Patents

Literature

114 results about "Fluid friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid Friction is the force that hinders the flow of a fluid. The surface of the fluid offers resistance to the flow.

Superhydrophobic coating

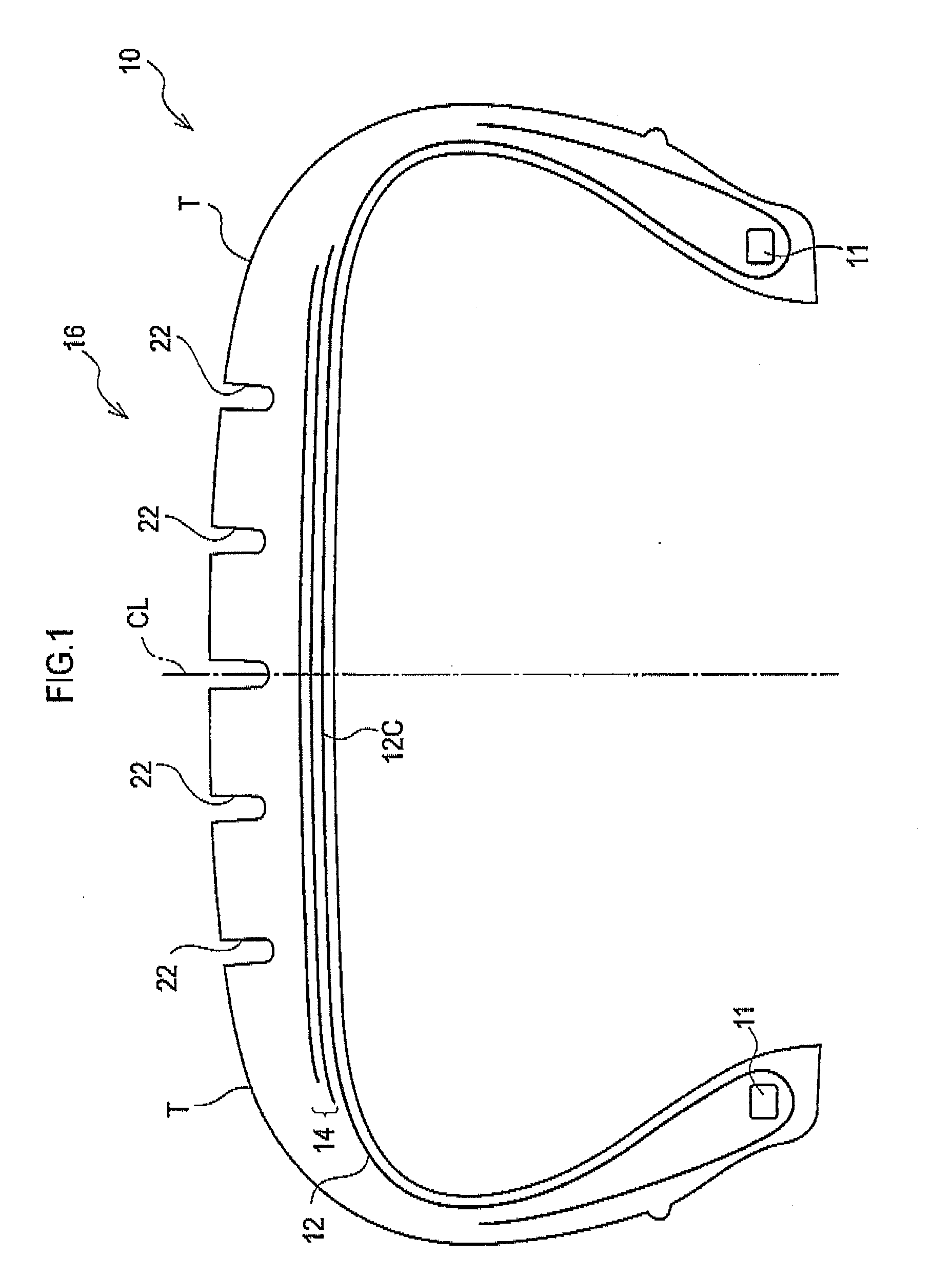

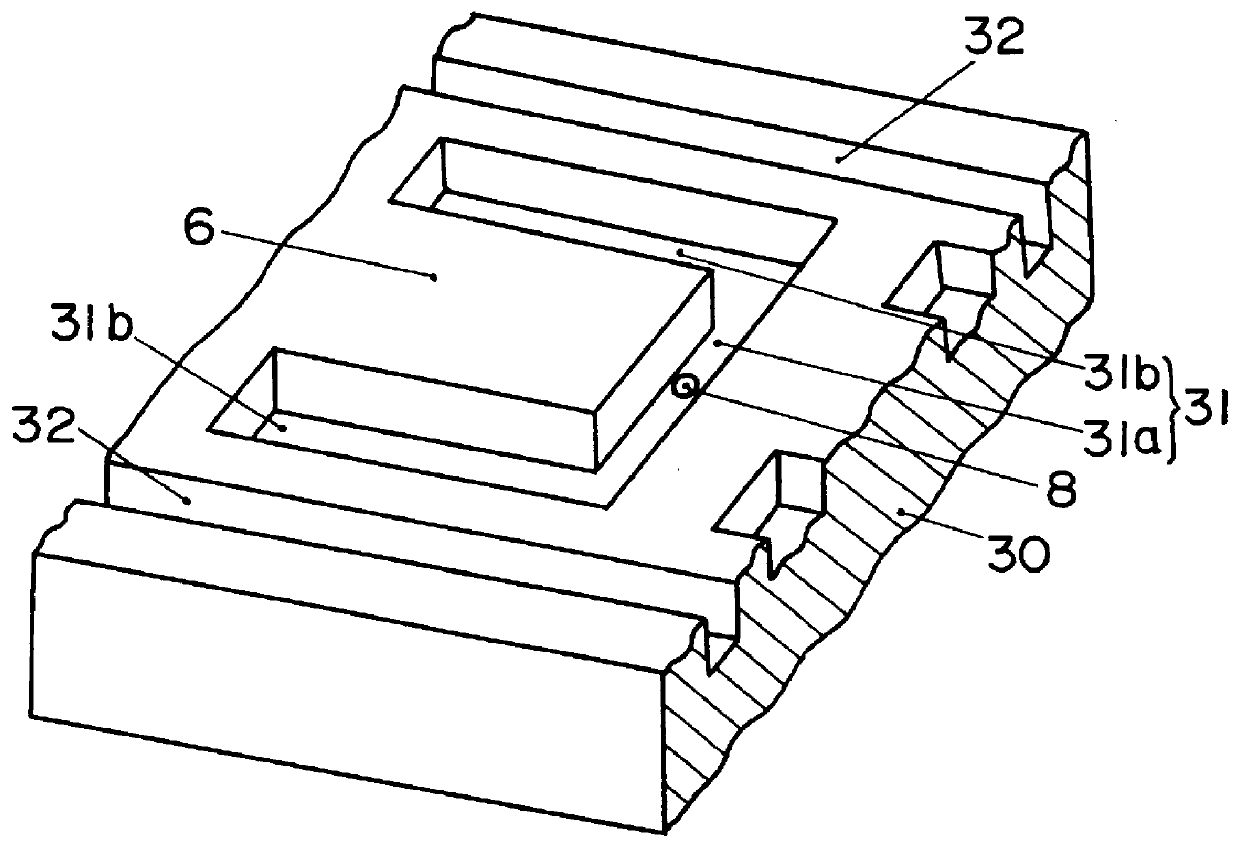

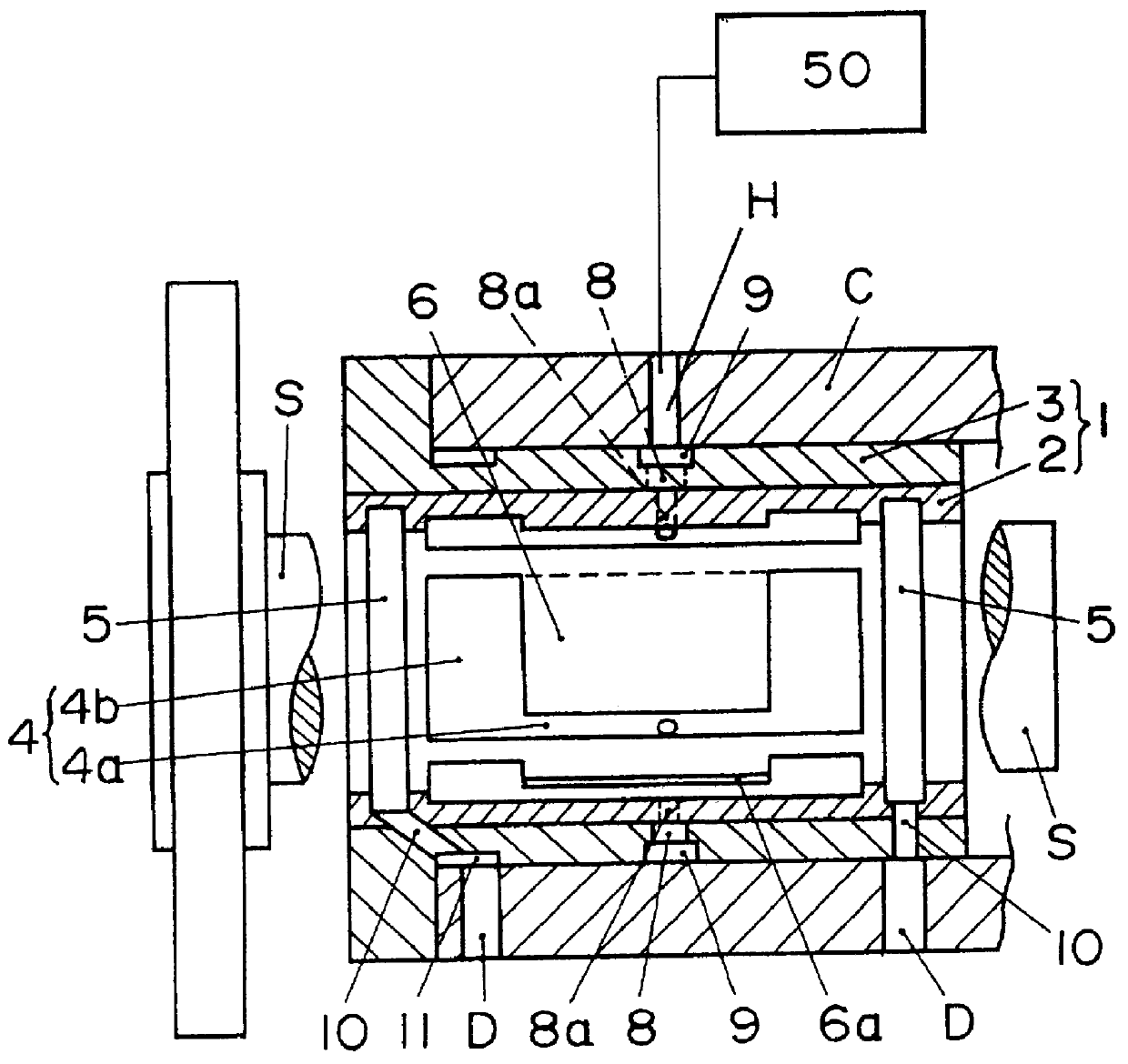

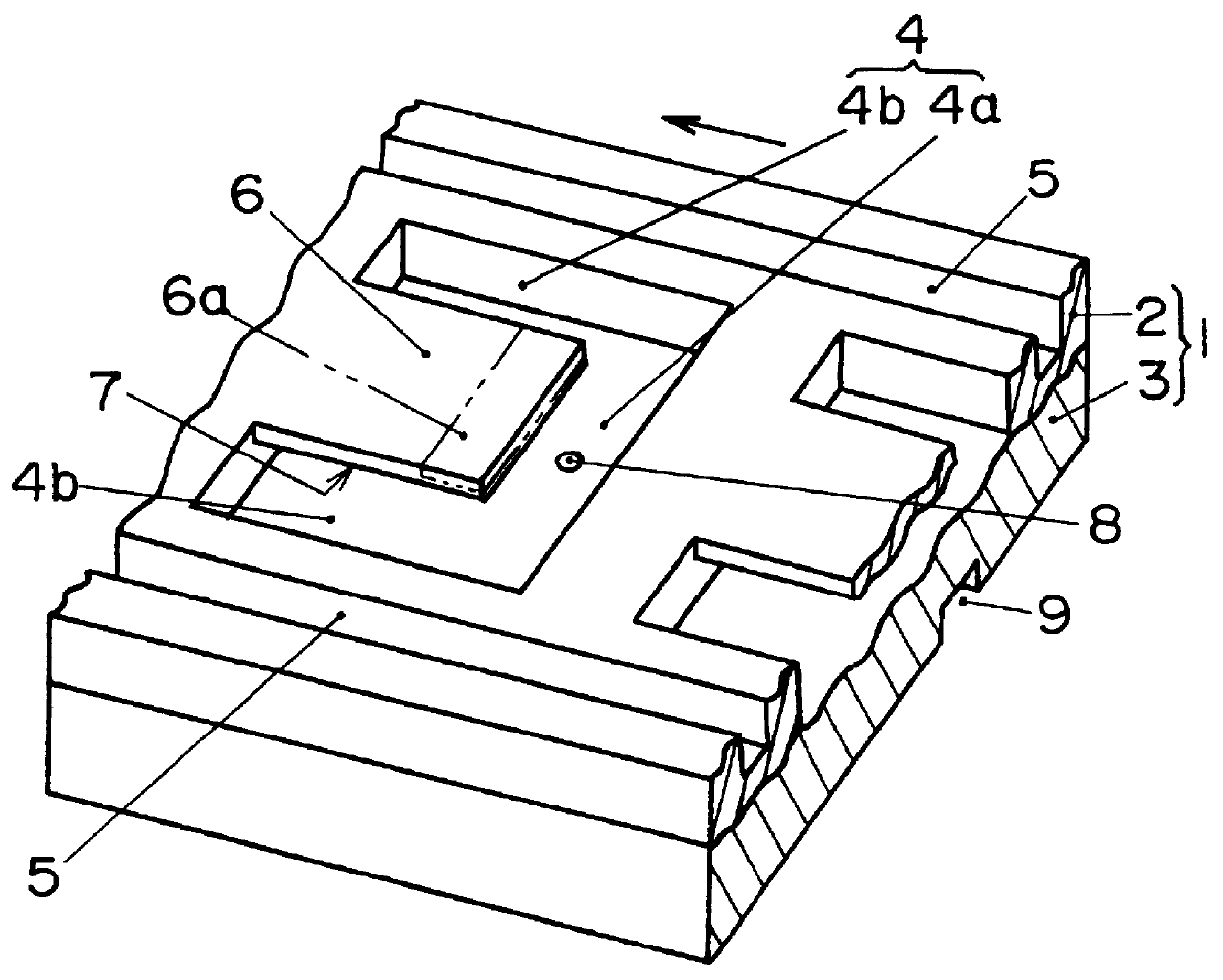

InactiveUS6994045B2Reduce frictionReduce resistanceWatercraft hull designWingsEngineeringProduct gas

