Patents

Literature

152results about How to "Reduce surface wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

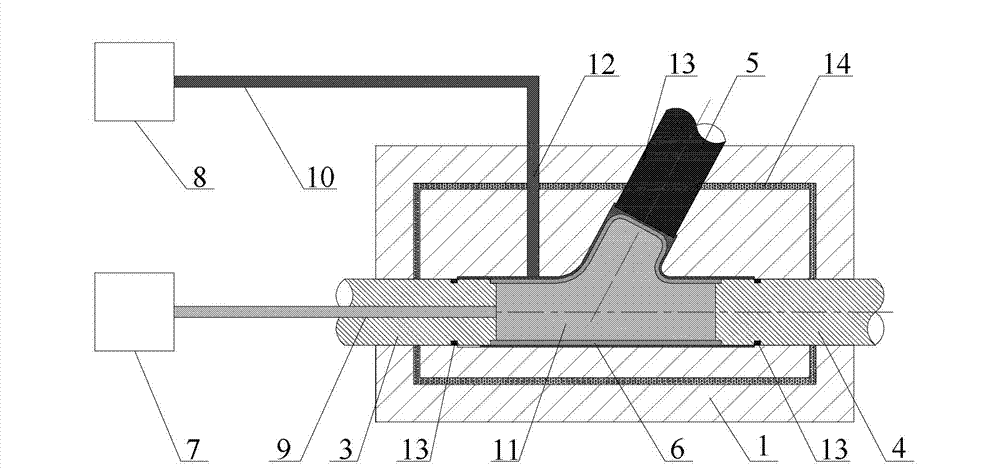

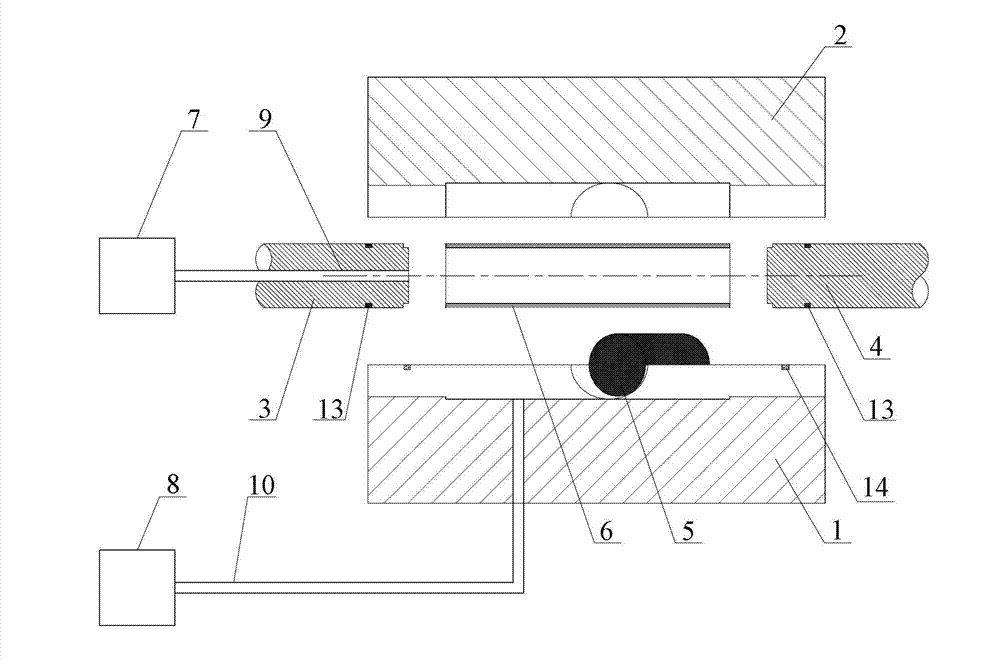

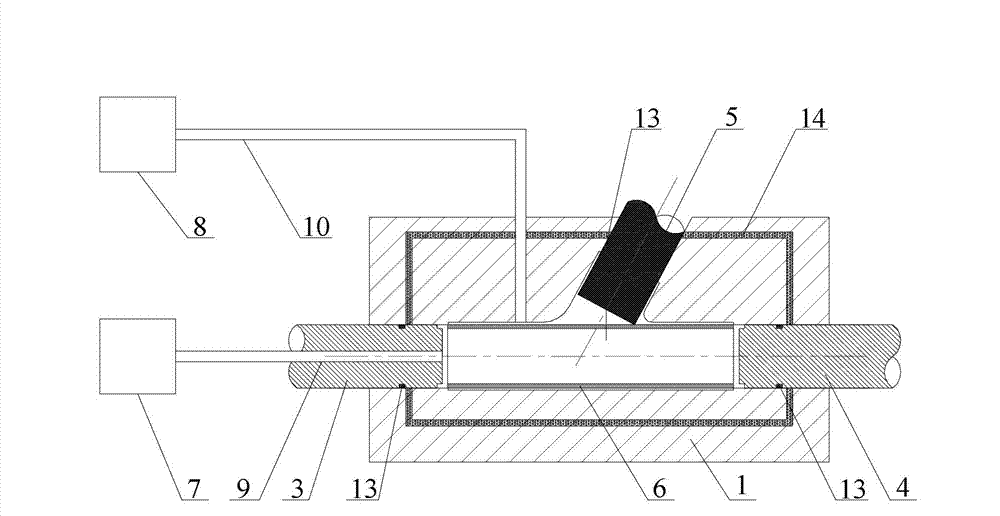

Composite inner and outer hydraulic pressure forming method for high-branch height thin-wall three-way pipe

ActiveCN102921792AReduce frictionImprove axial critical wrinkling stressInternal pressureHigh pressure

The invention discloses a composite inner and outer hydraulic pressure forming method for a high-branch height thin-wall three-way pipe, belongs to the technical field of inner high pressure forming and aims to solve the problem that the branch height of the formed three-way pipe is limited in the conventional inner high pressure forming method. The method comprises the following steps of: filling liquid media inside a pipe billet and discharging gases through a supercharger, and moving a left-side punch and a right-side punch forwards to finish pipe end seal, so that inner pressure of the pipe billet is insufficient, and the pipe billet deforms; filling liquid media on the outer side of the pipe billet through holes on a die, wherein outside hydraulic pressure is sealed by a sealing groove on the die and a sealing ring on the punch, so that the pipe billet has plastic deformation under the action of inner pressure, outer pressure, axial feeding of the left and right punches and retreating of the branch punch, and obtaining the high-branch height three-way pipe. Compared with the traditional inner high pressure forming method, the method has the advantages of high branch pipe height and high pipe surface quality, and is particularly suitable for thin-wall three-way pipe forming.

Owner:抚顺三方机械制造有限公司

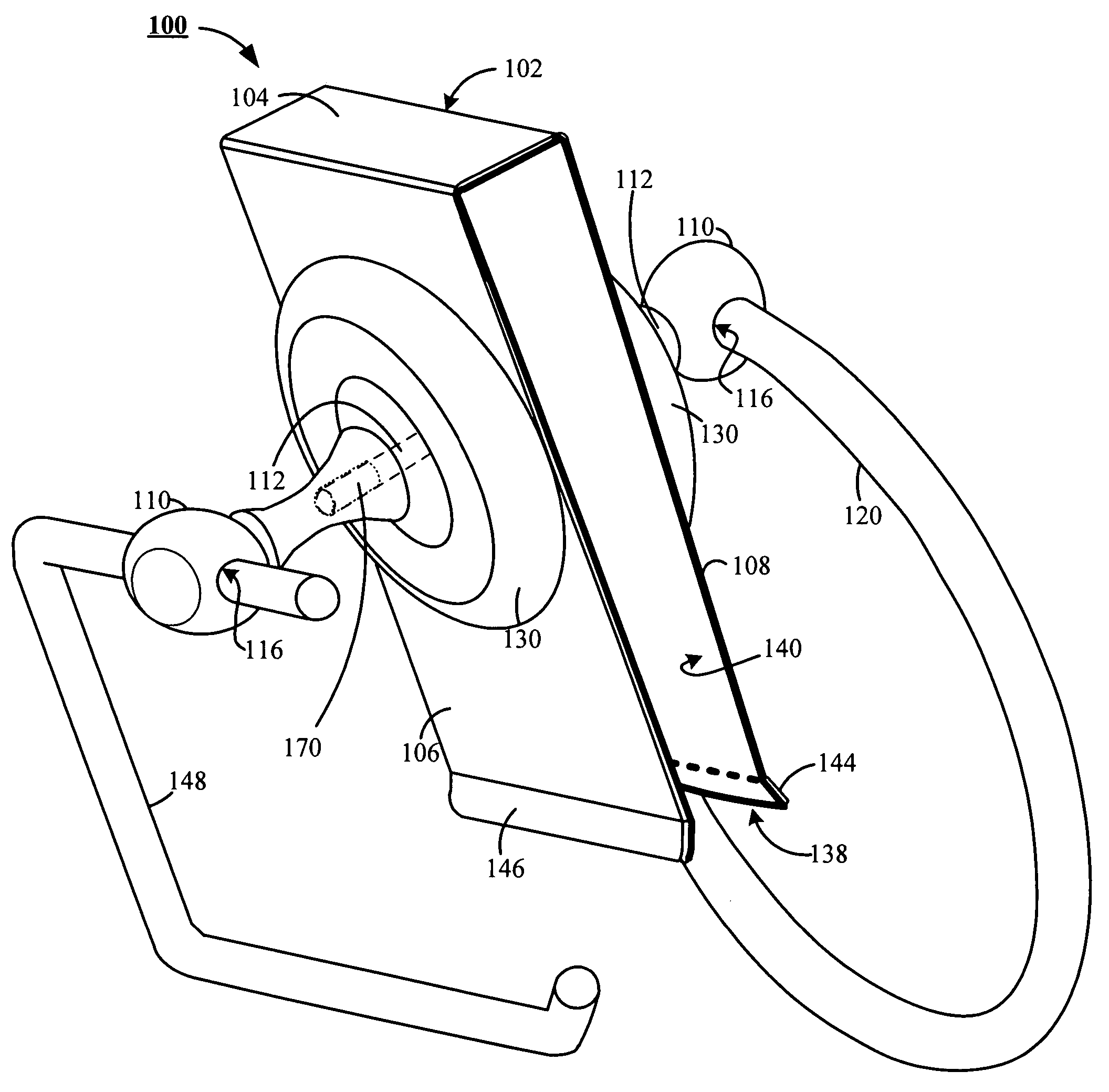

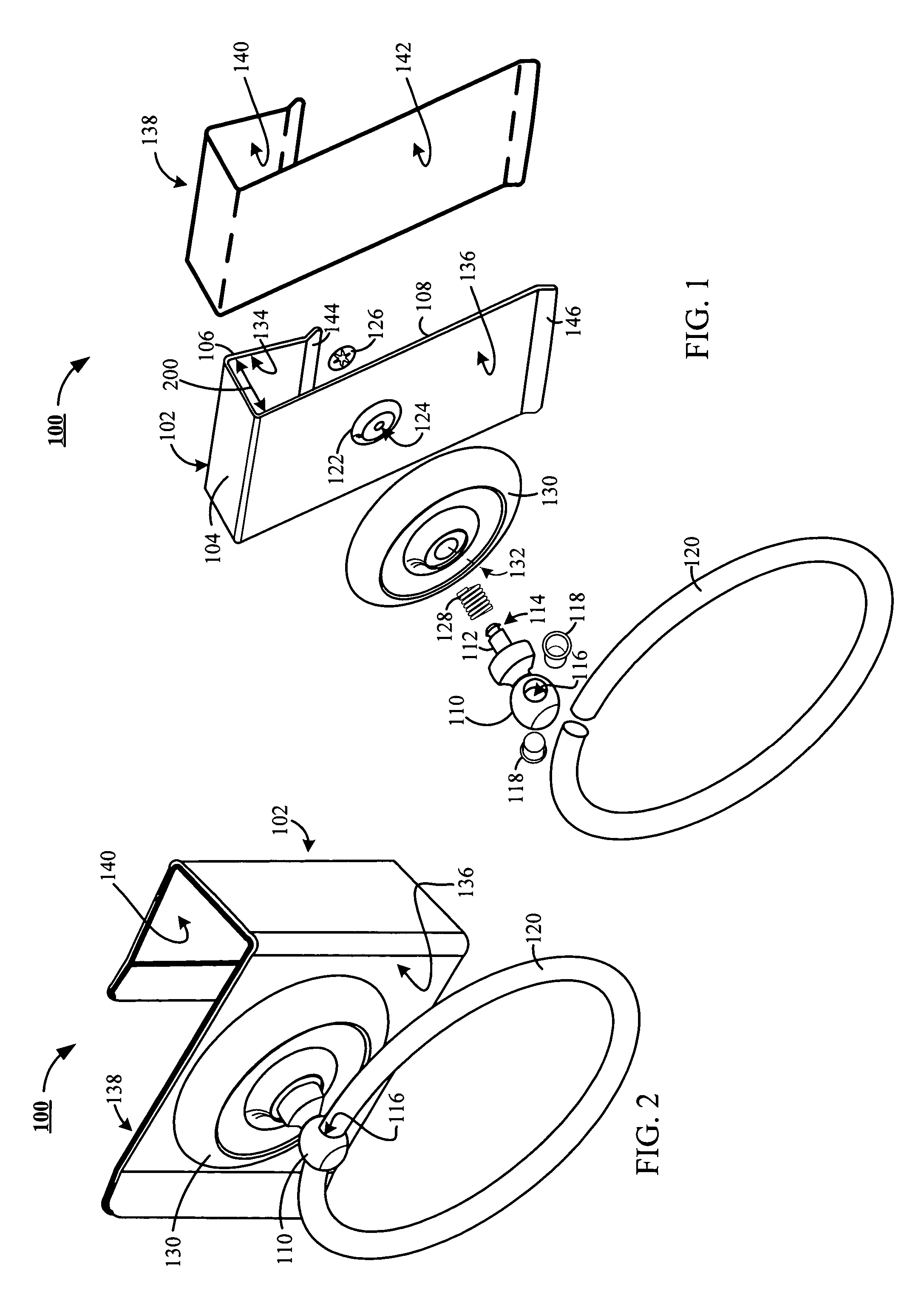

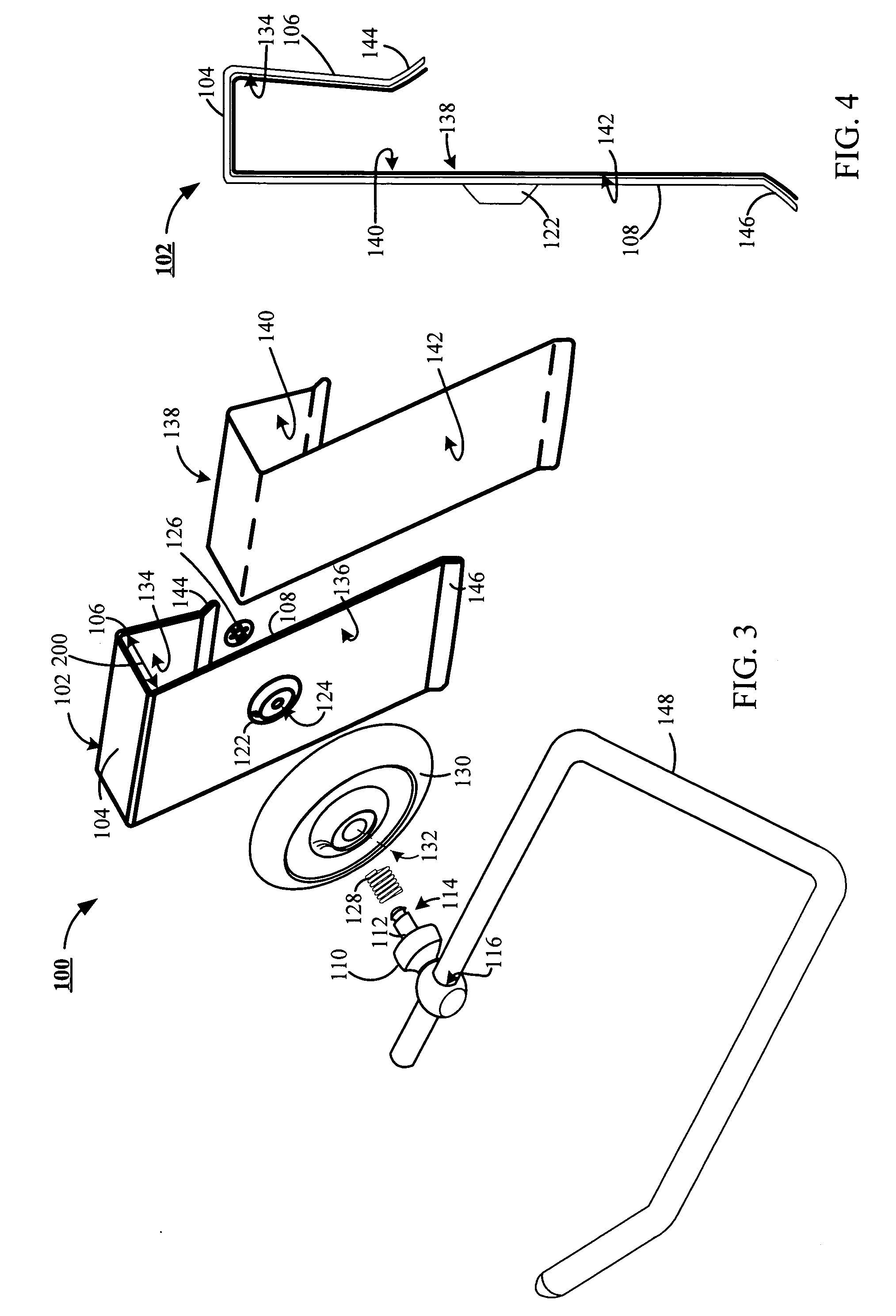

Portable article support apparatus

An apparatus with a first and second loaf spring portions extending from a bridge portion, the second leaf spring portion provides an article support mounting aperture for attachment of an article support to the second leaf spring portion by structure for attaching said article support, and additional structure for securing the article support to the second leaf spring portion is disclosed. In a first embodiment, the article support is a towel ring, the structure for attaching the towel ring to the second leaf spring portion includes a shaft extending from a distal end of a post, and a retention groove formed at a distal end of the shaft. The additional structure for securing the shaft to the second leaf spring portion includes: a compression spring enclosing the shaft and interposed between the second leaf spring portion and the post; and a fastener affixed to the retention groove.

Owner:SIMONSEN JOSEPH M

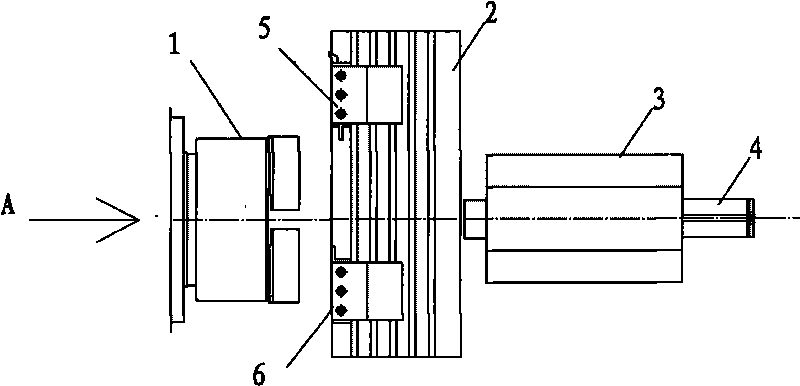

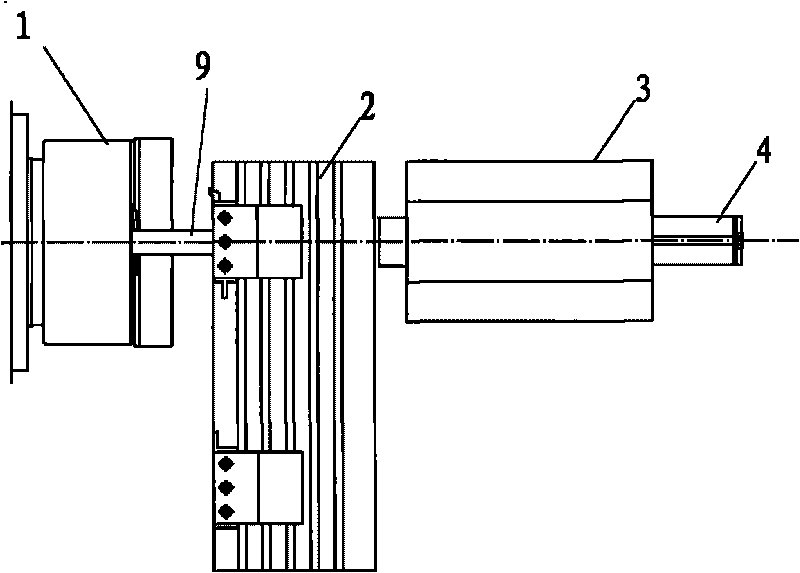

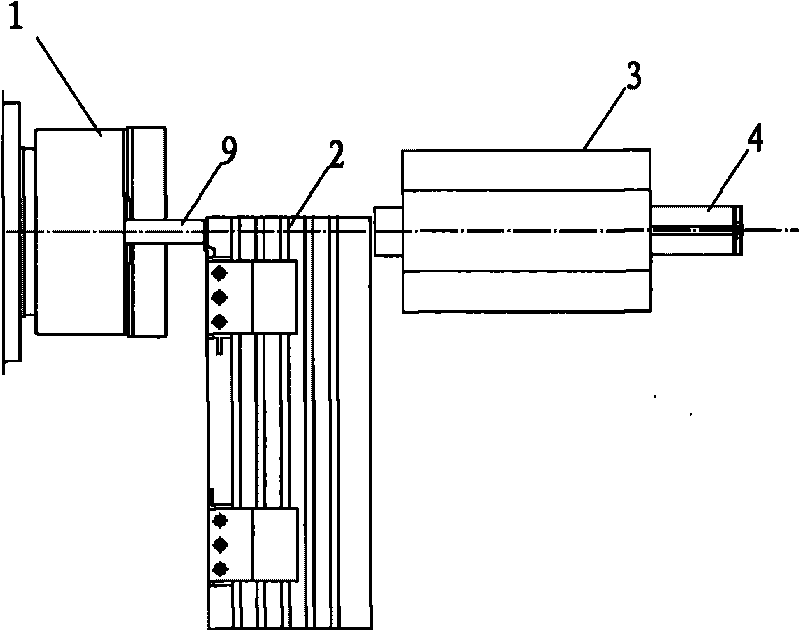

Numerical control lathe for automatically machining cylindrical roller for bearing

ActiveCN101704113AReduce frictionReduce cumbersomeAutomatic/semiautomatic turning machinesWork holdersNumerical controlEngineering

The invention discloses a numerical control lathe for automatically machining a cylindrical roller for a bearing, which comprises a lathe main body unit (2), wherein the lathe main body unit (2) comprises a chuck component used for clamping a bar, a motor unit driving the chuck component to rotate, and a cutter component realizing machining on a work bench, wherein 1 to 10 material holding units spaced in a straight line and a feed unit are arranged on the rear side of the chuck component; and a material receiving unit is arranged on the front side of the cutter component. The numerical control lathe can automatically complete bar machining, produces a semi-finished product and even a finished product of the cylindrical roller, is suitable for high-speed machining, and has the characteristics of low manpower cost, high production efficiency and high product quality.

