Patents

Literature

181results about "Wooden sticks manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

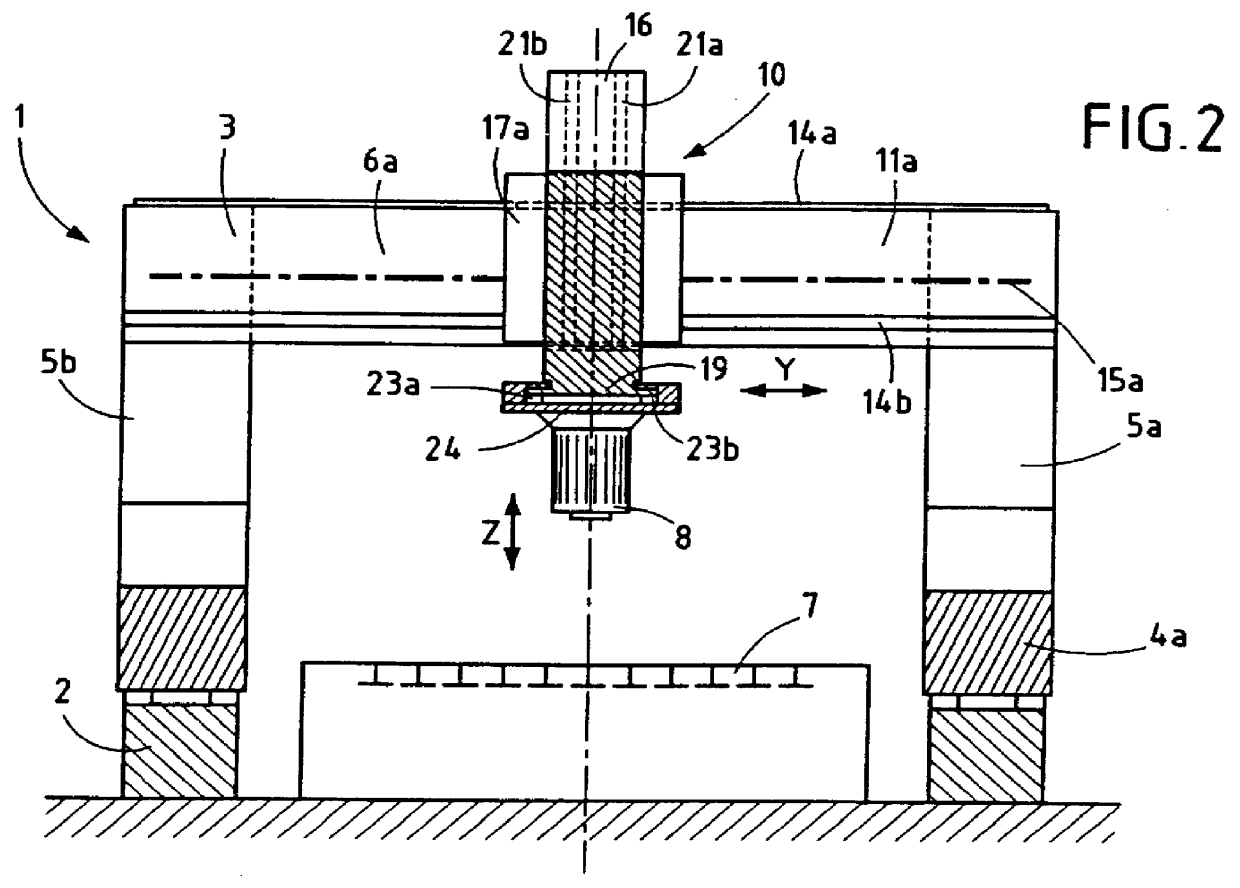

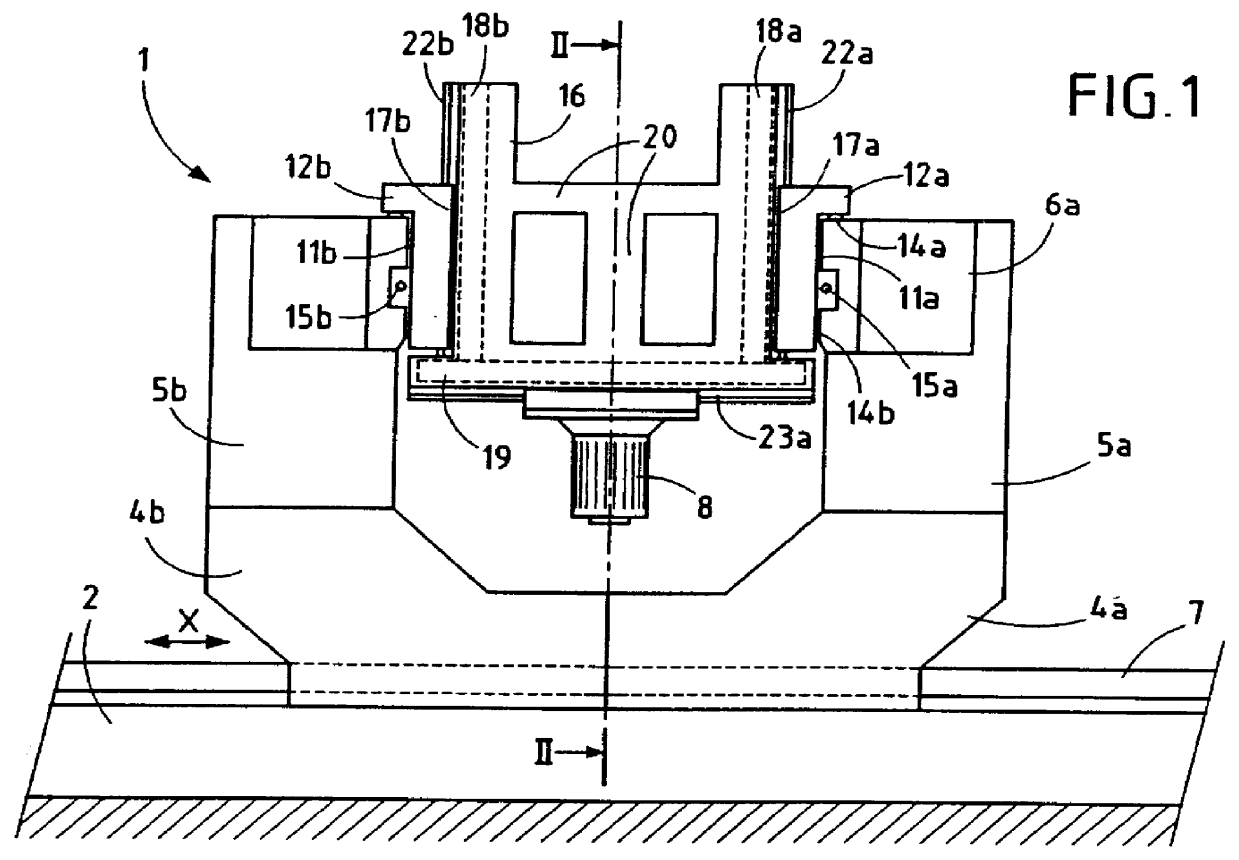

Machine tool having a gantry and a vertical spindle

InactiveUS6068431AEasy to remedy deformationReduce the total massWooden sticks manufactureMulti-purpose machinesNumerical controlEngineering

The invention relates to a machine tool having a gantry that is movable along an X axis and having a vertical spindle supported by the cross-member of the gantry. The cross-member comprises two beams that are spaced apart in the X axis direction and that have facing inside faces. Two carriages are mounted to slide on said facing faces, on opposite sides of a vertically movable cursor-carrier. The tool-carrier spindle is carried by a cursor mounted to slide on the bottom face of the cursor-carrier and movable along the X axis. Movements of the carriages, of the cursor-carrier and of cursor are under numerical control. The tool-carrier spindle can move in the X axis direction without it being necessary to move the gantry.

Owner:HELIS

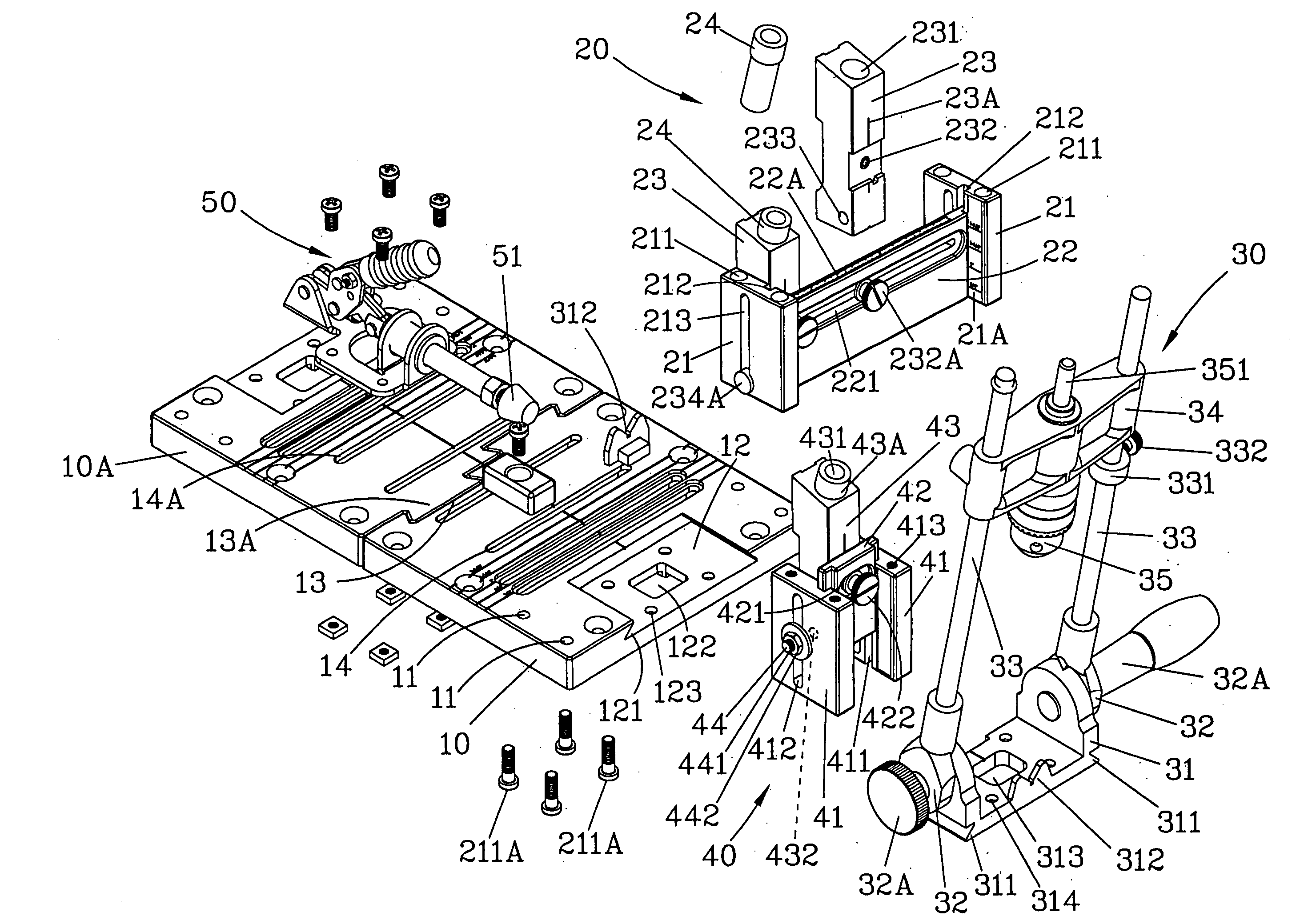

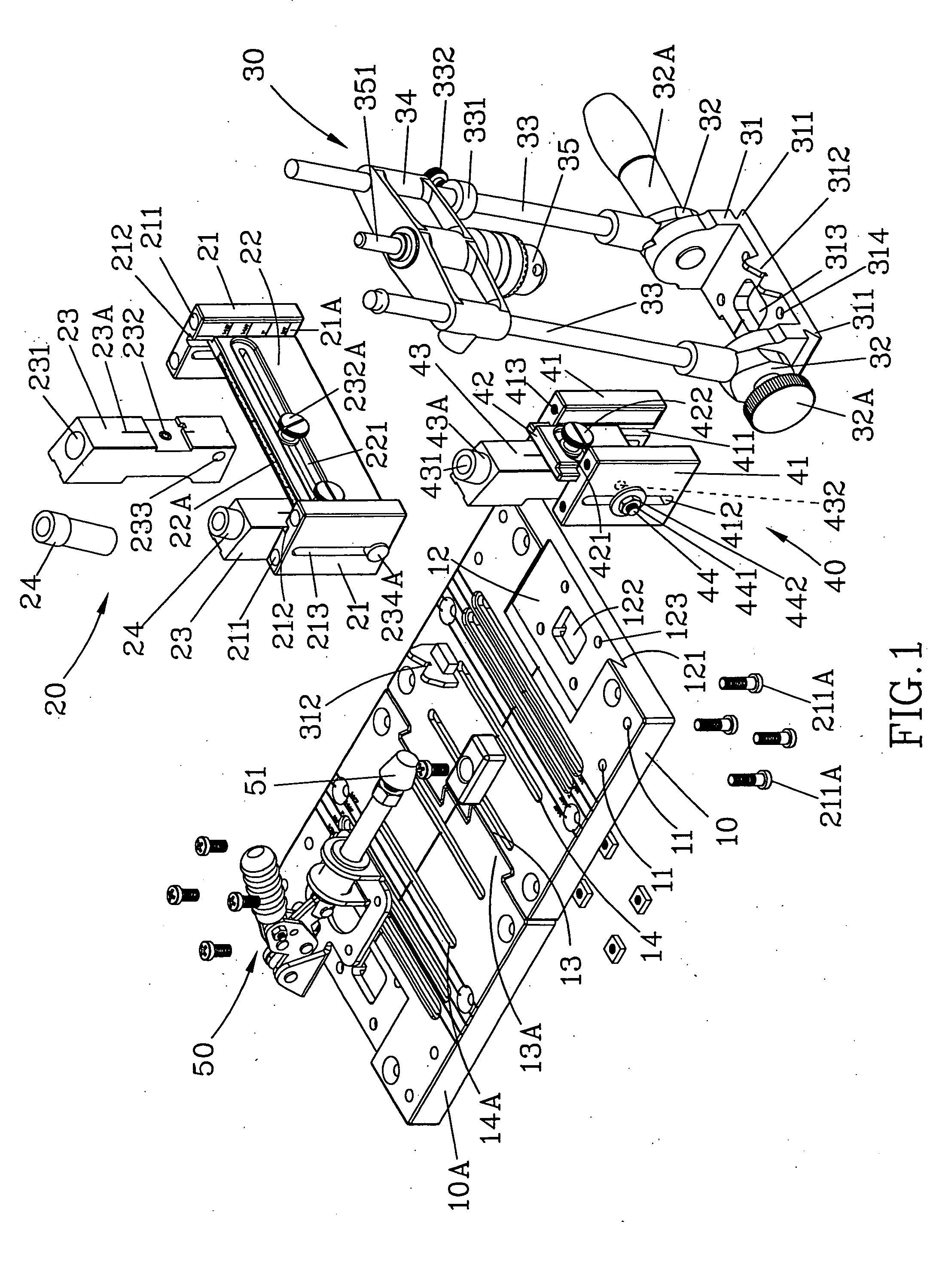

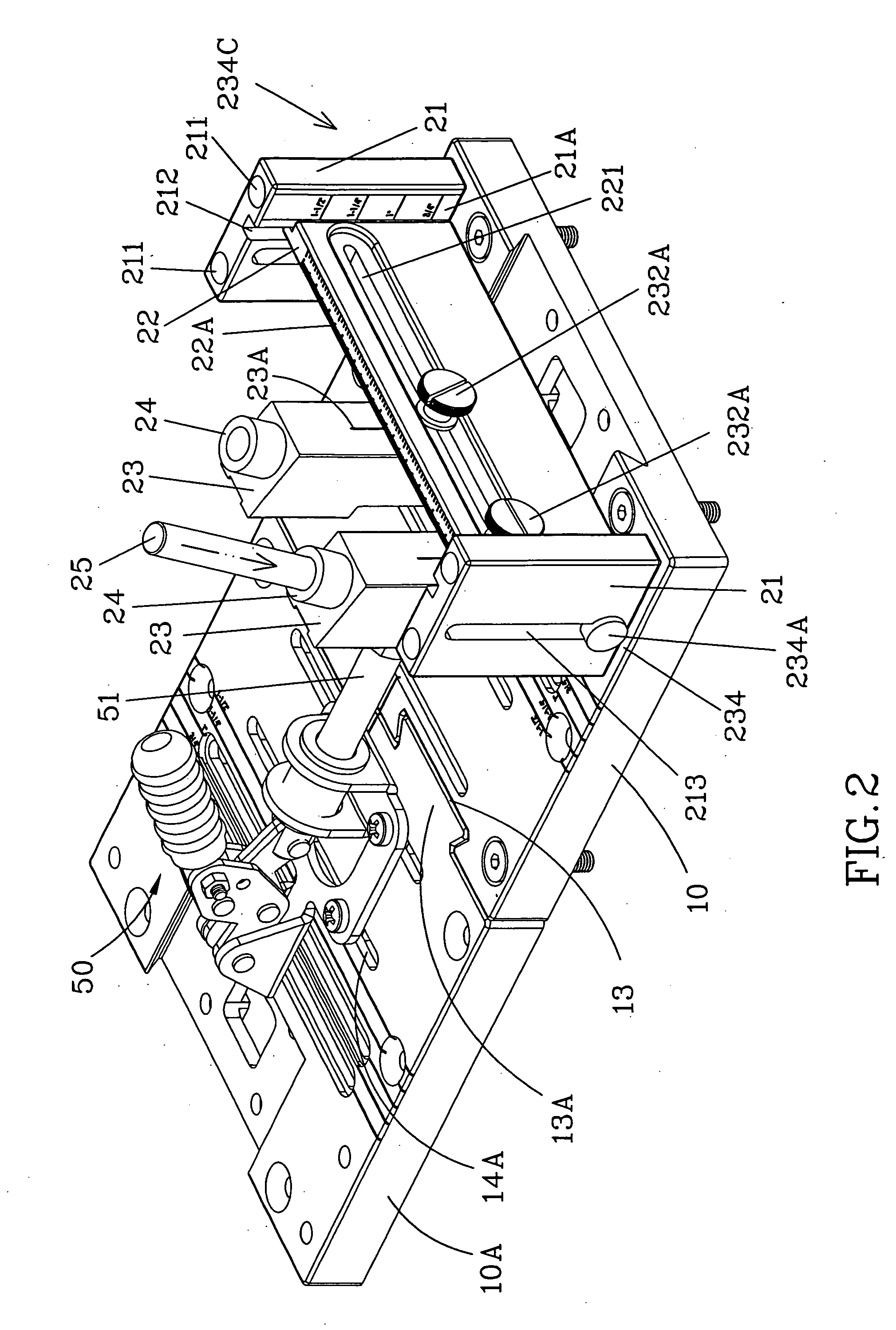

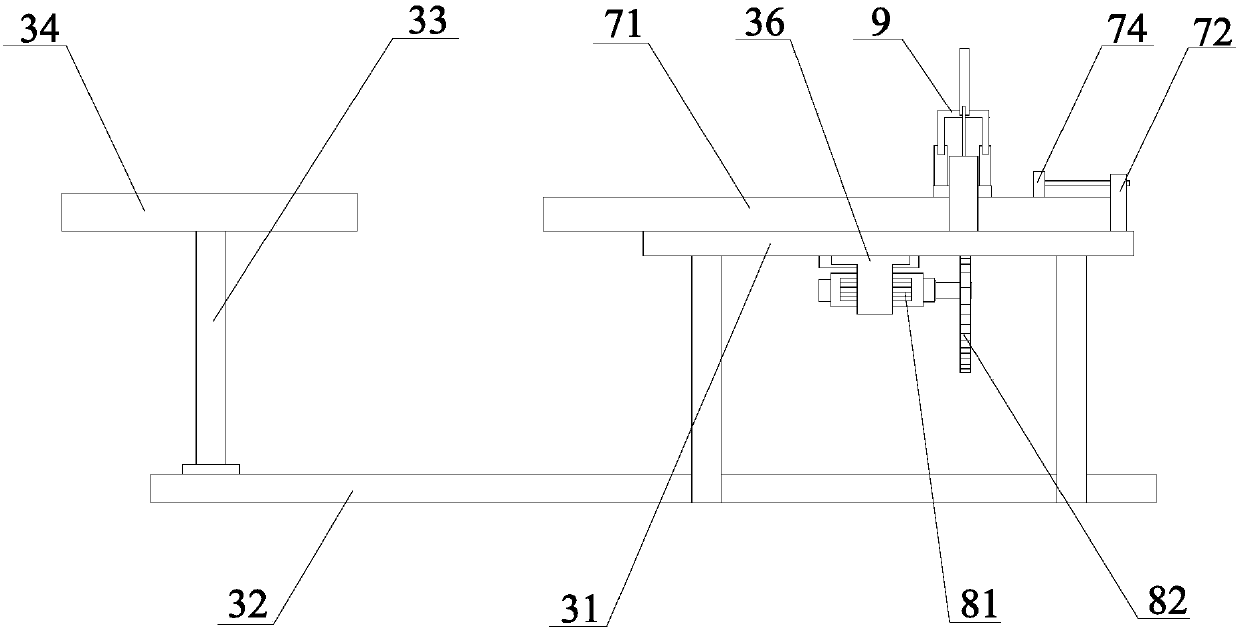

Holding fixture for all types of drilling concerning woodworking

InactiveUS20080099101A1Easy to adjustWooden sticks manufactureMulti-purpose machinesEngineeringFront edge

The invention proposes a holding fixture for use in all types of drilling concerning woodworking, comprised of at least one flat worktable having a set of dovetailing portions at the rear end for two flat worktables to dock together horizontally; a longitude-transverse adjustment module vertically arranged on the flat worktable, which secures the guide members for guiding the adjustments of height or latitude during drilling; an angle adjustment module being aligned at the front edge of said flat worktable, which guides the drilling operation on workpieces attached thereof; a height adjustment module vertically arranged at the front edge of flat worktable; a clamp member being secured on the flat worktable for securing workpieces to be worked on; as a result, the holding fixture is suitable for use in guiding the drilling operation on workpiece of all shapes and sizes.

Owner:CHIANG VANCE

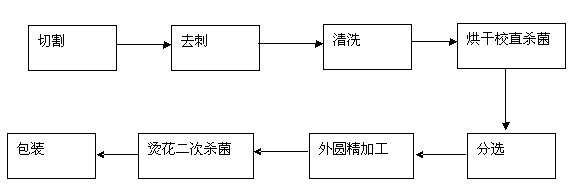

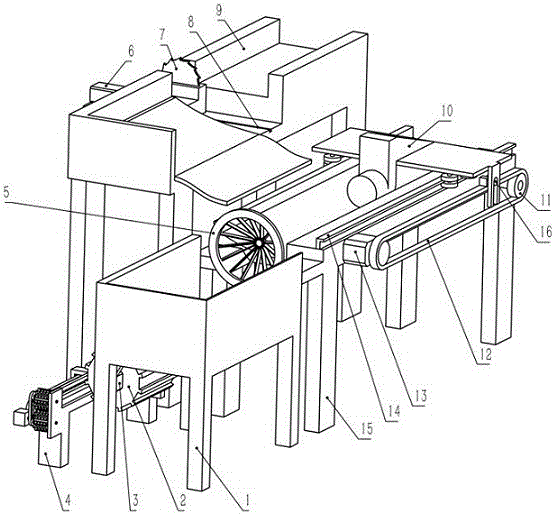

Fully-automatic production line of manufacturing chopsticks by using plant branches

InactiveCN103273549AQuality improvementImprove energy efficiencyEdge grinding machinesWooden sticks manufactureProduction lineMicrowave

A fully-automatic production line of manufacturing chopsticks by using plant branches is composed of a cutting machine, a burr removal machine, a cleaning machine, a drying, straightening and sterilizing machine, a separation device, an outer circle processing machine and a heat transfer machine, wherein the machines are connected with one another through conveying belts. According to the main processes, materials are conveyed into the cutting machine to be cut, and then sent to the burr removal machine, burr removal is carried out on the materials, and then the materials are conveyed into the cleaning machine through the conveying belts to be cleaned; microwave drying, straightening and sterilization are carried out on the materials conveyed into the drying, straightening and sterilizing machine; the materials are conveyed into the separation device through the conveying belts, the raw materials which can be processed are selected out rapidly, the matching raw materials automatically enter the outer circle processing machine after being screened out, and polishing is carried out on the outer circles; finally, the materials enter the heat transfer machine, and heat transfer printing and disinfection are carried out. The fully-automatic production line has the advantages of being a substitute of industrially producing the disposable wood chopsticks at high speed and with low cost, achieving good quality, low carbon, environment-friendliness, and hygienic security, conforming to industrial policies of the nation, and having wide market prospect.

Owner:大连杉禾草本箸业有限公司 +1

Bamboo chopsticks manufacturing technique

ActiveCN103171011ATake advantage ofReduce selection requirementsWooden sticks manufactureWood treatment detailsResource utilizationRaw material

The invention discloses a bamboo chopsticks manufacturing technique. Specifically, the method comprises a first step of sawing off a bamboo into a plurality of sections of bamboo tubes according to the lengths of bamboo joints and thicknesses of bamboo nanmu, a second step of classifying the bamboo tubes according to the thicknesses of the bamboo nanmu and the lengths of the bamboo joints, a third step of processing the bamboo tubes into a plurality of bamboo chips and molding the processed bamboo chips into bamboo chopsticks in an early form, a fourth step of classifying the bamboo chopsticks with joints, the bamboo chopsticks without the joints and the chopsticks with disorderly joints in the early form, a fifth step of sharpening one heads of the bamboo chopsticks in the early form, a sixth step of bleaching the formed bamboo chopsticks and drying the bleached bamboo chopsticks, a seventh step of polishing the formed bamboo chopsticks, an eighth step of evenly lacquering the bamboo chopsticks, a ninth step of pulling out paint of the bamboo chopsticks, a tenth step of printing the bamboo chopsticks with the paint pulled out at the first time, an eleventh step of pulling out the paint of the bamboo chopsticks at the second time, and a twelfth step of sorting and packing the bamboo chopsticks. The mechanical degree is improved, full utilization of the whole bamboo is achieved, at the same time, select requirements on raw materials are reduced, enterprise production cost is reduced, a resource utilization rate is greatly improved, production speed is accelerated due to the mechanical operation, and compared with original operation, the bamboo chopsticks manufacturing technique enables the yield to be greatly improved and production efficiency to be improved.