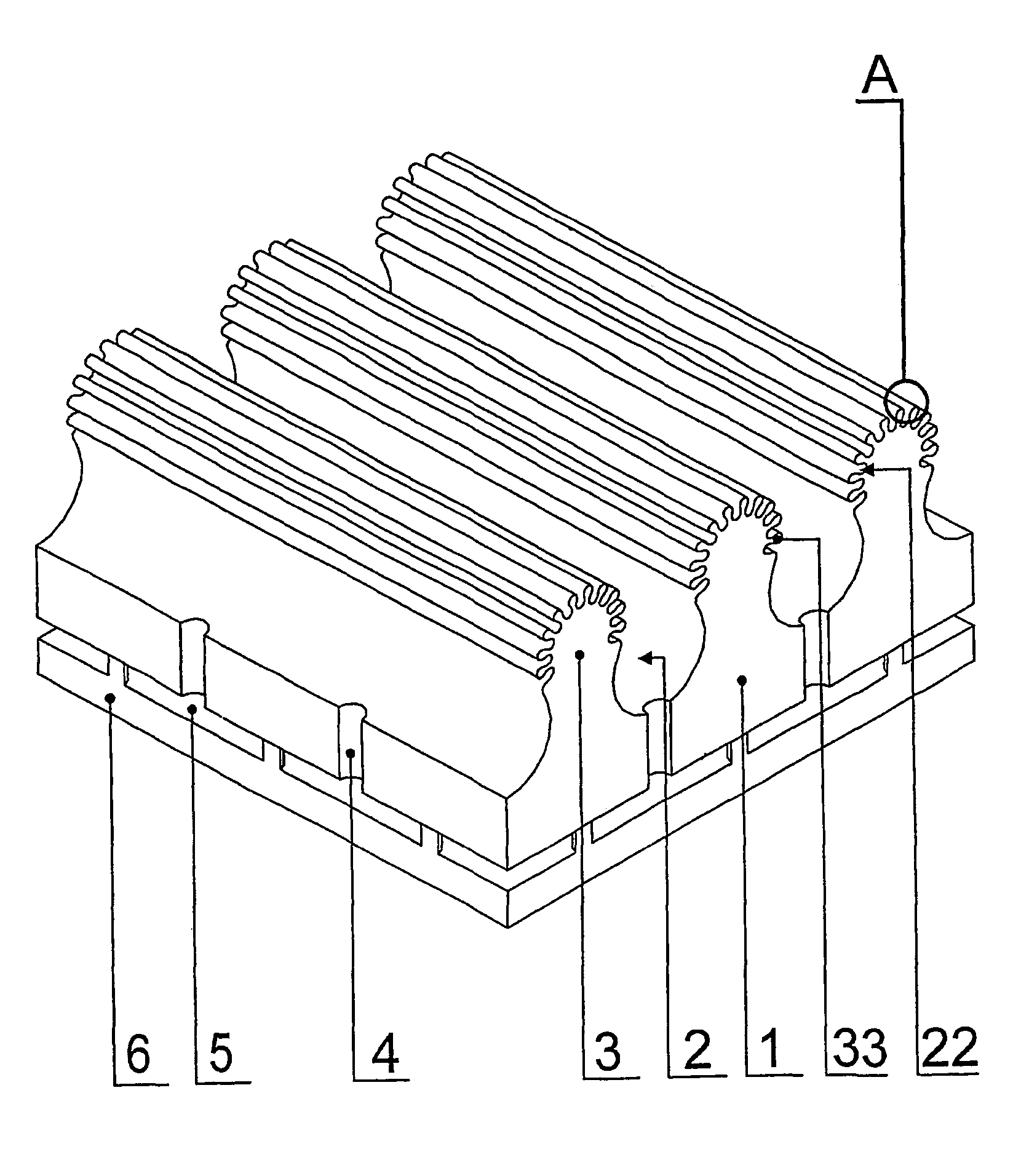

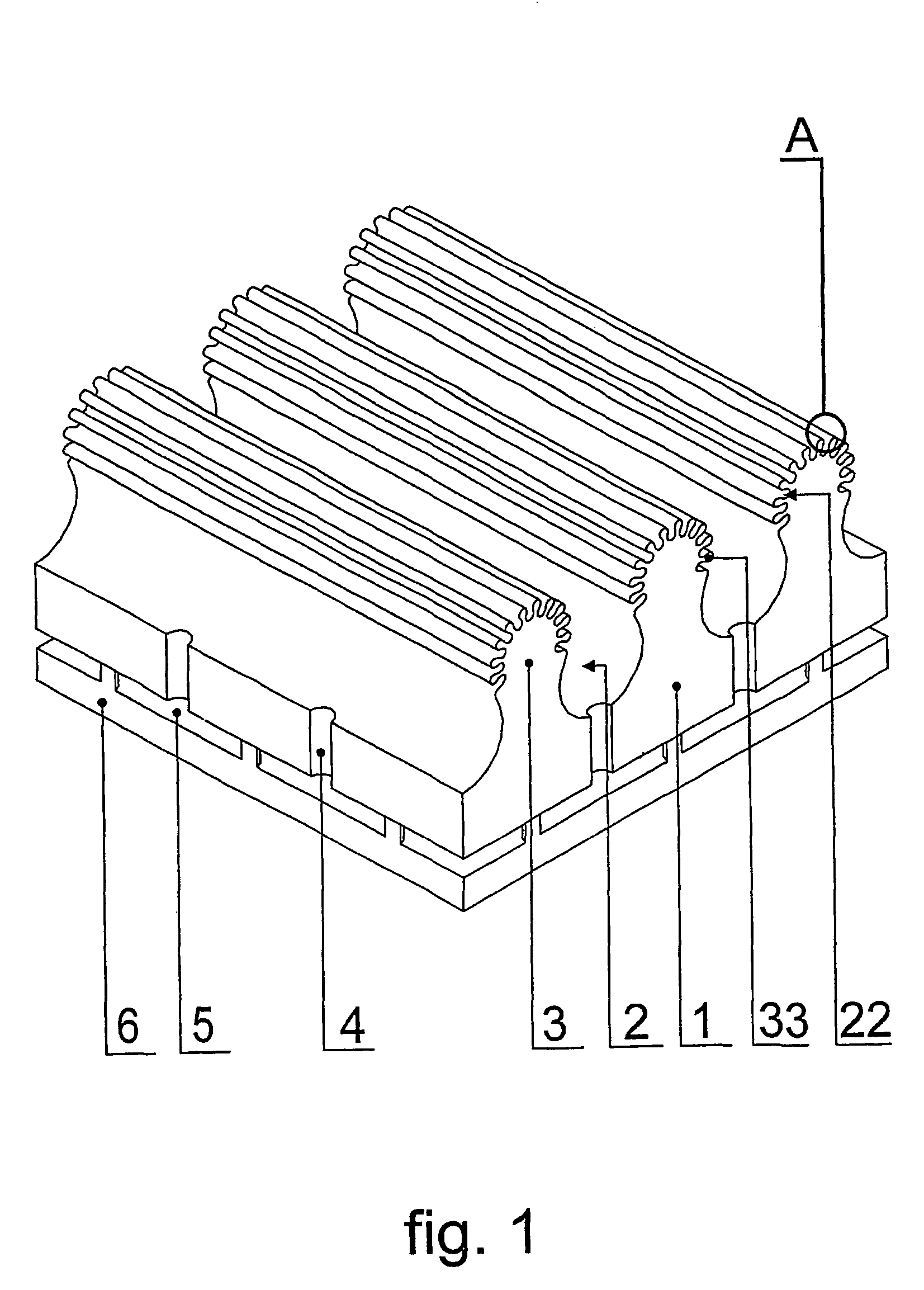

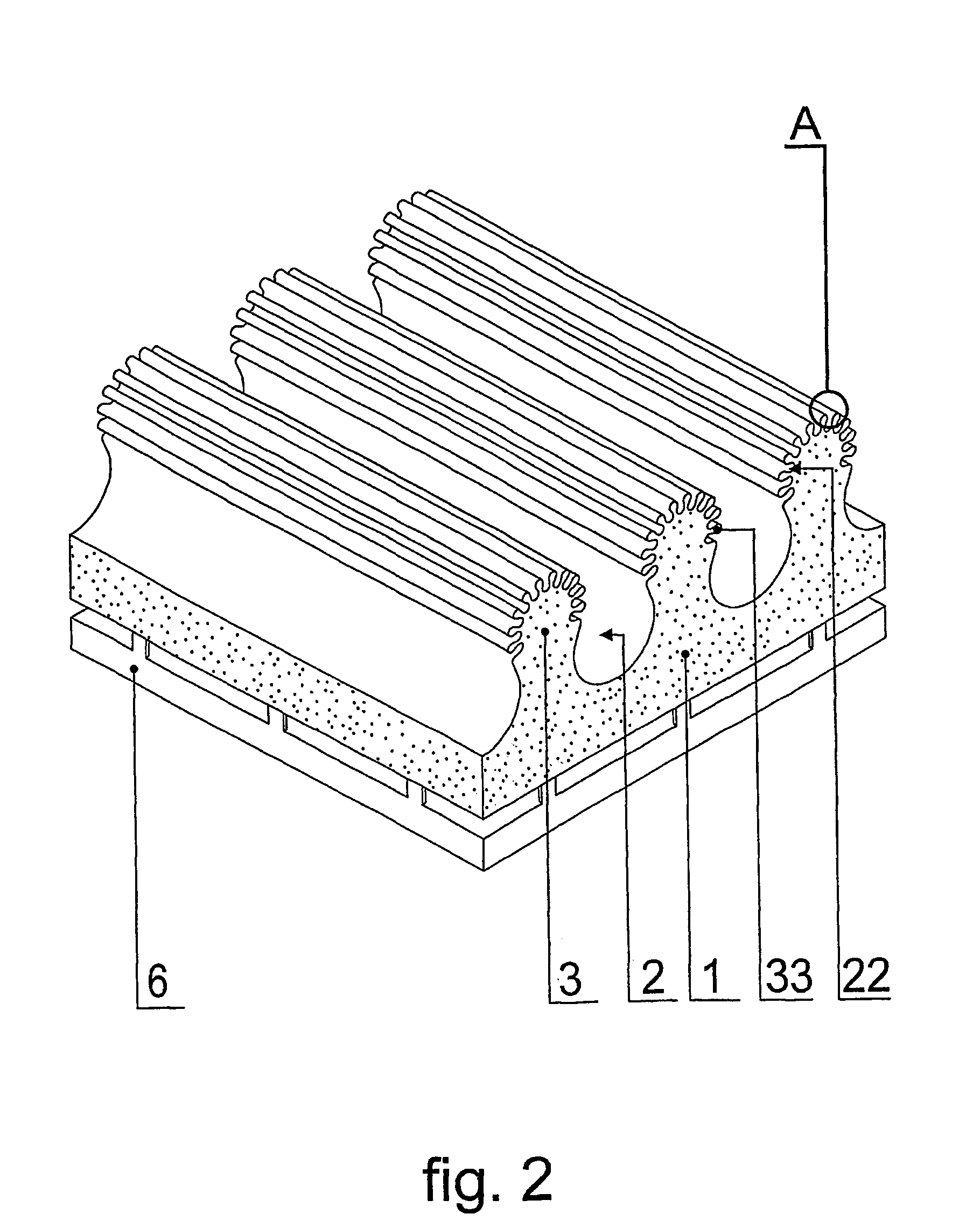

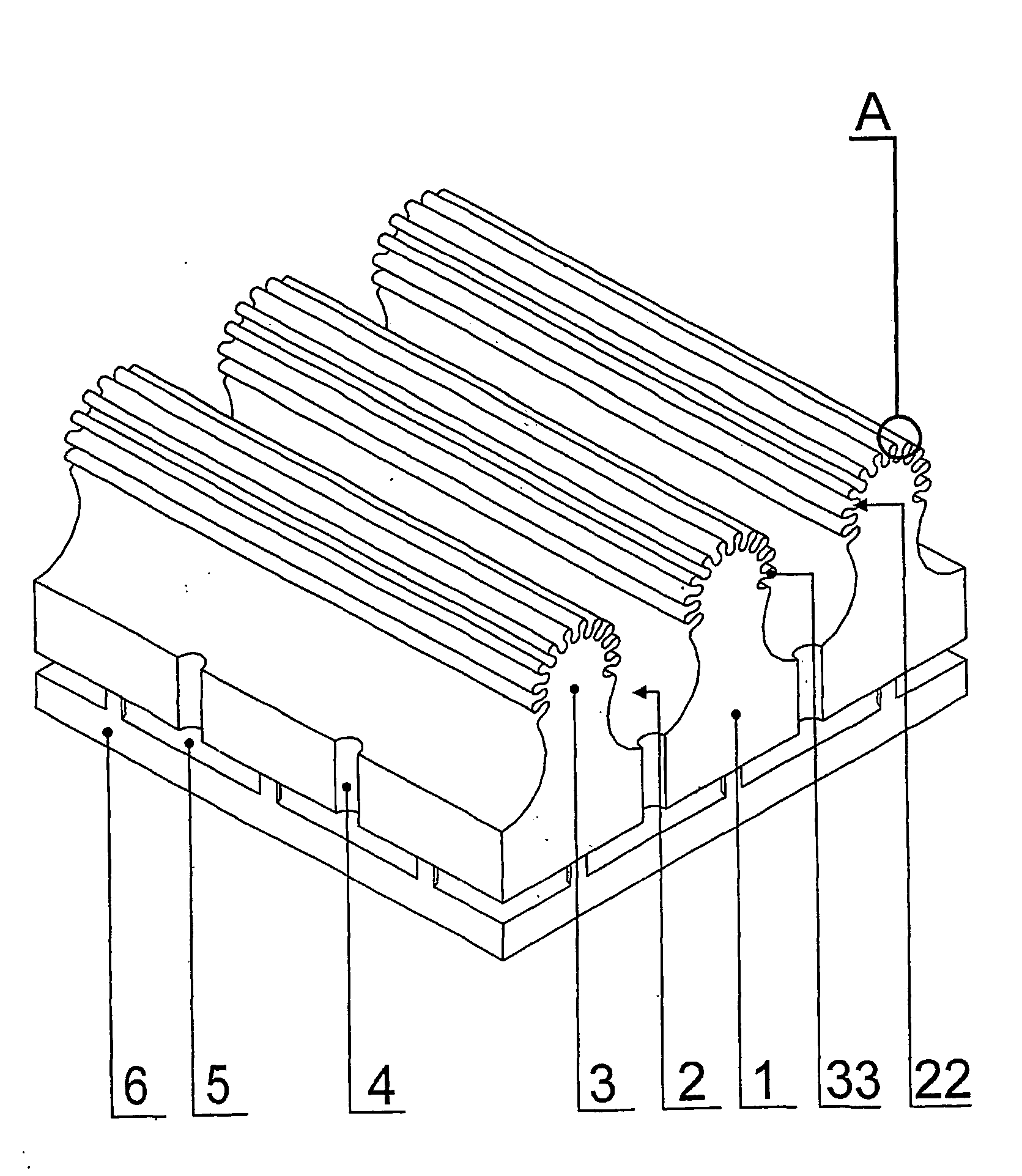

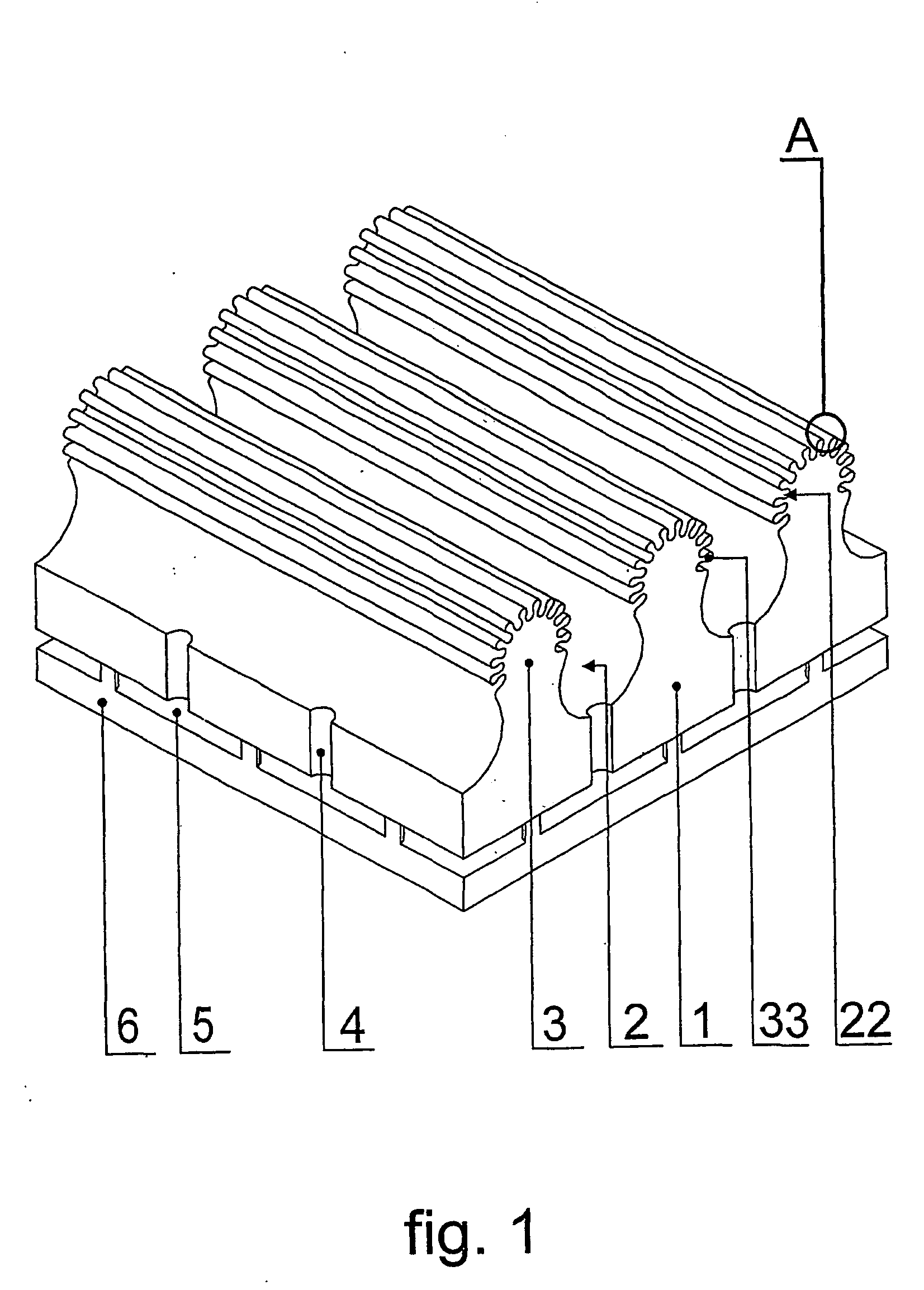

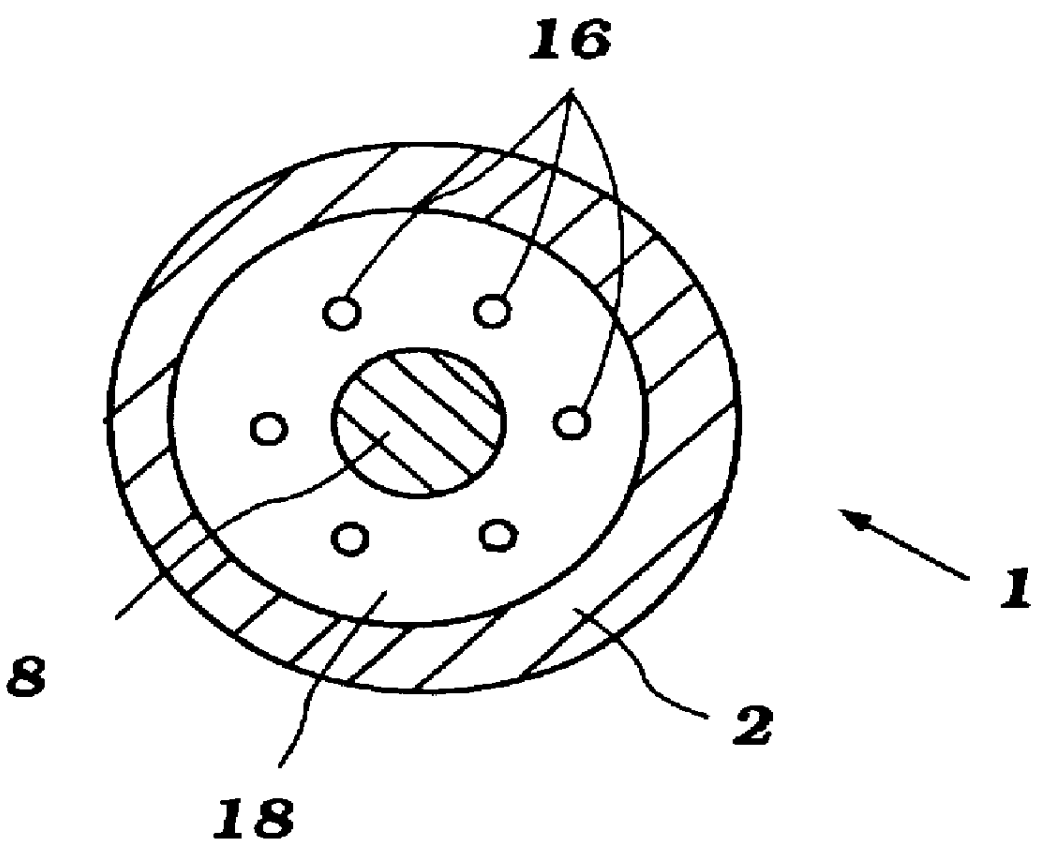

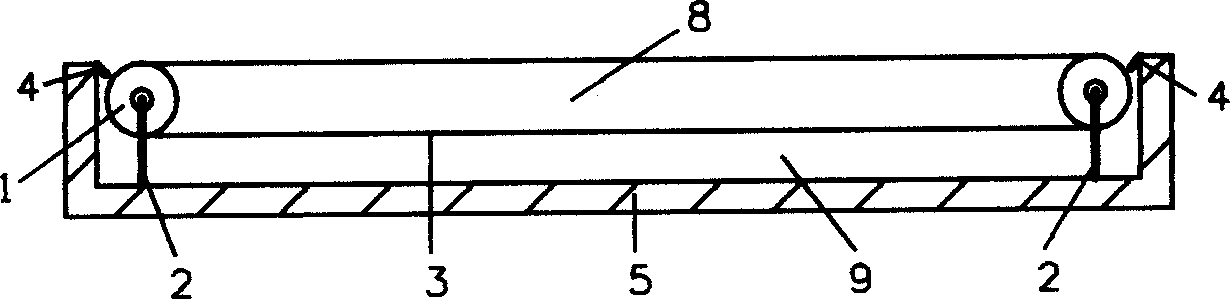

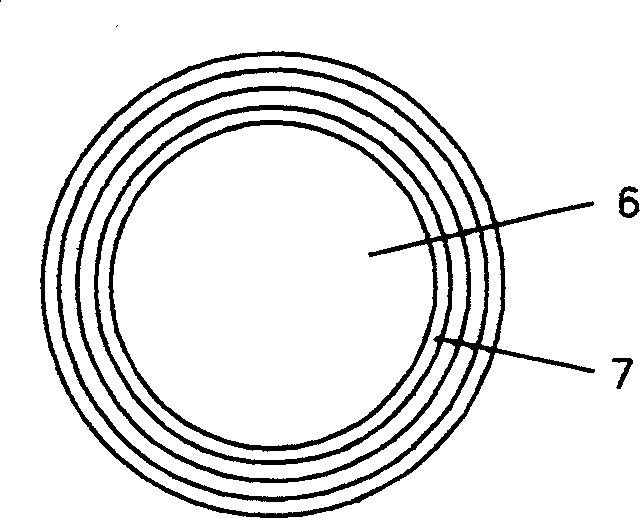

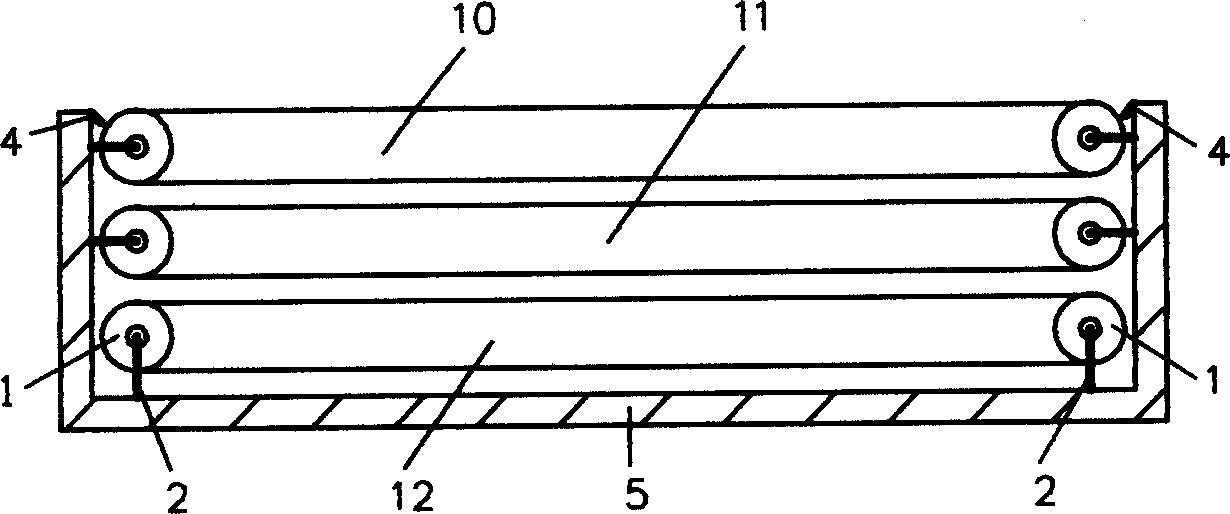

This invention solves the problem of reducing the fluid friction resistance accompanying relative movement of surfaces of a solid and a liquid. A superhydrophobic coating acting as a substrate for a gaseous lubricant of very low viscosity, reducing the fluid skin friction, has a hierarchic fracal structural of the surface wherein the forms of the first hierarchic level (2, 3, 9) are located at the coating's substrate, and the forms of each successive hierarchic level (22, 33, 99) are located on the surface of the previous hierarchic level and the forms of individual higher hierarchic levels reiterate the forms of the lower hierarchic levels. Forms of at least two hierarchic levels of rows (2, 22) and ridges (3, 33, 99) occur in the coating and, also, the surface has anisotropic geometry, maximally developed fractally in the direction transverse to the direction of flow and maximally smooth in the direction of flow and, also, has channels located in the coating's substrate to ensure gas flow.

Owner:CNT SPOLKA Z O O

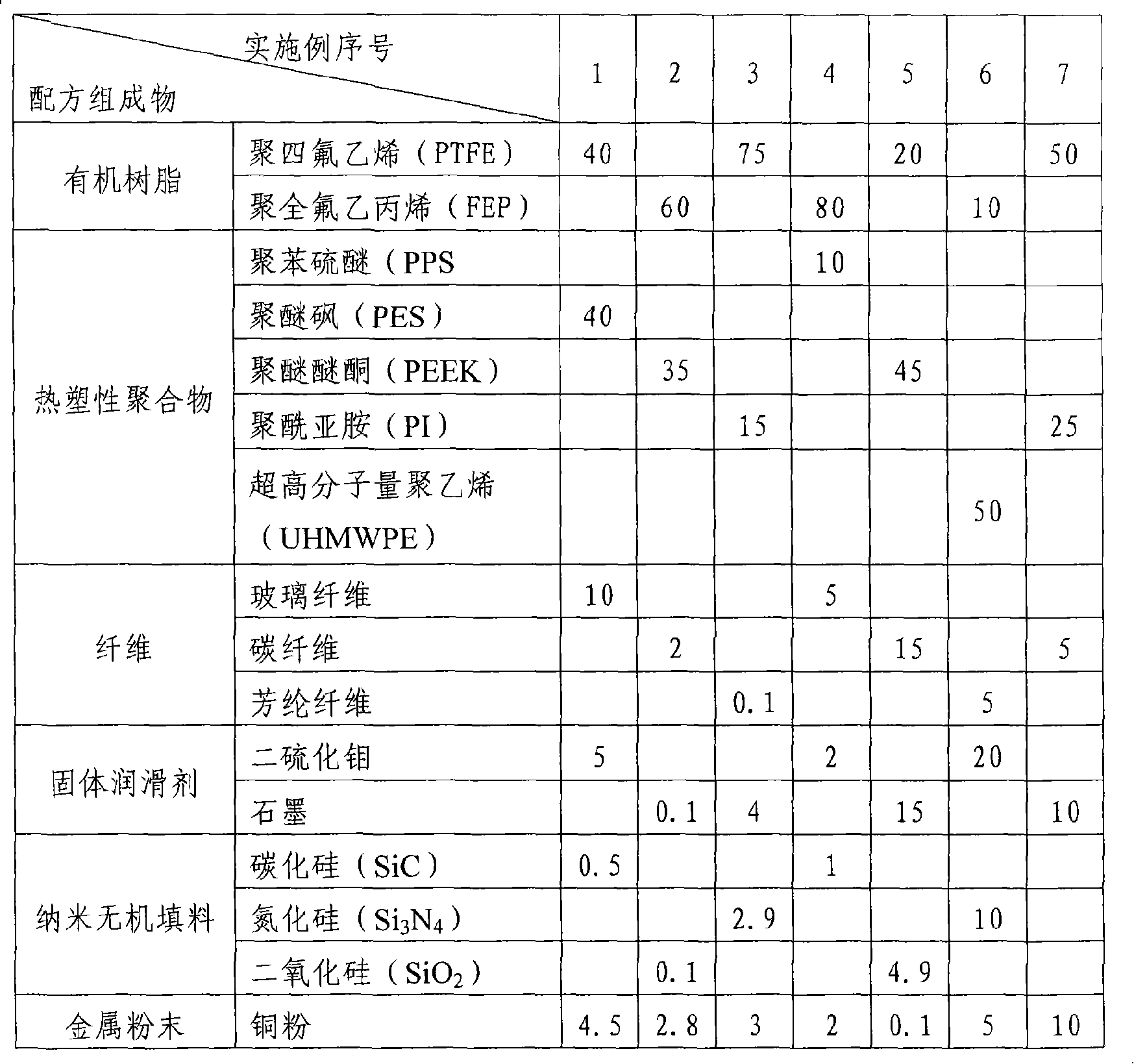

Self-lubricating sliding bearing material and its preparation method

ActiveCN101126417AImprove carrying capacityReduce frictionBearing componentsCarrying capacityMetal sheet

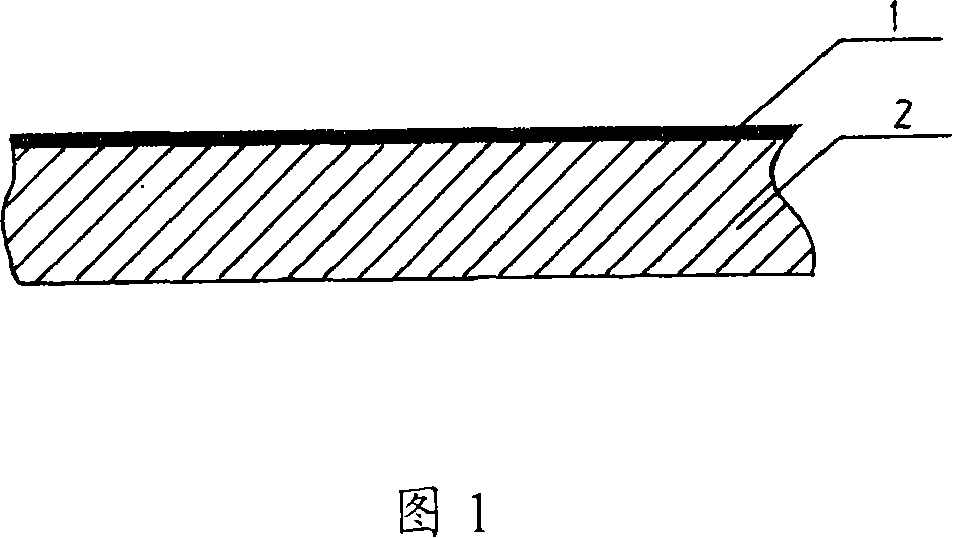

The invention discloses a self-lubrication sliding bearing material and the preparation method, the self-lubrication sliding bearing material includes a self-lubrication sliding layer made of composite material which adopts the organic resin as the basis and a metal substrate, the sliding layer and the metal substrate are directly adhered together. During the preparation, the composite material for the self-lubrication sliding layer is blended proportionally and is laid on the metal sheet after being mixed mechanically, the surface of the metal sheet is treated, and then the metal sheet is sintered in a sintering furnace, then rolled immediately after the sintering process so that the surface coat is adhered on the metal substrate. The sliding bearing made of the material provided by the invention has the characteristics of higher carrying capacity and low friction and good wearing resistance, the metal substrate and the self-lubrication sliding layer can be stably adhered with each other, and is suitable for the dry friction and boundary or fluid friction conditions.

Owner:COB PRECISION PARTS

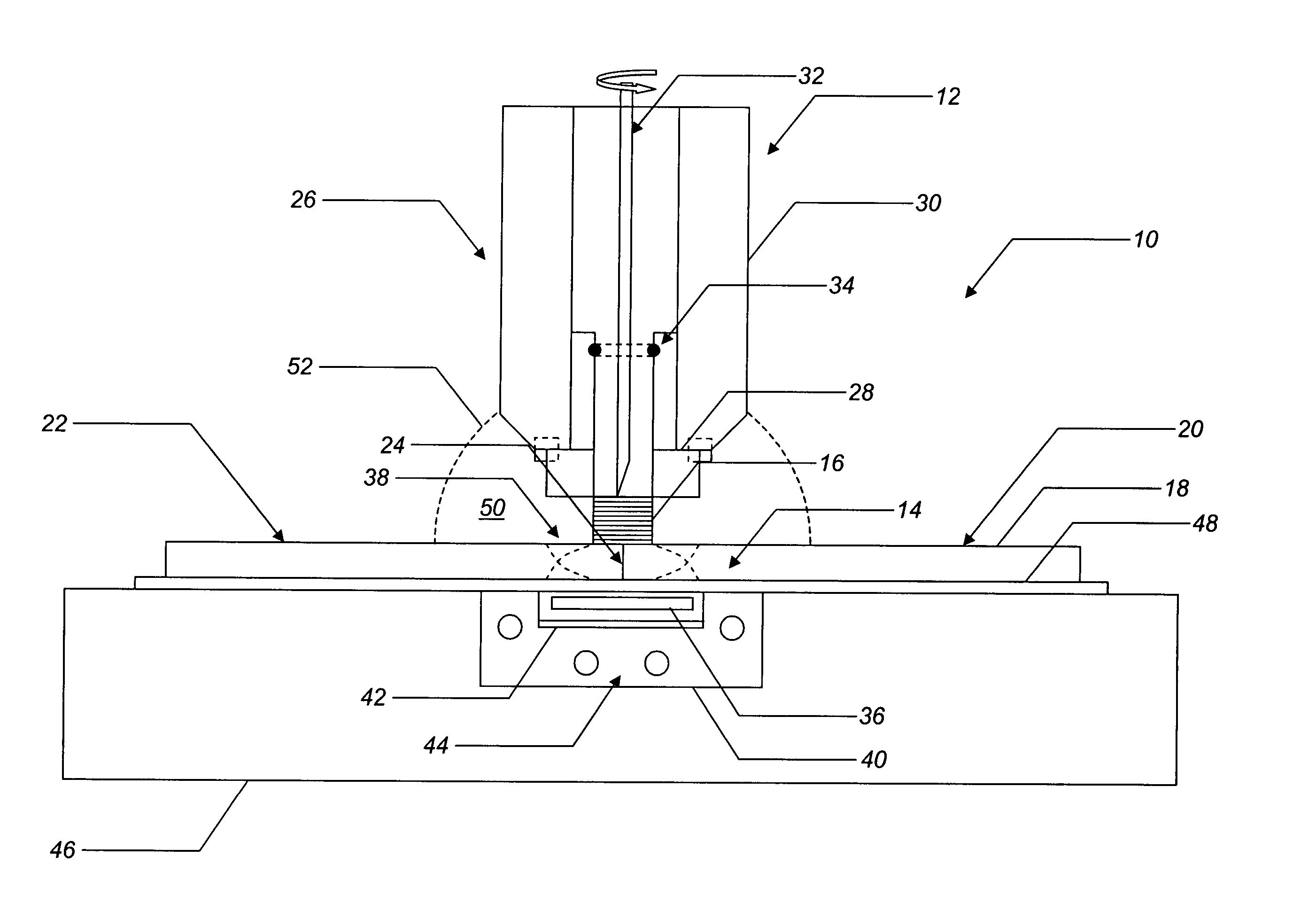

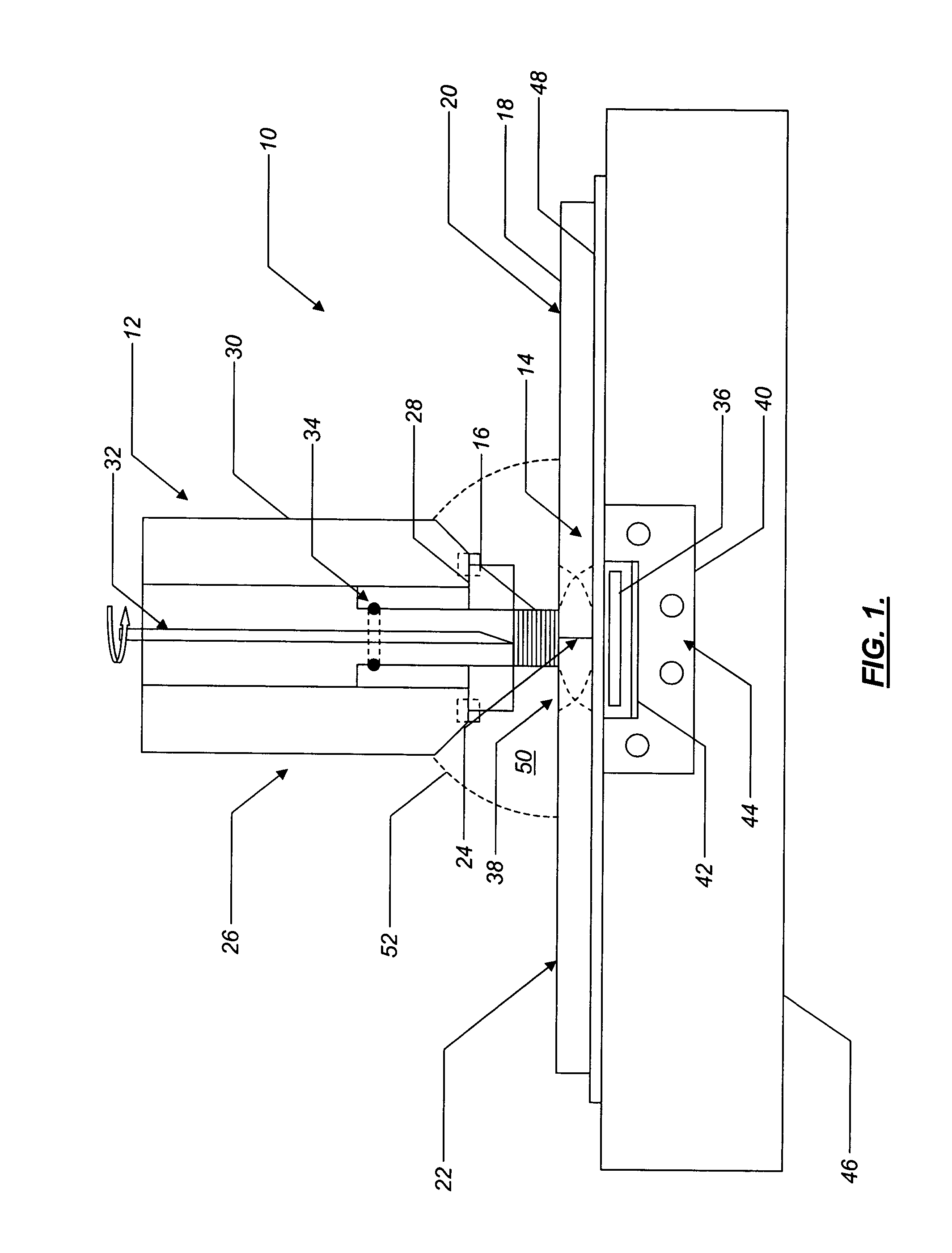

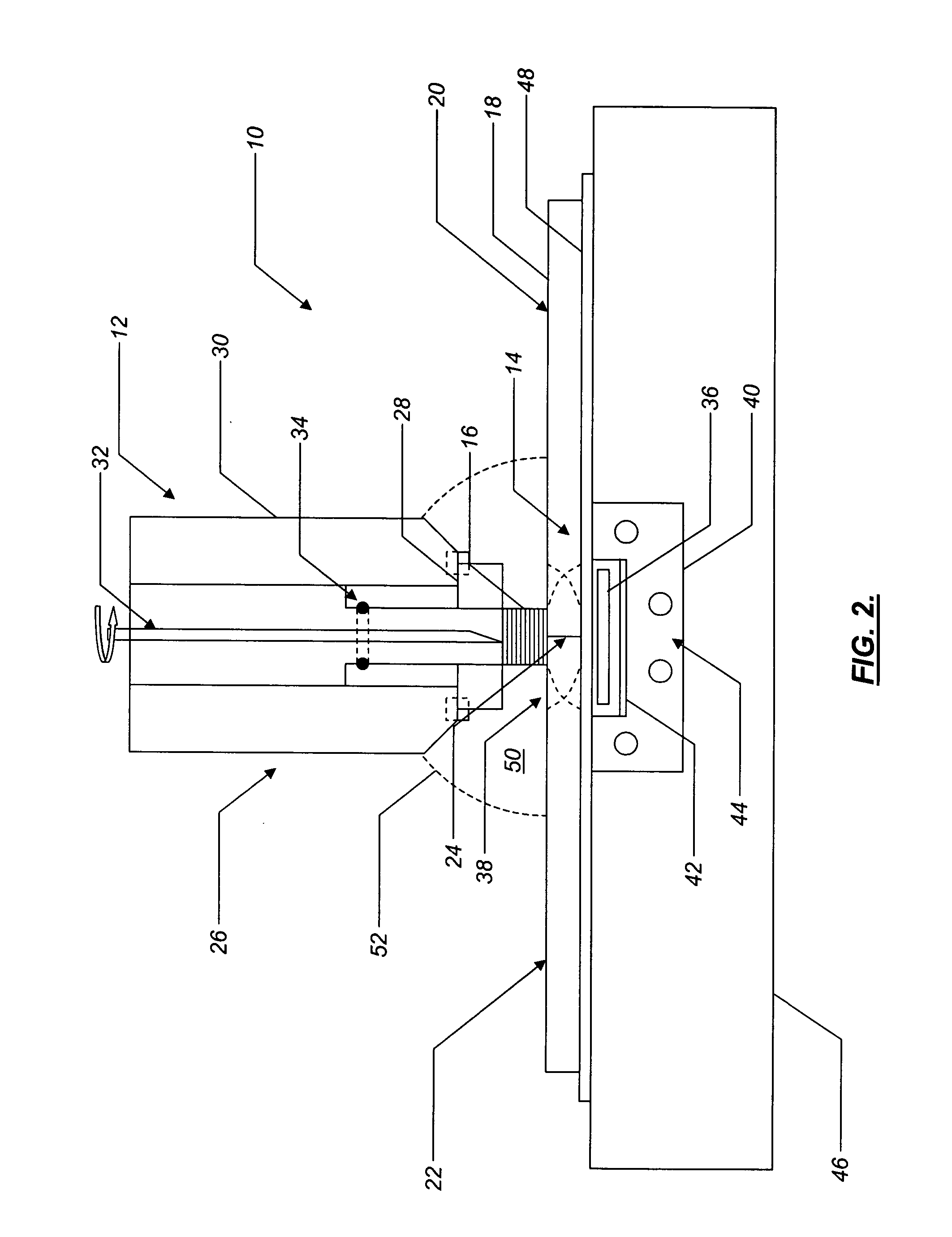

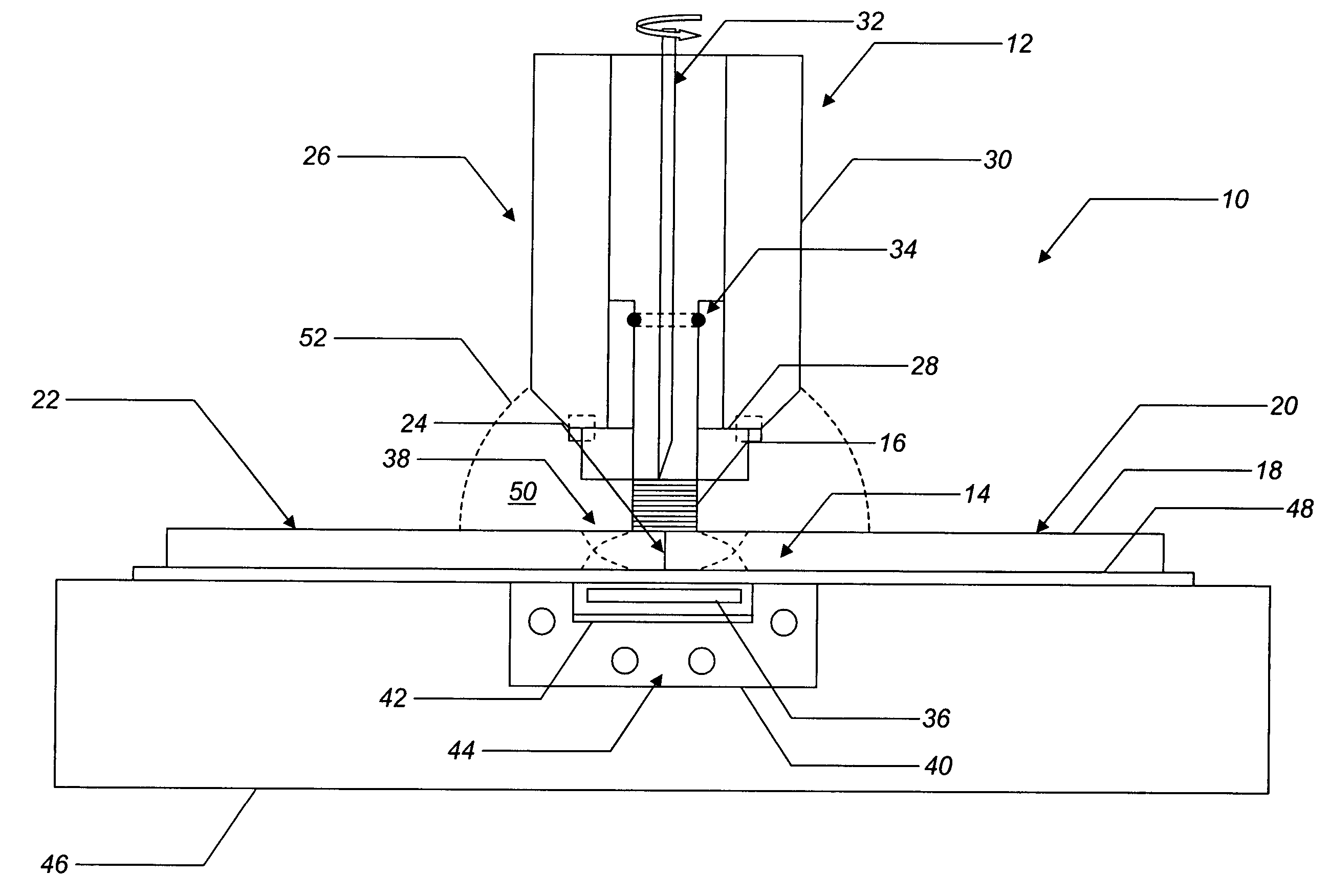

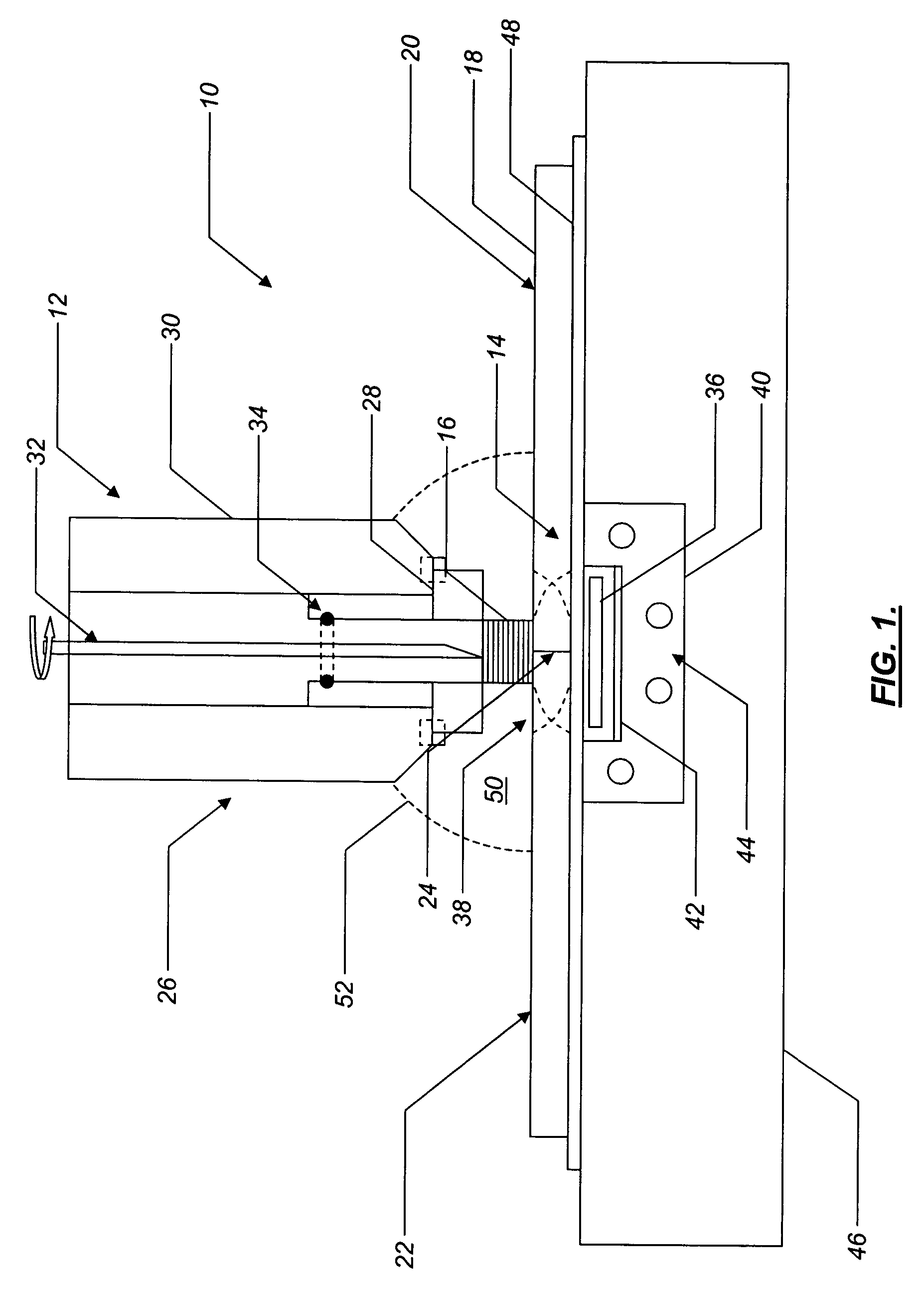

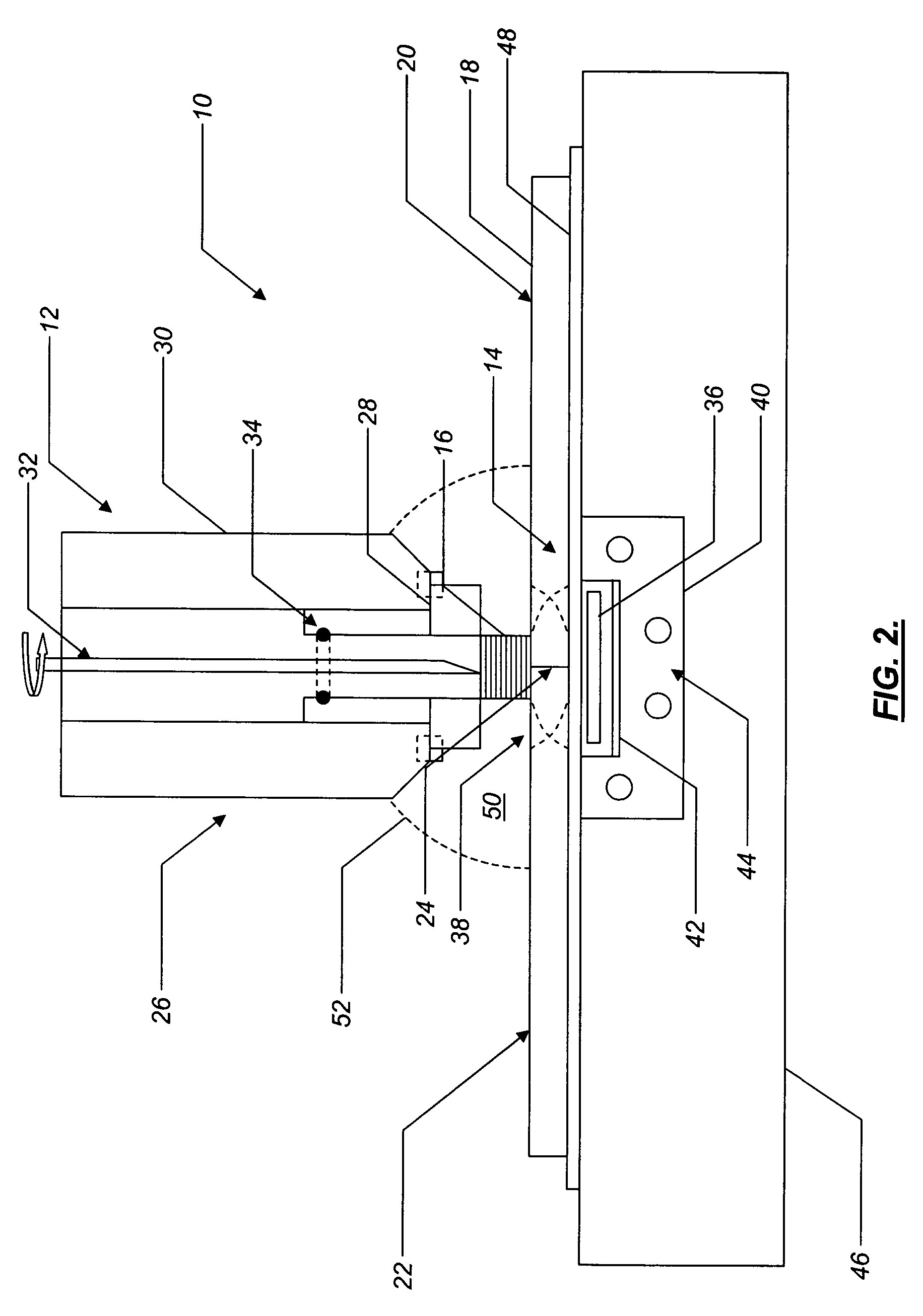

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

Superhydrophobic coating

InactiveUS20050061221A1Reduction of fluid friction resistanceReduce resistanceWatercraft hull designWingsEngineeringSuperhydrophobic coating

