Patents

Literature

124 results about "Wood processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

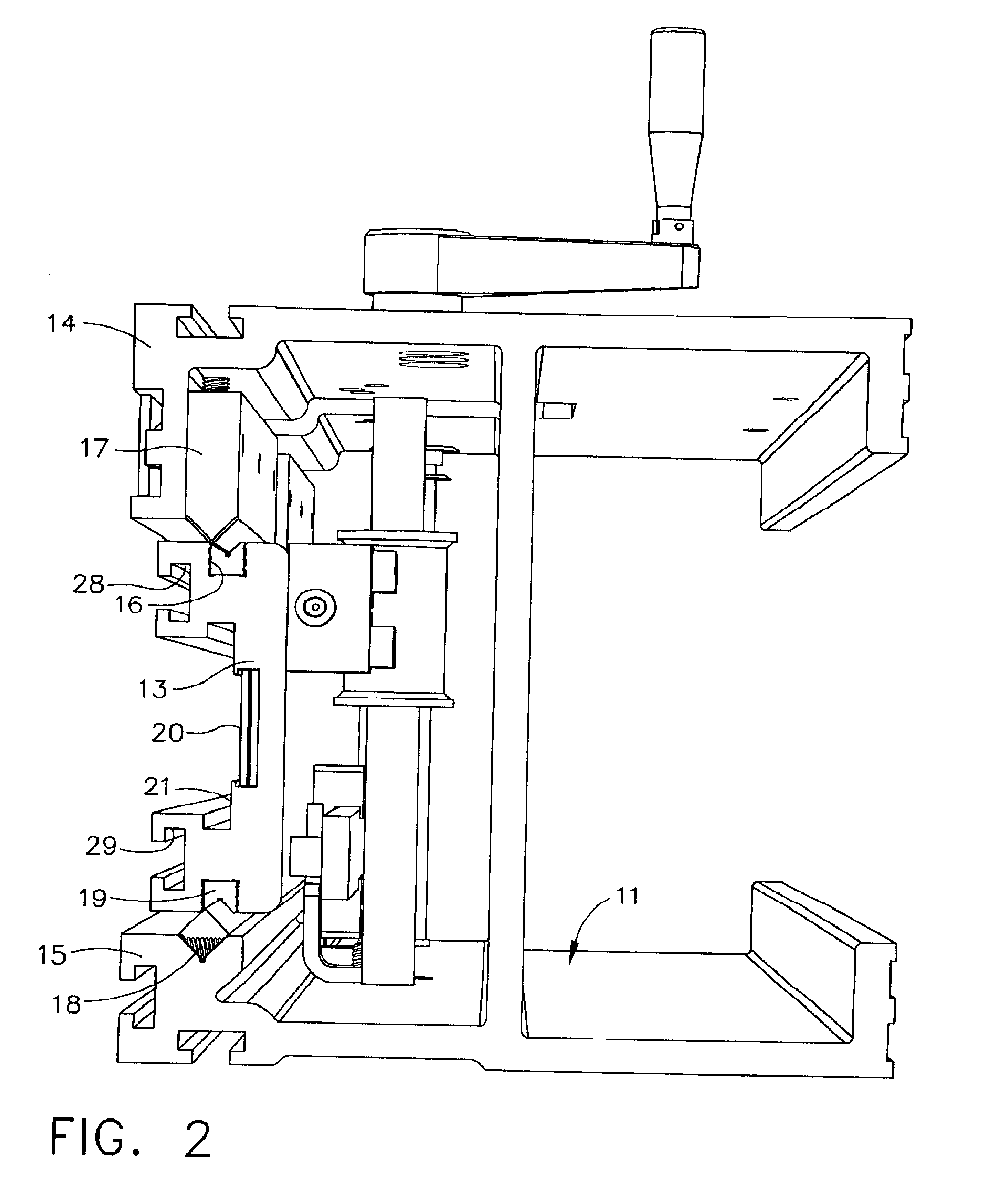

Wood Working Machine

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

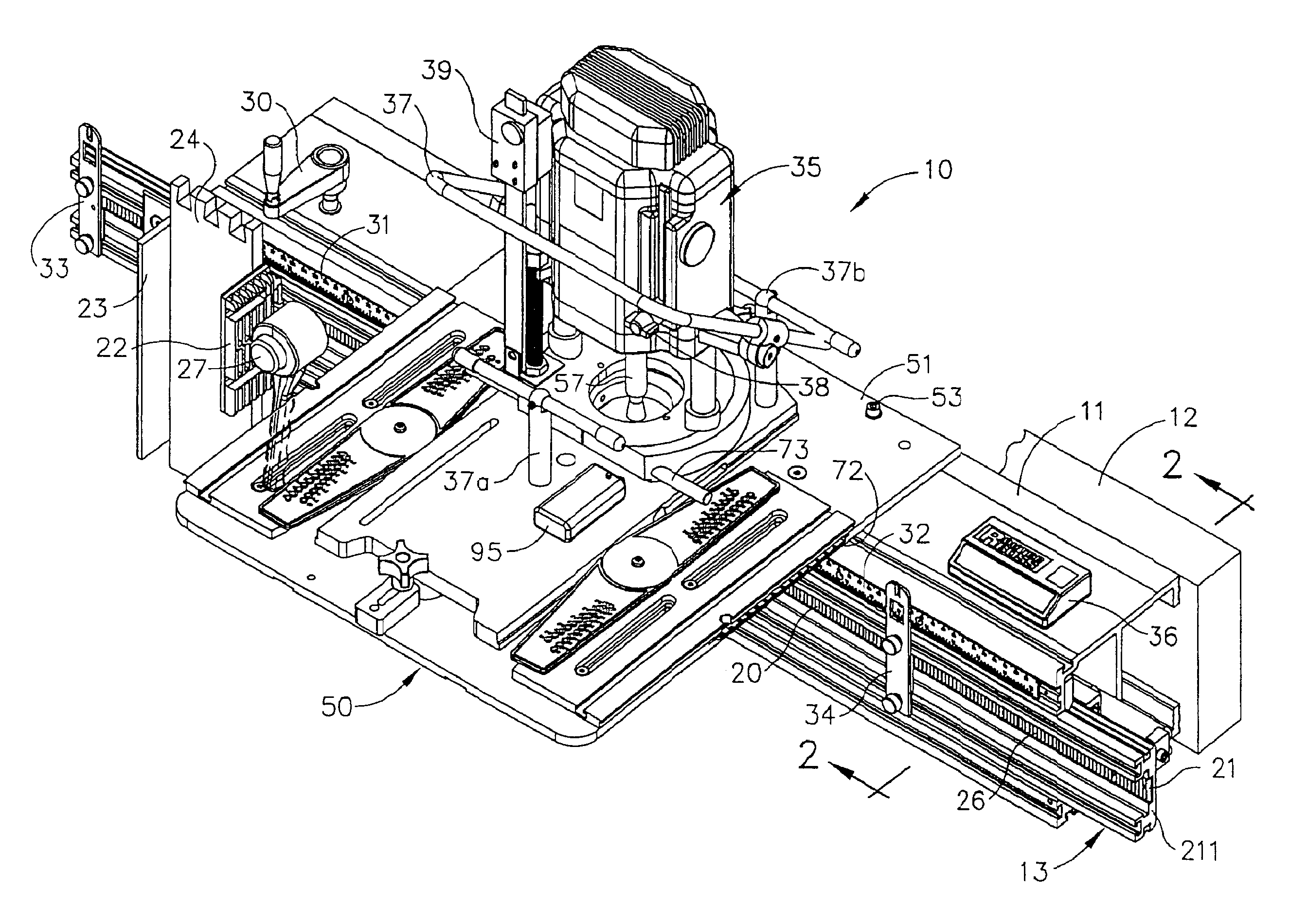

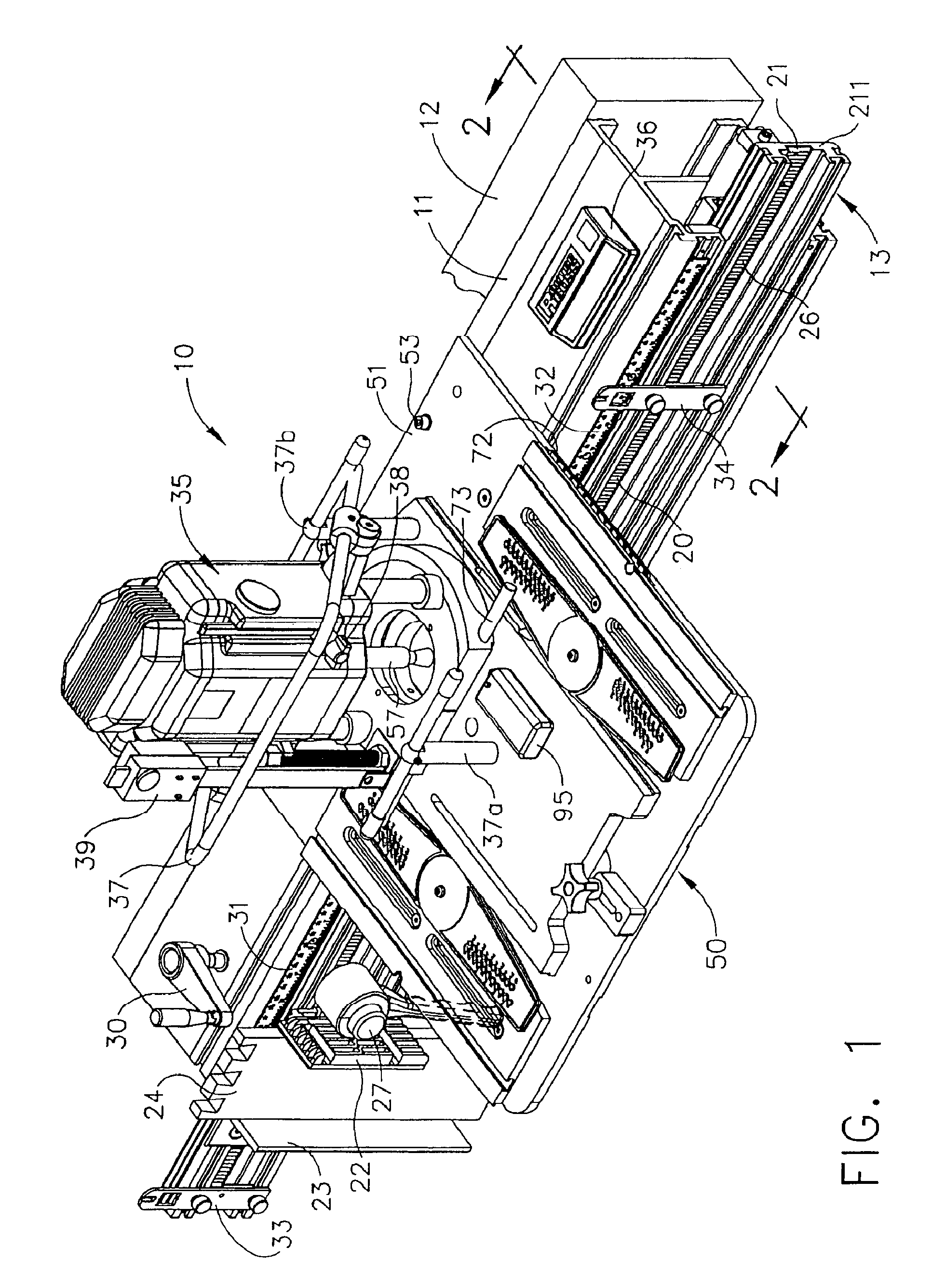

