Dynamic pressure lubrication drilling tool and drilling tool assembly with same

A drilling tool assembly and drilling tool technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problem of automatic separation between the outer surface of the drilling tool and the well wall or casing wall, so as to improve drilling efficiency and prevent well deviation. , the effect of reducing friction loss and surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

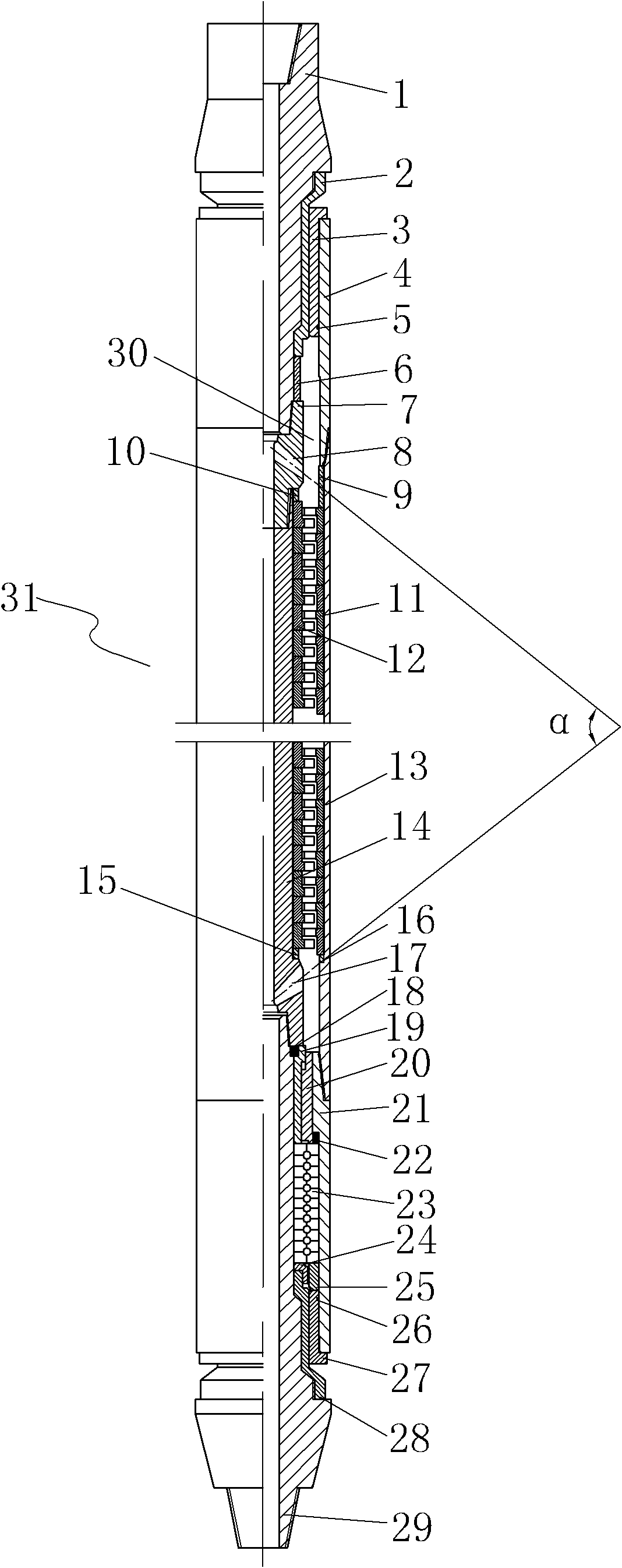

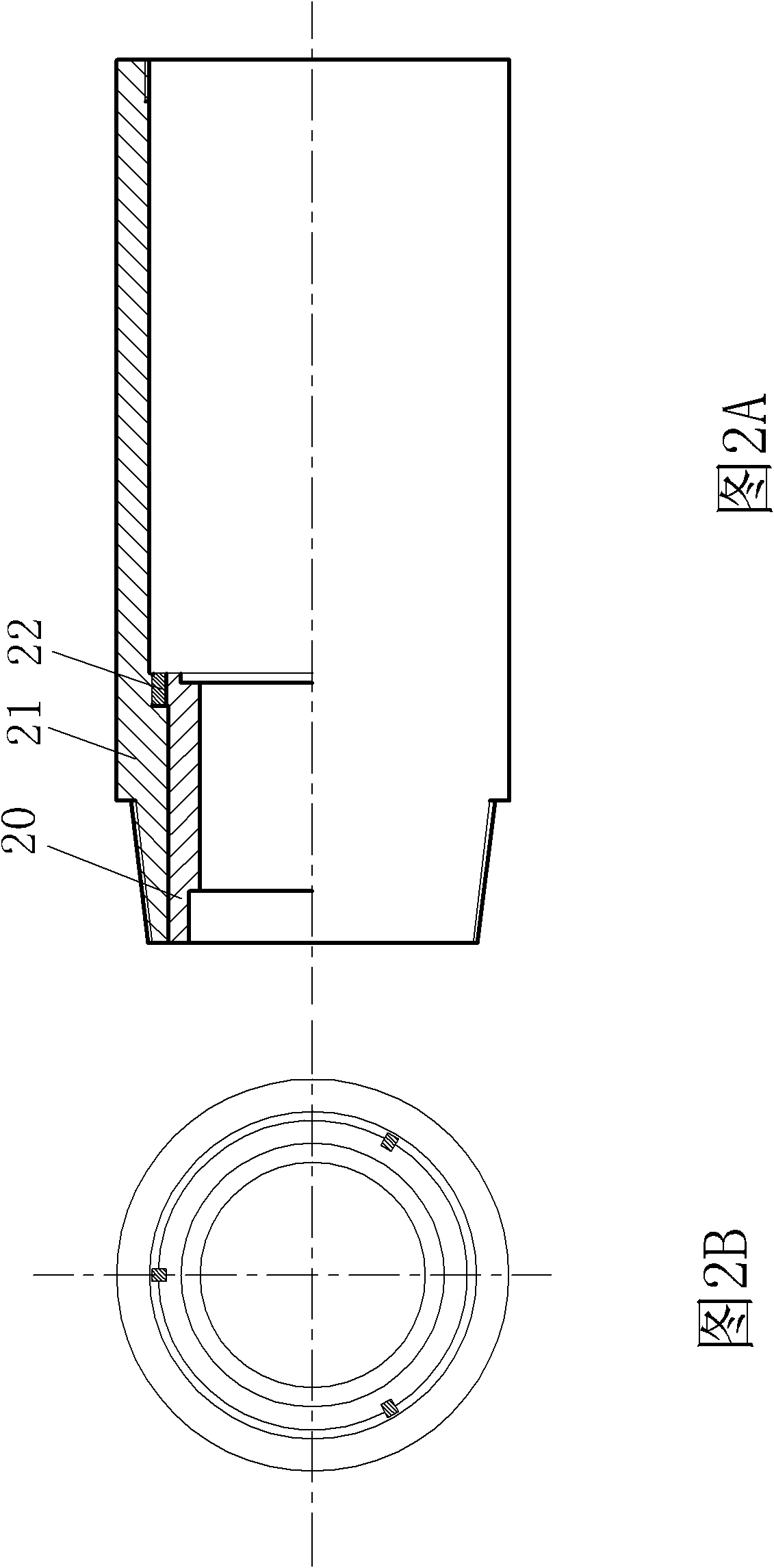

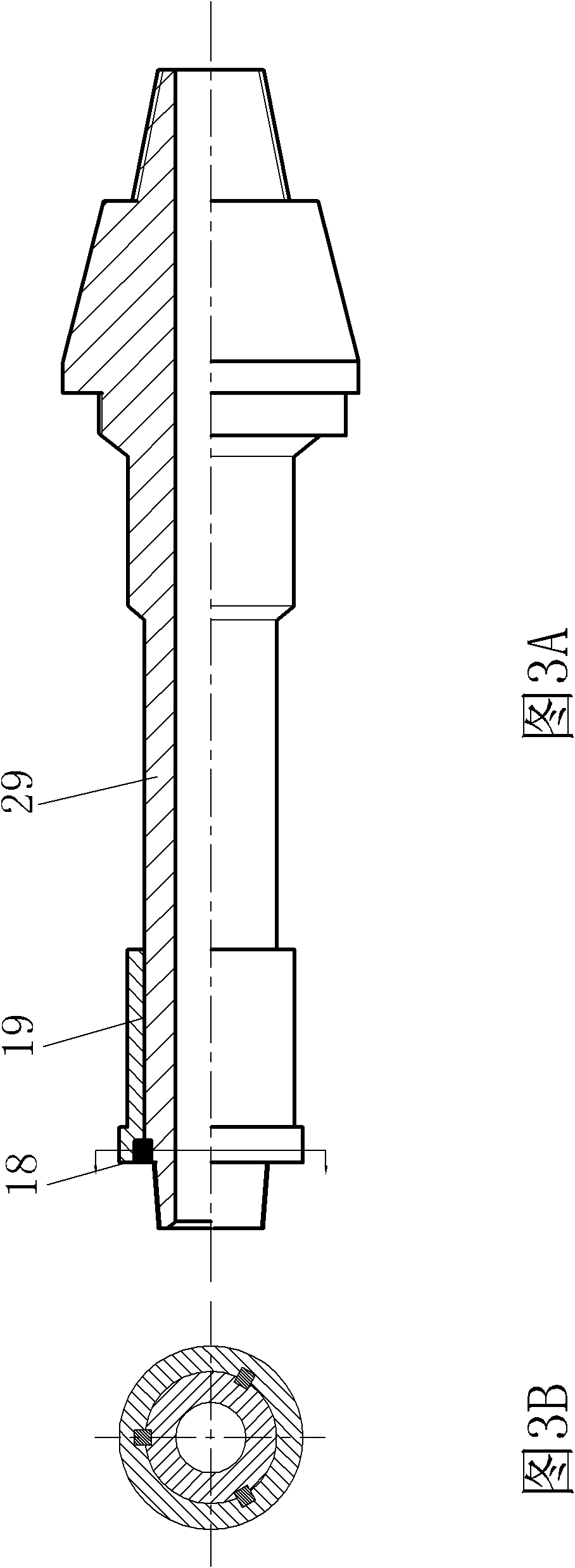

[0040] A dynamic pressure lubricating drilling tool proposed by the present invention includes: a hollow central shaft, a casing sleeved on the outside of the central shaft, and an inner wall of the casing and the outer peripheral surface of the central shaft are formed with a annulus; at least one or more rotors are arranged on the inner wall of the casing, each of the rotors has a plurality of inwardly protruding rotor blades, the rotor blades are located in the annulus; the central axis The side wall of the rotor is provided with more than one shunt hole, and the drilling fluid entering the central shaft can impact the rotor blade after passing through the shunt hole, so that the casing can rotate relative to the central axis.

[0041]Further, the central shaft is composed of an upper joint, a water cap joint, a central pipe, and a lower joint that are screwed and connected in sequence, and a plurality of the shunt holes are evenly distributed on the side wall of the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com