This invention solves the problem of reducing the fluid friction resistance accompanying relative movement of surfaces of a solid and a liquid. A superhydrophobic coating acting as a substrate for a gaseous lubricant of very low viscosity, reducing the fluid skin friction, has a hierarchic fracal structural of the surface wherein the forms of the first hierarchic level (2, 3, 9) are located at the coating's substrate, and the forms of each successive hierarchic level (22, 33, 99) are located on the surface of the previous hierarchic level and the forms of individual higher hierarchic levels reiterate the forms of the lower hierarchic levels. Forms of at least two hierarchic levels of rows (2, 22) and ridges (3, 33, 99) occur in the coating and, also, the surface has anisotropic geometry, maximally developed fractally in the direction transverse to the direction of flow and maximally smooth in the direction of flow and, also, has channels located in the coating's substrate to ensure gas flow.

Owner:CNT SPOLKA Z O O

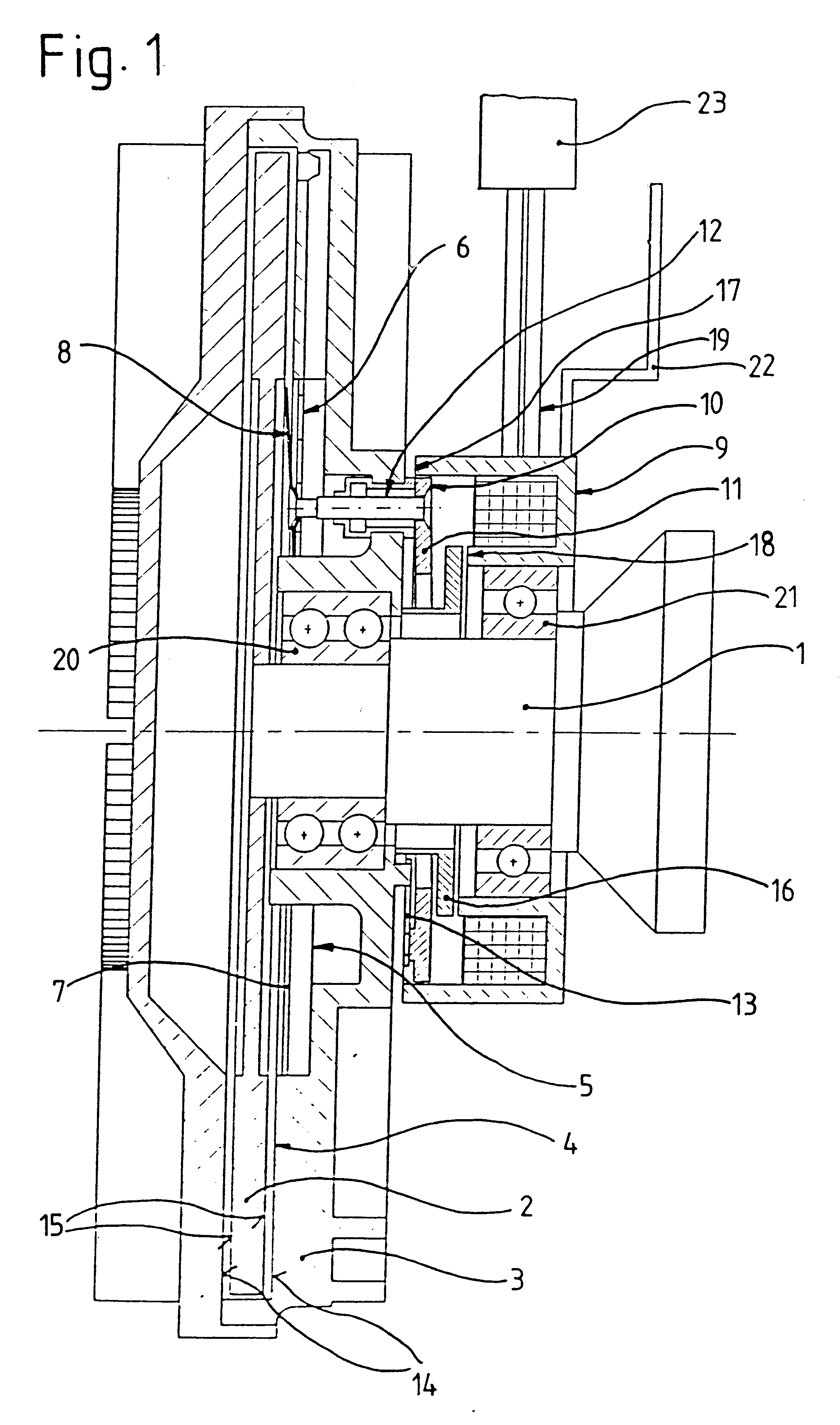

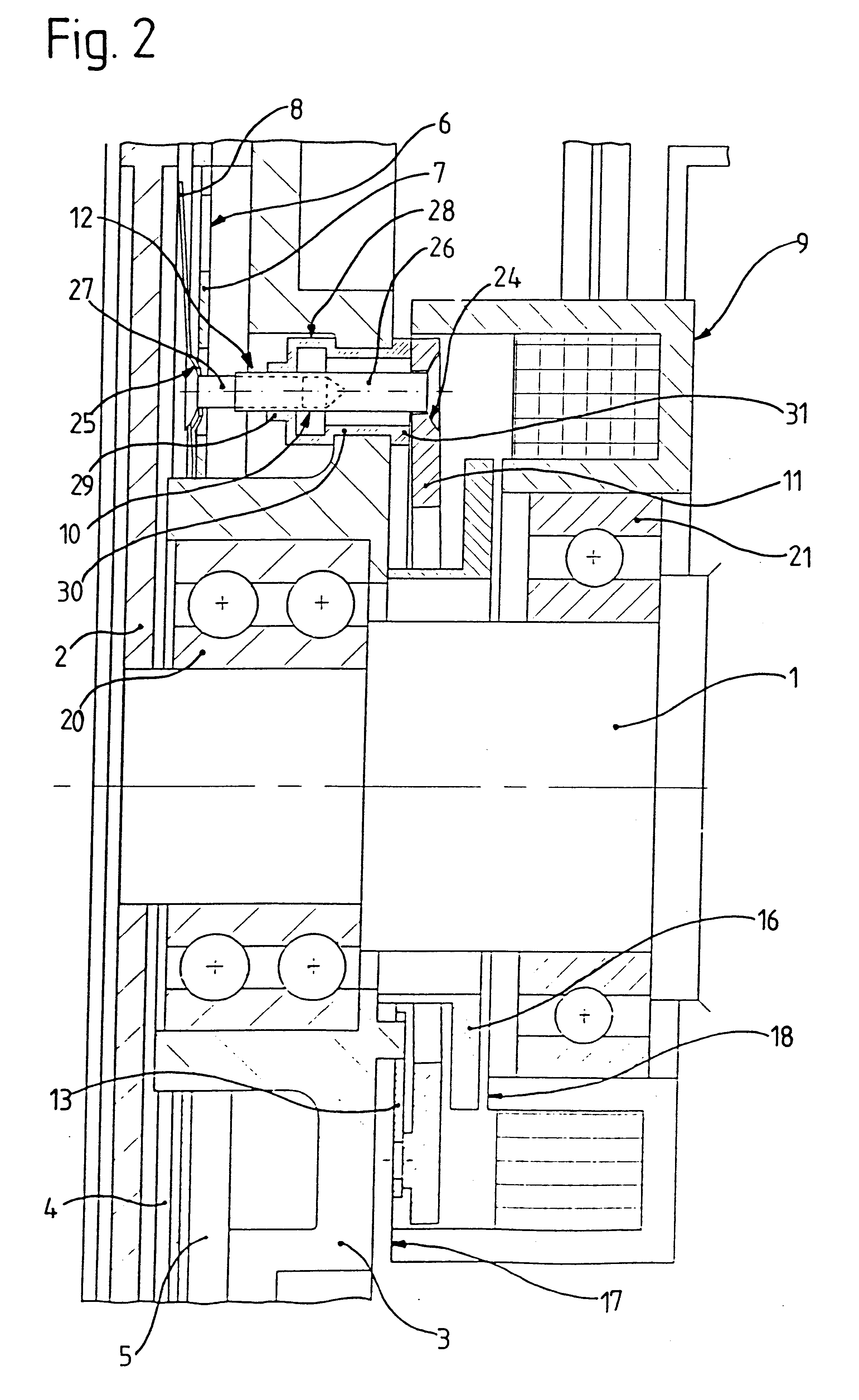

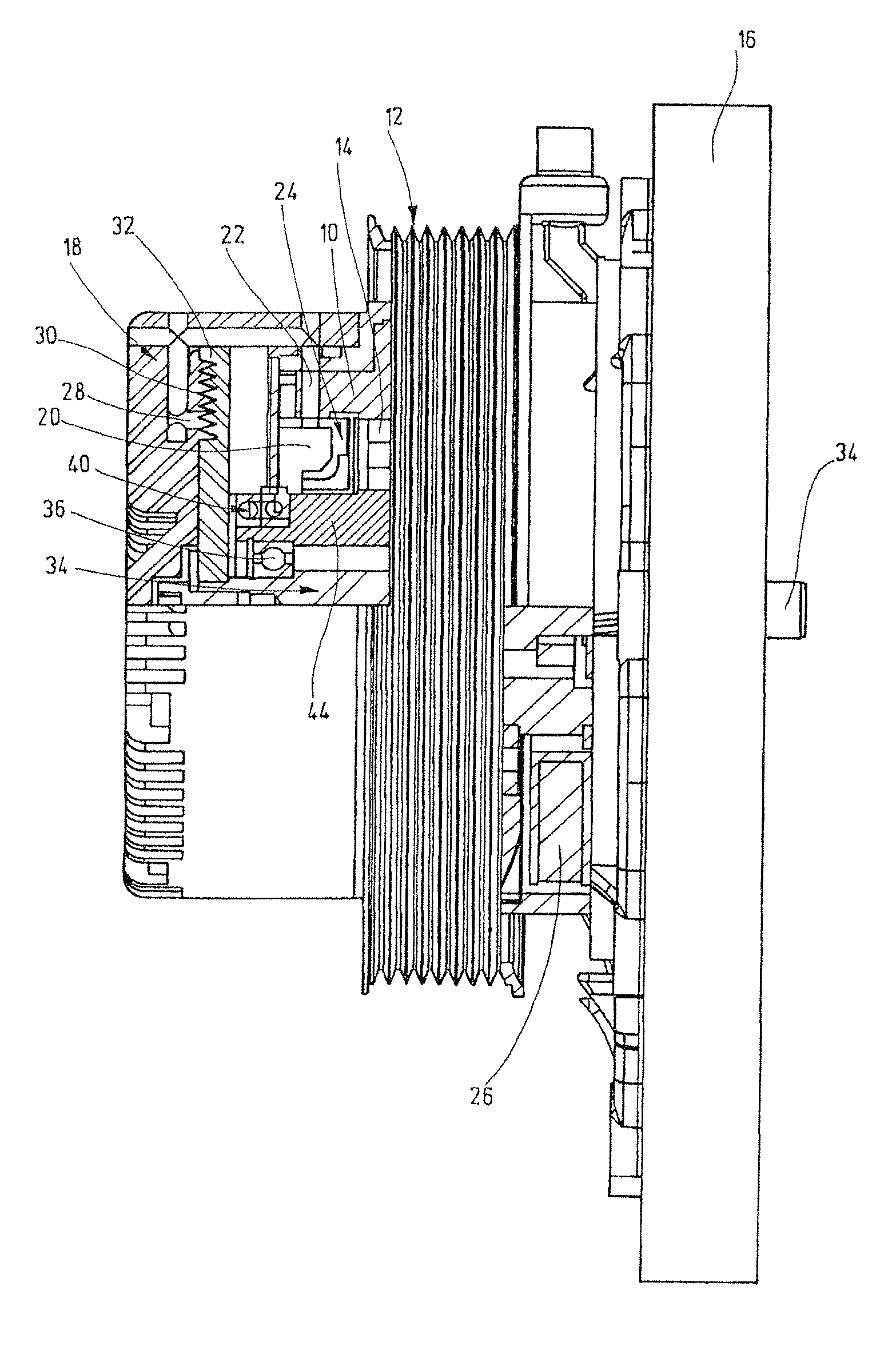

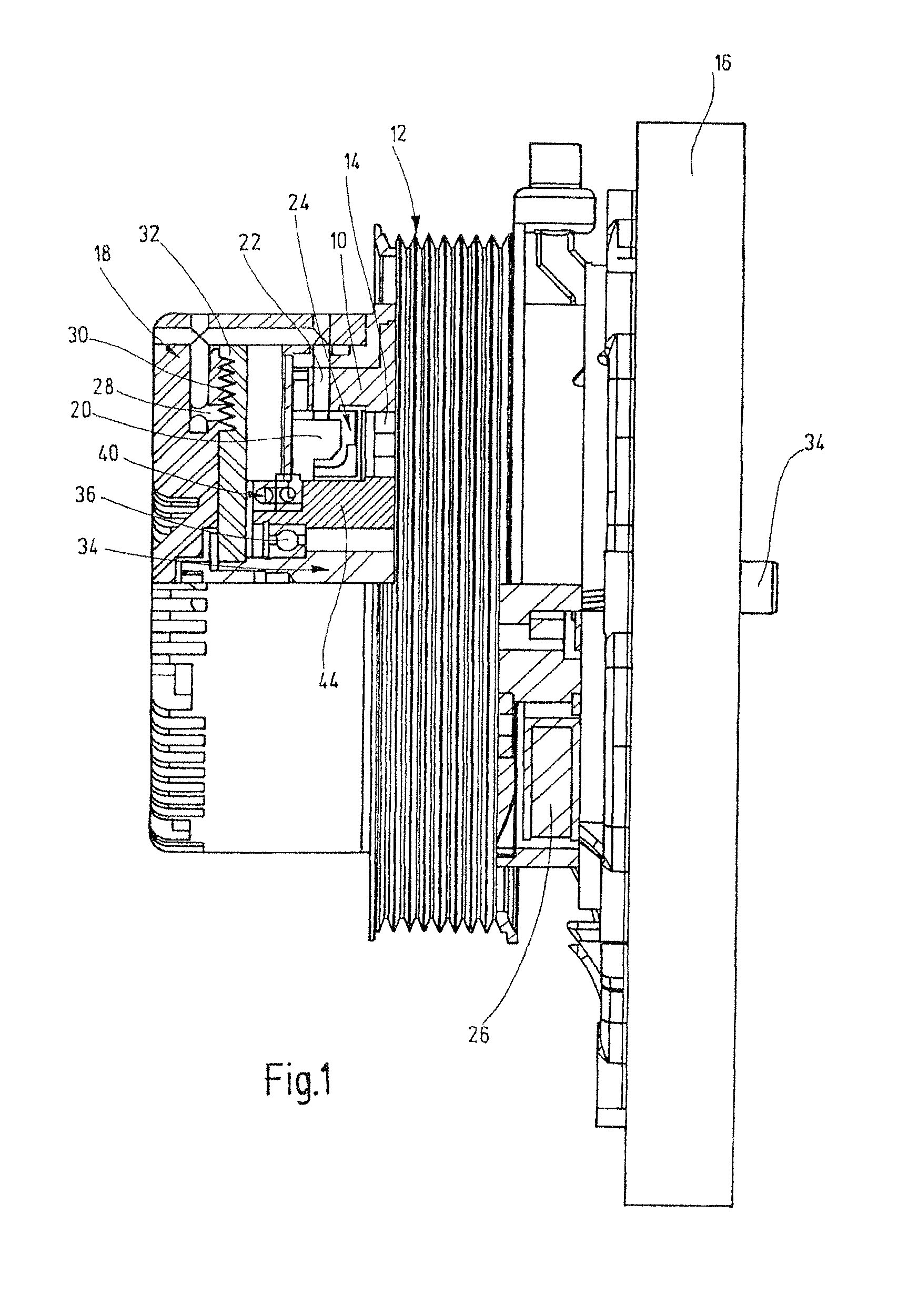

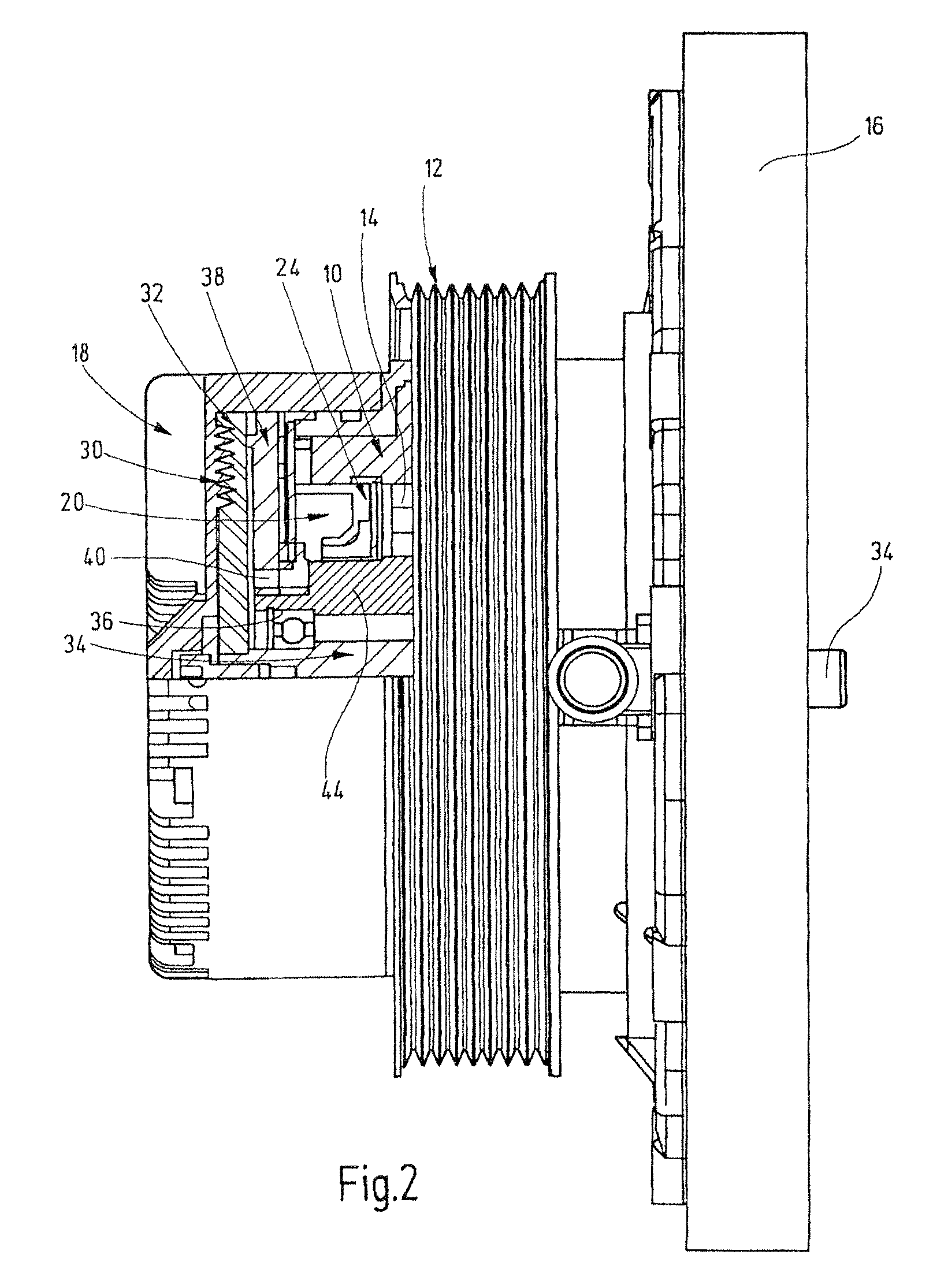

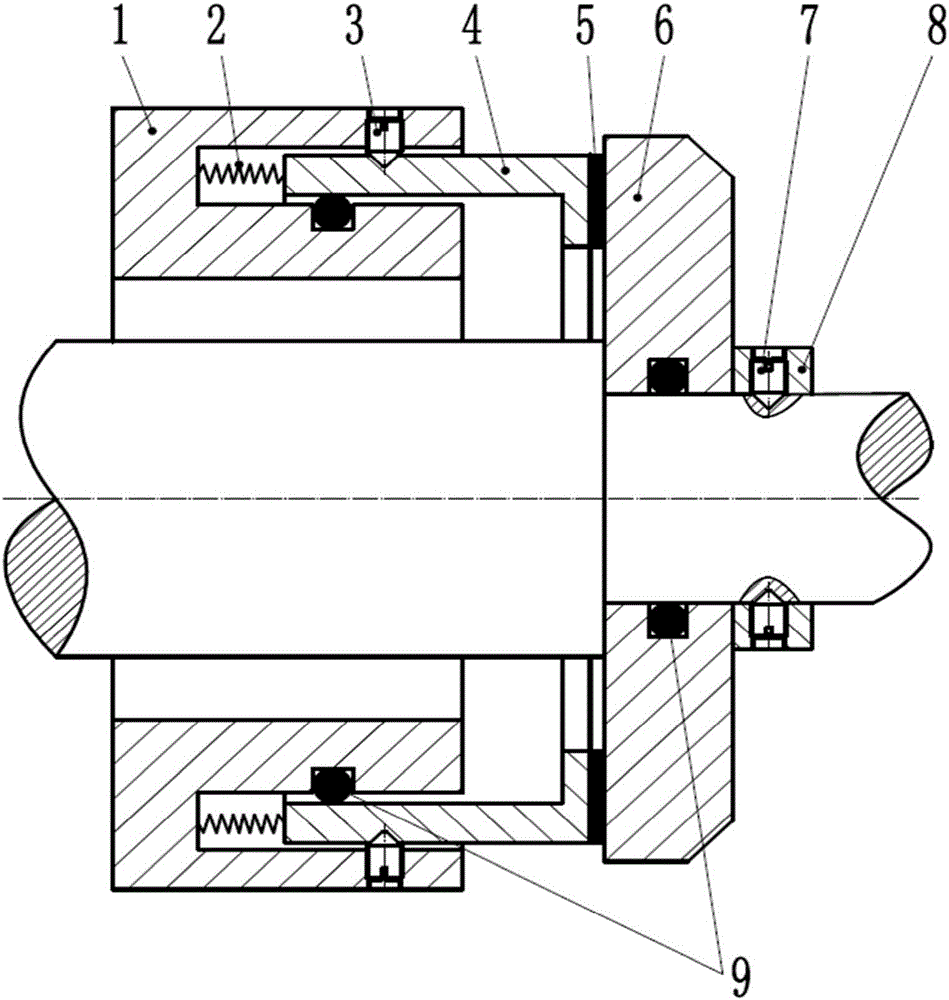

Fluid friction coupling

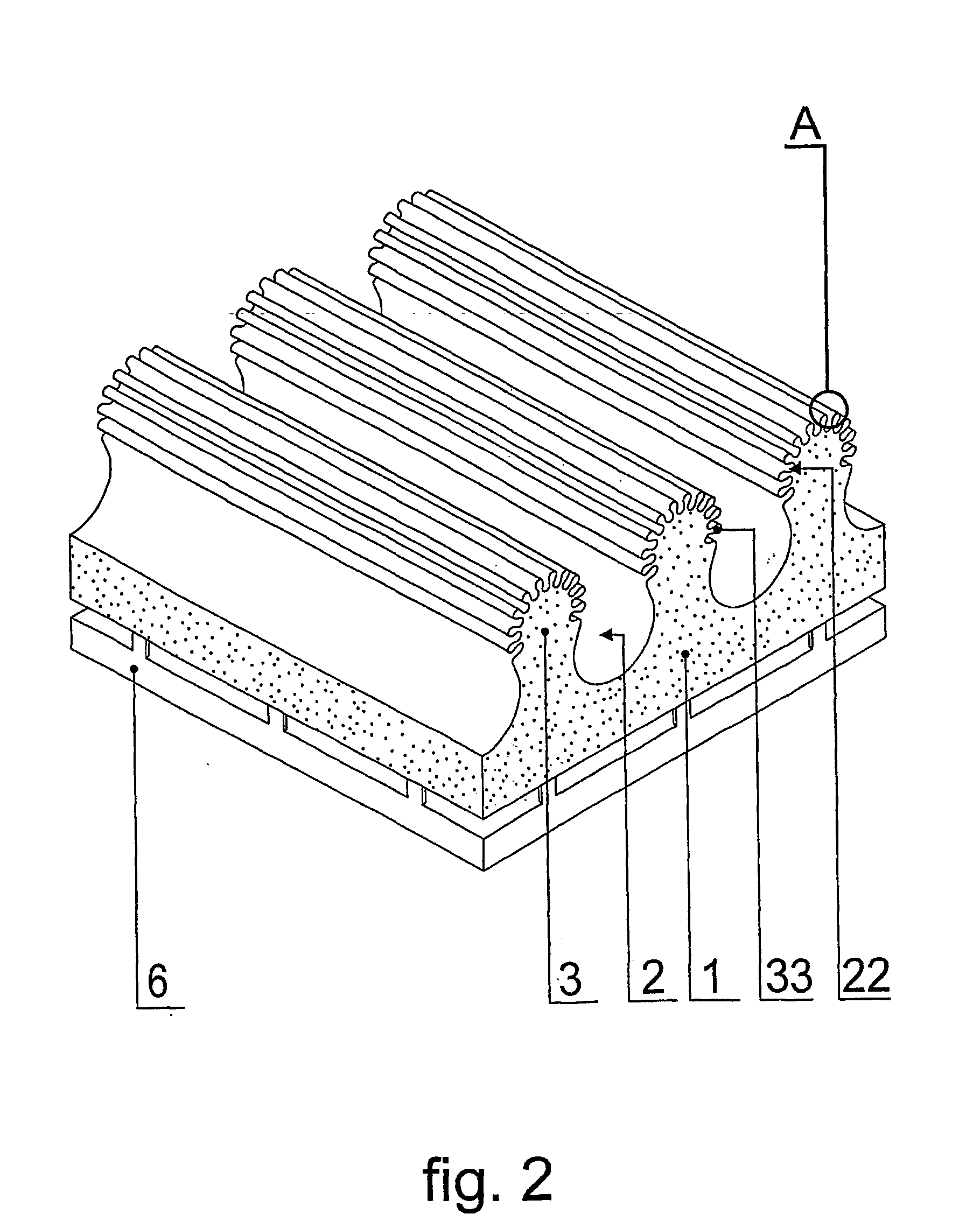

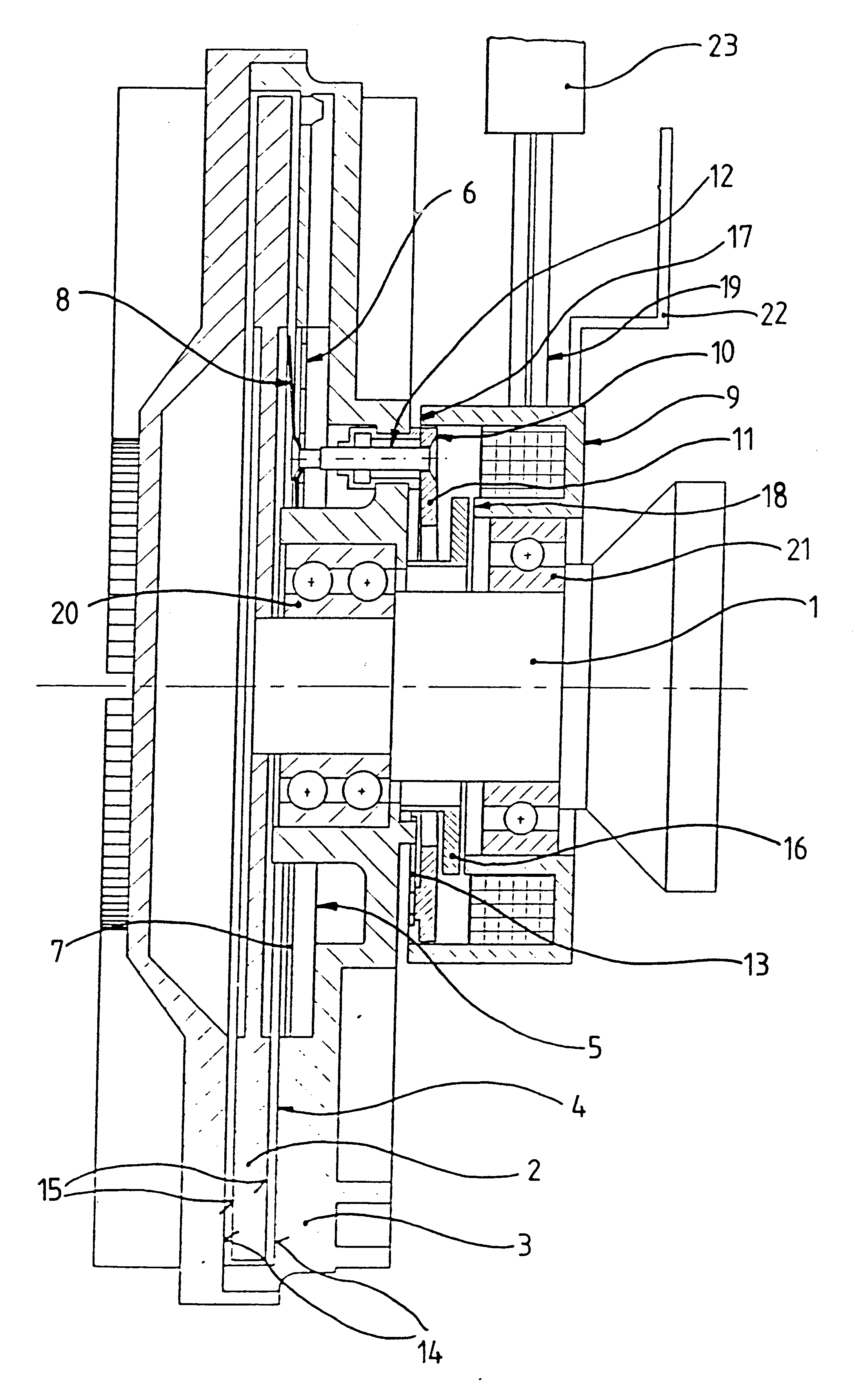

InactiveUS6419064B1Minimizes magnetic lossesMagnetic losses of the solenoid are particularly lowOperating means/releasing devices for valvesCoolant flow controlDrive shaftCoupling

A fluid friction coupling for driving a fan of an internal combustion engine includes a solenoid configured such that it surrounds a drive shaft and is operatively arranged for moving a control part. The control part moves a valve body which controls the flow of a viscous fluid into a working chamber. The fluid friction coupling is of particularly compact configuration and magnetic losses are kept particularly low.