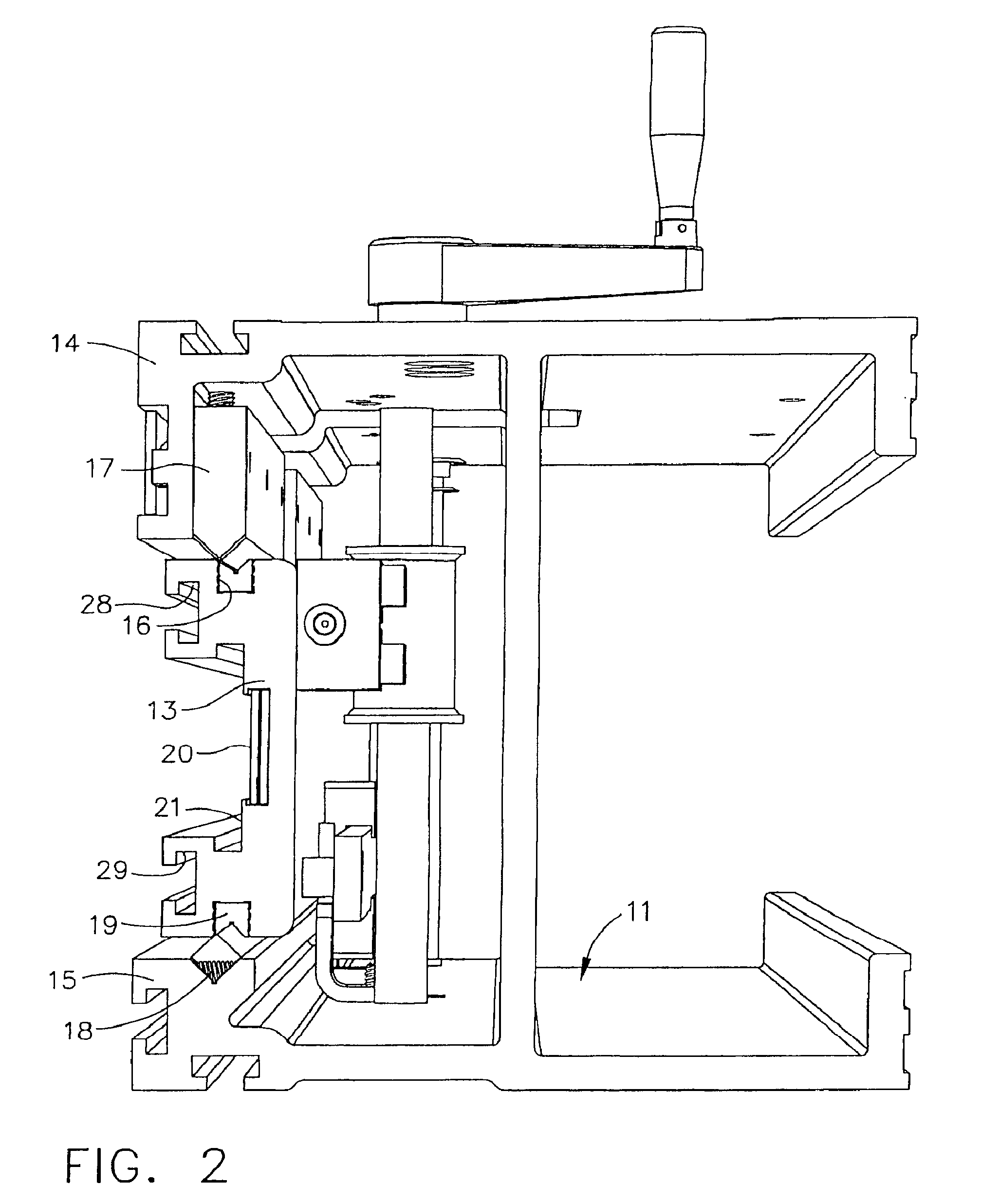

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

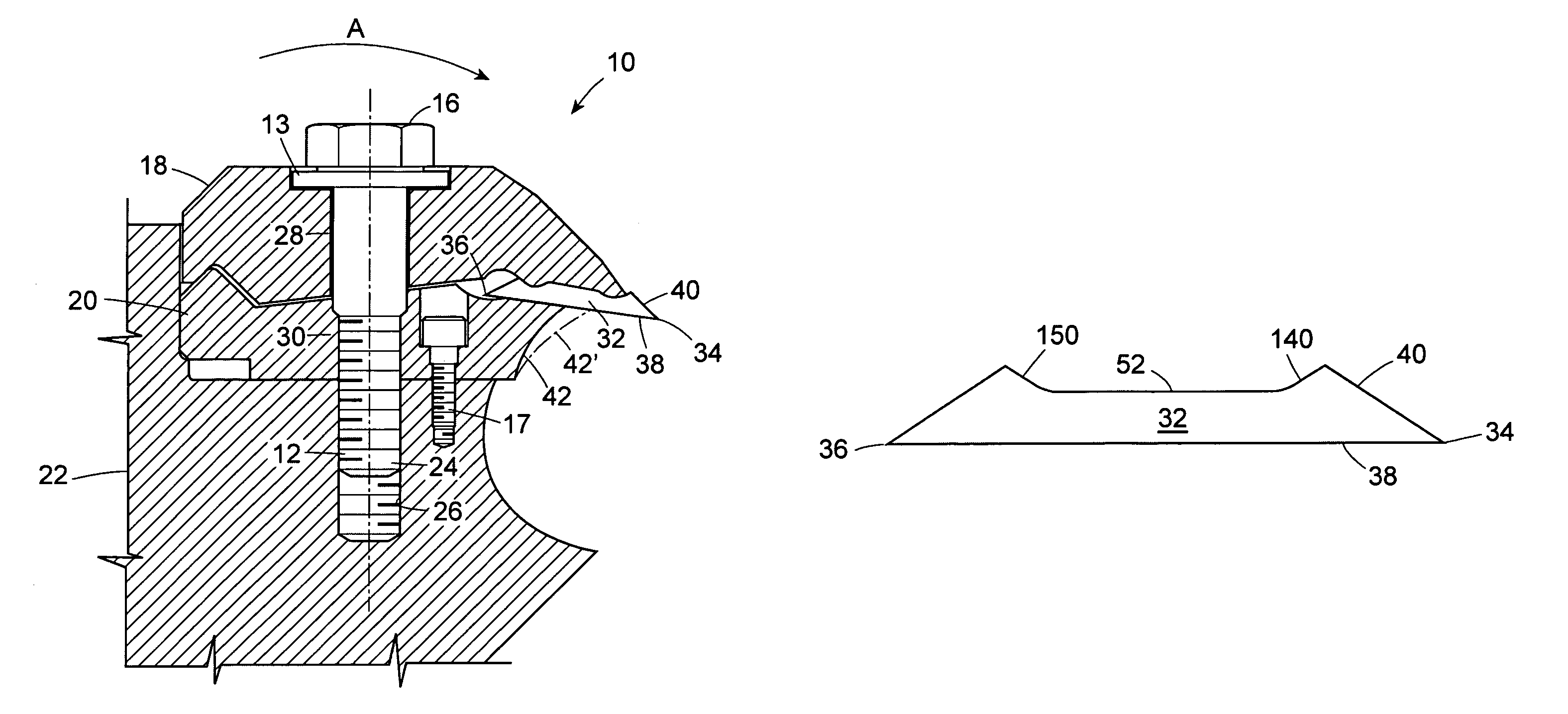

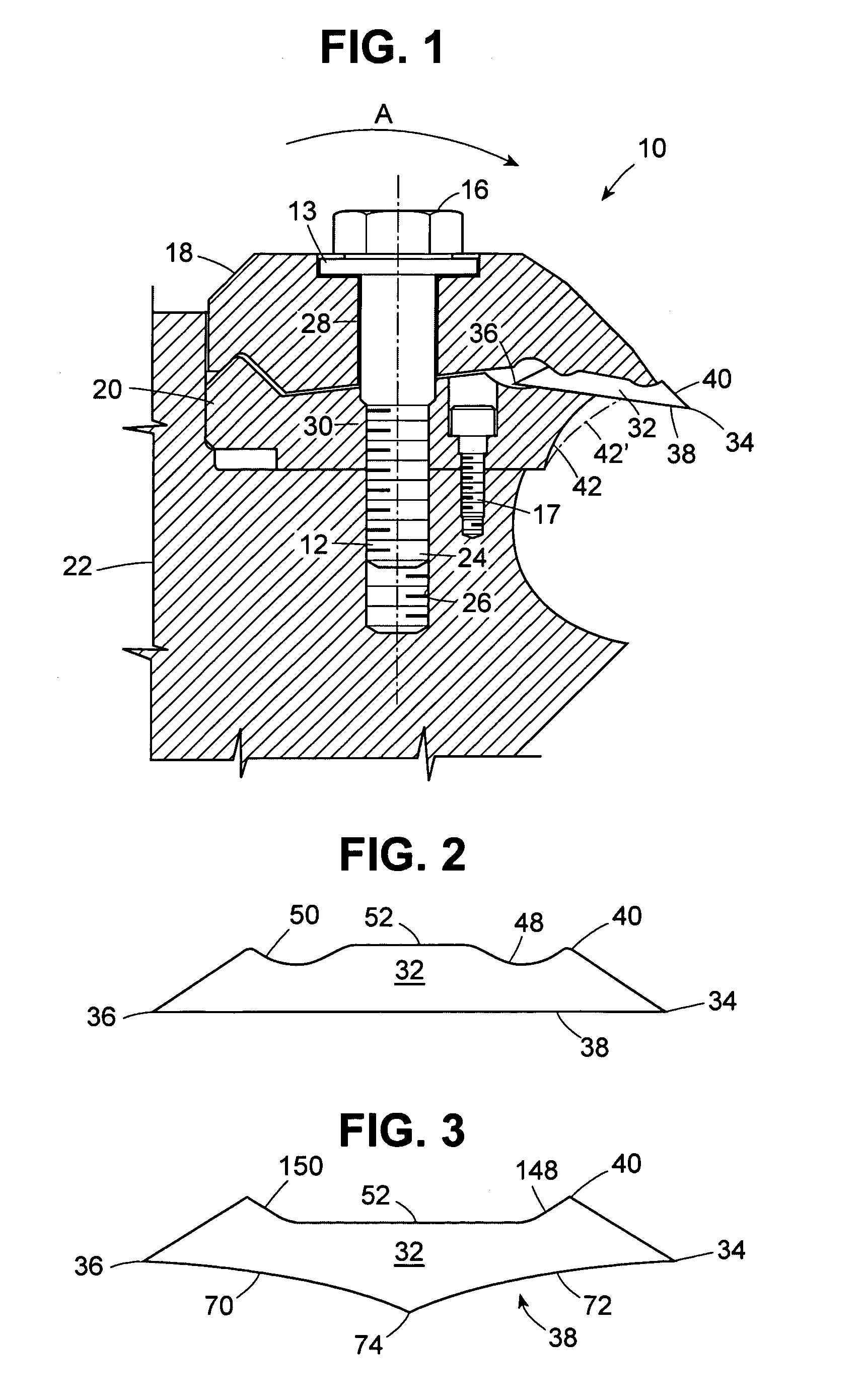

Multi-application wood working knife and clamping assembly

InactiveUS7159626B2Reduce riskAvoid prolonged useMulti-purpose machinesProfiling/shaping machinesWood processorEngineering

A wood working knife for use in a wood working machine, comprising a knife body having a first cutting edge and an opposed second cutting edge, the knife body having a first clamping surface and a second clamping surface. The first clamping surface has opposed clamping features separated by a middle section, the opposed clamping features and the middle section being sized and shaped such that, upon the knife body being inserted into a clamping assembly, the clamping forces are localized towards the opposed cutting edges and away from the middle section.