Owner:福建味家生活用品制造有限公司

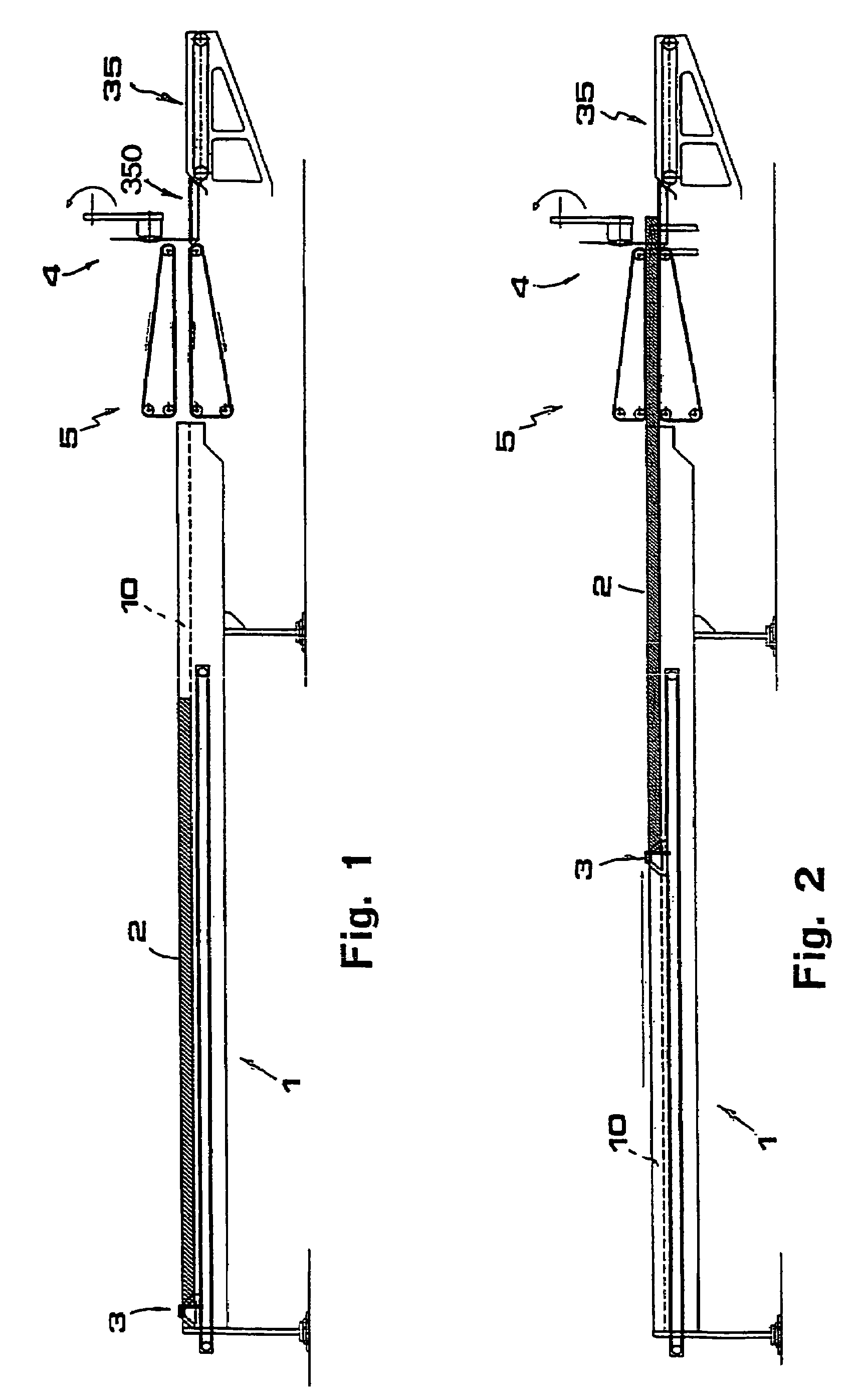

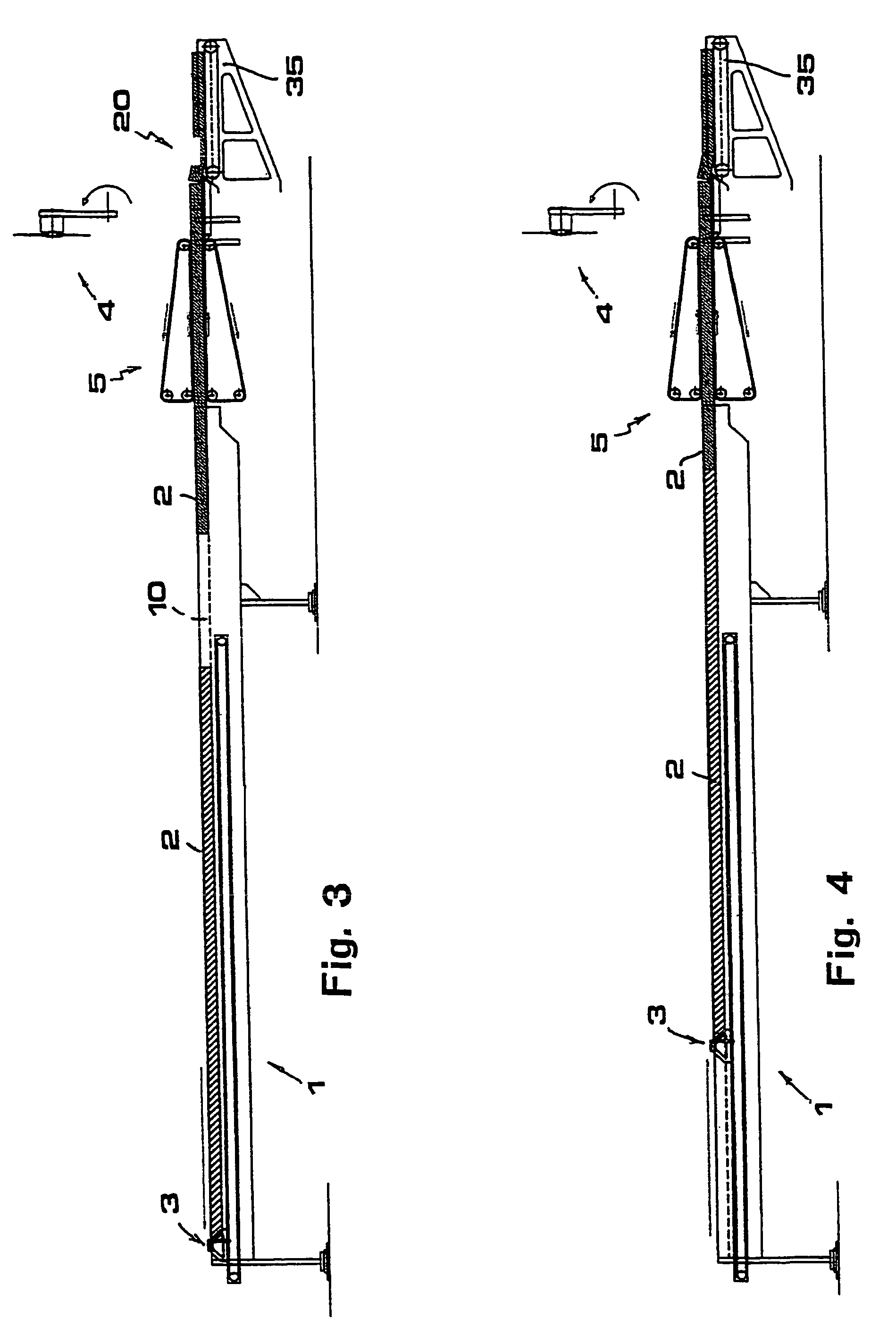

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

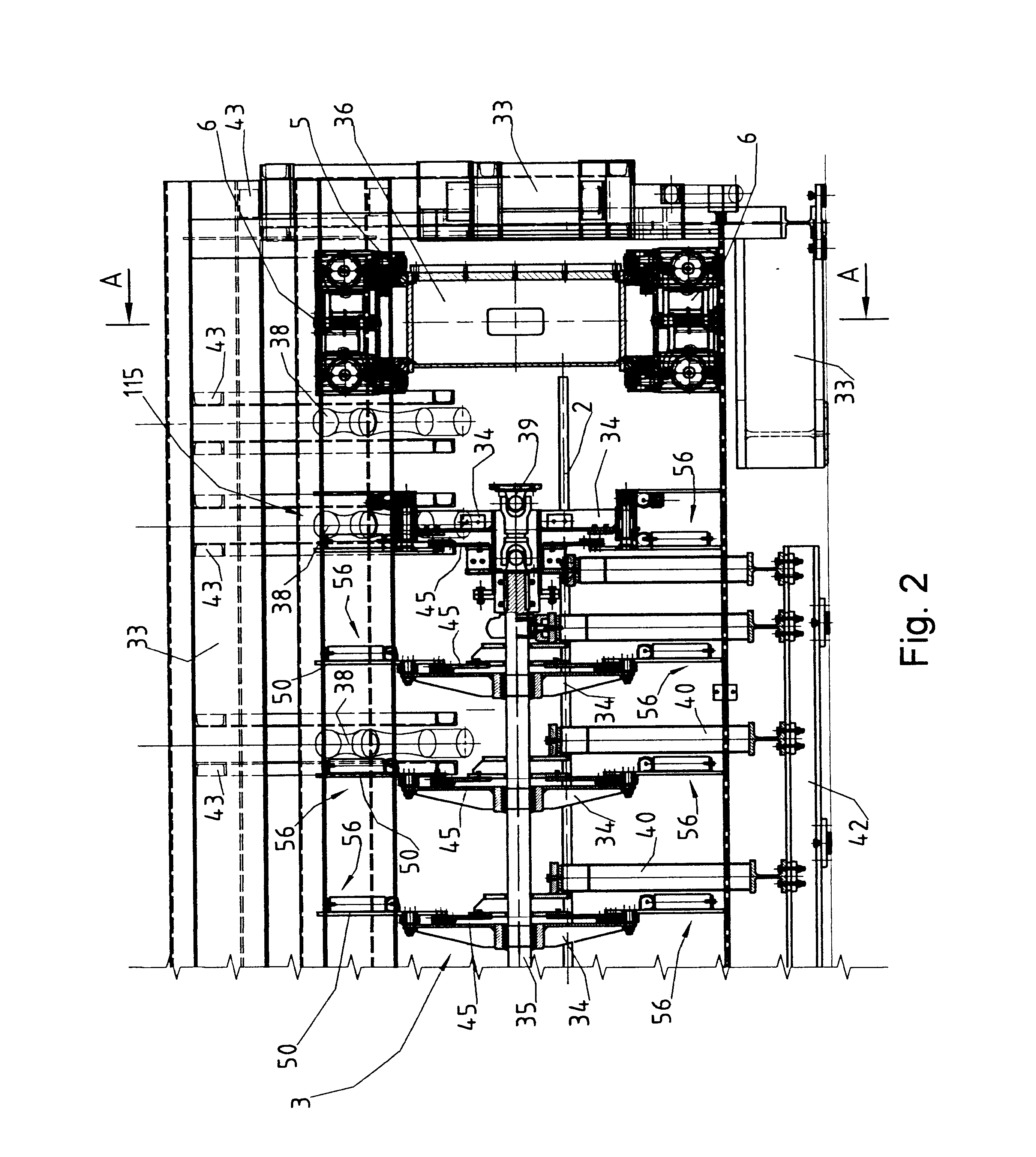

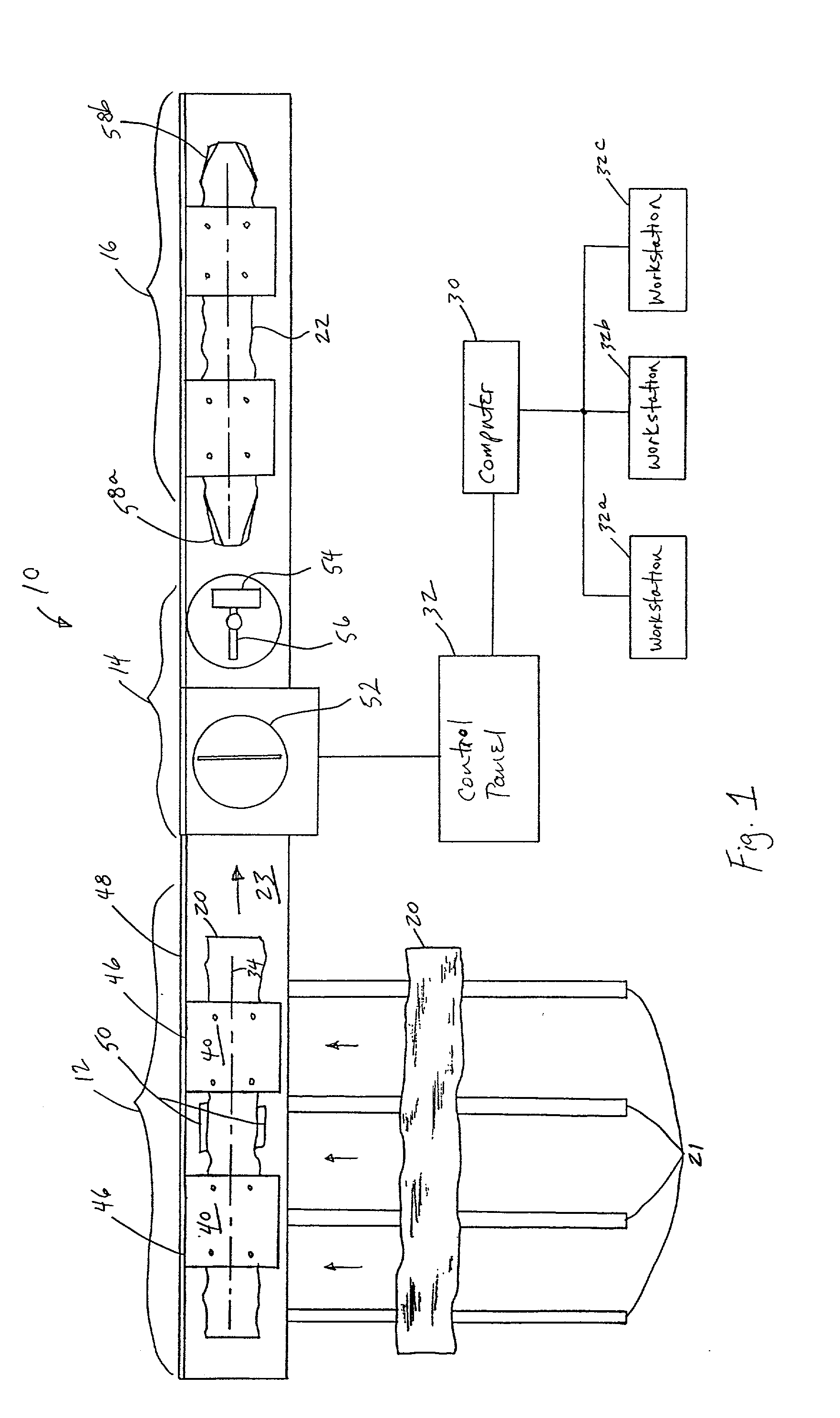

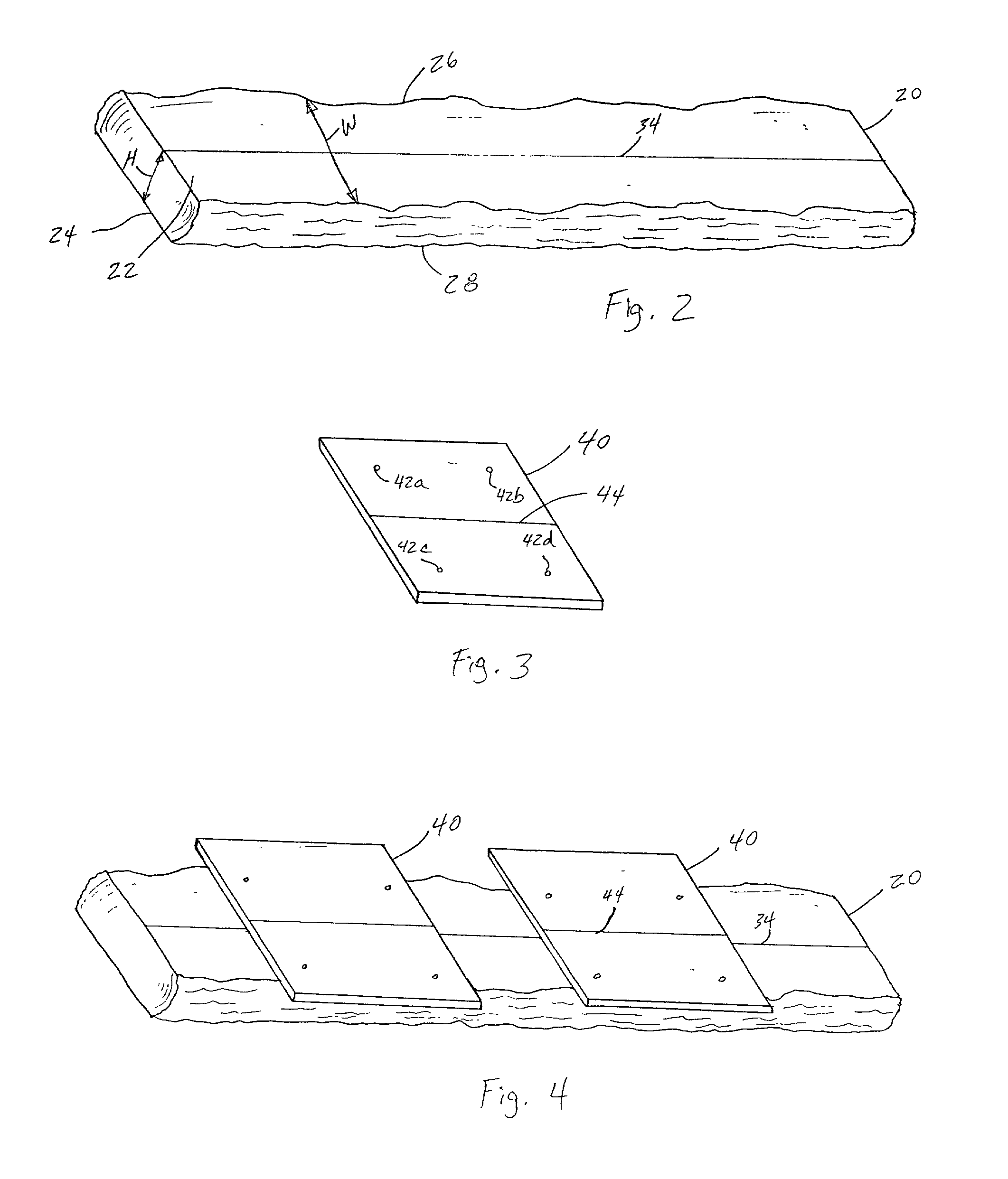

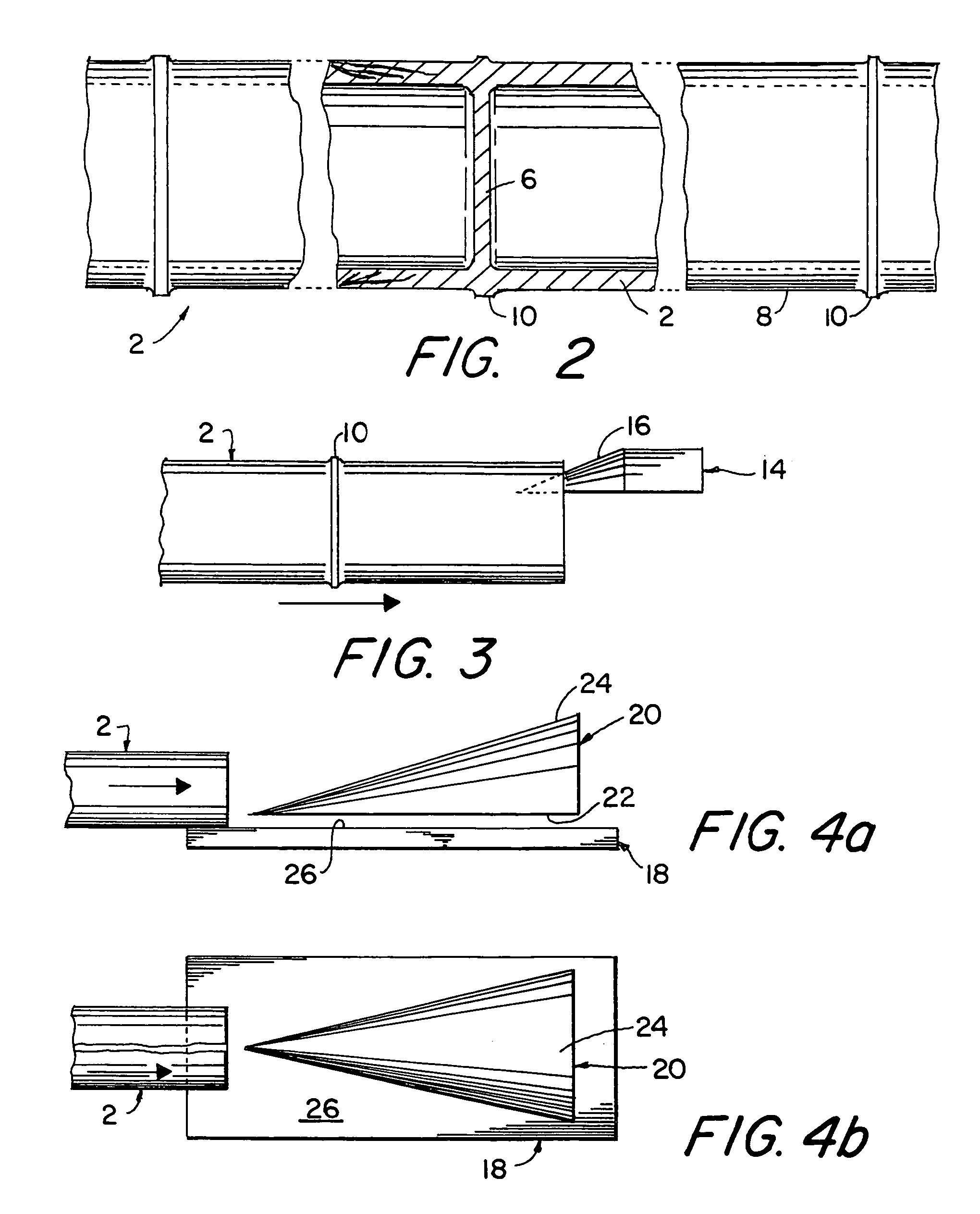

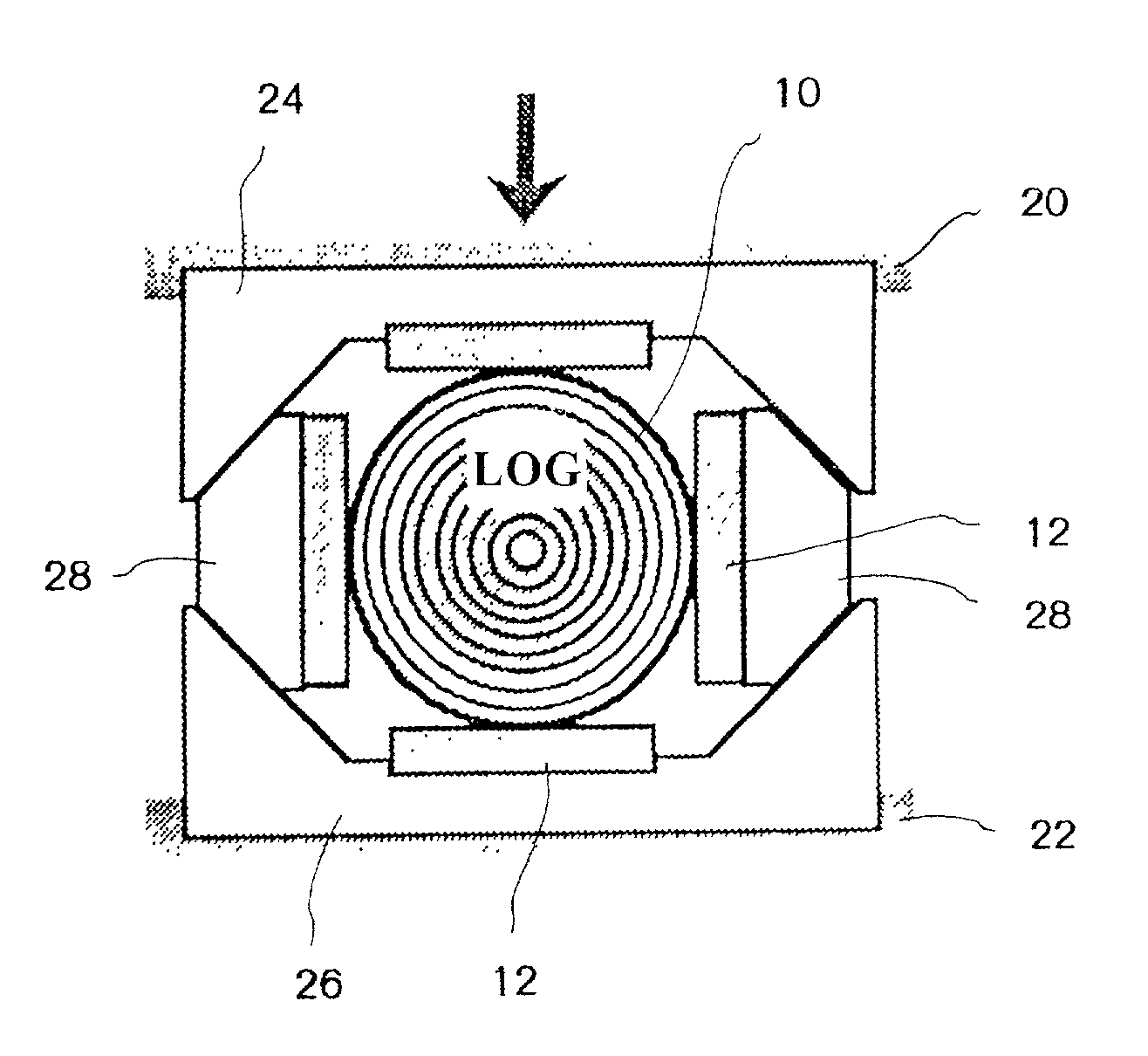

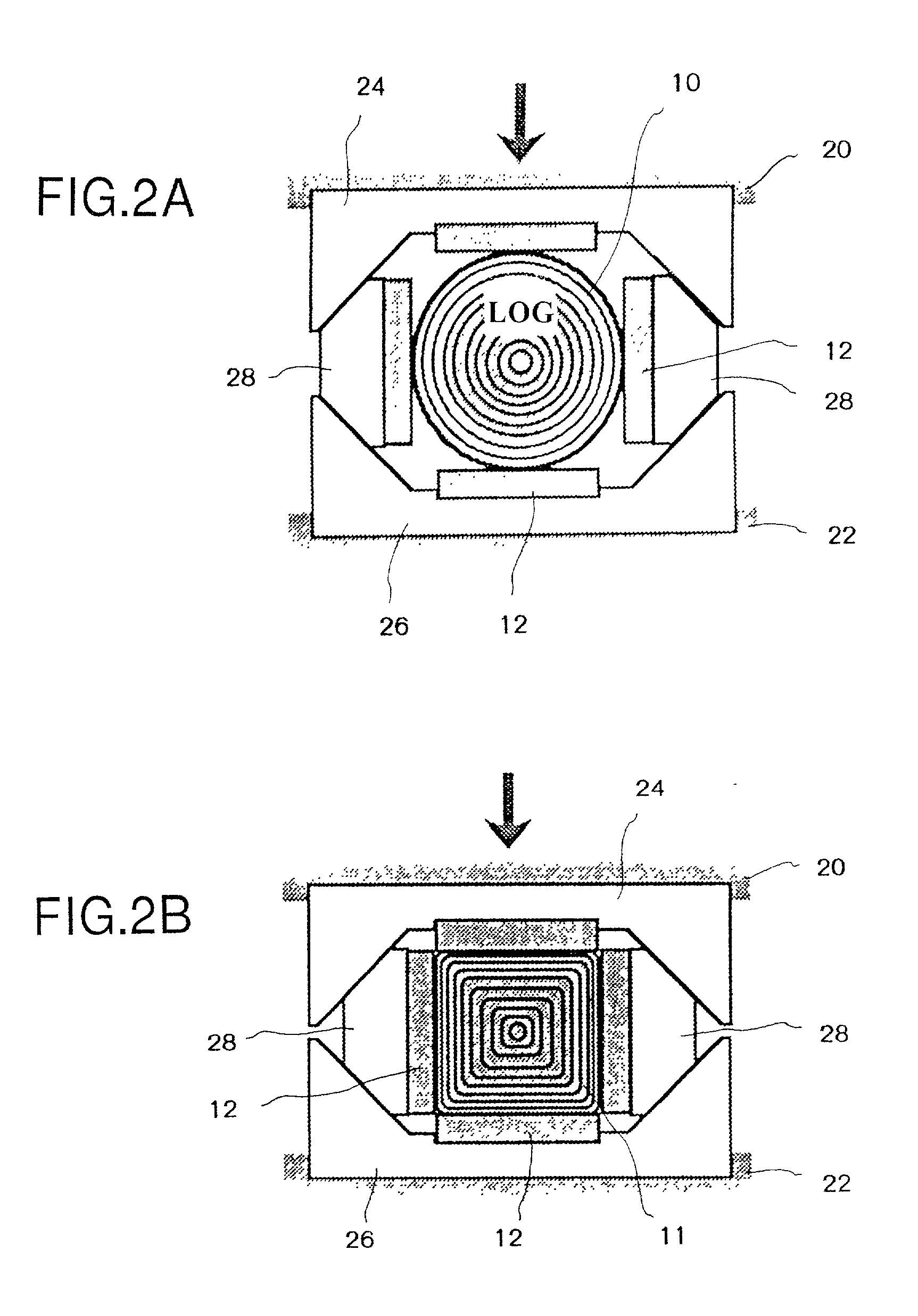

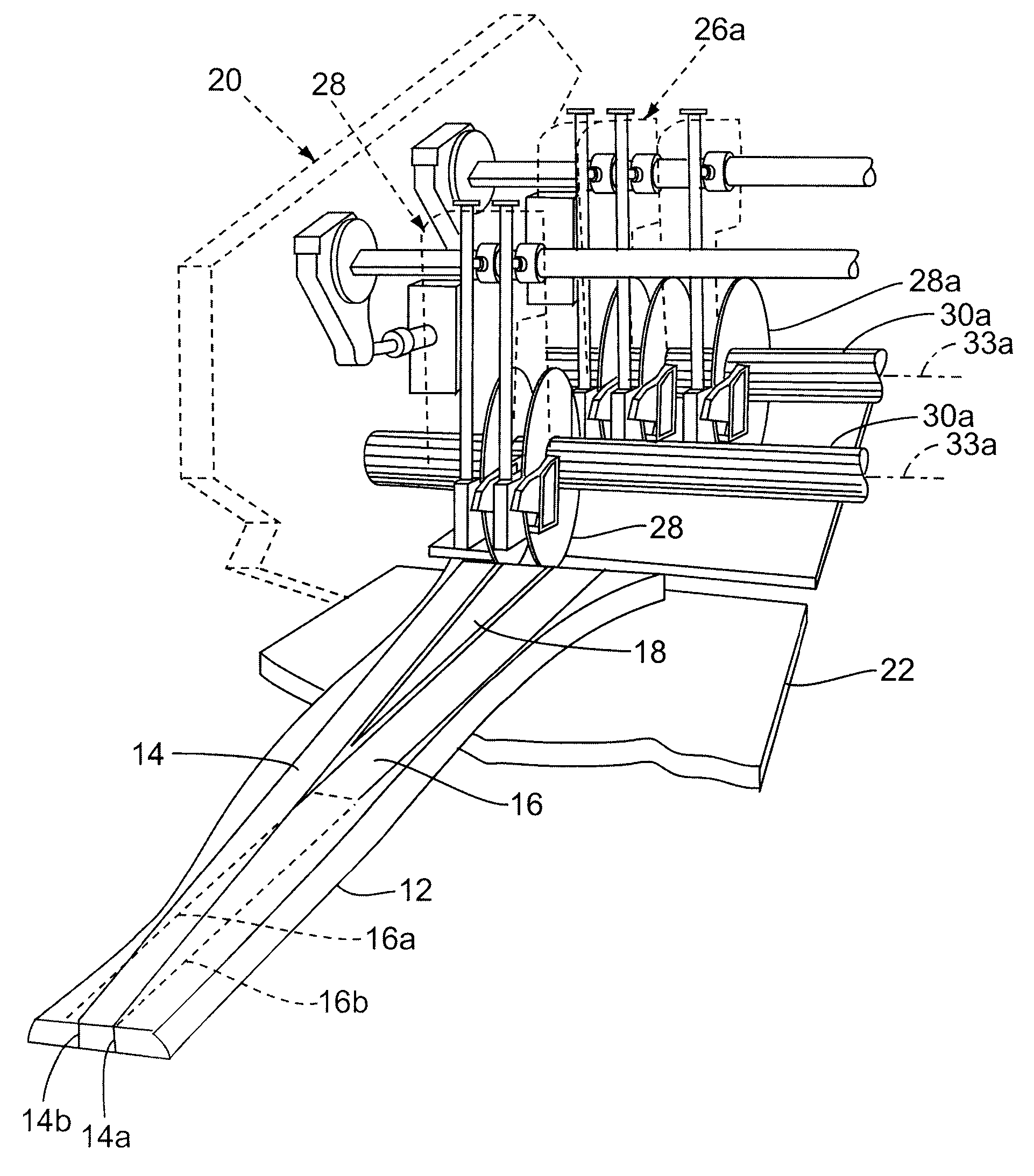

Log home fabrication process and associate log cutting machine

InactiveUS20030041919A1Tongue/grooves making apparatusMulti-purpose machinesComputer scienceComputer control

A log processing machine and associate method employs one or more log guides to make joinery cuts in a processed log which has at opposed edges of the processed log the raw log's natural external contour. In a preferred embodiment of the invention, each log guide includes a straight edge and is attached to the processed log to create an artificial straight edge for guiding the processed log through the joinery machine. Prior to attachment, centerlines are marked on the log guide and the processed log, and the centerlines are aligned when the log guide is attached to the processed log. The processed log, with the log guide attached, is then moved through the machine with the aid of computer control while the straight edge of the log guide follows a fence. In this manner, the position of the processed log and its centerline are always known so that the computer can make the programmed joinery cuts with high precision. An alternate embodiment of the invention employs one or more fence extensions as log guides. The fence extensions are positionable in guide channels formed in the contoured edges of the processed log. A further embodiment of the invention employs an opposed pair of clamping / alignment elements which are controlled by a computer to align and guide the log through the joinery machine.

Owner:HEARTHSTONE

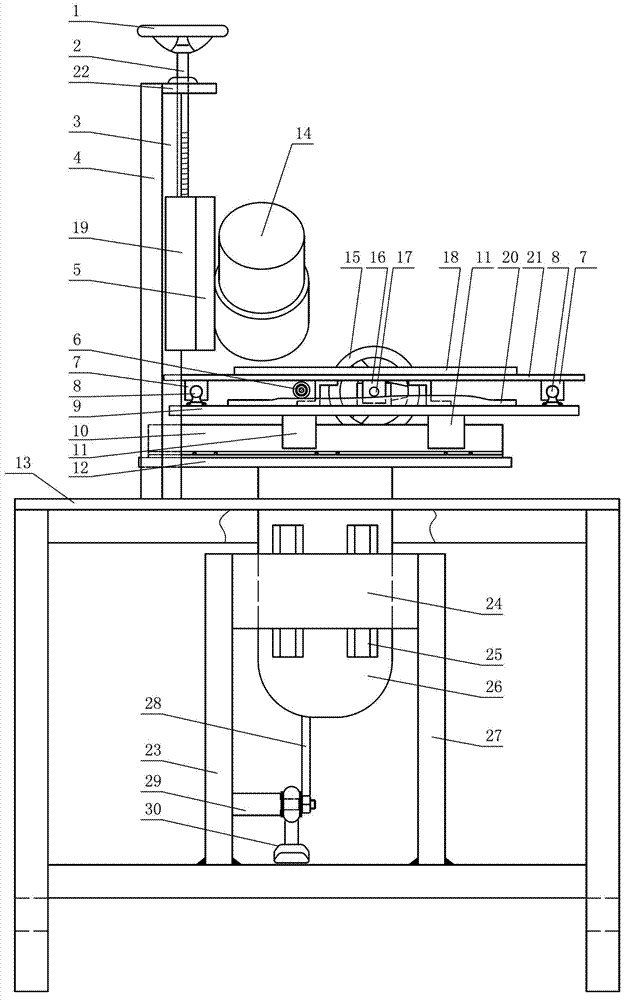

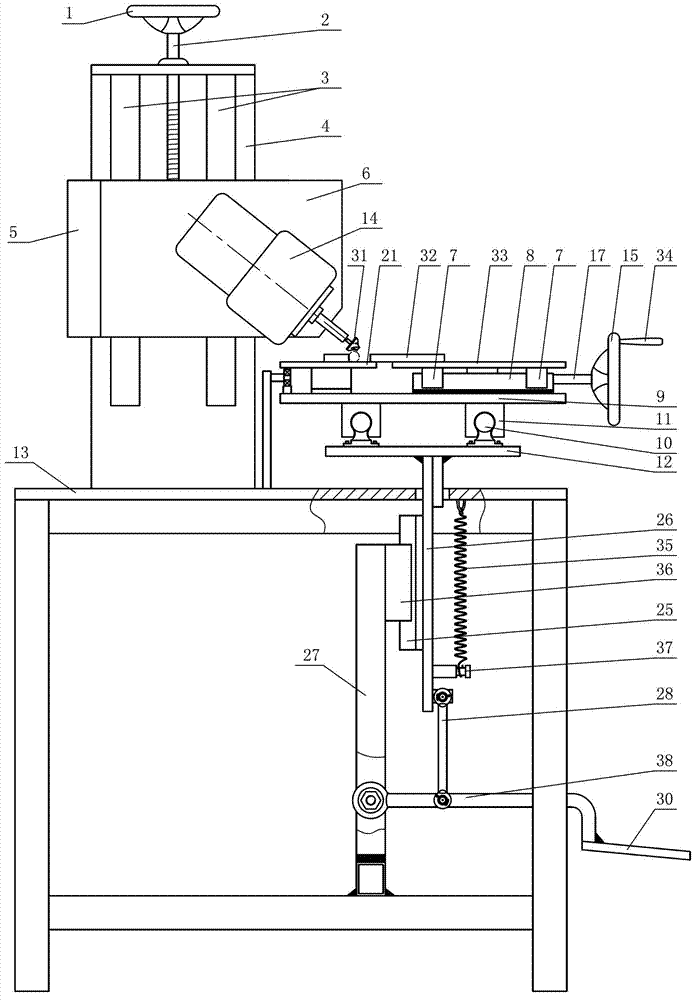

Equipment for carrying out shaping processing on chopsticks

ActiveCN102950636ATo achieve the purpose of modelingSolve problems with differences in shapesWooden sticks manufactureProfiling/shaping machinesMilling cutterEngineering

The invention belongs to the technical field of chopsticks processing, and particularly discloses equipment for chopsticks shaping. The equipment is characterized by completing the chopstick processing by adopting a milling cutter fixed and chopstick moving mode, realizing the purpose that chopsticks fluctuate up and down with the fluctuation change of the top surface of a shaping mould in the cutting process of a milling cutter by arranging a chopstick clamping mechanism installation seat capable of sliding up and down and matching with the upwards pulling action of an extension spring and the downwards pressing action of a pulley on the shaping mould, further realizing the purpose that surface shapes consistent to the fluctuation shape of the shaping reference surface of the shaping mould are processed on one surfaces of the chopsticks and finally realizing the purpose of shaping the chopsticks. The equipment disclosed by the invention can be used for carrying out automatic shaping by using the shaping mould with the determined shaping reference surface and completing the shaping processing of one surface by pushing for only a few seconds; and compared with manual multi-time turning or polishing shaping, the equipment disclosed by the invention can increase the efficiency by more than ten times and even dozens of times.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