Owner:KEDE NUMERICAL CONTROL CO LTD

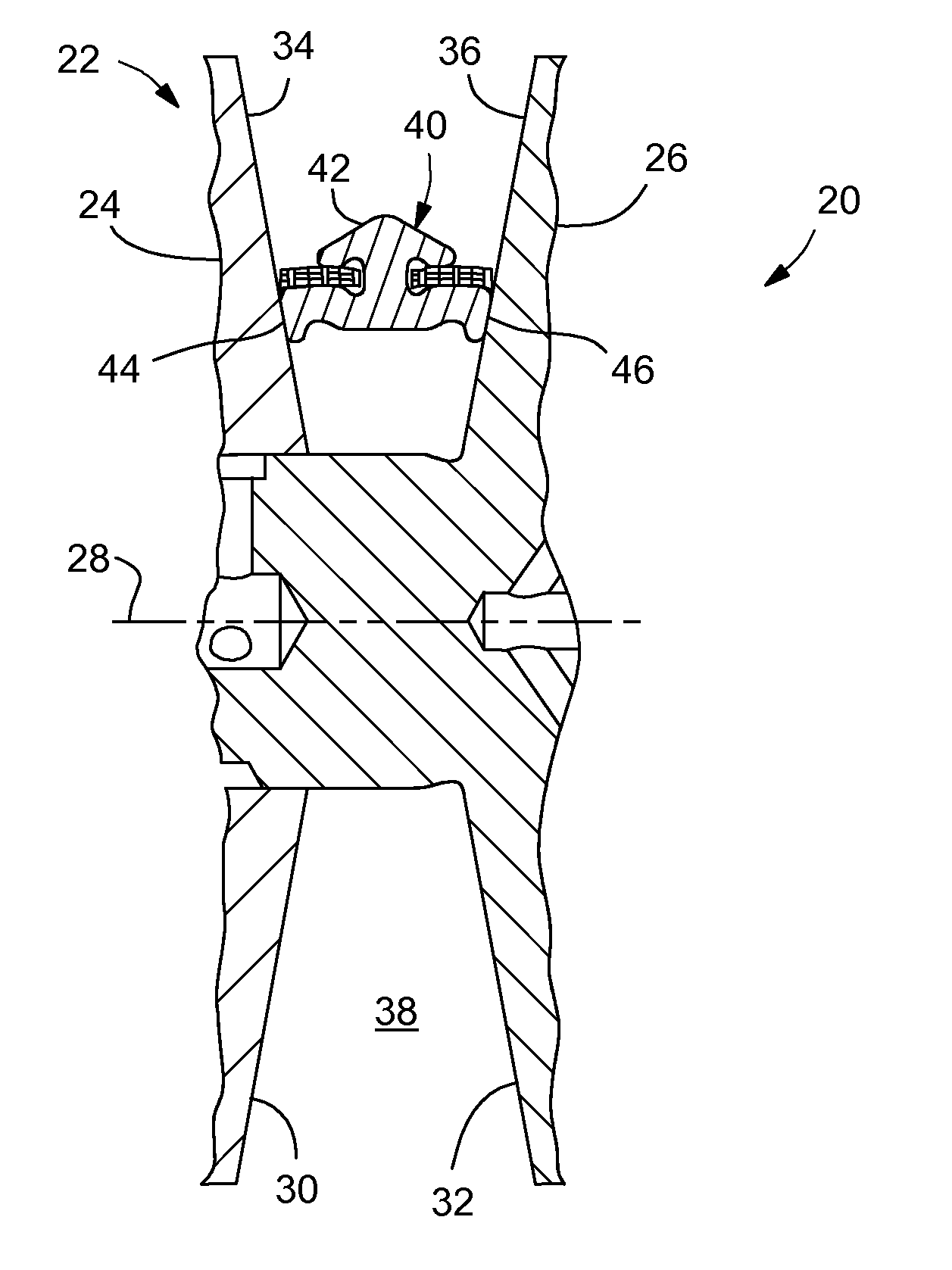

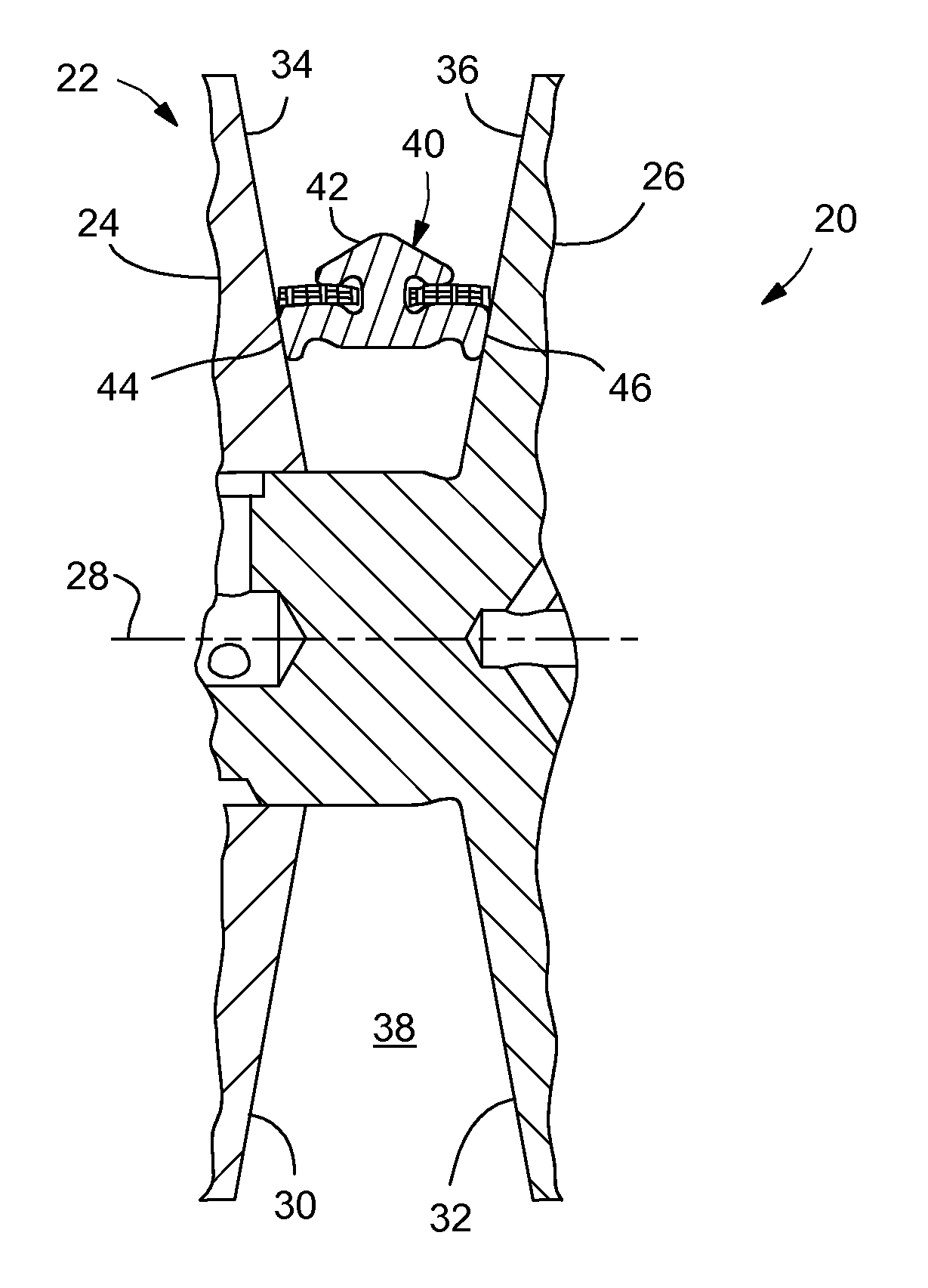

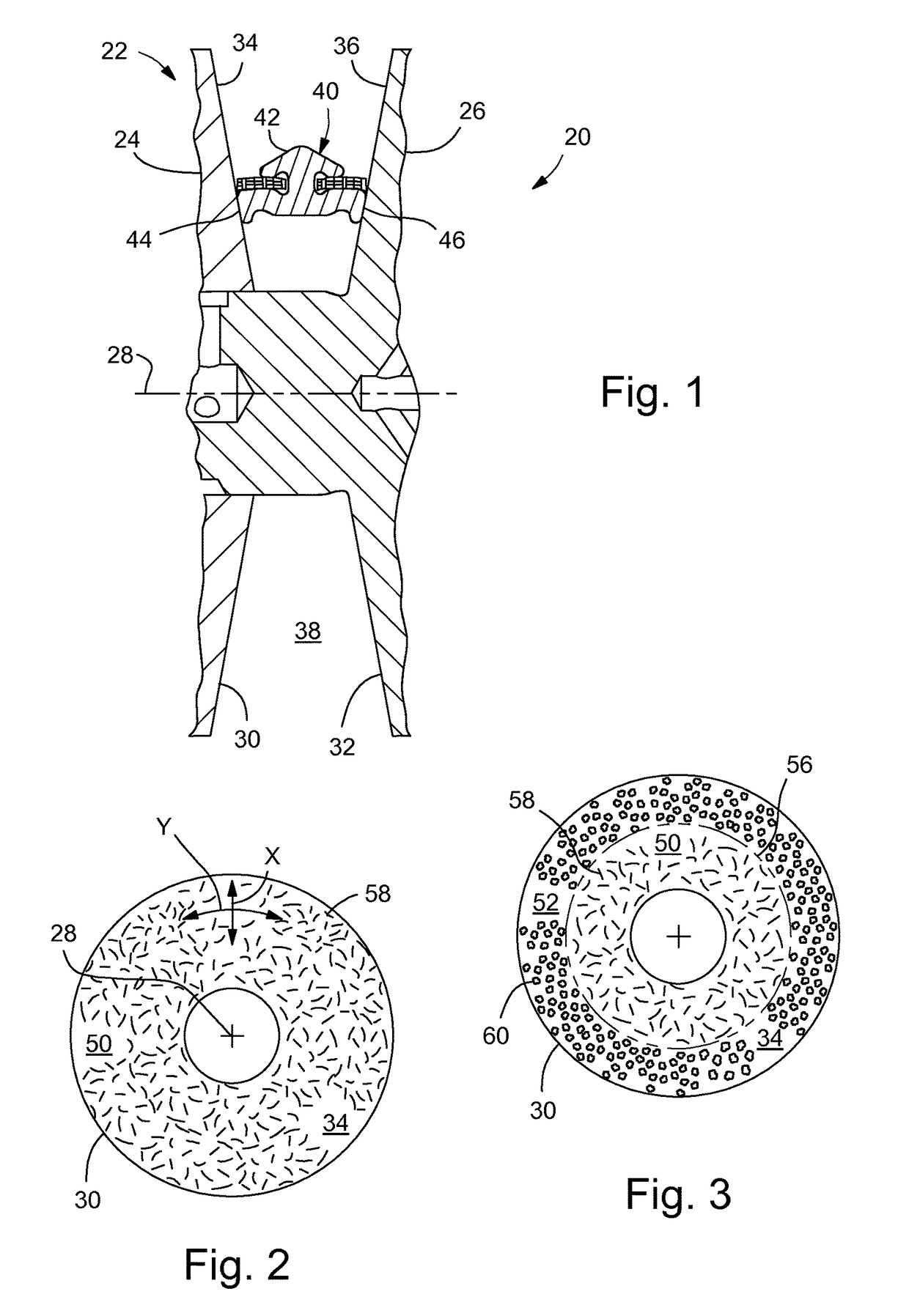

CVT Pulley With Engineered Surface

ActiveUS20120088615A1Reduce wearGood oil retentionVacuum evaporation coatingPortable liftingEngineeringFriction force

A pulley for a continuously variable transmission and a method of creating an engineered surface on an outer surface of a pulley of a continuously variable transmission, with the engineered surface engaging with a belt or chain of the continuously variable transmission. The method comprising the steps of: determining an actual engineered roughness (Rpk) on the outer surface needed to obtain a predetermined friction between the engineered surface and the belt or chain; and etching microgrooves in at least a portion of the outer surface to create the engineered surface by employing a laser to etch the microgrooves, the microgrooves being formed to a depth that produces the actual engineered roughness (Rpk).

Owner:GM GLOBAL TECH OPERATIONS LLC

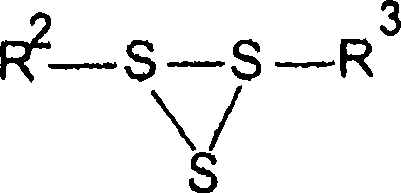

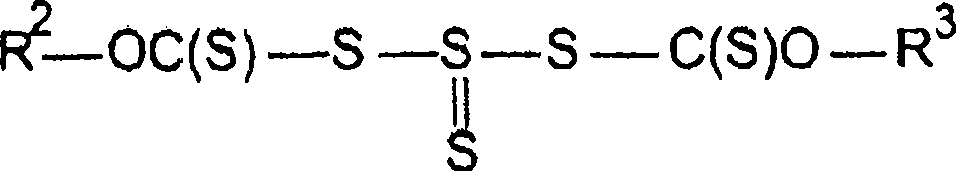

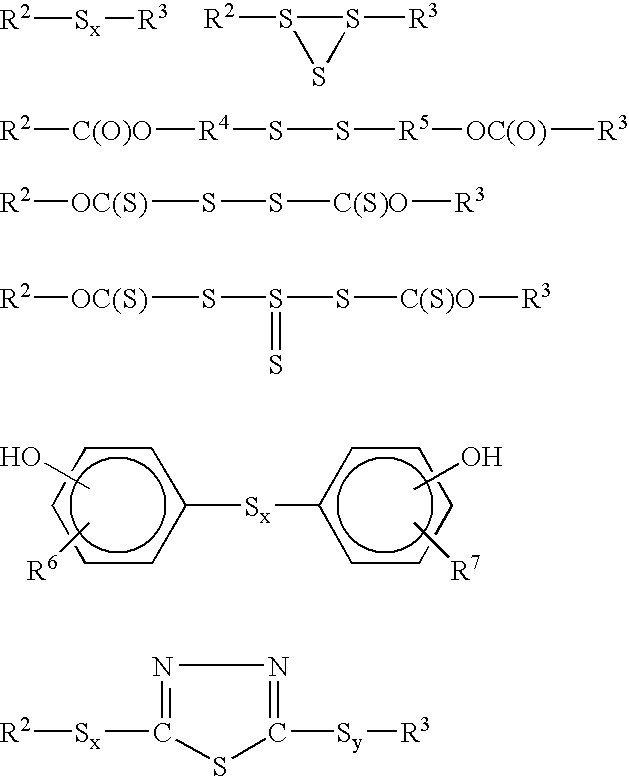

Lubricant formulations with improved antiwear properties

Owner:AFTON CHEMICAL

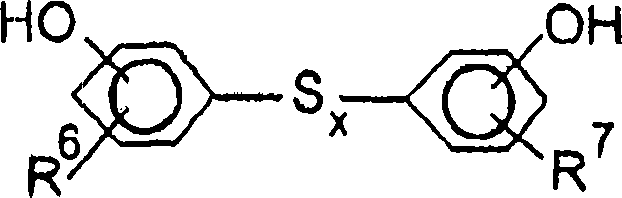

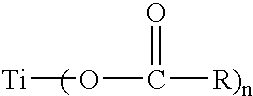

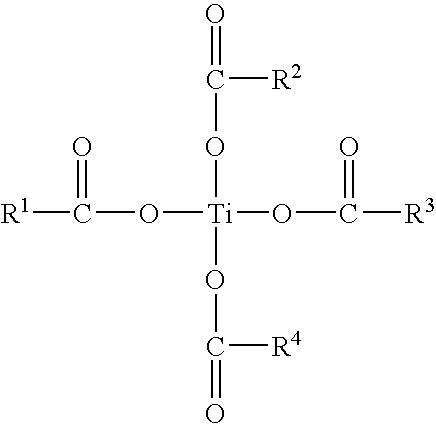

Additives and lubricant formulations for improved antiwear properties

ActiveUS20080223330A1Reduce pollutionReduced effectivenessLubrication of auxillariesMixingFriction modifierMaterials science

A lubricated surface, a method for reducing wear between moving parts, and lubricants, and lubricant additive concentrates containing a wear reducing agent. The lubricated surface contains a base oil of lubricating viscosity, a hydrocarbon soluble titanium compound, a metal-free friction modifier and an amount of at least one hydrocarbon soluble magnesium compound effective to provide a reduction in surface wear greater than a reduction surface wear for a lubricant composition devoid of the titanium compound, metal-free friction modifier, and magnesium compound. The lubricant composition contains no more than about 800 ppm phosphorus and is devoid of calcium detergents and organic molybdenum compound.

Owner:AFTON CHEMICAL

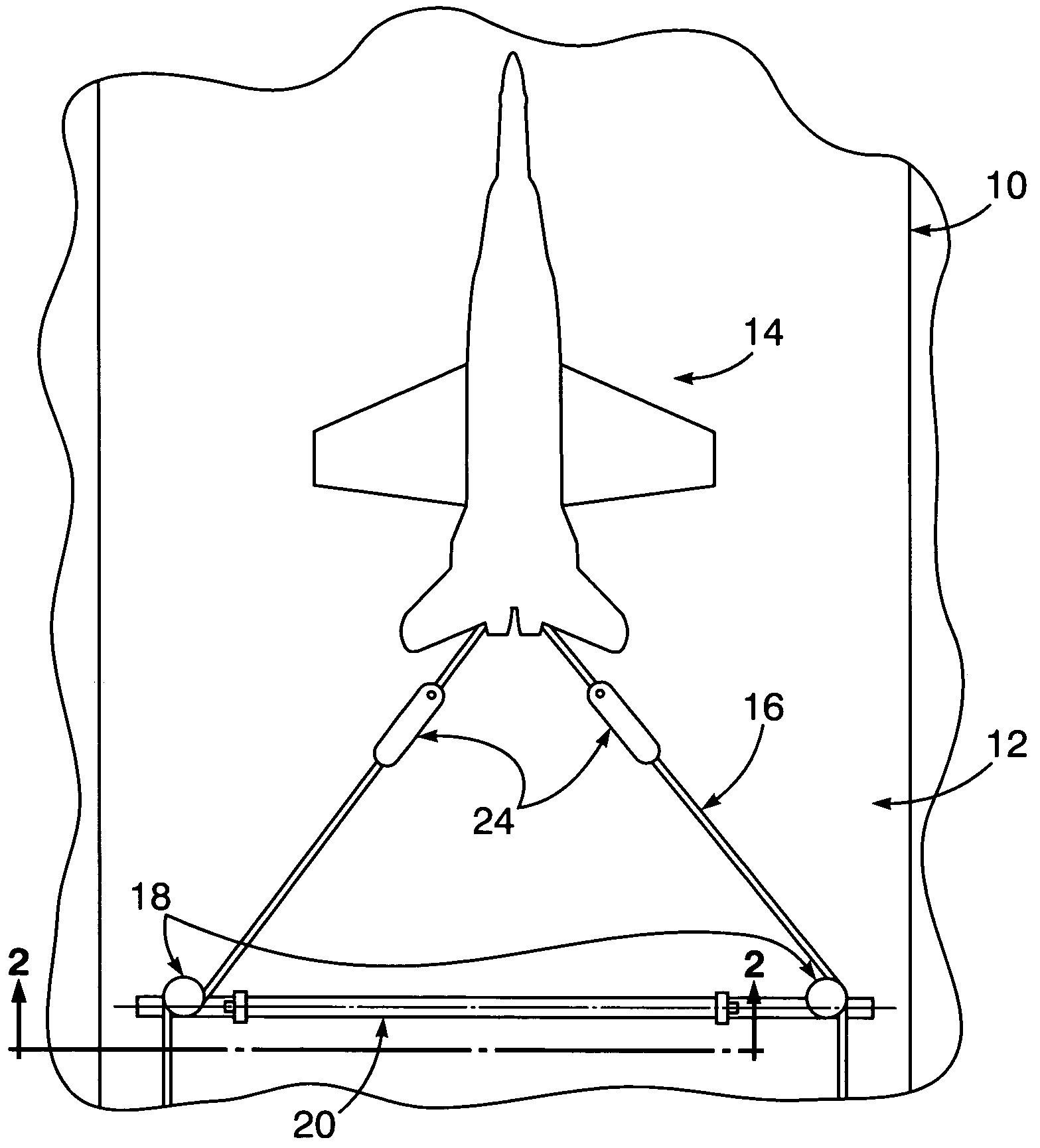

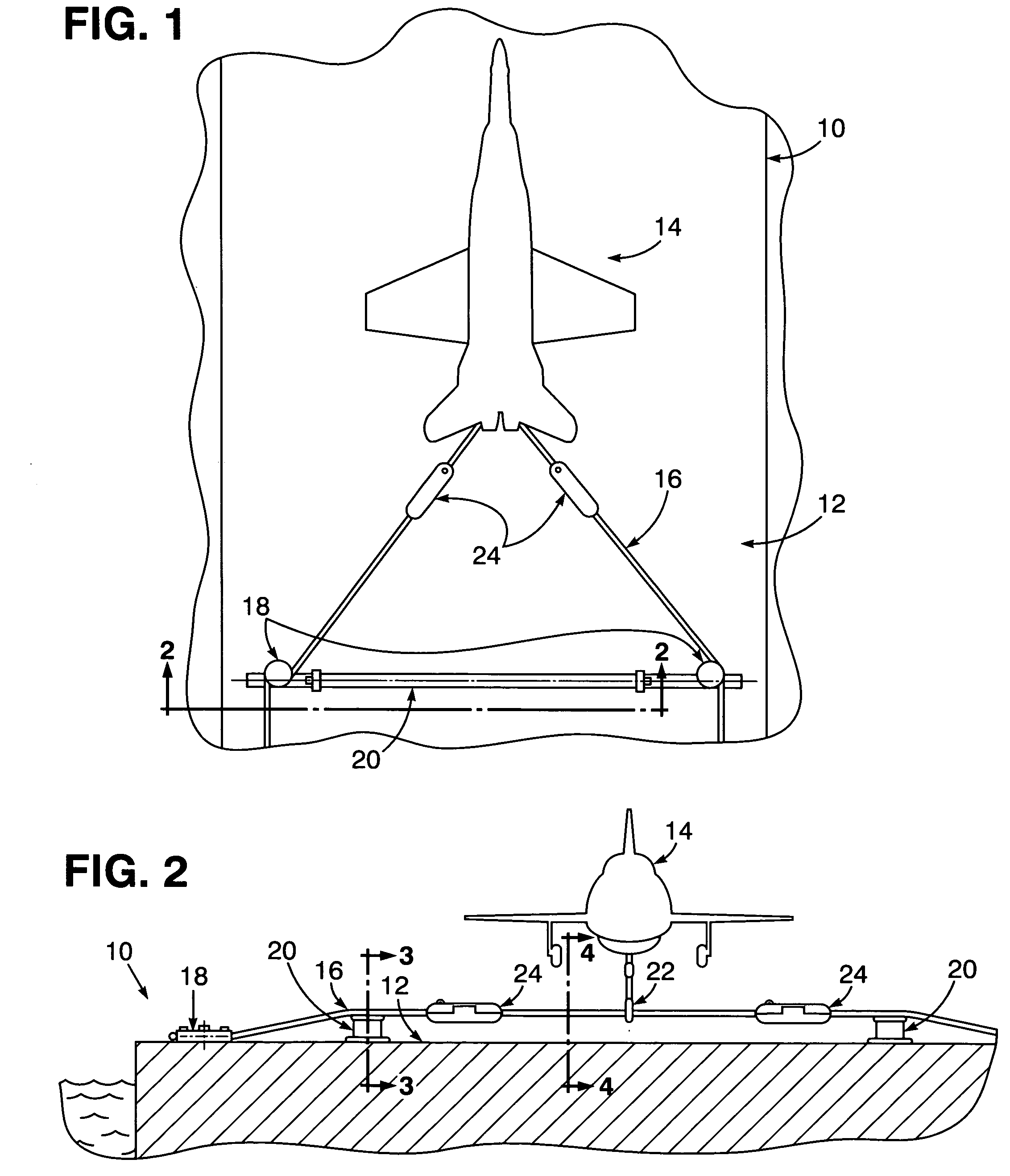

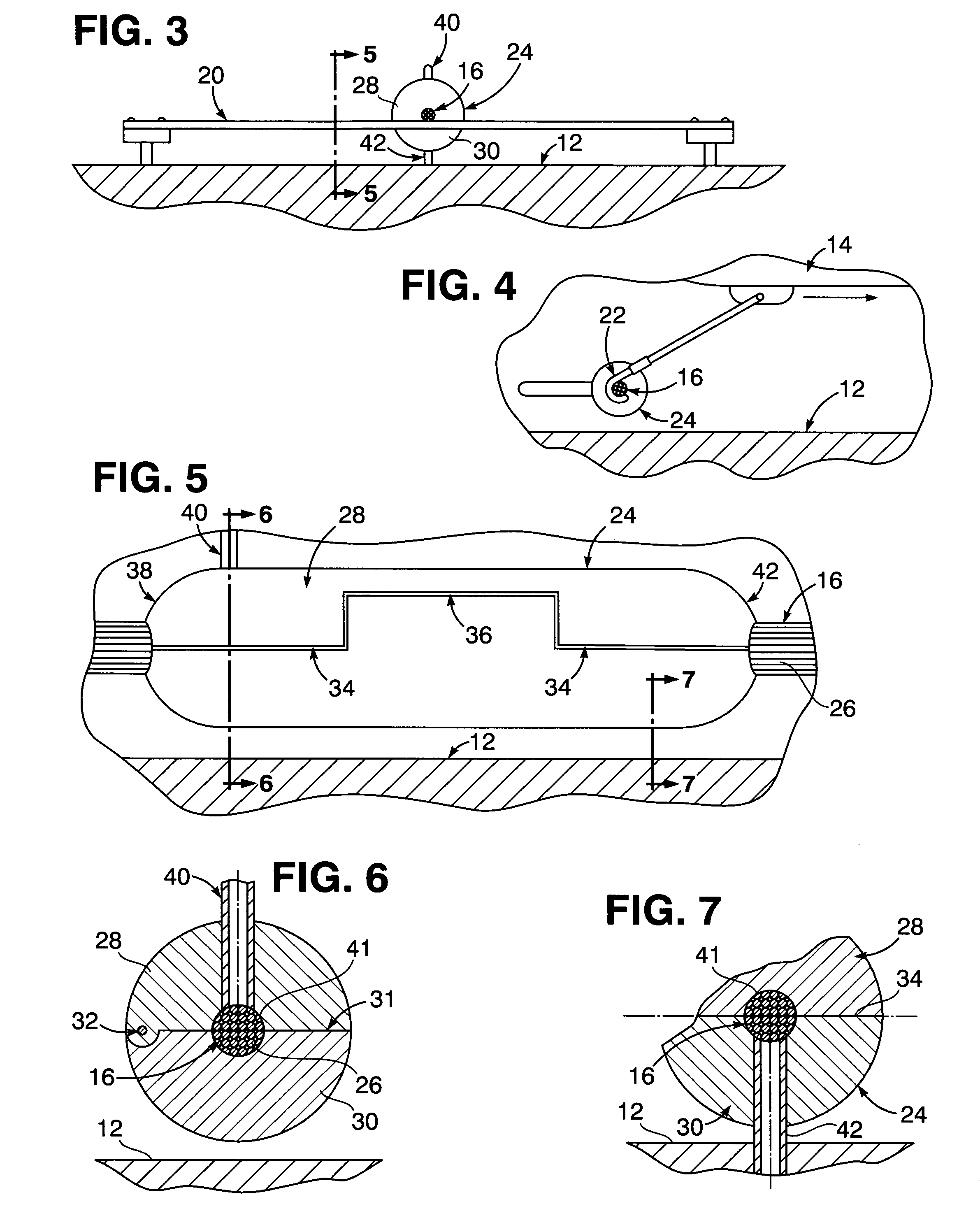

Wear resisting sleeve system for aircraft landing arresting cables

InactiveUS6981673B1Reduce cable surface abrasionReduce surface wearArrester hooksArresting gearAdhesiveAircraft landing

The aircraft landing arrest cable has wear resisting sleeves positioned thereon in spaced relation to each other to thereby hold the cable out of contact with a non-skid landing surface in a lowered position of the cable. Stresses imposed on the cable when engaged by a tail hook suspended from aircraft during landing, are absorbed by the wear resisting sleeves which are held clamped in positions on the cables by fluid adhesive previously injected into the sleeves. The wear resisting sleeves are respectively formed from pivotally connected sleeve sections made of an impact shatter-proof and durable material such as polyurethane with abutting edges held in contact with each other under a clamped condition of the sleeves on the cable, established by the injected adhesive.

