Intelligent dimming driver for networking-type high-power packaged LEDs

An optical driver and high-power technology, which is applied in the field of networked high-power group LED intelligent dimming drivers, can solve the problems of narrow voltage range, low reliability, and low efficiency, and achieve good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

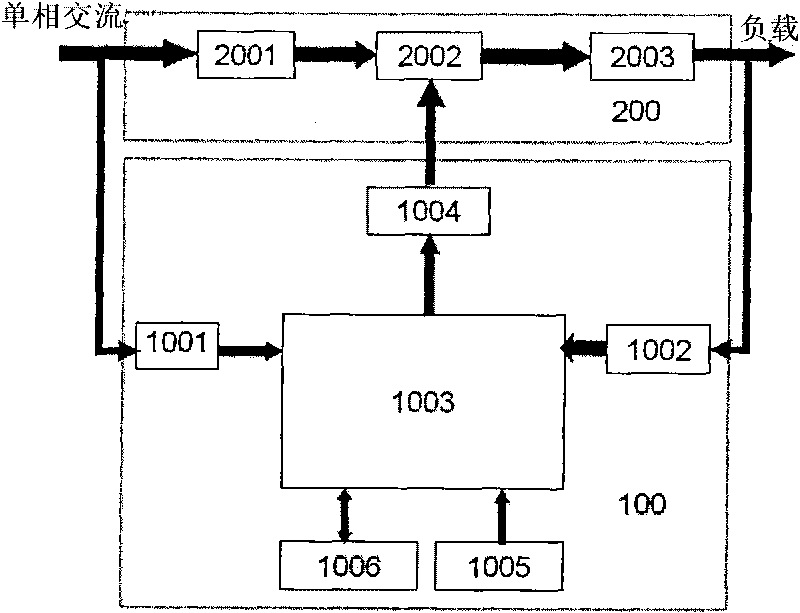

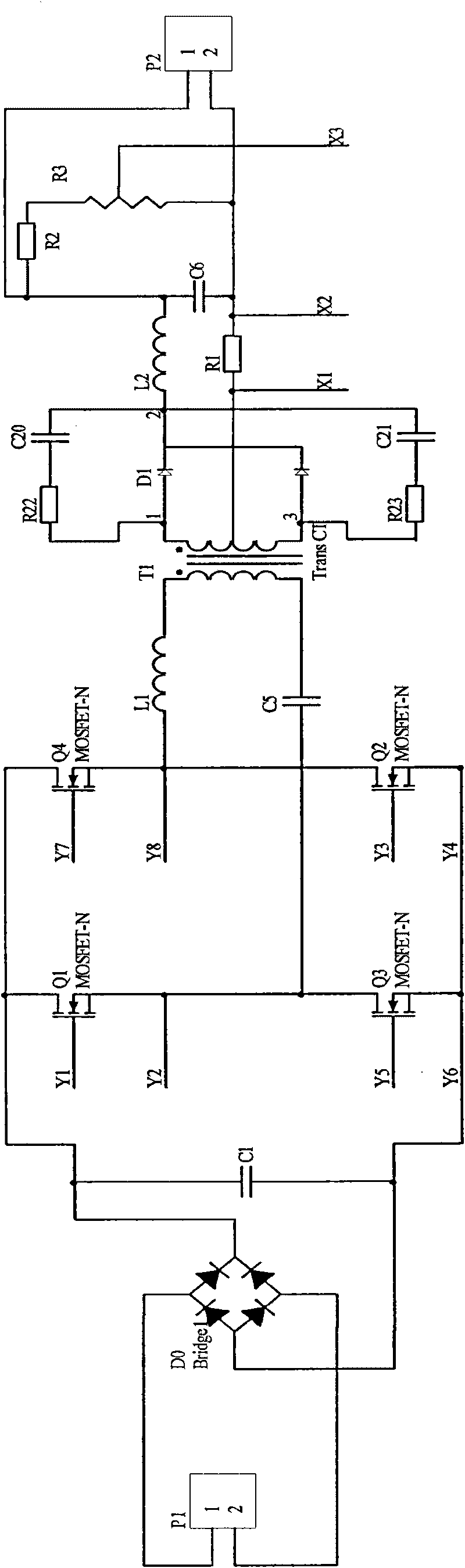

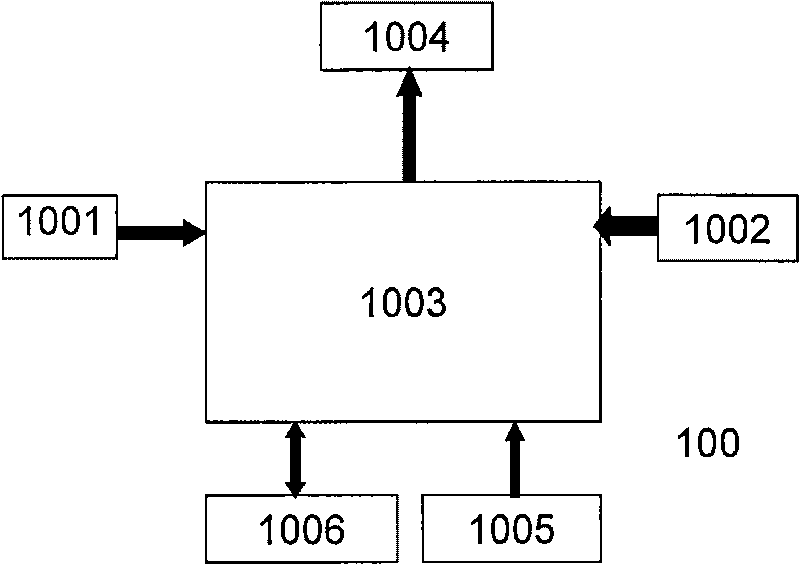

[0030] like figure 1 As shown, the network-type high-power group LED intelligent dimming driver of the present invention includes two parts: a digital control system 100 and a power regulation system 200; 2002, the transformation and rectification module 2003 is sequentially connected to form, the single-phase AC input power supply is connected to the single-phase rectification and filtering module 2001, and the transformation and rectification module 2003 is connected to the LED load; the digital control system 100 is composed of abnormal detection A protection module 1001, a sampling detection module 1002, an ARM microprocessor system 1003, a high-frequency drive module 1004, a parameter setting module 1005 and a serial bus communication module 1006 are connected to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com