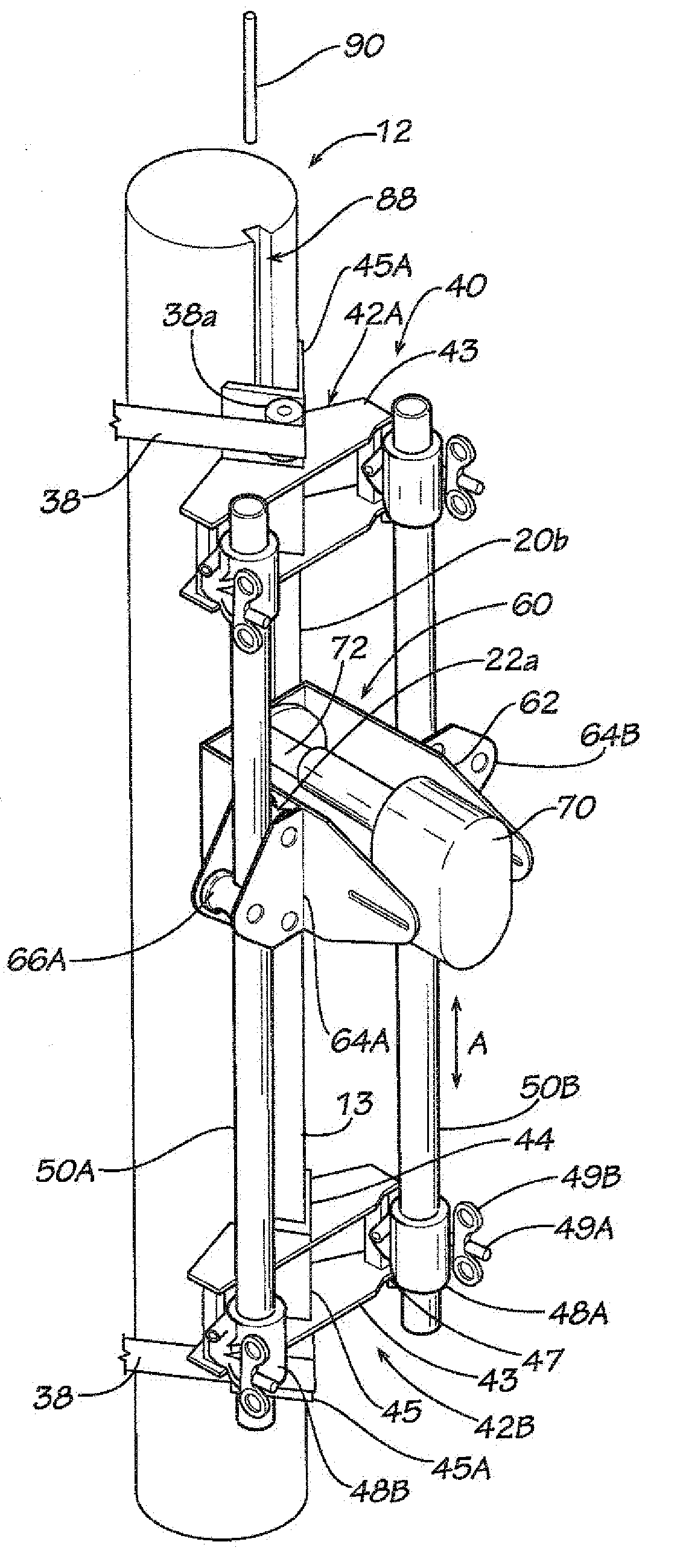

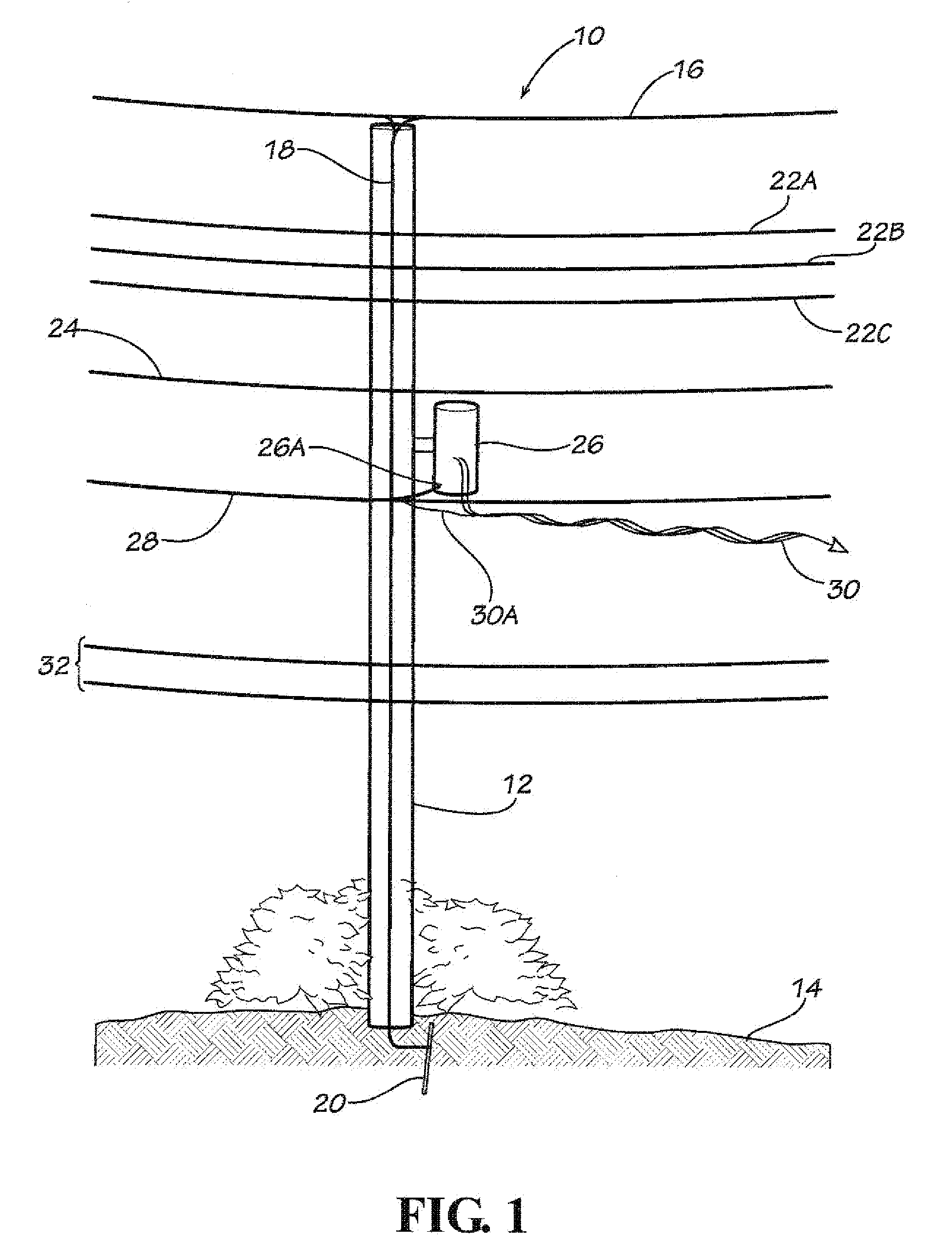

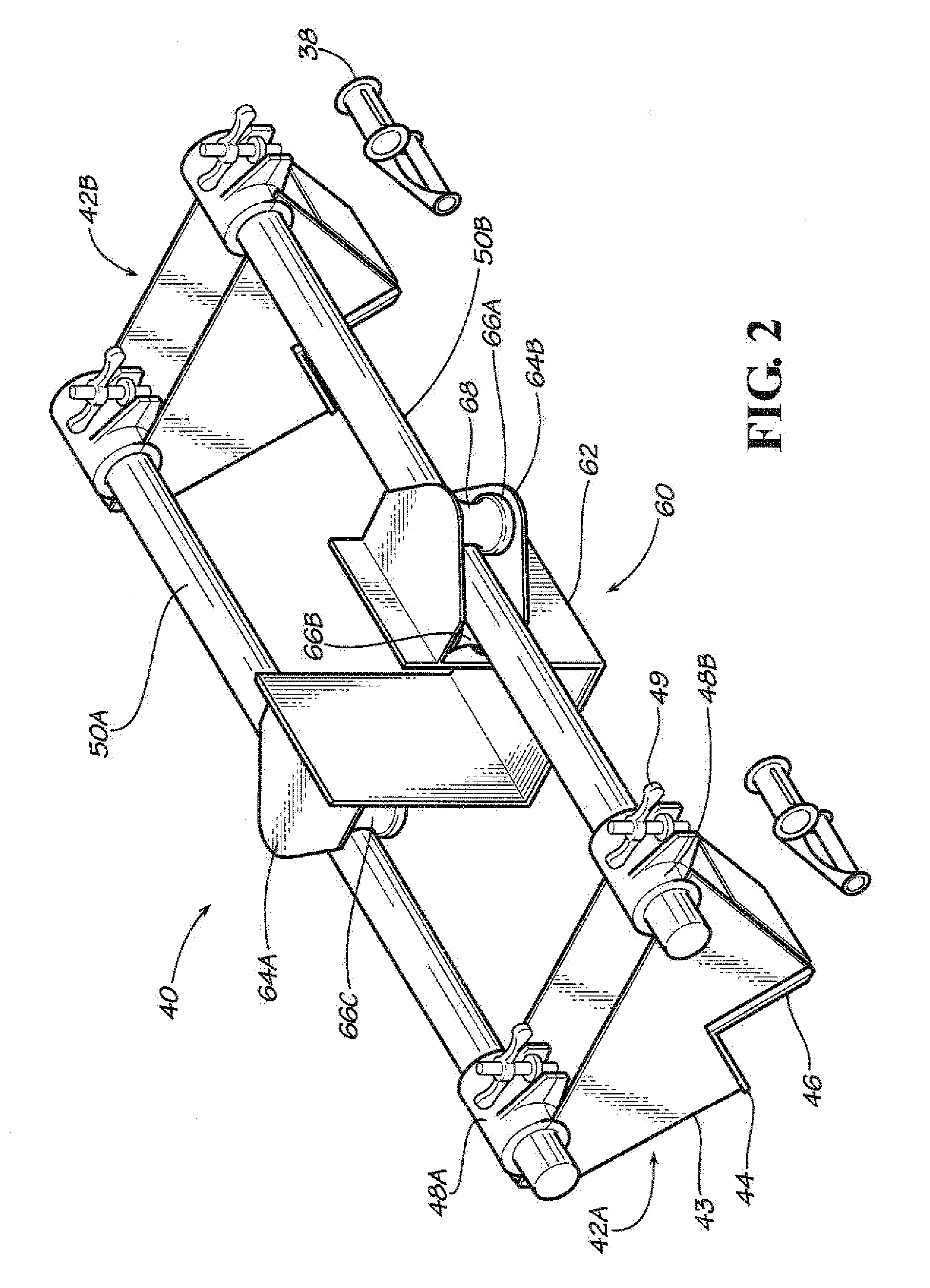

Utility Pole Grounding Wire Replacement with an Embedment Method and Device

An electric transmission wood pole is selected for installation of a grounding wire using a grounding wire slot cutting device generally having two bases, two elongate guide members, a trolley, and a power tool mounted in the trolley. The two bases are adapted to be strapped to the wood pole. With the grounding wire slot cutting device mounted on the wood pole, a groove is cut along the wood pole. This procedure can be repeated to create a continuous groove along the wood pole. A grounding wire is pushed into the groove, and a sealer is applied over the grounding wire to fill the groove and to seal the grounding wire.

Owner:QUANTA ASSOC

Integrated bamboo stick processing robot

ActiveCN106363754AFully automatedRealize integrationWooden sticks manufactureIndustrial engineeringAutomation

The invention discloses an integrated bamboo stick processing robot. The integrated bamboo stick processing robot comprises a first bracket, a feeding roller wheel, a first stepping motor, a wiredrawing component, a bamboo-wood slicing knife, an electric cylinder, a rotary saw, a dovetail groove, a third bracket, a pushing column component, two first chain wheels, a first chain, a second stepping motor, two sliding rails, a fourth bracket and a first roller. Multiple steps for bamboo processing are combined together through the robot disclosed by the invention, and the robot has the following advantages that the structure is compact, the integration degree is high, and the size is relatively small; the automation and the integration of the bamboo processing can be realized, the labor intensity is greatly lowered, and the production efficiency is improved.

Owner:平湖市宸信机械有限责任公司

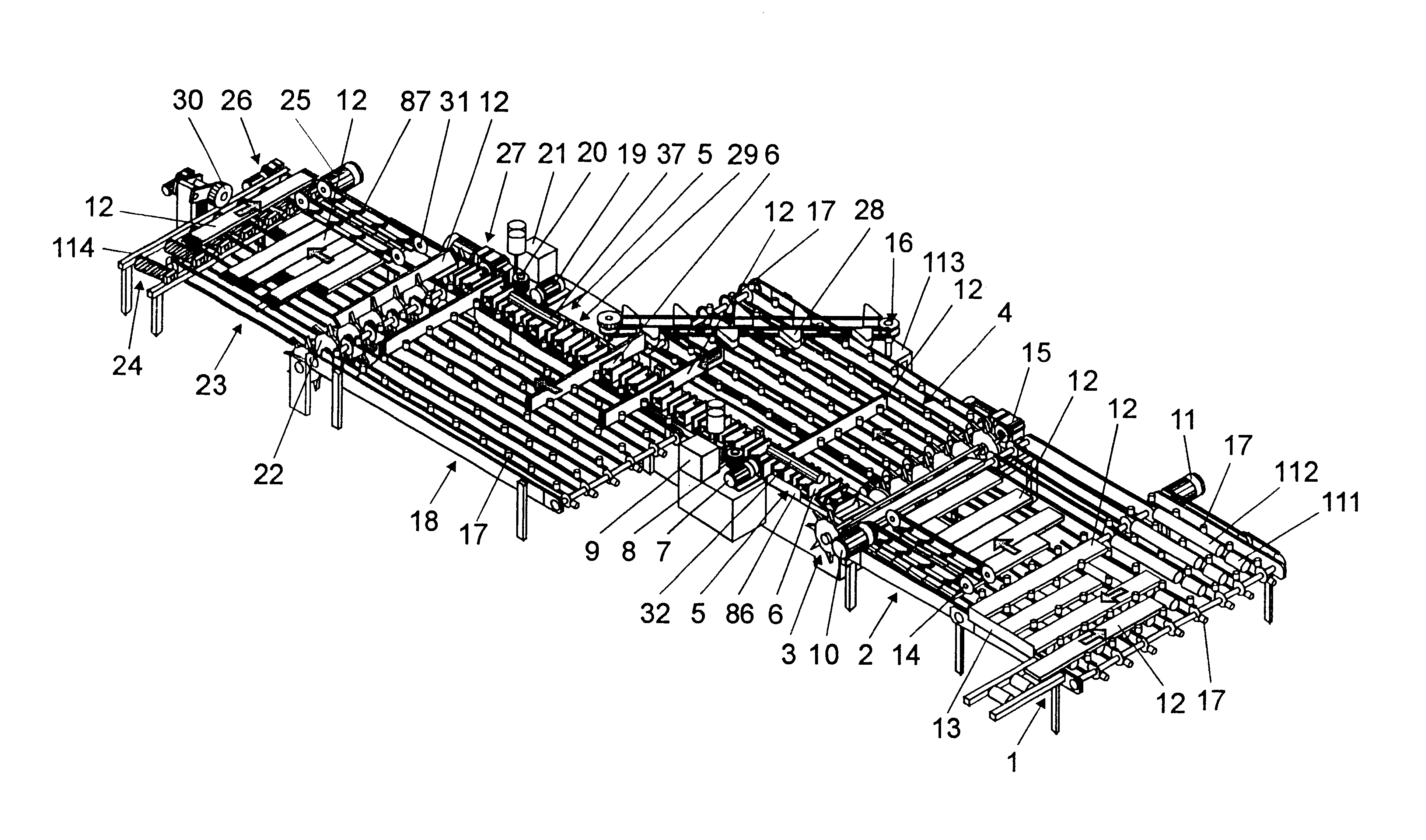

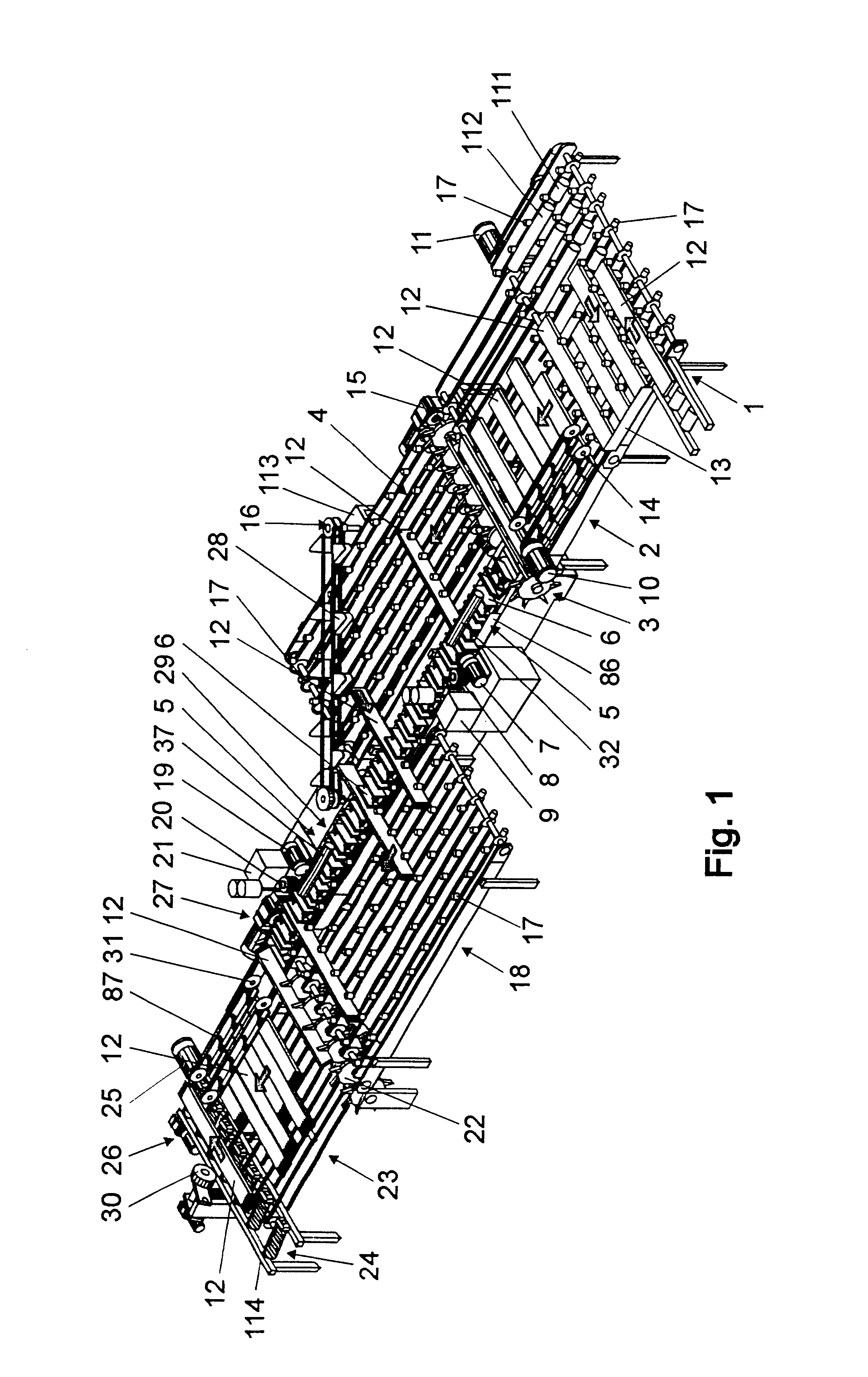

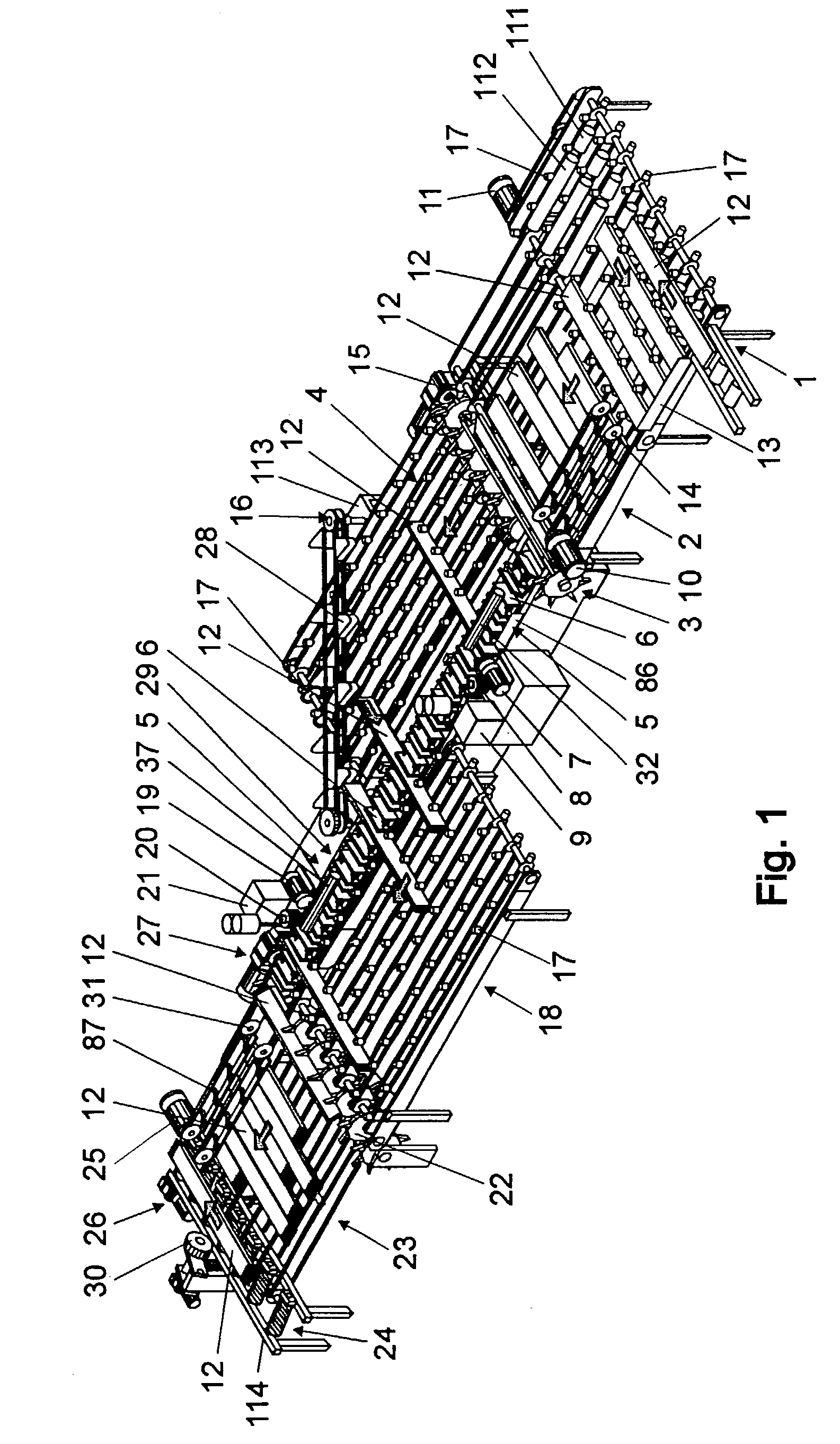

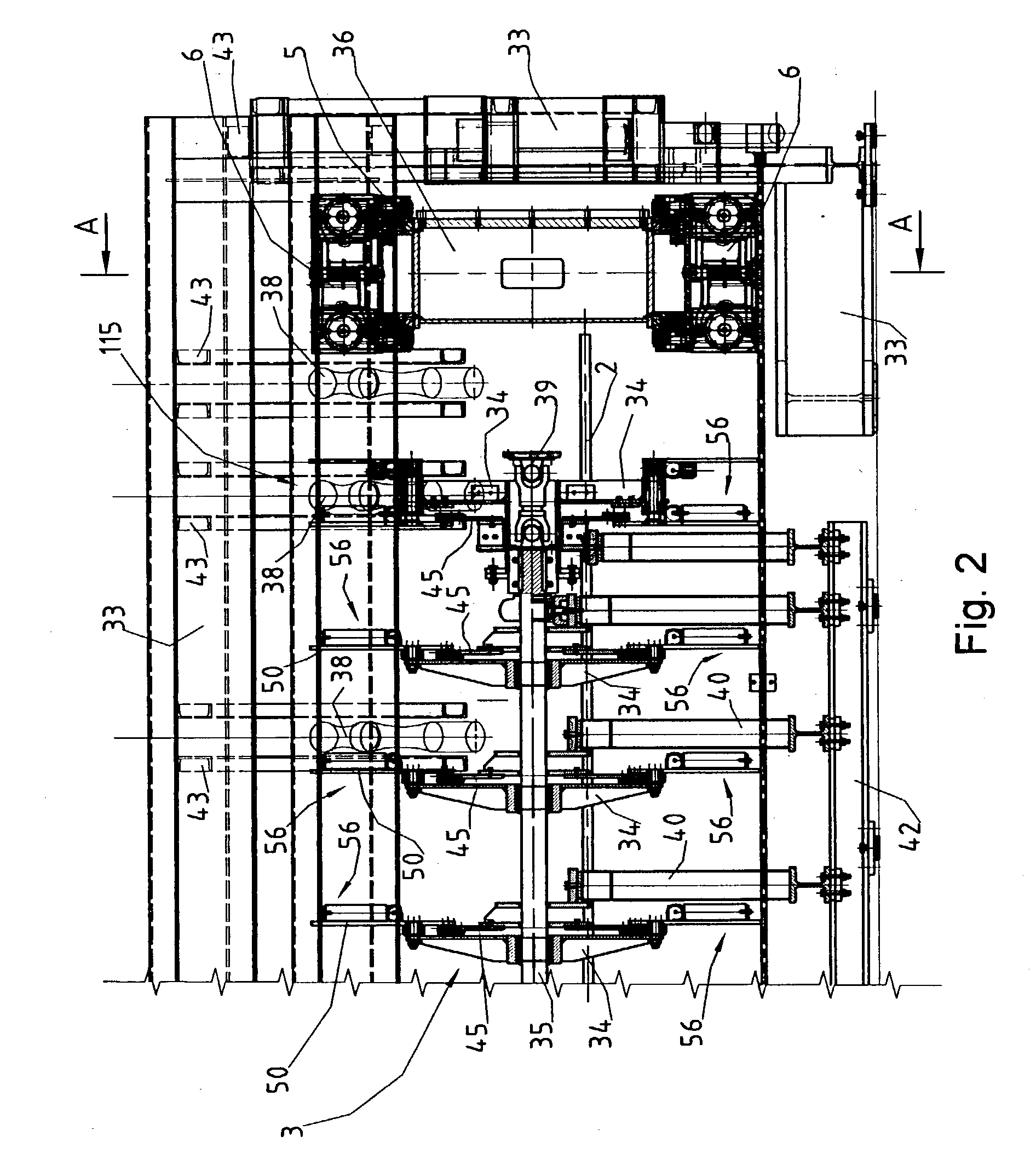

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

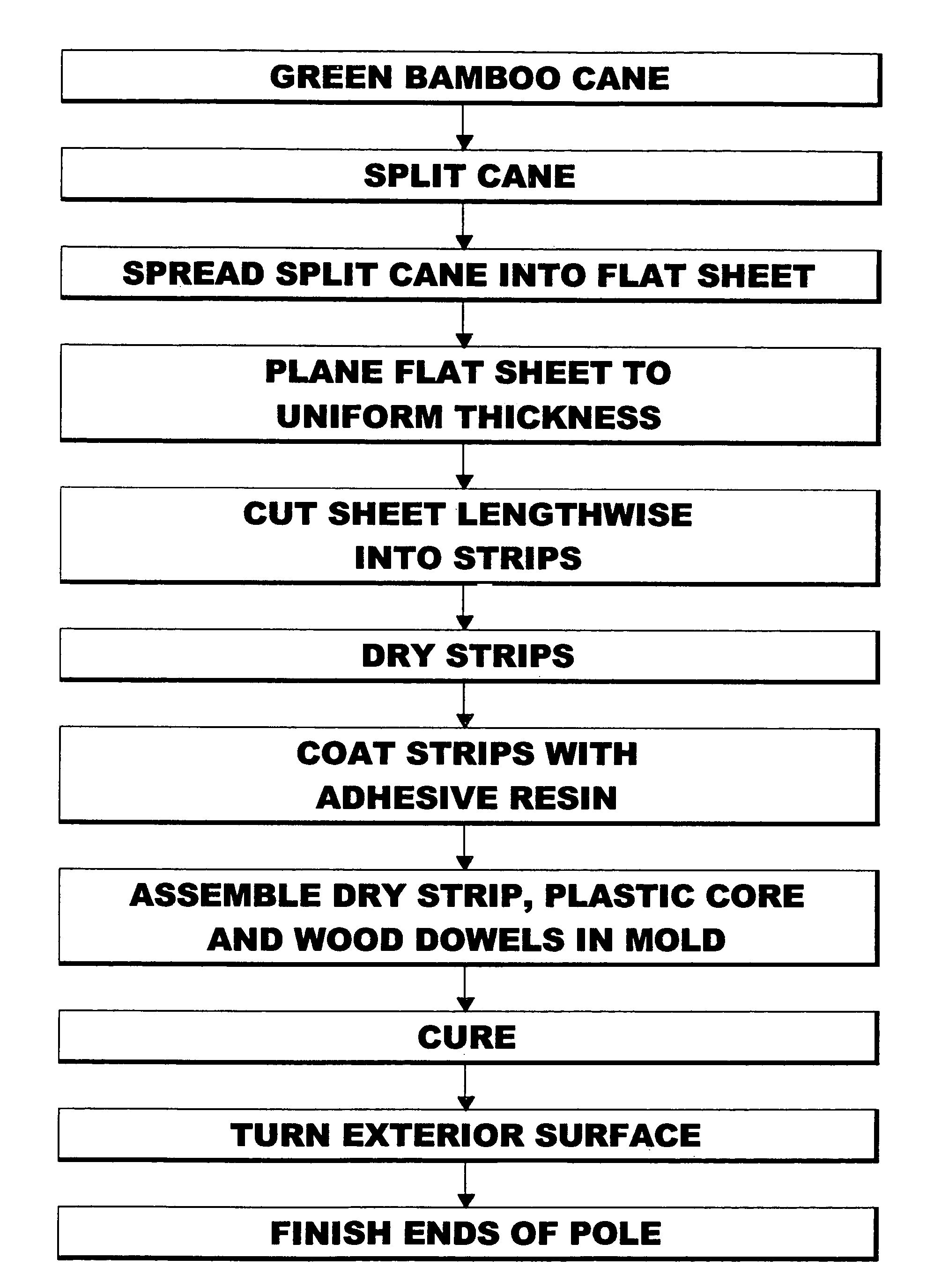

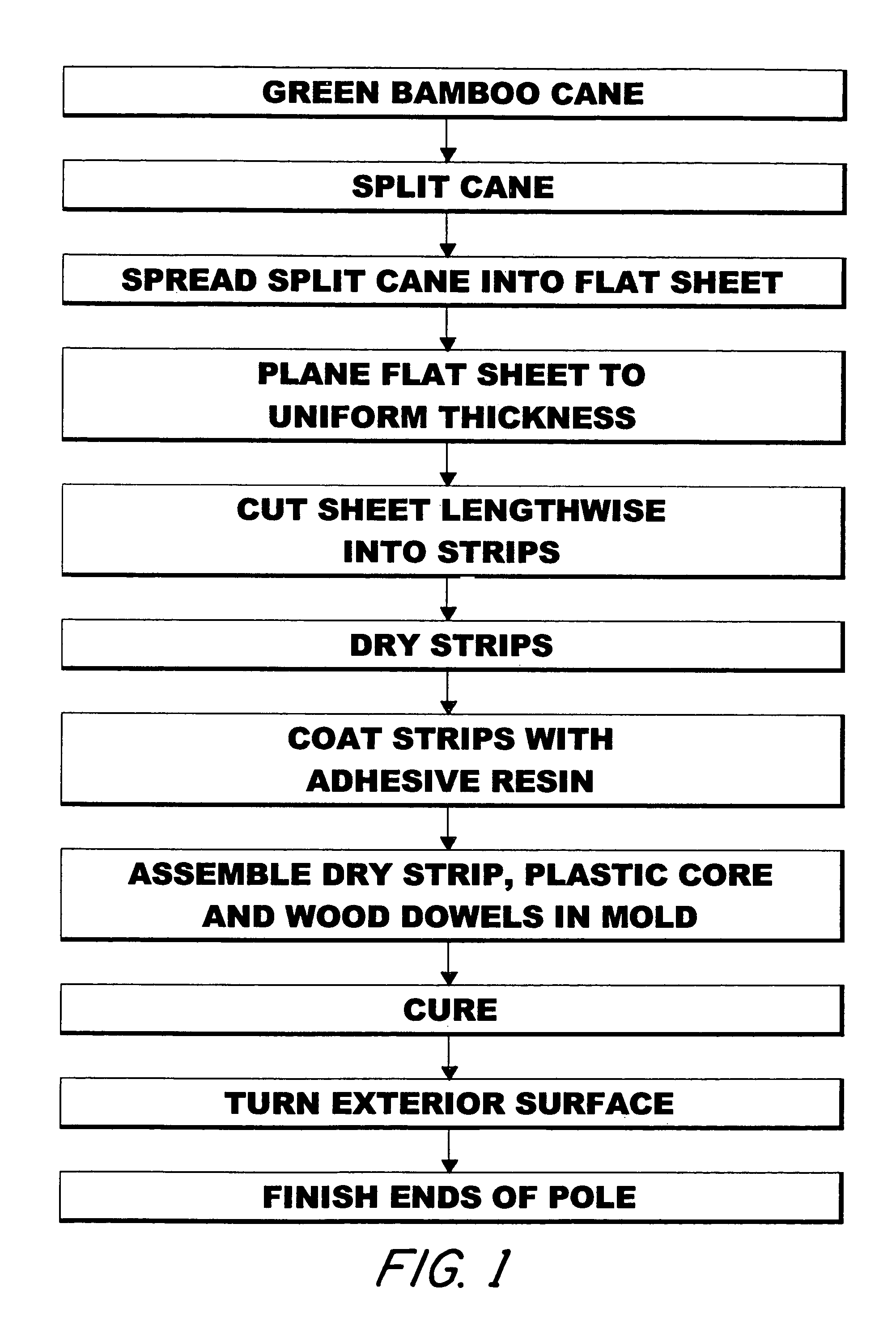

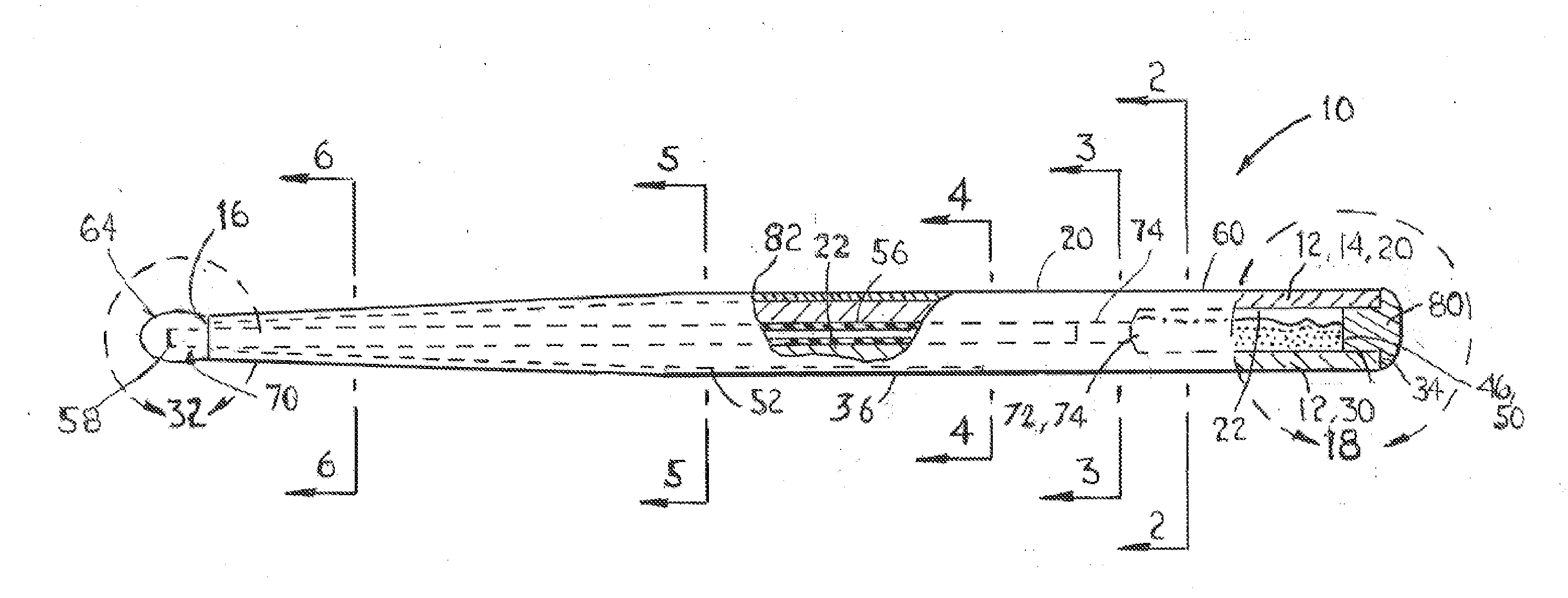

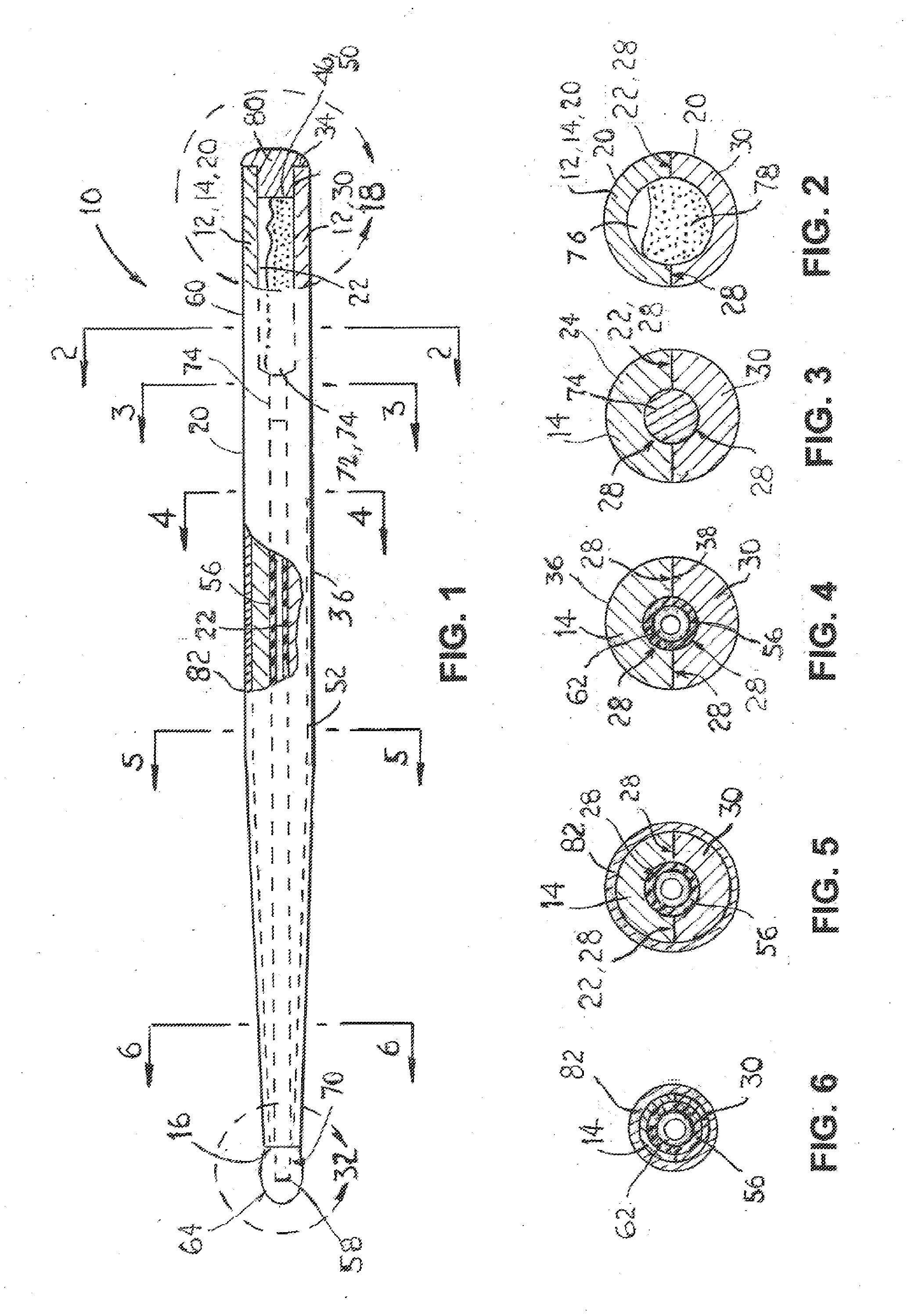

Elongate laminated wooden handles and method of manufacturing same

InactiveUS7785681B2Easy to manufactureLess laborWing handlesBrush bodiesAdhesiveBiomedical engineering

A method of manufacturing elongate wooden handles for floor mops and the like comprises (a) splitting a green bamboo cane lengthwise and then spreading it into the shape of a sheet, (b) planing both surfaces of the sheet to give it a substantially uniform thickness, (c) cutting the bamboo sheet into an elongate section of selected width, (d) drying that bamboo section, (e) providing an assembly comprising a pair of dowels, at least one elongate core member, said bamboo sections and an adhesive, with the bamboo section wrapped around the dowels and the core member and the adhesive disposed between the bamboo section and the dowels and core member, (f) heating that assembly under pressure so the adhesive will bond the dowels and core member to the surrounding bamboo section and thereby form an elongate pole, and (g) turning the elongate pole to a selected outer diameter.