Owner:CHIEF OF NAVAL RES OFFICE OF COUNSEL DEPT OF THE NAVY

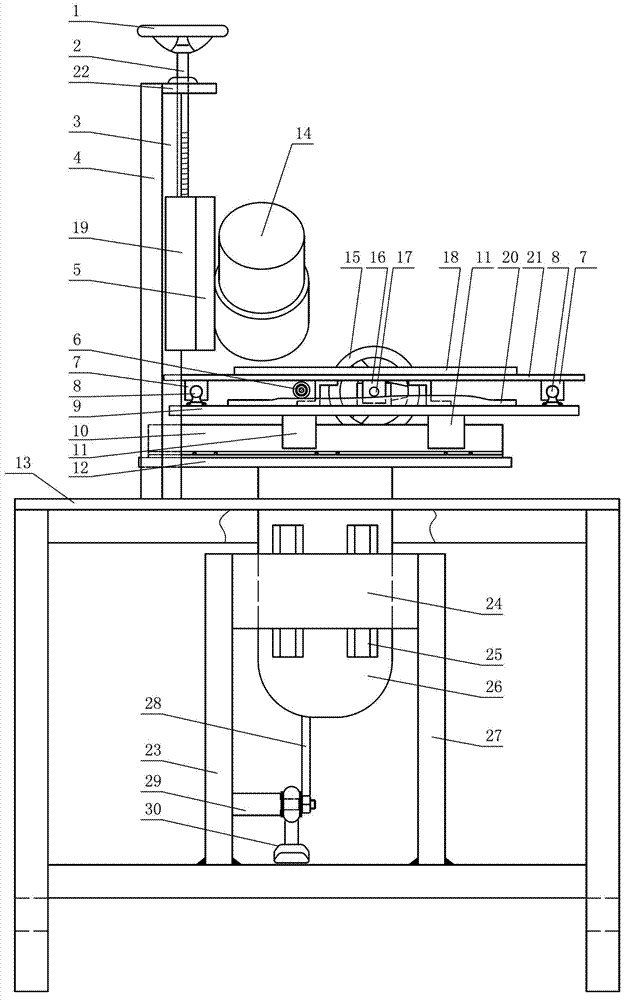

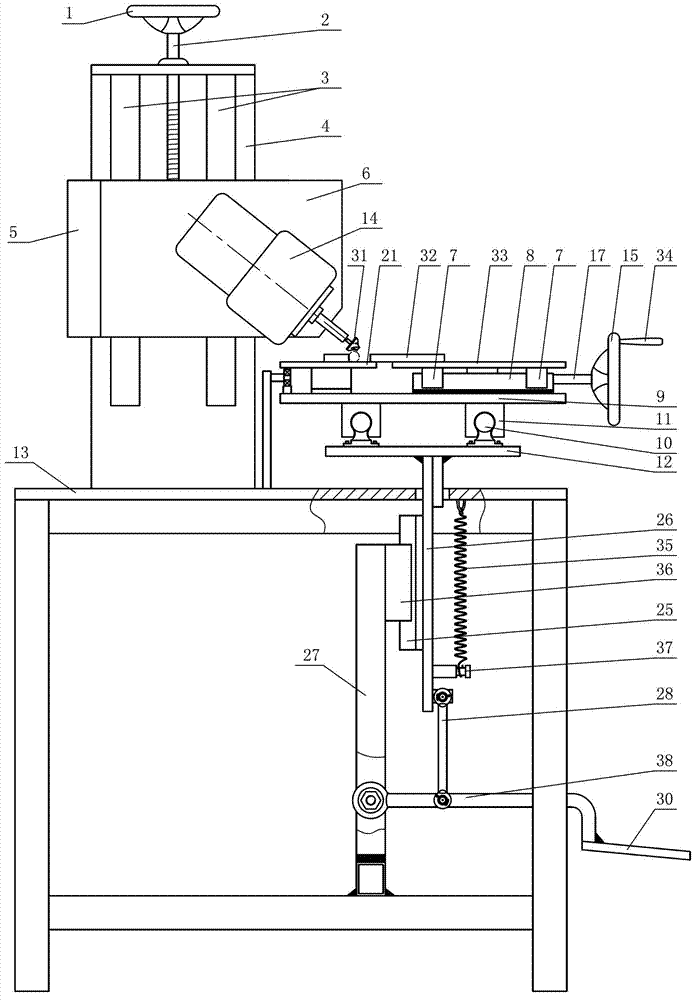

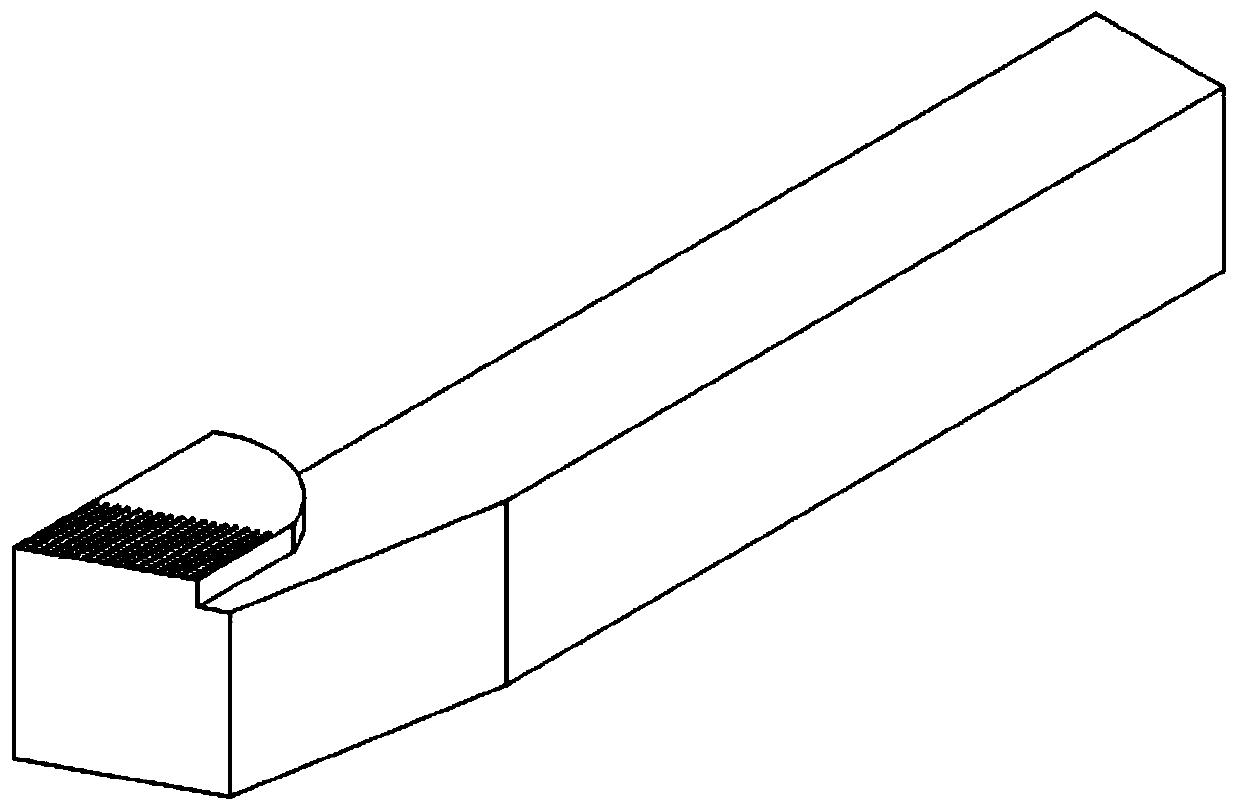

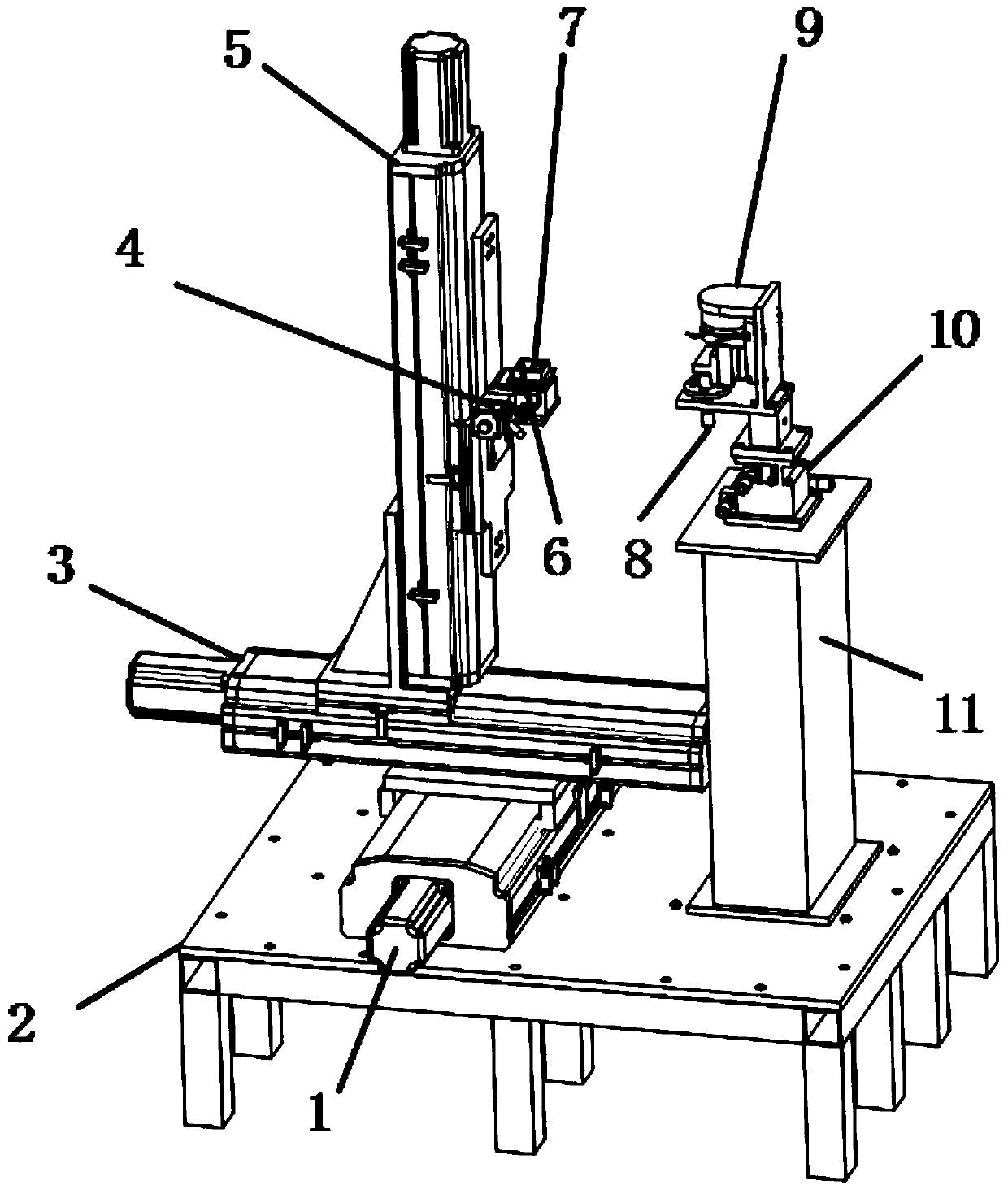

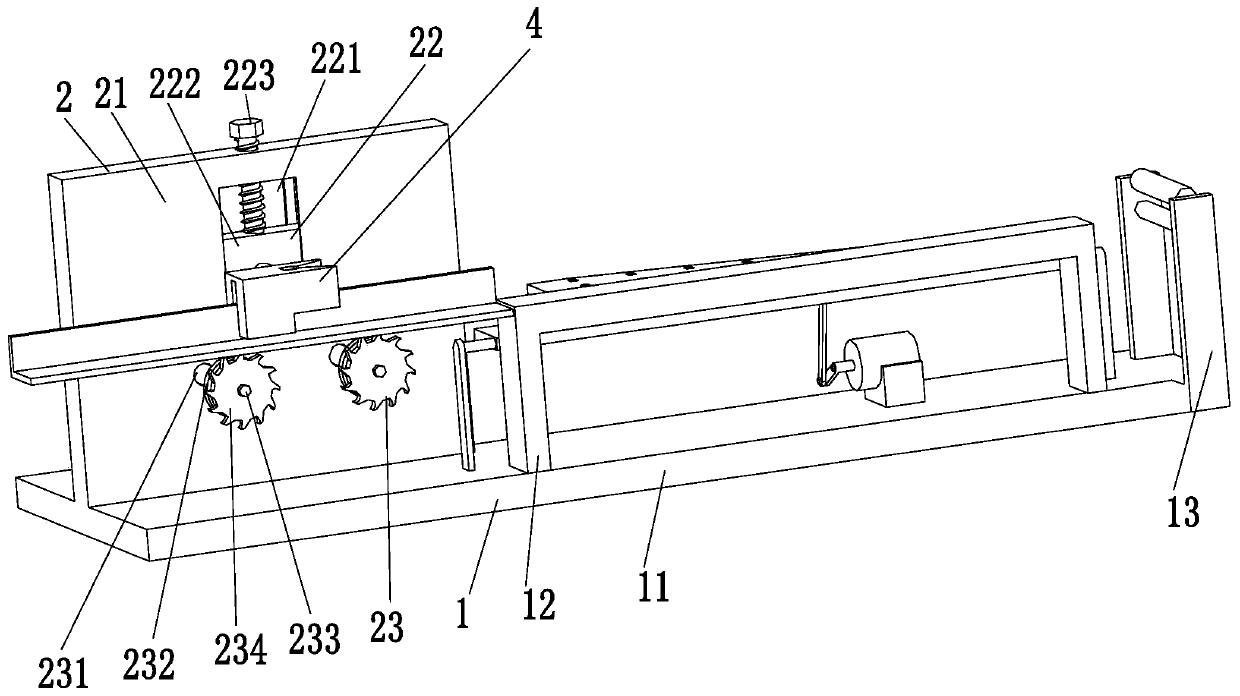

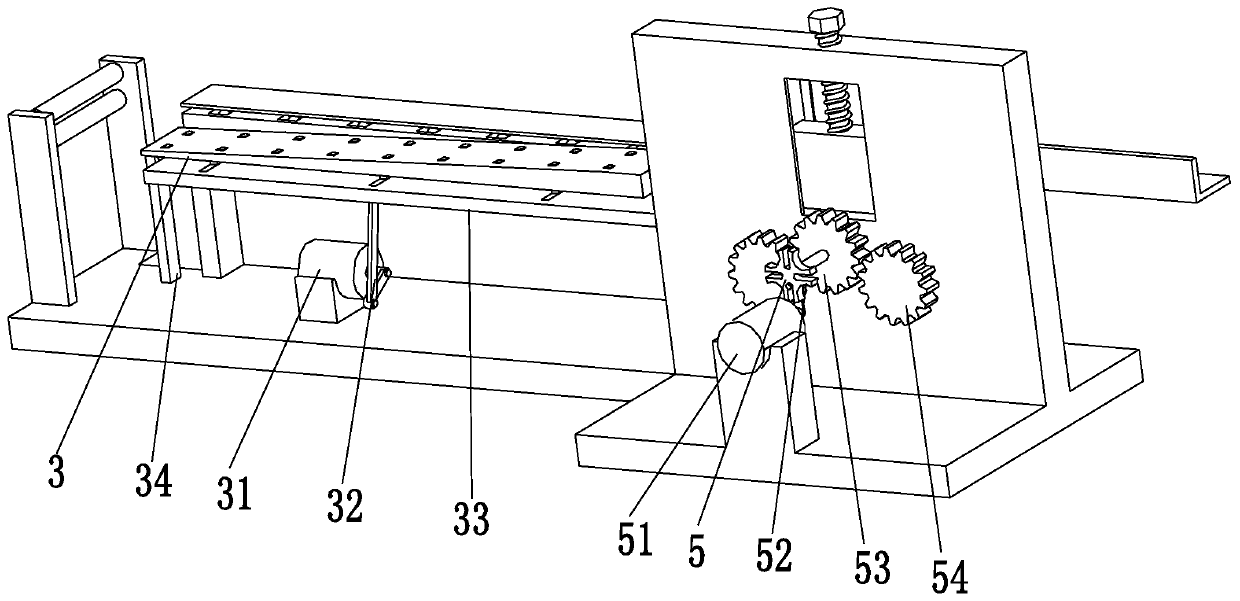

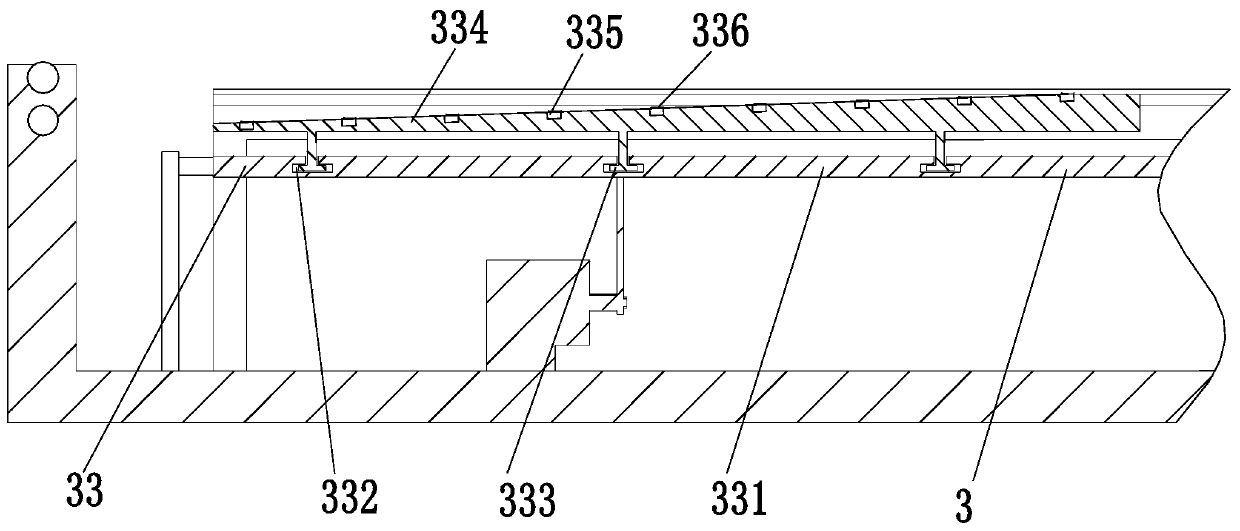

Equipment for carrying out shaping processing on chopsticks

ActiveCN102950636ATo achieve the purpose of modelingSolve problems with differences in shapesWooden sticks manufactureProfiling/shaping machinesMilling cutterEngineering

The invention belongs to the technical field of chopsticks processing, and particularly discloses equipment for chopsticks shaping. The equipment is characterized by completing the chopstick processing by adopting a milling cutter fixed and chopstick moving mode, realizing the purpose that chopsticks fluctuate up and down with the fluctuation change of the top surface of a shaping mould in the cutting process of a milling cutter by arranging a chopstick clamping mechanism installation seat capable of sliding up and down and matching with the upwards pulling action of an extension spring and the downwards pressing action of a pulley on the shaping mould, further realizing the purpose that surface shapes consistent to the fluctuation shape of the shaping reference surface of the shaping mould are processed on one surfaces of the chopsticks and finally realizing the purpose of shaping the chopsticks. The equipment disclosed by the invention can be used for carrying out automatic shaping by using the shaping mould with the determined shaping reference surface and completing the shaping processing of one surface by pushing for only a few seconds; and compared with manual multi-time turning or polishing shaping, the equipment disclosed by the invention can increase the efficiency by more than ten times and even dozens of times.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

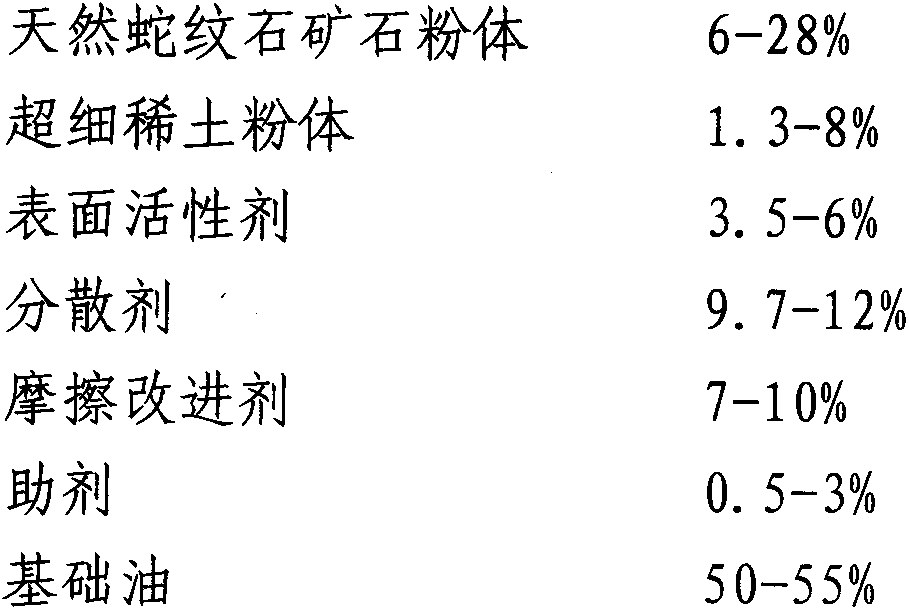

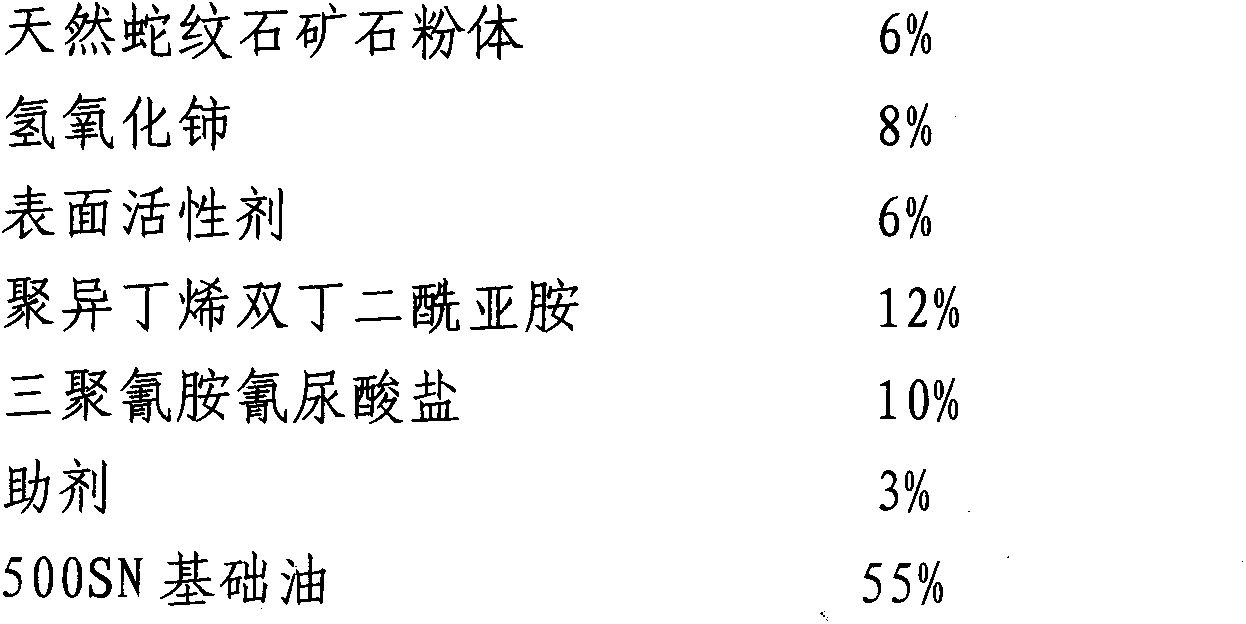

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569AAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Wear resistant and wearable die material

The invention relates to a material, in particular to a wear resistant and wearable die material. The die material is prepared by the following components in percentage by weight: 1.2 to 3.50% of C, 1.0 to 3.5% of Si, 0.5 to 1.2% of Mn, not greater than 0.02% of S, 0.3 to 1.0% of Cu, 0.5 to 5.0% of Cr, 0.5 to 3.0% of Al, and the balance of Fe. A heat-conducting property of the material is superior to that of steel, a mechanical performance is close to that of the steel, and the material is stable in chemical performance, prevent molten aluminum from polluting, and high in wear resistance; because graphite is contained in the material, the die material is excellent in heat-conducting property; the graphite is small, and a tail end of the graphite is circular and passivated, so that the mechanical performance of the material is slightly reduced; proper alloy elements are added to the material, so that a layer of protecting films without being infiltrated by aluminum and the molten aluminum can be formed in an internal chamber after a die is thermally processed during a manufacturing process; once a film of the internal chamber is broken during use, a new protection film can be continuously generated, so that erosion of the molten aluminum can be resisted. According to the die material, a Cr element and carbon form a metal compound, so that the die has an excellent wearable performance; the graphite in the material is a good solid lubricant, so that wear can be reduced, and the wear on surfaces of the aluminum and an aluminum alloy can be reduced.

