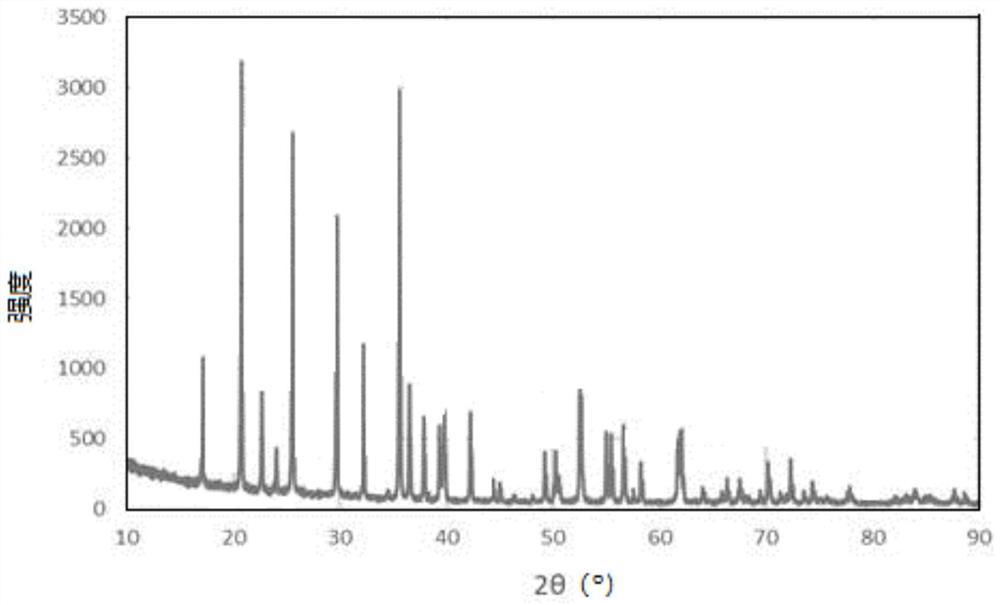

Lithium iron phosphate positive electrode material as well as preparation method and application thereof