Owner:LIAO DICK

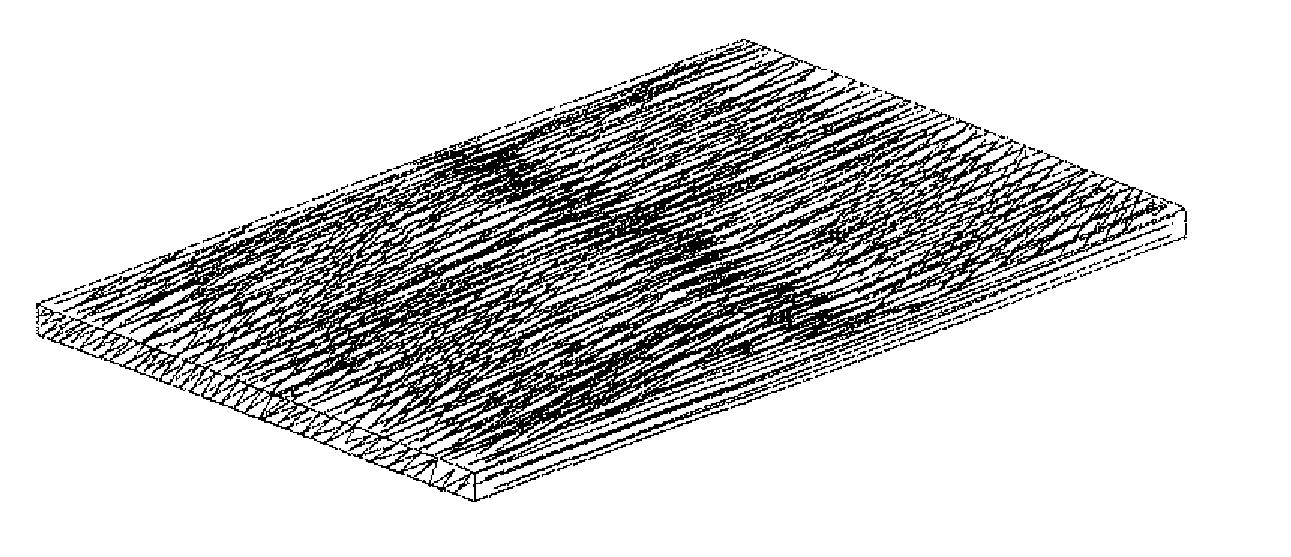

Bamboo artificial board unit, manufacturing method thereof and apparatus therefor

InactiveUS20110293885A1Easy to operateImprove production efficiencyWooden sticks manufactureMulti-purpose machinesFiberEngineering

The present invention provides a bamboo based panel unit comprising a hunk bamboo bundle mat and an oriented bamboo fiber mat (OBFM). Series of dotted and / or linear shaped cracks are formed on the cylinder wall of a semicircular bamboo tube which is split and whose inner nodes are removed. The upper surface and the lower surface of the bamboo based panel unit comprise an outer layer and an inner layer of said bamboo, wherein, a waxy layer and a siliceous layer are removed respectively therefrom.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

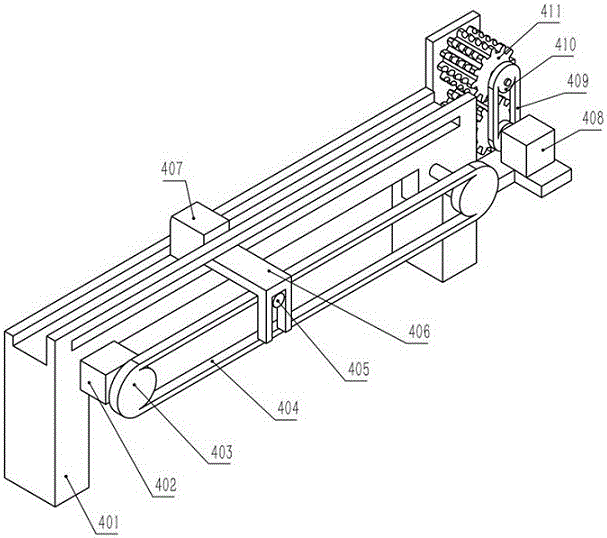

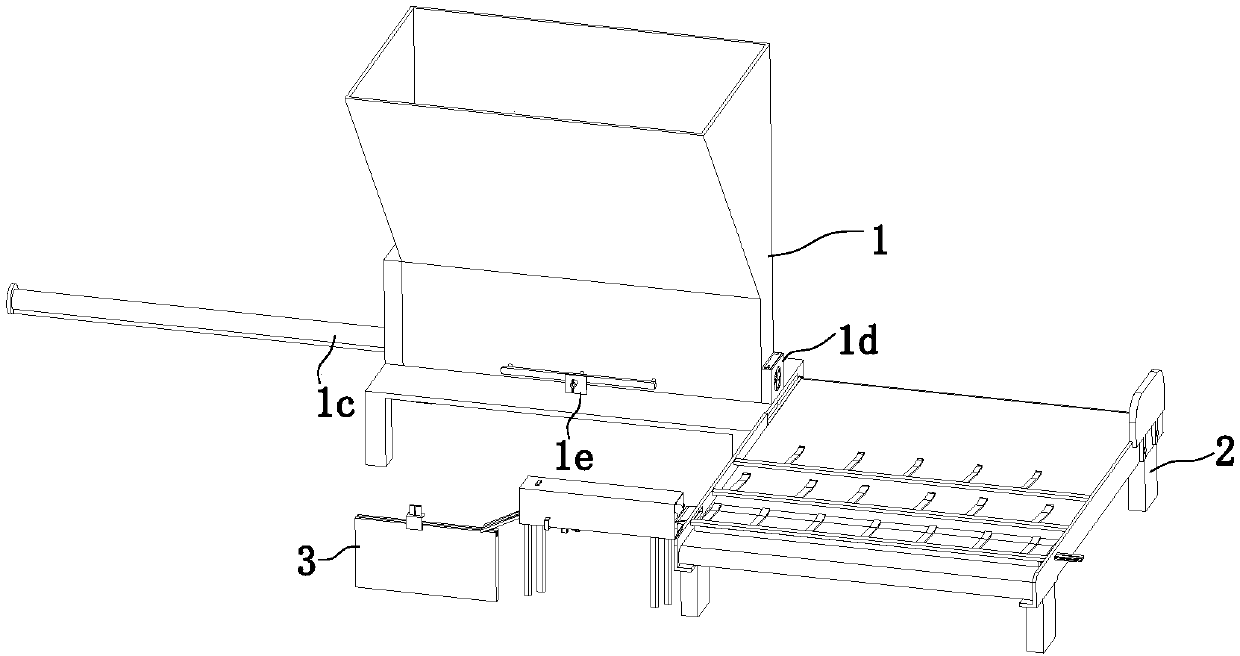

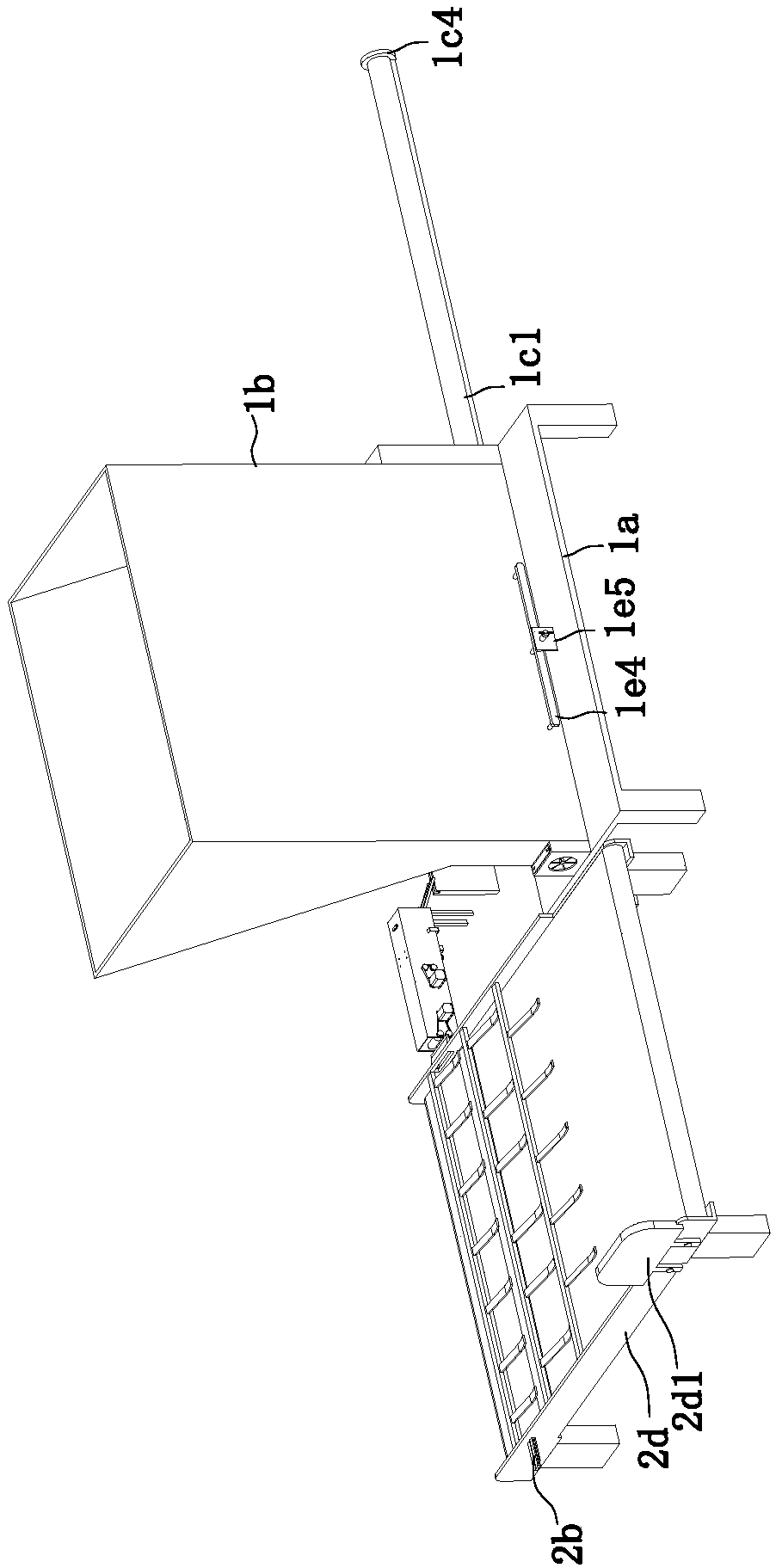

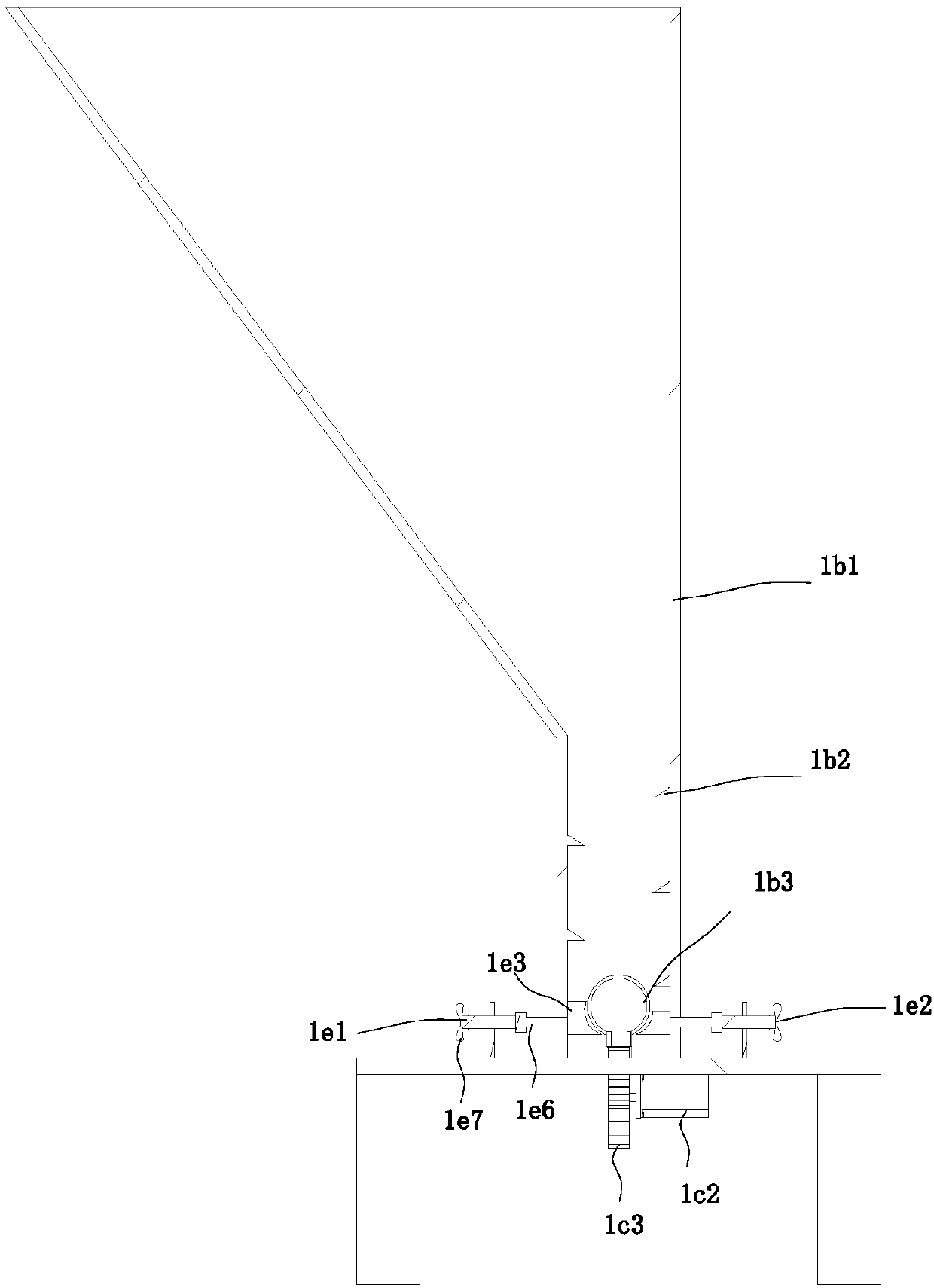

Automatic production line for bamboo chopsticks

ActiveCN107627428ARealize semi-automatic productionAvoid squeezingWooden sticks manufacturePlant material mechanical workingProduction lineSemi automatic

The invention relates to the field of mao bamboo processing, in particular to an automatic production line for bamboo chopsticks. The automatic production line comprises a loading device, a first conveyor belt and a grinding cutting device, wherein the loading device is positioned beside an input end of the first conveyor belt; the grinding cutting device is positioned beside the output end of thefirst conveyor belt; the loading device comprises a pedestal, a feeding assembly for supporting mao bamboos, a pushing assembly for moving the mao bamboos to the first conveyor belt from the feedingassembly, and a cutting part for cutting the mao bamboos into bamboo sheets; the feeding assembly, the pushing assembly and the cutting part are positioned on the top of the pedestal, and are fixedlyconnected with the pedestal; a limiting assembly for stacking bamboo sheets is arranged on the top of the first conveyor belt; one side, away from the grinding cutting device, of the first conveyor belt is equipped with a moving assembly for outputting the bamboo sheets on the top of the first conveyor belt to the grinding cutting device. The loading device, the first conveyor belt and the grinding cutting device realize semi-automatic production of bamboo chopsticks, and saves loss of human resources.

Owner:诸暨市景旺机械科技有限公司

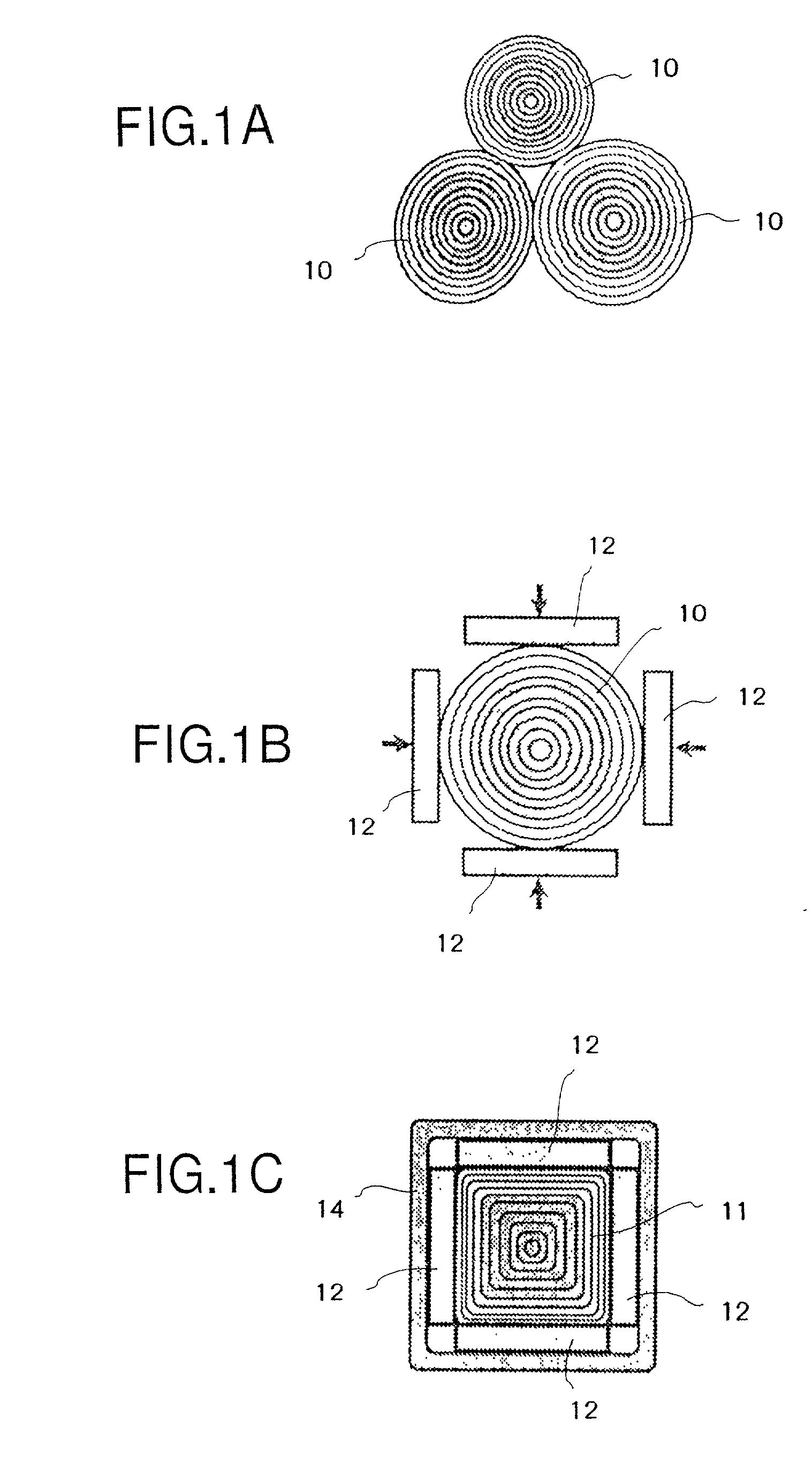

Prismatic wood compression molding method and compression molding device therefor

InactiveUS20020148532A1Fixed shapeEasy to manufactureWooden sticks manufactureWood compressionCompression moldingEngineering

A prismatic wood compression molding method capable of easily producing long-sized lumber usable as pillars or like by compression molding. The method is characterized by comparing the steps of: using a plurality of rigid plate-like bodies such as metal plates to compress an outer face of wood throughout length thereof to compression-mold it into prismatic wood which is polygonal, such as rectangular or hexagonal, in cross section; restraining the plate-like bodies by a restrain jig so as to hold flat surfaces of the prismatic wood in a state in which they are compressed by the plate-like bodies; and applying a heat treatment to the prismatic wood held in the compressed state by the plate-like bodies and the jig so as to permanently fix the shape of the prismatic wood.