Owner:IGGESUND TOOLS

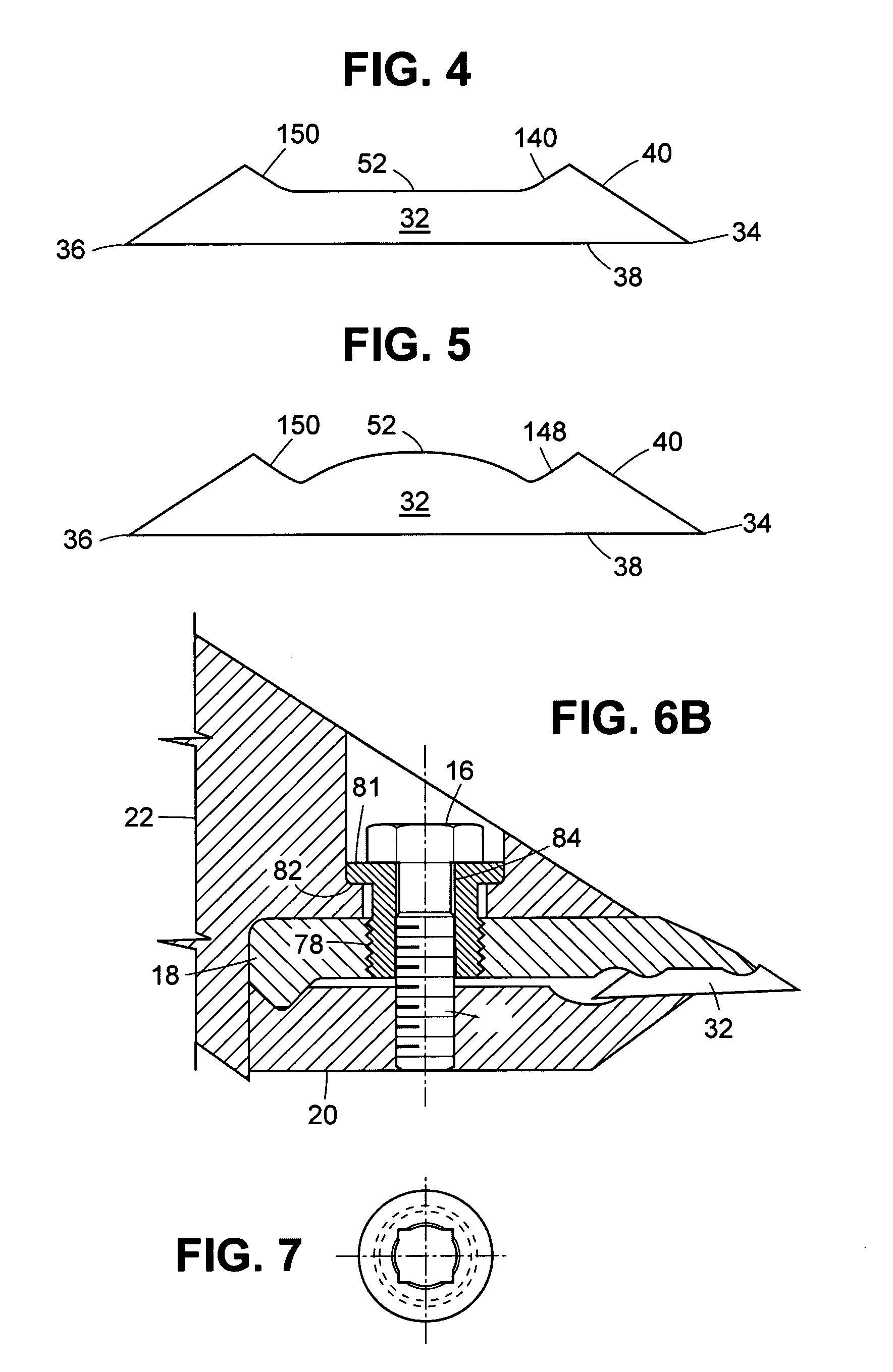

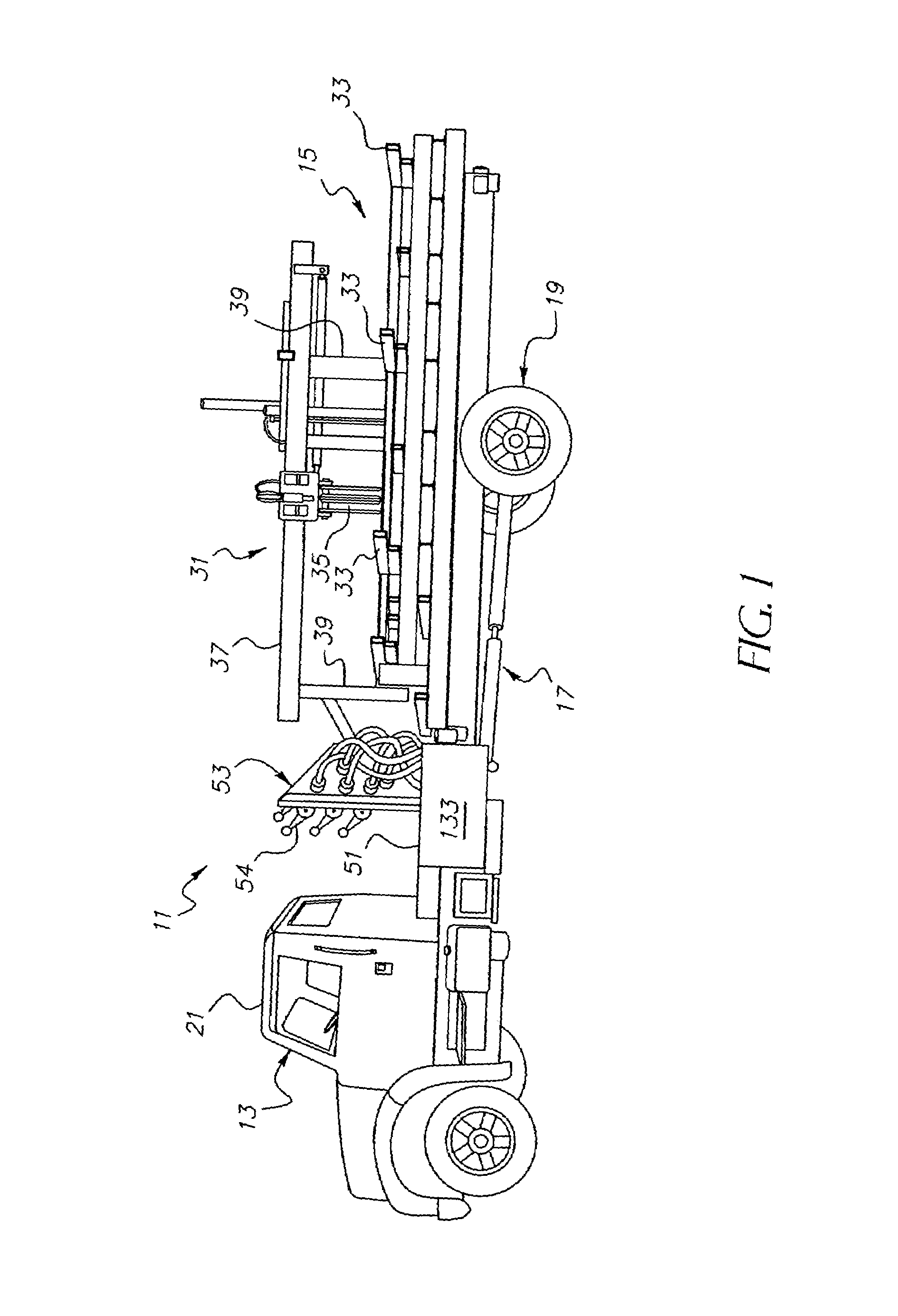

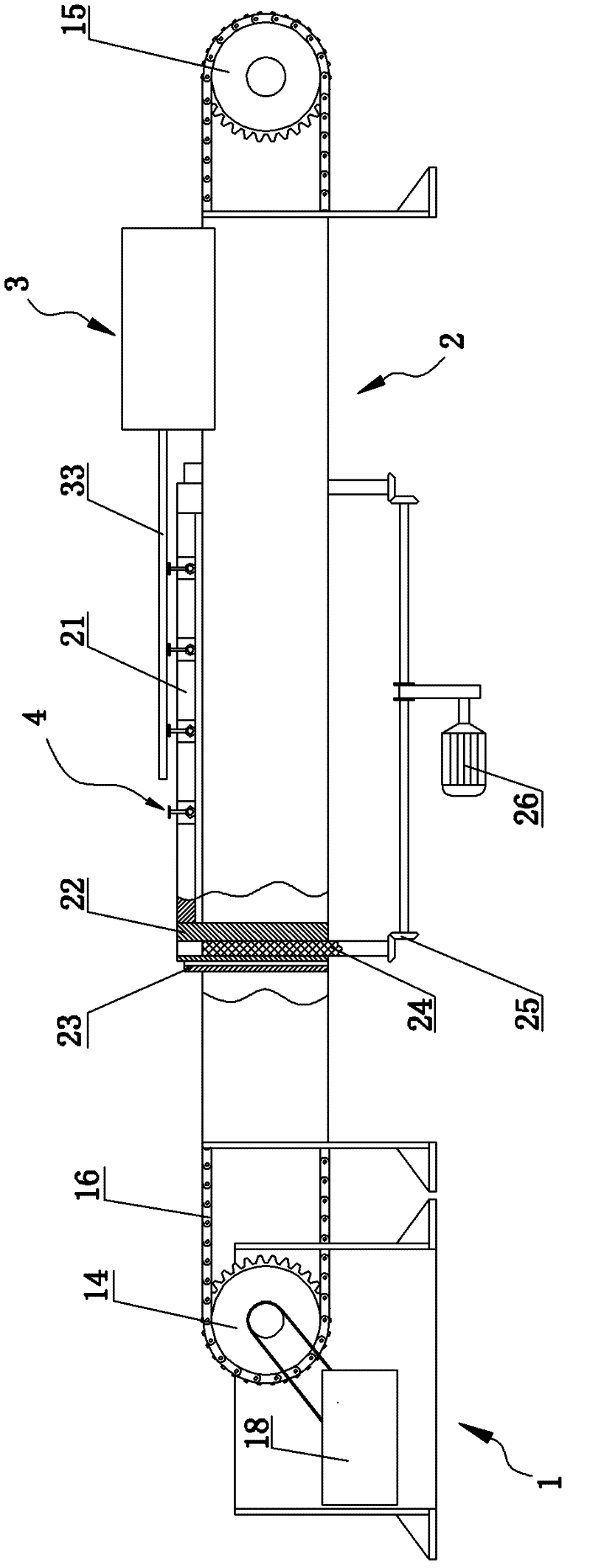

Wood processor

InactiveUS7228881B1Significant processingEasy constructionWood splittingMulti-purpose machinesWood processorWood machining

A wood processor including a motor vehicle having a bed structure, a clamping device on the bed structure for clamping a wood log and positioning it in a first processing position, a power saw for cutting predetermined length members from the wood log, and a splitting device for splitting the wood members into a specified number of pieces.