Owner:MANNESMANN SACHS AG

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS7121448B2Improve integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

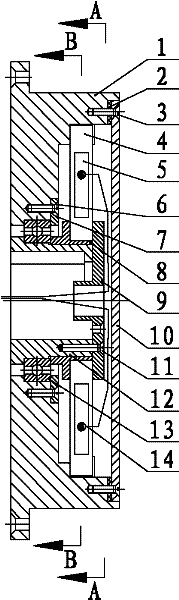

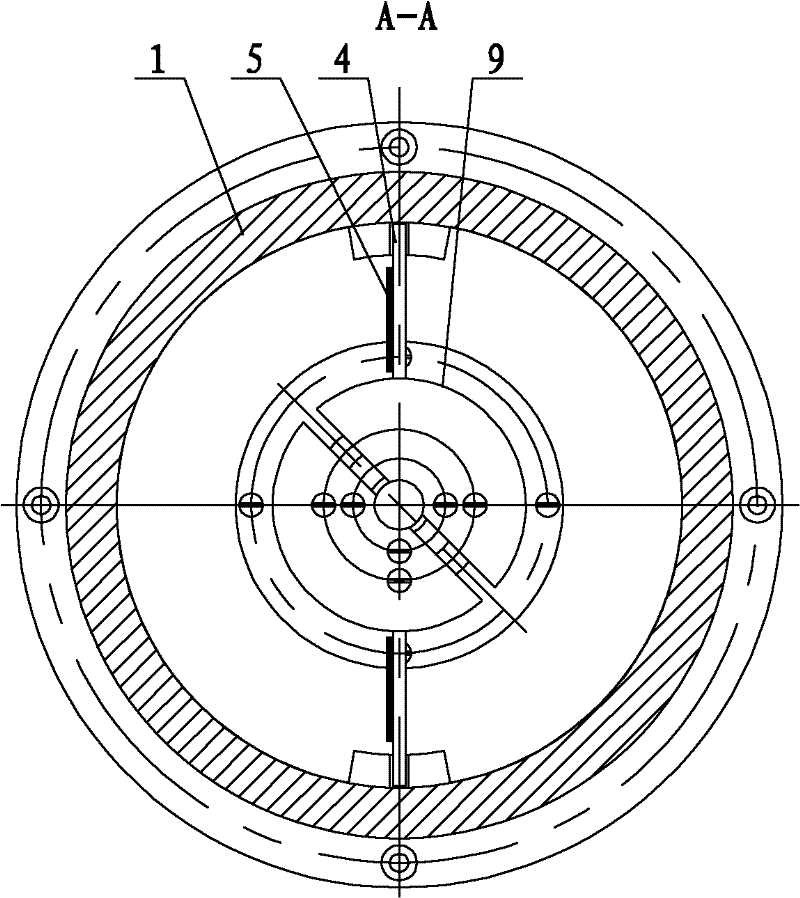

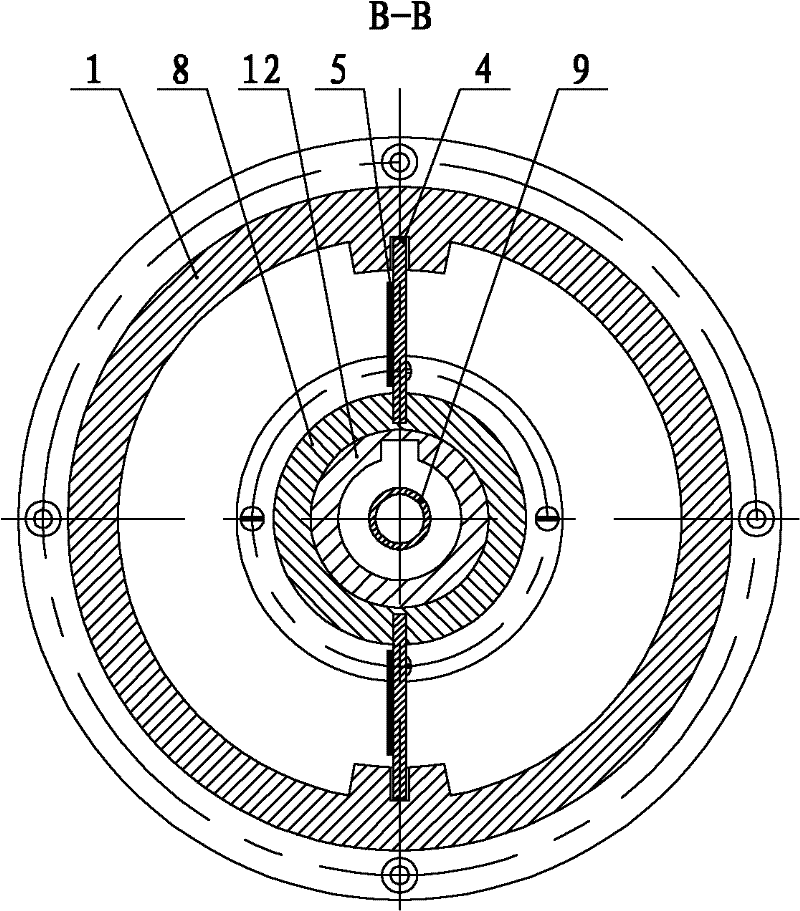

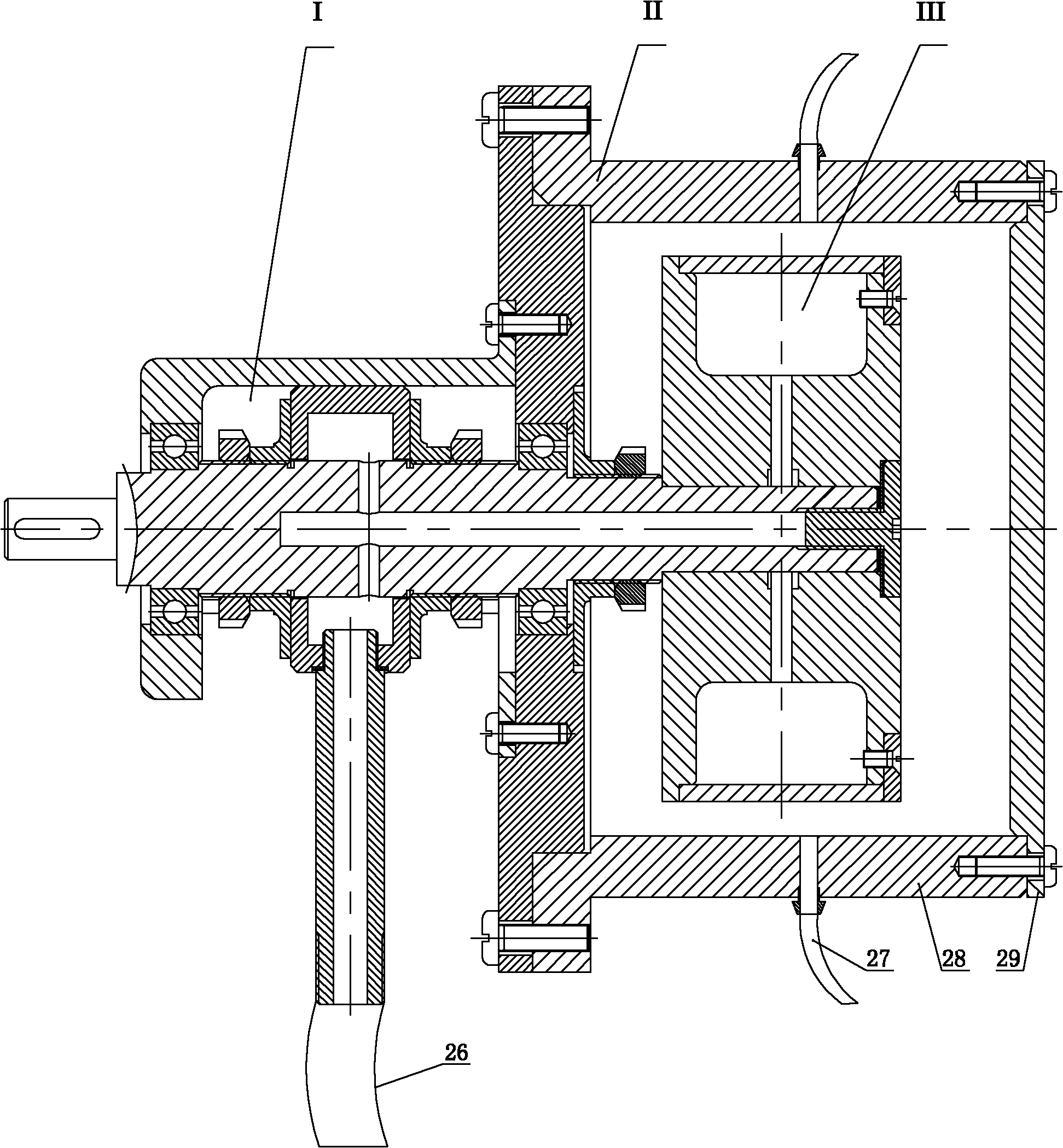

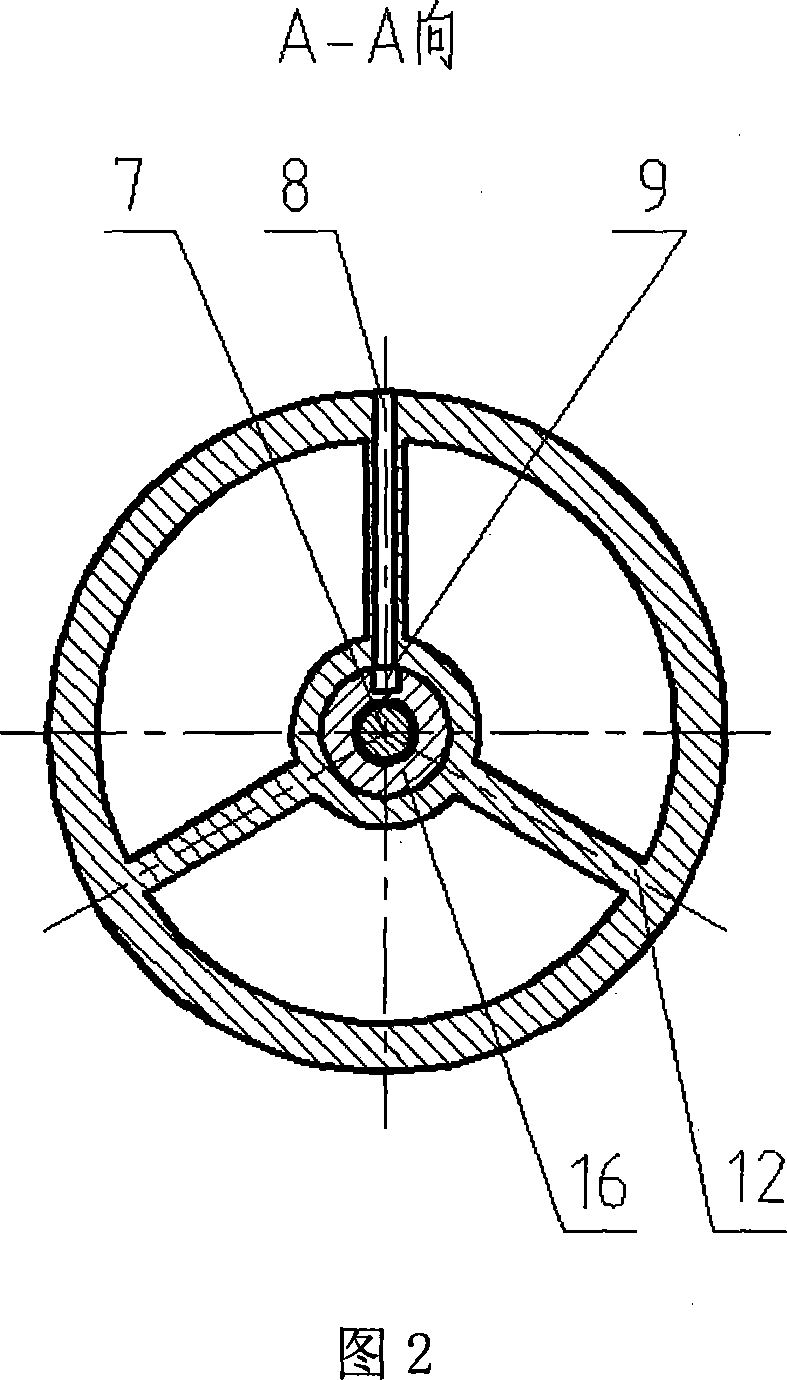

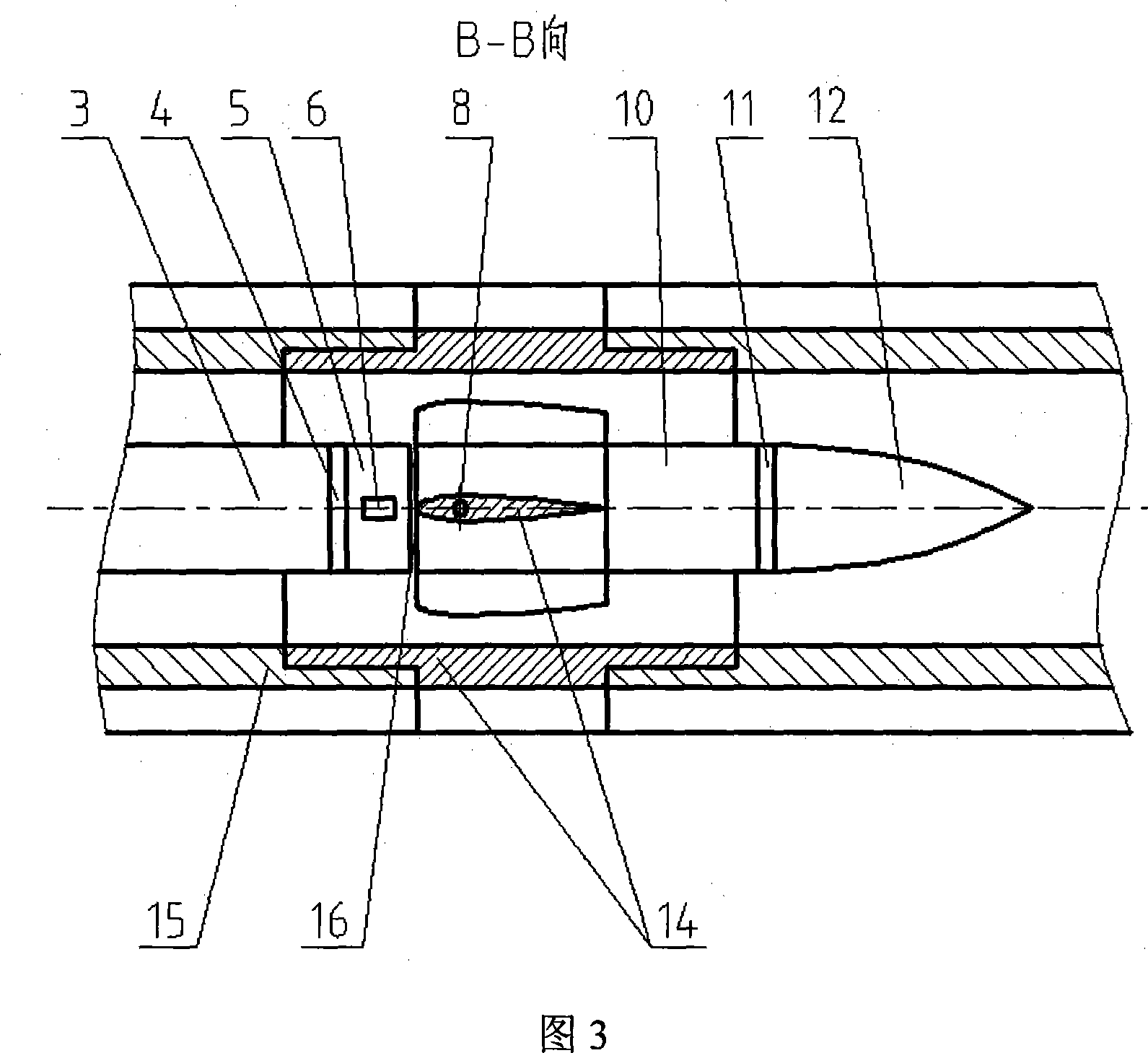

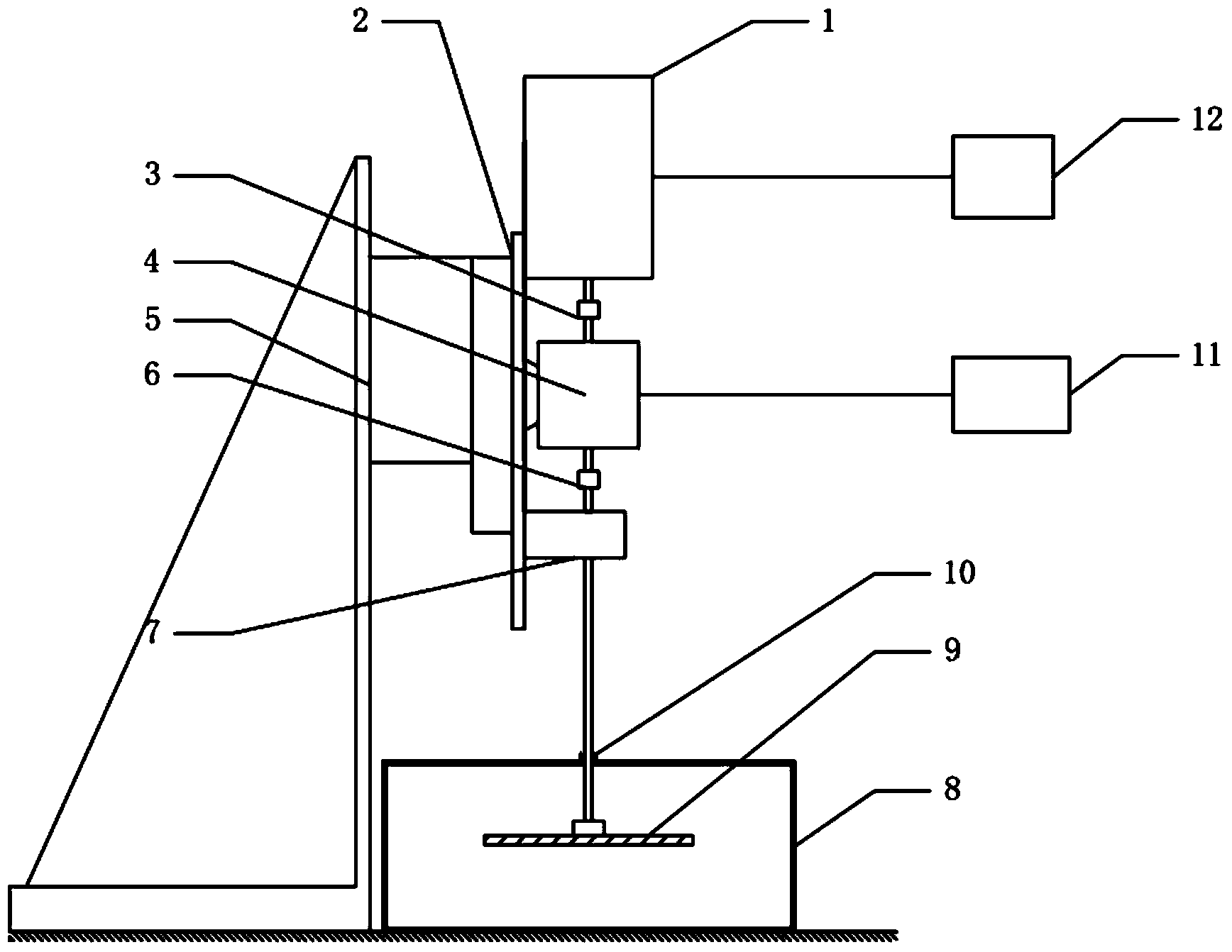

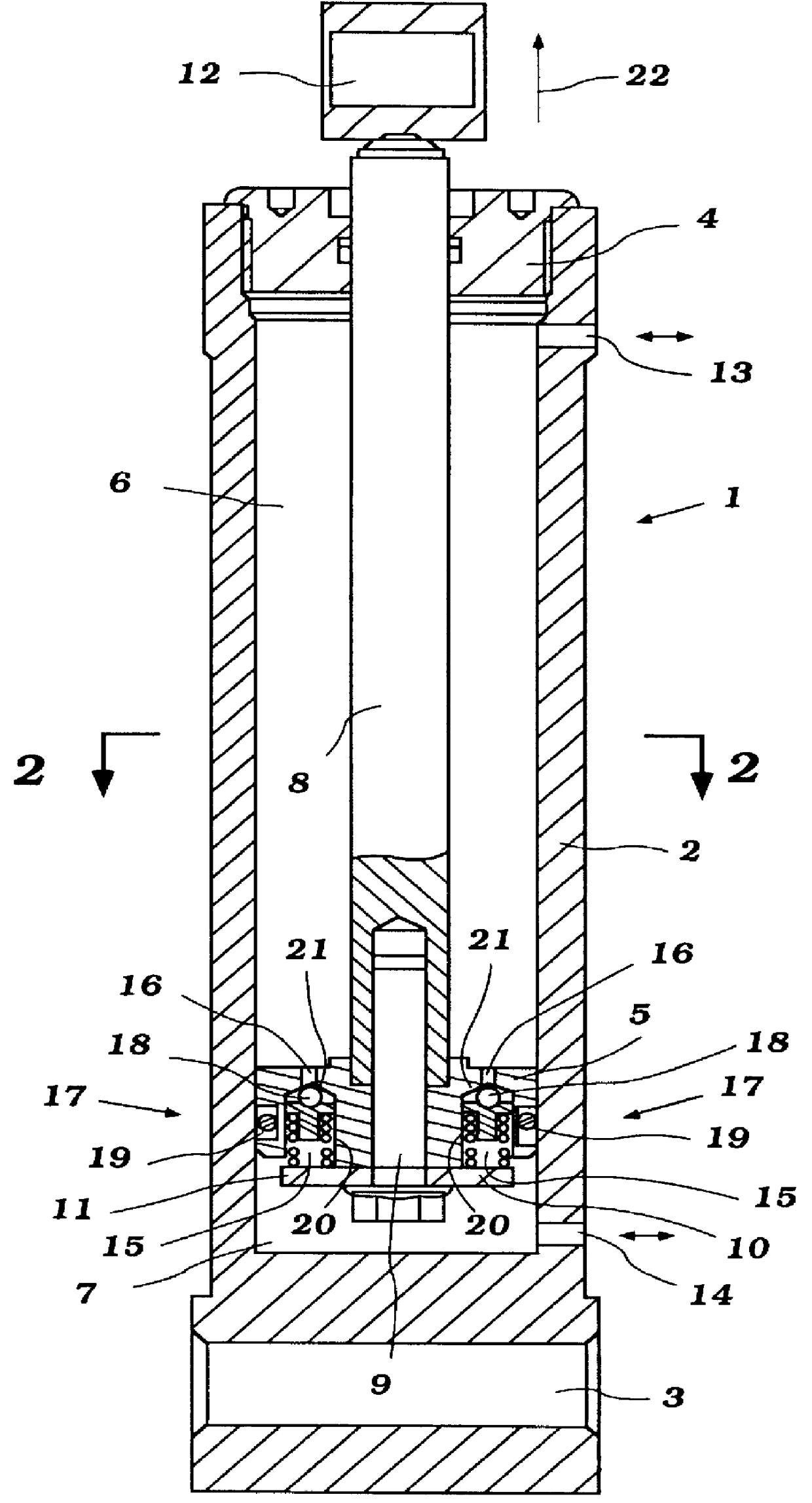

Testing apparatus for evaluating drag-reduction effects of bionic non-smooth surface and bionic jet surface

The invention provides a testing apparatus for evaluating the drag-reduction effects of a bionic non-smooth surface and a bionic jet surface. The testing apparatus comprises a sealing shaft, a power input and signal output mechanism, a sensor mechanism, a gas-tight silo and a water distribution mechanism, wherein the power input and signal output mechanism is arranged at one end of the sealing shaft, the sensor mechanism is arranged at the other end of the sealing shaft, and the gas-tight silo surrounds the sensor mechanism. The testing apparatus provided by the invention is suitable to be used for testing the drag-reduction effects of a non-smooth surface and a surface coating as well as a bionic jet surface; and a data acquisition system is simple in structure, easy to operate, and accurate in testing. By using the testing apparatus provided by the invention, both the drag-reduction effect of a non-smooth surface and the drag-reduction effect of a jet surface structure also can be evaluated. The fluid friction resistance values of the testing apparatus under different test sample conditions are acquired by using the data acquisition system, and then the data comparison is performed so as to obtain the drag-reduction effects of different surface structures, thereby studying the drag-reduction characteristics of a non-smooth surface structure and a jet surface structure.

Owner:HARBIN ENG UNIV

Open gear lubricant combination and preparation method thereof

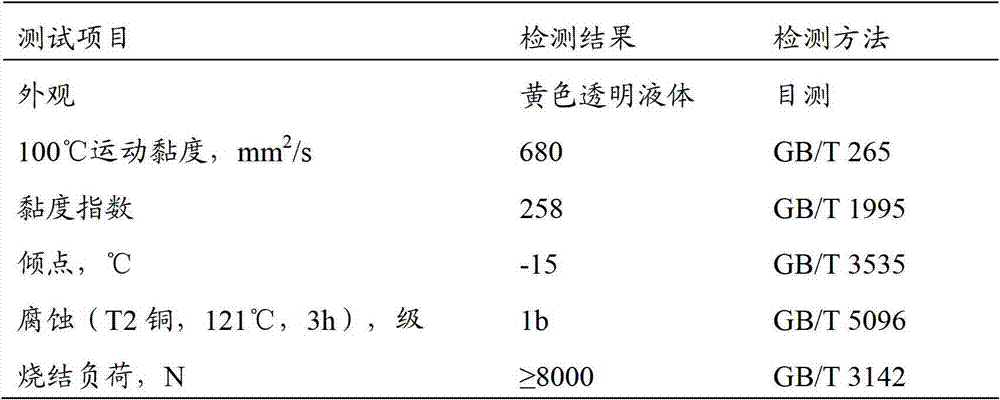

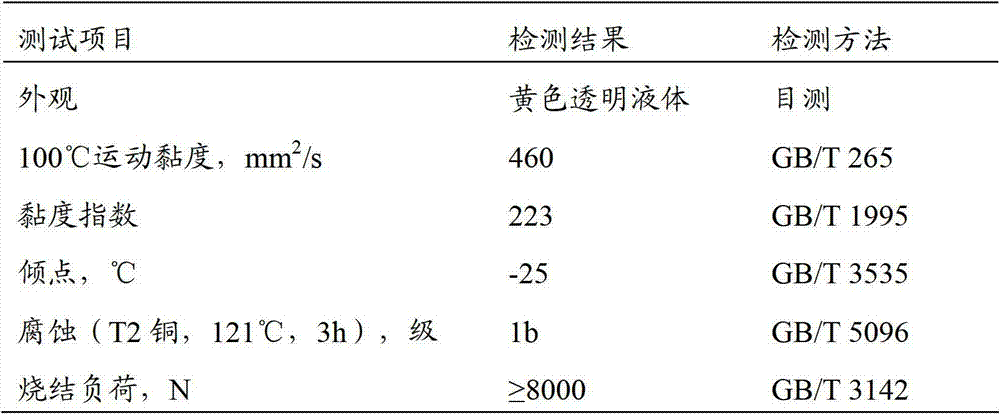

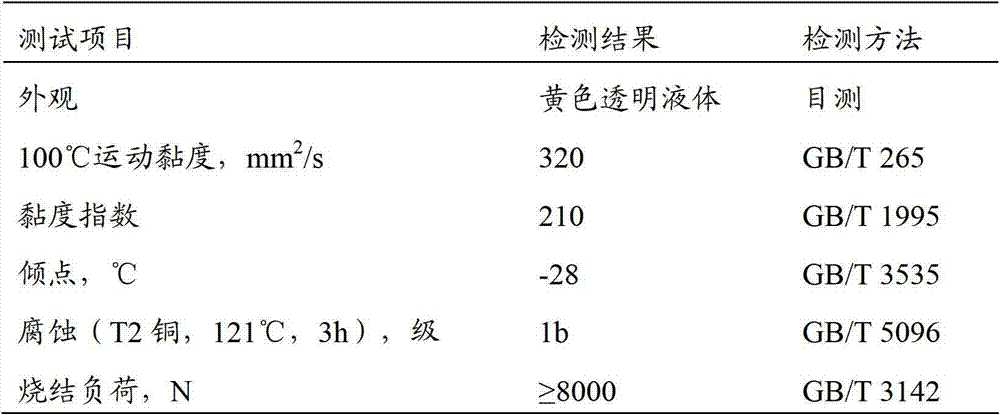

ActiveCN102776056AImprove efficiencyIncrease viscosityLubricant compositionSolubilityViscosity index

The invention discloses an open gear lubricant combination which comprises high-viscosity synthetic base oil, synthetic ester base oil and an additive having a weight ratio of (55-93):(5-25):(2-20). Because the high-viscosity synthetic base oil has the characteristics of high viscosity index, better high-temperature and low-temperature performance and lower friction coefficient, and the synthetic ester base oil has the characteristics of low pour point and excellent solubility and perceptibility of the additive, the high-viscosity synthetic base oil and the synthetic ester base oil are matched in the invention, and a proper amount of additive is added, thus ensuring that the lubricant combination has the following characteristics: the lubricant combination has higher viscosity and excellent viscosity-temperature performance, and is beneficial to formation and maintenance of a lubricant film in the process of using oil products; under the condition of the same viscosity range, the open gear lubricant has excellent low-temperature flowing performance, thereby enlarging in use temperature range; and in use, the low-fluid friction of a gear pair in a load region can be caused, the operation temperatures of a gear and a gear transmission device are lowered, and the efficiency of the gear is increased.