Owner:JIAXING JIECHENG MACHINERY

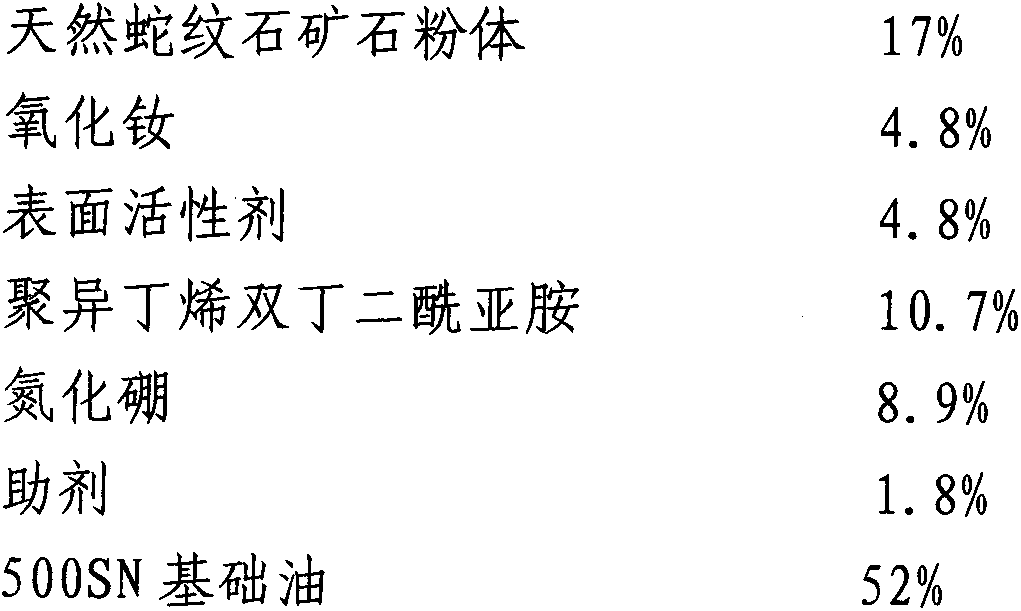

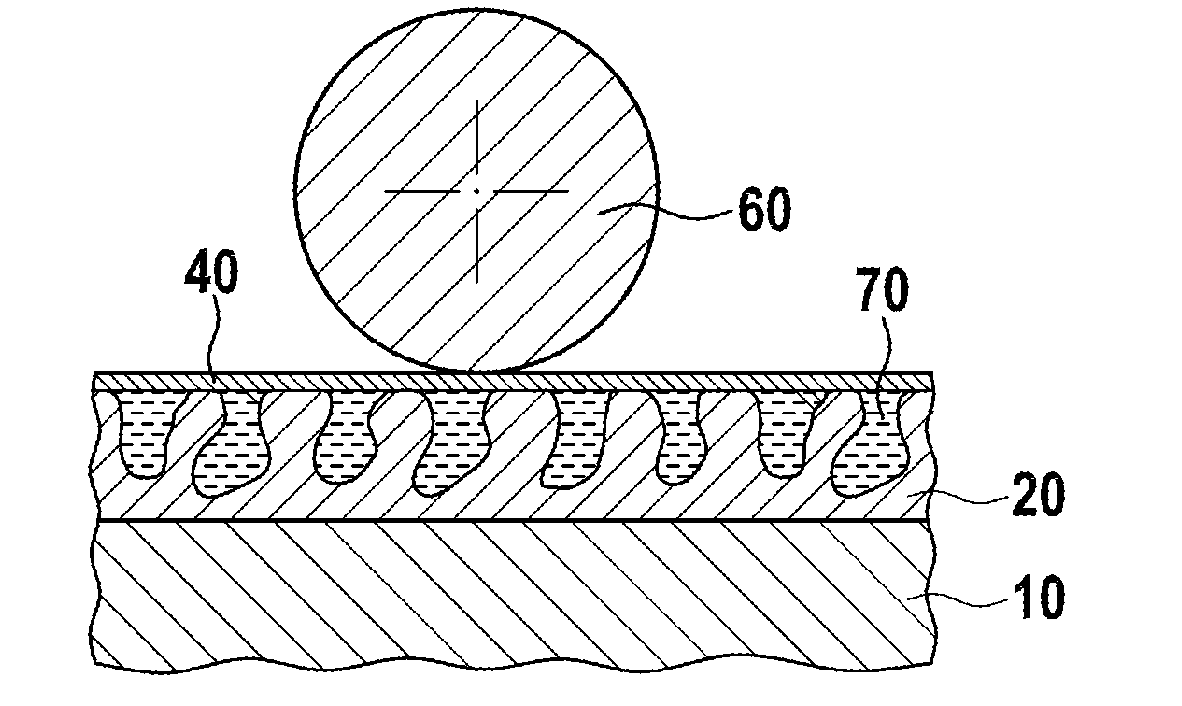

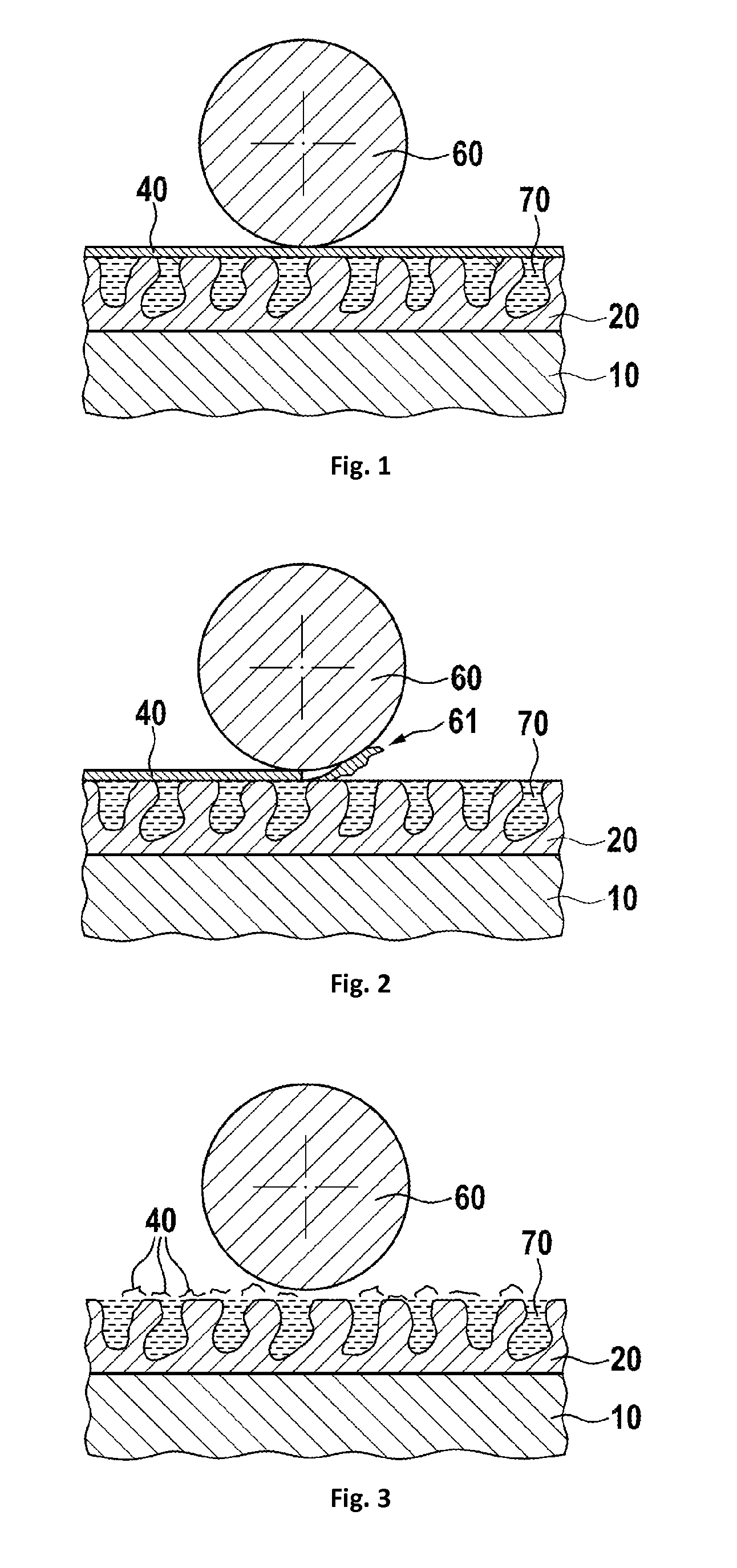

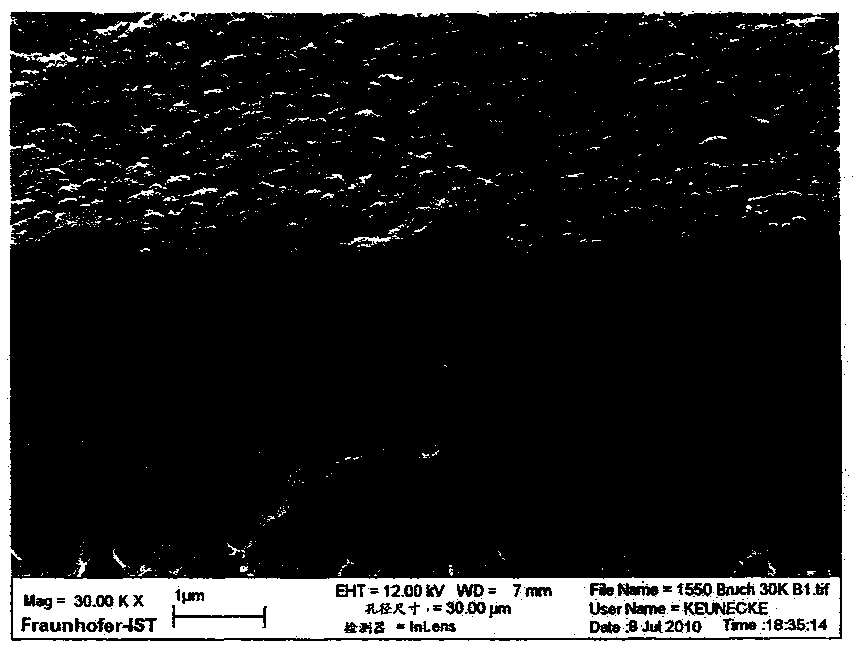

Self-Lubricating Slipring

ActiveUS20150288121A1Extended service lifeSafe storageRotary current collectorNon-rotary current collectorLubricantSlip ring

A slip ring has a slip ring track with a contact area, the contact area containing a plurality of pores or cavities. A lubricant is held within these pores and cavities and is enclosed by a top coating. When a slip ring brush is sliding over the slip ring track, it rubs off particles of the top coating, therefore opening some of the pores or cavities which release parts of the lubricant contained therein. This lubricant reduces surface friction of the slip ring brush at the slip ring track and therefore further wear, which results in an extended lifetime.

Owner:SCHLEIFRING & APPBAU

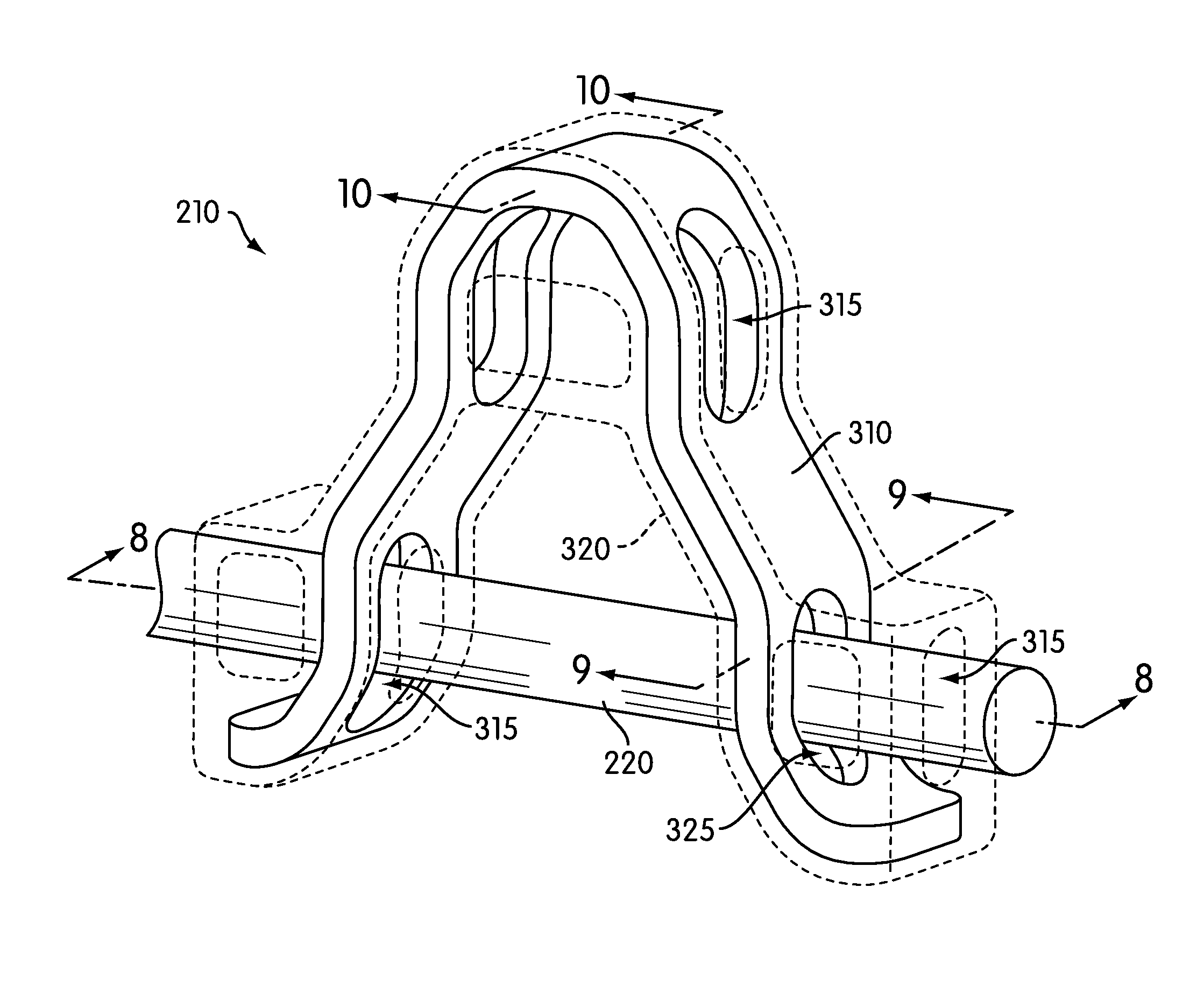

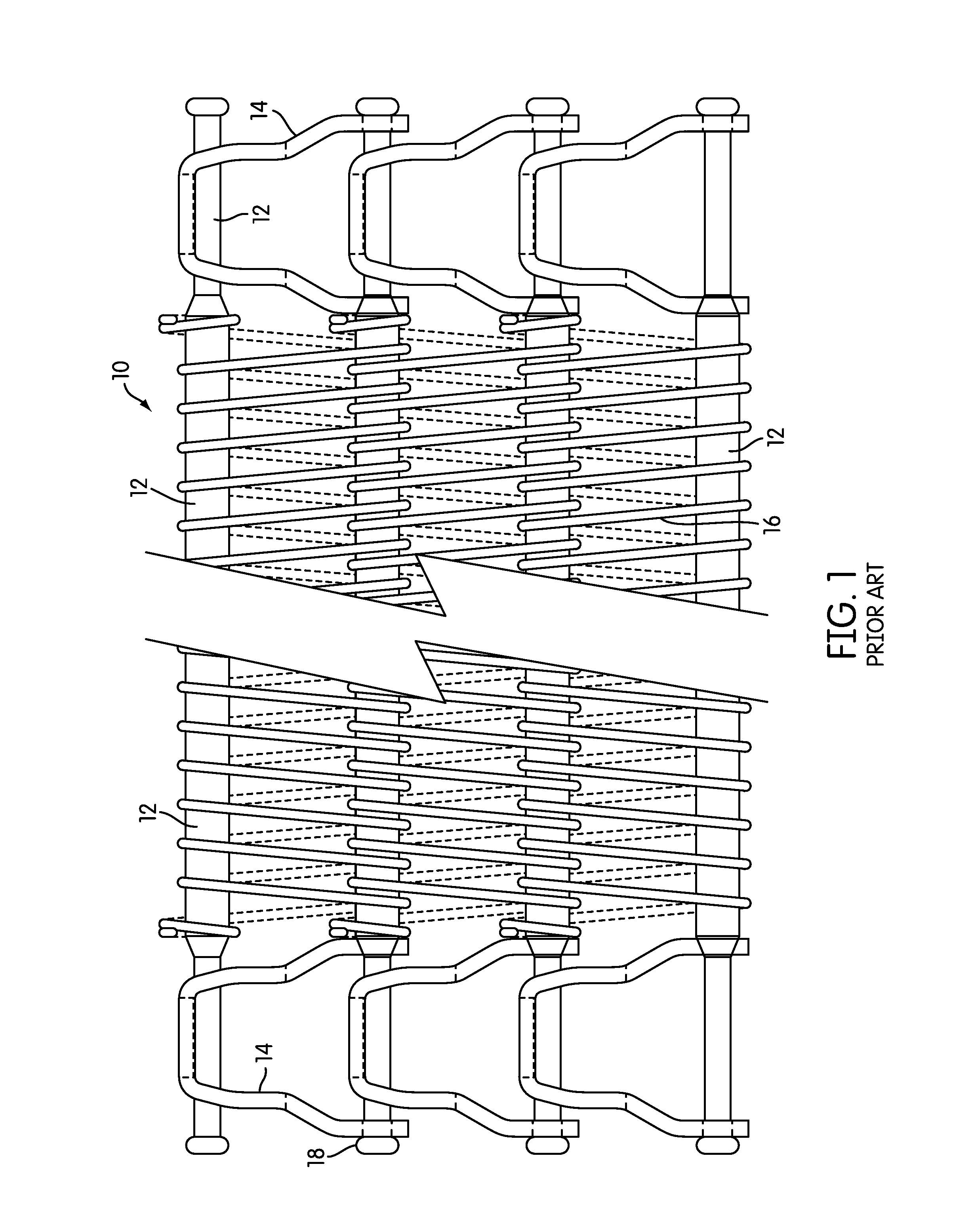

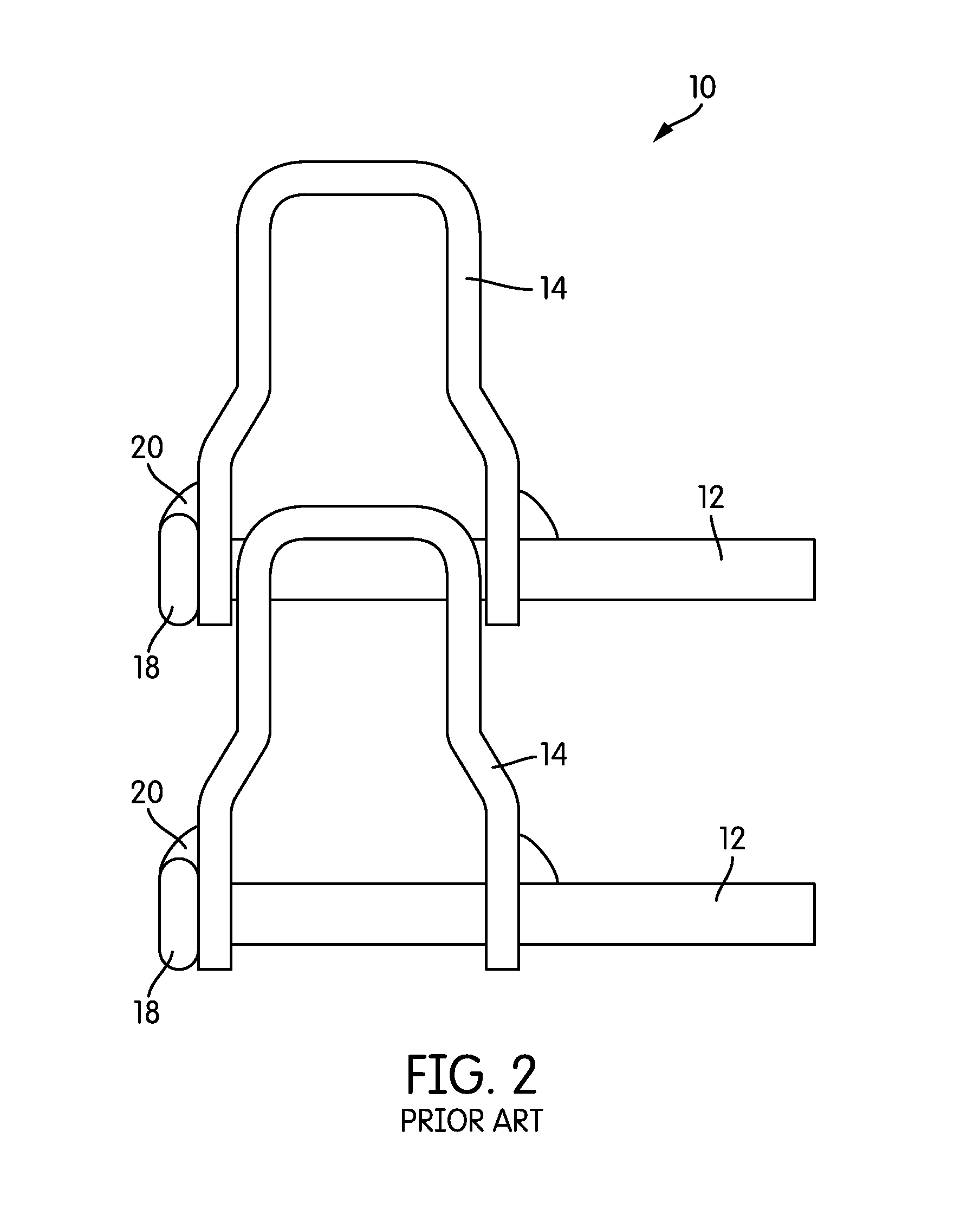

Conveyor belt with composite link

Owner:ASHWORTH BROS

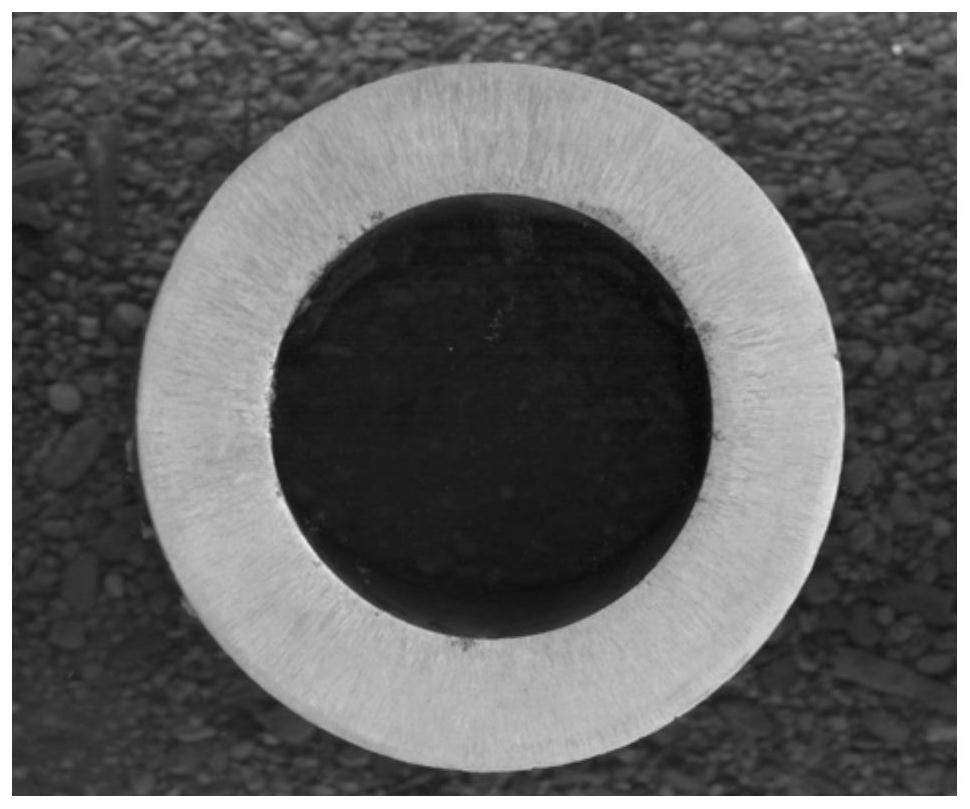

CVT pulley with engineered surface

ActiveUS9714700B2Reduce wearEnhance oil retention and desirable hydrodynamic film characteristicVacuum evaporation coatingPortable liftingEngineeringLaser

A pulley for a continuously variable transmission and a method of creating an engineered surface on an outer surface of a pulley of a continuously variable transmission, with the engineered surface engaging with a belt or chain of the continuously variable transmission. The method comprising the steps of: determining an actual engineered roughness (Rpk) on the outer surface needed to obtain a predetermined friction between the engineered surface and the belt or chain; and etching microgrooves in at least a portion of the outer surface to create the engineered surface by employing a laser to etch the microgrooves, the microgrooves being formed to a depth that produces the actual engineered roughness (Rpk).

Owner:GM GLOBAL TECH OPERATIONS LLC

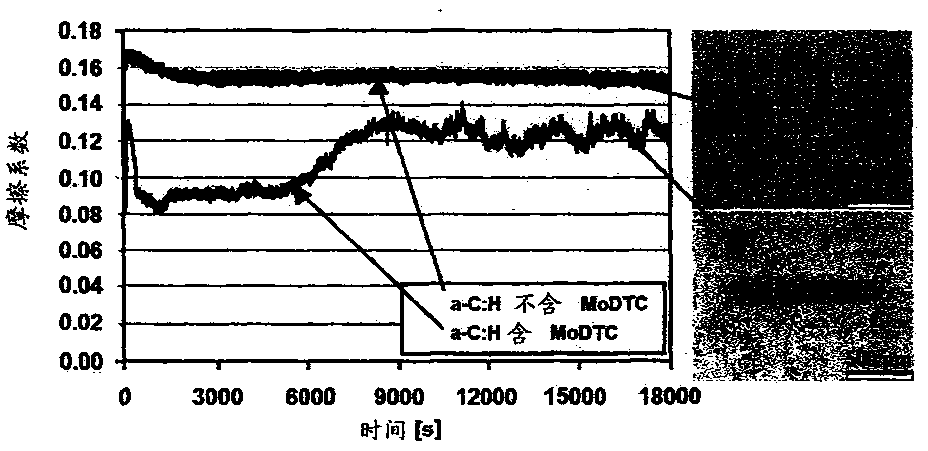

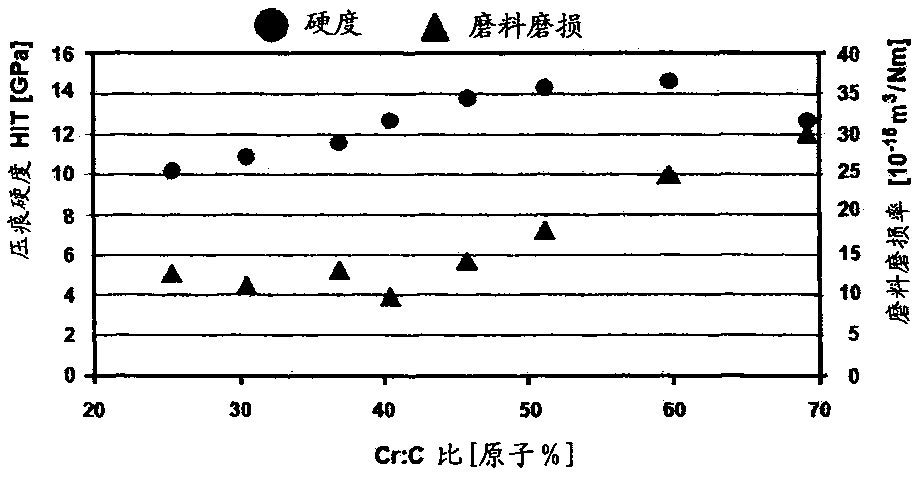

Sliding component coated with metal-comprising carbon layer for improving wear and friction behavior by tribological applications under lubricated conditions

ActiveCN103635602AReduce surface wearReduce frictionVacuum evaporation coatingSputtering coatingCarbon layerDiamond-like carbon

The present invention relates to a coating for sliding parts that allows using diamond like carbon (DLC) or DLC-comprising coatings in combination with Molybdenum- and / or Zinc-comprising lubricants in such a manner that enhanced reduction of wear and friction in comparison to the state of the art is attained. The coating system according to the present invention comprises at least a metal-comprising carbon layer of the type Me-C / a)-C:X, whose element composition can be expressed as (MeaC1-a)1-bXb with 0.3 <= a <=0.6 and 0<= b <=0.3, where Me is a metal or a combination of different metals and X is an element different from Me and different from C or X is a mixture of elements different from Me and which doesn't contain C. Me can be preferably Chromium (Cr) or Molybdenum (Mo) and X can be preferably hydrogen (H) or a mixture of silicon and hydrogen (Si + H).

