Integrated bamboo stick processing robot

A technology of robots and bamboo sticks, applied in the field of robots, can solve the problems of inability to realize the integration of bamboo stick processing, automation, large labor force, and single equipment function, and achieve the effects of compact structure, reduced labor intensity, and high degree of integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

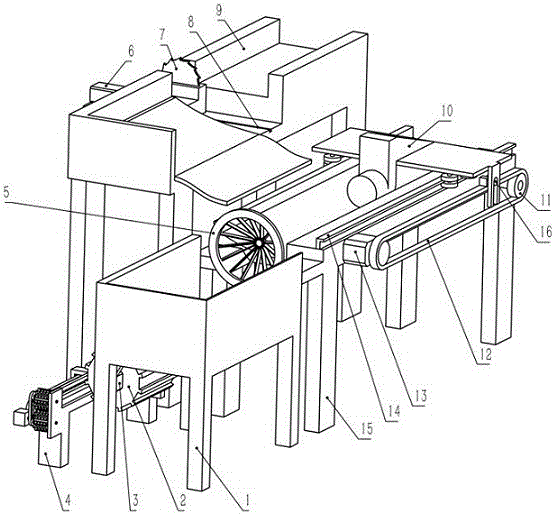

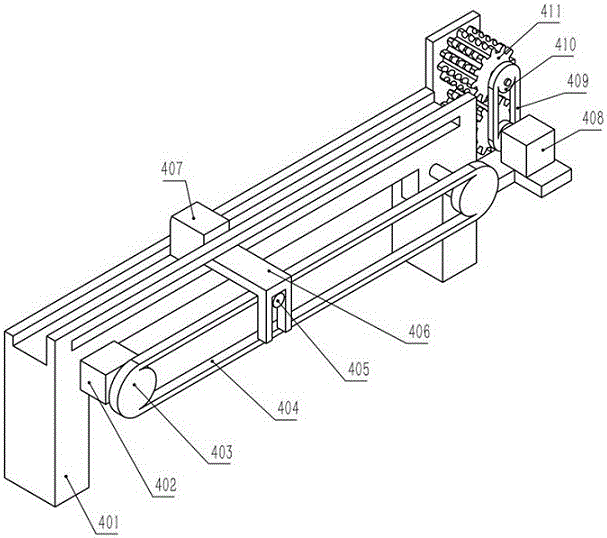

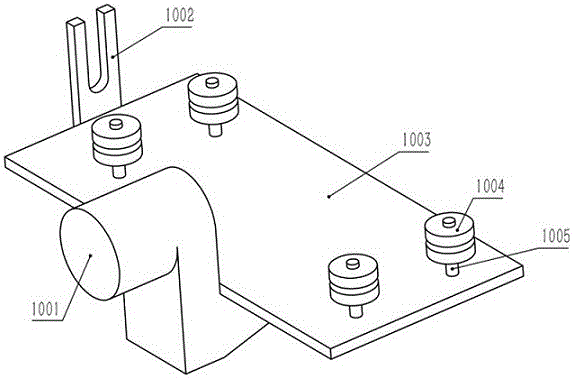

[0015] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, at first the third support 9 is set as the first step of bamboo stick processing, and the left half of the upper surface of the third support 9 is designed with a second curved surface 901 with a high back and a low front for receiving the cut bamboo. At the same time, it can automatically fall into the fourth bracket 15 installed in front of the third bracket 9 through the second arc surface 901, which is high at the back and low at the front; an adjustment area is arranged in the middle of the upper surface of the third bracket 9, and an adjustment area is provided on the bottom surface of the adjustment area. The dovetail groove 8, the bottom of the disc saw 7 is slidably installed in the dovetail groove 8 on the adjustment area, the rear end of the disc saw 7 is fixedly installed on the telescopic rod of the electric cylinder 6, and the cylinder body of the electric cylinder 6 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com