Owner:CHINA PETROLEUM & CHEM CORP

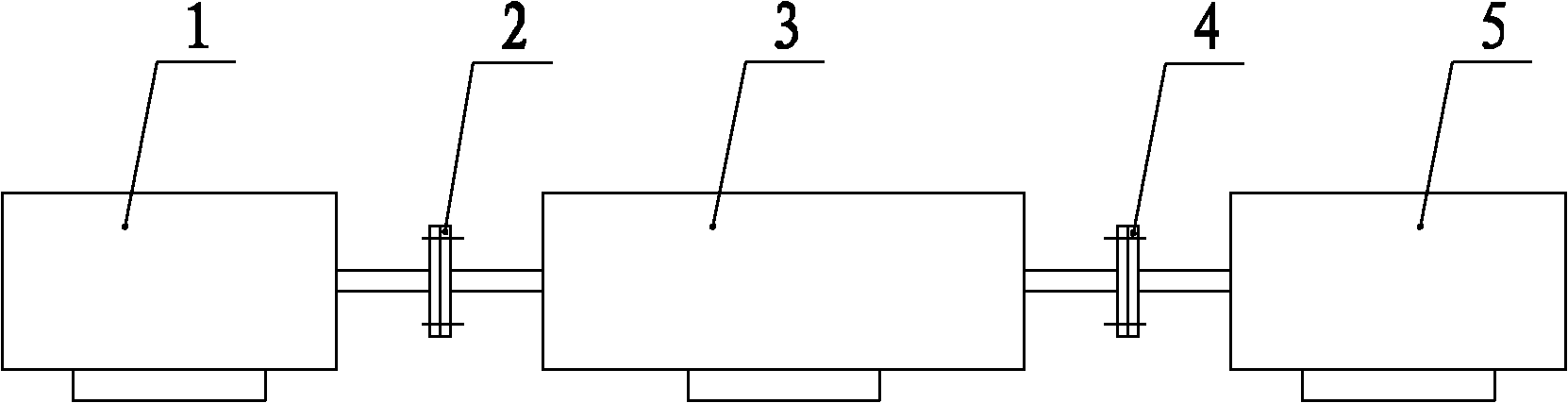

Device for testing fluid friction resistance

The invention provides a device for testing fluid friction resistance. The device comprises a motor, a first coupler, a second coupler, a torque signal coupler and a load, wherein the load comprises a shaft, an end cover sealing link part and a test sample link part; the end cover sealing link part comprises a large end cover, a first sealing end cover and a sealed cylinder; the large end cover is a fixture; the sealing end cover is a rotary member; the test sample link part comprises a test sample supporting frame, a test sample, a test sample end cover and a shaft end cover; the test sample supporting frame rotates along with the shaft; the test sample supporting frame is axially fixed at a shaft end through the shaft end cover; and the test sample is arranged on the test sample supporting frame. The device is suitable for testing a resistance reduction effect of a non-smooth surface and testing the resistance reduction effect of a jet surface. The device has a simple structure, is easy to operate and is accurate in test.

Owner:HARBIN ENG UNIV

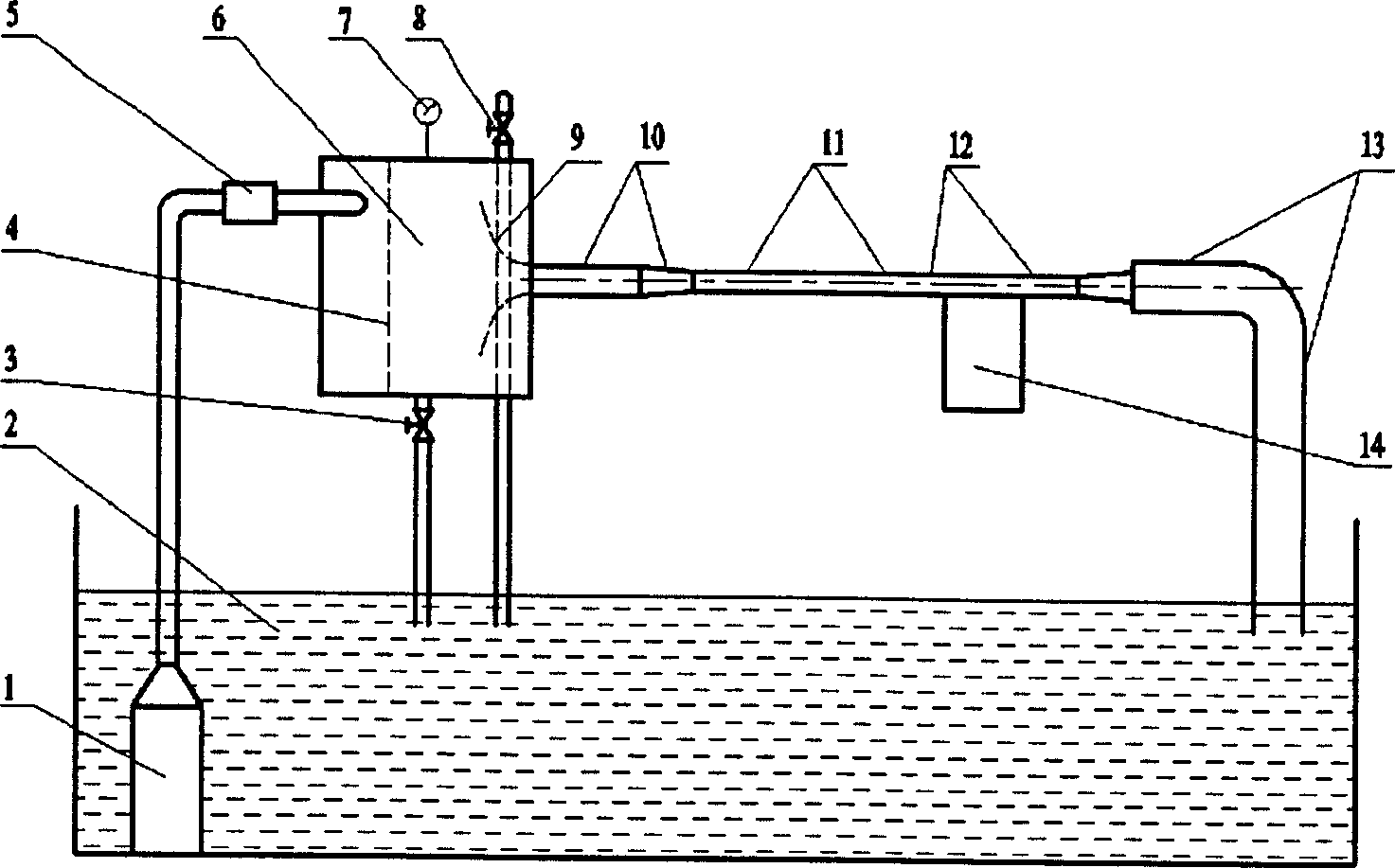

Flat plate wall fluid friction resistance mensuring device based on open circulation

A measuring device of fluid frictional resistance on flat plate wall surface is prepared as connecting buffer water tank to water pool and to water flow pipe separately; connecting water flow pipe to water pool through elbow; forming water flow pipe by reducing section, developing section and testing section with rectangular cross ¿C section; placing flat plate to be measured in testing section and using flat plate as plate wall of testing section for carrying out frictional resistance test on wall surface.

Owner:TSINGHUA UNIV

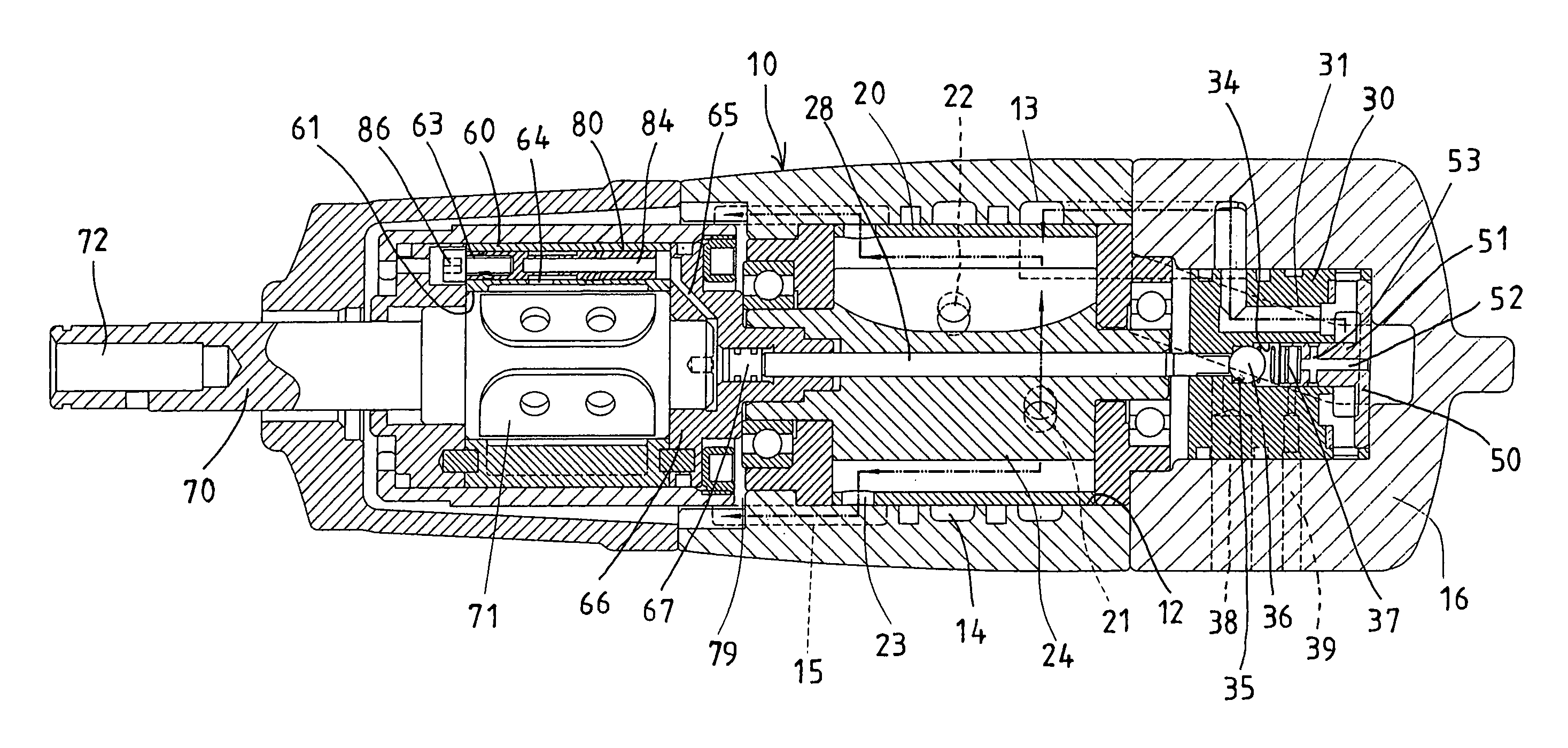

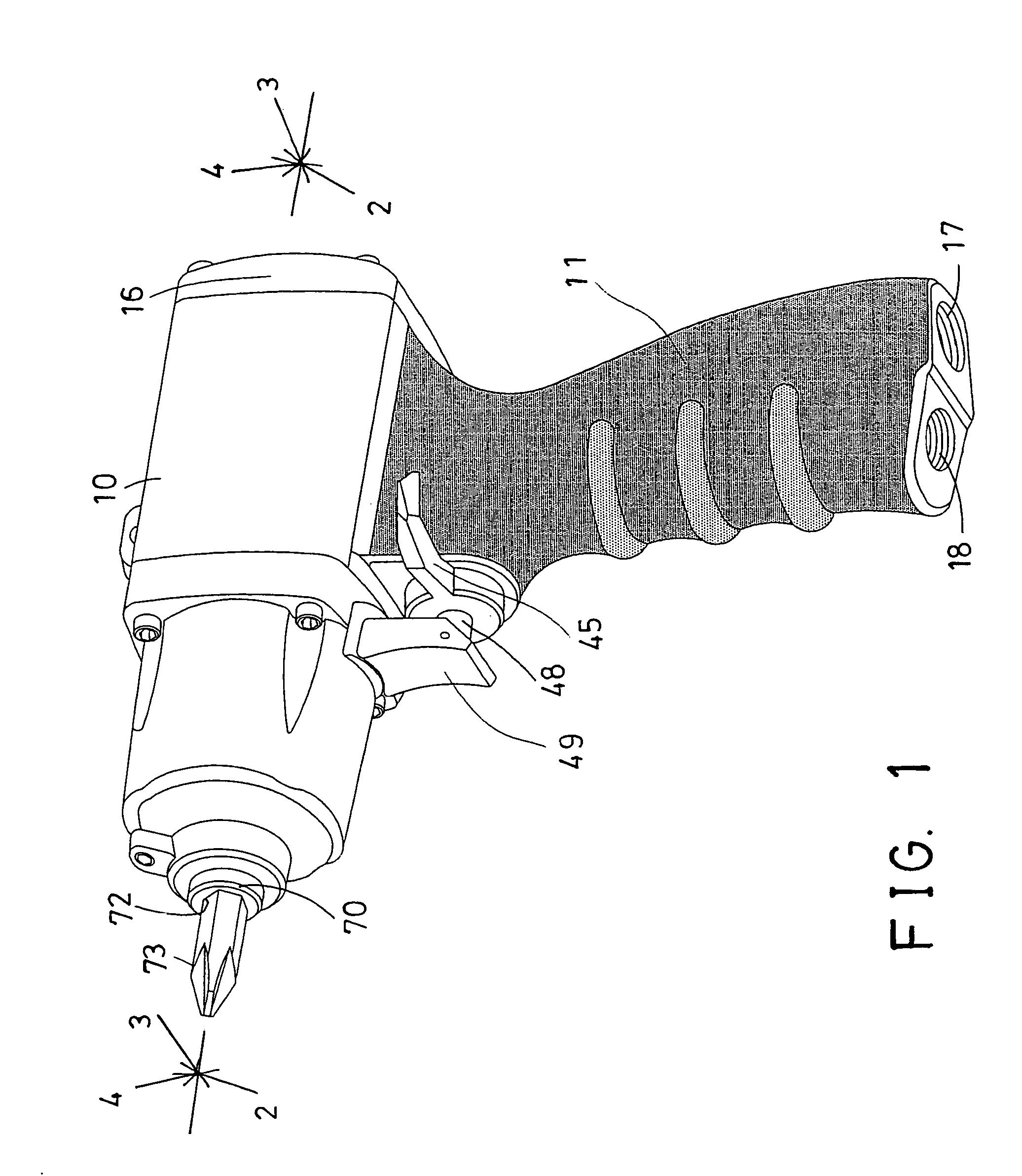

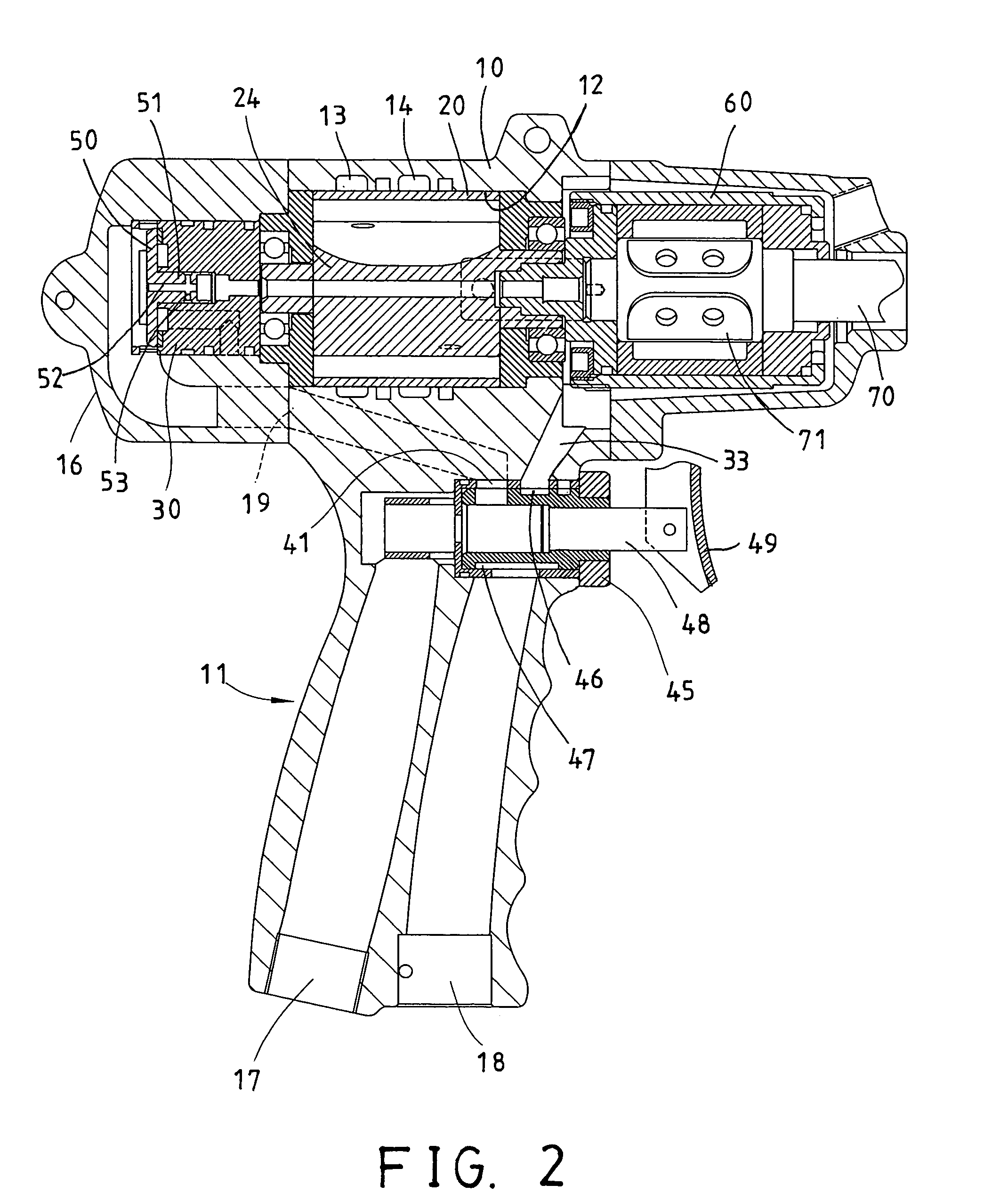

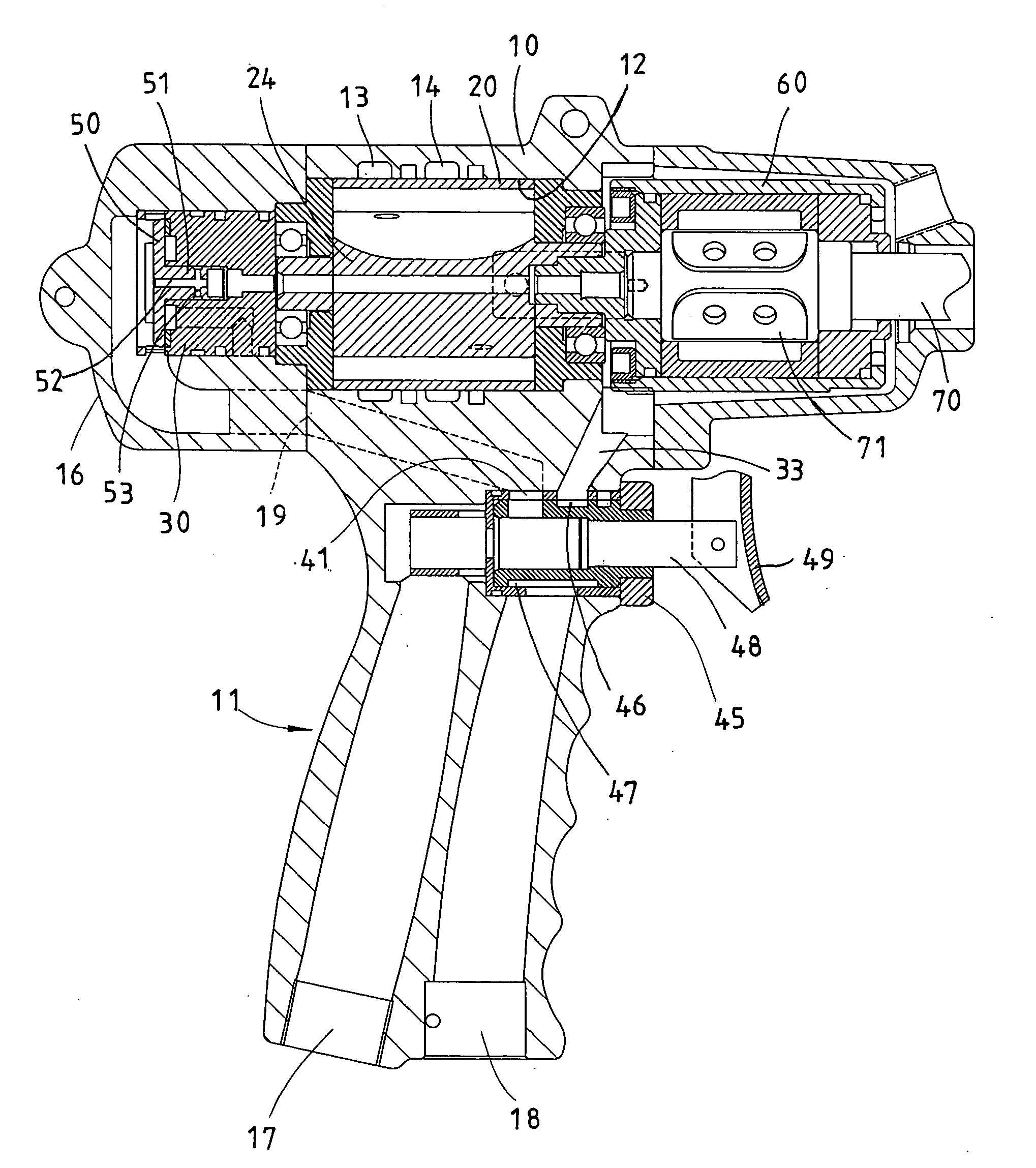

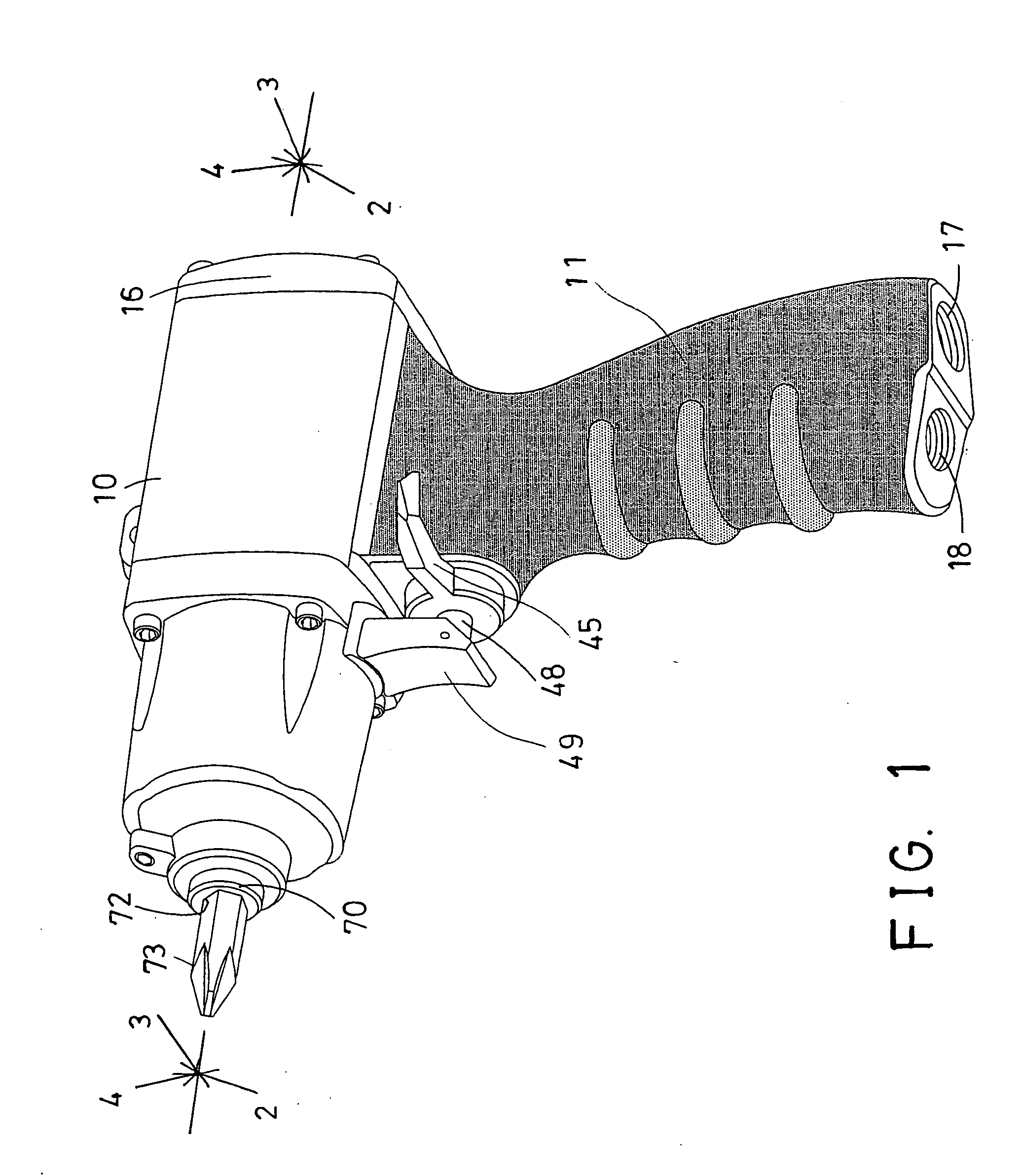

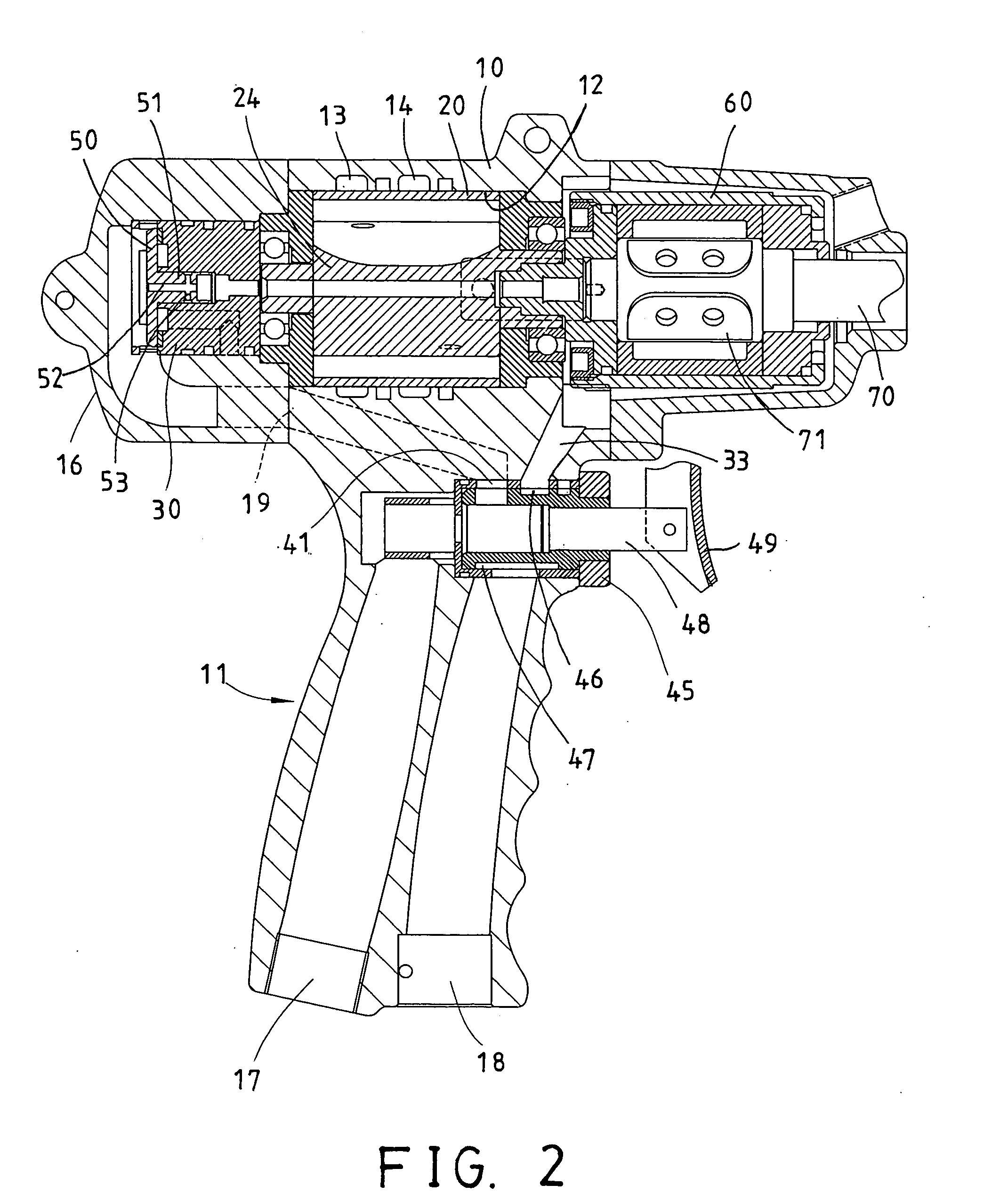

Pneumatic tool having pressure release device

A pneumatic tool includes a rotor rotatably received in a housing, a driving shank coupled to the rotor, for being rotated by the rotor and by a pressurized air and having one end for driving a fastener. A pressure releasing device may release the pressurized air after the fastener has been tightly threaded onto the object to be fastened. A fluid container is rotatably received in the housing and coupled to the rotor, for partially receiving the driving shank. The driving shank has one or more paddles for being frictionally driven by the container and by the fluid. A pole is slidably engaged through the rotor, and actuated to release the pressurized air when the fastener has been tightly threaded onto the object.

Owner:LIAO YU HUI

Detector for round cross section sample wall surface fluid friction resistance

InactiveCN101050995AIncrease frictional resistanceReduce the impactHydrodynamic testingMeasurement deviceFixed frame

A frictional resistance measurement device of wall-surface fluid on round section test sample consists of model support unit including model head, front slide support ring, back slide support ring, model tail, fixing frame and support rod; and resistance measurement unit including transmission ring, radial transmission pin, axial transmission pin, transducer support sheath, transducer and transducer base. It is featured a setting measured test sample to be cylindrical form, placing transducer in runner and leading signal line out through hole.

Owner:TSINGHUA UNIV

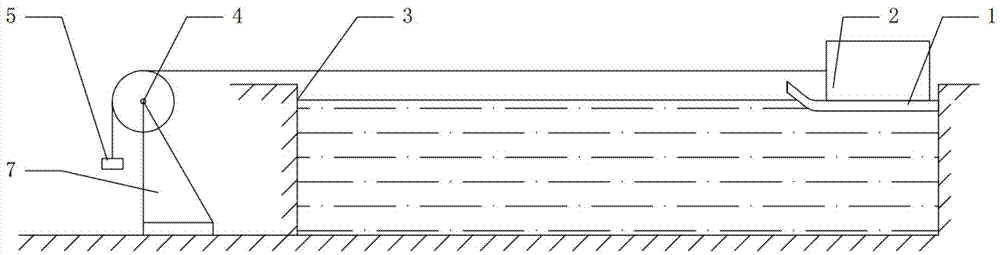

Non-smooth surface fluid friction resistance testing device and testing method

InactiveCN103674479ASimple structureSimple test principleHydrodynamic testingEngineeringResistance test

The invention aims to provide a non-smooth surface fluid friction resistance testing device and a testing method. The testing device comprises a pool, a buoyancy material, a support, a fixed pulley, a weight and a pull rope. A flat plate to be tested and the buoyancy material are fixed together, the pool is filled with fluid, and the flat plate to be tested and the buoyancy material jointly float on the fluid. The support is fixed to the position beside the pool, the fixed pulley is installed on the support, the pull rope is wound around the fixed pulley, one end of the pull rope is connected with the buoyancy material, and the other end of the pull rope is connected with the weight. The pull rope keeps horizontal between the fixed pulley and the buoyancy material and is higher than the wall surfaces of the pool, namely the tension exerted on the buoyancy material is equal to the gravity of the weight, the gravity of the weight is larger than the friction resistance of the flat plate, and thus the flat plate can move forward under the effect of gravity of the weight. The testing principle is simple and visualized, the testing device is different from other devices used for estimating a resistance reduction effect of a non-smooth surface, the friction resistance of the non-smooth surface can be directly tested, and the testing result is reliable.

