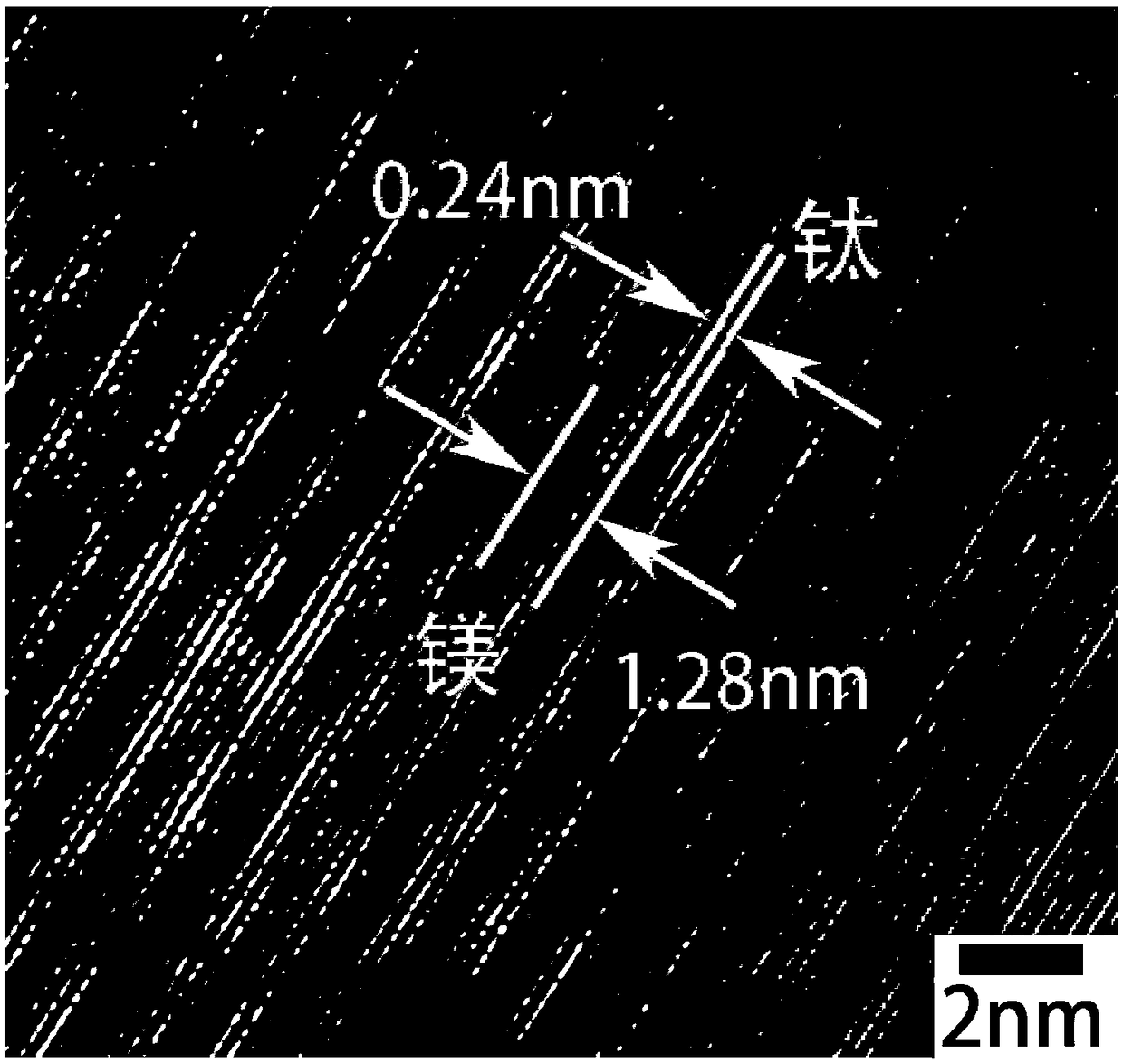

Mg-TM super-multilayer composite hydrogen storage film and preparation method thereof