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

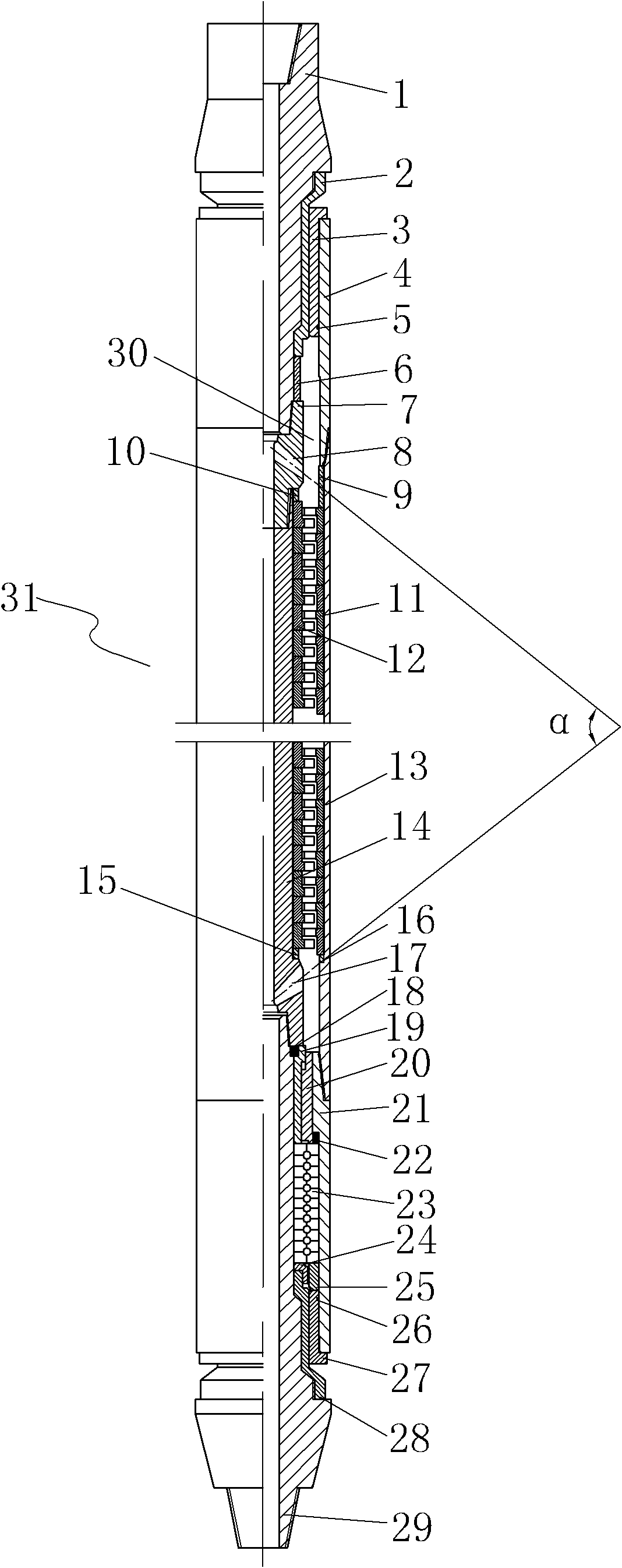

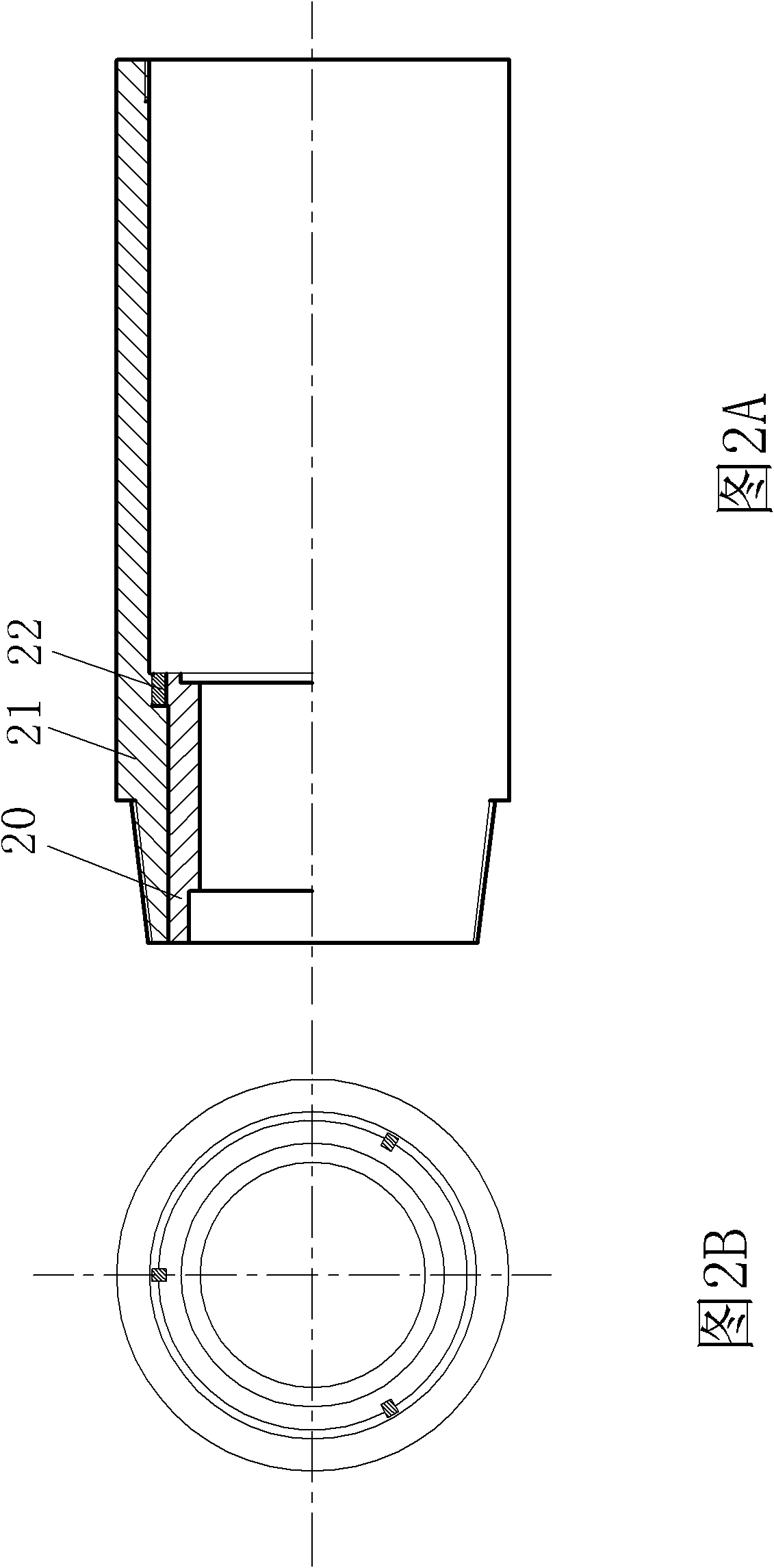

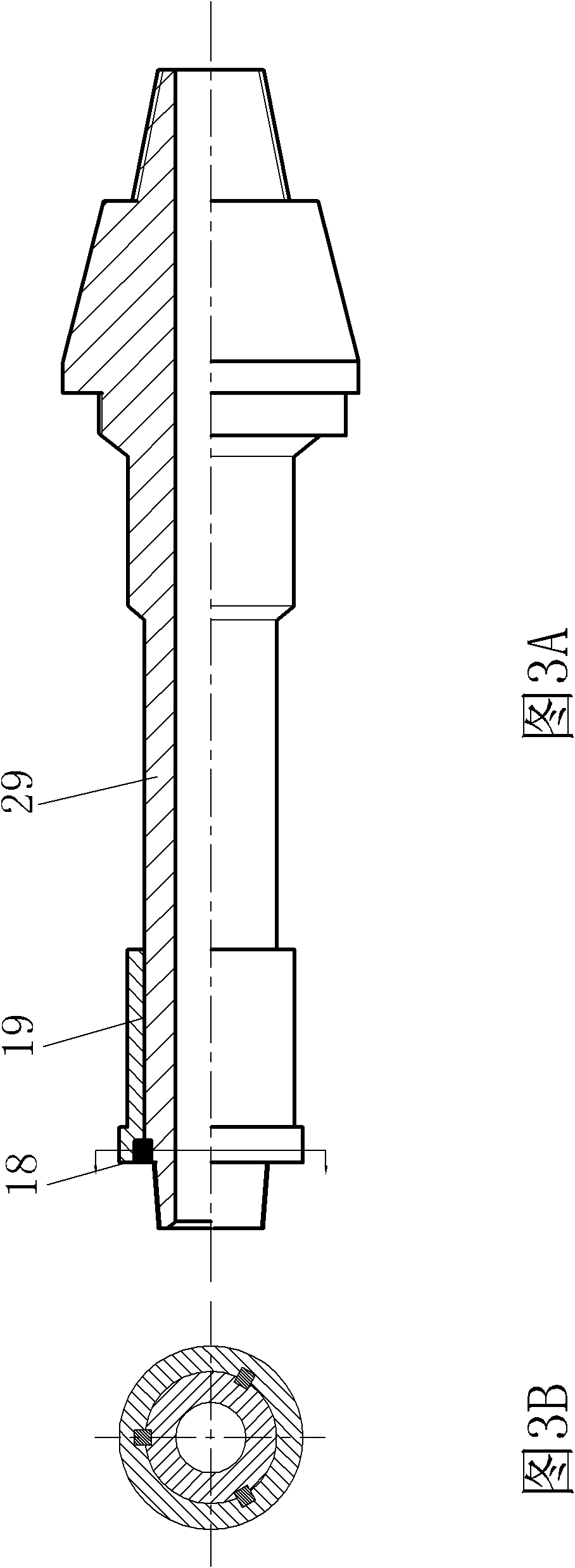

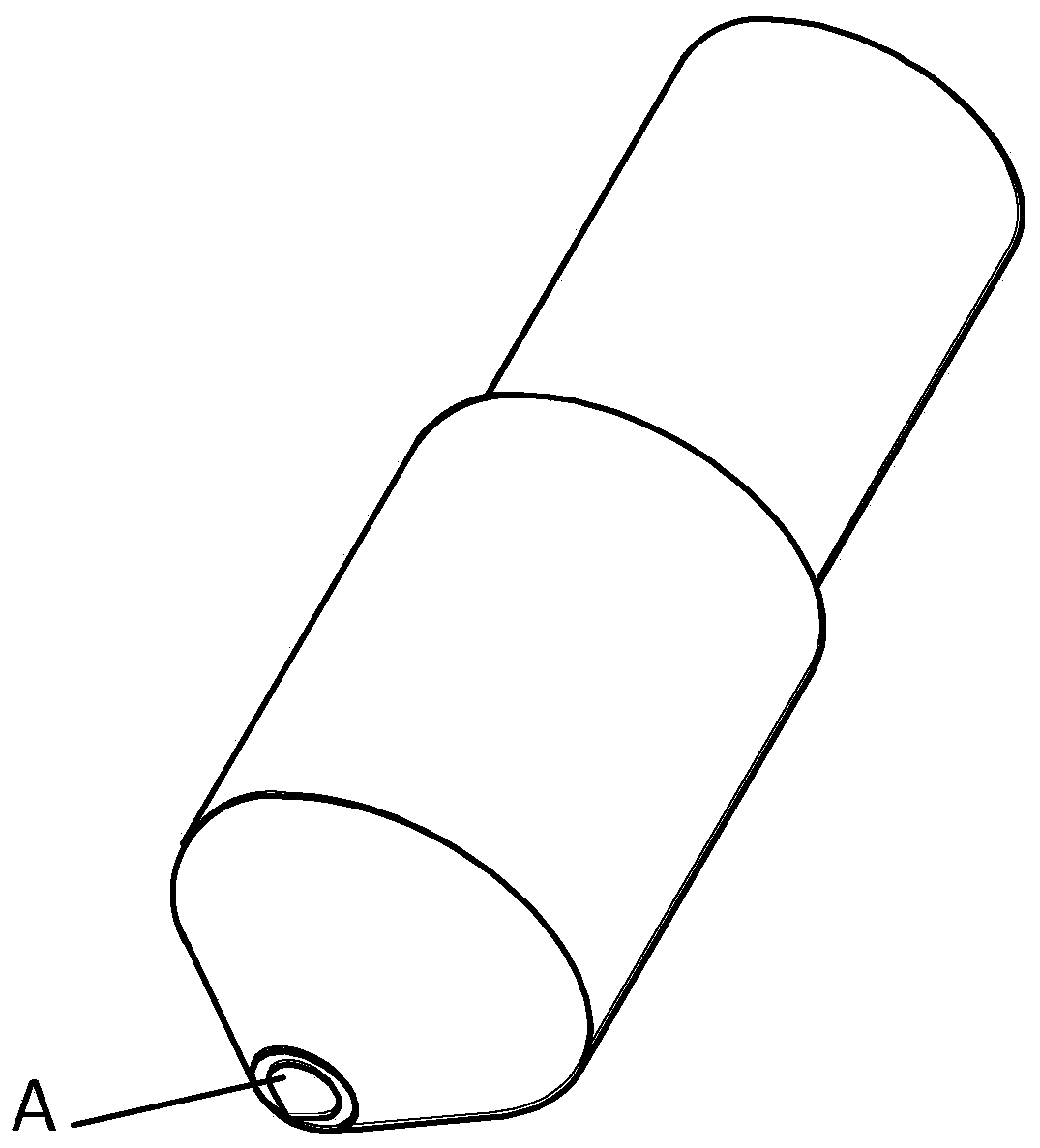

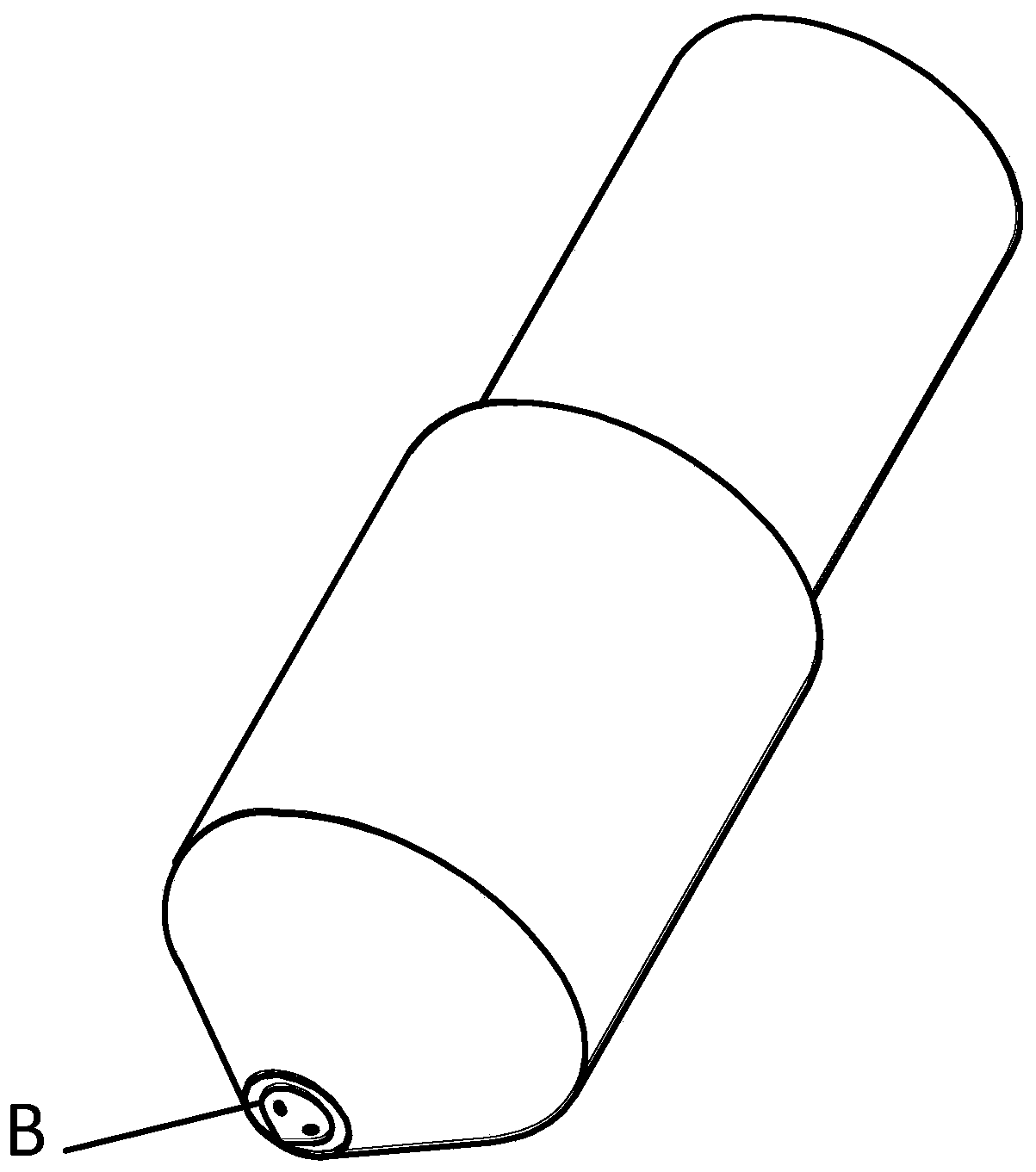

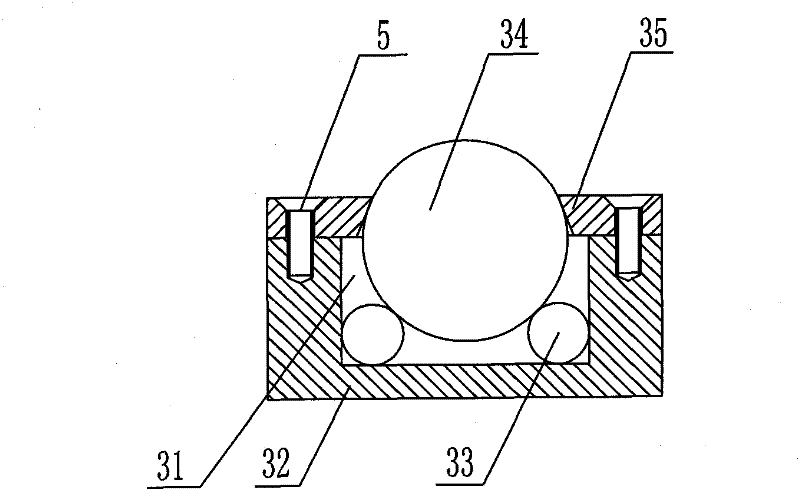

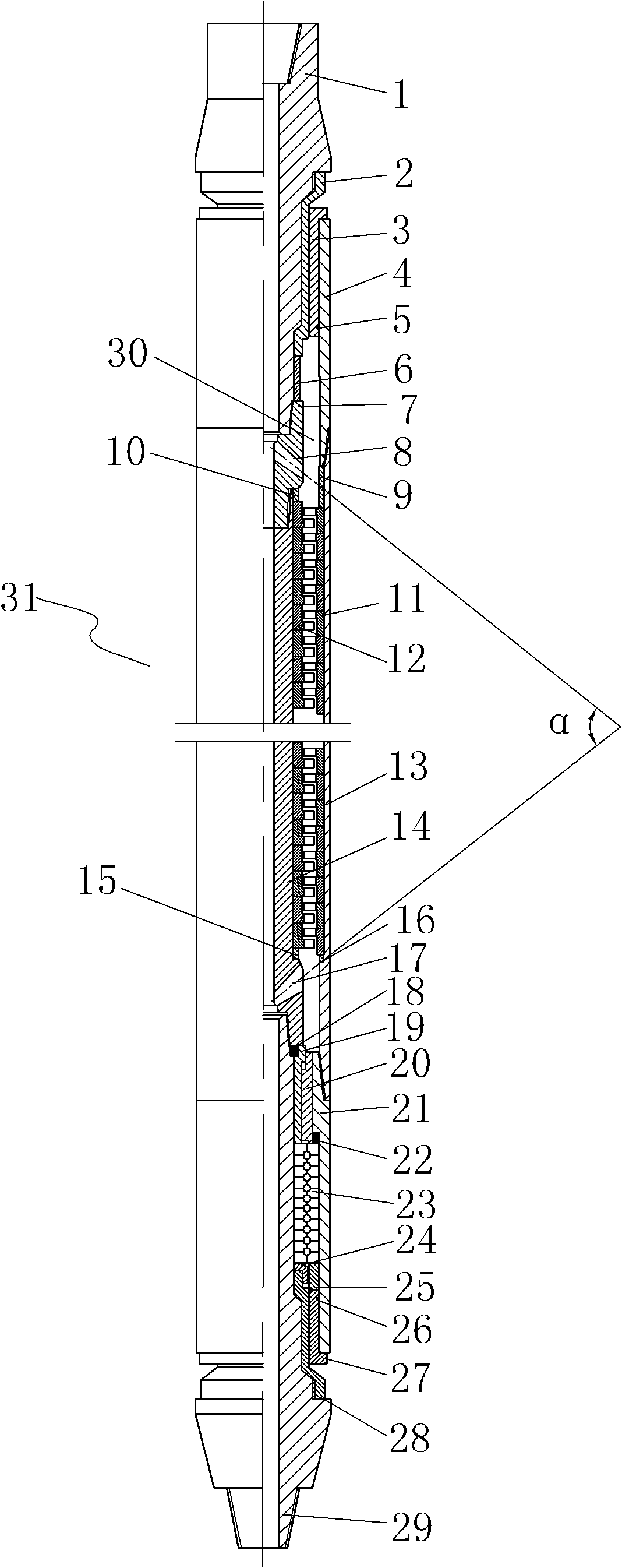

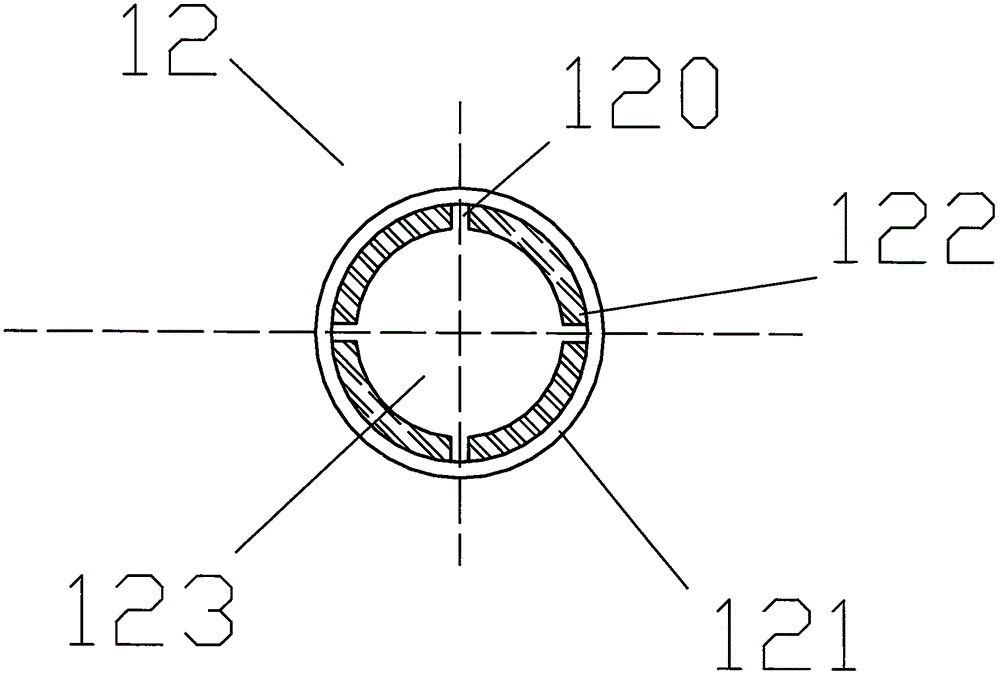

Dynamic pressure lubrication drilling tool and drilling tool assembly with same

InactiveCN102425382AReduce friction lossReduce surface wearDrilling rodsDirectional drillingWell drillingBoundary friction

The invention relates to a dynamic pressure lubrication drilling tool and a drilling tool assembly. The dynamic pressure lubrication drilling tool comprises a central shaft, wherein a shell can be sleeved on the outer part of the central shaft in a rotating manner relative to the central shaft, and an annular space is formed between the inner wall of the shell and the peripheral surface of the central shaft; more than one rotor is arranged on the inner wall of the shell, each rotor is provided with a plurality of inwards protruding rotor blades, and the rotor blades are positioned in the annular space; and the side wall of the central shaft is provided with more than one shunting hole. The drilling tool assembly is provided with a drill column, wherein the drill column comprises a plurality of sequentially connected conventional drilling tools and at least one dynamic pressure lubrication drilling tool; and the dynamic pressure lubrication drilling tool is arranged between two adjacent conventional drilling tools. when a well is drilled, the drilling tool assembly brings drilling fluid to the space between the drilling tool and a well wall or a sleeve wall under the fluid pumping action when the dynamic pressure lubrication drilling tool rotates, and the outer surface of the drilling tool is separated from the well wall or the sleeve wall, so that dry friction or boundary friction between the outer surface of the drilling tool and the well wall or the sleeve wall is changed into fluid friction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Lubricating grease for centrifugal pump sliding bearing

InactiveCN105316096AReduce manufacturing costReduce coefficient of frictionLubricant compositionDiethanolamideCetyl alcohol

The invention discloses a lubricating grease for a centrifugal pump sliding bearing, and relates to the technical field of centrifugal pump manufacturing. The lubricating grease is prepared from the following raw materials in parts by weight: 50-60 parts of mineral base oil, 20-25 parts of modified lard, 13-16 parts of sodium rosin soap, 12-15 parts of sodium bentonite, 10-14 parts of rice bran wax, 7-12 parts of coconut oil fatty acid diethanolamide, 7-12 parts of cetyl alcohol, 6-10 parts of a hydrogenated styrene diene copolymer, 5-8 parts of turpentine oil, 5-8 parts of an oxidation and corrosion inhibitor, 4-7 parts of N, N'-di-salicylidene propanediamine and 3-5 parts of maltodextrin. According to the lubricating grease, mineral base oil and modified lard are used as main raw materials, various functional additives are added in an assistant manner, and the prepared lubricating grease is uniform and transparent and low in manufacturing cost, so that bearing friction coefficients and surface abrasion are greatly reduced, and the service life of the centrifugal pump sliding bearing is prolonged.

