Equipment for carrying out shaping processing on chopsticks

A technology of chopsticks and equipment, which is applied in the manufacture of tools, wood processing utensils, wooden sticks, etc., can solve the problems of low efficiency of manual work, achieve the effect of improving efficiency and solving the difference in shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

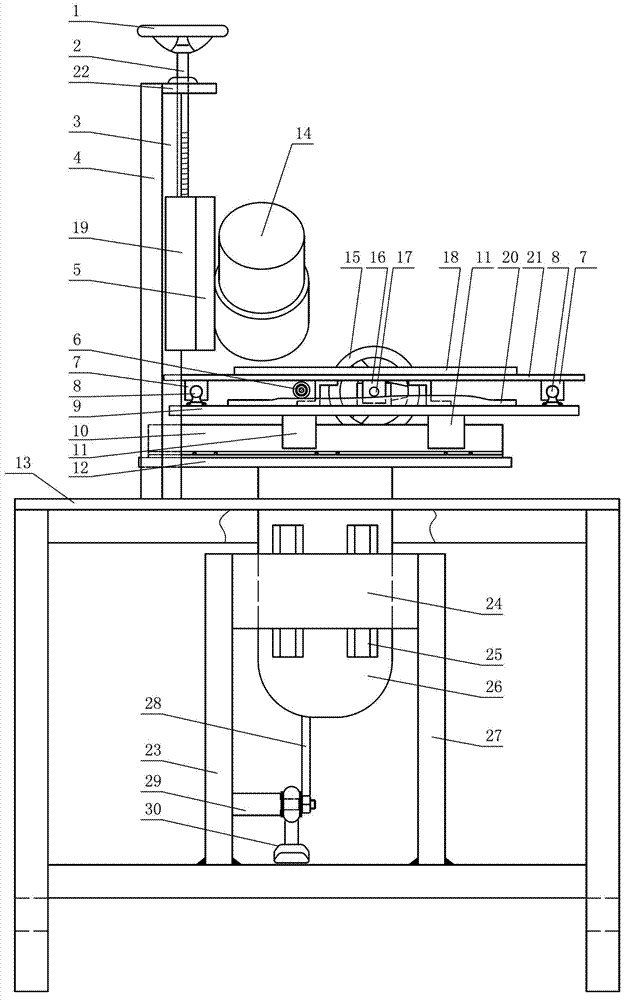

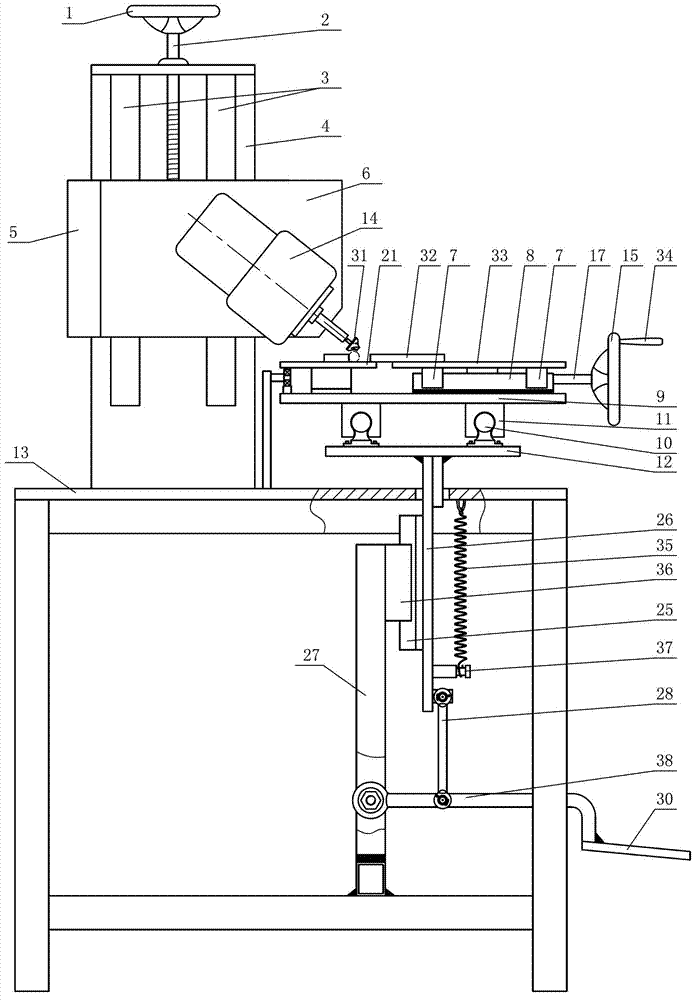

[0032] The device of the present invention will be further described below in conjunction with a specific embodiment.

[0033] refer to figure 2 , 3 , what this figure shows is a kind of specific implementation of the chopsticks molding equipment of the present invention, in this example, the equipment includes a frame, the top of the frame is a table top 13, and the table top 13 is fixed with a vertical The tool rest vertical plate 4, one side of the tool rest vertical plate 4 is provided with two vertically arranged linear guide rails 3, and a milling cutter motor 14 is fixed on a plate-shaped milling cutter motor mount 5, and the milling cutter motor Two sliding sleeves 19 cooperating with the two linear guide rails 3 are fixed on the other side of the mounting seat 5, and the two sliding sleeves are assembled on the two linear guide rails respectively. A screw rod 2 installed parallel to the linear guide rail (the assembly structure that does not restrict the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com