Owner:HARBIN ENG UNIV

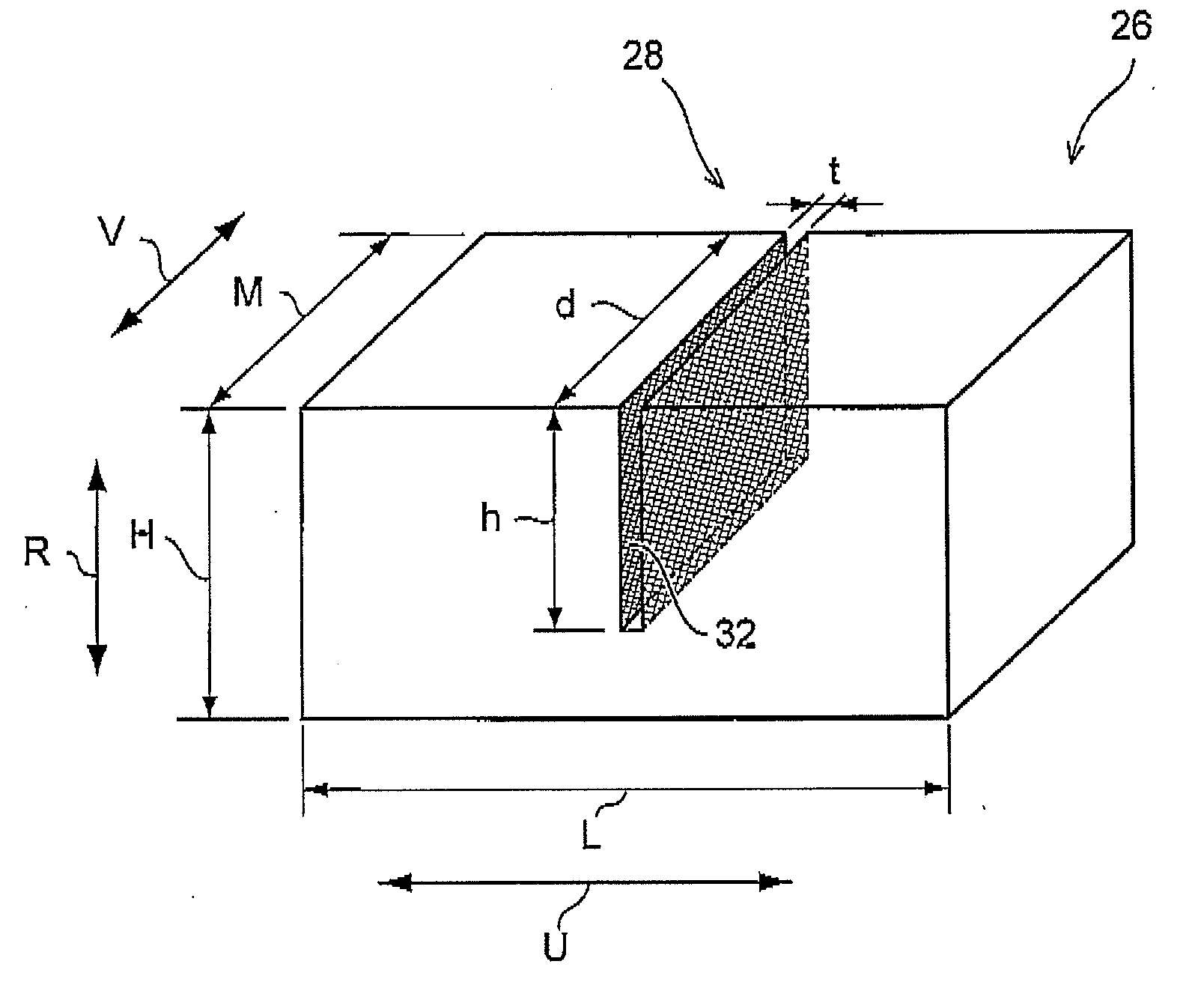

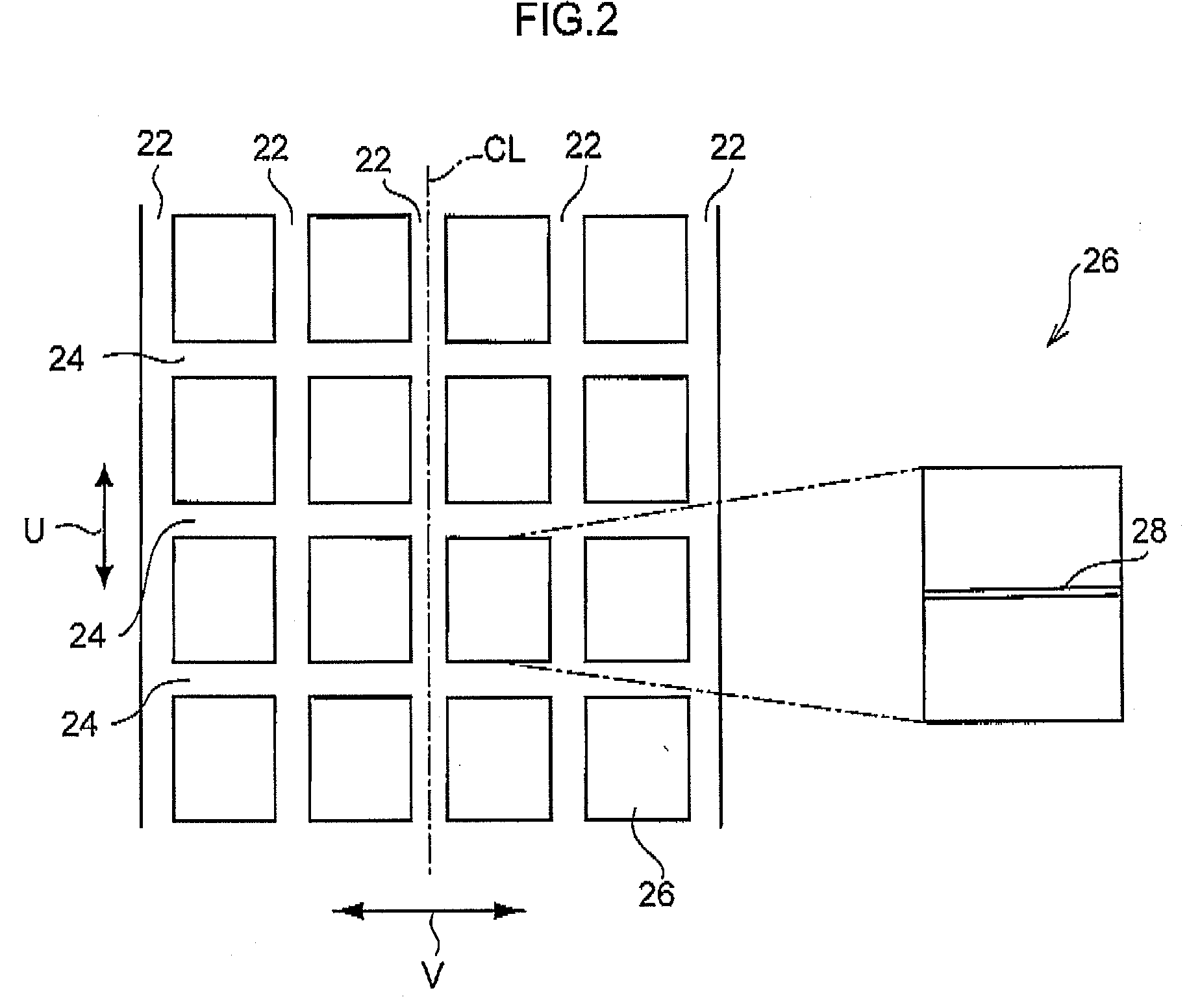

Pneumatic tire

ActiveUS20100154953A1Increase the amount of waterImprove braking effectTyre tread bands/patternsNon-skid devicesFine structureEngineering

A pneumatic tire having enhanced on-ice braking performance achieved by further increasing the amount of water that can be sucked up into sipes. In the pneumatic tire, blocks (26) partitioned by circumferential grooves and lateral grooves are formed in the tread. A sipe (28) is formed in a block (26), and a fine structure (32) having a height in the range of from 1 / 50 of the sipe width t to less than 1 / 10 of the sipe width t is formed on a sipe wall surface. This reduces fluid friction coefficient of water relative to the sipe wall surface to a lower level than conventional products. As a result, when water staying on ice comes into contact with the sipe wall surface, the water is more easily sucked up into the sipe. The construction increases the amount of water that can be sucked up into the sipe (28) or the removal amount of water that stays on ice etc., and this enhances braking performance (friction characteristics) on ice.

Owner:BRIDGESTONE CORP

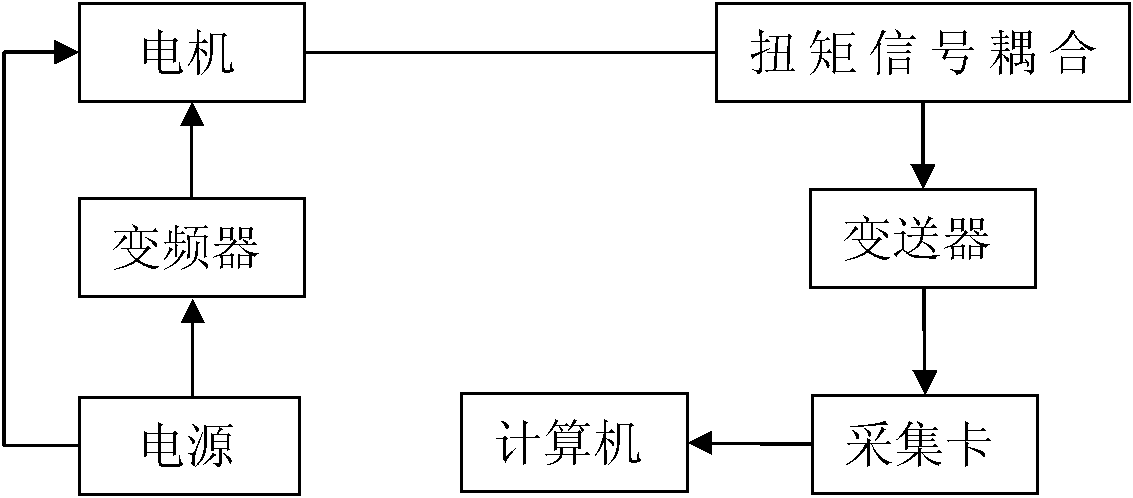

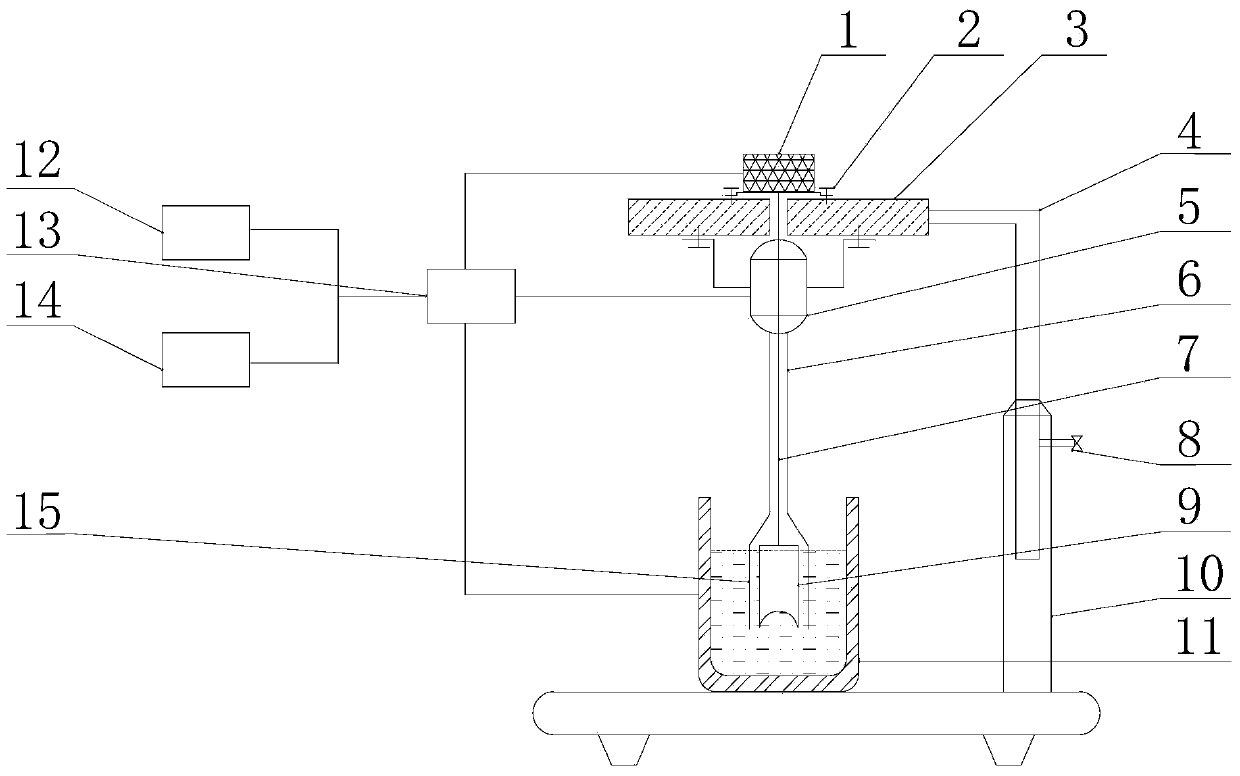

Rotary drum type fluid friction resistance tester

ActiveCN103471806AOvercoming complexityOvercome precisionHydrodynamic testingElectric machineTest sample

The invention relates to a rotary drum type fluid friction resistance tester. A speed regulating motor and a torque sensor are fixed on a cantilever-shaped mounting plate of a support, the speed regulating motor is vertically arranged, the lower end of an output shaft of the speed regulating motor is vertically connected a hollow rotating shaft, the lower end of the hollow rotating shaft is connected with an outer rotary drum of coaxial rotary drums, the upper end of the rotating shaft is connected with the torque sensor, and the lower end of the rotating shaft is connected with an inner rotary drum of the coaxial rotary drums. The coaxial rotary drums are arranged in a constant-temperature sample cup placed under the coaxial rotary drums and immersed in fluid in the cup. The constant-temperature sample cup comprises a temperature sensor and a heating device, the temperature sensor, the heating device, the torque sensor and the speed regulating motor are all connected with a single chip microcomputer of a digital processing device, and the single chip microcomputer is connected with a computer and a displayer. A sample board is pasted on the inner side wall face of the outer rotary drum. The tester is simple in structure, a tested sample can be manufactured easily, testing is simple and convenient, precision is high, stability and reliability are good, and the tester can be conveniently and reliably used for resistance testing analysis and assessment of the fluid resistance reduction technology and the resistance reduction effect.

Owner:WUHAN UNIV OF TECH

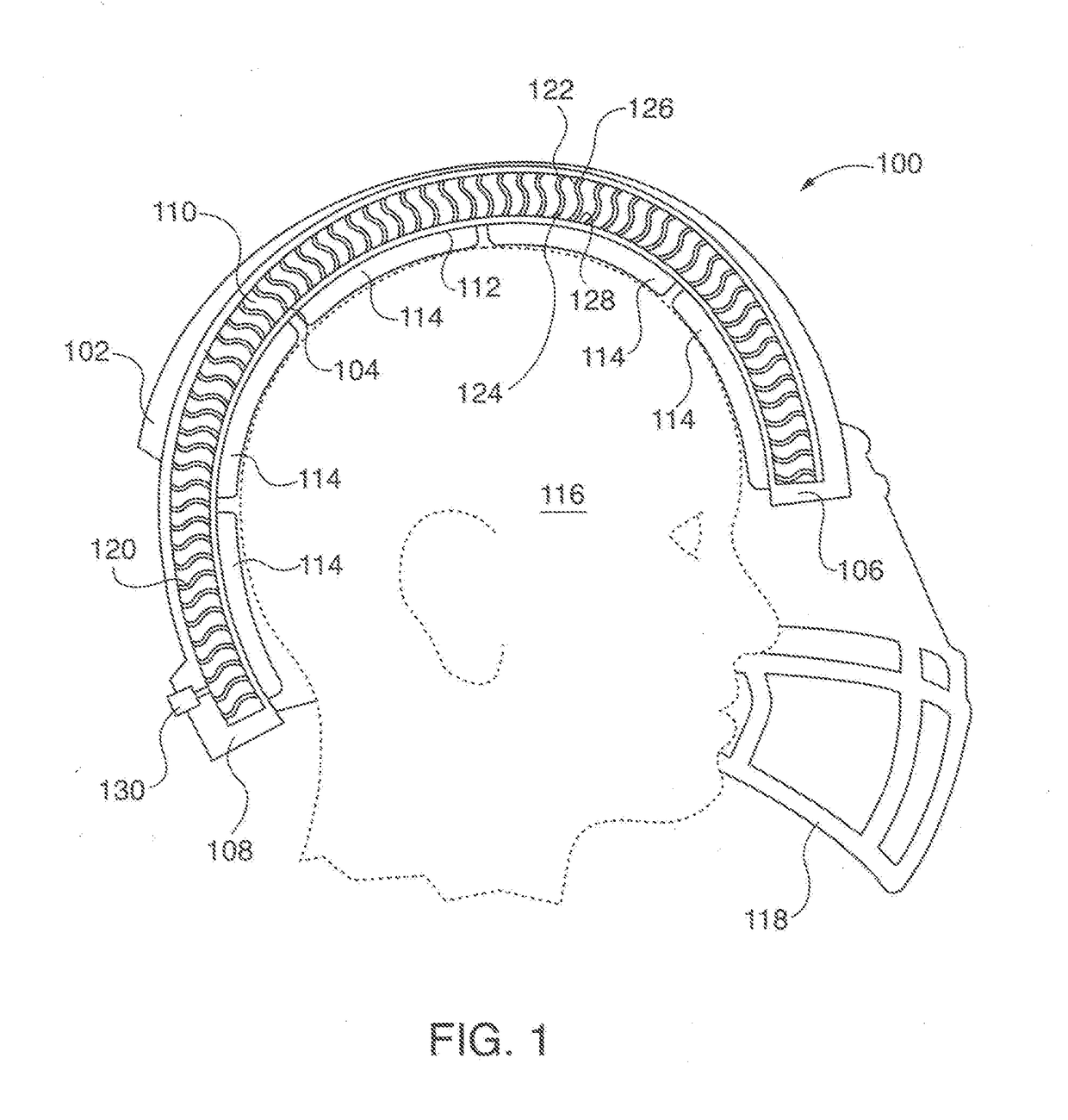

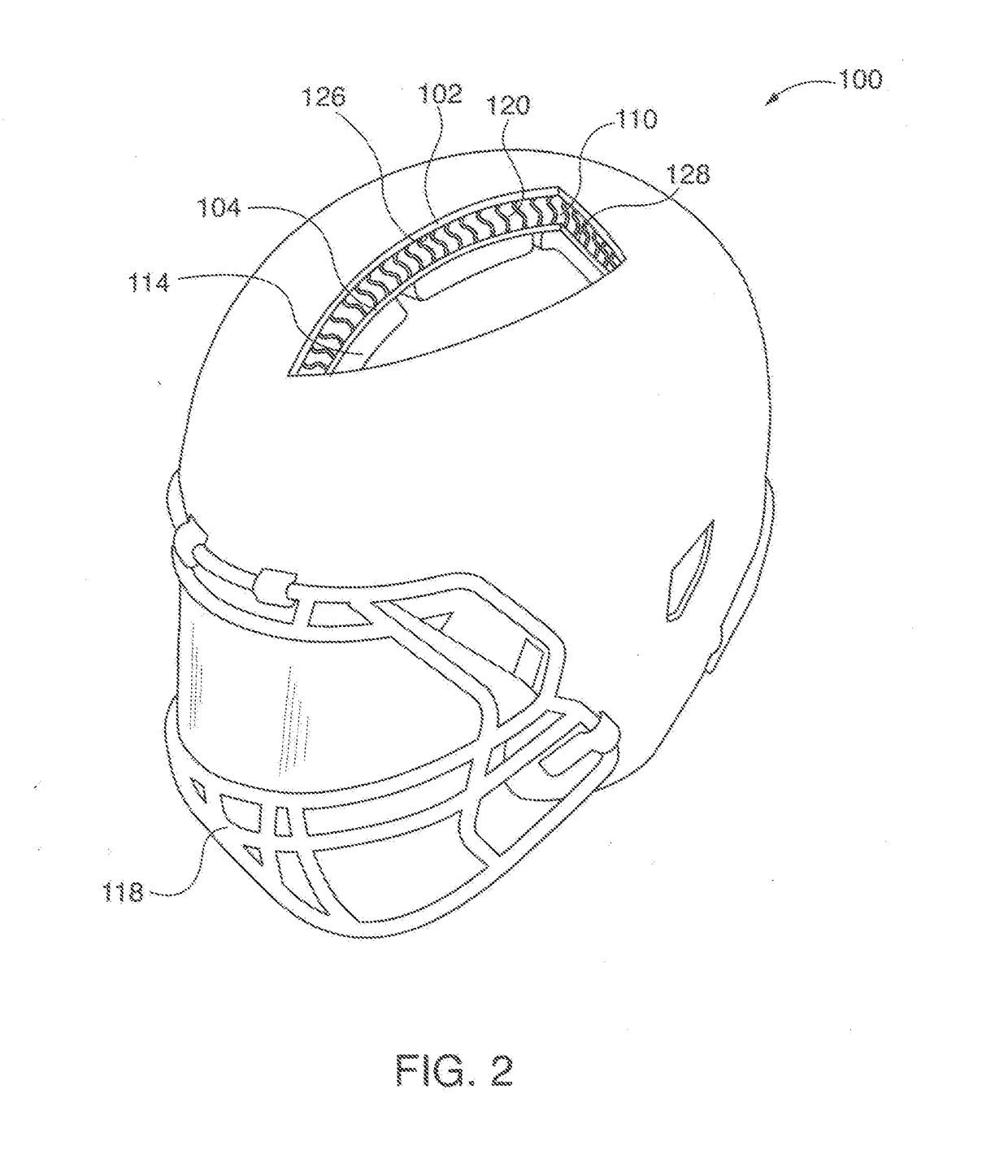

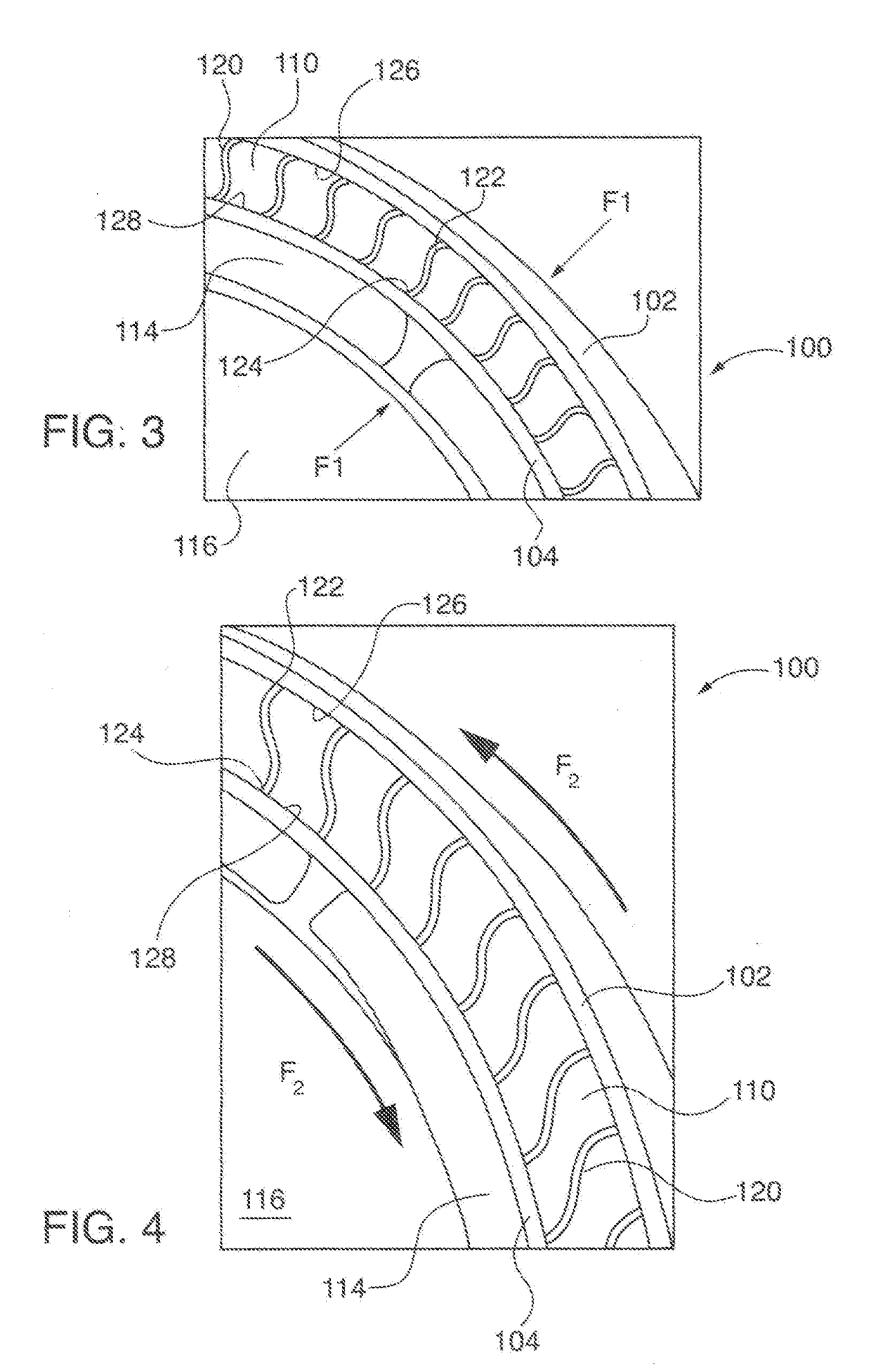

Biomimetic and inflatable energy-absorbing helmet to reduce head injuries and concussions

ActiveUS20190029352A1Increase fluid frictionReduce the amount requiredHelmetsHelmet coversEngineeringHead injury

A helmet for protecting the head of a user. The helmet includes an outer shell, an inner shell having padding that contacts the head and a cavity formed between the inner and the outer shells, wherein the cavity is filled with a fluid such as air. The helmet also includes a plurality of resilient strands located in the cavity and affixed between the outer and inner shells, wherein an impact force on the outer shell causes the head to impact the padding with a reaction force that compresses the cavity. Compression of the cavity pushes fluid through the strands to increase fluid friction and alter a velocity of the fluid. This decreases the energy of impact and consequently reduces an amount of force transferred to the head thereby protecting the head from normal and shear force.

Owner:SADEGH ALI M +2

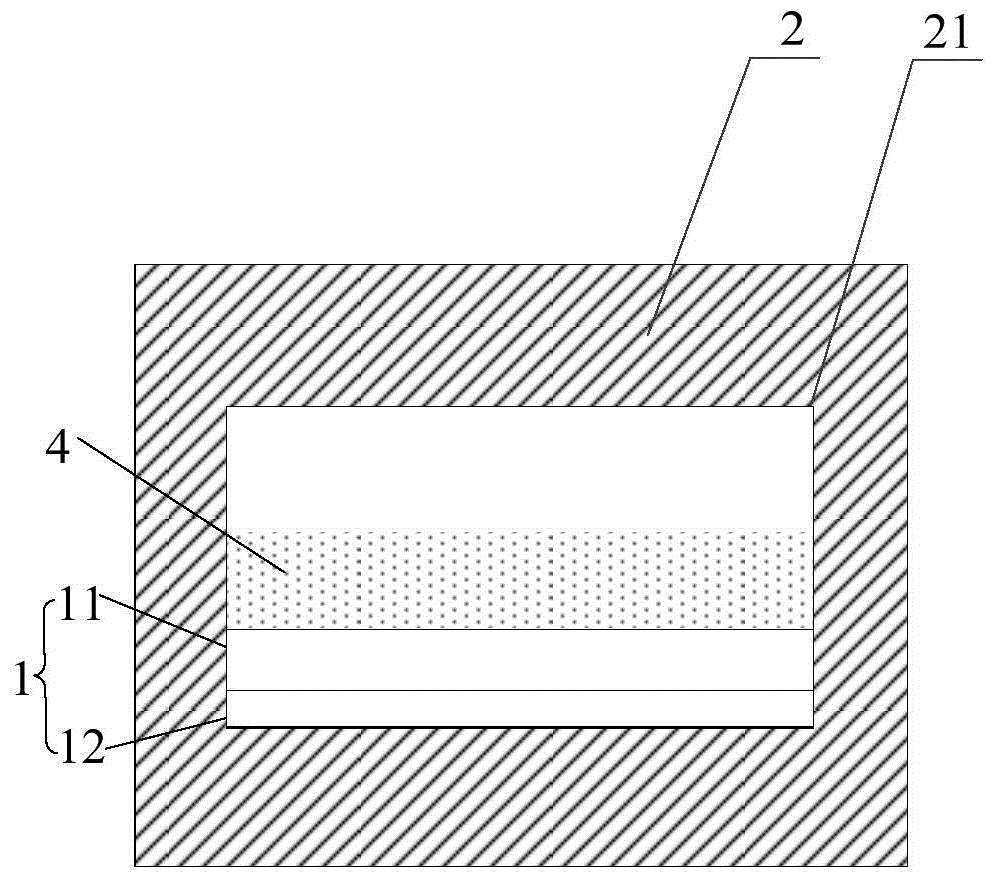

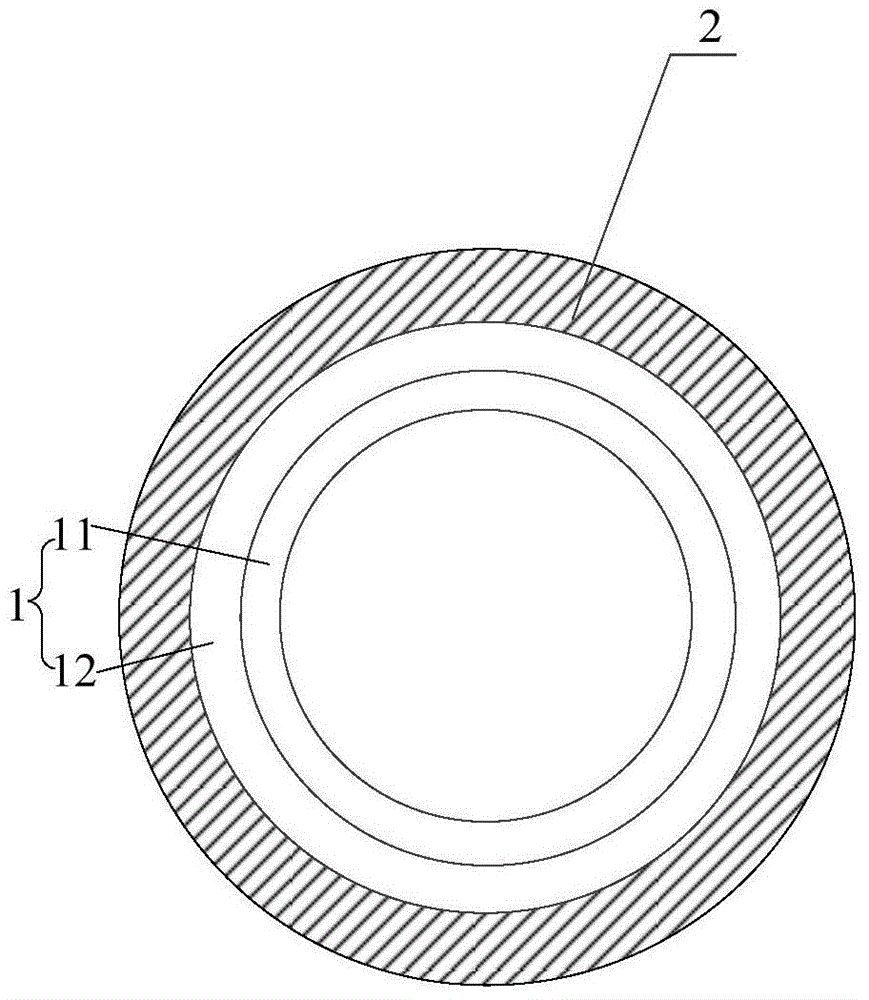

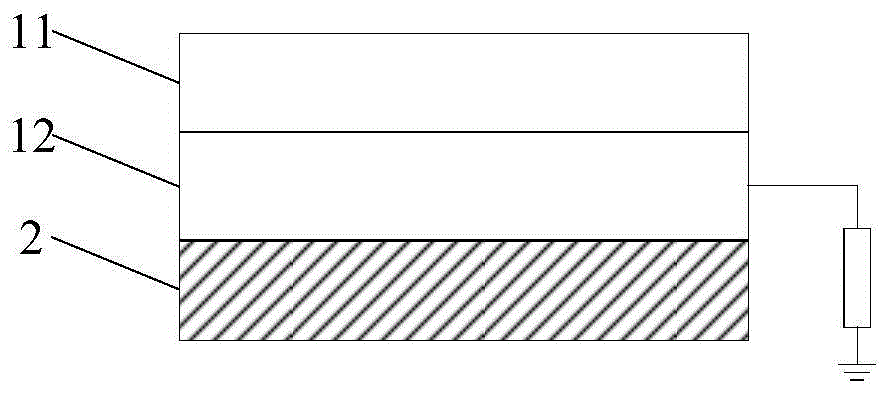

Fluid friction nanometer sensor, sensing network and fluid detection system

The invention relates to the technical field of friction power generation, and discloses a fluid friction nanometer sensor, a sensing network and a fluid detection system. The fluid friction nanometer sensor comprises a first part arranged on the inner wall of a cavity, wherein the first part comprises a first frictional layer, on which friction charges representing fluid parameter is generated when fluid in the cavity flows by the surface of the first frictional layer, and a first electrode layer which is attached to the first frictional layer and used to generate sensing charges on corresponding position thereof when friction charges are generated on the first frictional layer. The fluid friction nanometer sensor can realize detection of fluid parameters without an external power.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