Owner:SHINSHU UNIVERSITY +1

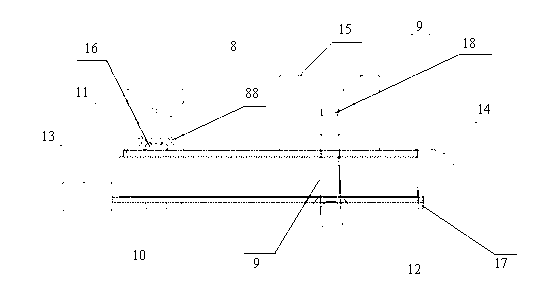

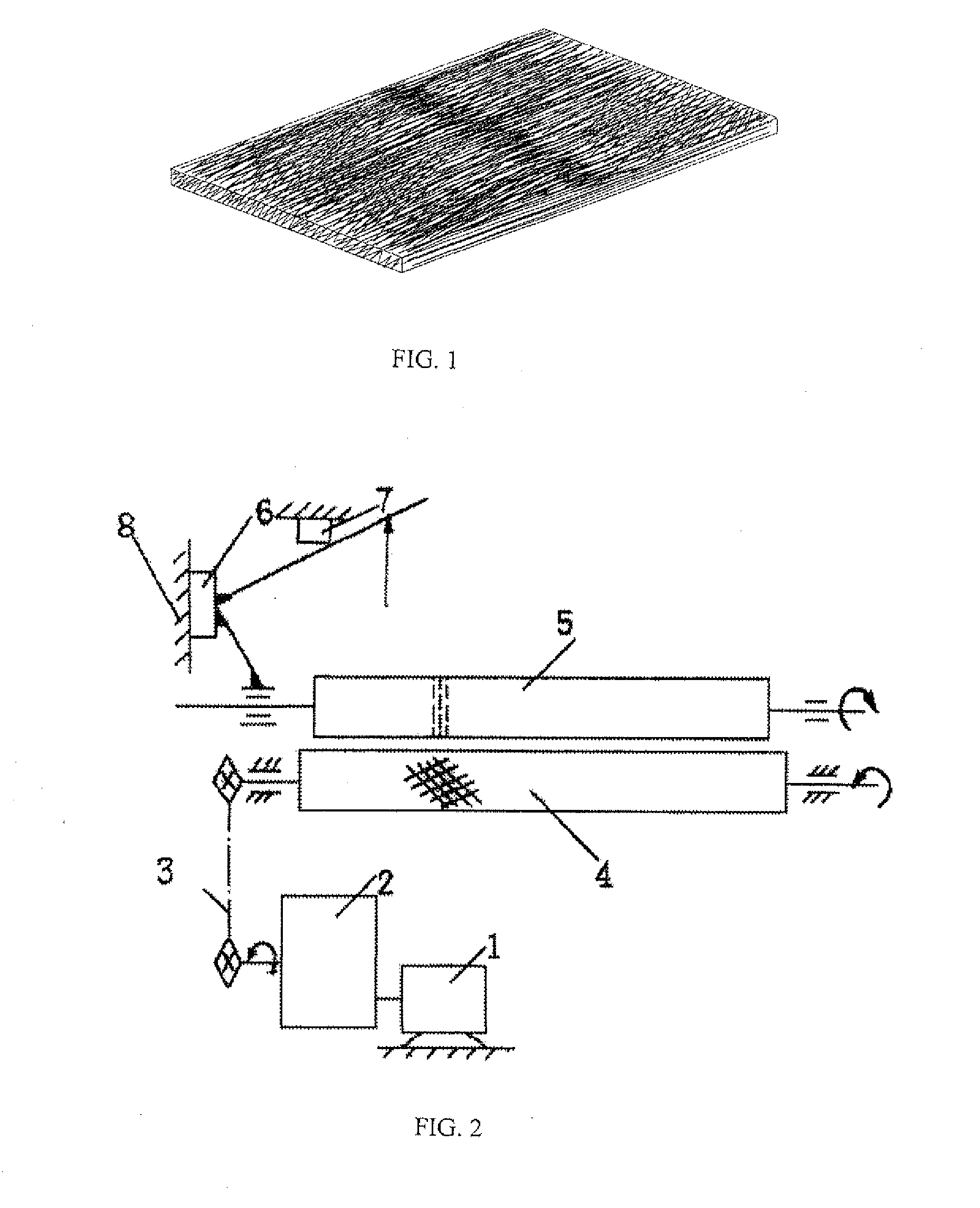

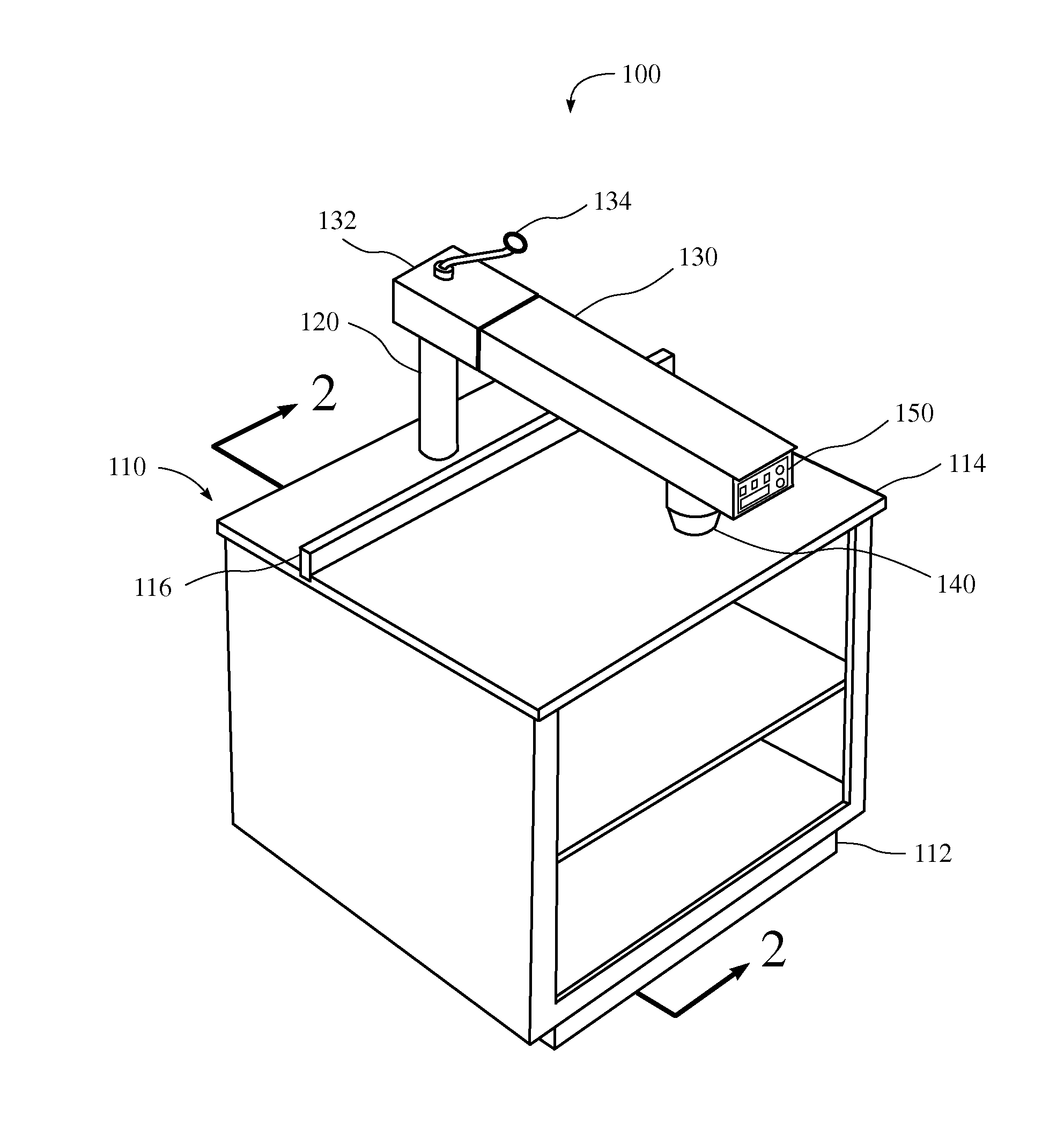

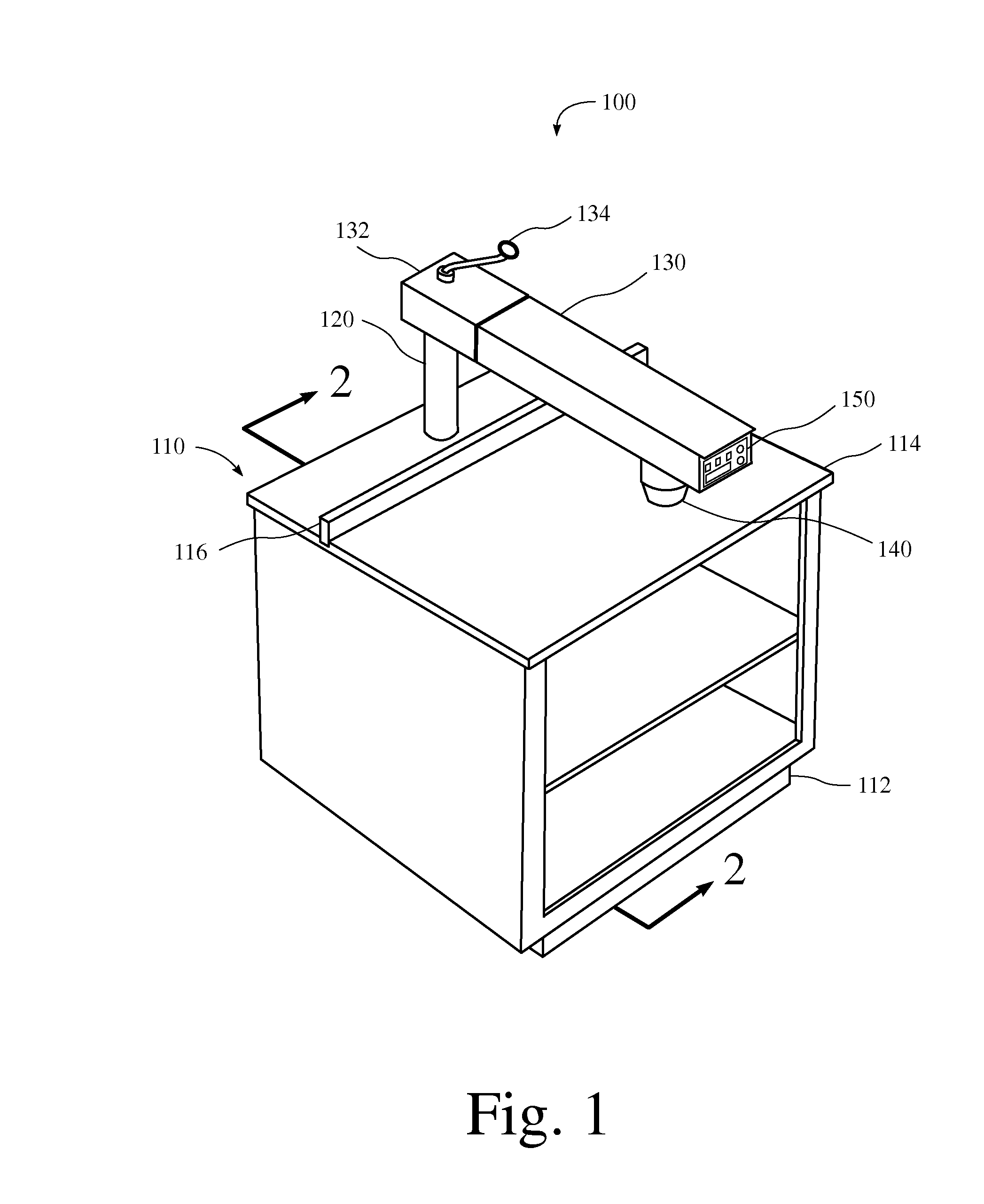

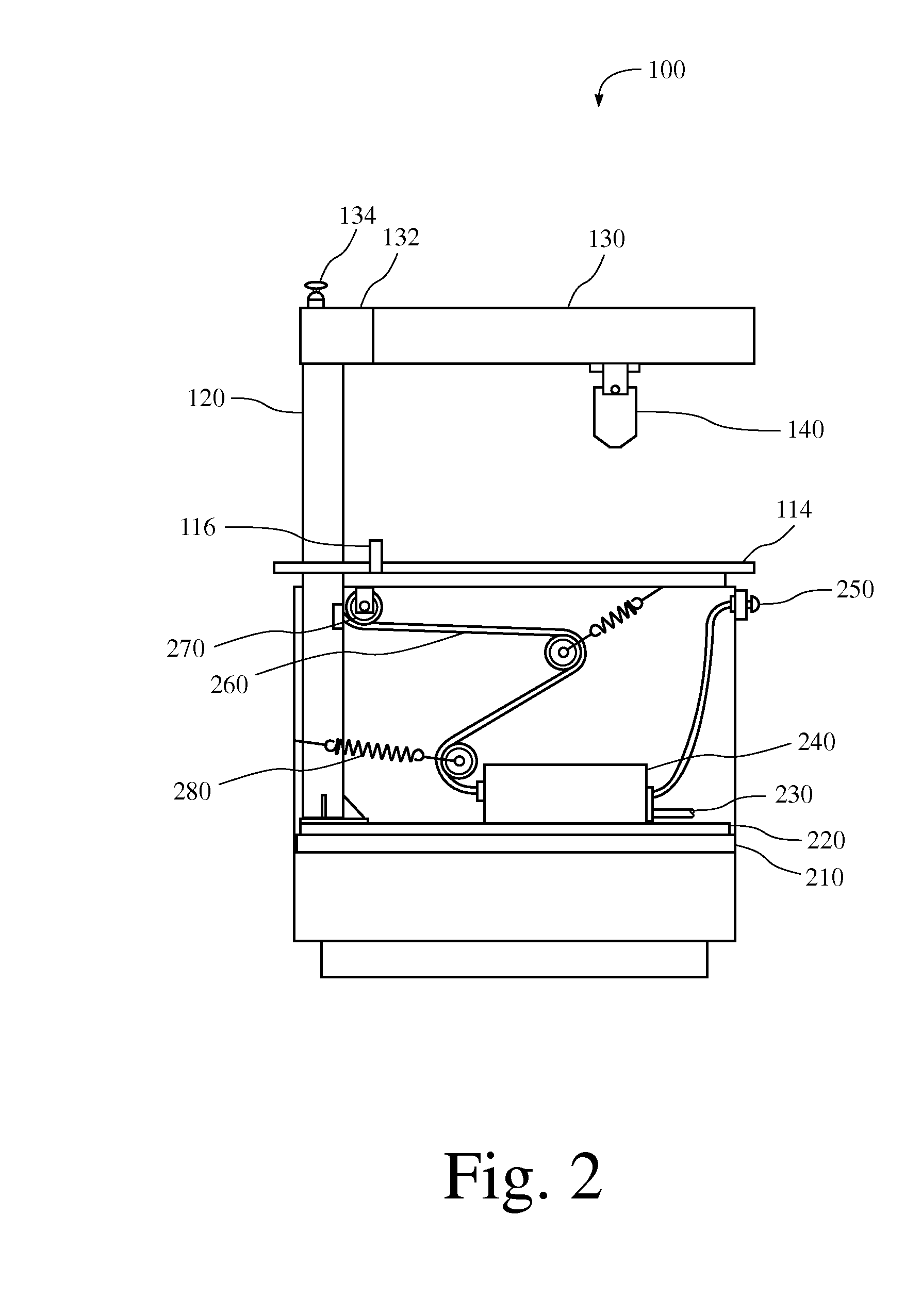

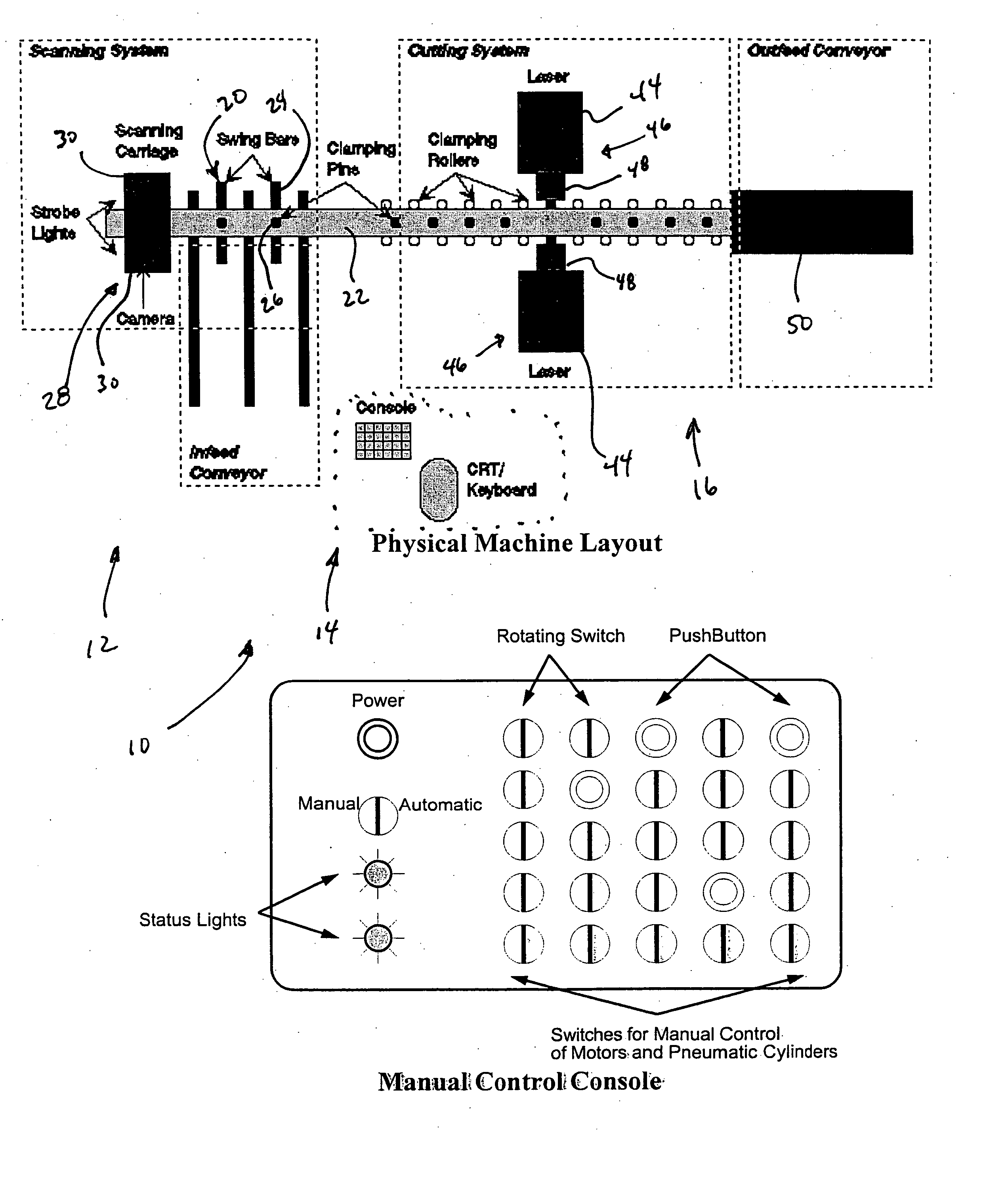

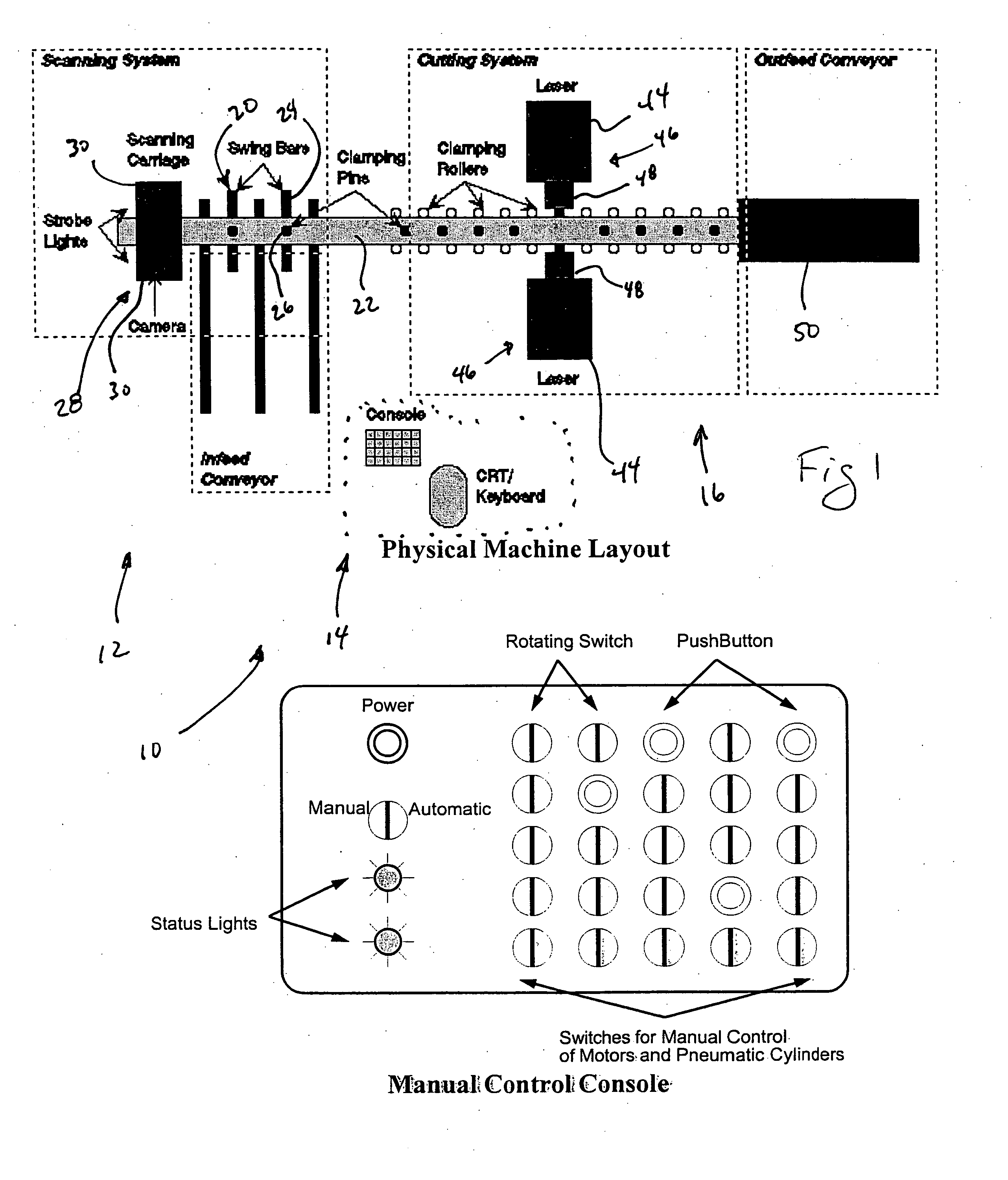

Laser Woodworking Machine

InactiveUS20120037274A1Reasonable space requirementImprove the security environmentWooden sticks manufactureMulti-purpose machinesEngineeringLaser cutting

Owner:HENDERSON CHARLES L

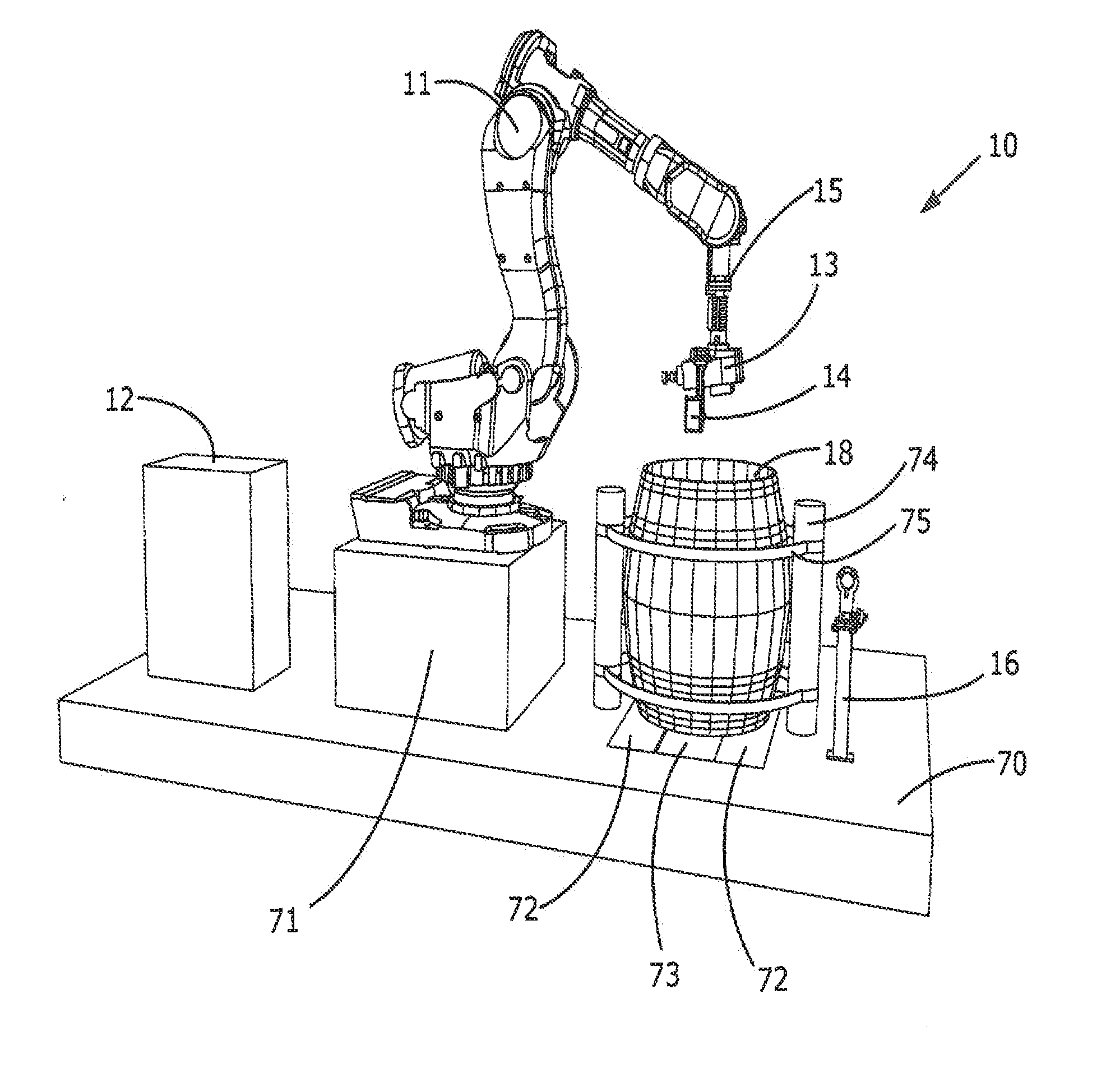

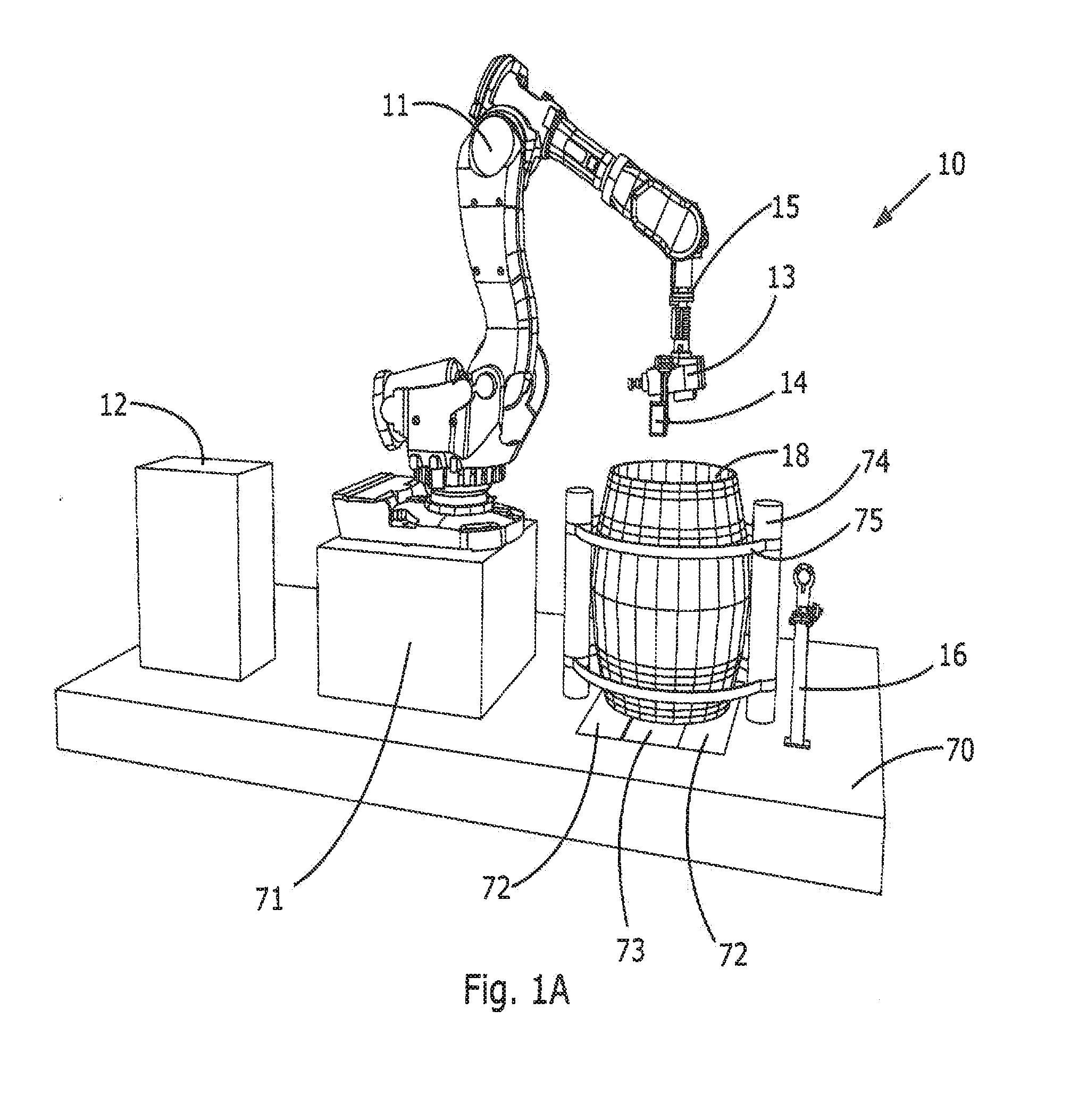

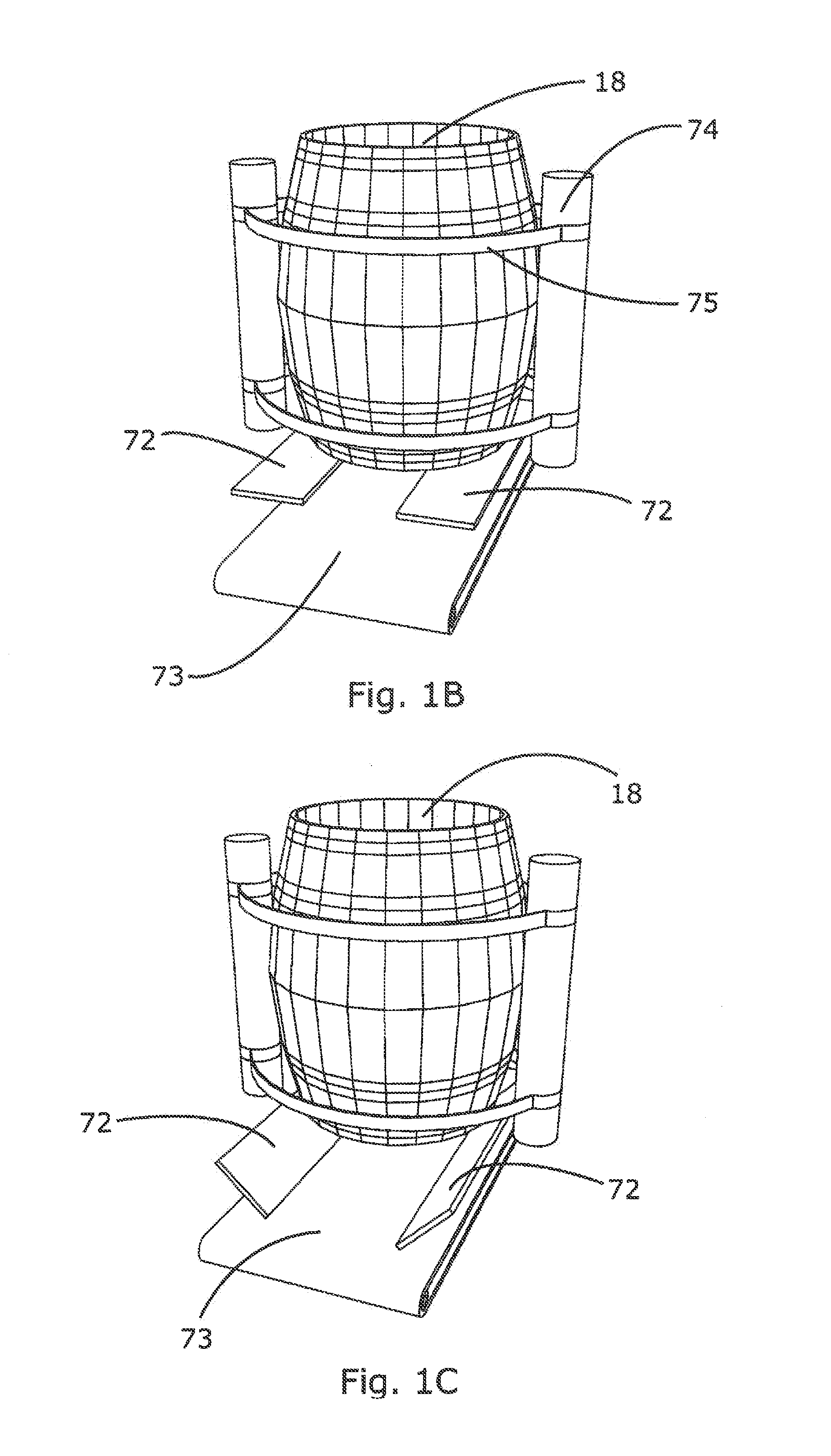

System and method for the reconditioning of barrels including a robotic arm with a removable laser module

A system for reconditioning barrels comprising: a robot arm; a router assembly for routing the inside surface of a barrel; and a laser assembly for measuring the inside profile of a barrel, wherein: the router assembly is fixedly attached to the robot arm; and the laser assembly is removably attached to the router assembly thus allowing the laser assembly to be removed whilst the barrel is being routed in order to protect the laser from airborne particles and vibrations from the router.

Owner:DIVERSE BARREL SOLUTIONS

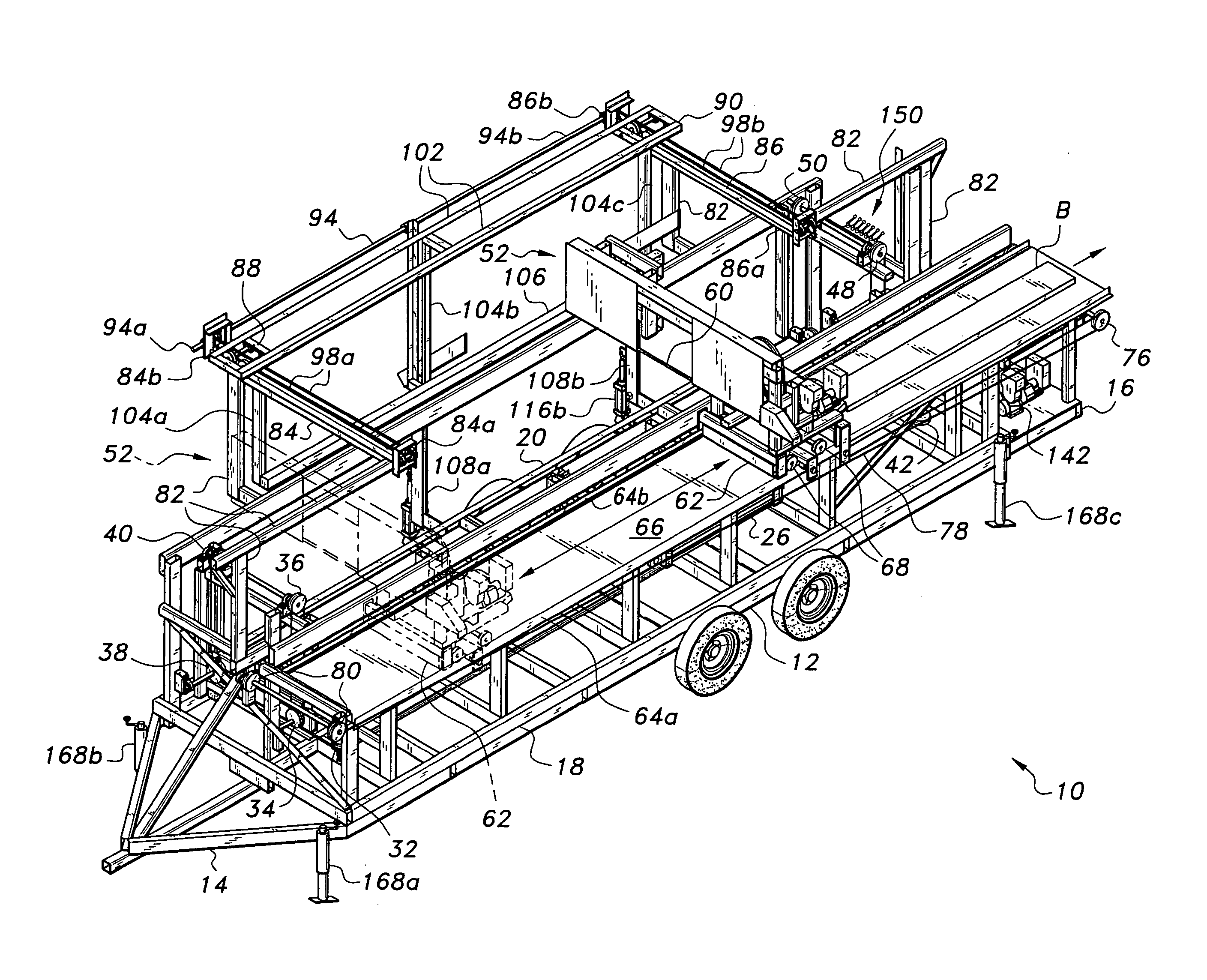

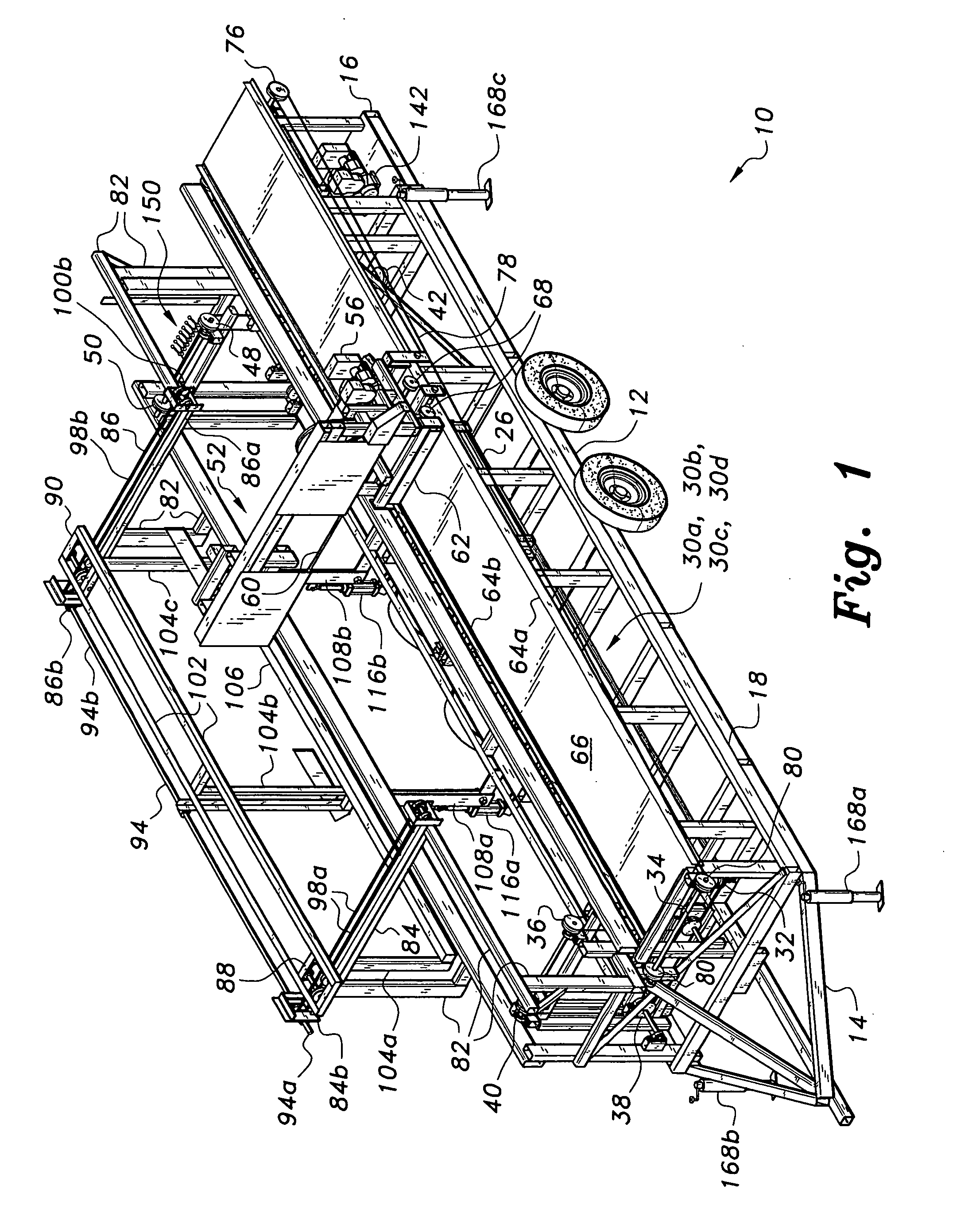

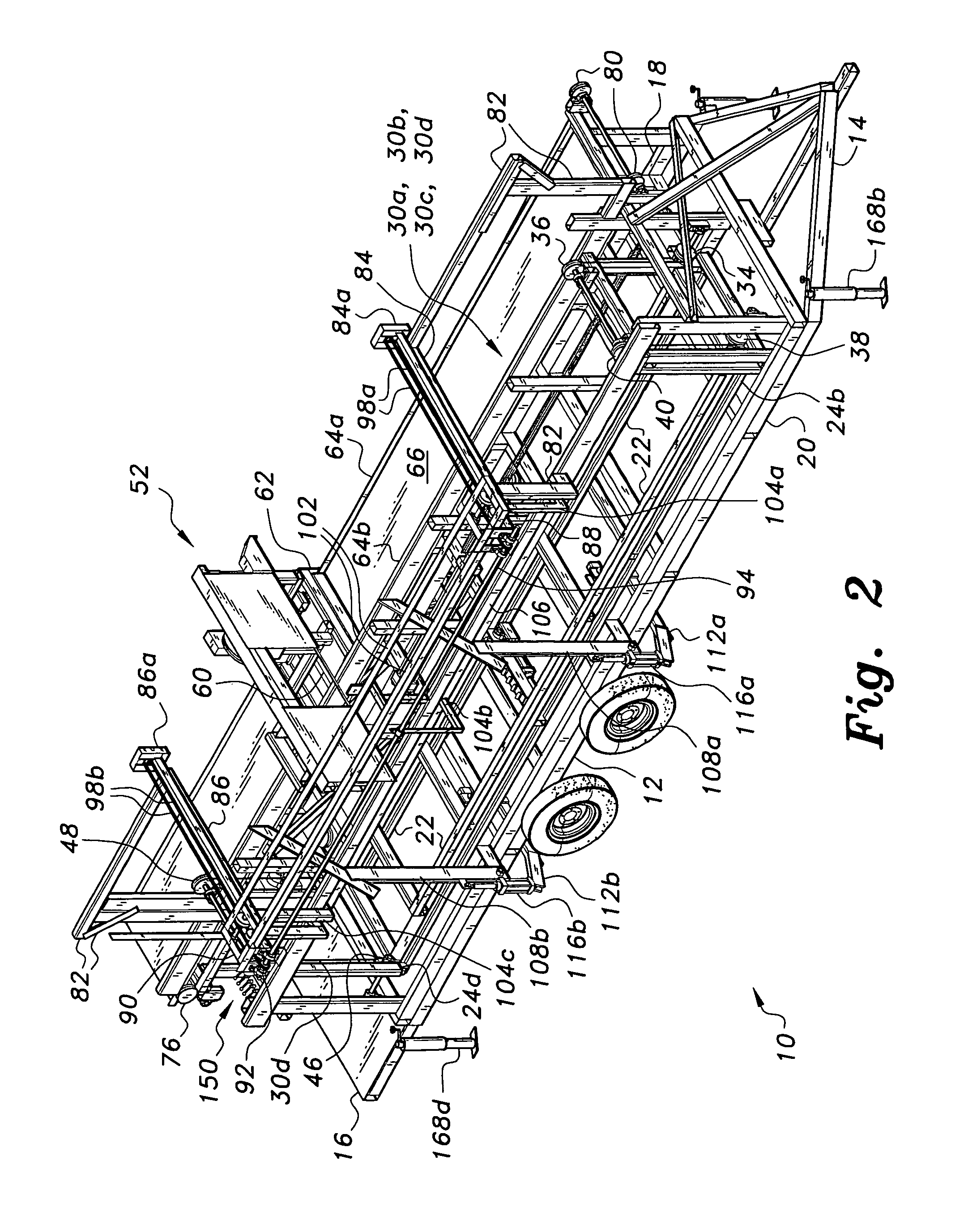

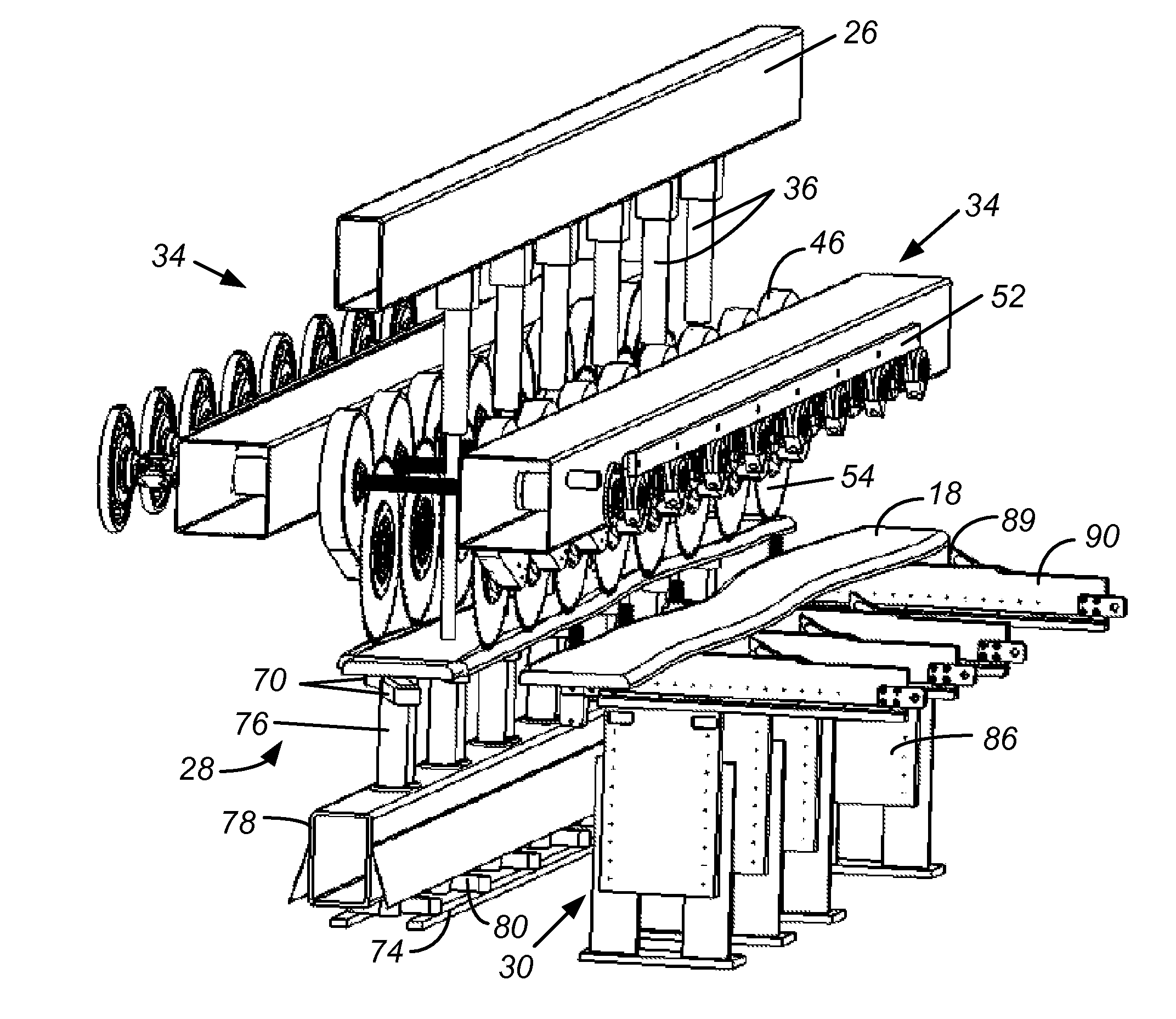

Portable sawmill

The portable sawmill is constructed on a frame having a series of mechanisms for loading and manipulating a log thereon and removing boards cut from the log. Powered tines load a log onto a vertically adjustable log deck, the deck including powered mechanisms for turning and securing the log in the desired orientation for cutting. Cuts are made by a horizontally traveling band saw. The saw has no vertical adjustment. Board thickness is determined by the height of the vertically adjustable log deck. Cut boards are removed by a board sweep that pushes the board laterally from the top of the log onto a tray. The saw travels along the tray to push the board longitudinally onto a suitable platform for transport. All of the above mechanisms are controlled hydraulically from a single operator station on the mill, thus freeing the operator from many manual tasks and increasing production.