InactiveCN108149211ALower the dehydrogenation temperatureGood dynamic performanceVacuum evaporation coatingSputtering coatingSputteringComposite film

The invention discloses a Mg-TM super-multilayer composite hydrogen storage film and a preparation method thereof. The Mg-TM super-multilayer composite hydrogen storage film is a Mg-TM composite filmwhich is formed by alternating deposition of Mg and TM atom layers, a Pd sealing cover layer is arranged on the external surface of the Mg-TM composite film, and TM is a transition group metallic element Ti, Ni or Nb. The Mg-TM super-multilayer composite hydrogen storage film is prepared by a semi-co-sputtering technique of a low-cost ultrahigh vacuum magnetron sputtering system. A preparation technology is simple, the cost is low, the repeatability is good, and the high-quality Mg-TM super-multilayer composite hydrogen storage film having obvious Mg preferred orientation is prepared; the prepared Mg-TM super-multilayer composite hydrogen storage film has lower hydrogen absorption / dehydrogenation temperature and higher hydrogen absorption / dehydrogenation speed; the hydrogen absorption quantity in 500s achieves 3.4wt%, with the temperature being 423 K and the hydrogen pressure being 1.15 MPa; and the hydrogen absorption quantity in 600s achieves 2.1wt% with the temperature being 423 K.