Owner:ESKE PUMP

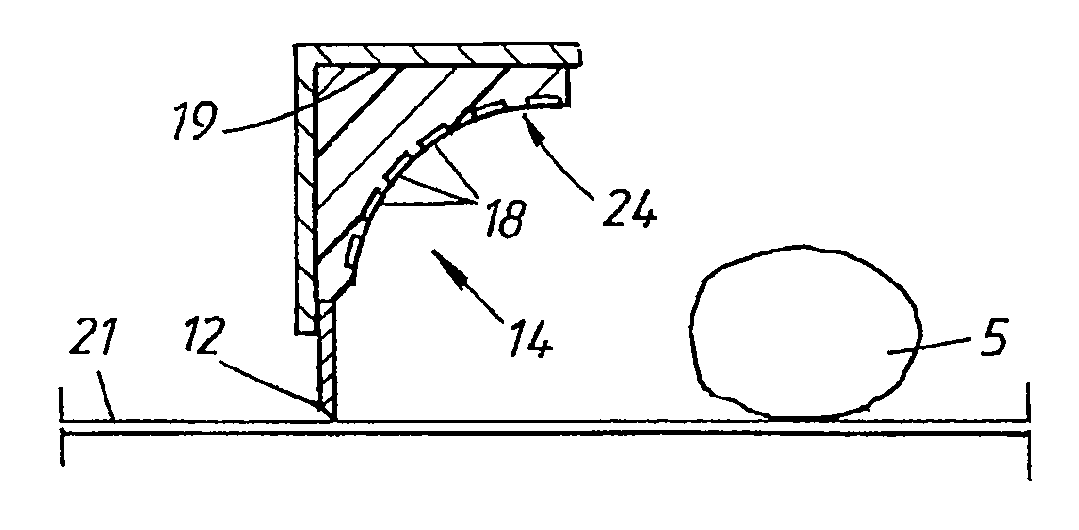

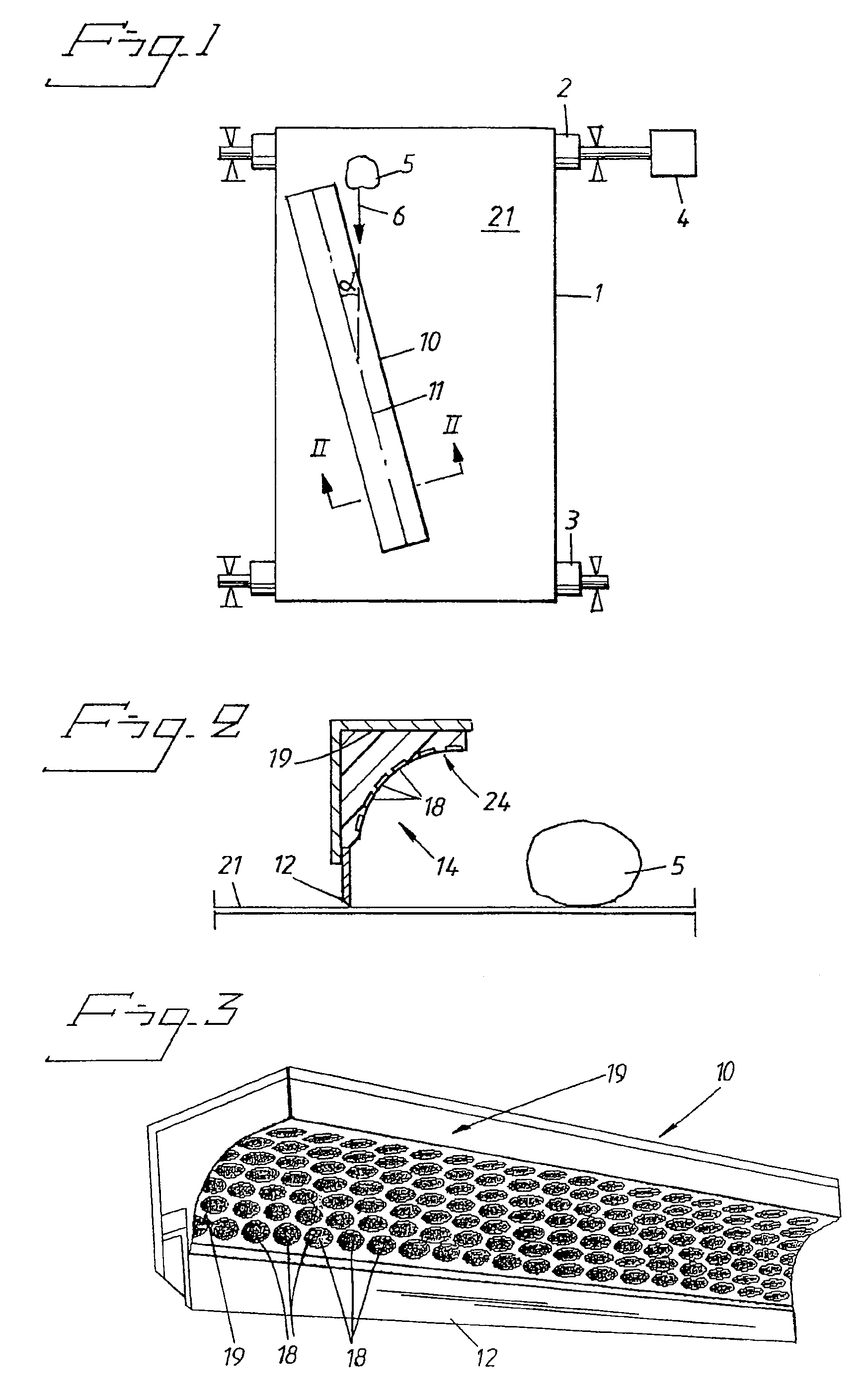

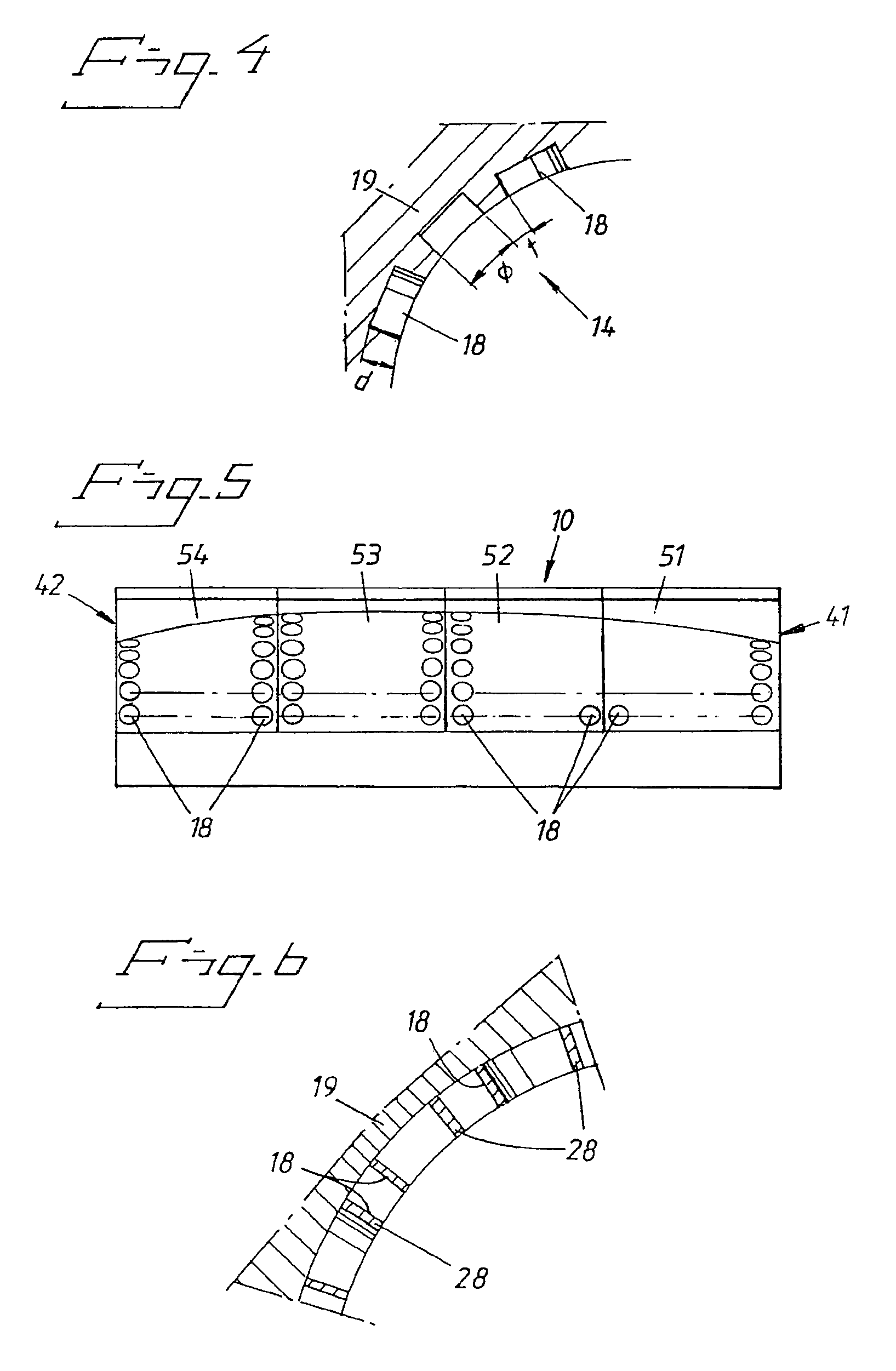

Device for rounding of dough pieces

InactiveUS7527492B2Increase frictionReduce surface wearDough treatmentConfectioneryRoundingAcute angle

Device for the rounding of dough pieces, comprising a support surface for the dough pieces, an elongate rounding rail having a concave rounding surface, the rounding rail extending to the support surface, members being provided in order to move the rounding rail in relation to the support surface having the dough pieces carried thereby, the longitudinal direction of the rail forming an acute angle to the direction of motion of the dough pieces, whereby the dough pieces being kneaded and rounded while rolling off on the rounding surface. The rounding surface is provided with a plurality of recesses distributed over the rounding surface and open toward the rounding surface, which recesses have a diameter in the range of 5-15 mm and a depth in the range of 3-8 mm

Owner:FORTES TREVOR

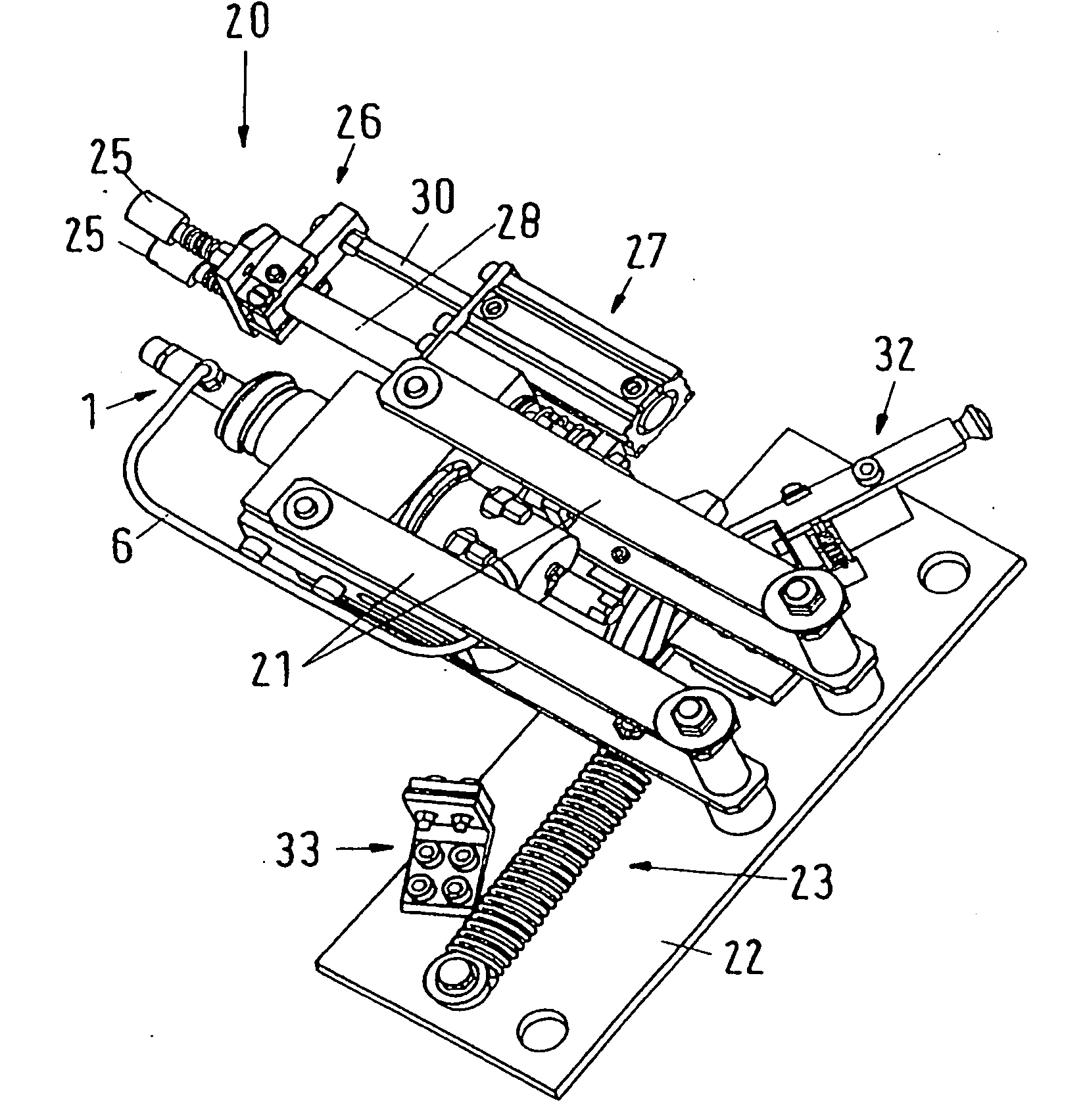

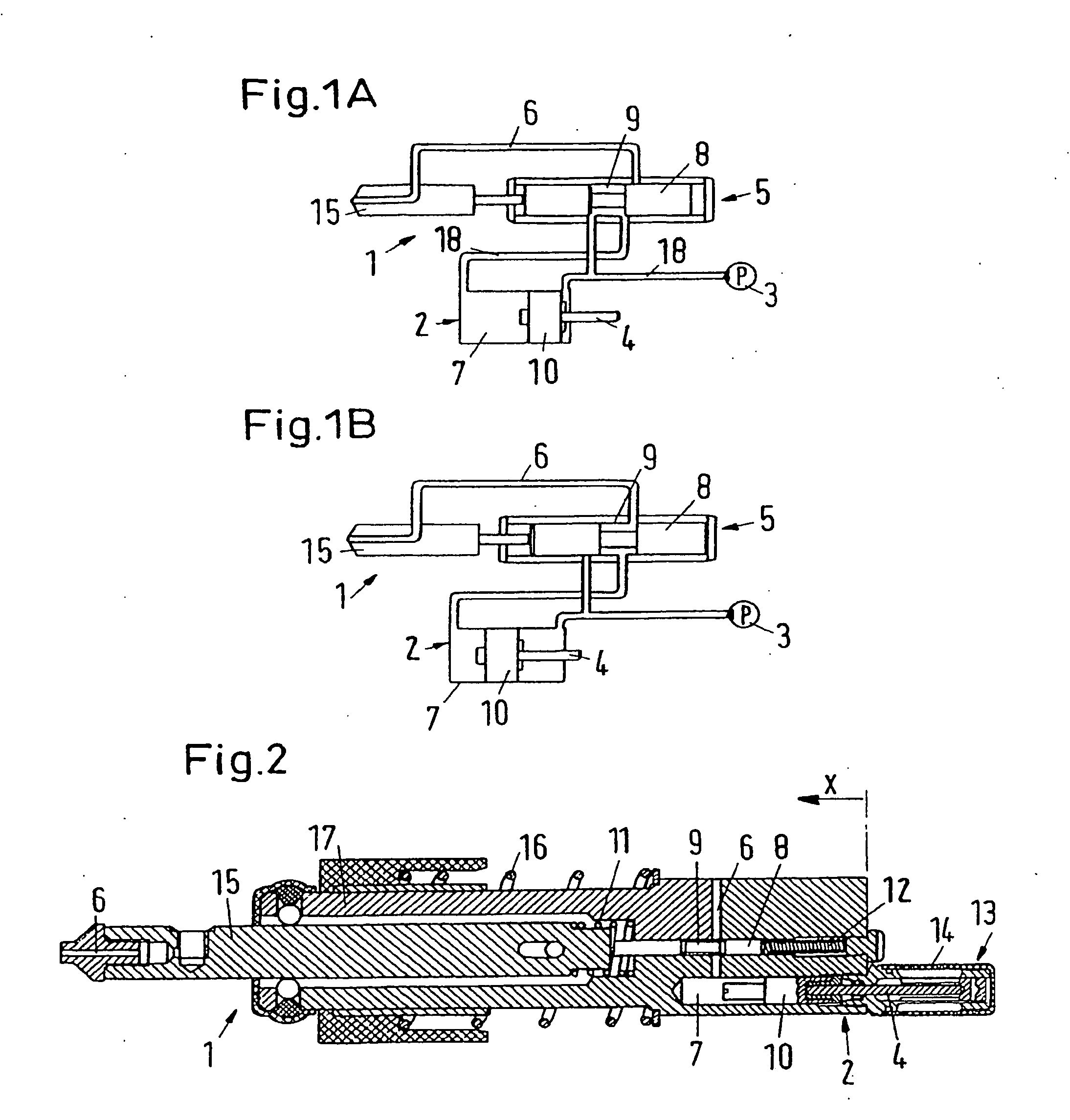

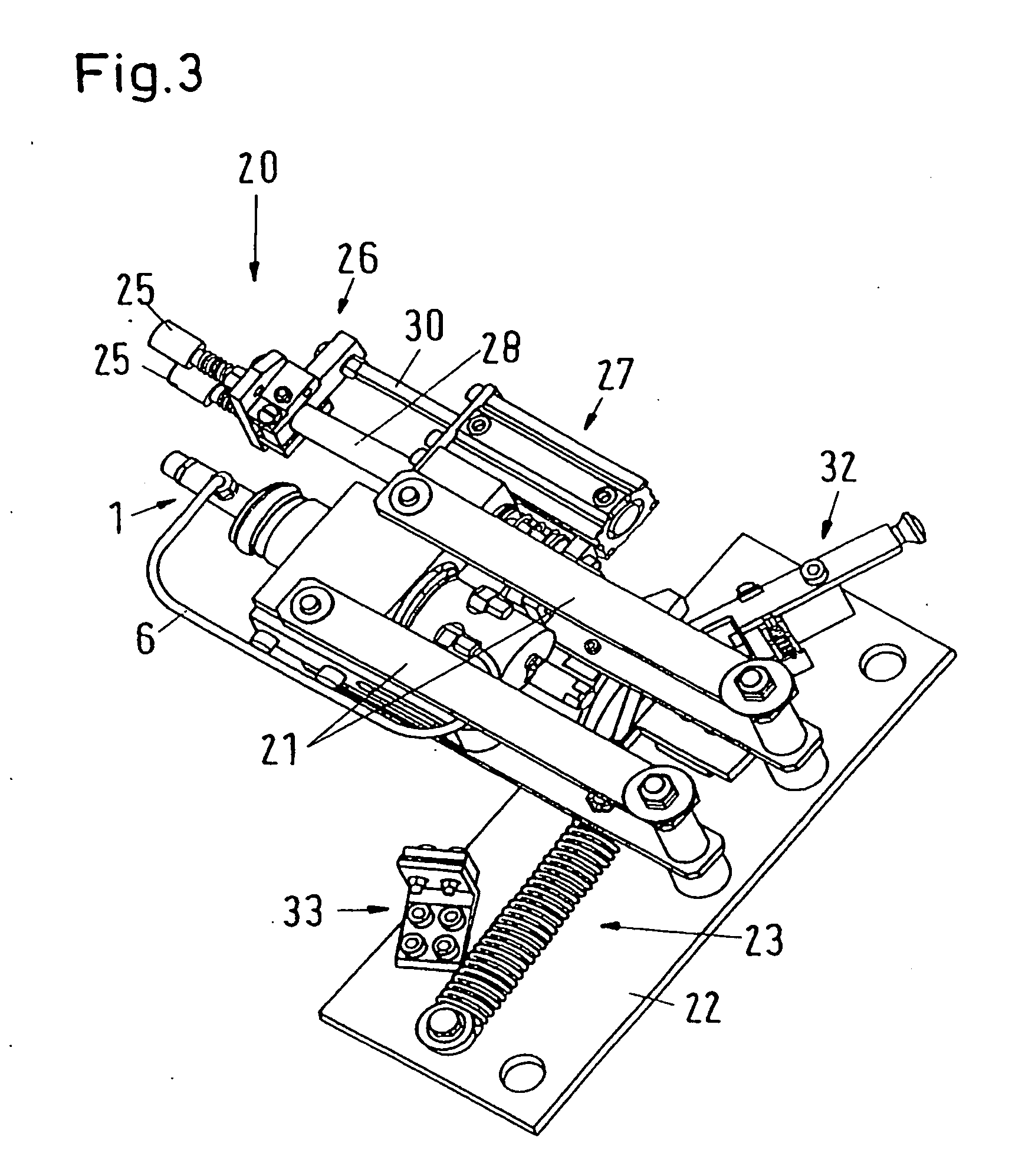

Lubricating device and lubrication apparatus comprising said device

ActiveUS20100038178A1Reduce surface wearAvoid damageMachines/enginesLubricating pumpsLubricationFeeding pumps

The invention relates to a lubricating device, particularly for use in an apparatus which is used to lubricate mobile lubrication points e.g. on a rotating belt or chain belt. A lubricant discharge body of a lubricating head, which when lubricant is conveyed by a feed pump into a dosing chamber which is separated from the lubricant discharge channel, is placed in a front standby position and, counter to the effect of a restoring force, is moved into a locking and lubricant release position wherein the link between the pump and the dosing chamber is blocked by a reversing piston and the dosing chamber is fluidic ally connected to the lubricant discharge channel and a predefined volume of lubricant can be pumped out of the dosing chamber into the lubricant discharge channel. The lubricant discharge body cooperates with a reversing piston in such a way that the feed pump is fluidic ally connected to the dosing chamber of a dosing piston / cylinder arrangement via an annular area of the reversing piston when the lubricant discharge body is located in a front standby position, and such that the dosing chamber is fluidically connected to the lubricant discharge channel via the angular area when the lubricant discharge body is placed in a retracted position in which the lubricant is released. The reversing piston blocks the fluidic connection between the feed pump and the dosing chamber such that the amount of lubricant provided for discharge can be pumped out of the dosing chamber in the direction of the annular area by a dosing piston which is impinged upon by the feed pump.

Owner:LINCOLN GMBH

High-strength anti-nodulation CNRE rare earth heat-resistant steel for furnace bottom roller and preparation method of high-strength anti-nodulation CNRE rare earth heat-resistant steel

InactiveCN112410664AImprove initial strengthReduce surface wearSolid solution strengtheningUltimate tensile strength

The invention relates to the field of metallurgical machinery, in particular to high-strength anti-nodulation CNRE rare earth heat-resistant steel for a furnace bottom roller and a preparation methodof the high-strength anti-nodulation CNRE rare earth heat-resistant steel. The steel comprises the following chemical components in percentage by weight: 0.2 to 0.5 percent of C, 1.5 to 2.5 percent ofSi, 6.0 to 13.0 percent of Mn, 16.0 to 26.0 percent of Cr, 1.0 to 6.0 percent of Ni, 0.3 to 2.0 percent of Mo, 0.05 to 0.50 percent of V, 0.05 to 0.50 percent of Nb, 0.2 to 0.6 percent of N, 0.005 to0.5 percent of RE and the balance of Fe. According to the high-strength anti-nodulation rare earth heat-resistant steel for the furnace bottom roller, strong solution strengthening and precipitationstrengthening effects are generated through C and N co-alloying and V and Nb micro-alloying, and the initial strength of the furnace bottom roller is improved; a high-temperature structure is stabilized by means of rare earth microalloying; the attenuation rate of high-temperature strength is reduced; surface abrasion of the furnace bottom roller is reduced; the anti-nodulation capacity is improved; moreover, an intermediate frequency furnace high-nitrogen alloying technology, a high-purity rare earth treatment technology and a centrifugal casting technology are adopted, so that a furnace bottom roller casting which is uniform in component, compact in structure and excellent in performance is obtained; and the technical problems of deformation, nodulation and the like of the furnace bottomroller can be effectively solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