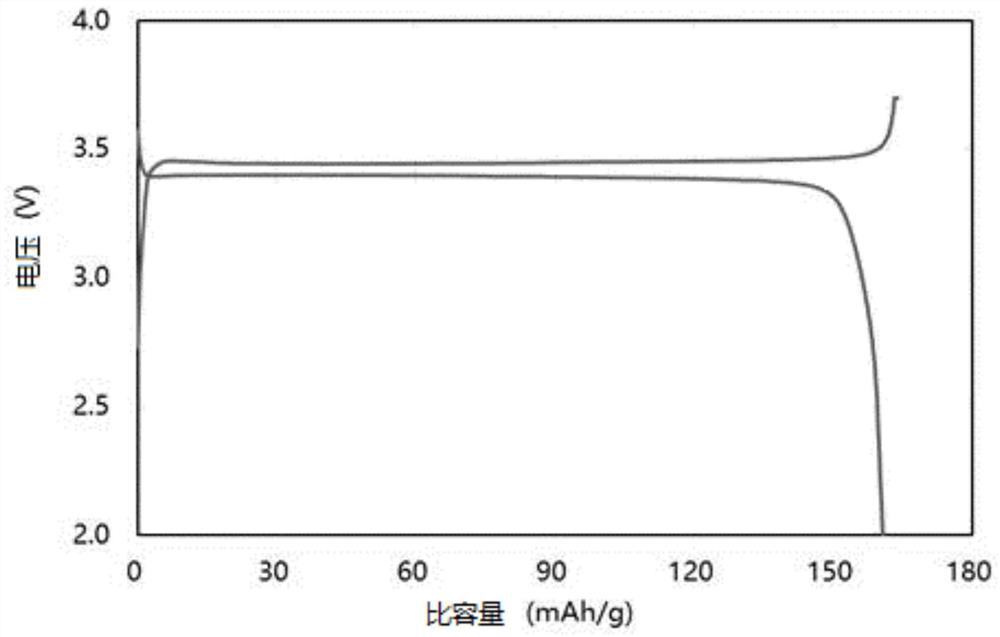

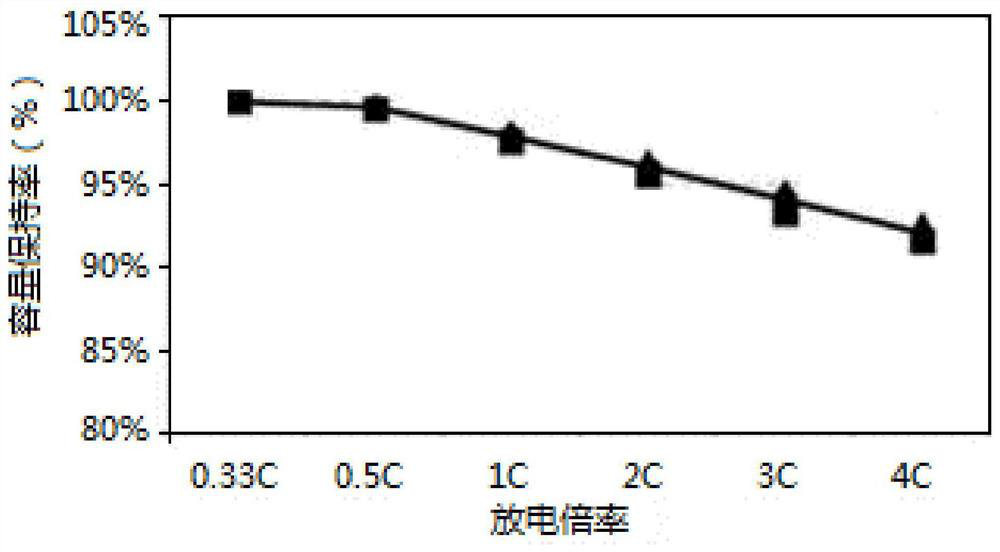

A technology for lithium iron phosphate and positive electrode materials, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., to achieve the effects of improving diffusion capacity, improving electrical conductivity, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to another aspect of the present invention, there is also provided a method for preparing a lithium iron phosphate positive electrode material, which includes the following steps: preparing a mixed solvent of water and an organic solvent, adding a binary solution, a complexing agent solution and an acid solution therein , carry out the first stage reaction under the condition of pH value 1.8~2.4, form the intermediate reaction solution; adjust the pH value of the intermediate reaction solution to 2.6~3.2, carry out the second stage reaction, form Fe 3(PO 4 ) 2 Precursor; Wherein binary solution is the solution of soluble ferrous salt and phosphate ion-containing soluble compound; Fe 3 (PO 4 ) 2 Precursor dispersed to Li 3 PO 4 Nucleation growth in the crystal solution to obtain LiFePO 4 Precursor; LiFePO 4 The precursor and the carbon source are mixed, and then calcined under an inert atmosphere to obtain the lithium iron phosphate cathode material.

...

Embodiment 1

[0048] 1. Configure FeCl 2 and (NH 4 ) 2 HPO 4 binary aqueous solution, the total concentration of solute is 2mol / L, Fe 2+ with PO 4 3+ The mol ratio is 3:2; Citric acid aqueous solution is as complexing agent solution, and its molar concentration is 3mol / L; Carbonic acid aqueous solution is as acid solution, and its molar concentration is 0.2mol / L;

[0049] 2. Configure a mixed solvent of ethylene glycol and deionized water as the reaction solution, wherein the volume ratio of deionized water and ethylene glycol is 3:1, and at the same time add the above binary aqueous solution, citric acid aqueous solution and carbonic acid aqueous solution to the reaction solution , to carry out the reaction of stage 1 and stage 2, and continuously bubble high-purity N during the reaction process 2 to remove oxygen from the solution. Wherein, the add-on of binary solution is 85% of reaction solution volume, and the add-on of complexing agent solution is 15% of reaction solution volum...

Embodiment 2

[0056] 1. Configure FeSO 4 and NH 4 h 2 PO 4 binary aqueous solution, the total concentration of solute is 1.5mol / L, Fe 2+ with PO 4 3+ The mol ratio is 3.15:2; Aqueous oxalic acid is used as complexing agent solution, and its molar concentration is 5mol / L; Aqueous acetic acid is used as acid solution, and its molar concentration is 0.2mol / L;

[0057] 2. Configure the mixed solvent of polyethylene glycol 200 and deionized water as the reaction liquid, wherein the volume ratio of deionized water and polyethylene glycol is 2:1, and add the above-mentioned binary aqueous solution, oxalic acid aqueous solution and acetic acid aqueous solution to In the reaction solution, the reaction of stage 1 and stage 2 is carried out, and high-purity N is constantly bubbled in during the reaction 2 to remove oxygen from the solution. Wherein, the add-on of binary solution is 85% of reaction solution volume, and the add-on of complexing agent solution is 15% of reaction solution volume, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com