Owner:SOUTH CHINA UNIV OF TECH

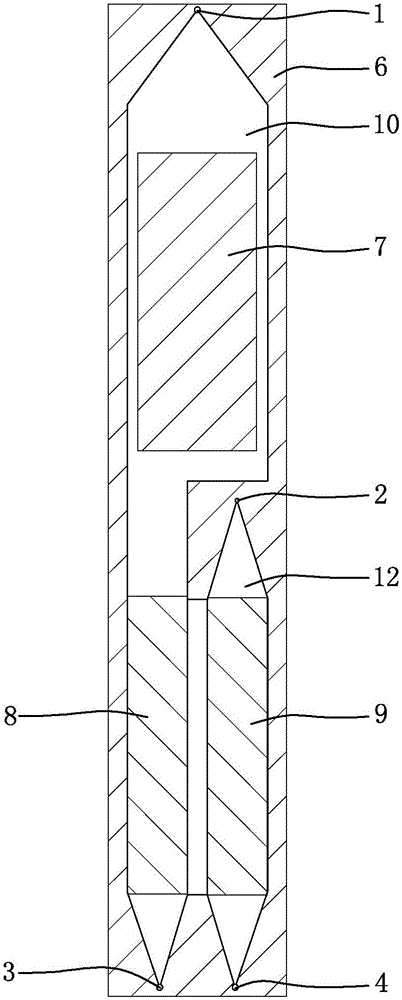

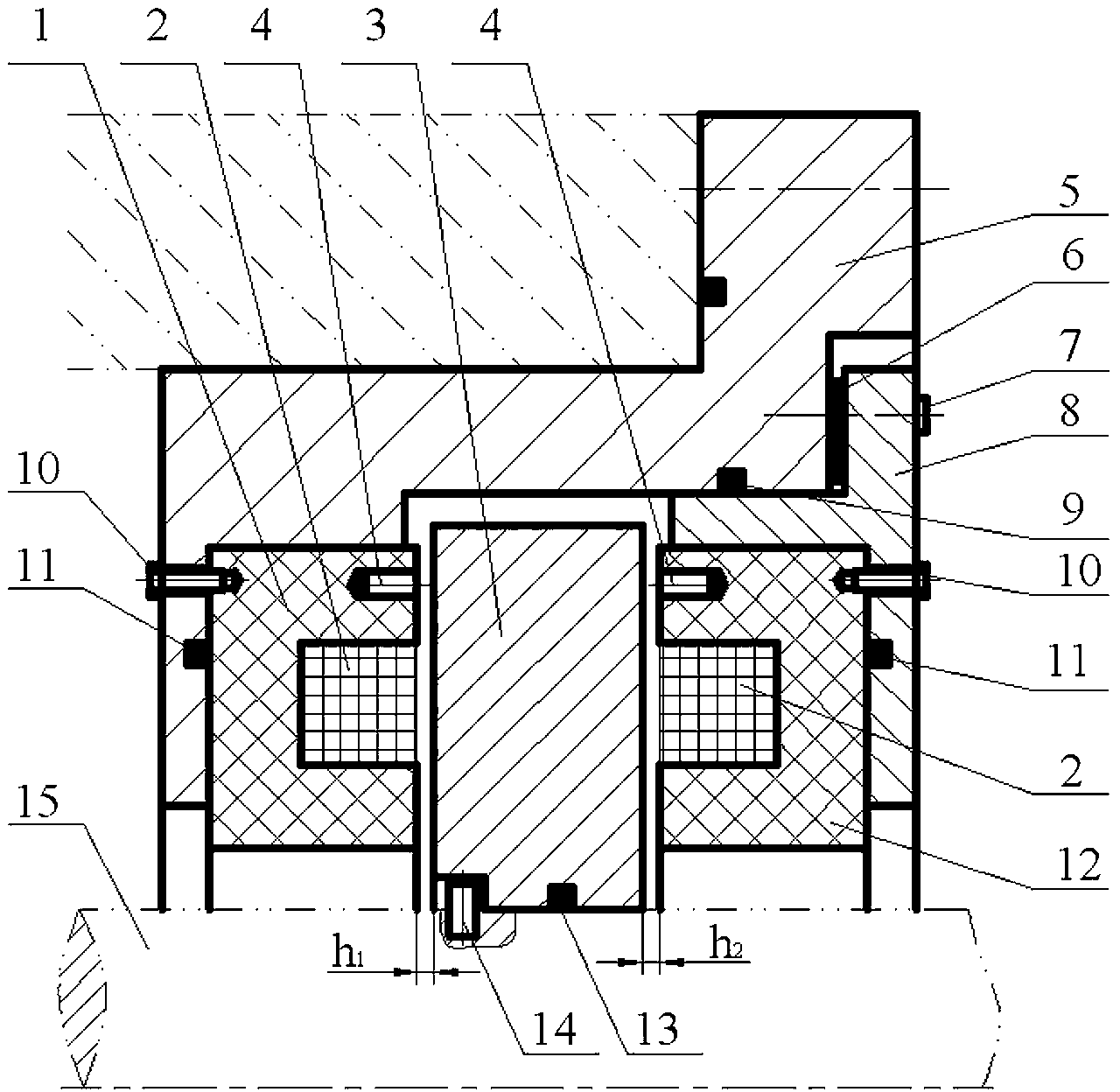

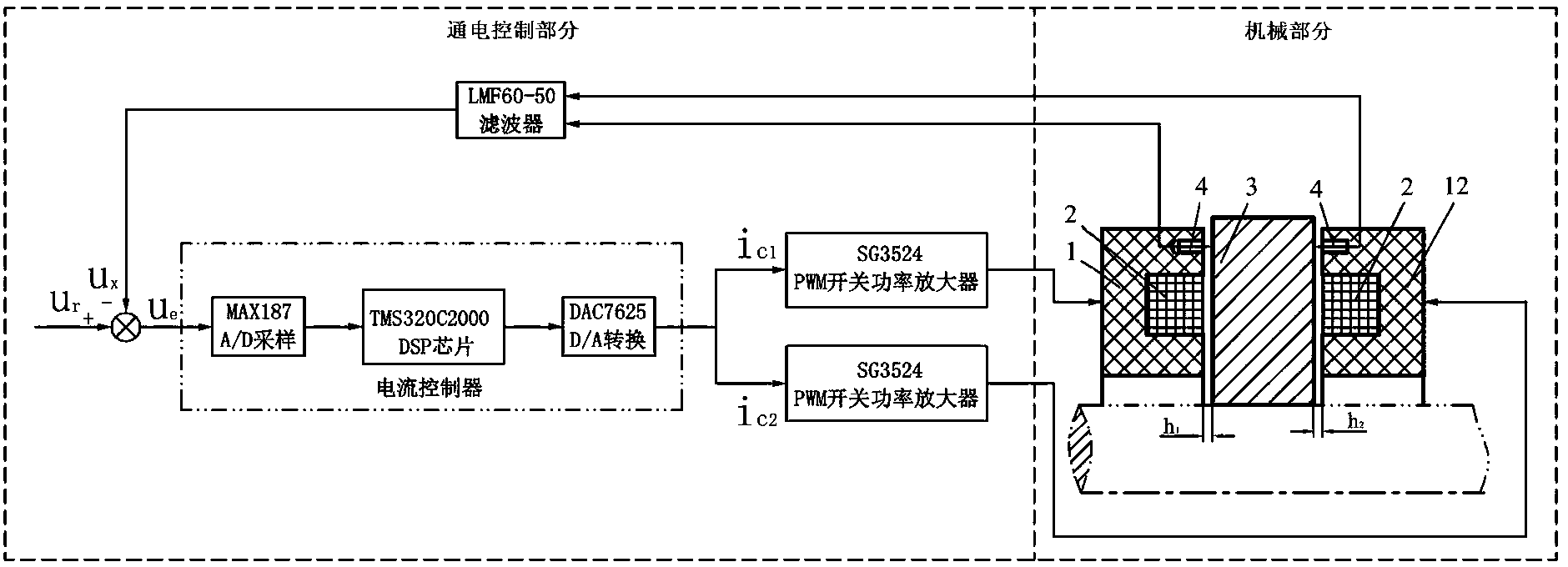

Non-contact type mechanical sealing device

InactiveCN103267131AGood dynamic performanceImprove stability and reliabilityEngine sealsMaterial structureElectromagnetic coil

The invention discloses a non-contact type mechanical sealing device. A rotating sealing ring and a static sealing ring are coaxially arranged, and sealing is achieved through the axial end surface of the rotating sealing ring and the axial end surface of the static sealing ring. A sealing ring structural body of a first sealing unit comprises a sealing ring and a ferromagnetic material structure or a permanent magnet material structure, wherein the sealing ring can make axial displacement, and both two axial end surfaces of the sealing ring are sealing surfaces. A second sealing unit comprises two sealing structural bodies which are axially arranged at two axial ends of the sealing ring structural body of the first sealing unit, a sealing ring and a corresponding electromagnet structure are arranged on each sealing ring structural