Non-contact type mechanical sealing device

A mechanical sealing device, non-contact technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem that the seal end face gap cannot be adjusted actively, achieve a wide range of speed adaptation, reduce maintenance costs, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

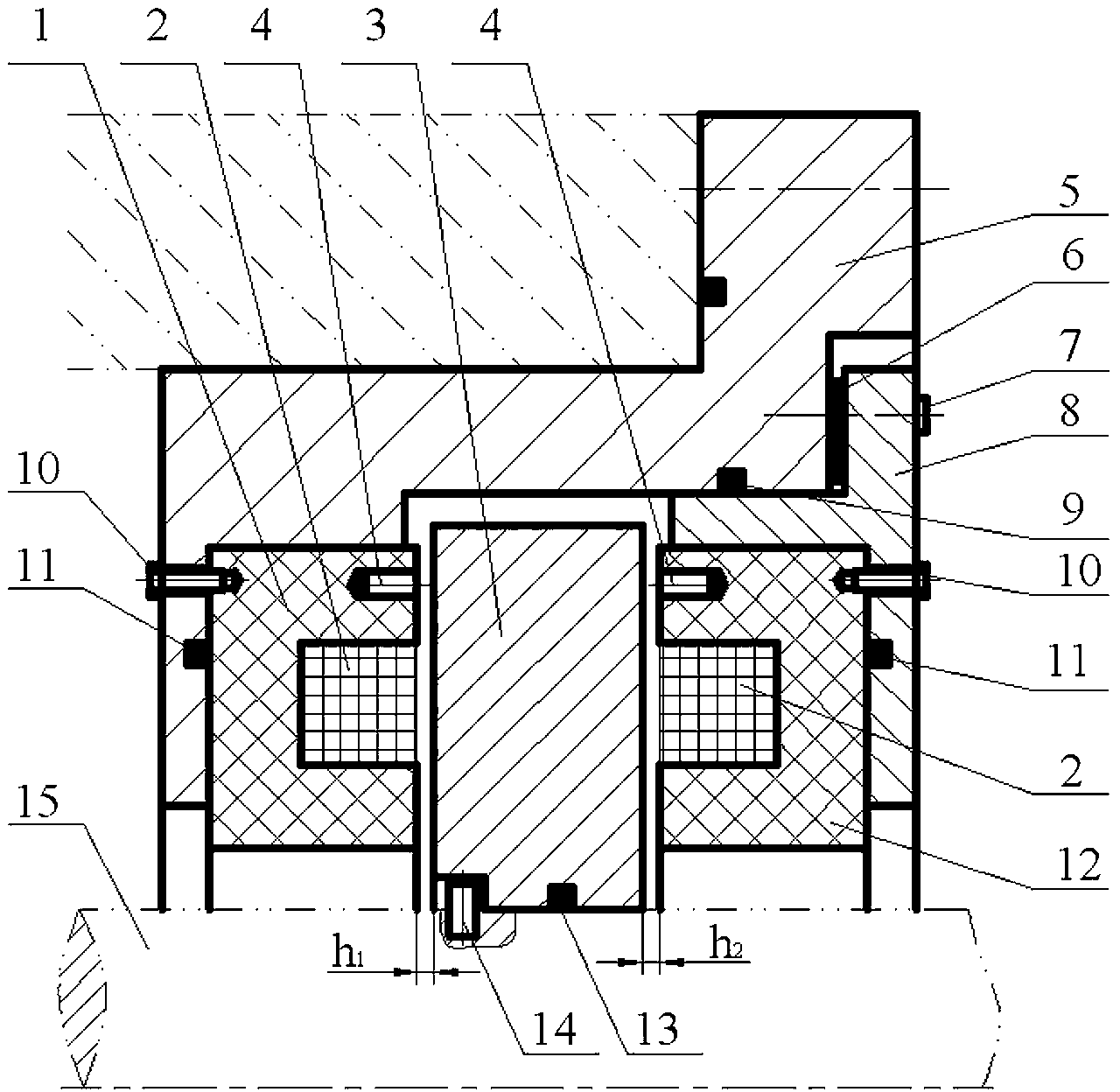

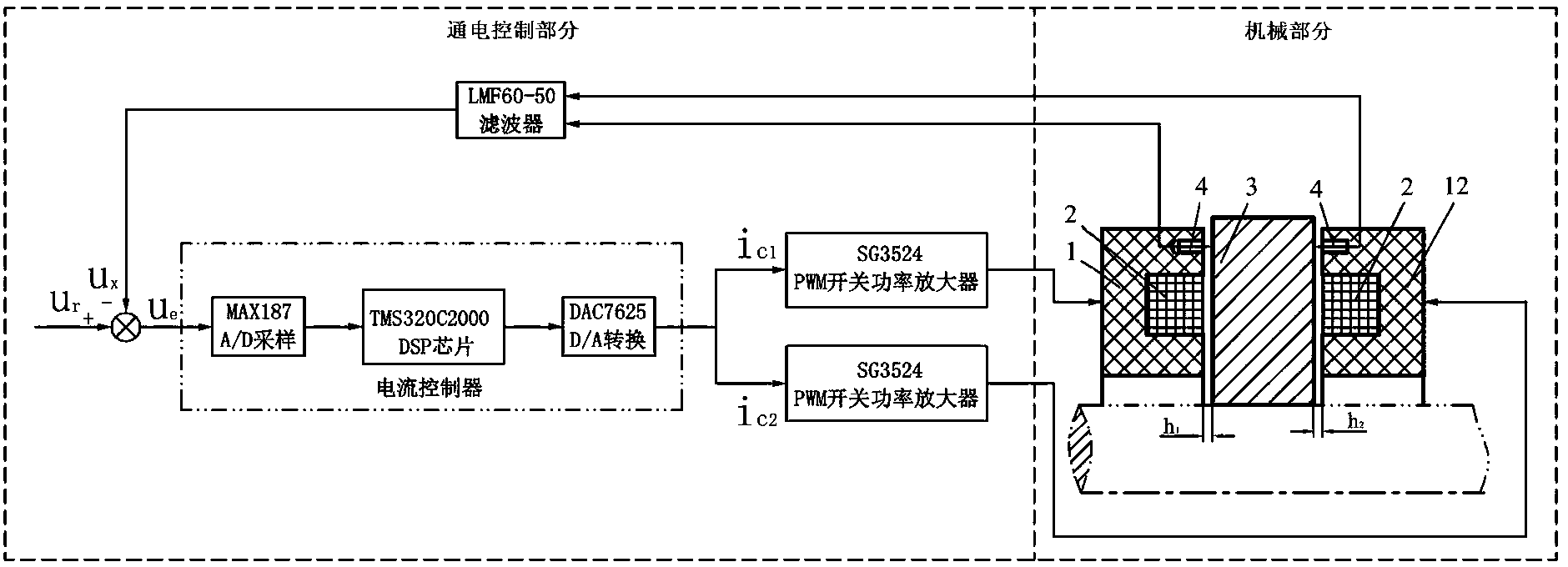

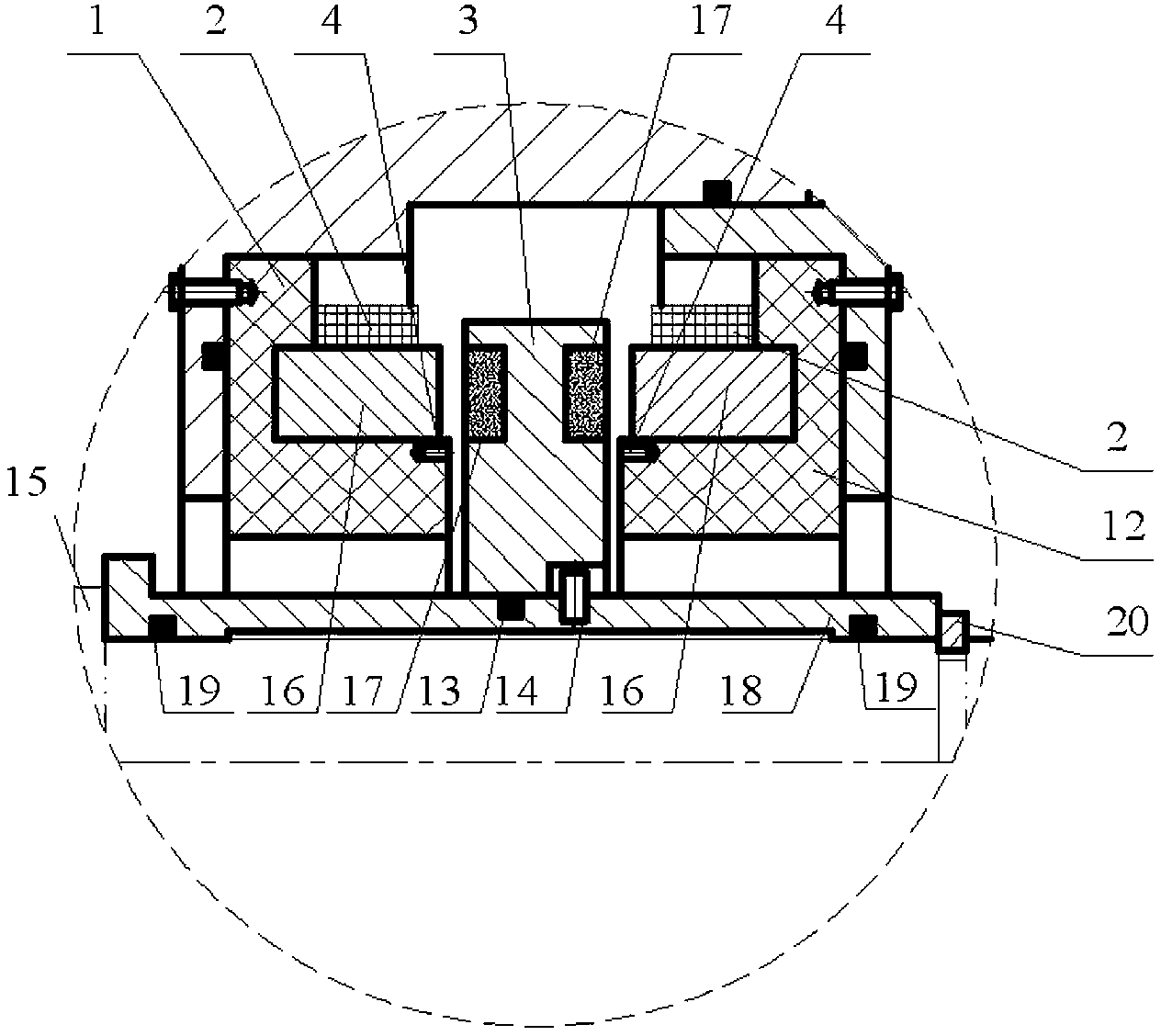

[0027] Such as figure 1 As shown, the structure of the non-contact mechanical seal device includes seal ring 1 and seal ring 12, coil 2, seal ring 3, sensor 4, stationary ring seat 5, gasket 6, screw 7, end cover 8, seal Ring 9, screw 10, static sealing ring 11, dynamic sealing ring 13, transmission pin 14 and other structures. figure 1 The sealing ring 3 in the figure is a rotating sealing ring arranged in the first sealing unit; the sealing ring 1 and the sealing ring 12 are stationary sealing rings respectively arranged in the second sealing unit.

[0028] The sealing ring 3 made of commonly used ferromagnetic materials such as silicon steel or iron-nickel alloy is directly connected with the rotary shaft 15 of the unit in a circumferentially fixed transmission connection with the pin 14 and the groove with the axial displacement gap allowed by the design, so that the sealing The ring 3 can rotate with the rotating shaft 15 during operation, and can also move axially b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com