Drumstick

a drumstick and drum technology, applied in the field of drumsticks, can solve the problems of inability to maintain, damage wood causes to the cymbal, and inability to meet the needs of use, and achieve the effect of reducing vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

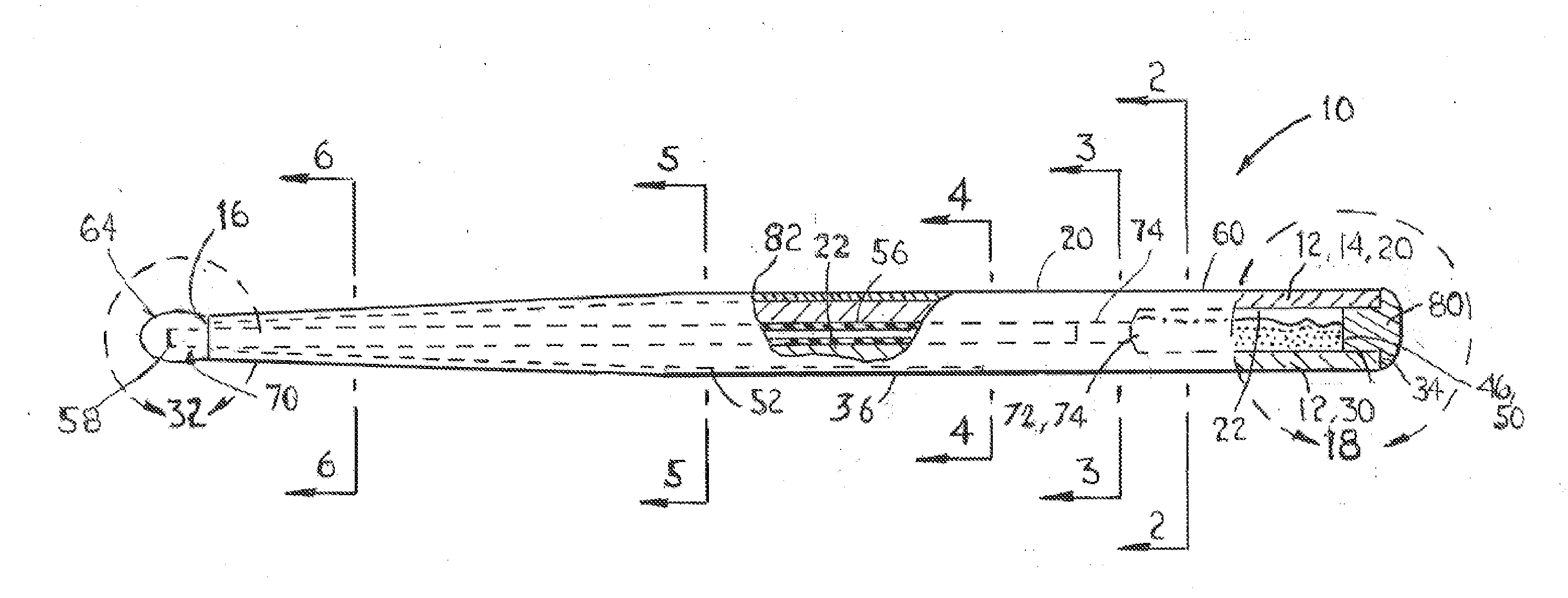

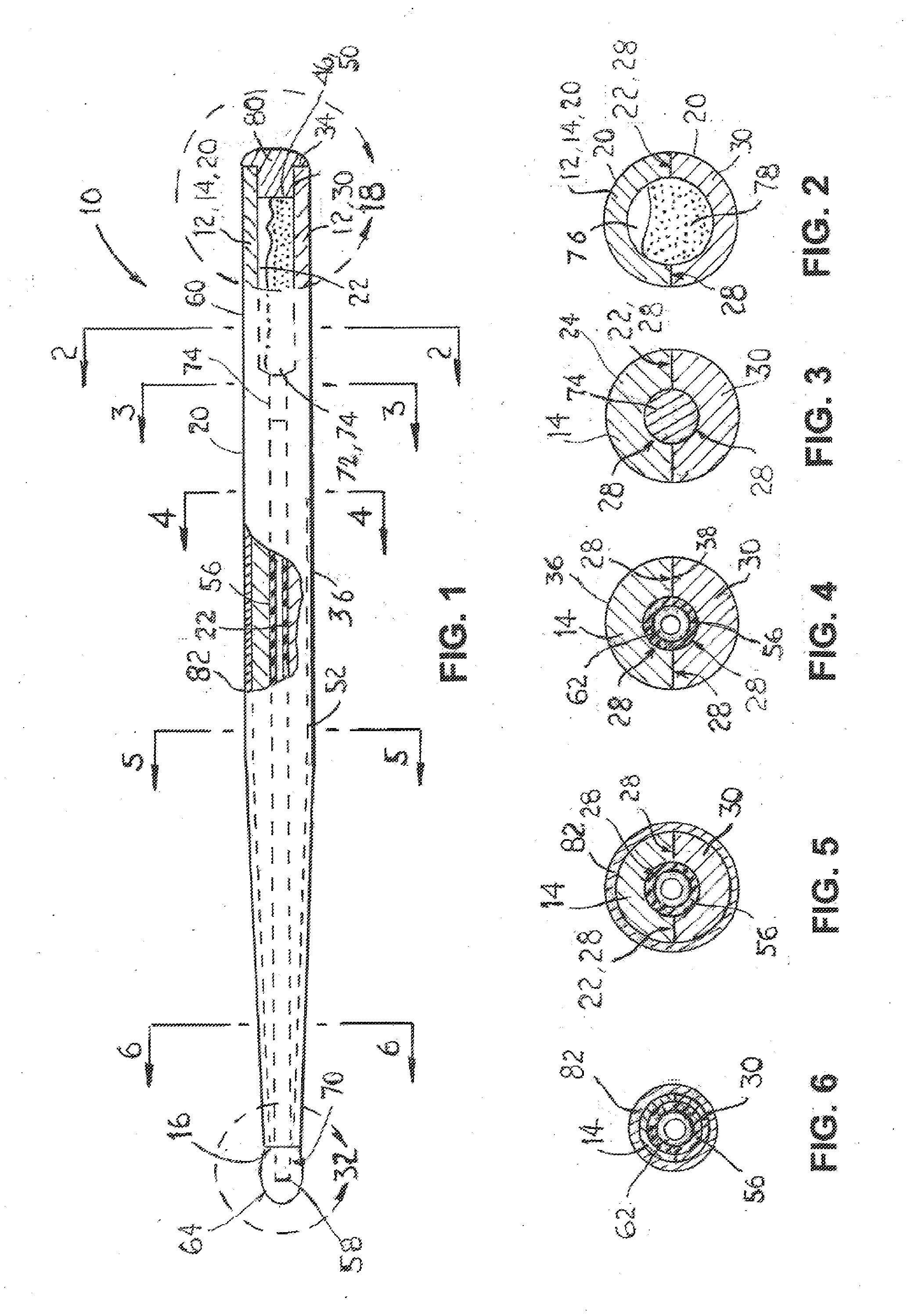

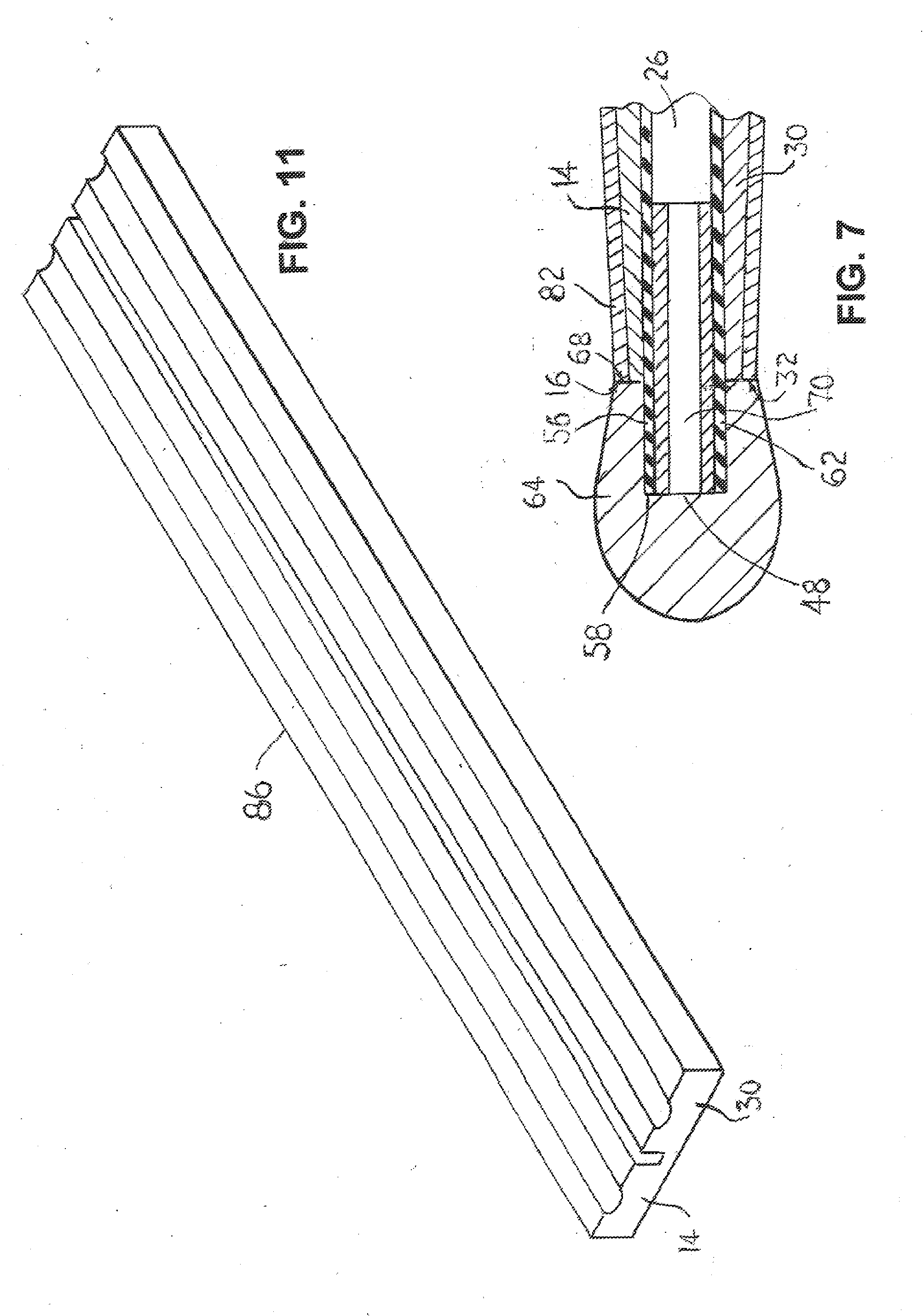

[0041]The best mode for carrying out the invention is presented in terms that disclose a preferred embodiment of a drumstick. The preferred embodiment, as shown in FIGS. 1-17, is comprised of the following major elements: the drumstick 10, an elongated structure 12, a core tube 56, a metal bushing 62, a drumstick tip 64, an obstruction 72, a multiplicity of glass micro-spheres 78, a rear cap 80 and a resilient sleeve 82.

[0042]The elongated structure 12, as shown in FIGS. 1-17, is comprised of a first section 14 and a second section 30. The first section 14 has a front end 16, a rear end 18, a radiused outer surface 20 and a flat inner surface 22. Extending from the front end 18 is a first cavity 75 followed by a second cavity 76. The flat inner surface 22 has a first half 24 of a radiused opening 26 that extends longitudinally across the elongated structure 12. The elongated structure 12 is made of wood that is preferably selected from the group consisting of hickory, maple and popl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com