Automatic machining production line device for bamboo toothpicks

An automatic processing and production line technology, applied in sugarcane mechanical processing, metal processing equipment, wood processing equipment, etc., can solve the problems of difficult product quality assurance, low efficiency, and increased labor costs, so as to reduce labor costs, improve product quality and Productivity, excellent usability and creative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

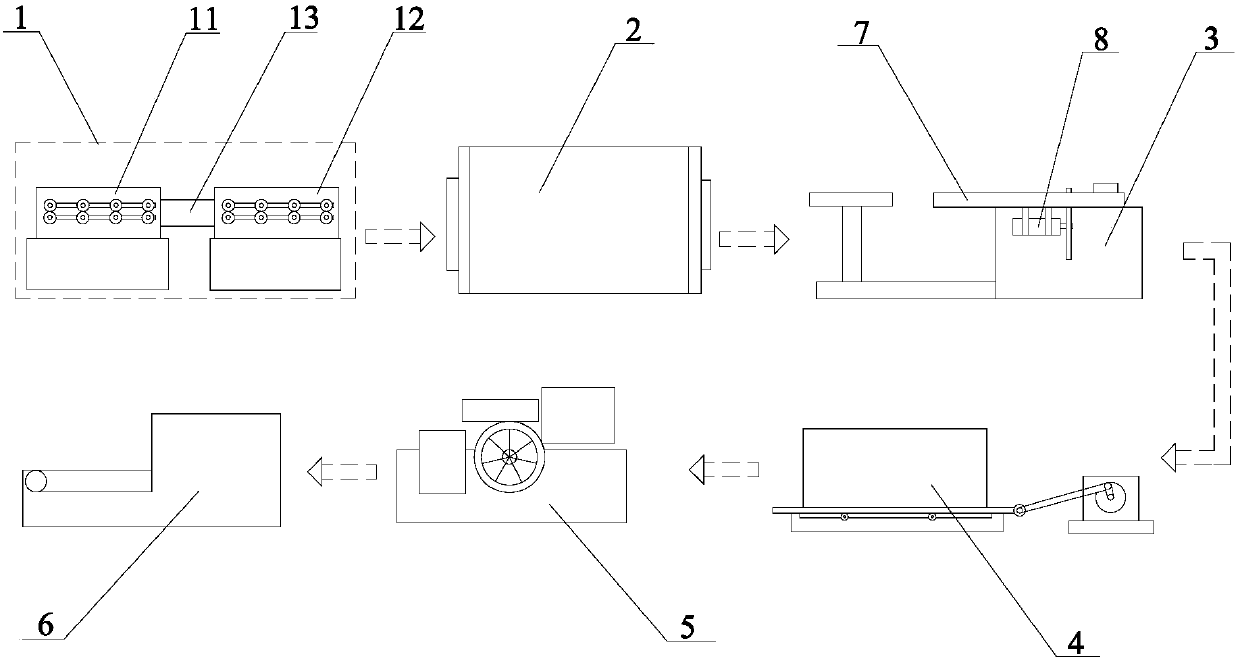

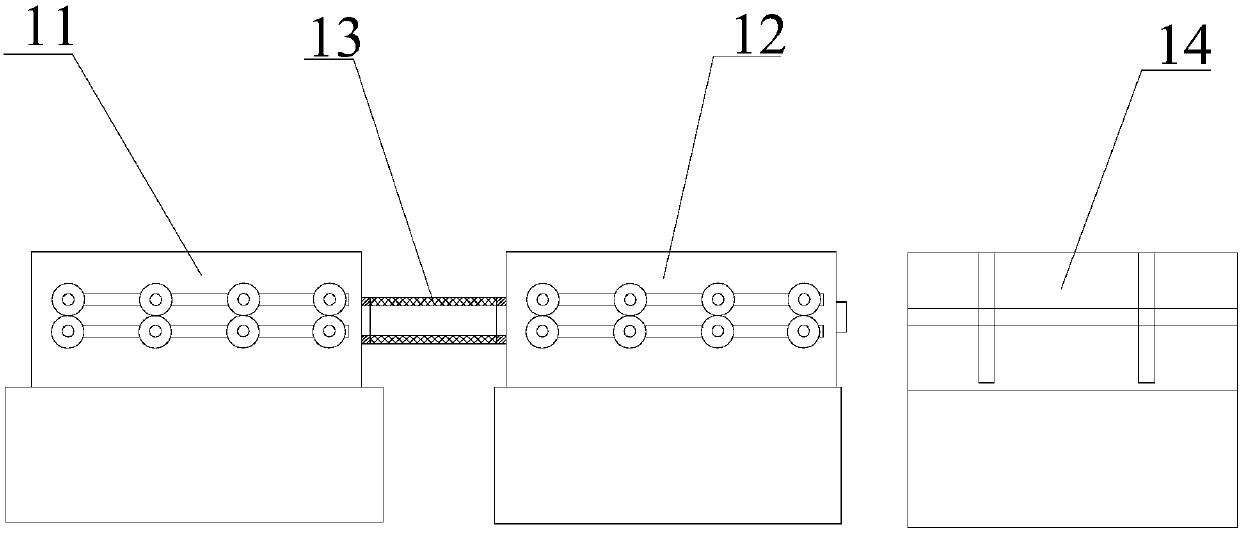

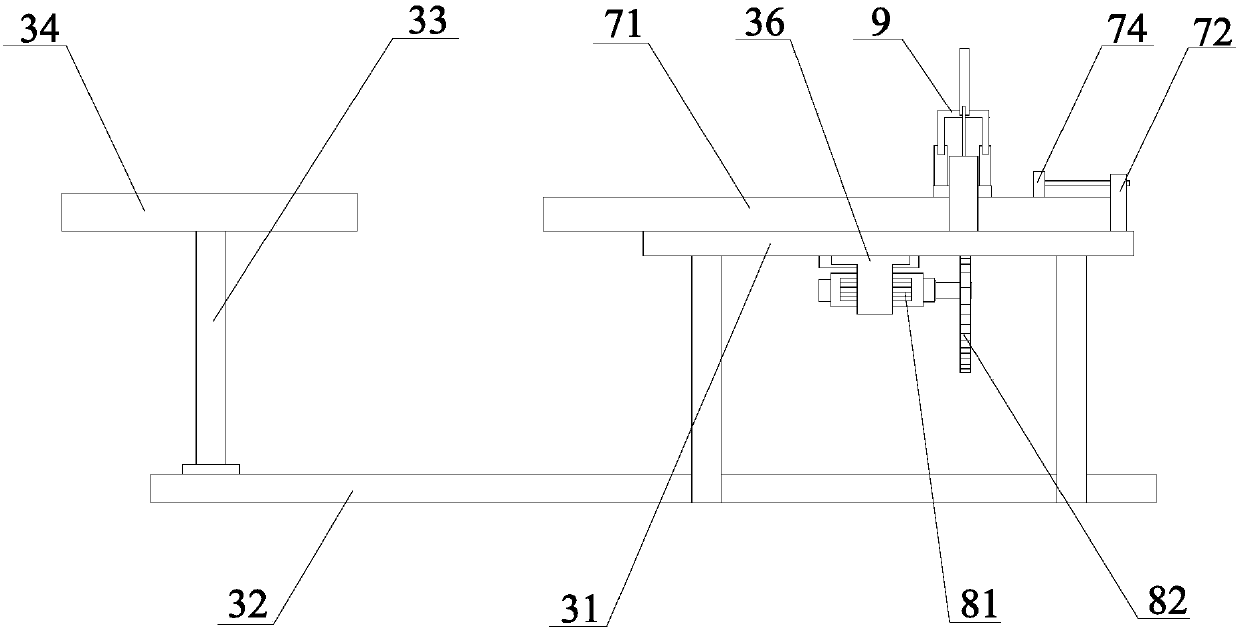

[0022] Such as figure 1 As shown, an automatic processing production line device for bamboo toothpicks, according to the processing flow, sequentially includes a conjoined wire drawing machine 1, a drying and carbonization chamber 2, a material cutting device 3, an automatic polishing and sorting device 4, a toothpick grinding device 5 and packaging machine 6; wherein, the conjoined spinning machine 1 is used to process the bamboo slices into bamboo filaments of a certain specification, the dry carbonization chamber 2 is used for drying and carbonizing the bamboo filaments, and the cutting device 3 is used to The dried and carbonized bamboo shreds are cut into fixed-length toothpicks, the automatic polishing and picking device 4 is used to polish the toothpicks, and the defective products are automatically picked out simultaneously, and the toothpick grinding device 5 is used to polish the toothpicks. The toothpick stick is carried out end grinding process, obtains the toothpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com