Owner:BURTON LARRY C

Convenient chopsticks made from Conyza canadensis and processing technique

InactiveCN101323122AEasy to manufactureHigh surface finishWooden sticks manufactureWood treatment detailsCuticleHigh surface

The invention discloses a convenient chopstick made from conyza japonica and a production process, which is characterized in that, the stem of the mature conyza japonica is adopted; branches are cut off; epidermis is skinned in water and xylem is presented; the material is cut into the normal size of common chopsticks; the integral shape is straightened, dried, disinfected and made into chopsticks; or the material can be steamed and boiled in sticky slurry made from boiled glutinous rice, and then extrusion, formation, drying, cutting and packaging are carried out. The production process of the invention can also be applied to the production of ice cream sticks, toothpicks, medical tongue depressor, cotton swab sticks and other products. The convenient chopsticks and the tooth picks made from the conyza japonica have the advantages of high surface smoothness, low cost, convenient manufacture, large cultivation acreage, high productivity and strong reproducibility; the conyza japonica can be used for replacing precious forest wood resources.

Owner:王玉华 +1

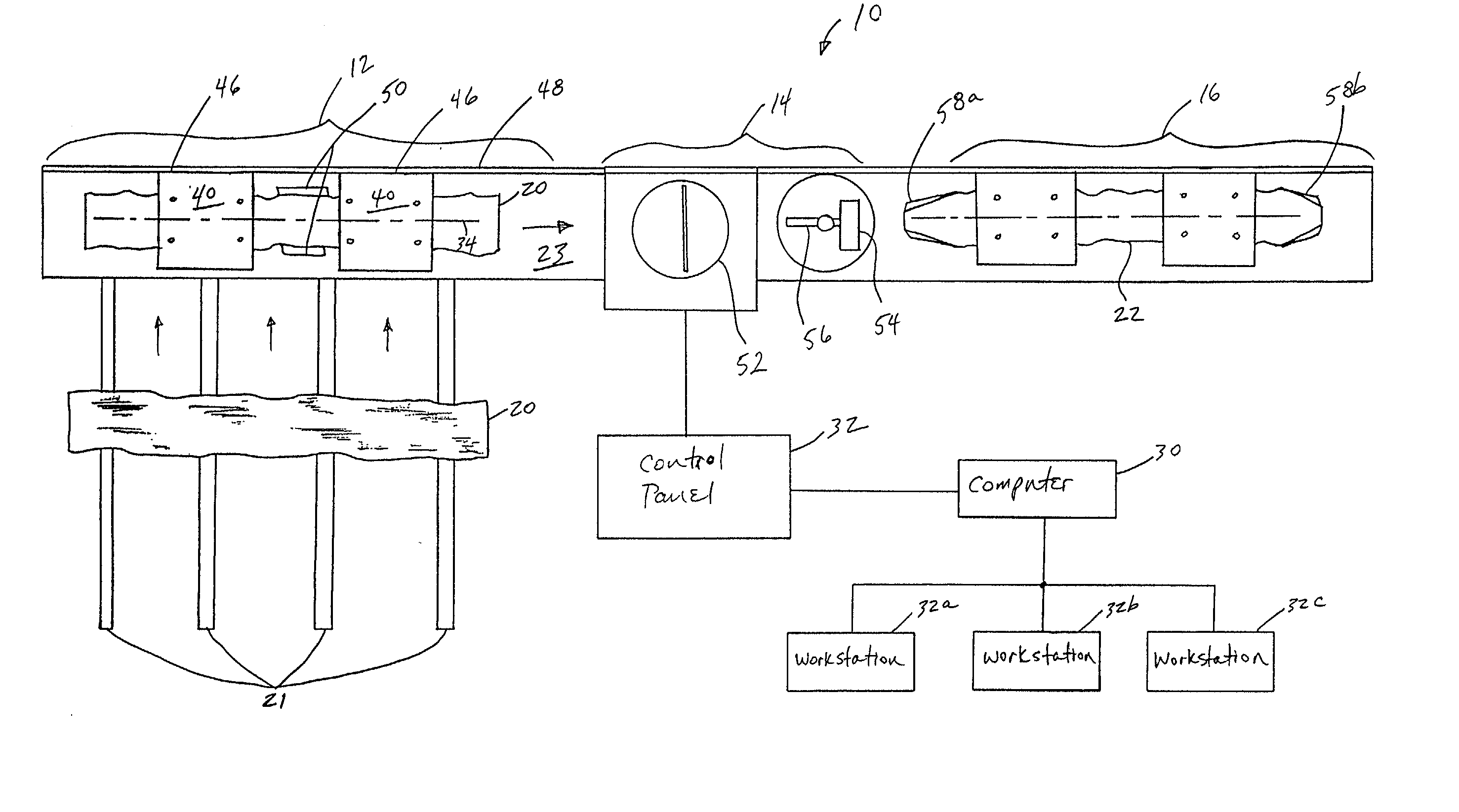

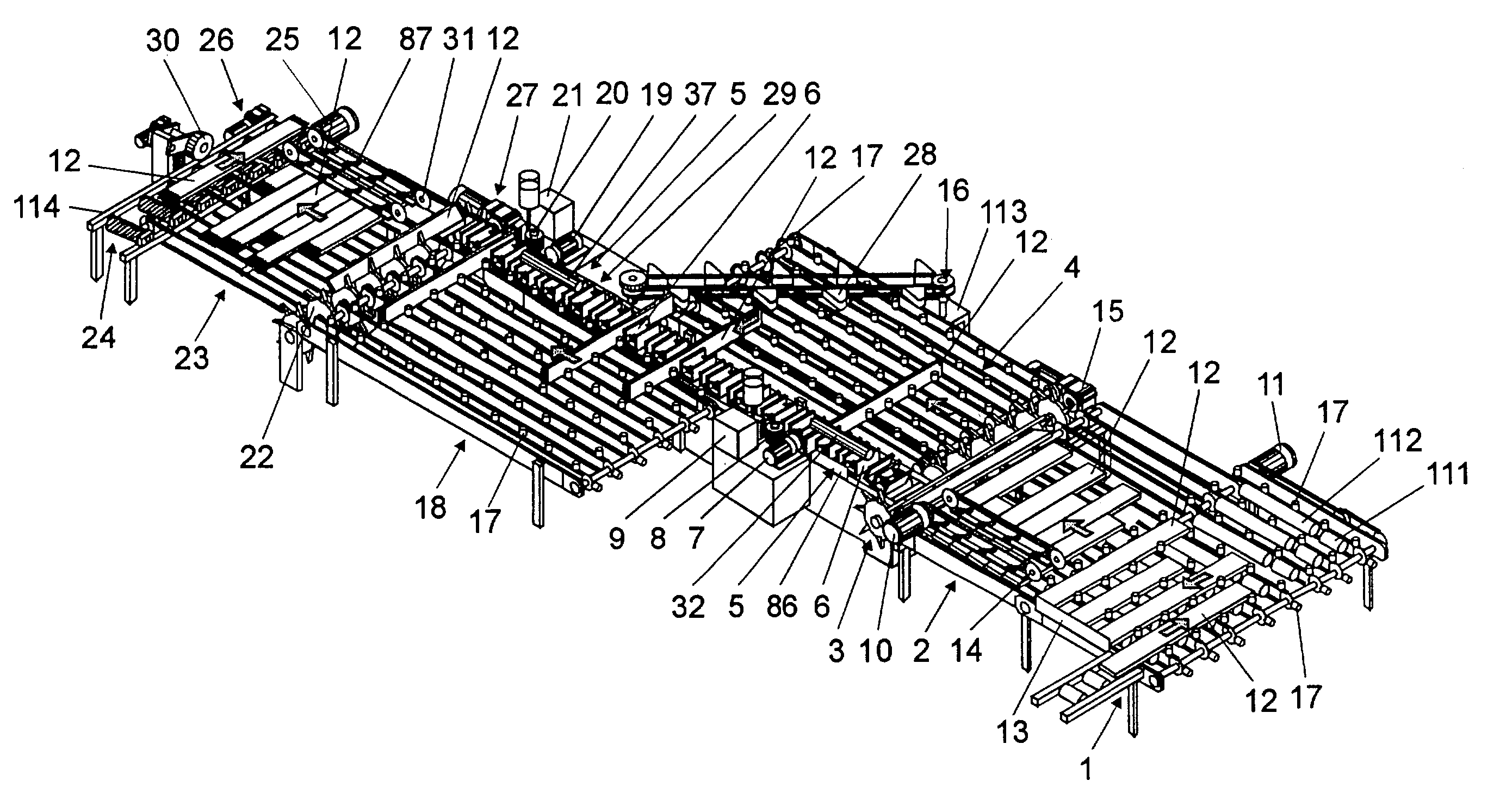

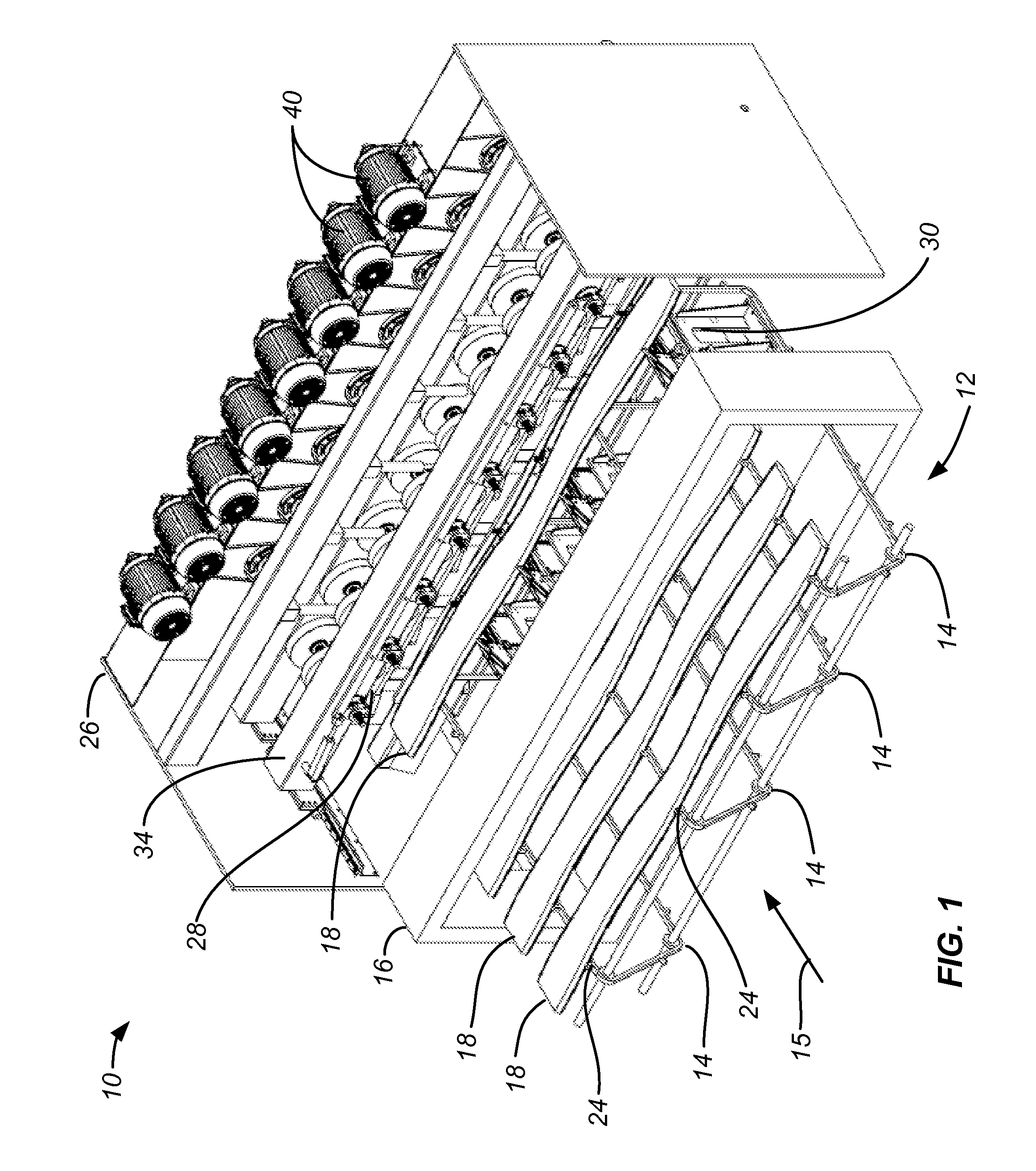

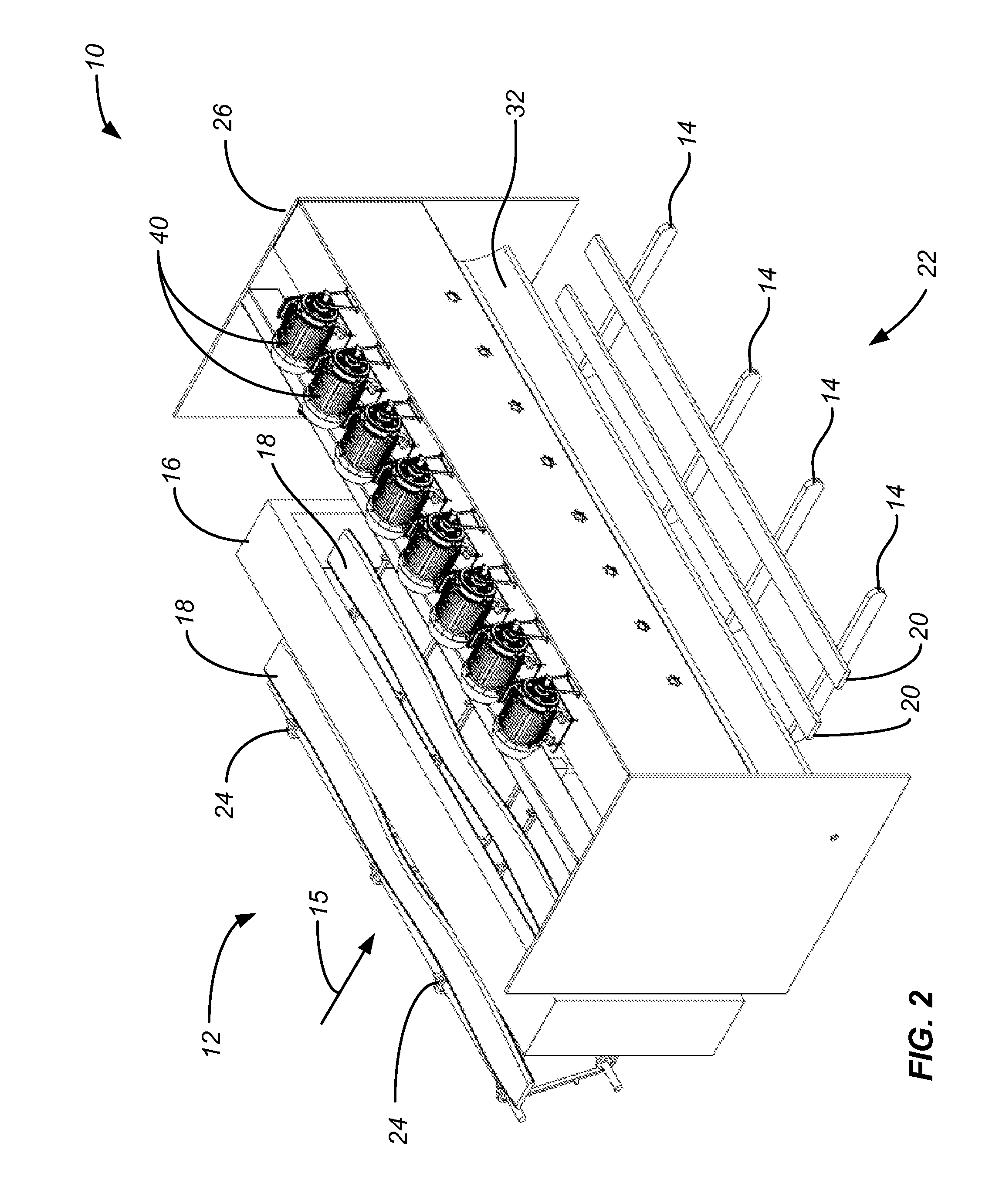

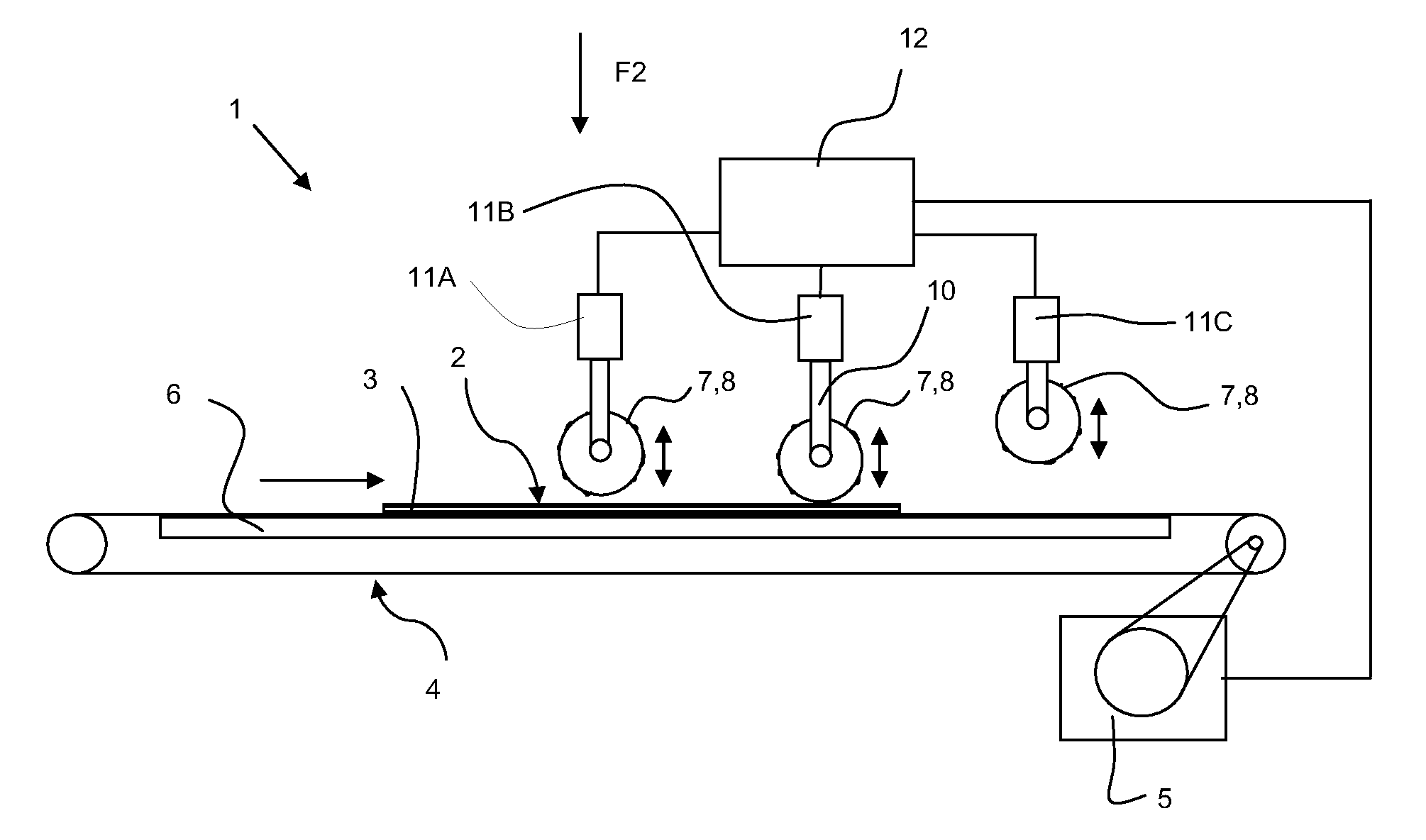

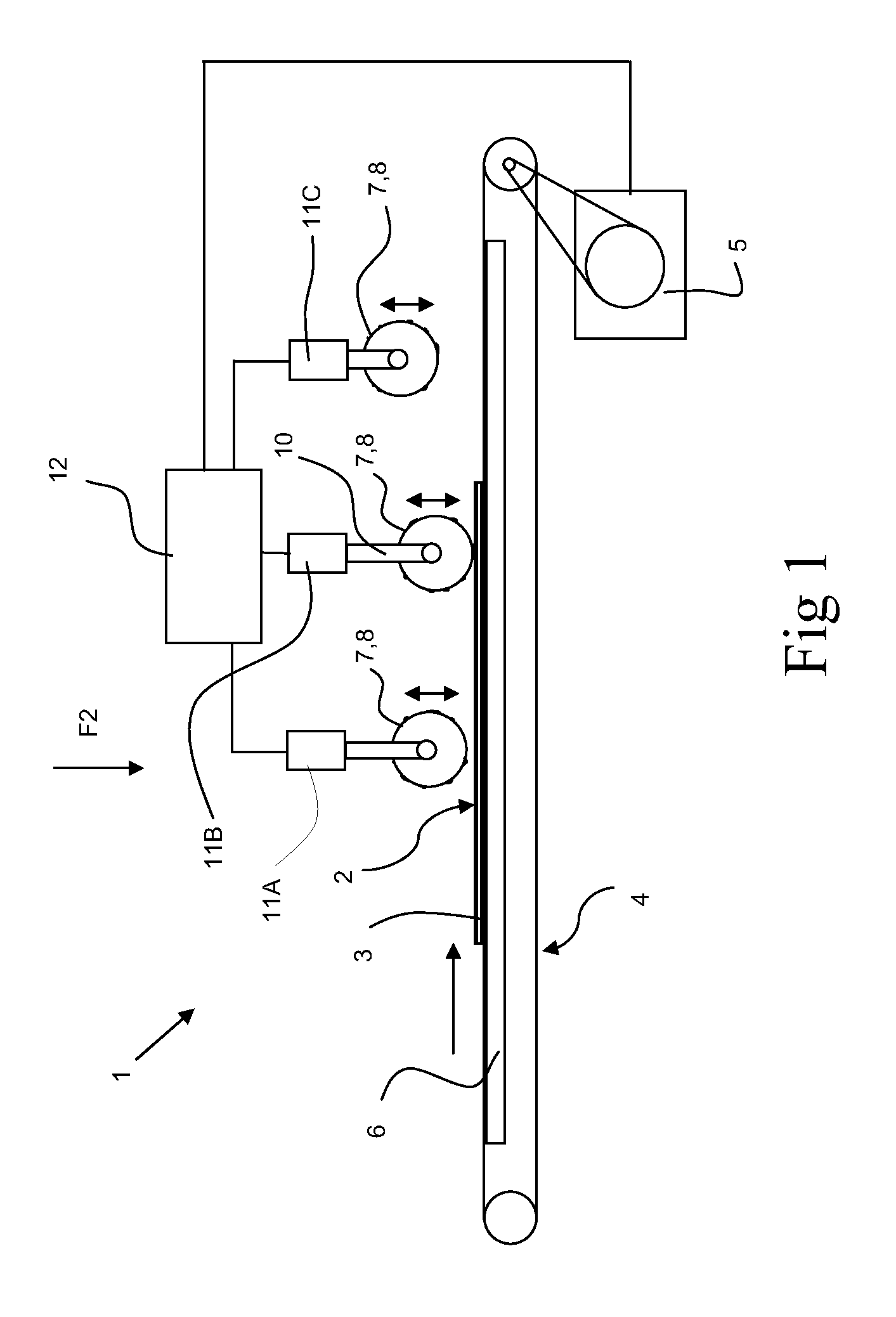

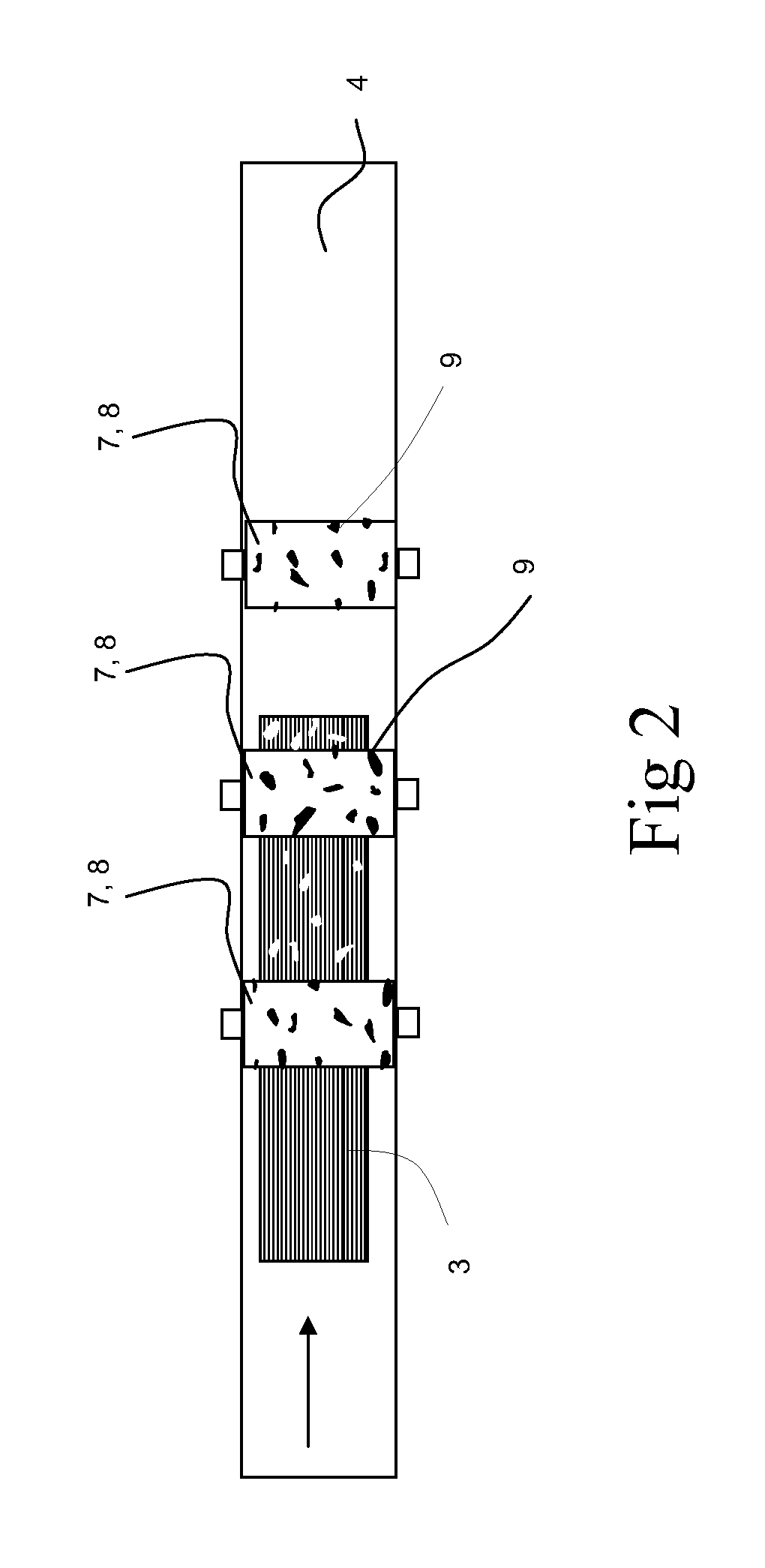

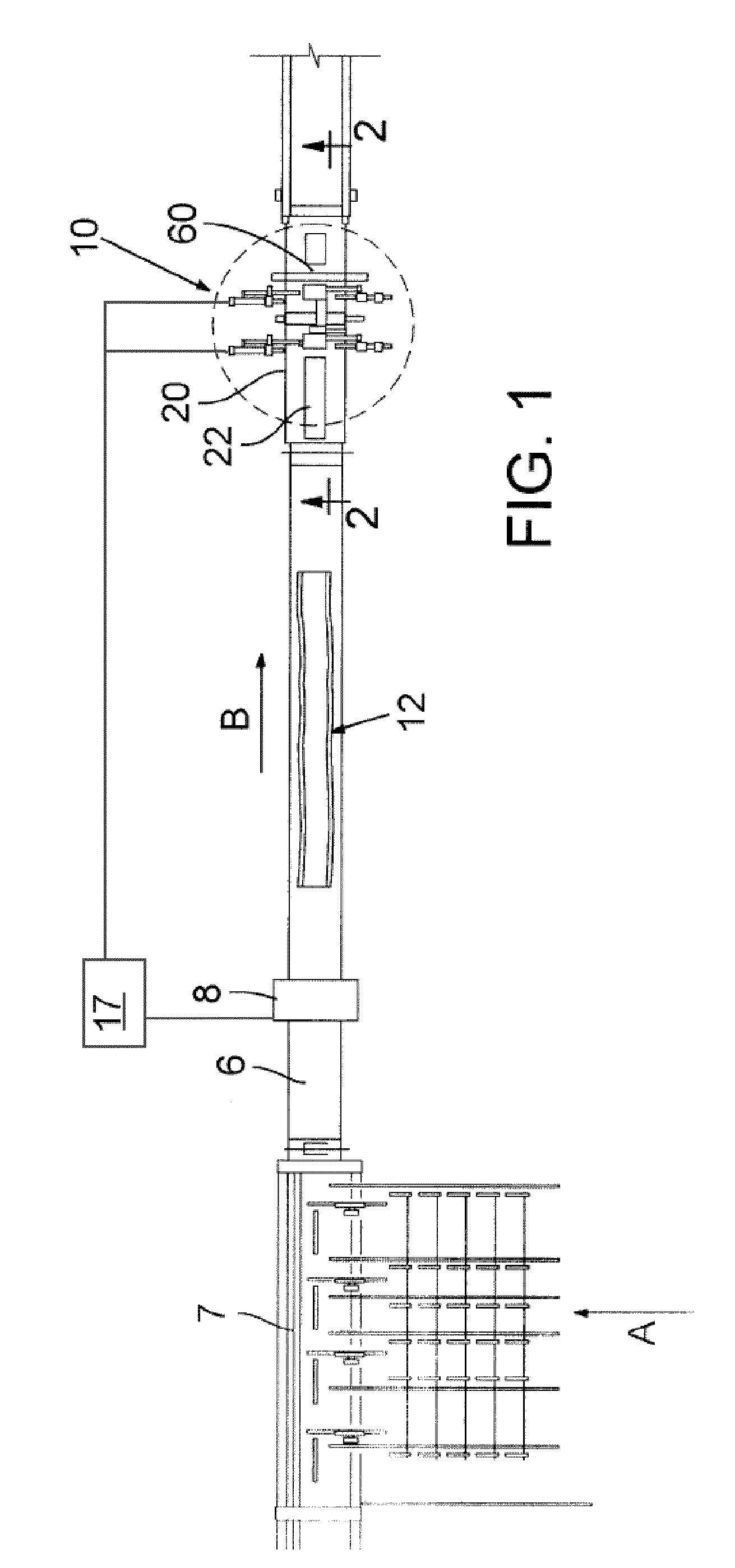

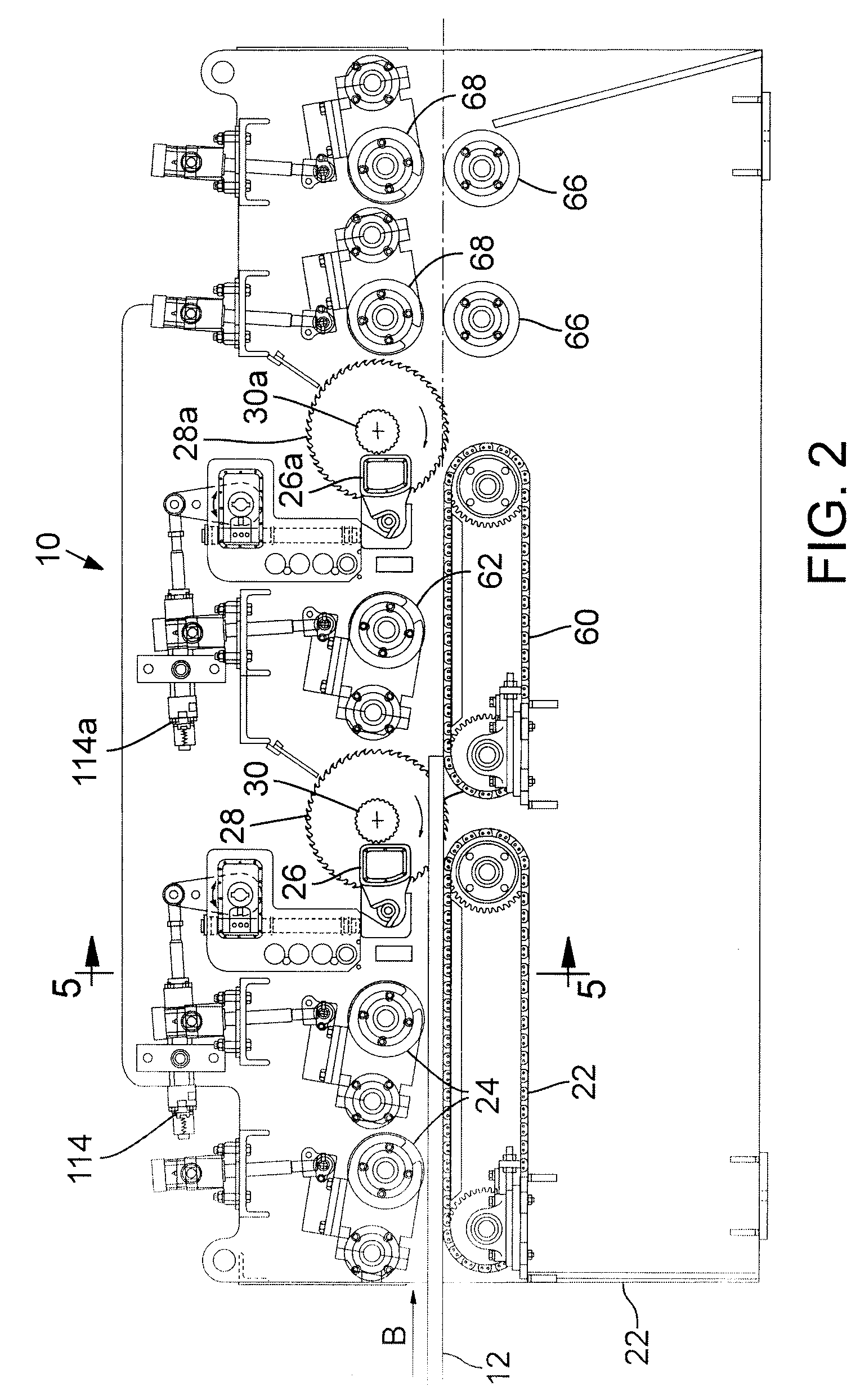

Automatic Workpiece Edging and Ripping Device and Method

InactiveUS20110253261A1Precise alignmentFor precise cuttingMetal sawing devicesWooden sticks manufactureEngineeringMechanical engineering

A sawing apparatus for a wood products sawing system comprises a frame, a sawing table, a workpiece clamping element, and an overhead saw assembly. A workpiece can be supported on the sawing table and releasably secured to the table by the workpiece clamping element. The overhead saw array is supported by the frame and includes a saw driver and a row of at least three saw assemblies so to sever the workpiece along the cut line by movement of the saw blades along two dimensional paths. A variable width sawing table comprises a driving assembly and a row of support arm assemblies mounted to the frame member and coupled to the driving assembly for movement to at least first and second positions.