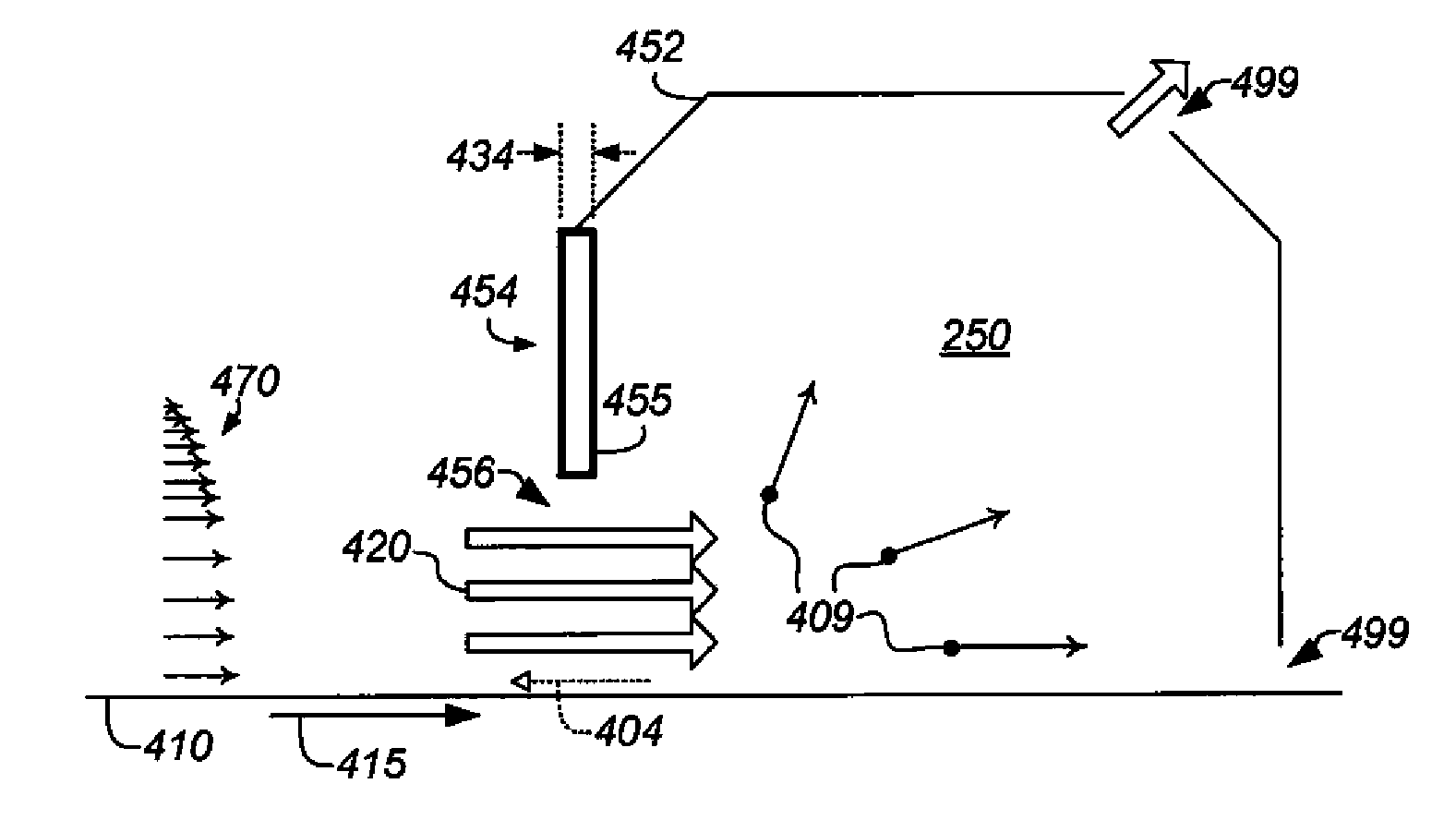

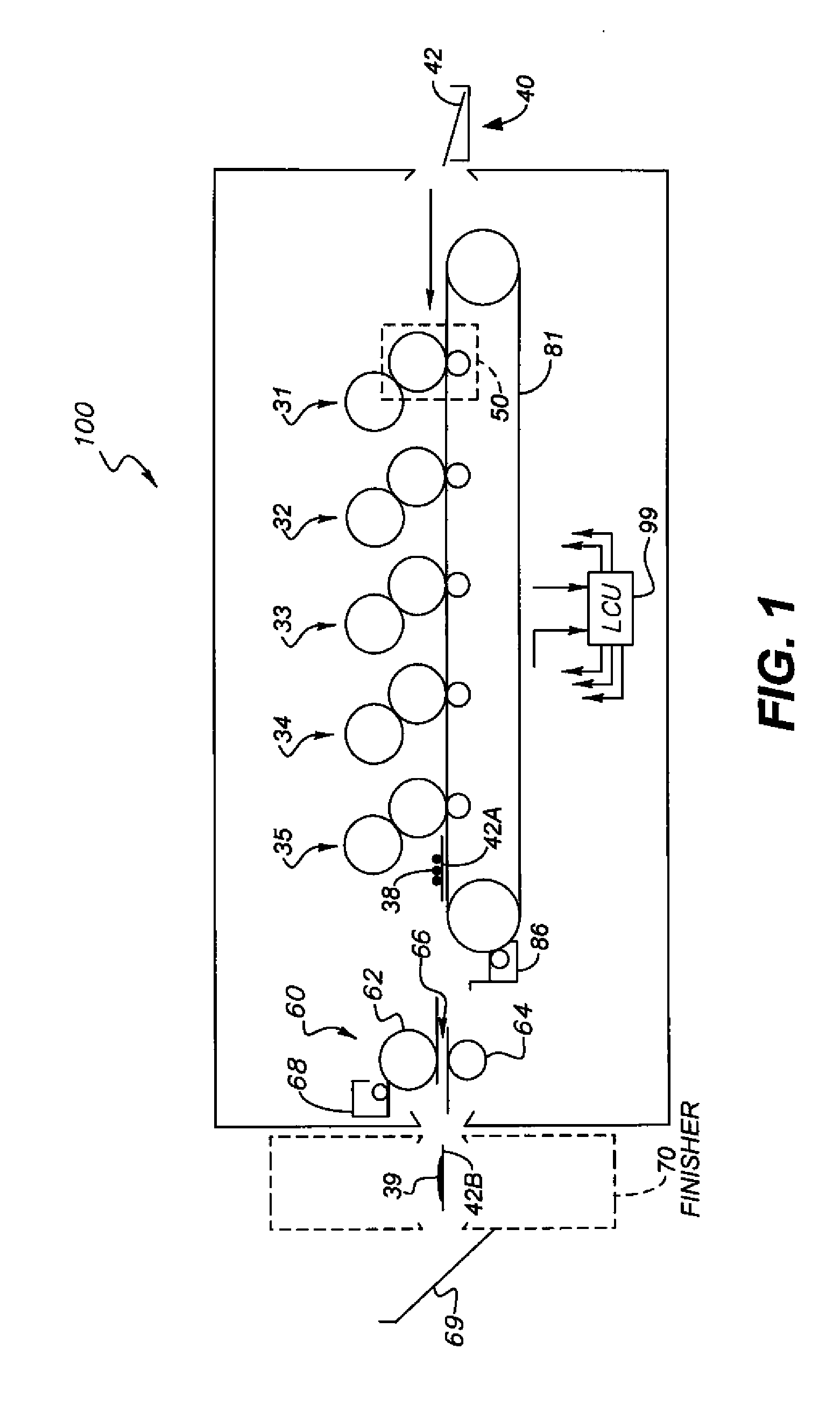

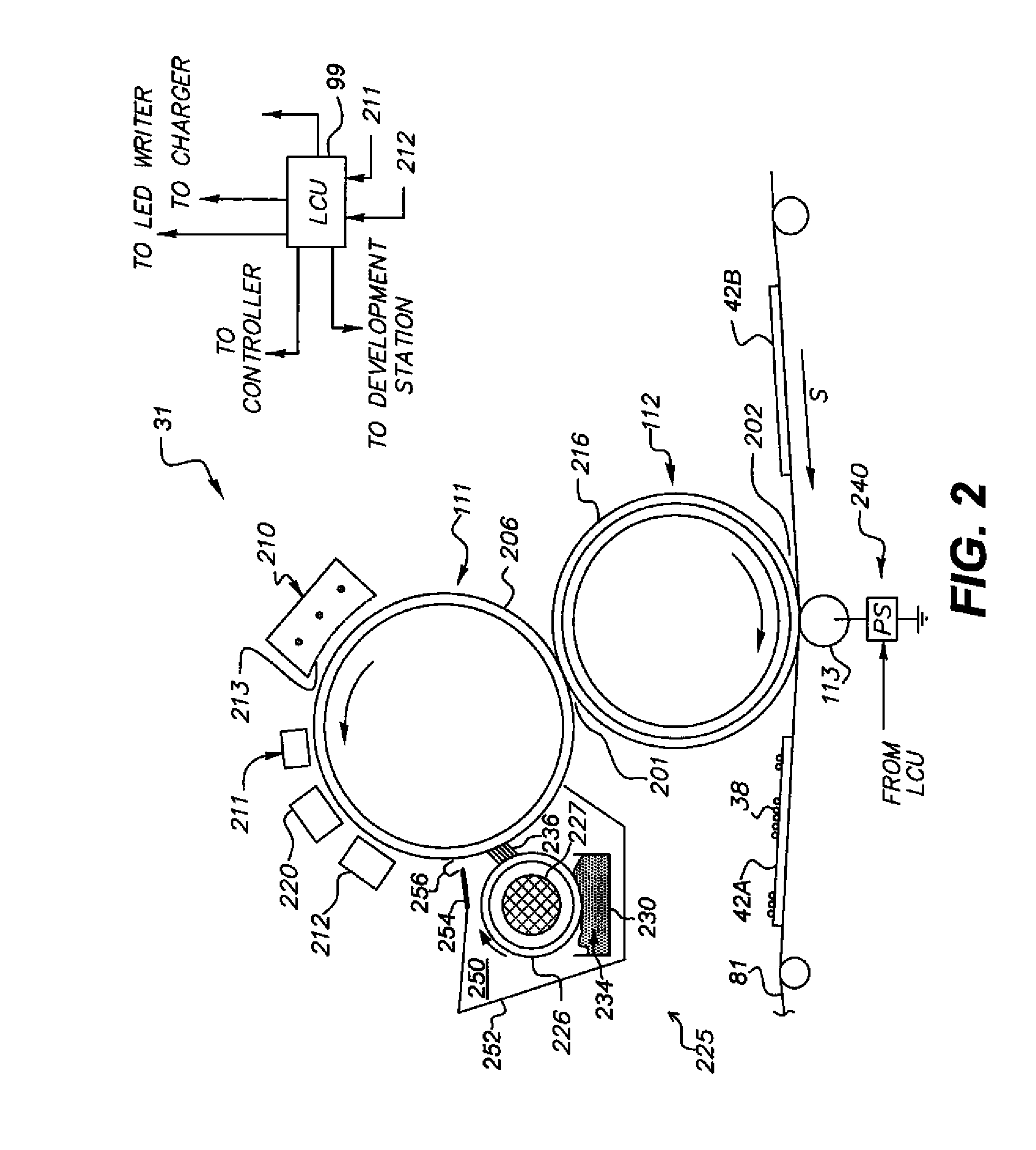

Reducing contamination by regulating flow

InactiveUS20120107011A1Reduce trafficReduce generationElectrography/magnetographyEngineeringContamination

Apparatus for retaining a contaminating substance in a working volume containing a gas includes a movable surface disposed adjacent to the working volume. A barrier is spaced apart from the surface ahead of the working volume in the direction of motion of the surface so that a gap is defined between the barrier and the surface. The gap is selected so that a stream of gas is carried by the moving surface through the gap into the working volume and the contaminating substance in the working volume is urged away from the gap, thereby reducing flow of the contaminating substance through the gap.

Owner:EASTMAN KODAK CO

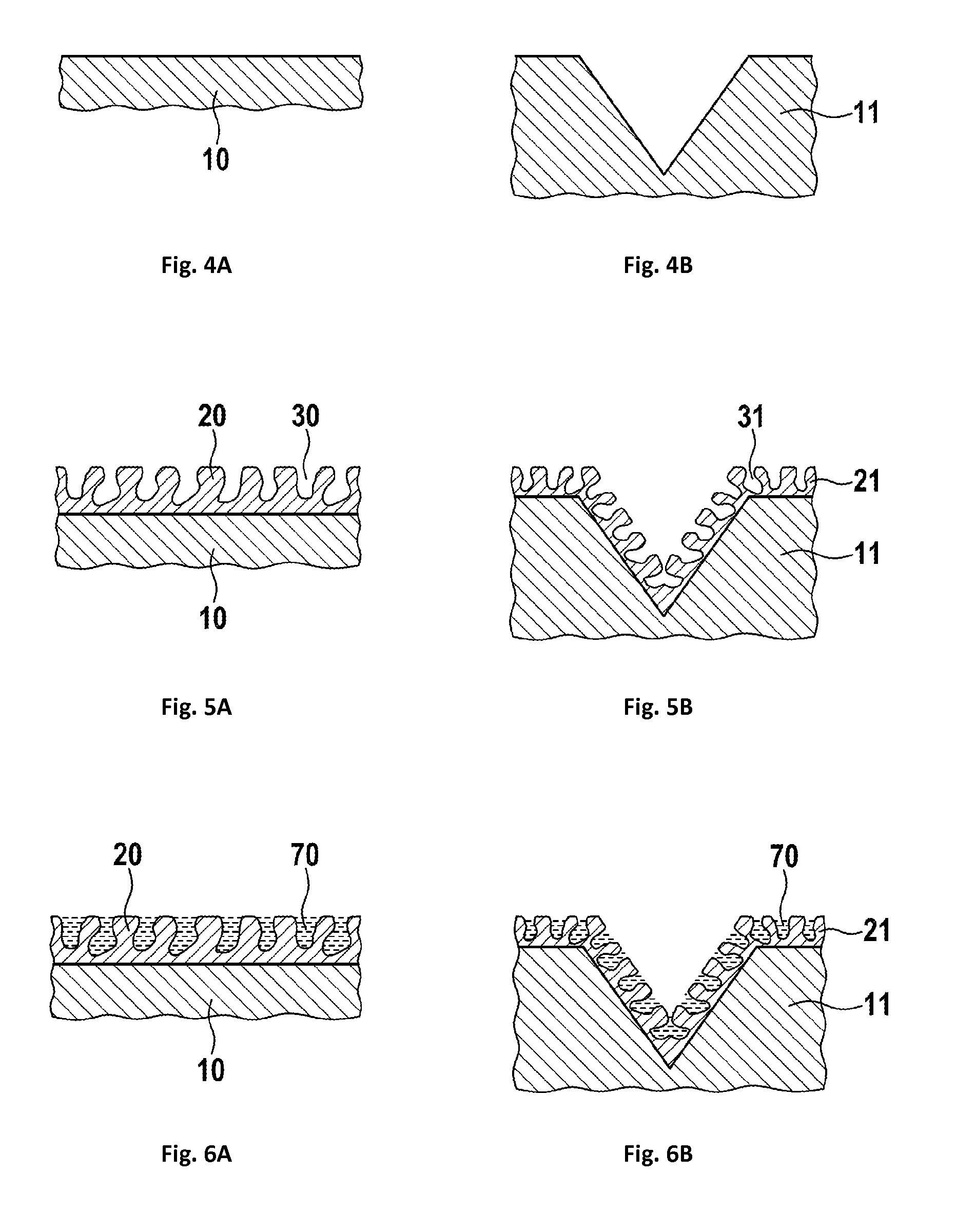

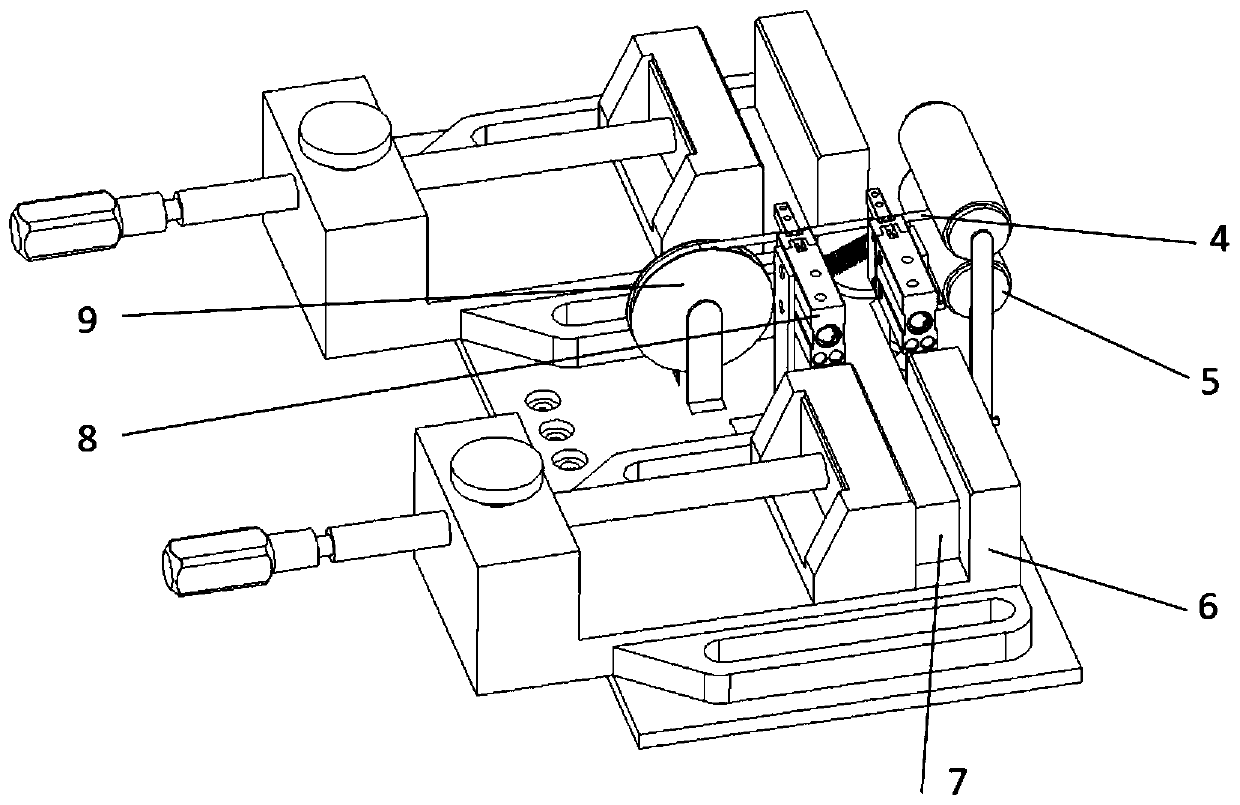

Carbon fiber implanted high-hardness surface microstructure and preparation method and device thereof

ActiveCN110524103AExtended service lifeEasy to keep sharpNon-electric welding apparatusFiberCarbon fibers

The invention discloses a carbon fiber implanted high-hardness surface microstructure and a preparation method and device thereof. The service life of an existing high-hardness surface needs to be prolonged. According to the invention, a carbon fiber inverted cone is welded in a central inverted circular truncated cone pit of each bionic microstructure. The preparation method of the microstructurecomprises the following steps: imprinting a bionic microstructure group by using a single-point diamond imprinting knife, and then welding a carbon fiber inverted cone in each central inverted circular truncated cone pit of the bionic microstructure group. The microstructure preparation device comprises a vibration single-point diamond imprinting instrument, a single-point diamond imprinting cutter, a vibration single-point diamond welding instrument and a diamond welding cutter, the vibration single-point diamond imprinting instrument comprises a single-point diamond three-dimensional driving mechanism and a first vibration exciter. The vibration single-point diamond welding instrument comprises a single-point diamond three-dimensional driving mechanism and a second vibration exciter. The hardness, strength, wear resistance and precision of the high-hardness surface can be improved.

Owner:HANGZHOU DIANZI UNIV

CrN/MoS2 solid self-lubricating composite film

InactiveCN110965015AHigh resistance to sliding wearReduce coefficient of frictionVacuum evaporation coatingSputtering coatingComposite filmPhysical chemistry

Provided is a CrN / MoS2 solid self-lubricating composite film. On the basis of super-lubricating performance of MoS2, a composite plating permeation method is adopted for further reducing the dry friction resistance of a CrN-base composite film, that is, a new method for processing a CrMoN composite film through low-temperature ion sulfurization is adopted to synthesize the CrN / MoS2 solid self-lubricating composite film with excellent tribology performance in situ. After sulfurization treatment is performed on the CrMoN composite film, a MoS2 lubricating phase is mainly synthesized, a sulfurization layer has the thickness of about 500 nm, and the main phase has the structure of CrN, MoS2 and slight MoN. Compared with the CrMoN composite film, the CrN / MoS2 solid self-lubricating composite film is low in friction coefficient and low in wear size and has high wear resistance and anti-friction quality.

Owner:张亮东

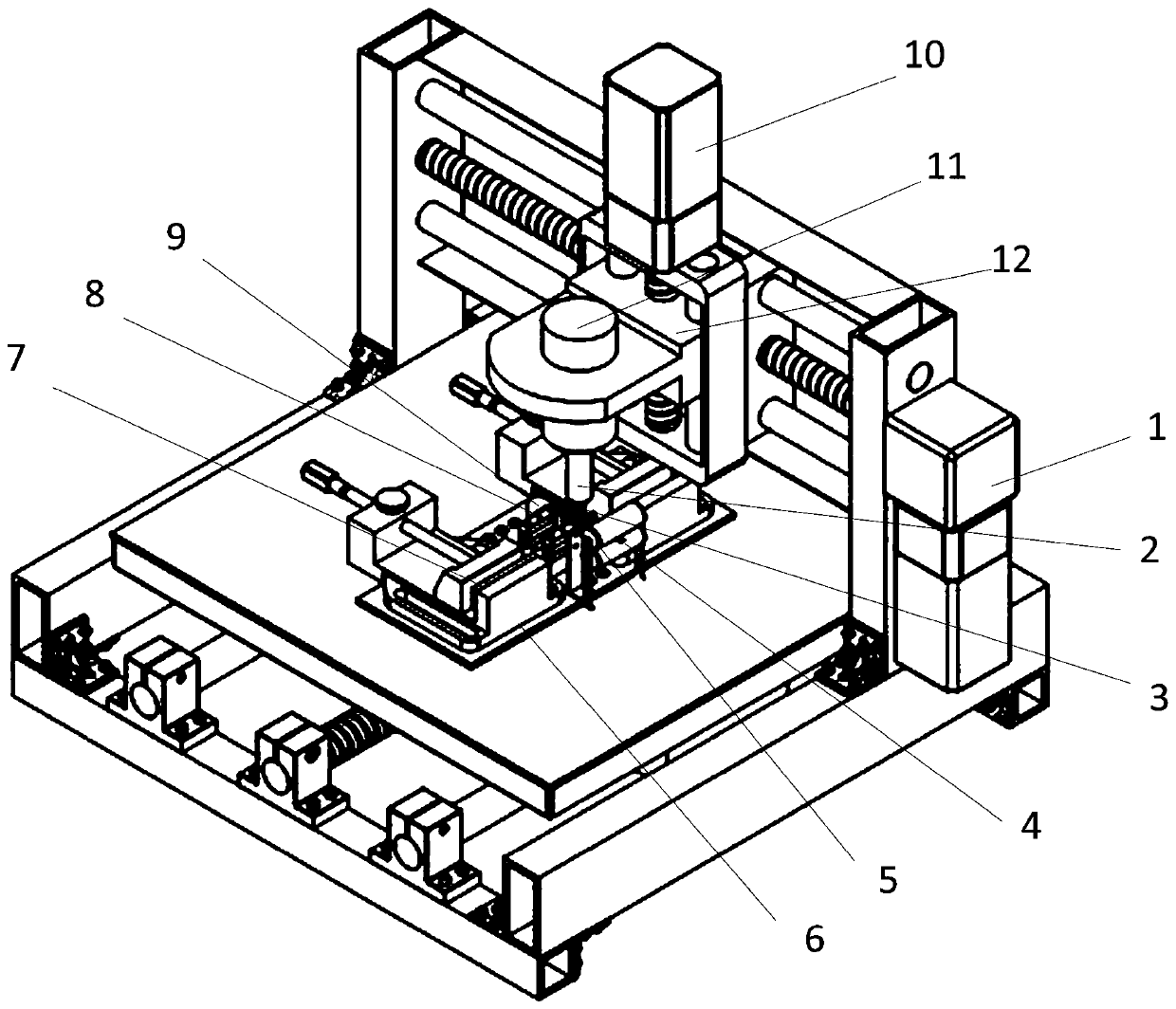

Method and device for preparing multi-scale functional microstructure on high-hardness surface

ActiveCN111320132AHigh hardnessHigh strengthDecorative surface effectsChemical vapor deposition coatingMachined surfaceDiamond knife

The invention discloses a method and device for preparing a multi-scale functional microstructure on a high-hardness surface. It is very necessary to develop an efficient and convenient multi-scale functional microstructure preparation method and device. The method comprises the steps that a single-point diamond cutter and a multi-edge diamond cutter are manufactured; then, a central inverted circular truncated cone pit microstructure array or a V-shaped groove microstructure array is imprinted on the to-be-machined surface of the to-be-machined workpiece; and finally, preparing a micron or submicron functional microstructure on the central inverted circular truncated cone pit microstructure array or the V-shaped groove microstructure array. The device comprises a four-degree-of-freedom positioning mechanism, a clamp, a vibration exciter, a single-point diamond cutter and a multi-edge diamond cutter. The multi-scale functional microstructure is machined on the high-hardness surface, the hardness, strength, abrasion resistance and precision of the high-hardness surface can be improved, and the method has very important significance in development of the high-hardness machining industry.