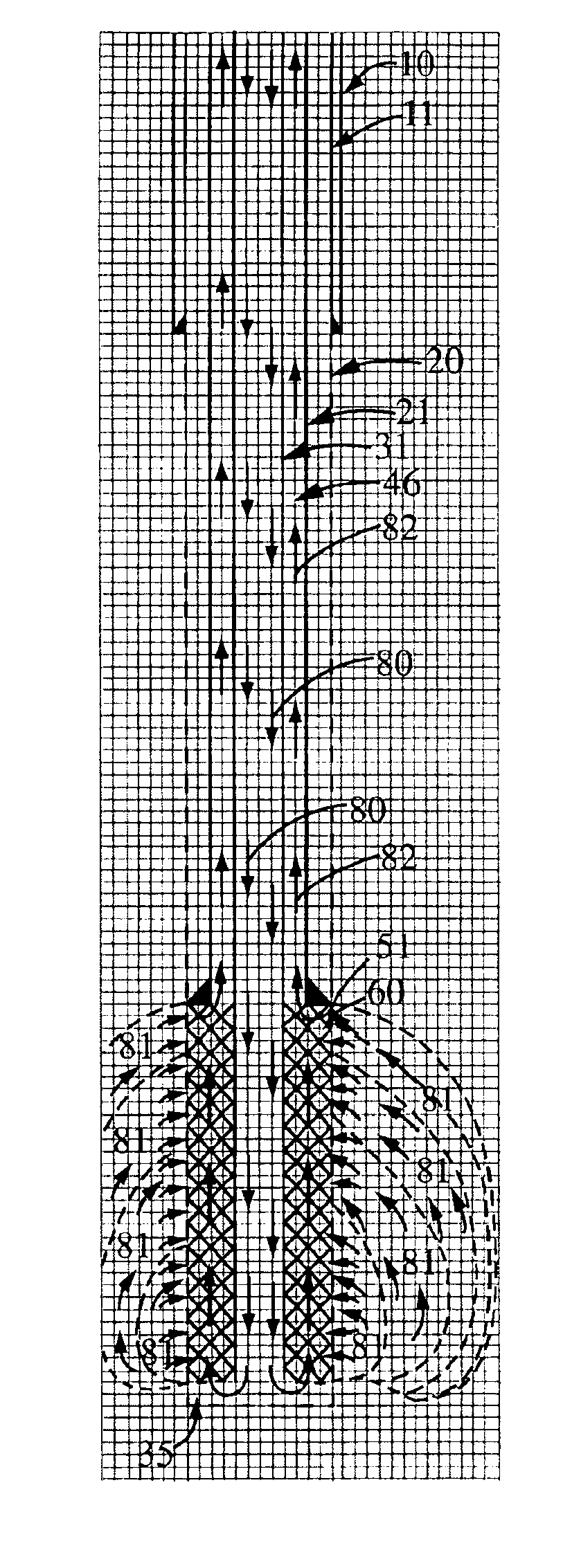

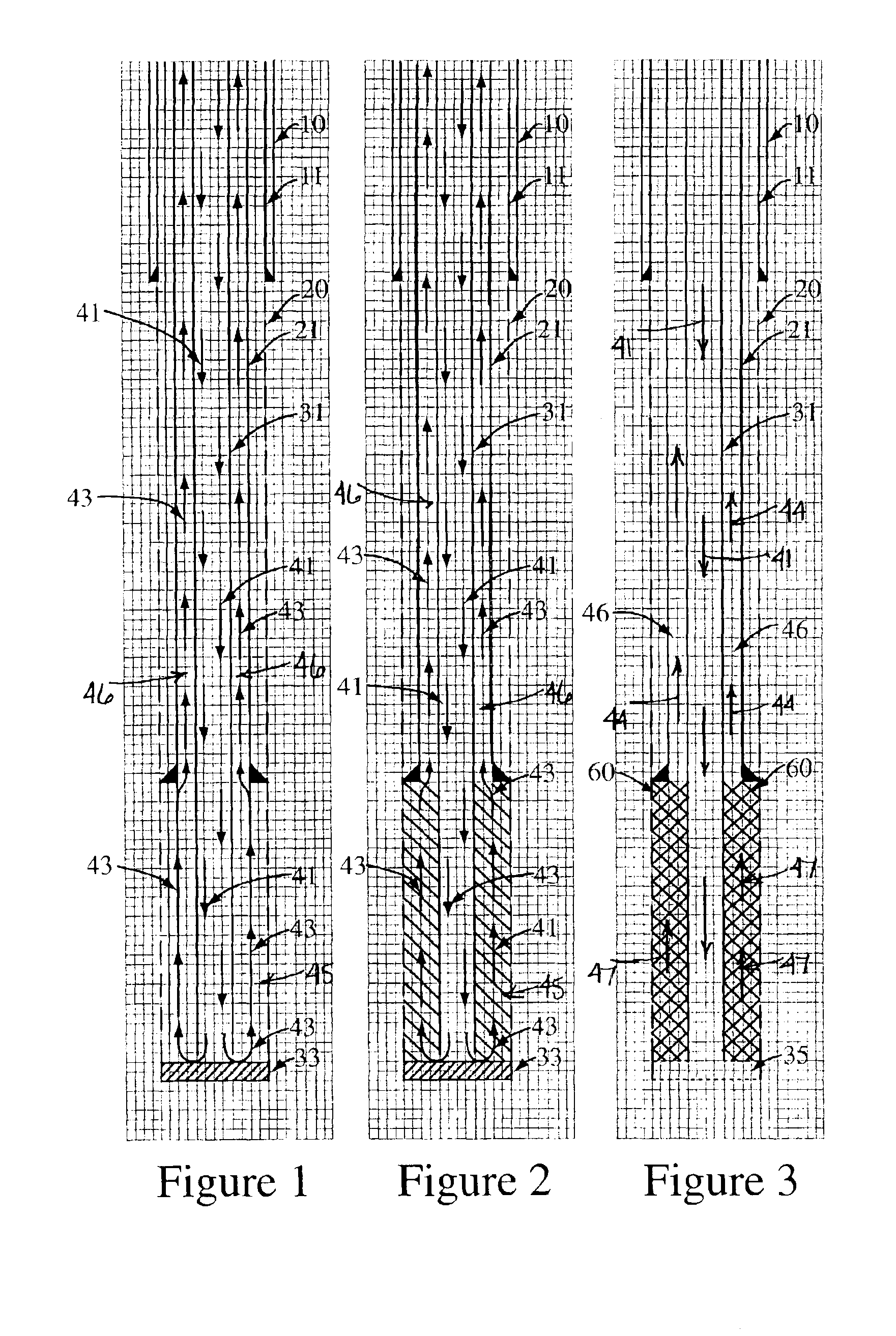

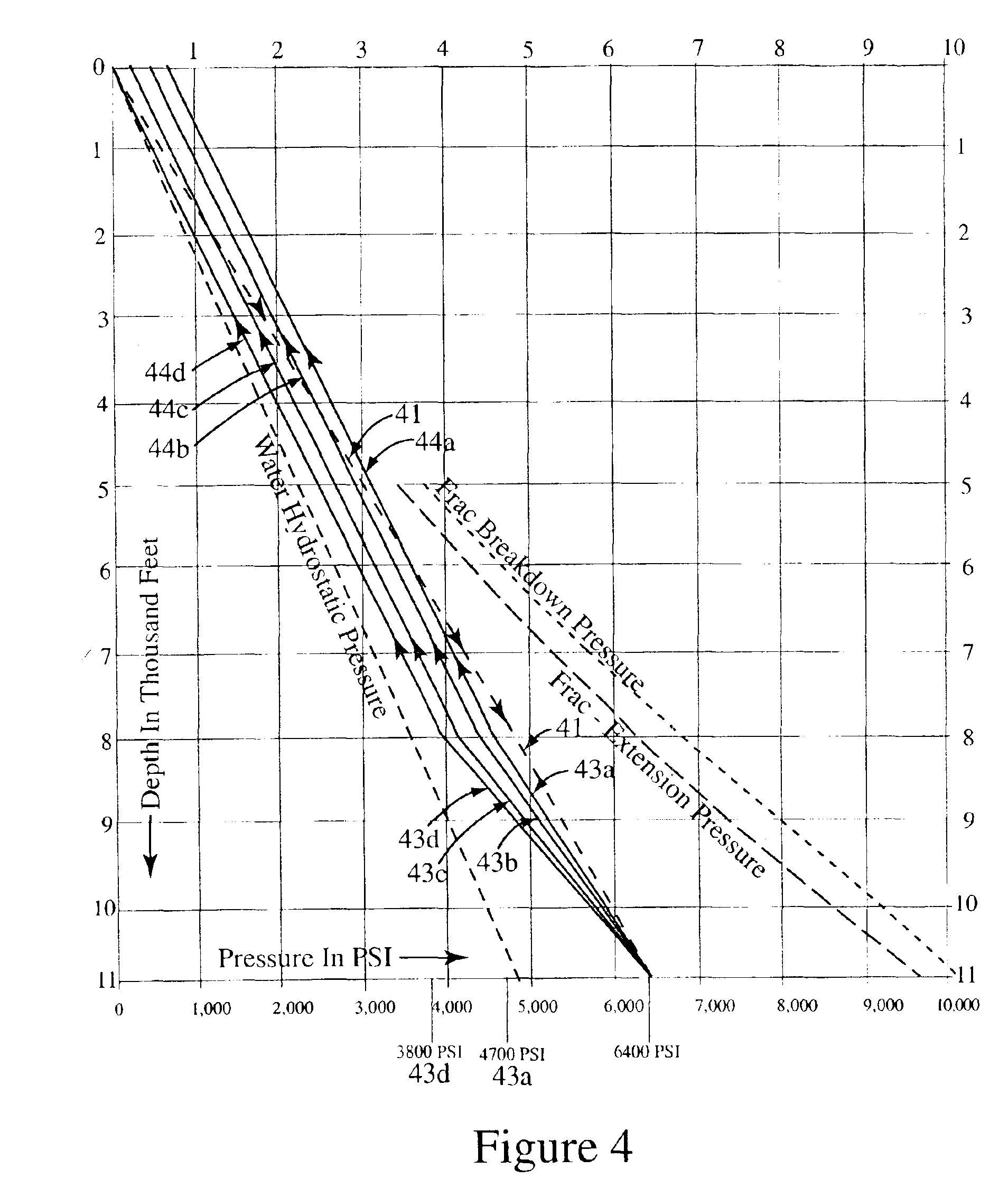

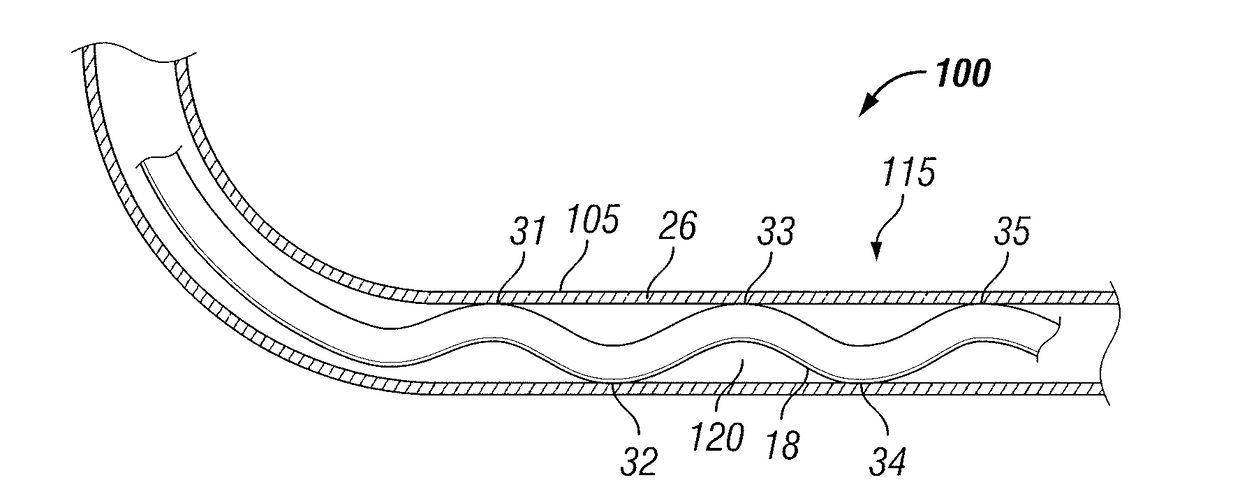

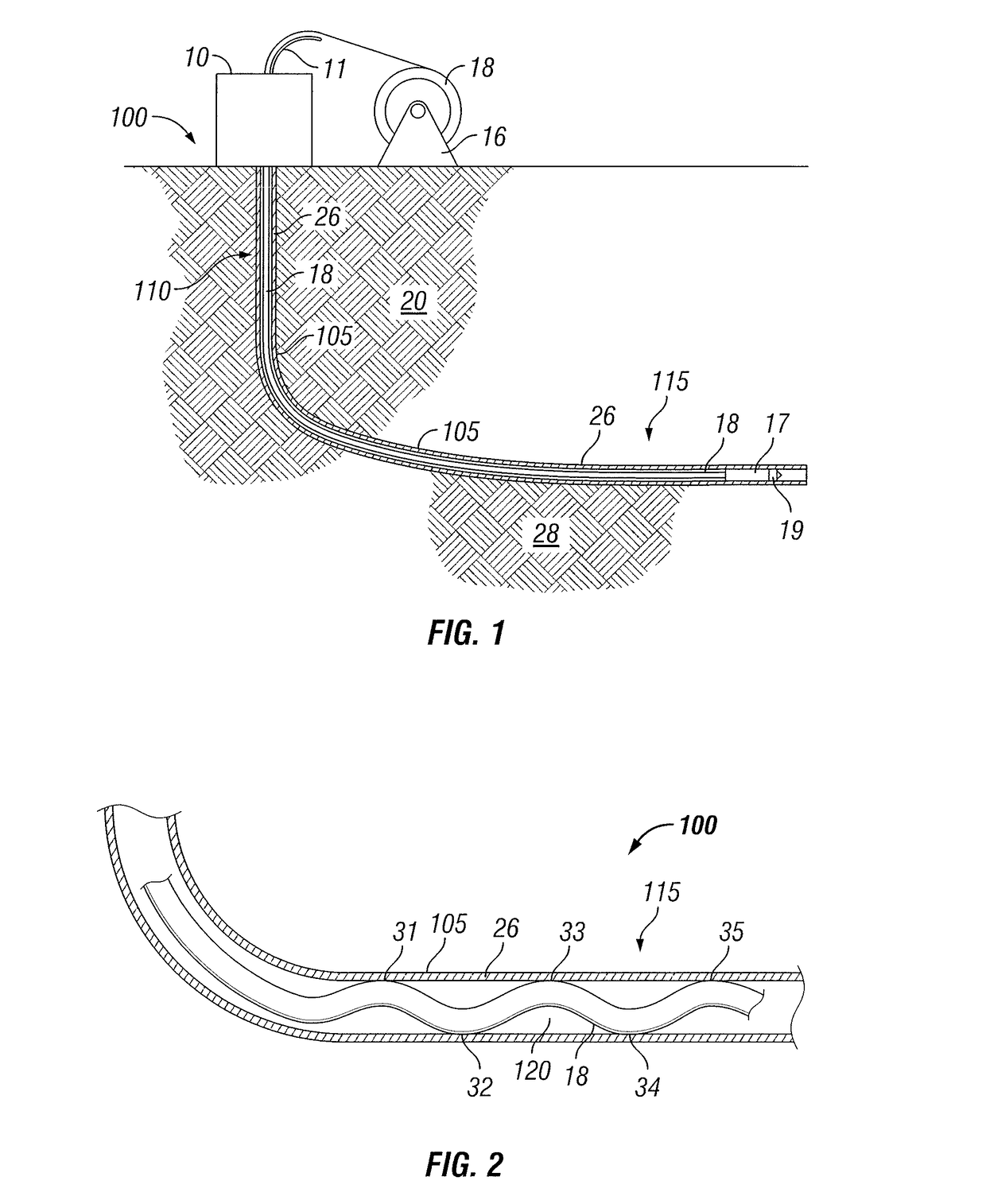

Method for upward growth of a hydraulic fracture along a well bore sandpacked annulus

A method for outward and upward growth of a hydraulic fracture along a well bore sandpacked annulus and over a selected rock formation interval along a length of a well bore. The fracture is created along the interval encompassing a multitude of oil and gas saturated sand formations and intervening silt and shale formations for more efficiently producing oil and / or gas from the formations. The method includes creating a linear sourced, cylindrical, stress field by maneuvering an intersection of a fluid friction controlled first pressure gradient and a second pressure gradient of a frac pad fluid traversing through a well bore sandpacked annulus and a hydraulic frac in the adjacent rock formation interval. The first pressure gradient is created by controlling a fluid flow rate of the frac pad fluid through a portion of the sandpacked annulus located above the top of an upwardly propagating hydraulic fracture. The first pressure gradient is substantially greater than an average gradient of rock formations frac-extension pressure gradient. The second pressure gradient is equal to or less than the average frac-extension pressure gradient and is created by a friction loss of a volume flow rate of the frac pad fluid flowing through combined parallel paths of the sandpacked annulus and the hydraulic fracture propagating outward and upward in the adjacent rock formation.

Owner:HILL GILMAN A

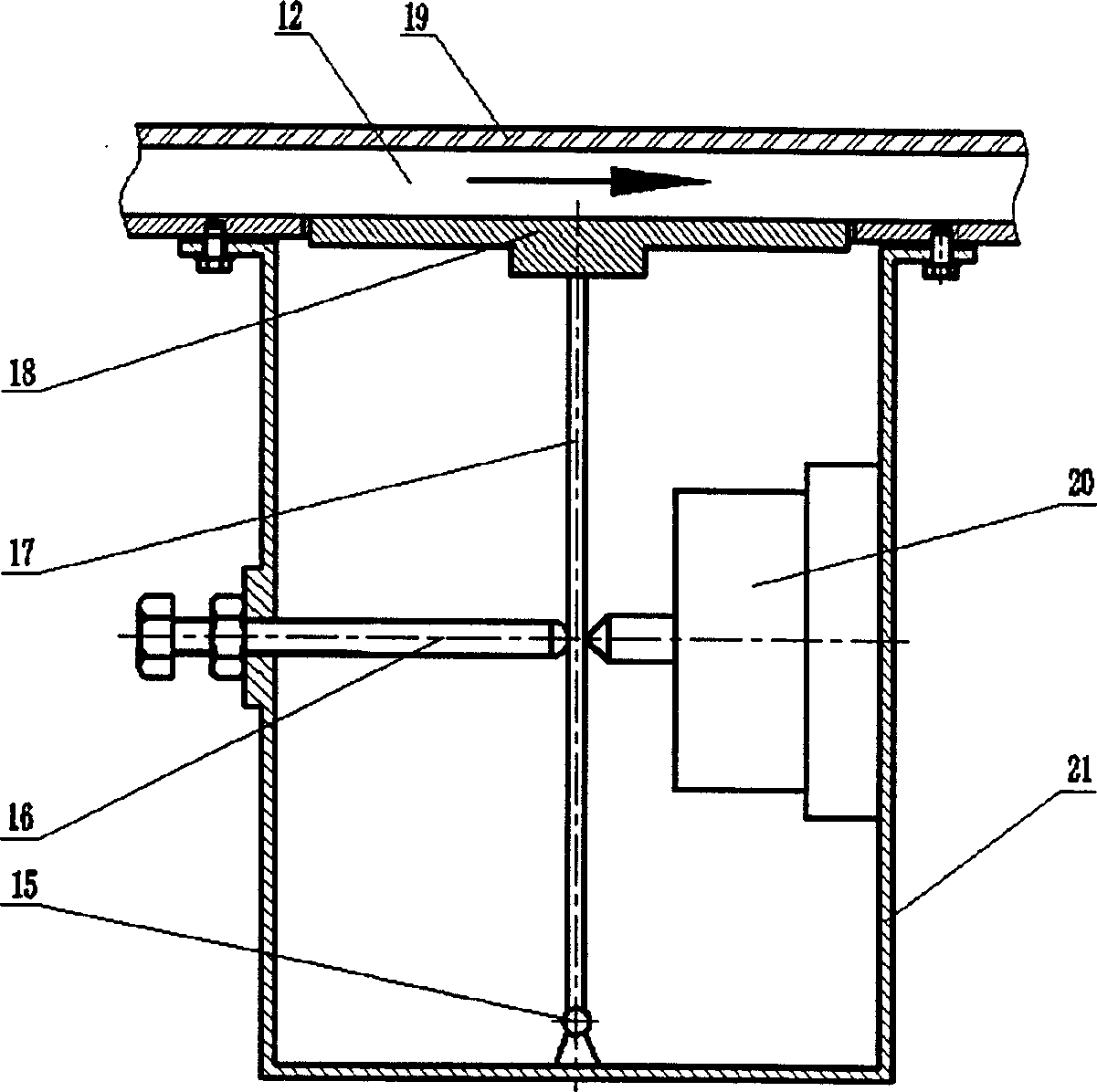

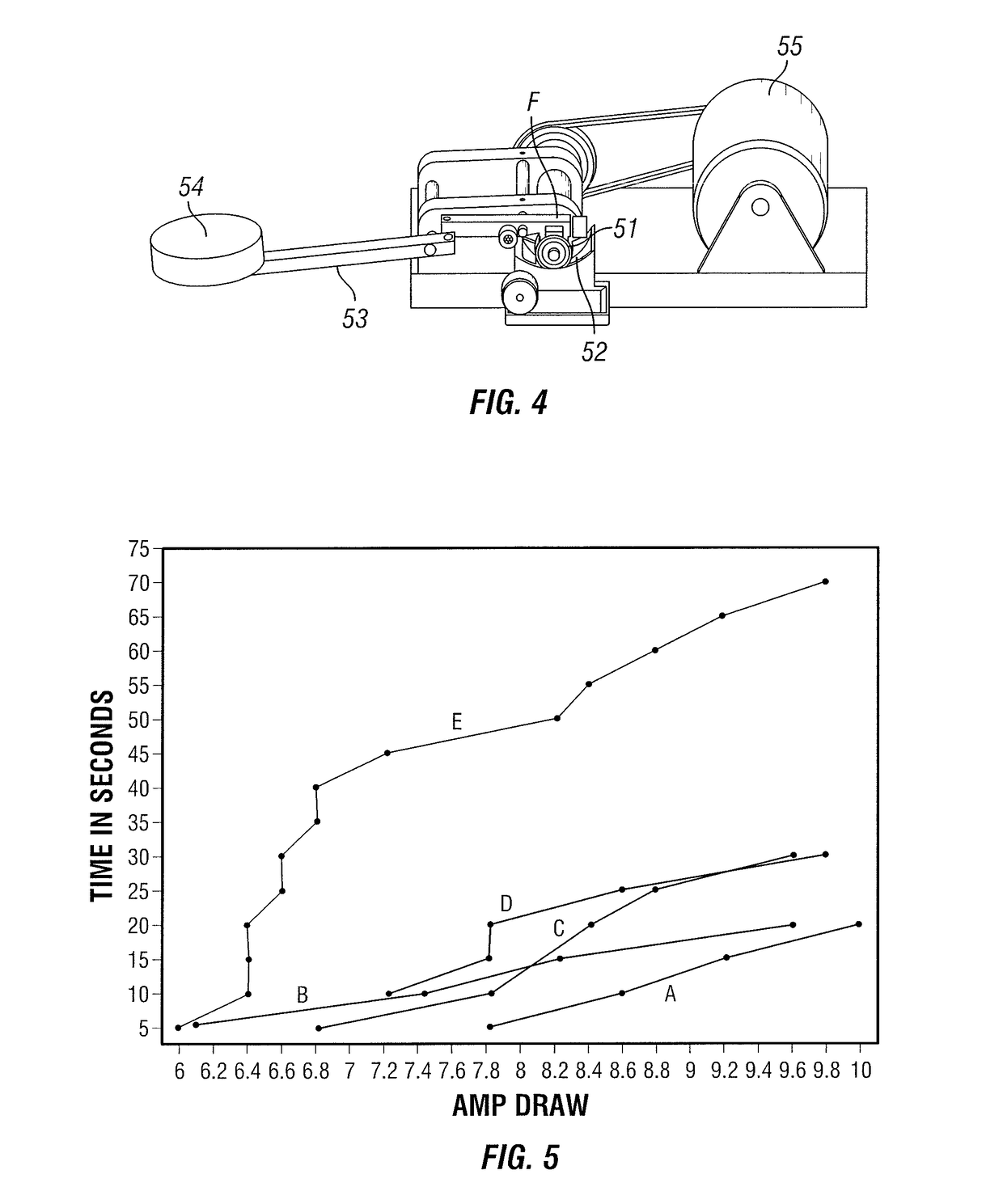

Nonsmooth surface fluid friction resistance testing device and nonsmooth surface anti-drag effect evaluating method

InactiveCN103512844AEasy to operateSimple structureUsing mechanical meansMaterial analysisCircular discControl theory

The invention aims to provide a nonsmooth surface fluid friction resistance testing device and a nonsmooth surface anti-drag effect evaluating method. The device comprises a stepper motor, a torque signal coupler, a rotating shaft and a water tank, wherein the stepper motor is connected with the torque signal coupler through a first flexible diaphragm coupling; an output shaft of the torque signal coupler is connected with the rotating shaft through a second flexible diaphragm coupling; a rotating disc is mounted at the end of the rotating shaft, arranged in the closed water tank, and driven by the stepper motor to rotate; the torque signal coupler acquires torque, power and rotating speed signals of the rotating disc, and transmits into a computer; the stepper motor and the torque signal coupler are both fixed on a guide rail; the guide rail is mounted on a supporting table; the rotating shaft is parallel to the guide rail. The device adopts the structure of the rotating disc, so that the processing of the nonsmooth surface structure on the surface of the disc or the implementing of the surface coating is easier and more convenient, and the dismantling of the rotating disc is simpler.

Owner:HARBIN ENG UNIV

Fluid friction clutch

Owner:BORGWARNER INC

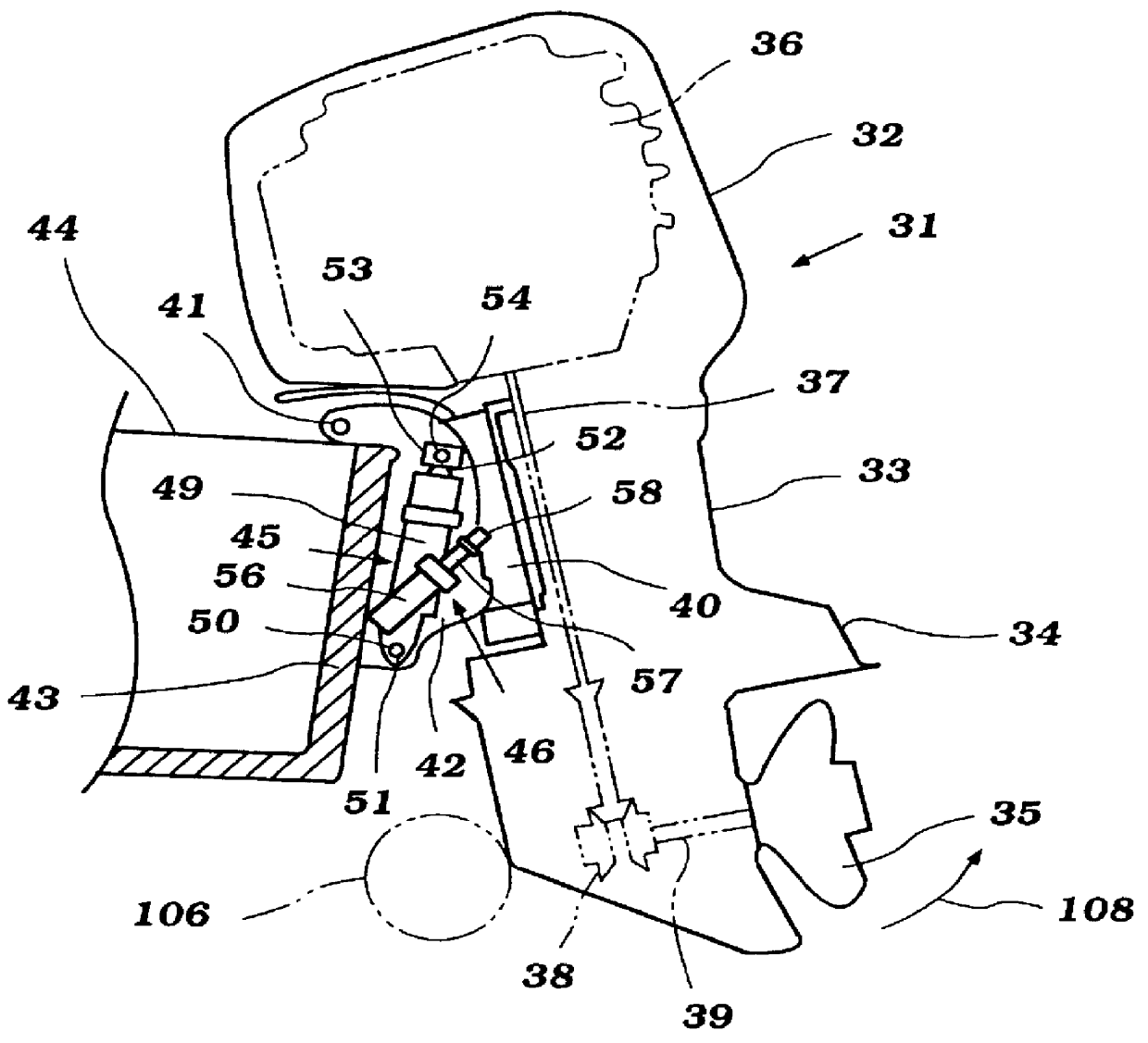

Shock absorbing arrangement for marine outboard drive

A shock absorbing arrangement integrates in a compact manner into a fluid motor of a tilt cylinder, and consequently is particularly well suited for a small outboard drive that may only have a slimed tilt cylinder. The shock absorbing arrangement is provided in a piston for permitting flow from the first chamber to the second chamber upon the application of a predetermined force tending to cause the outboard drive to tilt-up. The shock-absorbing mechanism comprises a check valve assembly accommodated in a hollow space that is formed in the piston and is closed by a plug attached to the piston. A piston rod extends through the first chamber from the piston and is separately formed with the piston. The piston rod includes a passage that communicates with the hollow formed in the piston. A diameter of the passage provided in the piston rod is larger than the diameter of a valve seat for the check valve assembly in order to reduce fluid friction loss across the shock-absorbing valve assembly.

Owner:SANSHIN KOGYO CO LTD

Multiple moveable wall surface drag reduction device for fluid

InactiveCN1730950ASimple structureEconomic structureWatercraft hull designFluid dynamicsEngineeringReducer

One kind of fluid friction force reducer is arranged between fluid to be resistance reduced and object surface. It consists of turntable, bearing, rack, movable walls and subsidiary parts. The movable walls around the turntable move with the turntable and have their parts contacting fluid moving with the fluid to reduce resistance to the fluid. Each of the movable walls consists of several layers of wall, and the wall layers can slide freely in fixed direction. Between different wall layers, lubricating fluid is filled, and the internal fluid and external fluid are maintained in balanced pressure. There may be subsidiary movable walls inside the device. The present invention may be used in different fluid resistance reducing fields.

Owner:邹立松

Hydraulic bearing device

InactiveUS6071013AAvoid thermal expansionIncrease the areaSliding contact bearingsBearing coolingRotational axisThermal expansion

A hydraulic bearing device includes a cylindrical bearing metal, a groove-like pocket, a dynamic pressure generation land, a fluid flowing space and an oil supply hole. The cylindrical bearing metal supports a rotating shaft. The pocket is formed in an inner peripheral surface of the bearing metal. The pocket defines the dynamic pressure generation land. The fluid flowing space is formed in the dynamic pressure generation land. The oil supply hole supplies fluid from a fluid pressure source to the pocket and the fluid flowing space. The dynamic pressure generation land which has been heated due to fluid friction is cooled by the fluid passing through the fluid flowing space formed in the dynamic pressure generation land. It is thus possible to inhibit thermal expansion of the hydraulic bearing device, especially the dynamic pressure generation land.