Owner:BID GRP TECH US INC

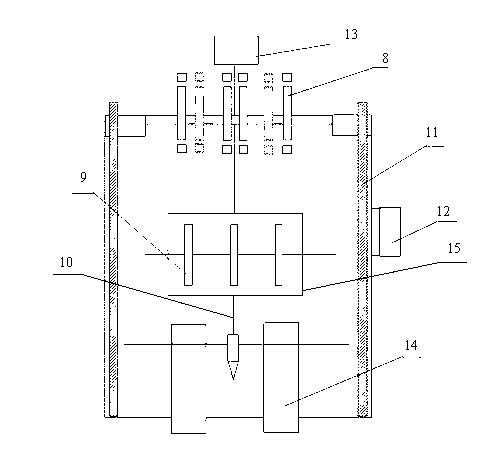

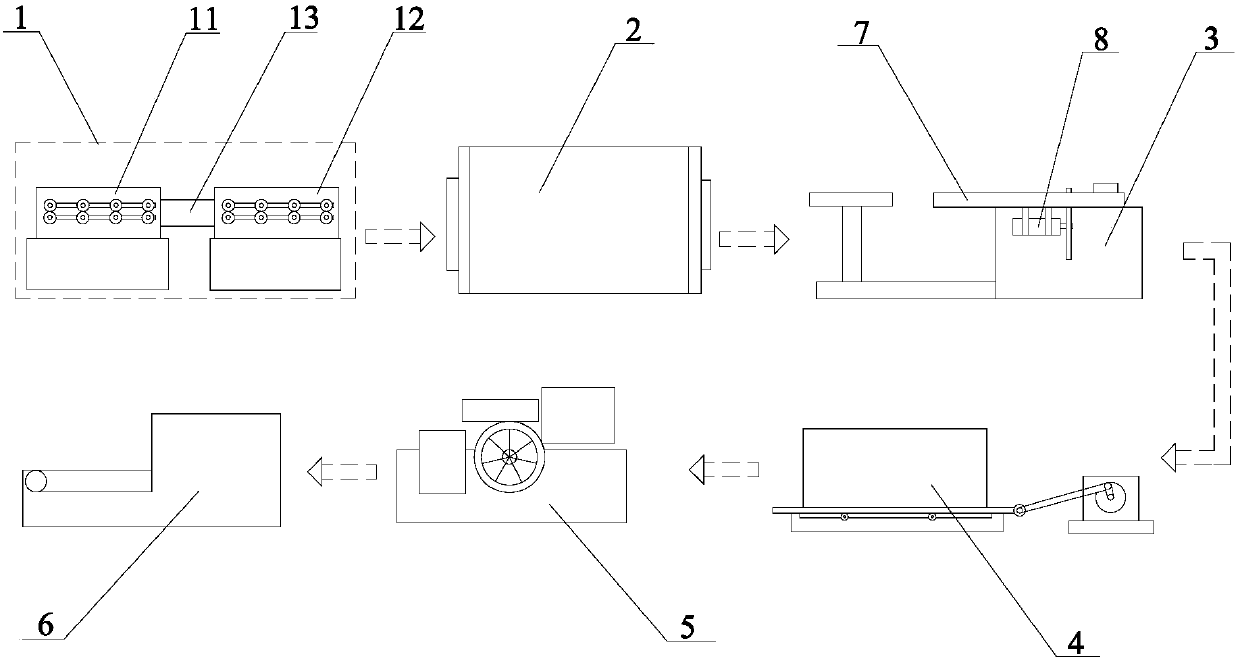

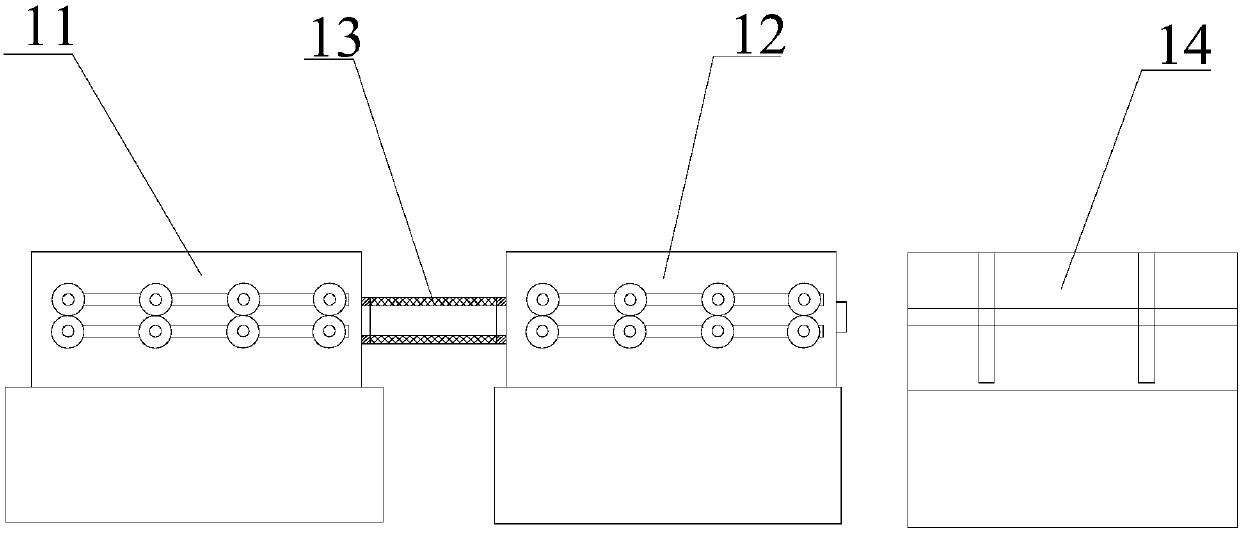

Automatic machining production line device for bamboo toothpicks

ActiveCN105946082AReduce labor costsImprove quality and efficiencyEdge grinding machinesWooden sticks manufactureProduction lineEngineering

The invention discloses an automatic machining production line device for bamboo toothpicks. According to the machining process, a conjoined drawing machine, a drying and carbonizing chamber, a material cutting device, an automatic polishing and sorting device, a toothpick grinding device and a packaging machine are sequentially included; the conjoined drawing machine is used for machining bamboo sheets into bamboo filaments of a certain specification; the drying and carbonizing chamber is used for drying and carbonizing the bamboo filaments; the material cutting device is used for cutting the dried and carbonized bamboo filaments into toothpick sticks of a fixed length; the automatic polishing and sorting device is used for polishing the toothpick sticks and meanwhile sorting out defective goods automatically; the toothpick grinding device is used for conducting end grinding treatment on the polished toothpick sticks, and the toothpicks of a certain specification are obtained; and the packaging machine is used for packaging the toothpicks according to the number. The automatic machining production line device has the beneficial effects that the drawing process, the cutting process, the polishing process and the like in a machining system are optimized, labor cost is reduced greatly, besides, the quality of products is improved, production efficiency is improved, and the excellent practicability and creativeness are achieved.

Owner:JINGDE COUNTY HUANGSHAN BAMBOO WOOD PROD FACTORY

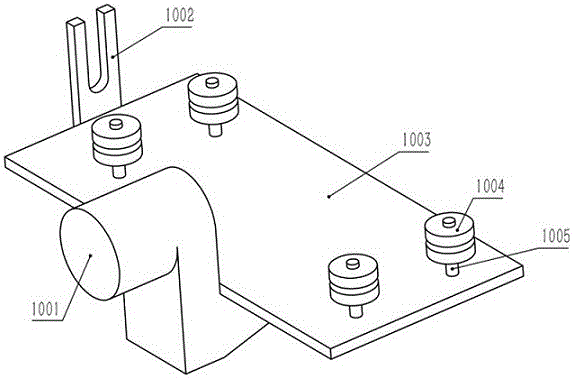

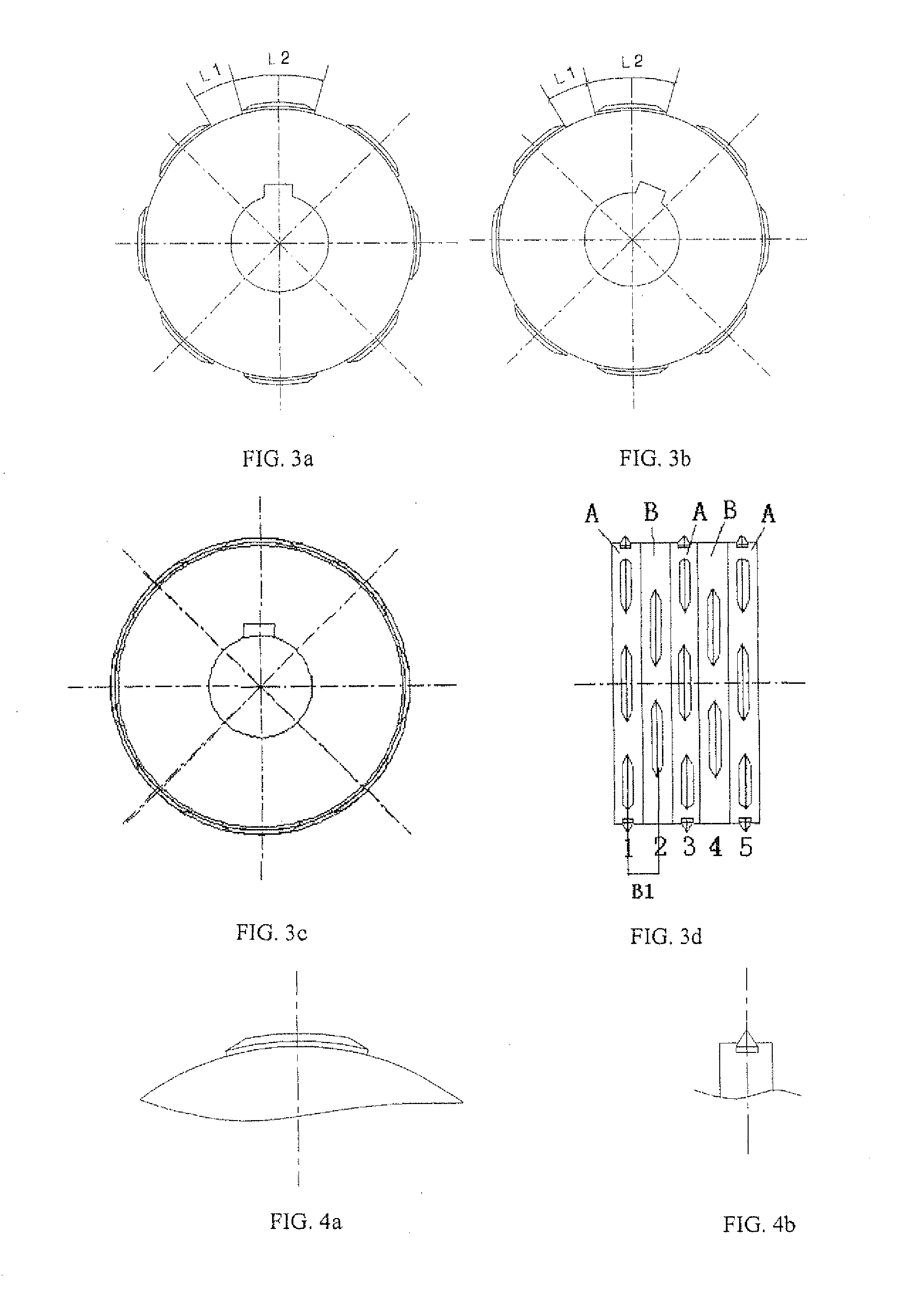

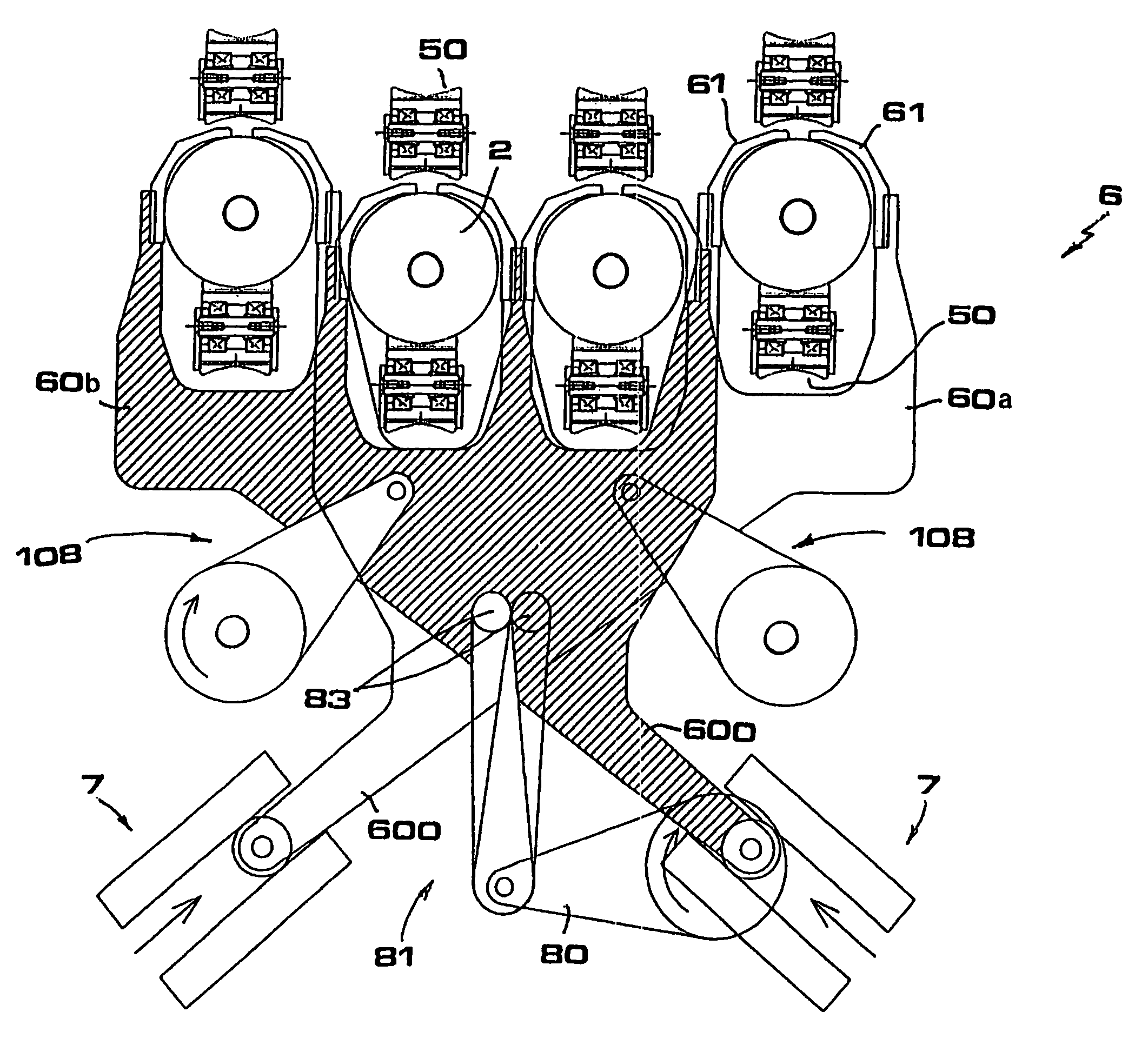

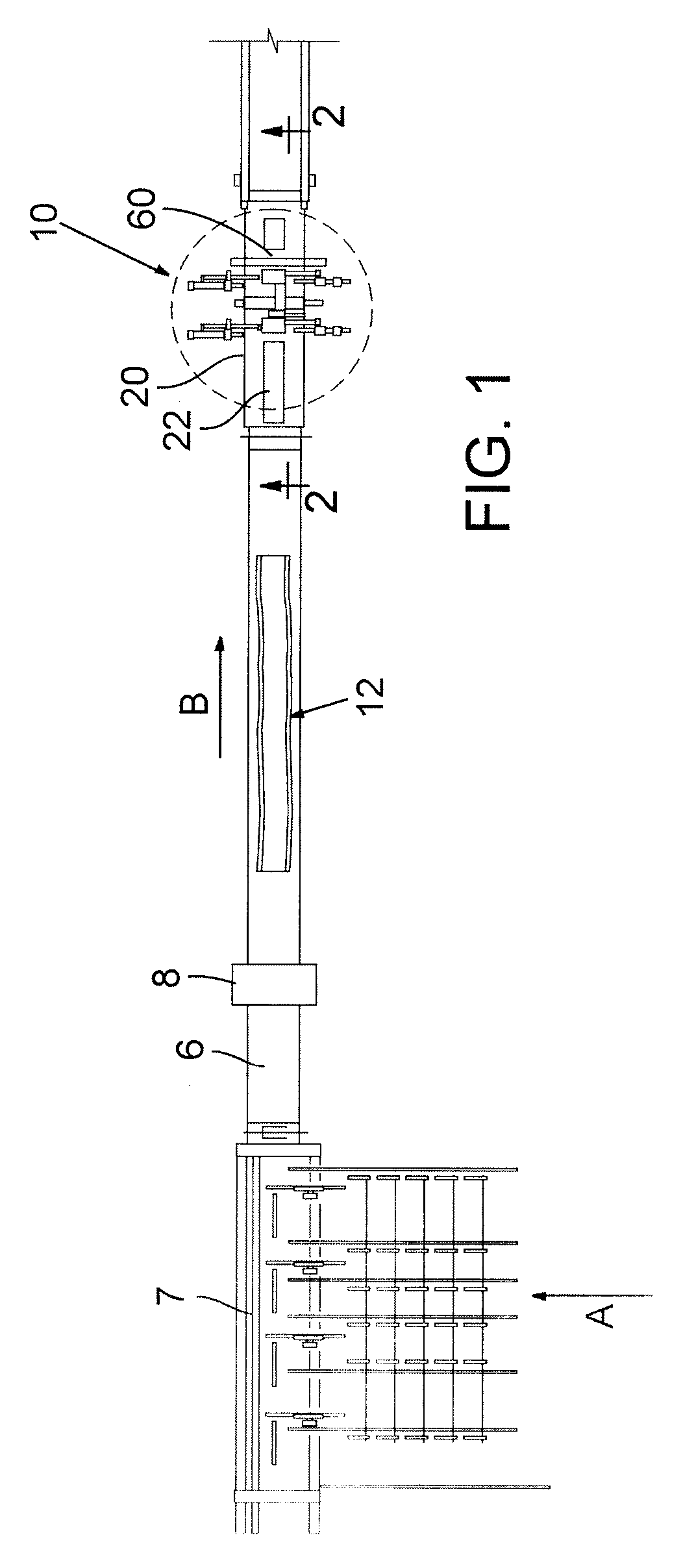

Apparatus for temporarily holding logs within cutting-off machines

InactiveUS7617852B2Effective and safe holdSpeed up preparationWooden sticks manufactureMulti-purpose machinesEngineeringActuator

An apparatus for temporarily holding logs within cutting-off machines including two plates (60), each of which exhibits a plurality of pressers (61) and an appendix sliding within a guide (7). The plates (60) are associated with an actuator (8) which drive them, under control, in a substantially straight movement in the direction of the relevant guides (7). The pressers are disposed in mirror-like and parallel relationship to each other, that is, orthogonally to the logs (2) to be treated.

Owner:PERINI

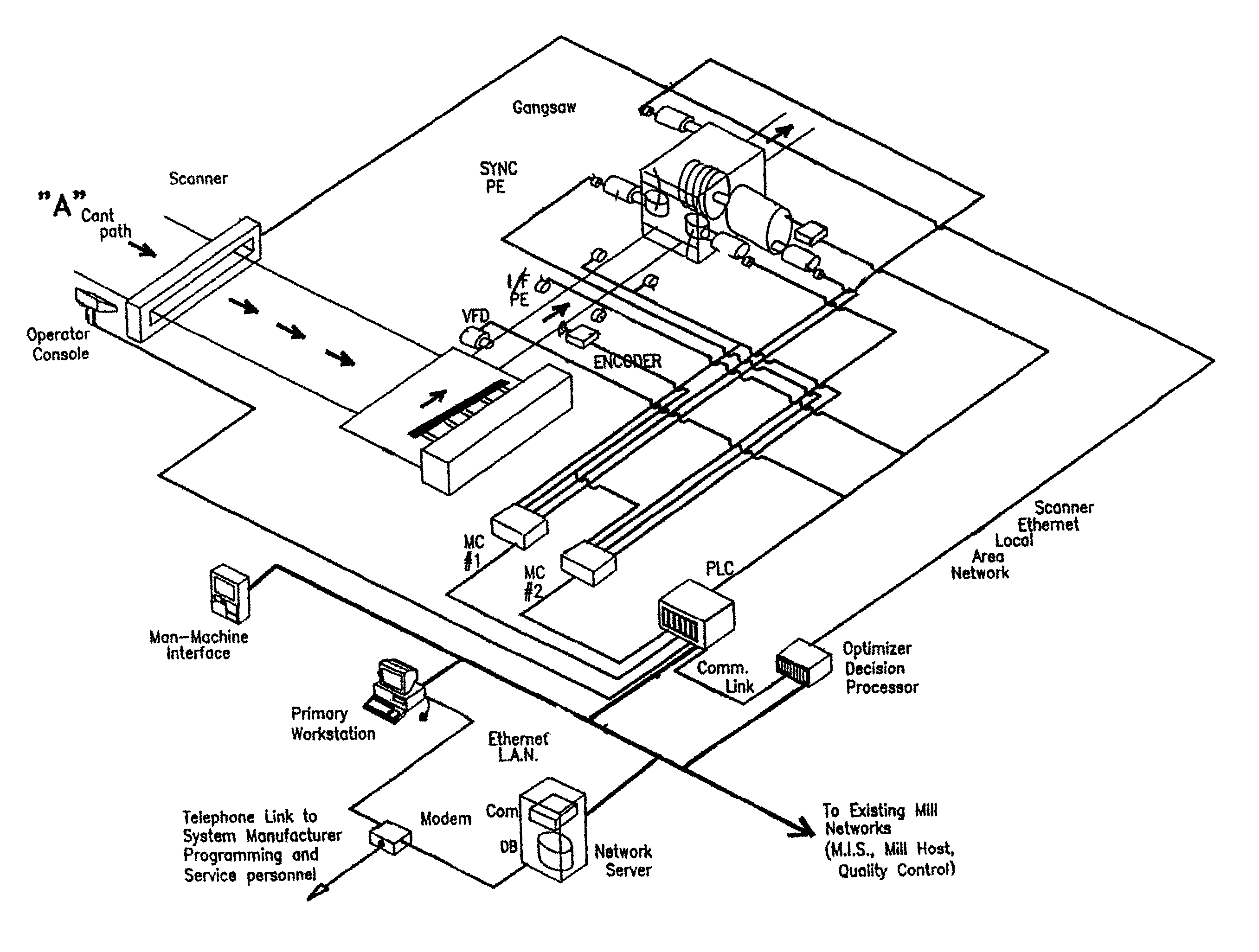

Lumber processing system

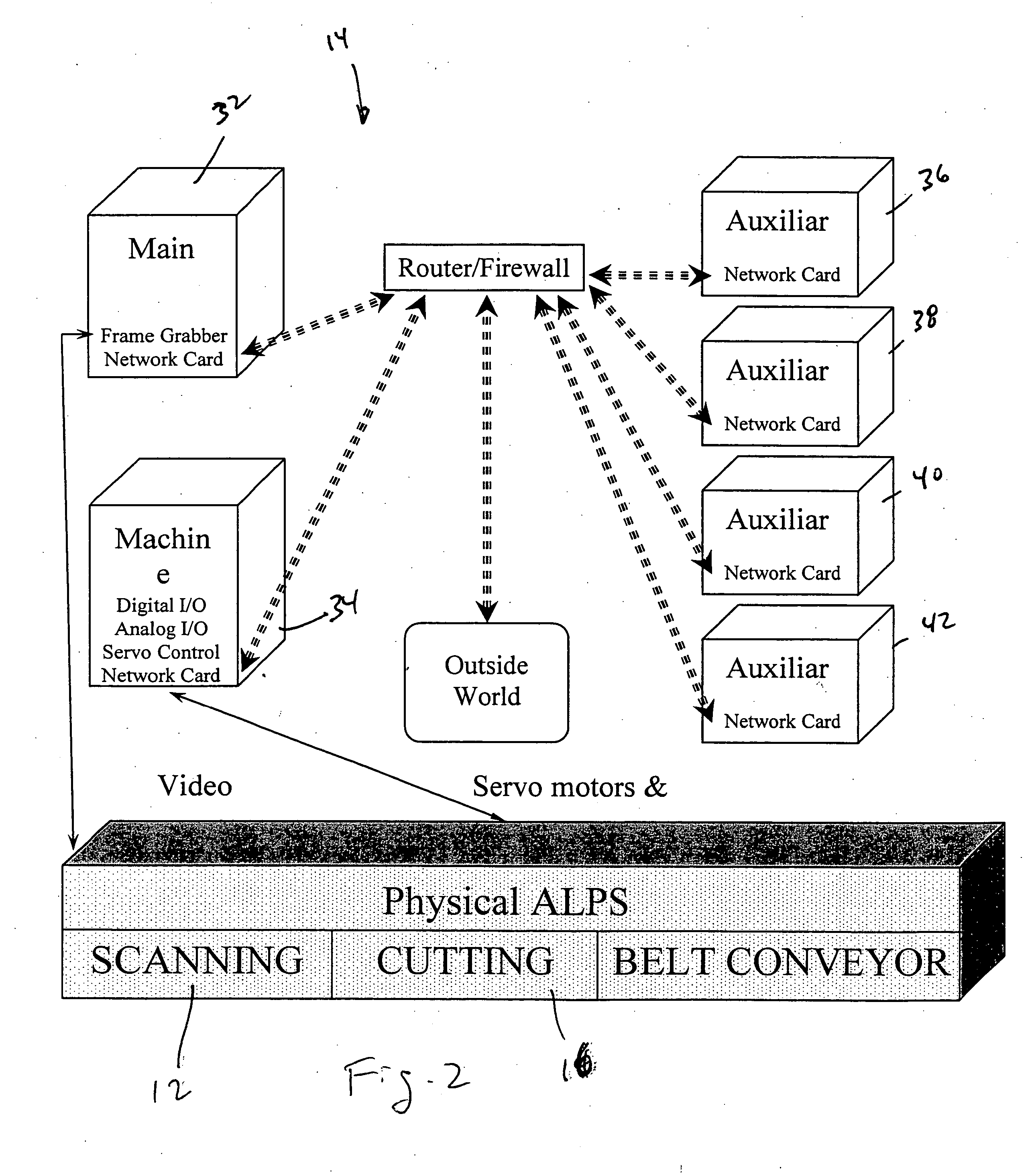

InactiveUS20070034297A1Multi-purpose machinesIrregularity removal devicesHigh power lasersComputer graphics (images)

A lumber processing system for cutting lumber into predetermined shapes broadly includes a scanning section, a computer section and a cutting section. Incoming lumber is scanned in the scanning section using two-color cameras capturing images first under normal lighting and second under ultraviolet (black) lighting for illumination of pre-marked defects. Images are processed in the computer section to produce a polygonal model of the lumber. A series of auxiliary packing computers review the model and determine separate solutions for cutting the lumber. Parts are then ‘punched’from the lumber in the cutting section utilizing high power lasers cutting from both sides of the lumber simultaneously.