Owner:HANGZHOU DIANZI UNIV

Heat-resistant high-strength mould material

The invention discloses a heat-resistant high-strength mould material. The mould material comprises 1.4%-5.2% of C, 1.2%-5.0% of Si, 0.4%-1.2% of Mn, 0.01%-0.02% of S, 0.4%-1.0% of Cu, 0.6%-5.0% of Cr, 0.4%-4.8% of Ti, 1%-6% of Mg, 0.5%-3.0% of Al and 80%-96% of Fe in proportion. According to the heat-resistant high-strength mould material, the heat-conducting property is superior to that of steel, and the wetting property can be significantly improved through the Mg and the Ti which are added to the material; in addition, the material is free of brittleness, and the mechanical strength is close to that of the steel; graphite is a good solid lubricant, and hence the surface abrasion of aluminum and alloy of the aluminum can be reduced.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

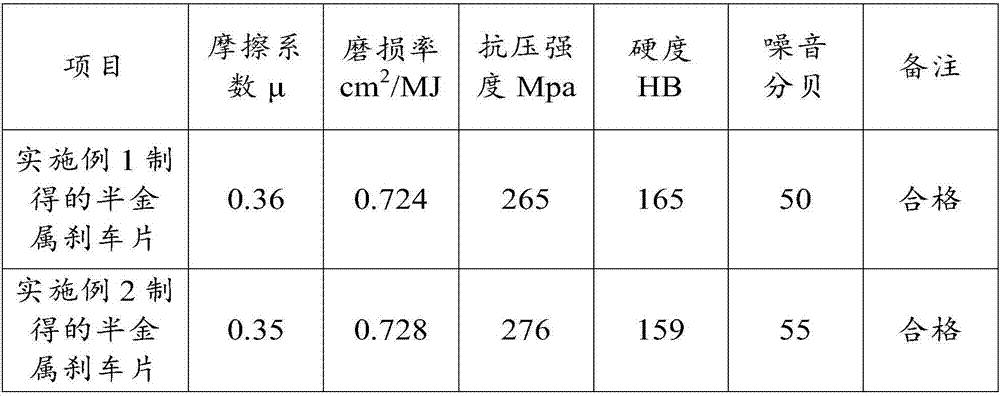

Semimetal brake pad and preparation method thereof

ActiveCN106917837AReduce noiseImprove insulation performanceFriction liningActuatorsMetal fiberEpoxy

The invention discloses a semimetal brake pad and a preparation method thereof. The semimetal brake pad comprises a stainless steel back plate and a friction block, wherein the friction block is prepared from raw materials as follows: iron powder, metal fiber, jute fiber, ferrous chromite, epoxy resin, rubber powder, silicon dioxide aerogel, silicon carbide, nanometer titania, a compatilizer and graphene. The preparation method comprises steps as follows: the raw materials of the friction block are blended in percentage by mass and put in a high-speed mixer to be mixed, and a mixed material is obtained; the mixed material is injected into a forming mold and subjected to hot-press forming, and a hot-press formed semi-finished product is obtained; the hot-press formed semi-finished product is placed in a drying oven and dried, and the friction block is obtained; the friction block is bonded on the stainless steel back plate for constant hot-pressure processing, and the semimetal brake pad is obtained. The semimetal brake pad prepared with the method has the advantages of moderate strength, good wear resistance and low noise.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

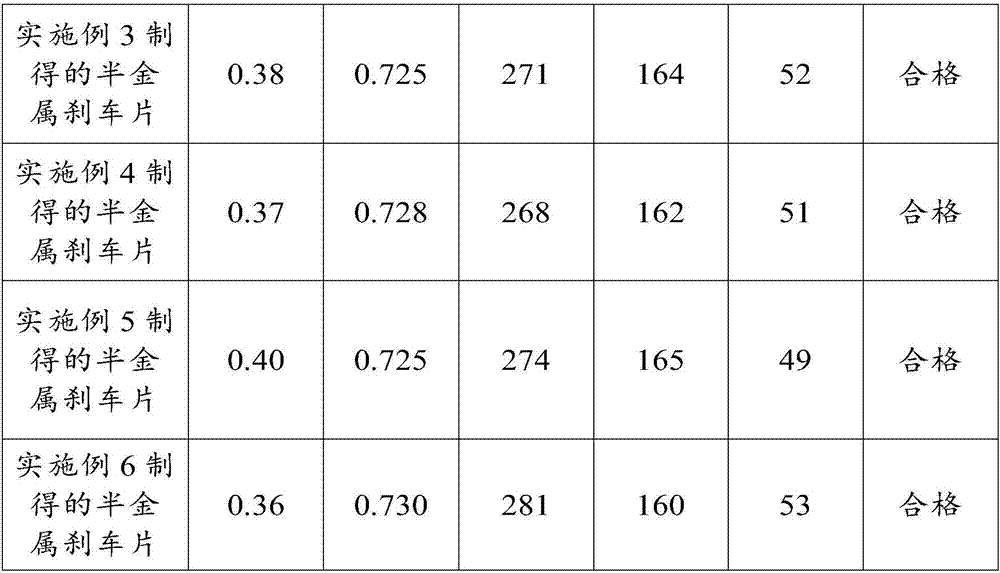

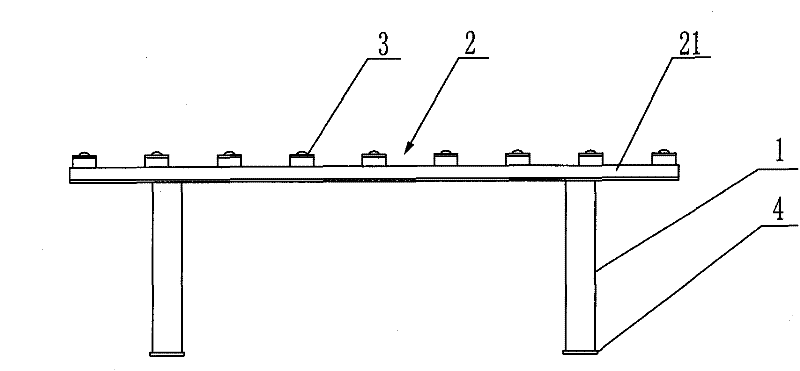

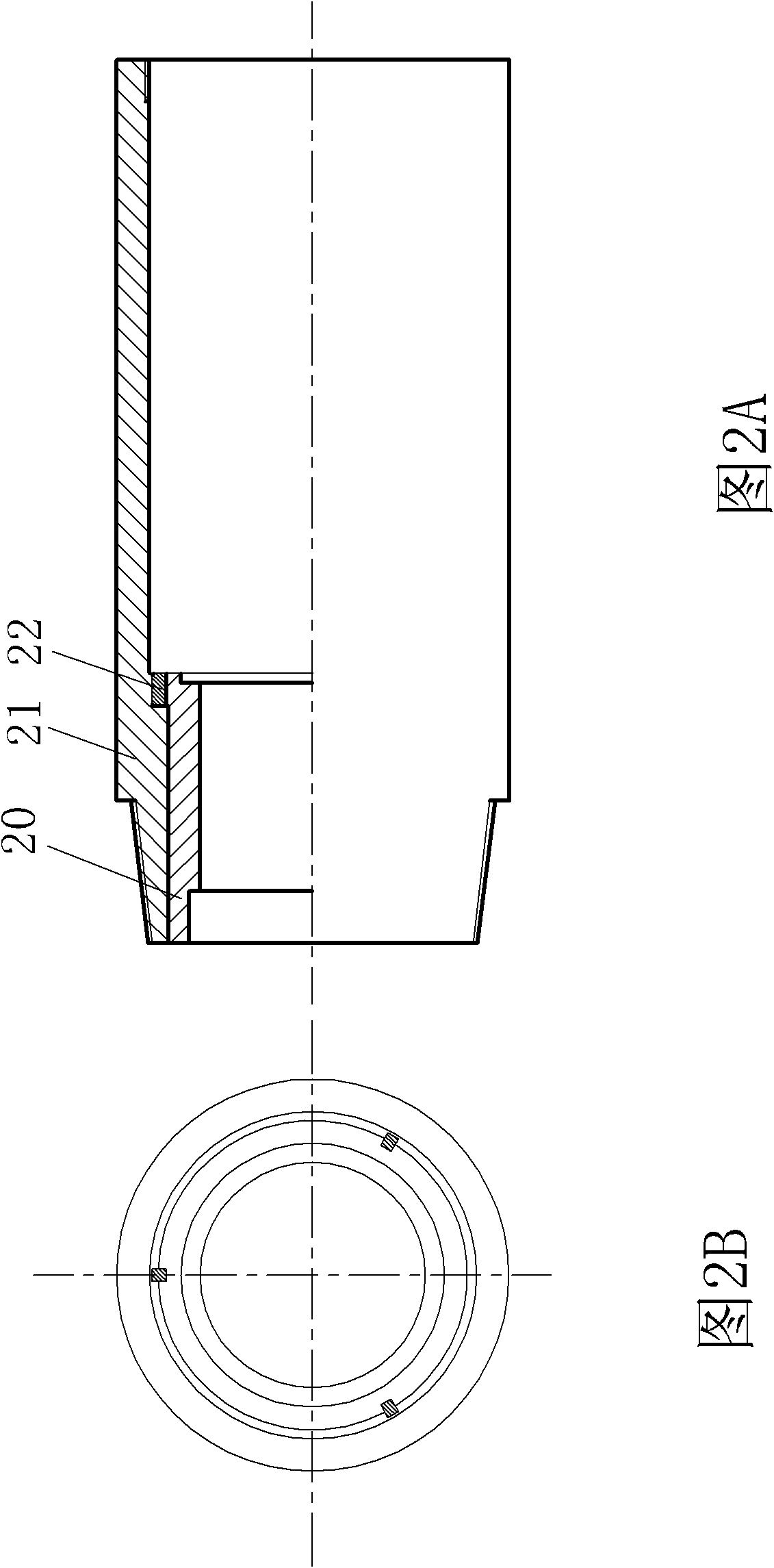

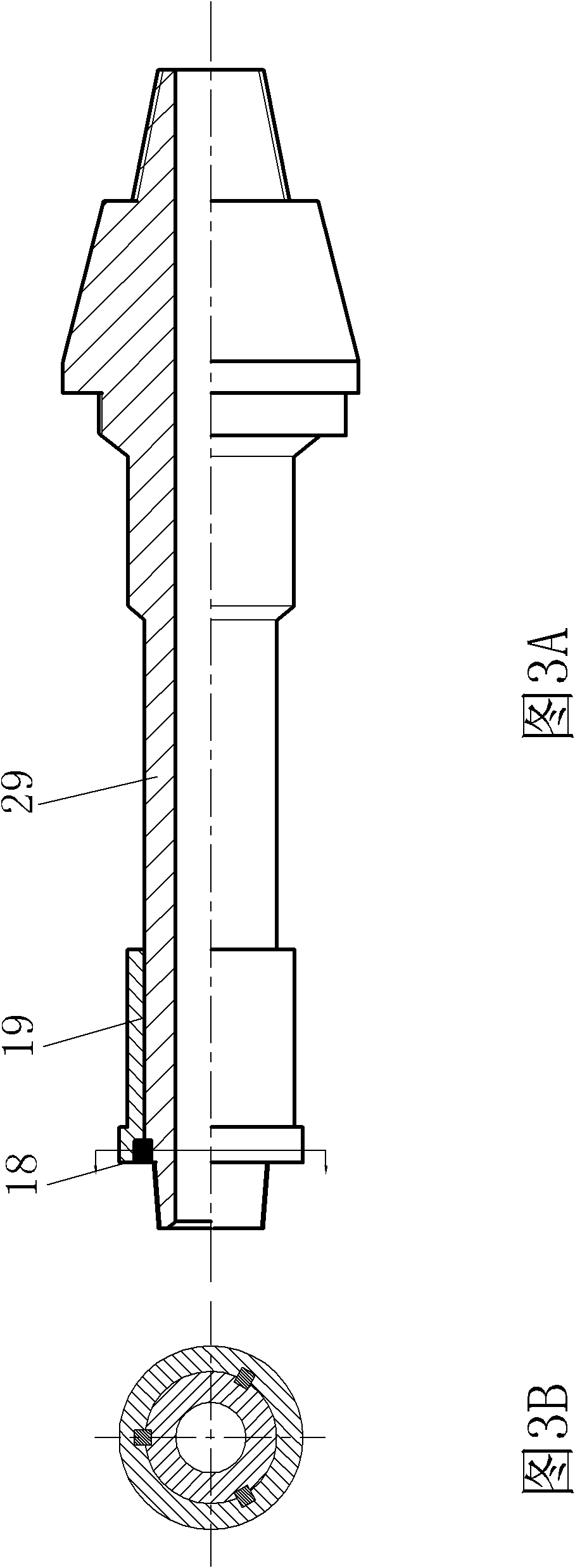

Plate feeding table

InactiveCN102241324AEasy to replaceReduce surface wearArticle feedersMechanical conveyorsMulti degree of freedomEngineering

The invention discloses a plate feeding table, which comprises a support, wherein a worktable is arranged on the support; and a supporting and conveying device is arranged on the worktable. The 360-degree omni-directional multi-degree-of-freedom conveying can be realized; round balls are adopted as rolling carriers, with smoother contact surface and smaller friction, the plate feeding table has the advantage of creating convenience in conveying and reducing abrasion to the surfaces of plates; and the detachable way is adopted and the round balls can be conveniently replaced after being abraded, therefore the plate feeding table has high convenience.

Owner:QINGDAO TRANSFORMER GRP CO LTD

Dynamic pressure lubrication drilling tool and drilling tool assembly with same

InactiveCN102425382BThe drilling tool assembly hasReduce friction lossDrilling rodsDirectional drillingWell drillingBoundary friction

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Automatic machining equipment for steel hot-rolling manufacturing forming

ActiveCN111545636AReduce the occurrence of deformation damageReduce frictionMetal-working feeding devicesNon-rotating vibration suppressionStructural engineeringMachining

The invention relates to automatic machining equipment for steel hot-rolling manufacturing forming. The automatic machining equipment comprises a fixed base, a mounting base, a bending device, a shaping device and an intermittent transmission device, wherein the mounting base is mounted at the left end of the fixed base, the bending device is mounted at the right end of the fixed base, the shapingdevice is mounted on the front side of the upper end of the mounting base, and an intermittent transmission device is mounted on the rear side of the upper end of the mounting base. The automatic machining equipment can solve the following problems that in the process that traditional steel manufacturing and forming equipment directly bends steel generally, due to the fact that large-amplitude angle changes occur in a short time, the bent position can be damaged, due to the fact that the steel to be treated is generally long, irregular deformation can occur at the bent position and the non-bent position after bending, and the next bending treatment of the steel is influenced; and due to the fact that a bending plate is usually in direct contact with the steel, in the bending process, thebending plate can rub against the steel, and the smoothness of the surface of the steel is affected.

Owner:广东习创实业发展有限公司

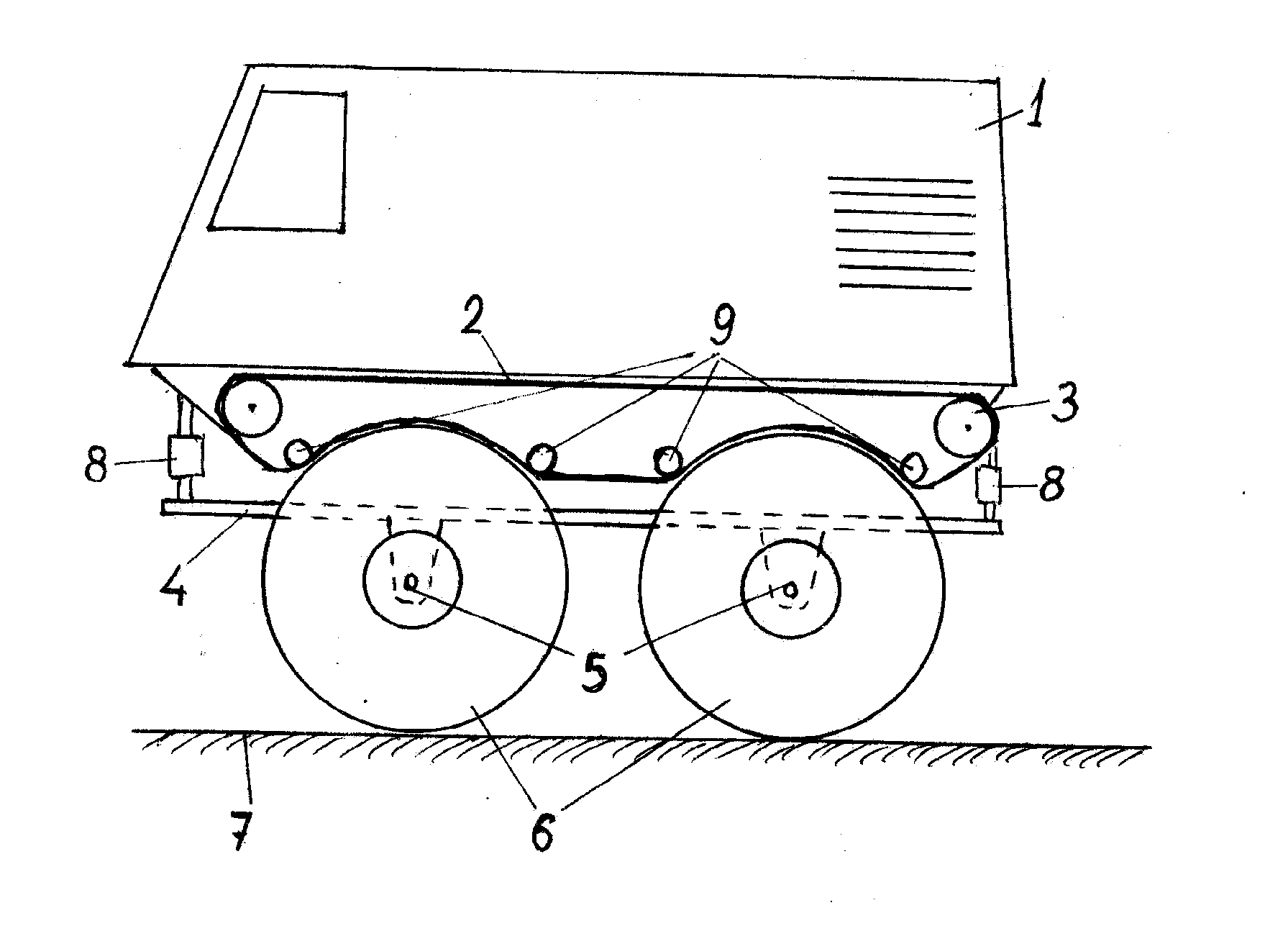

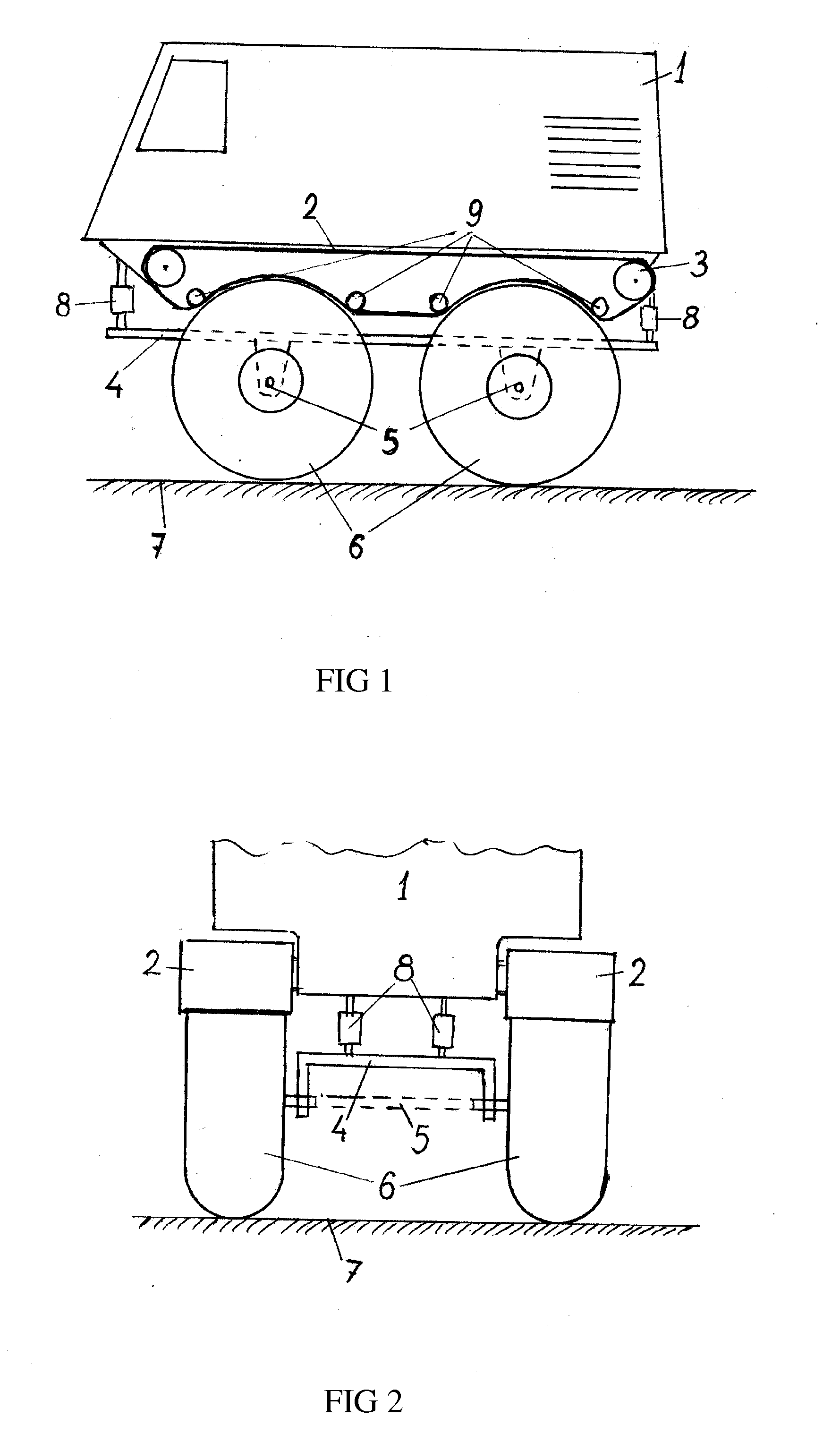

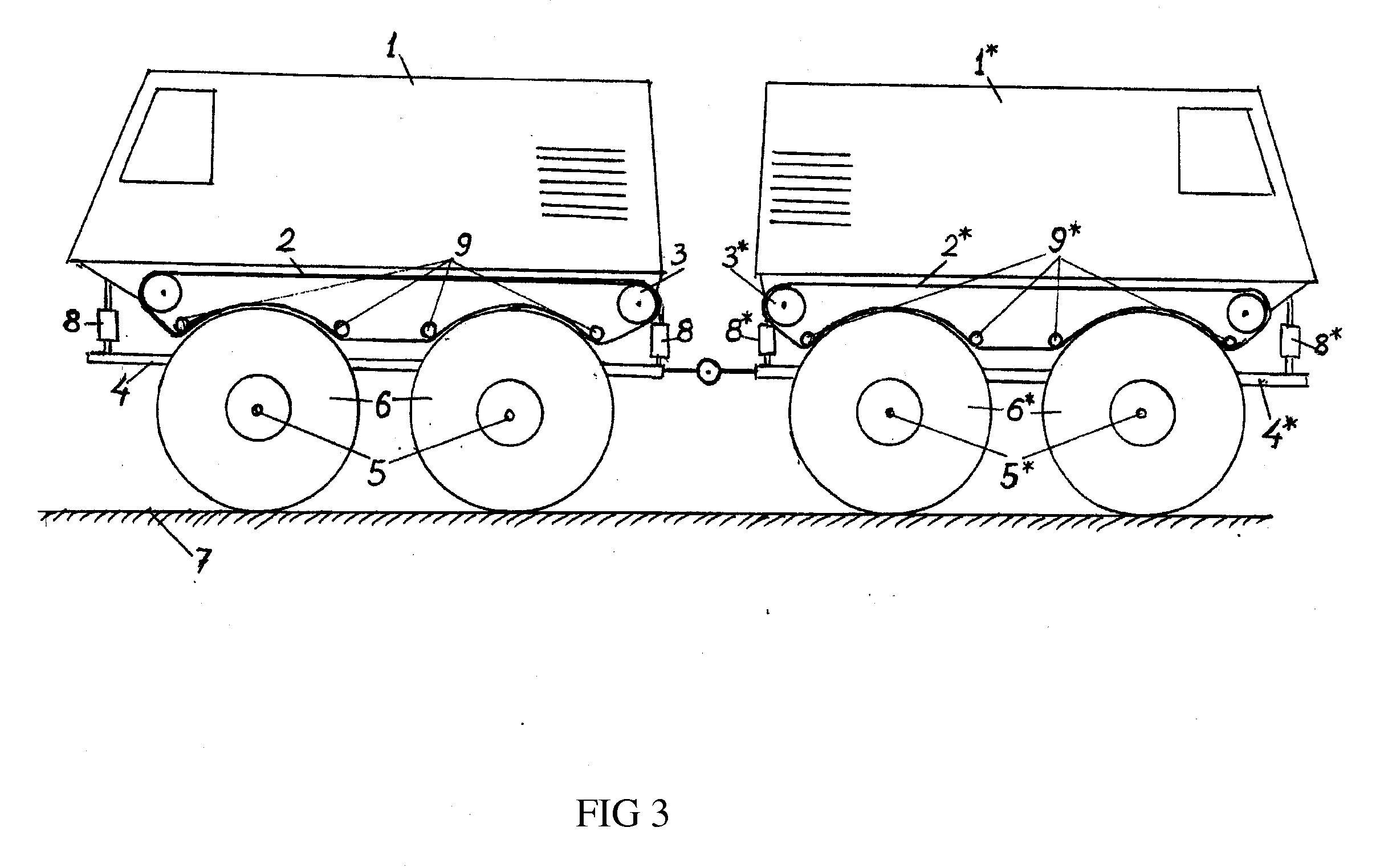

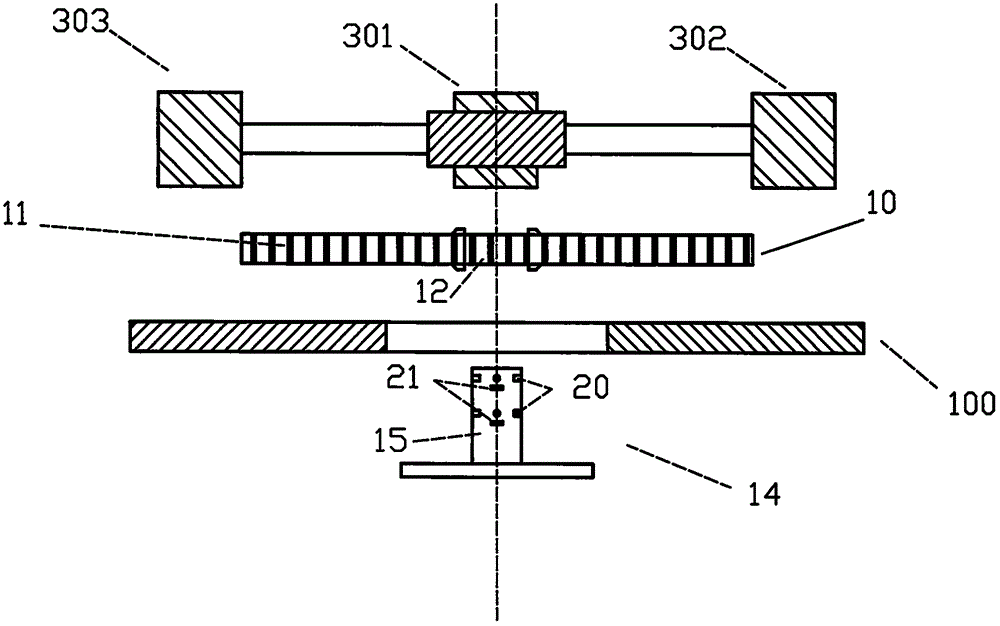

All-Terrain Vehicle and Method of Increasing Passability Thereof

InactiveUS20110180335A1Easy transferImprove reliabilityAgricultural machinesElectric propulsion mountingMiddle lineLandform

The invention relates to the automotive technique. Its use while creating new and improving current all-terrain vehicles allows to ensure the achievement of the technical result in the form of simplifying the all-terrain vehicle transmission, increasing the reliability, and decreasing the wheels surface wear, specifically for wheels having a non-hub drive. For this purpose, an all-terrain vehicle comprises: an engine transmission section; a pair of caterpillar drives from each of the side faces of the engine transmission section; a support frame provided with at least two rotatably mounted axles, on each of which at least two wheels are fixed so as the distance between the maximal radius circles of those wheels at each of those axles corresponding approximately the distance between the midline of the caterpillar drives; wherein the engine transmission section being fixed on the support frame so as a contact pattern of each of the caterpillar drives with a surface of the corresponding wheel being not less than a contact pattern of the lower portion of this wheel with the movement supporting surface.

Owner:IVANKOV MIKHAIL V +1

Gear subjected to surface treatment process

ActiveCN105927725AInjection implementationNo human intervention requiredPortable liftingGearing elementsWear resistantResin coating

The invention provides a gear subjected to a surface treatment process. The surface of gear is coated with a wear-resistant high-strength resin coating which is formed by pre-heating the gear and a mold, and then injecting a molten wear-resistant high-strength resin in a mold cavity between the mold and the gear face of the gear so that the wear-resistant high-strength resin is highly crystallized in the gradual cooling process. The gear has an intermediate hub portion. The intermediate hub portion has a first end face located outside the side of a body of the gear, and a second end face obliquely connecting the side and the first end face of the body of the gear. Grooves are disposed in the first end face and the face of a hub hole of the intermediate hub portion, so that the gear can be clamped and fixed to a predetermined axial fixed position.

Owner:重庆大合汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com