Owner:TOYODA MASCH WORKS LTD

High-temperature mechanical sealing structure

The invention discloses a high-temperature sealing structure. The big end of a shaft is sleeved with a sleeve tube, and an annular groove is formed in the end face of the sleeve tube. One end of a static ring is mounted into the annular groove in an inserted mode and is in sealing connection with the inner wall of the annular groove through an O-shaped rubber ring. First fastening screws are arranged on the two symmetric sides of the outer side of the sleeve tube, and the first fastening screws penetrate through the sleeve tube to be connected to the outer side of the static ring, so that the static ring is fixedly in the axial direction and is restrained from rotating. The end face, mounted in the annular groove, of the static ring is connected with the bottom face of the annular groove through a spring, and the end face, located outside the annular groove, of the static ring is connected with a movable ring through a special ally coating. The small end of the shaft is sleeved with the movable ring, and the movable ring is positioned through a shaft shoulder and then is fixed axially through a locking baffle ring and a second fastening screw. According to the high-temperature sealing structure, the friction condition between the movable ring and the static ring under the high-temperature state is changed to fluid friction from high friction, friction, abrasion and dielectric leakage between the movable ring and the static ring are reduced, the service life of the movable ring and the static ring is prolonged, and the good mechanical sealing performance between the end face of the movable ring and the end face of the static ring is guaranteed.

Owner:ZHEJIANG UNIV

Completion Fluid Friction Reducer

InactiveUS20170233627A1Reduce coefficient of frictionDirectional drillingAdditivesReducerSURFACTANT BLEND

A method and composition for reducing a coefficient of friction are disclosed. In an embodiment, a method for reducing a coefficient of friction between two surfaces in a borehole includes preparing a mixture comprising a primary lubricating agent, a primary surfactant, a spreading agent, and an aqueous fluid. The method also includes pumping the mixture into the borehole such that the mixture contacts the two surfaces and reduces the coefficient of friction for the two surfaces.

Owner:NOLES INTPROP

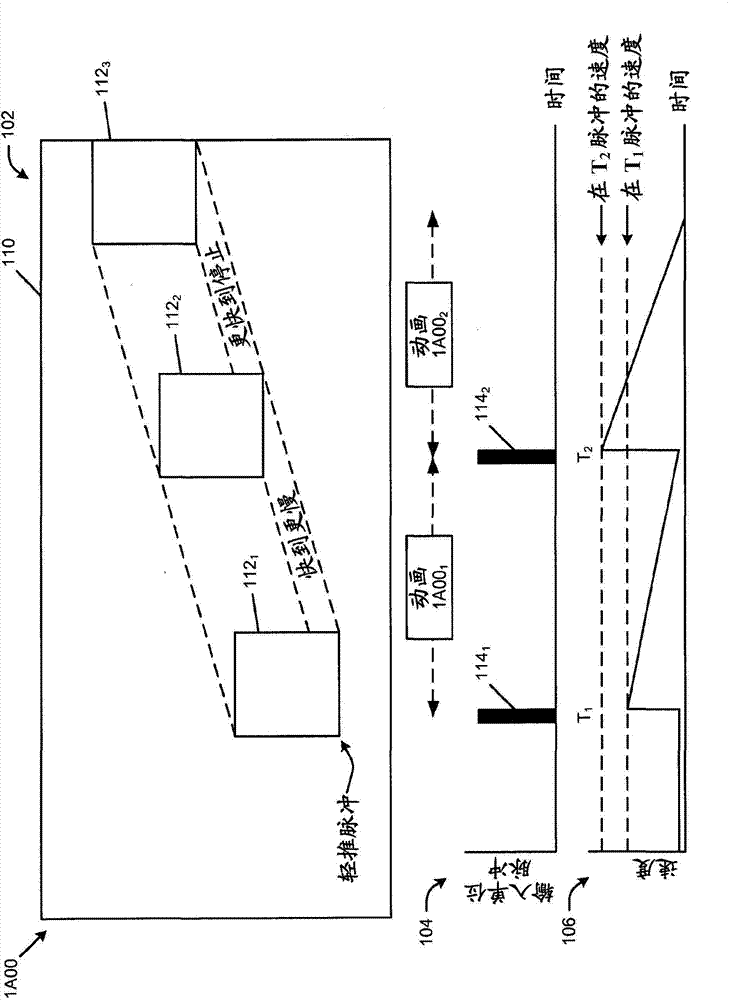

Moving an object about a display frame by combining classical mechanics of motion

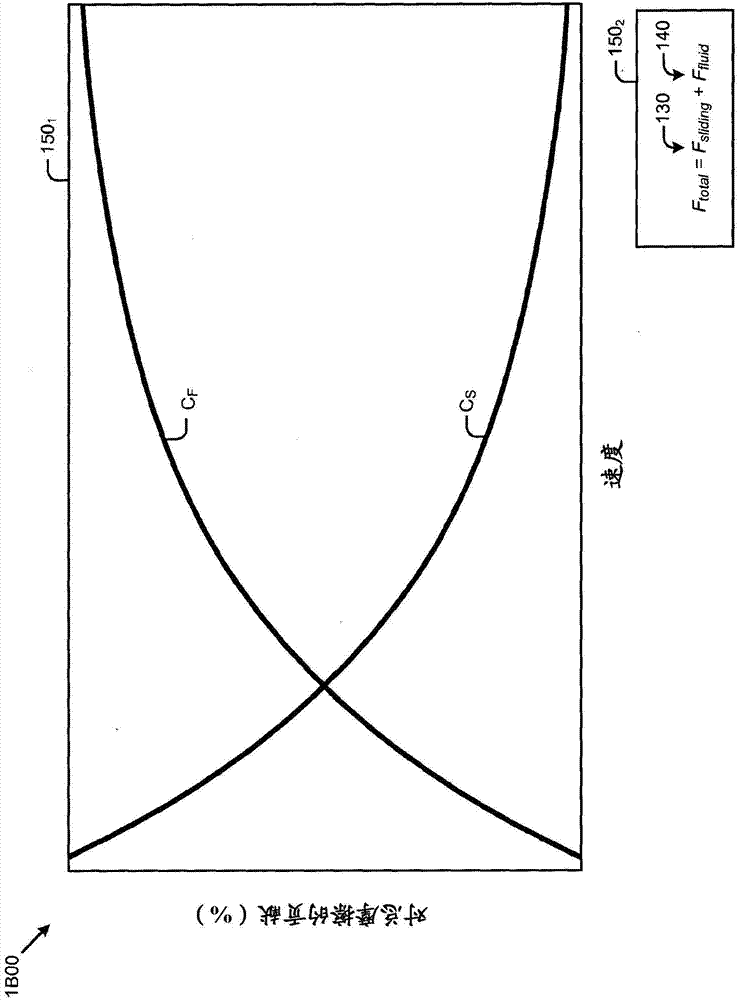

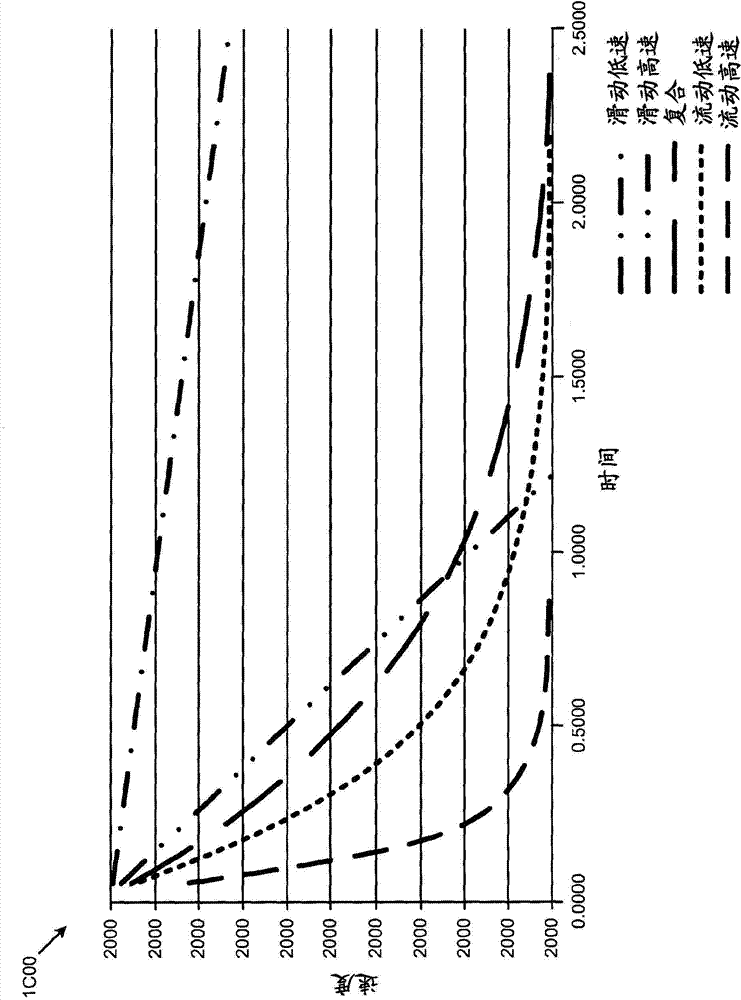

A method, system, and computer program product for moving objects such as a display window about a display frame by combining classical mechanics of motion. A window nudging method receives a discrete user interface gesture from a human interface device, and based the discrete user interface gesture, instantaneously accelerating the window object to an initial velocity. Once the window is in motion, then the method applies a first movement to animate the window object using realistic motion changes. Such realistic motion changes comprise a friction model that combines sliding friction with fluid friction to determine frame-by-frame changes in velocity. The friction model that combines sliding friction with fluid friction can be applied to any object in the display frame. Collisions between one object and another object or between one object and its environment are modeled using a critically-damped spring model.

Owner:ORACLE INT CORP

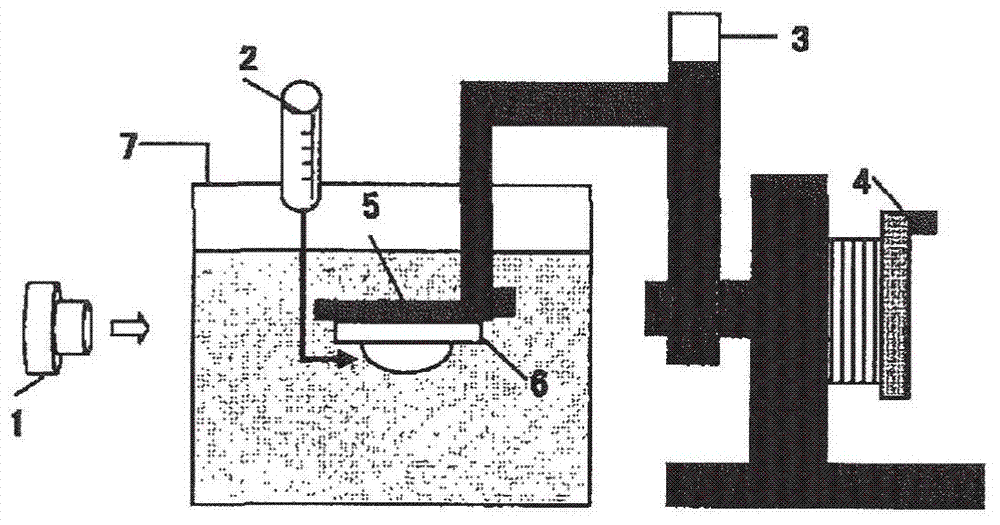

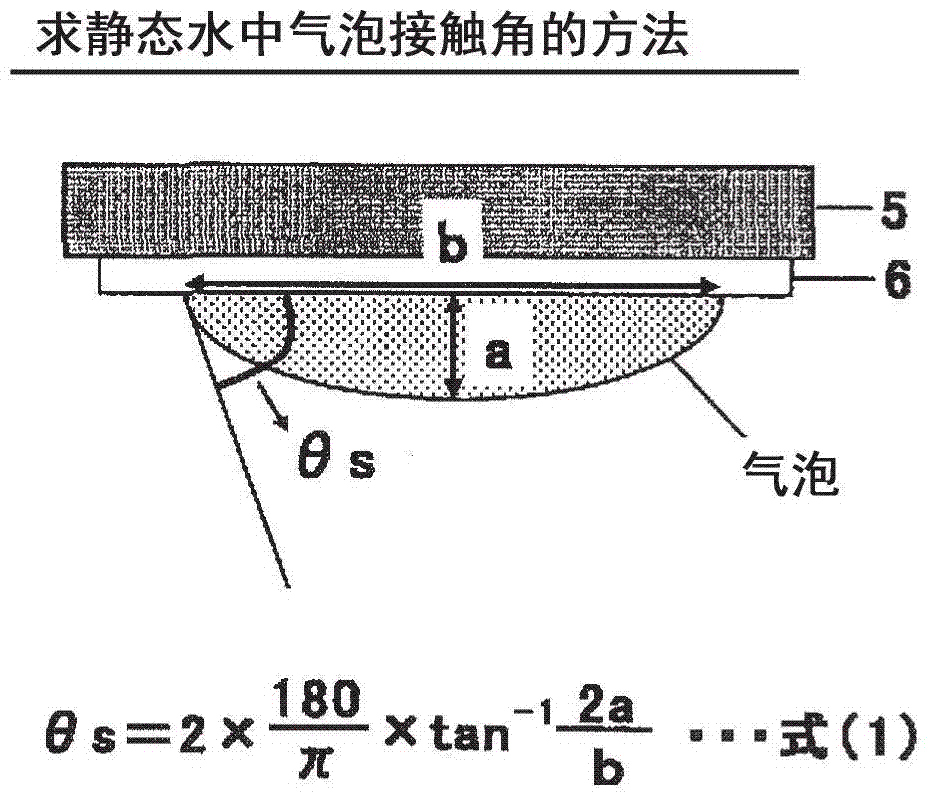

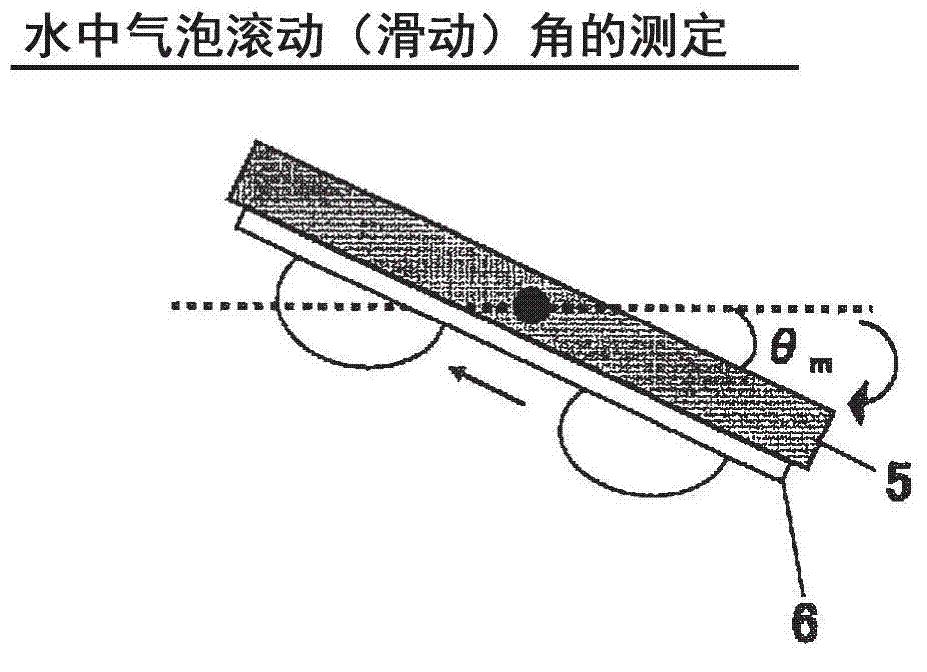

Coating composition for use in ship with reduced friction drag utilizing gas-lubricating function in water, coating film formed from said composition, ship coated with said coating film, method for manufacturing said ship, method for predicting said friction drag reduction effect, device used for prediction of said friction drag reduction effect, and friction drag reduction system for use in said ship with reduced friction drag

ActiveCN104854204AShows air lubrication effectReduce frictional resistanceVessel cleaningAntifouling/underwater paintsMarine engineeringProduct gas

The present invention addresses the problem of providing: a ship with a reduced friction drag, which can keep the affinity for a gas such as air in water for a long period, has a high fluid friction drag reduction effect, is economically advantageous and has little influence on the environment; a coating composition which enables the formation of a coating film that can keep the affinity for a gas such as air in water for a long period, has a friction drag reduction effect and can exhibit a stain-proof function under stream or under static conditions; and others. The present invention relates to a coating composition which enables the formation of a coating film having a specified static in-water bubble contact angle and a specified in-water bubble roll (slip) angle and can be used for a ship with a reduced friction drag utilizing a gas-lubricating function in water. The present invention also relates to a stain-proof coating composition which comprises a specific organopolysiloxane (A), a specific organosilane (B) and a specific hydrophobic material (C) in specified amounts and can be used for a ship with a reduced friction drag utilizing a gas-lubricating function in water.

Owner:CHUGOKU MARINE PAINTS

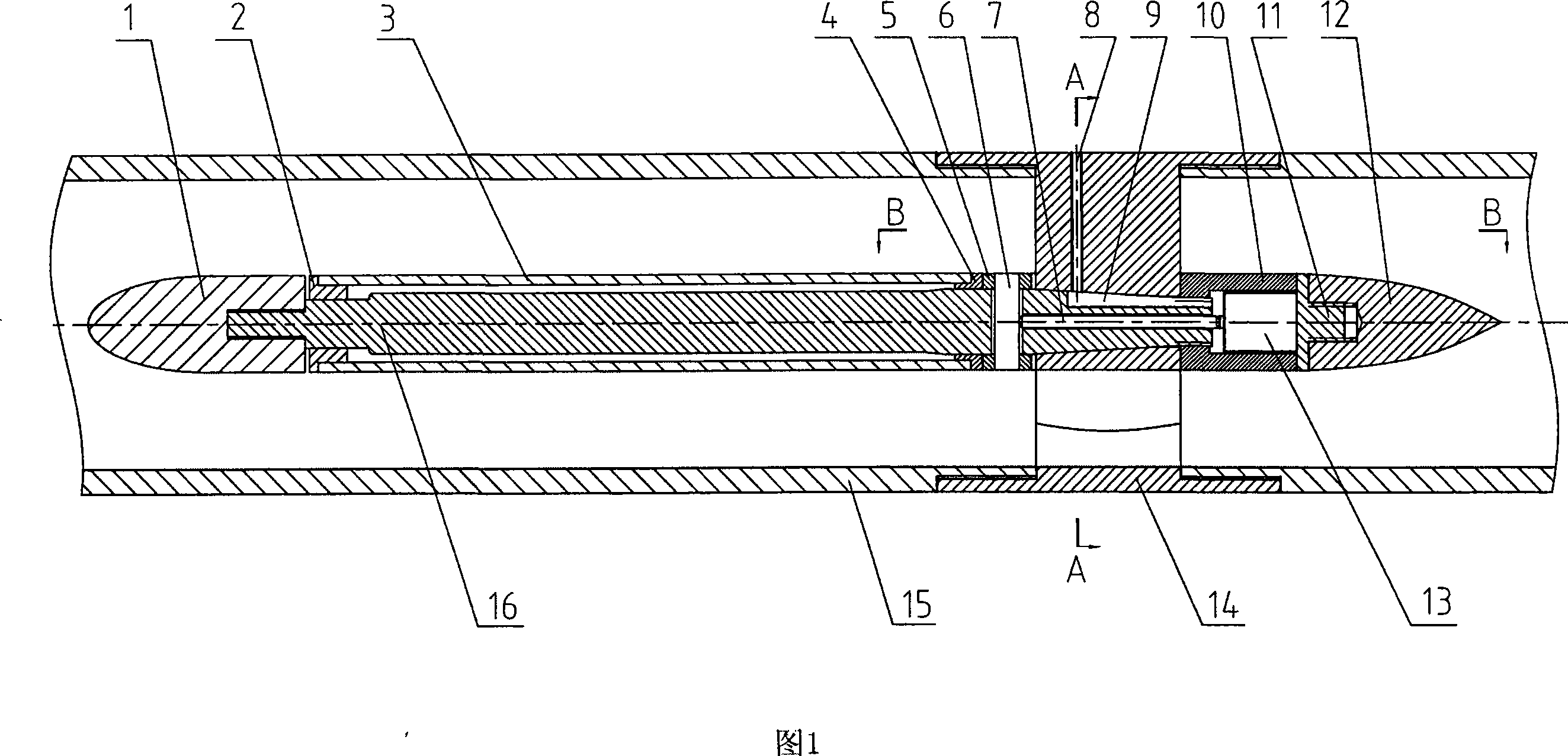

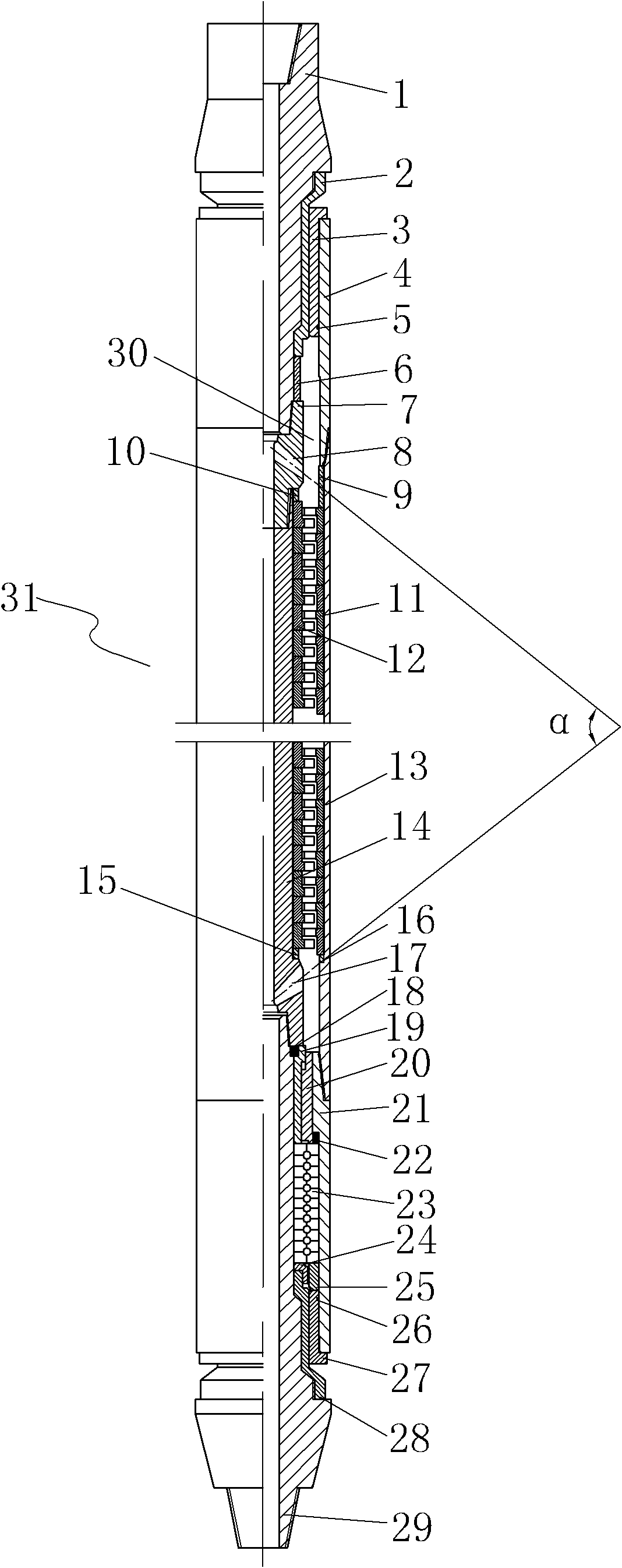

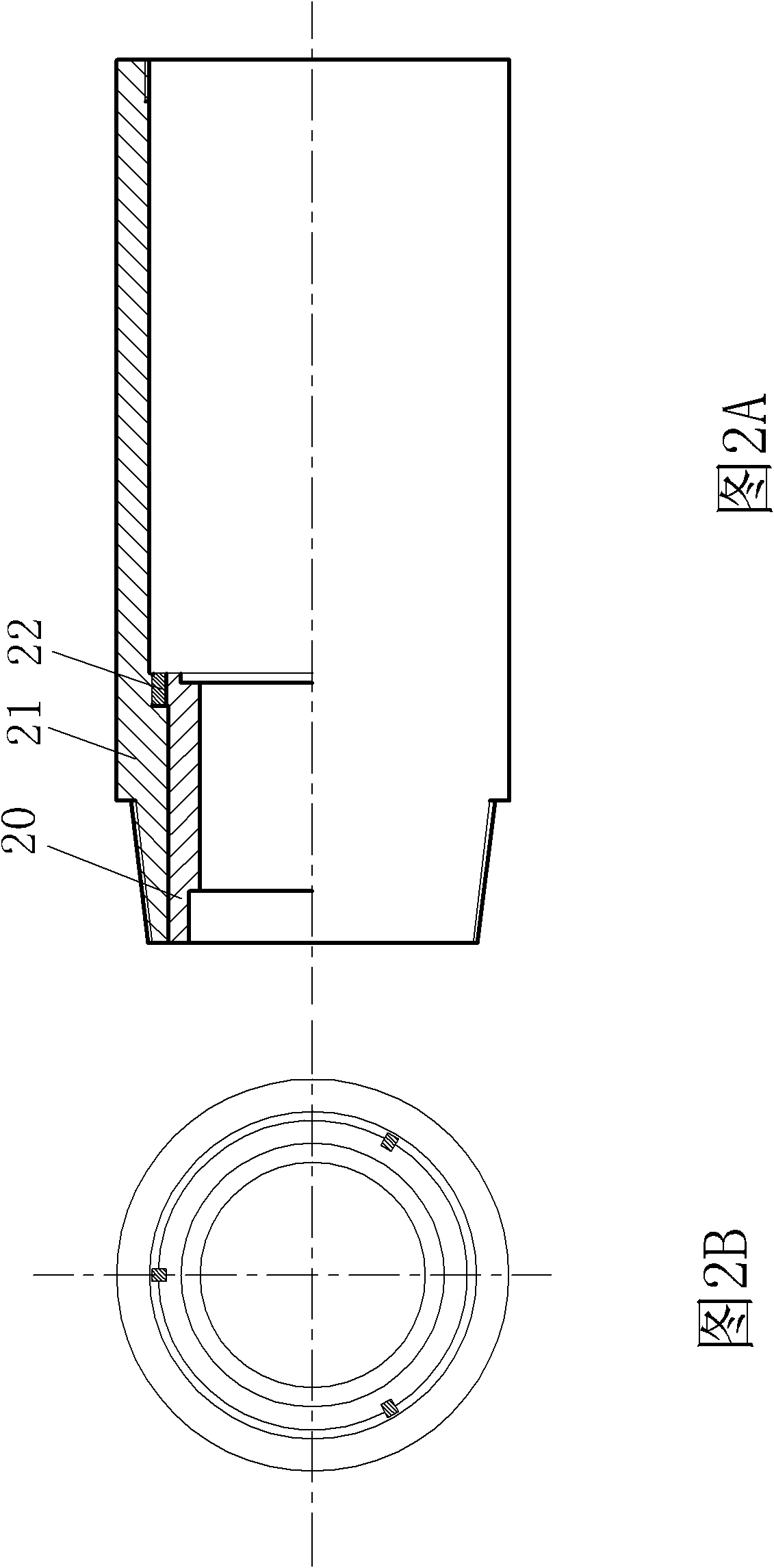

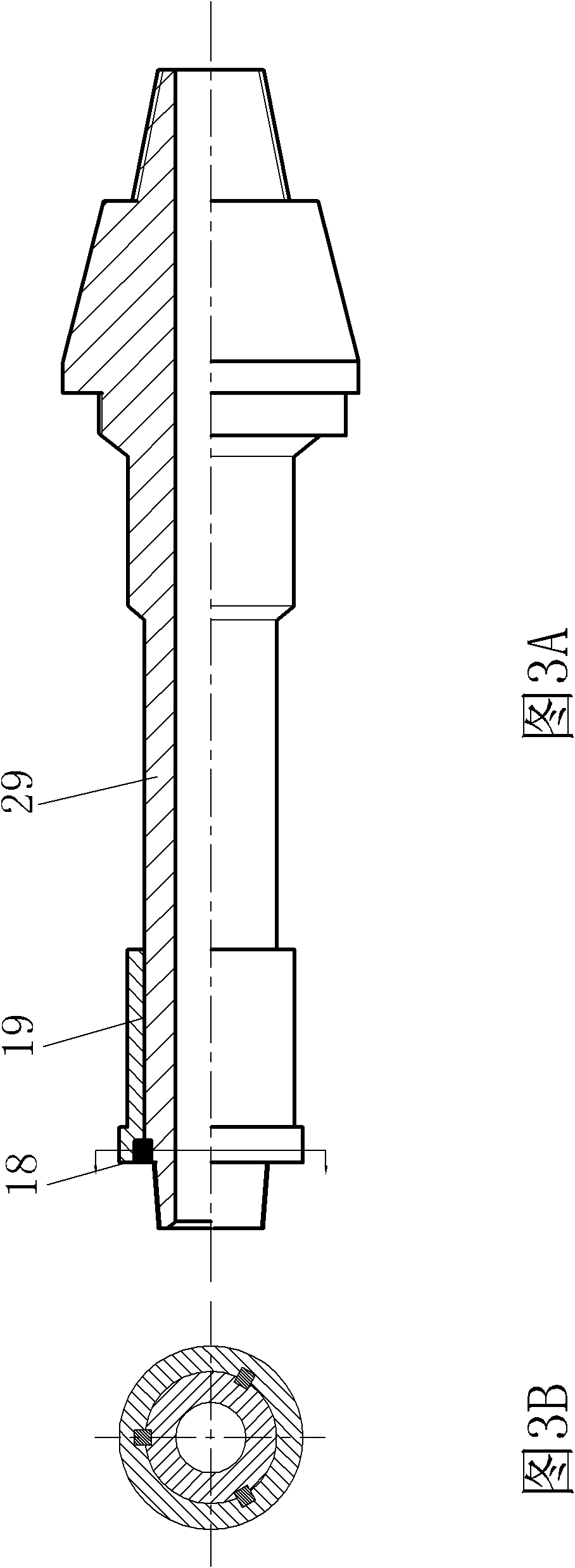

Dynamic pressure lubrication drilling tool and drilling tool assembly with same

InactiveCN102425382AReduce friction lossReduce surface wearDrilling rodsDirectional drillingWell drillingBoundary friction

The invention relates to a dynamic pressure lubrication drilling tool and a drilling tool assembly. The dynamic pressure lubrication drilling tool comprises a central shaft, wherein a shell can be sleeved on the outer part of the central shaft in a rotating manner relative to the central shaft, and an annular space is formed between the inner wall of the shell and the peripheral surface of the central shaft; more than one rotor is arranged on the inner wall of the shell, each rotor is provided with a plurality of inwards protruding rotor blades, and the rotor blades are positioned in the annular space; and the side wall of the central shaft is provided with more than one shunting hole. The drilling tool assembly is provided with a drill column, wherein the drill column comprises a plurality of sequentially connected conventional drilling tools and at least one dynamic pressure lubrication drilling tool; and the dynamic pressure lubrication drilling tool is arranged between two adjacent conventional drilling tools. when a well is drilled, the drilling tool assembly brings drilling fluid to the space between the drilling tool and a well wall or a sleeve wall under the fluid pumping action when the dynamic pressure lubrication drilling tool rotates, and the outer surface of the drilling tool is separated from the well wall or the sleeve wall, so that dry friction or boundary friction between the outer surface of the drilling tool and the well wall or the sleeve wall is changed into fluid friction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Pneumatic tool having pressure release device

A pneumatic tool includes a rotor rotatably received in a housing, a driving shank coupled to the rotor, for being rotated by the rotor and by a pressurized air and having one end for driving a fastener. A pressure releasing device may release the pressurized air after the fastener has been tightly threaded onto the object to be fastened. A fluid container is rotatably received in the housing and coupled to the rotor, for partially receiving the driving shank. The driving shank has one or more paddles for being frictionally driven by the container and by the fluid. A pole is slidably engaged through the rotor, and actuated to release the pressurized air when the fastener has been tightly threaded onto the object.

Owner:LIAO YU HUI

Lubrication oil composition

The present invention provides a lubricating oil composition having an extremely high viscosity index and a low coefficient of traction as a low coefficient of fluid friction in an elastohydrodynamic lubrication which is excellent in saving of energy and reduction in fuel consumption. The lubricating oil composition according to the present invention includes the following components (A) and (B): (A) a low-viscosity synthetic oil comprising a compound containing ether bond(s) in a molecule thereof and having a kinematic viscosity of less than 10 mm2 / s as measured at 40° C., in which a ratio of the number of oxygen atoms to the number of carbon atoms as constituents of the compound (O / C ratio) and the kinematic viscosity (mm2 / s) of the compound as measured at 40° C. satisfy the following formula (1); Kinematic Viscosity at 40° C.≦12−[(O / C ratio)×30] (1); and (B) a high-viscosity synthetic oil as a hydrocarbon-based synthetic oil having a kinematic viscosity of 40 mm2 / s or more as measured at 100° C. which includes at least one compound selected from the group consisting of an α-olefin oligomer, a hydrogenated α-olefin oligomer and an ethylene-propylene co-oligomer.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com