Owner:SMITH RICHARD H

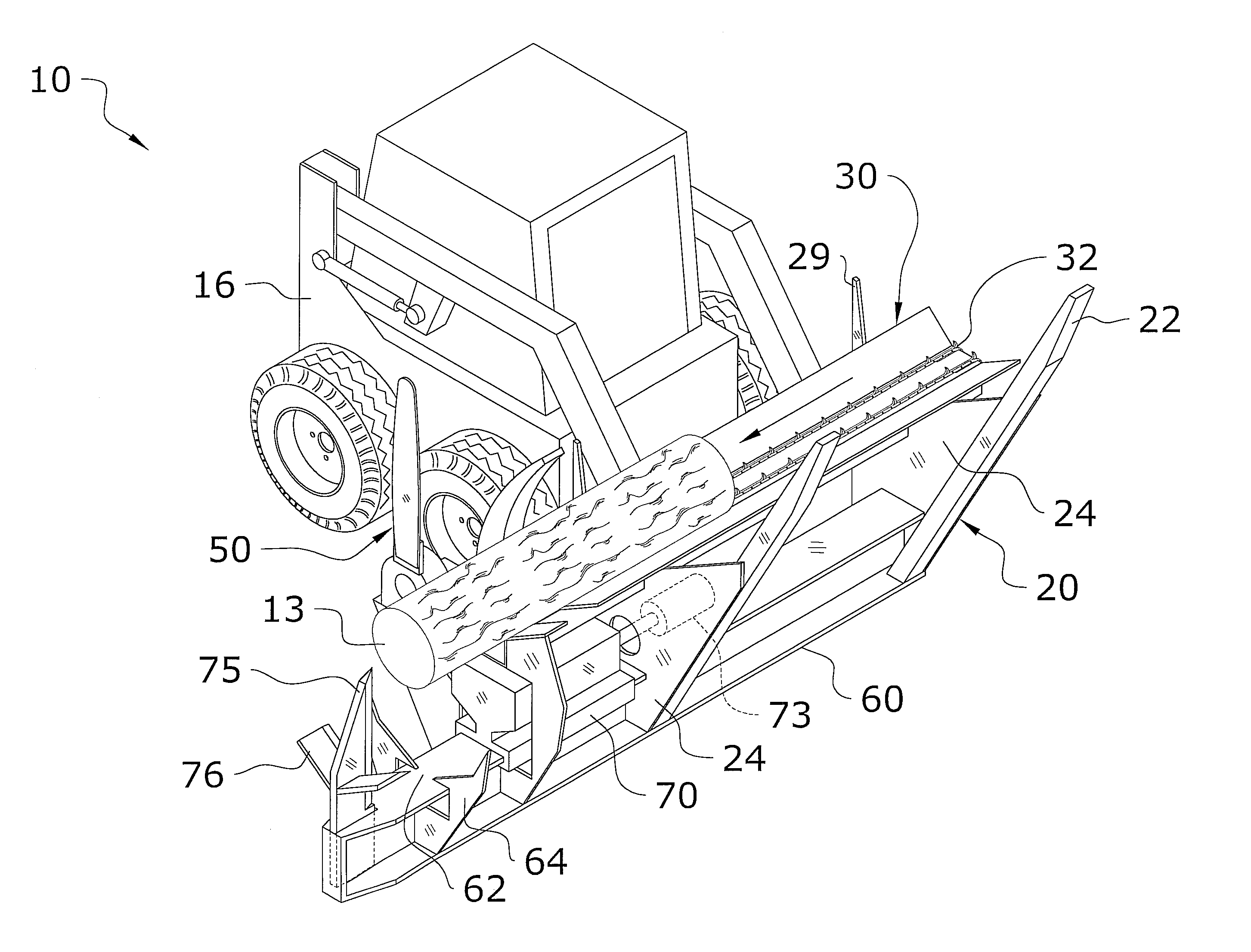

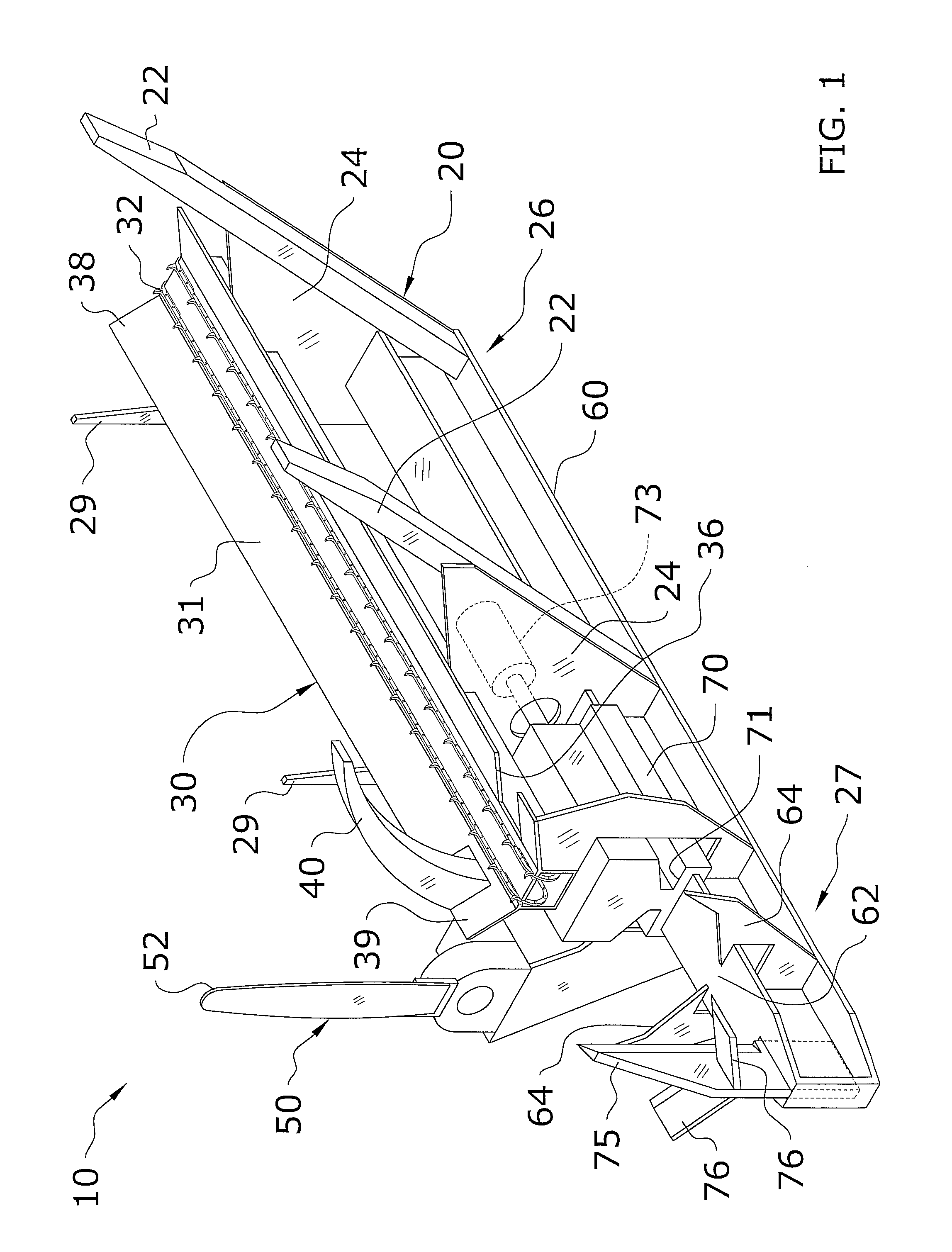