body of the second sealing unit in a sealing clearance mode, and each sealing ring and each electromagnet structure are opposite to the axis of the sealing ring of the first sealing unit. When one sealing ring of the two sealing units is the rotating sealing ring, the sealing ring of the other sealing unit is the static sealing ring. A sensing structure which detects the distance between the sealing clearances is arranged on at least one side of the two sealing structural bodies which are opposite to the sealing clearances, and an electromagnetic coil and the sensing structure of each electromagnet structure are respectively connected with an energizing control structure. The non-contact type mechanical sealing device can achieve active control of the sealing clearances in a magnetic levitation mode, enables the sealing to have a good dynamic property, and is reliable and stable in operation, easy to maintain, long in service life and wide in application range.

Owner:XIHUA UNIV

Method for preparing AB5-AB3 composite alloy

InactiveCN102242286AImprove discharge capacityImprove cycle stabilityAlkaline accumulator electrodesHydrogenIngot

The invention discloses a method for preparing an AB5-AB3 composite alloy. The method comprises the following steps of: respectively preparing an AB5 type M1Ni3.5Co0.6Mn0.4Al0.5 master alloy and an AB3 type alloy Mm0.89Mg0.11Ni2.97Mn0.14Al0.20Co0.54 as a modifier by a vacuum induction smelting method, respectively mechanically crushing two alloy ingots, ball milling the crushed alloy ingots at 225-250 rpm for 30-60min, and screening 200-300 meshes of particle powder for preparing the composite alloy; and mixing the prepared two alloy ingots in percentage by weight: 90-99.9% of M1Ni3.5Co0.6Mn0.4Al0.5 and 0.1-10% of Mm0.89Mg0.11Ni2.97Mn0.14Al0.20Co0.54, and ball milling to obtain the composite alloy, wherein the weight ratio of ball to powder is 20:1, the rotating speed is 200-300rpm and the time of ball milling is 30-60min. According to the method for preparing the AB5-AB3 composite alloy, an AB5 type hydrogen-storing alloy as an Ni / MH battery negative electrode material is compositely modified, thus an alloy electrode with higher discharge capacity, better cyclical stability and excellent dynamic performance can be obtained.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