Owner:REMINGTON ARMS

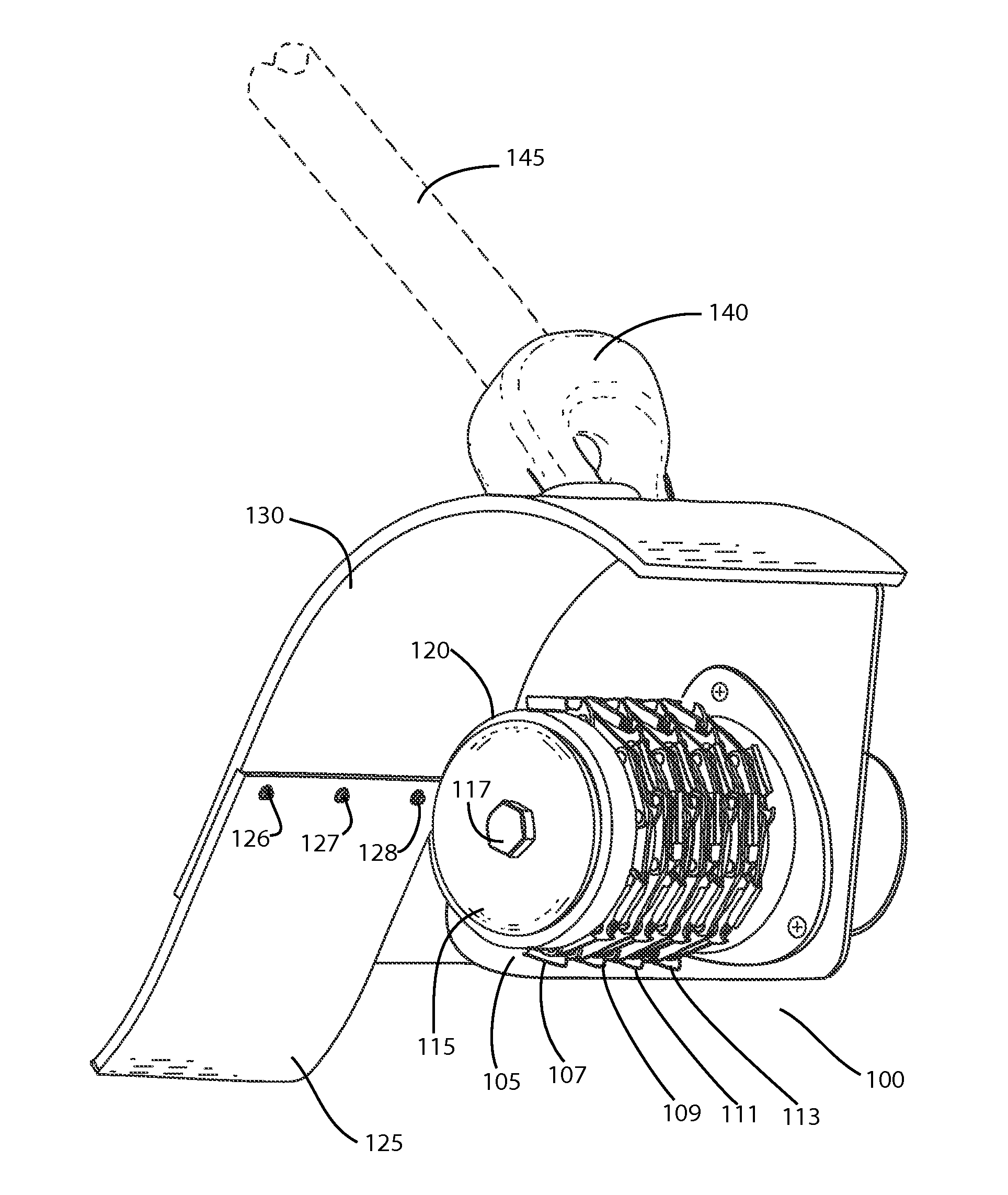

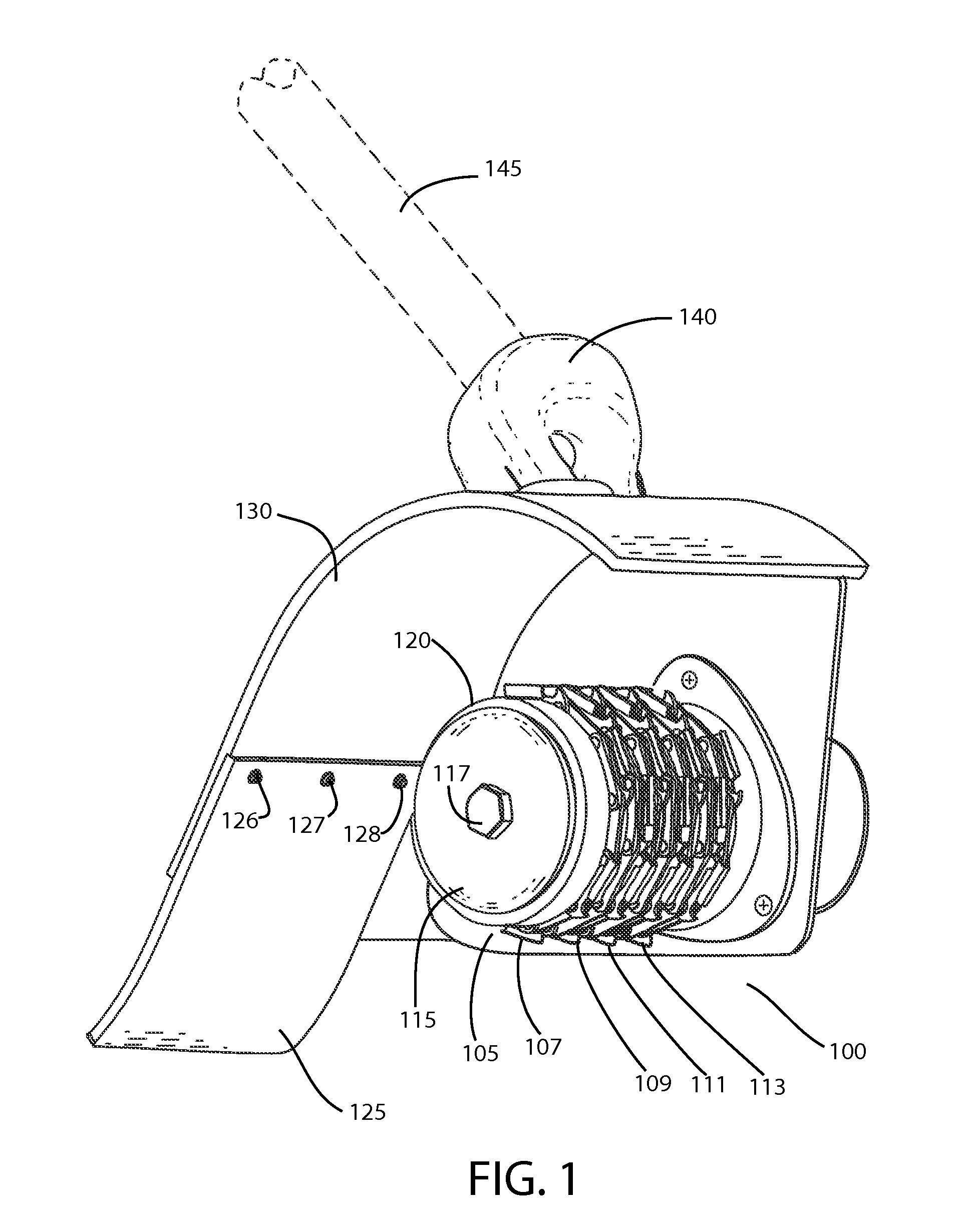

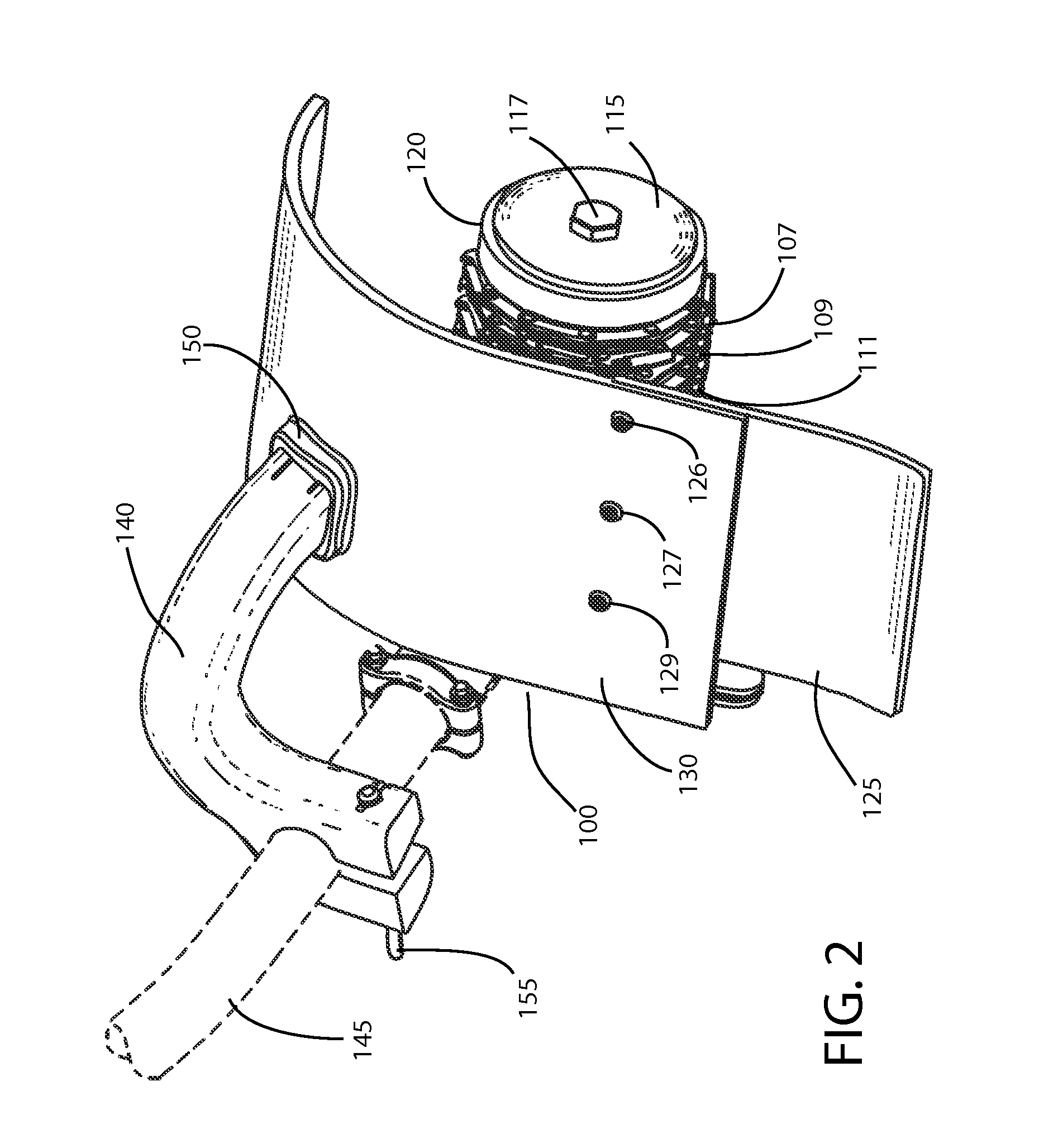

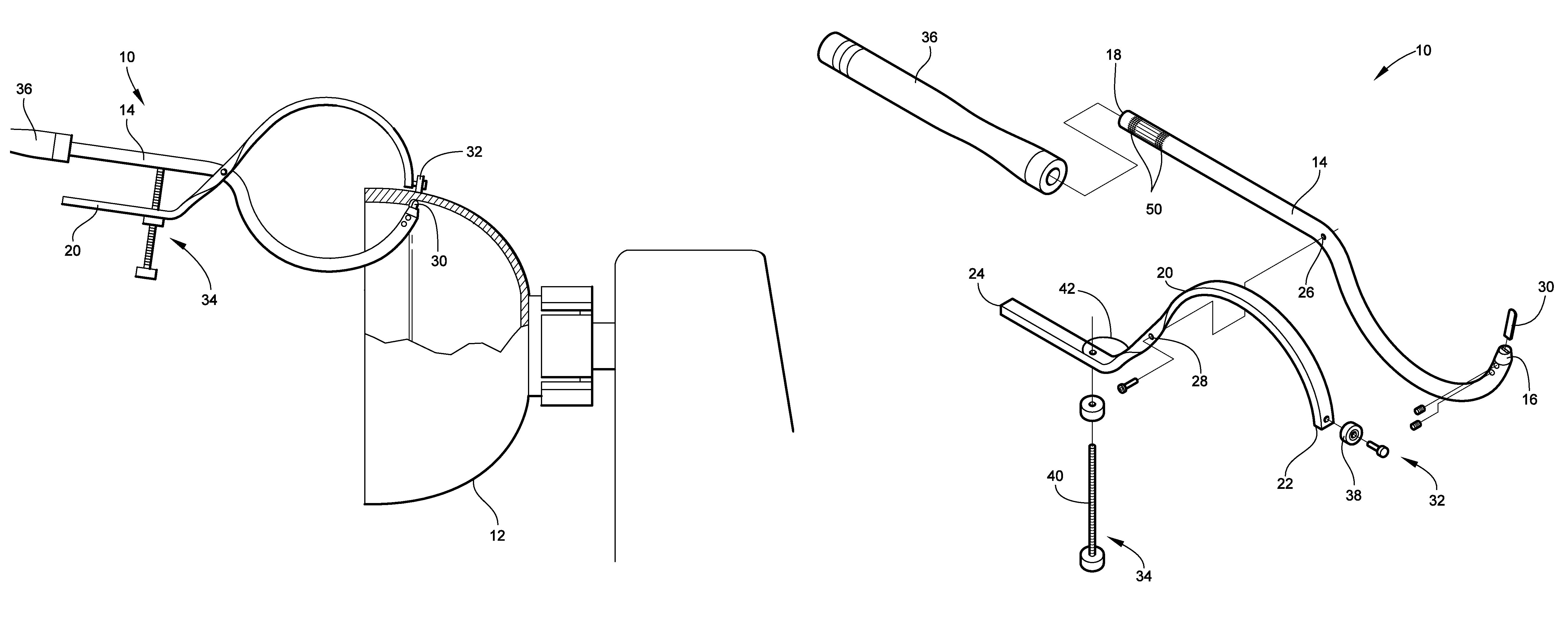

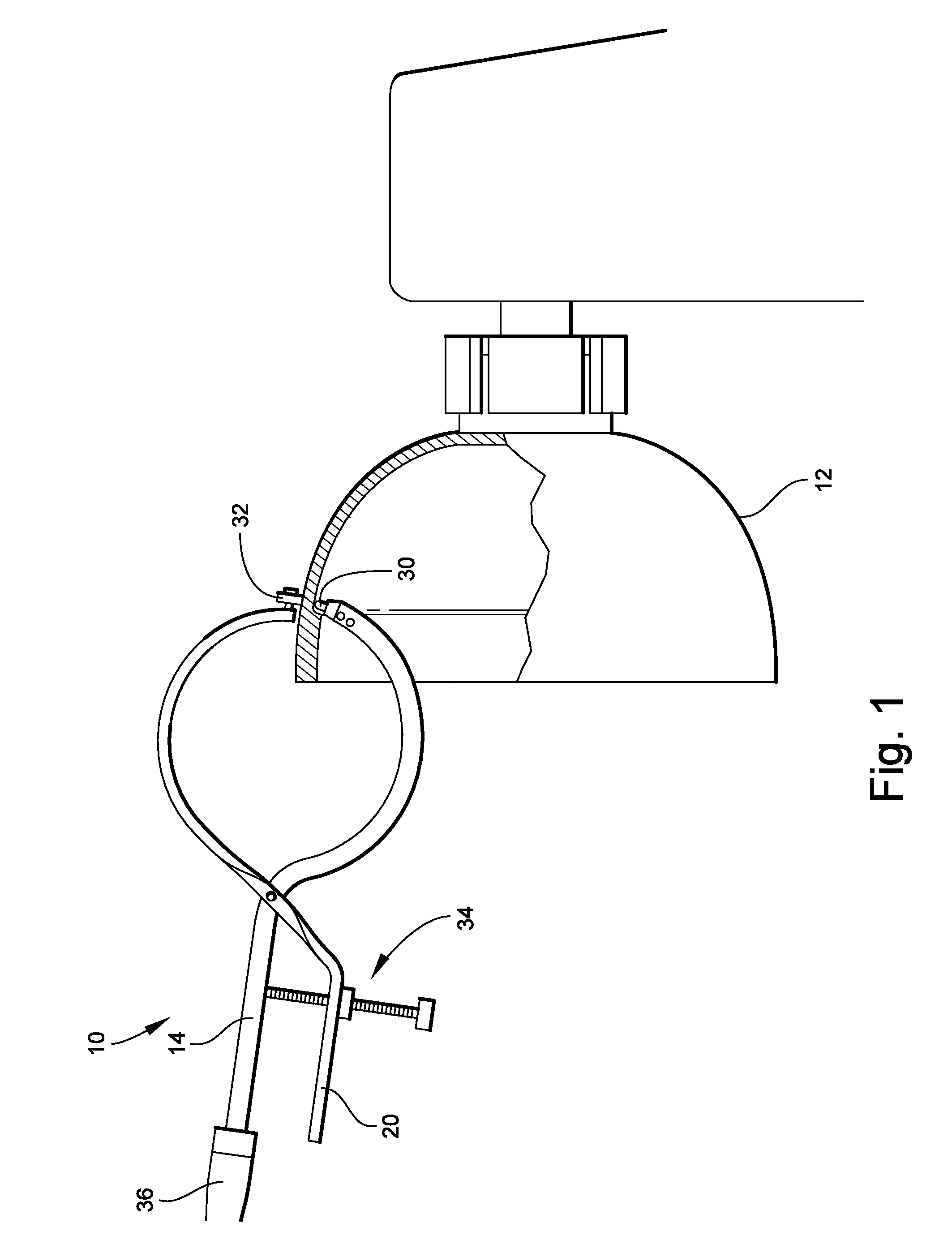

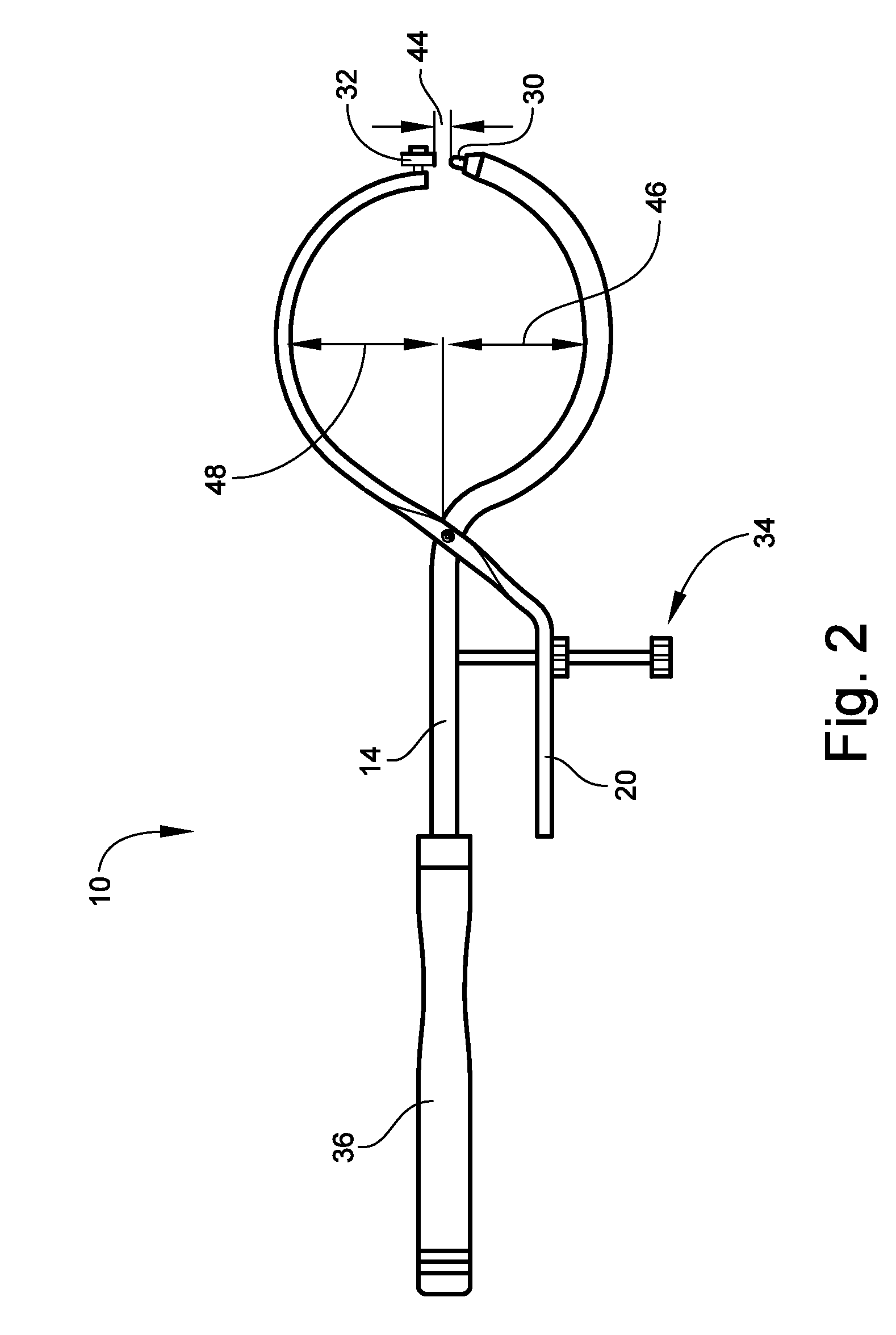

Root resurfacing attachment for hand held gas powered edgers

ActiveUS20120180906A1Efficient grindingWooden sticks manufactureMulti-purpose machinesTree rootHand held

A rotating cutting head includes multiple, separate, spaced-apart, parallel loops of chainsaw chains positioned around a central hub. The hub is attached to a spindle of a lawn edger. A safety shield is provided adjacent to the rotating cutting head. As the cutting head rotates, the chainsaw chains cut the tree roots. The rotating cutting head is used for resurfacing exposed tree roots to avoid tripping hazards and tree root strike damage to residential and commercial lawn maintenance equipment.

Owner:RBGONE

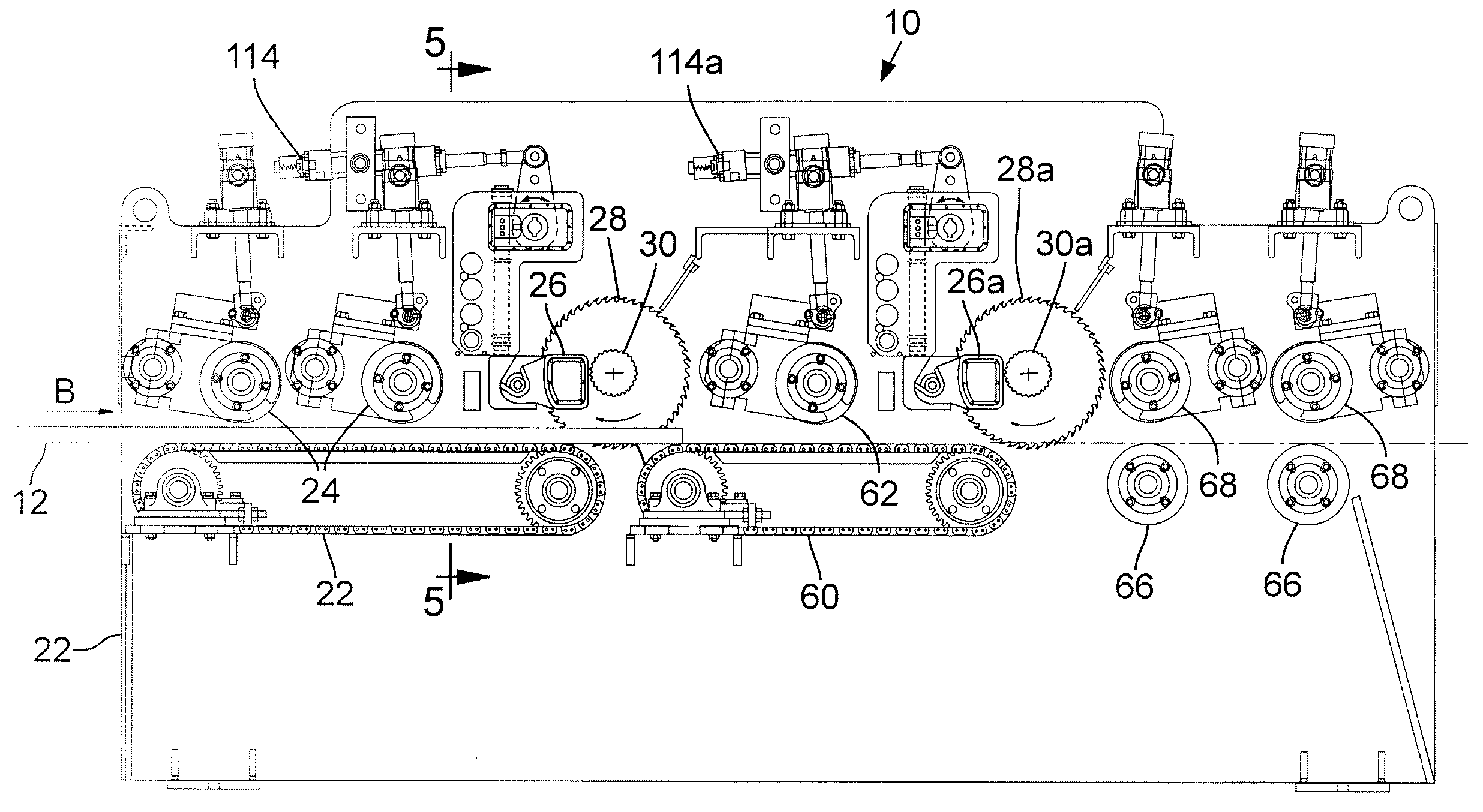

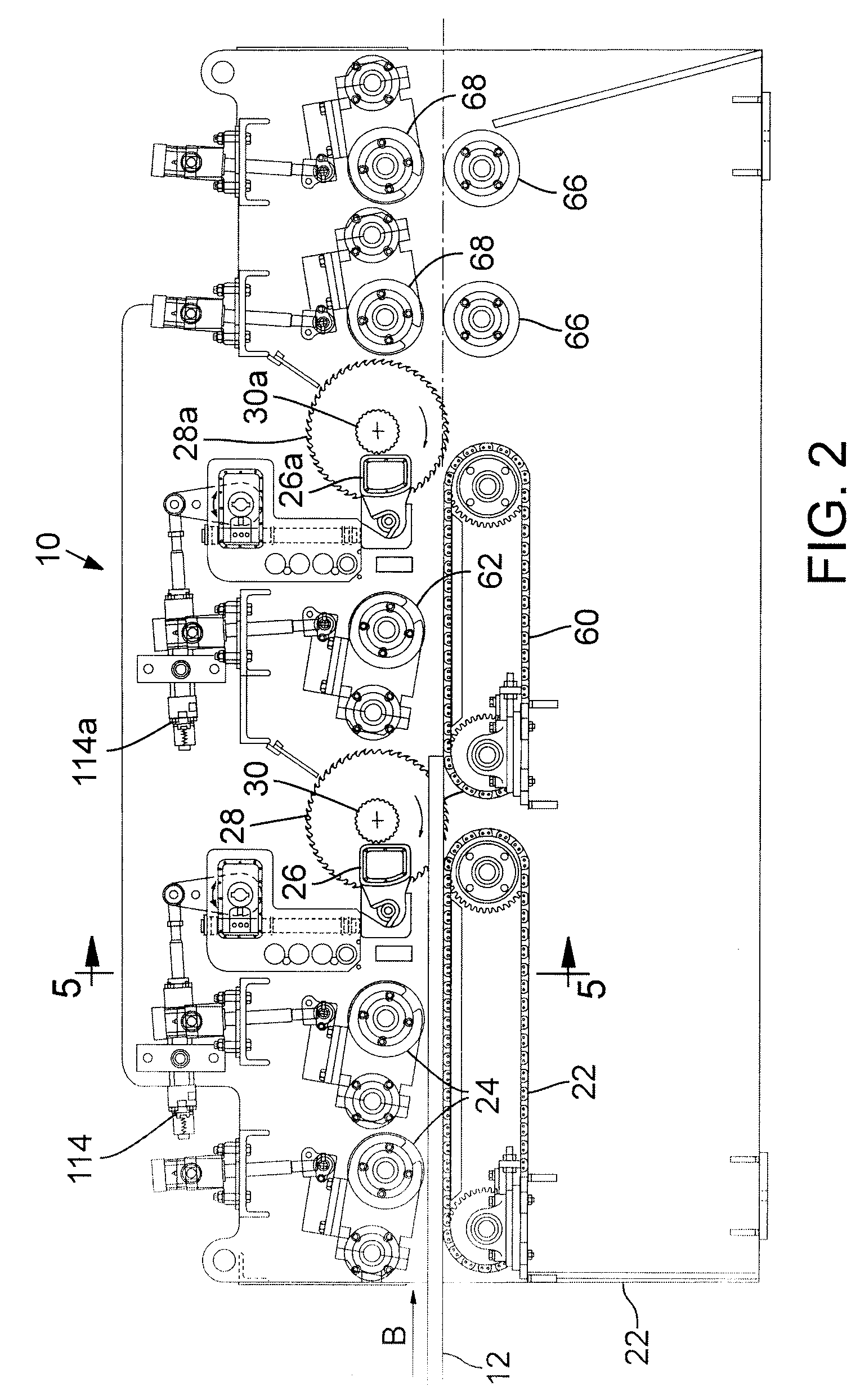

Edger with staggered saws

InactiveUS20080314478A1Most recoveryPromote recoveryMulti-purpose machinesFeeding apparatusWood processorEngineering

Embodiments of the present invention provide a wood processing machine adapted to cut wood workpieces along multiple optimized cutting paths. In various embodiments, the wood processing machine includes a first saw assembly and a second saw assembly that is disposed down stream from the first saw assembly. The first saw assembly is adapted to cut the workpiece along the first optimized cutting path and the second saw assembly is adapted to cut the workpiece along the second optimized cutting path.

Owner:USNRKOCKUMS CANCAR

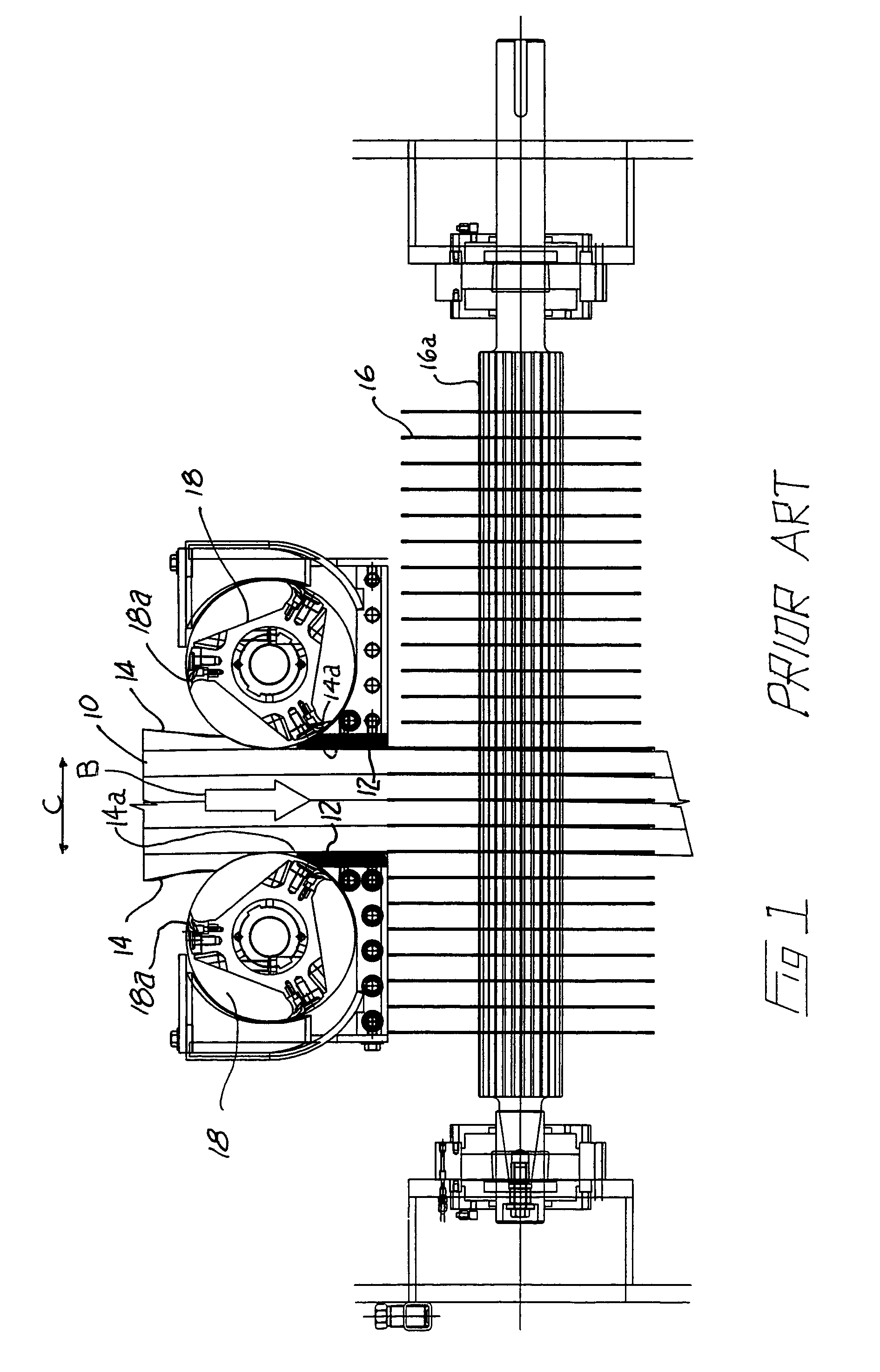

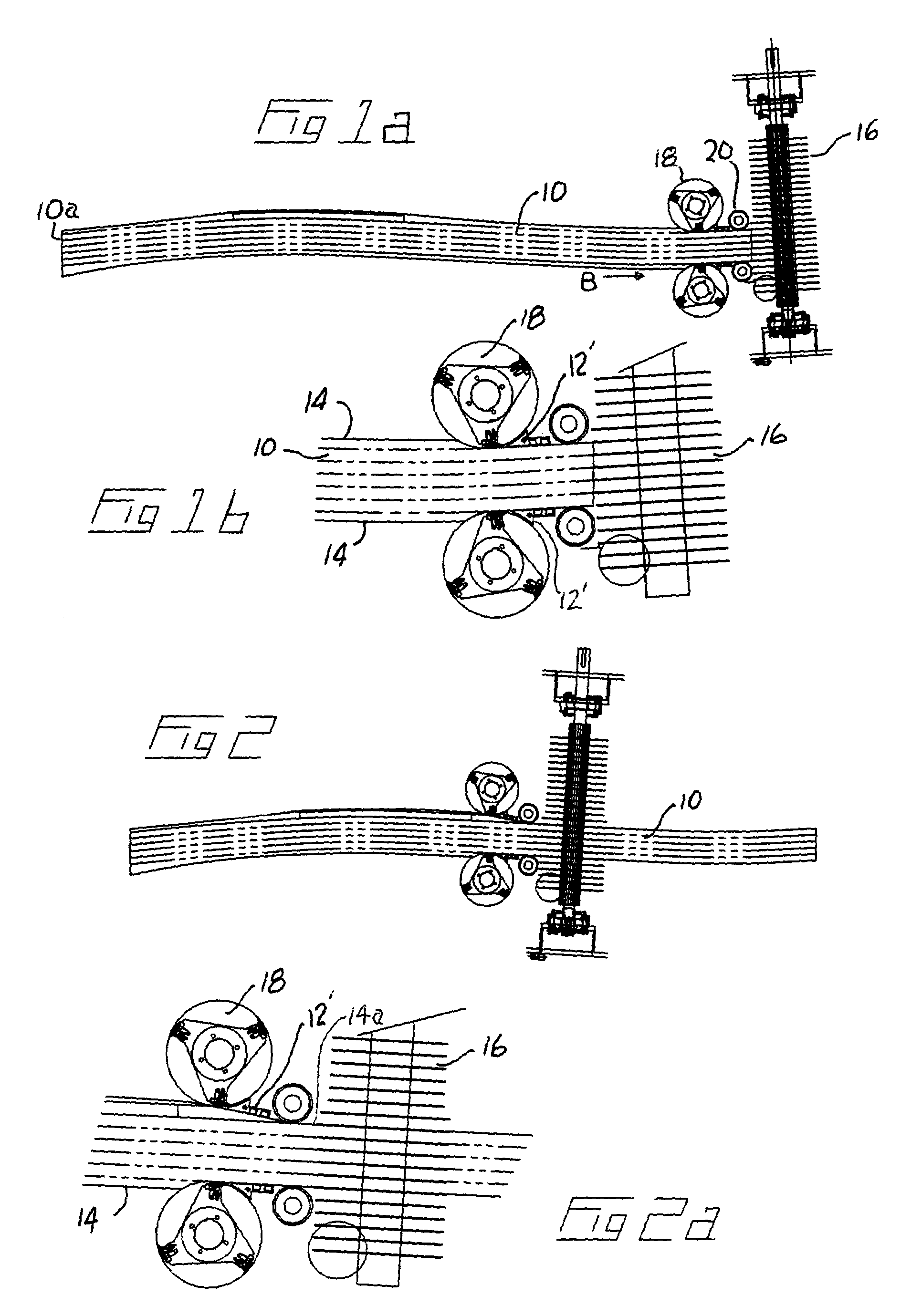

Apparatus for sawing a workpiece

InactiveUS6991012B2Improve stabilityReduce distanceAutomatic control devicesWooden sticks manufactureEngineeringHome position

A method of forming a workpiece into sectioned parts using a pair of laterally translatable chipping heads and, downstream, a cutting device of the type having a plurality of rotatable cutting members mounted for rotation on a common axis which is movable and including workpiece transport means for moving the workpiece from a starting position to a final position along a path which extends first past the chipping heads and then past the cutting device.

Owner:USNRKOCKUMS CANCAR

Distressing process and apparatus for applying such process

InactiveUS8051886B2Simple resultWooden sticks manufactureAutomatic control devicesDistressingEngineering

Owner:UNILIN FLOORING NC

Edger with staggered saws

InactiveUS7861754B2Promote recoveryIncrease valueMulti-purpose machinesFeeding apparatusWood processorEngineering

Embodiments of the present invention provide a wood processing machine adapted to cut wood workpieces along multiple optimized cutting paths. In various embodiments, the wood processing machine includes a first saw assembly and a second saw assembly that is disposed down stream from the first saw assembly. The first saw assembly is adapted to cut the workpiece along the first optimized cutting path and the second saw assembly is adapted to cut the workpiece along the second optimized cutting path.

Owner:USNRKOCKUMS CANCAR

Woodturning tool

A woodturning tool for creating containers has a first rigid arm, and a second rigid arm. The first rigid arm has two ends with a cutting blade at the first end. The second rigid arm has two ends with a guiding device at the first end. The cutting blade and the guiding device are operatively aligned. The first and second rigid arms are adapted to move relative to one another.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

Machining method of high-temperature-resisting barbecue bamboo sticks

ActiveCN107498664ABactericidalOxidizing abilityRadiation/waves wood treatmentWooden sticks manufactureSofteningMachining

The invention discloses a machining method of high-temperature-resisting barbecue bamboo sticks. The method is characterized by comprising following steps of firstly, bamboo stick machining, wherein a moso bamboo is machined through a machine into rough bamboo sticks, and through grinding, the bamboo sticks are obtained; secondly, sterilization, wherein ozone and a sterilization concentrated solution are used for sterilizing the bamboo sticks; thirdly, acid-base softening, wherein an acetate solution and a sodium hydroxide solution are used for heating and softening the bamboo sticks; fourthly, dipping, wherein the sterilization concentrated solution is added into functional liquid, and dipping is carried out at the temperature of 130 DEG C to 134 DEG C and 90 DEG C to 95 DEG C; fifthly, baking, wherein baking is carried out in three temperature areas of 120 DEG C to 130 DEG C, 150 DEG C to 160 DEG C and 90 DEG C to 95 DEG C, and the temperature rising and falling speed is controlled; sixthly, cleaning drying, wherein the bamboo sticks are boiled and cleaned in boiled water after the barbecue, drying is carried out, and the high-temperature-resisting barbecue bamboo sticks are obtained.

Owner:安徽久越竹业有限公司

Drumstick

InactiveUS20140311320A1Improve rigidityReduce vibrationWooden sticks manufactureElectrical transducersMechanical engineeringMicro spheres

Owner:GROSSMAN RICHARD D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com