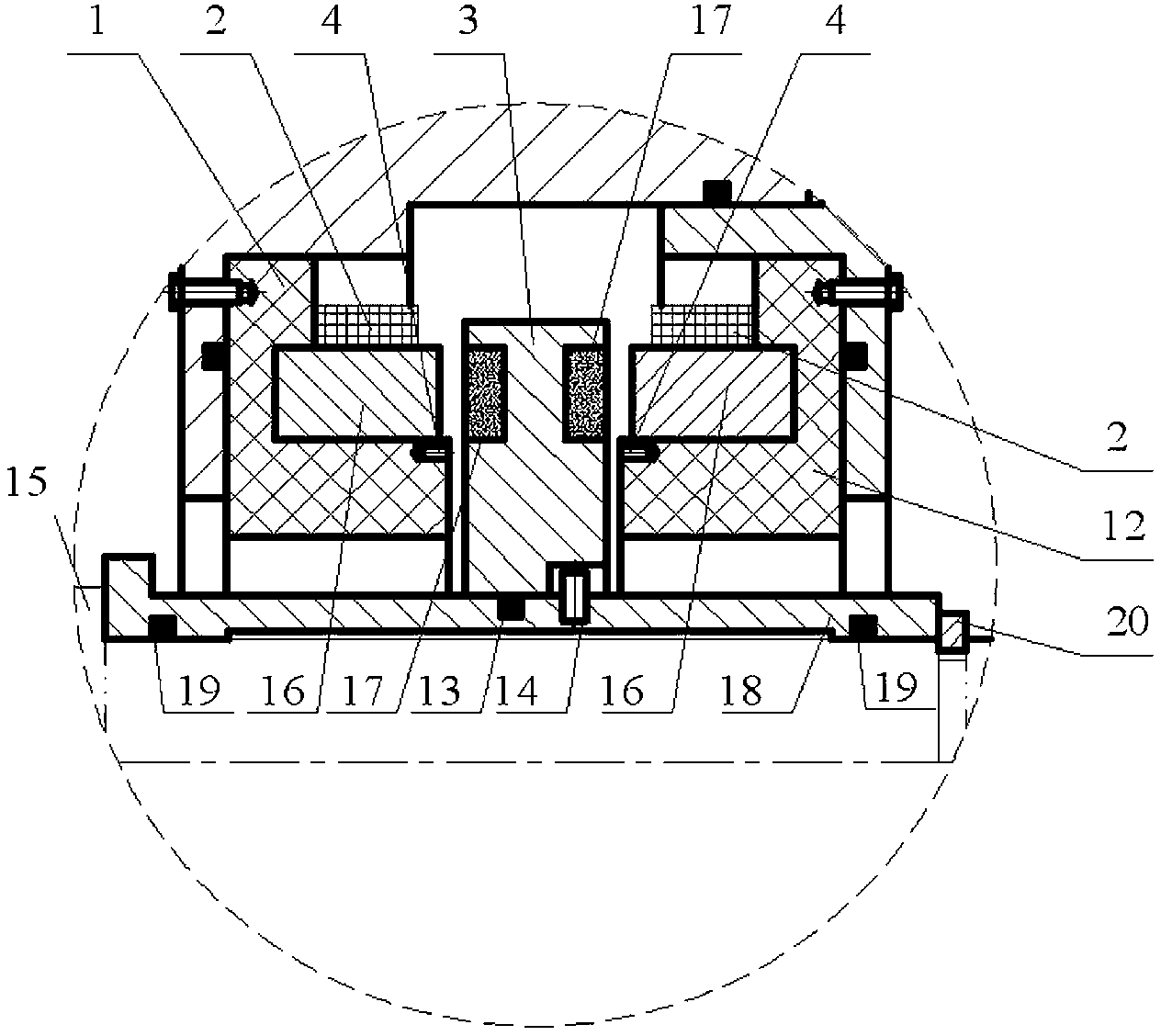

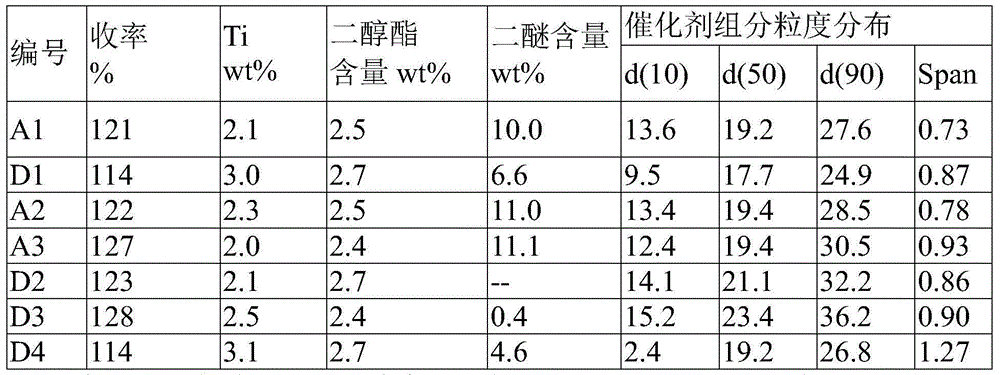

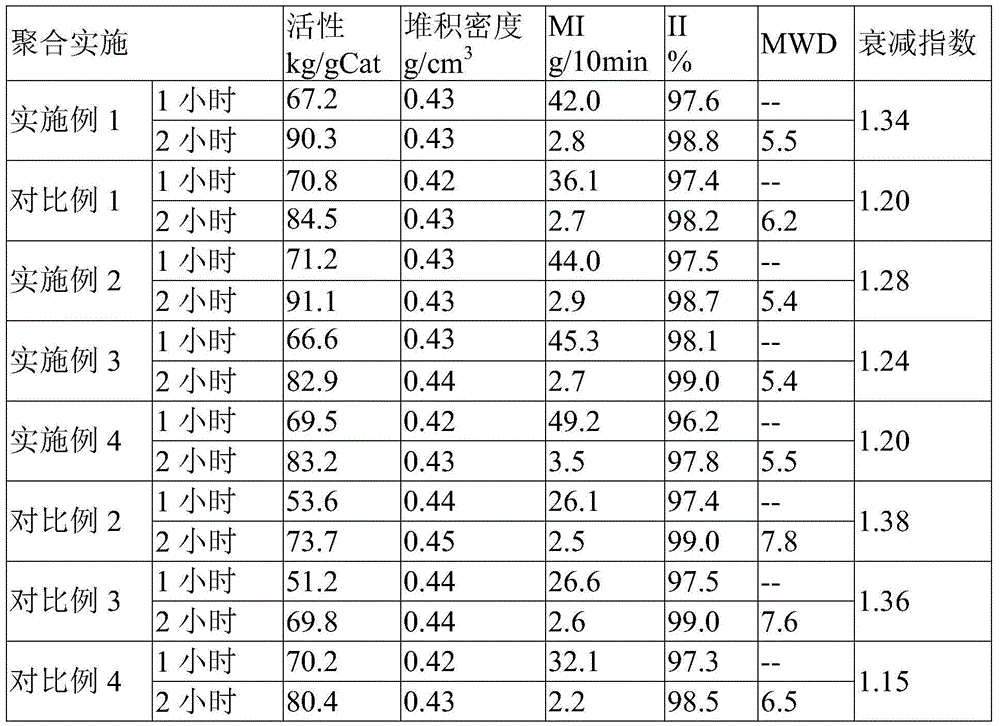

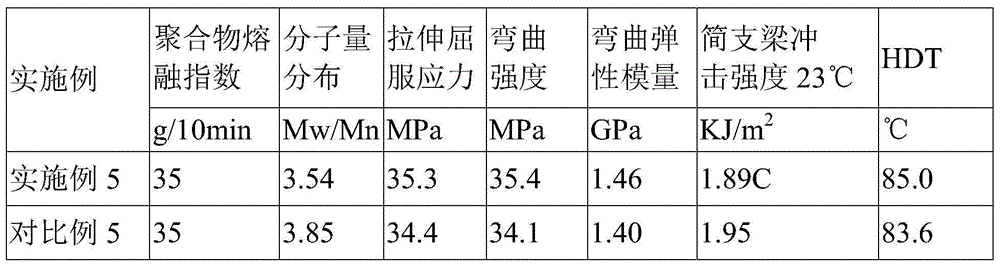

Catalyst compound for preparing polyolefin for fibers, and preparation method and application thereof, catalyst system, application of catalyst system, and olefin polymerization method

The invention discloses a method for preparing a catalyst compound for preparing polyolefin for fibers, wherein the method comprises the steps: carrying out a first contact reaction of magnesium halide with an alcohol compound in the presence of a hydrocarbon solvent, to form a uniform solution; in the presence of a precipitation aid, carrying out a second contact reaction of the uniform solution with a titanium compound, to obtain a mixture containing a solid precipitate; and carrying out a third contact reaction of the obtained mixture with an internal electron donor compound d, to obtain a suspension, wherein the internal electron donor compound d is a 1,3-diether compound. The invention also discloses the prepared catalyst compound and an application thereof in a catalyst system, the catalyst system for preparing the polyolefin for the fibers, an application of the catalyst system in olefin polymerization reaction for preparation of a fiber material, and a polymerization method for preparing the polyolefin for the fibers. A polymer prepared by using the prepared catalyst compound has the advantages of narrow molecular weight distribution and high regularity, and is suitable for production of fiber-graded polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Air floatation motion platform

PendingCN111900896AImprove the stiffness of the air bearingGood dynamic performanceMagnetic holding devicesClassical mechanicsMagnetic levitation

The invention discloses an air floatation motion platform. The air floatation motion platform comprises a base; a first linear motor, which is arranged on the base; a second linear motor, which is arranged on the base, is opposite to the first linear motor, and is separated from the first linear motor; a moving device, which is arranged between the first linear motor and the second linear motor and is connected with a rotor of the first linear motor and a rotor of the second linear motor; a first guide rail, which extends in the length direction of a stator of the first linear motor; a first air floatation device, which forms air floatation between the first air floatation device and the first guide rail; a second guide rail, which extends in the length direction of a stator of the secondlinear motor; a second air floatation device, which forms air floatation between the second air floatation device and the second guide rail; a first magnetic levitation assembly, which forms a magnetic preload between the first magnetic levitation assembly and the first guide rail; and a second magnetic levitation assembly, which forms a magnetic preload between the second magnetic levitation assembly and the second guide rail. Compared with the prior art, the air floatation rigidity is improved, the dynamic performance is good, the requirement for installation and adjustment is low, the structure is compact, and engineering implementation can be achieved.

Owner:FUDAN UNIV

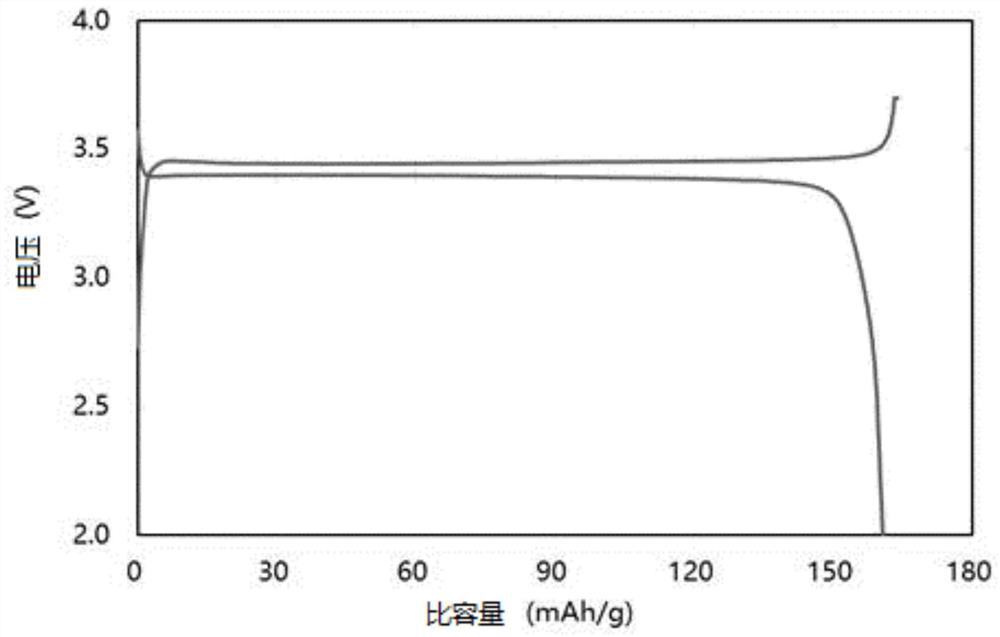

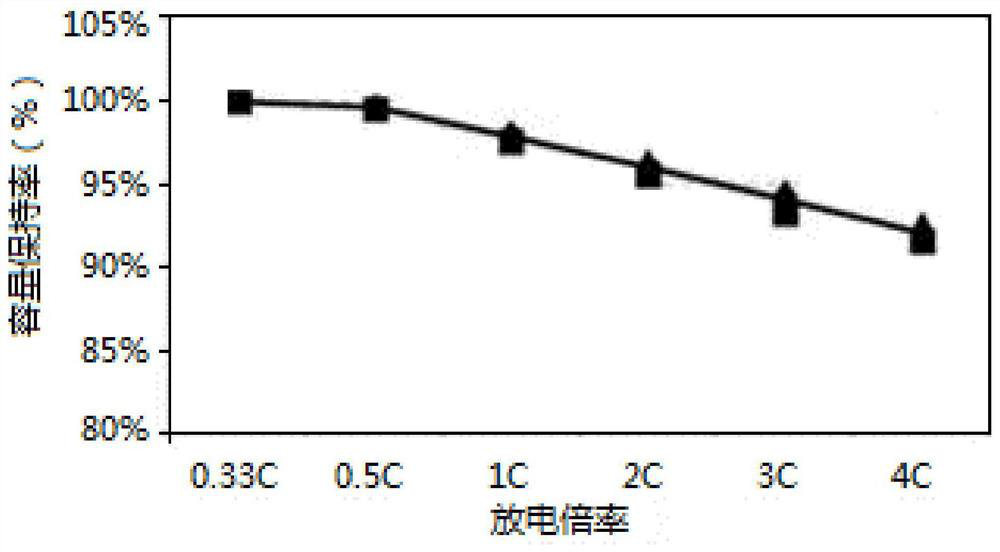

Lithium iron phosphate positive electrode material as well as preparation method and application thereof

PendingCN113555557AImprove thermal stabilityHigh specific surface areaSecondary cellsPositive electrodesLithium iron phosphateElectrical battery

The invention provides a lithium iron phosphate positive electrode material as well as a preparation method and application thereof. The lithium iron phosphate positive electrode material comprises spherical lithium iron phosphate and carbon compounded on the surface of the spherical lithium iron phosphate, the spherical lithium iron phosphate is provided with an inner core and a surface layer located on the periphery of the inner core, the surface layer is coated with the carbon, and the porosity of the inner core is larger than that of the surface layer. The lithium iron phosphate positive electrode material provided by the invention has good dynamic performance (rate capability) and discharge gram capacity after being applied to the lithium ion battery, has excellent electrochemical performance, and has outstanding performance in the aspects of capacity, service life and safety.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com