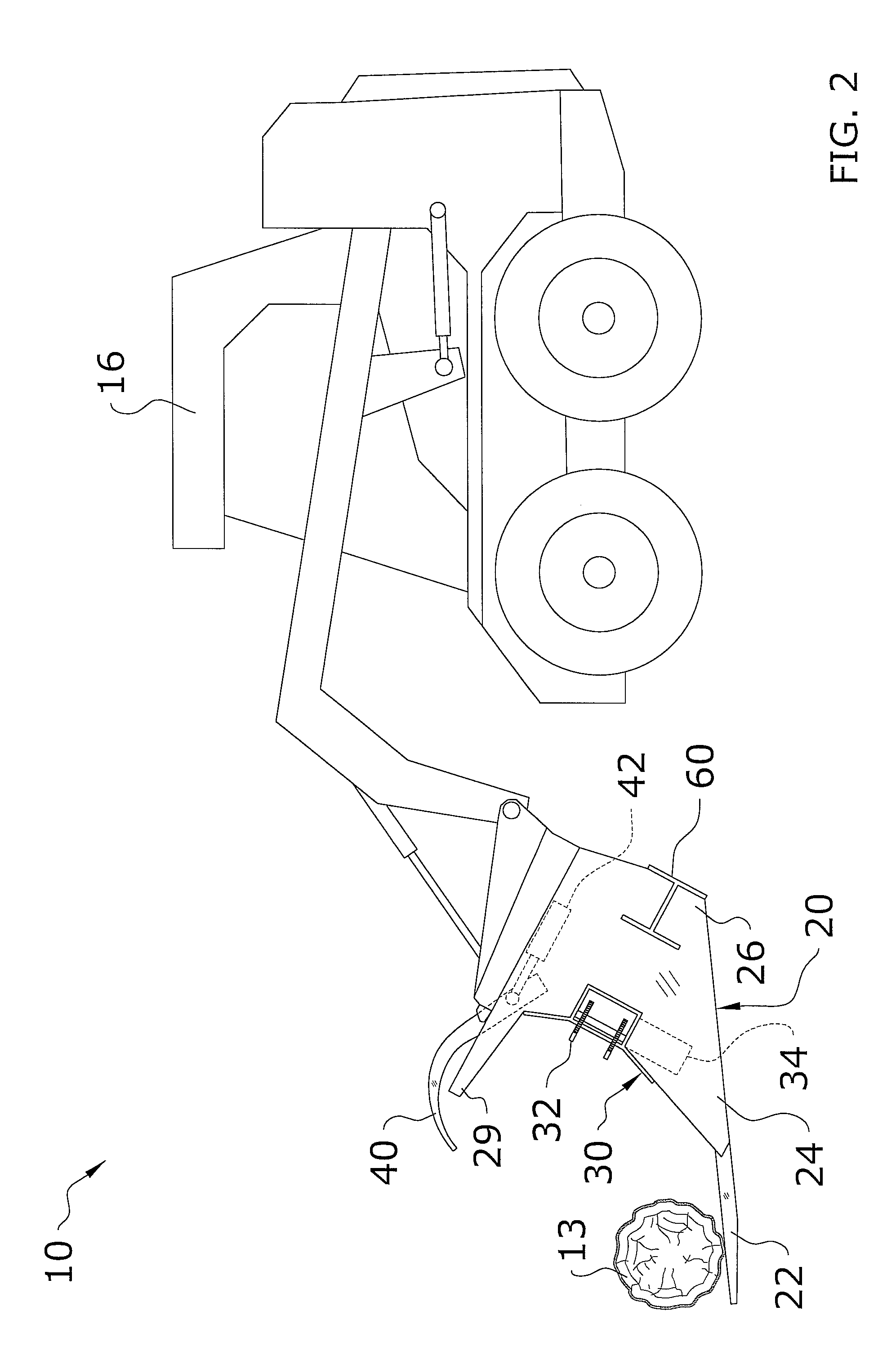

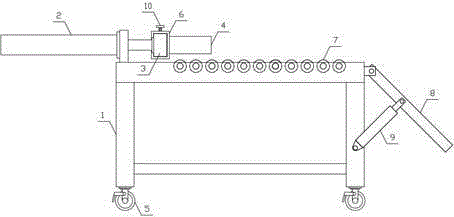

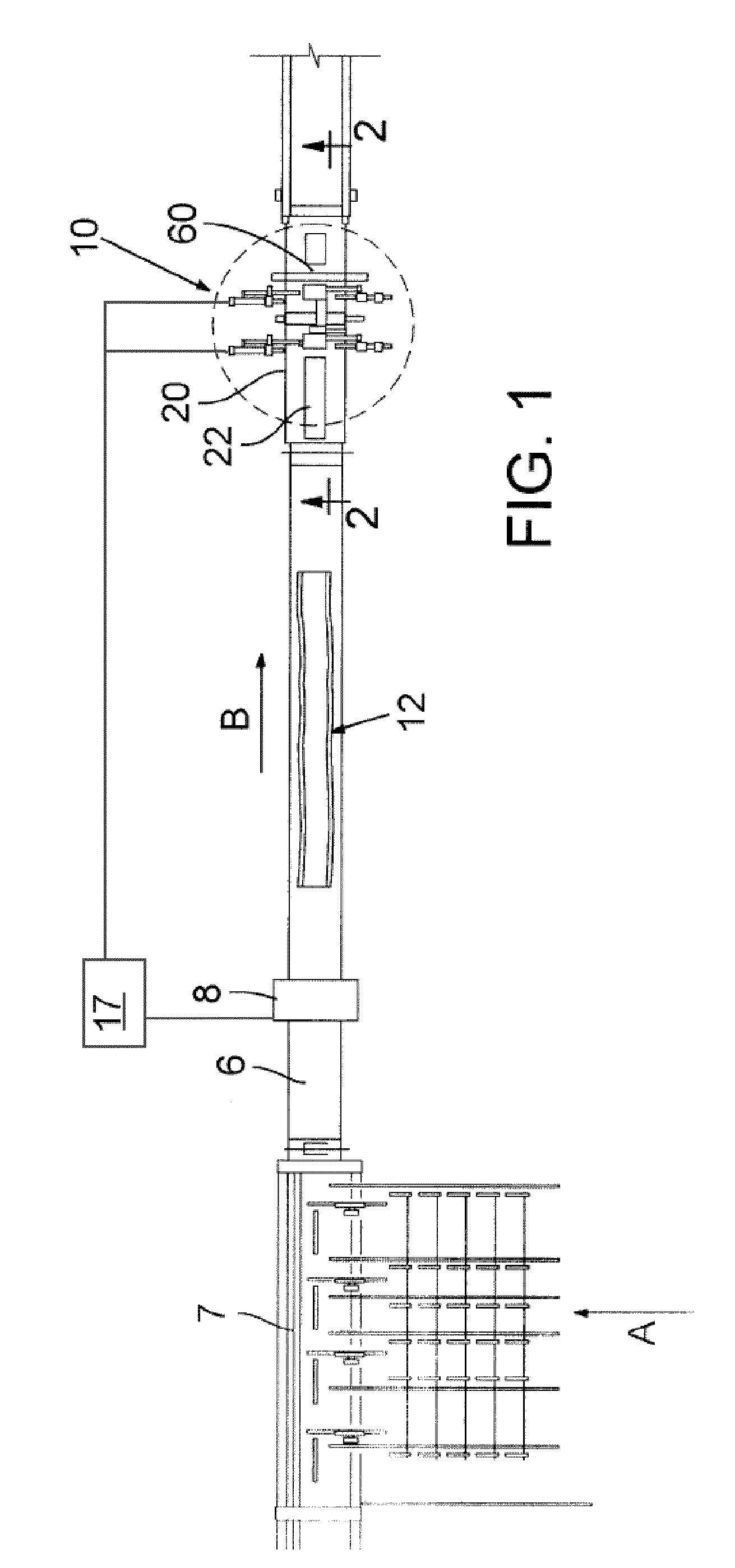

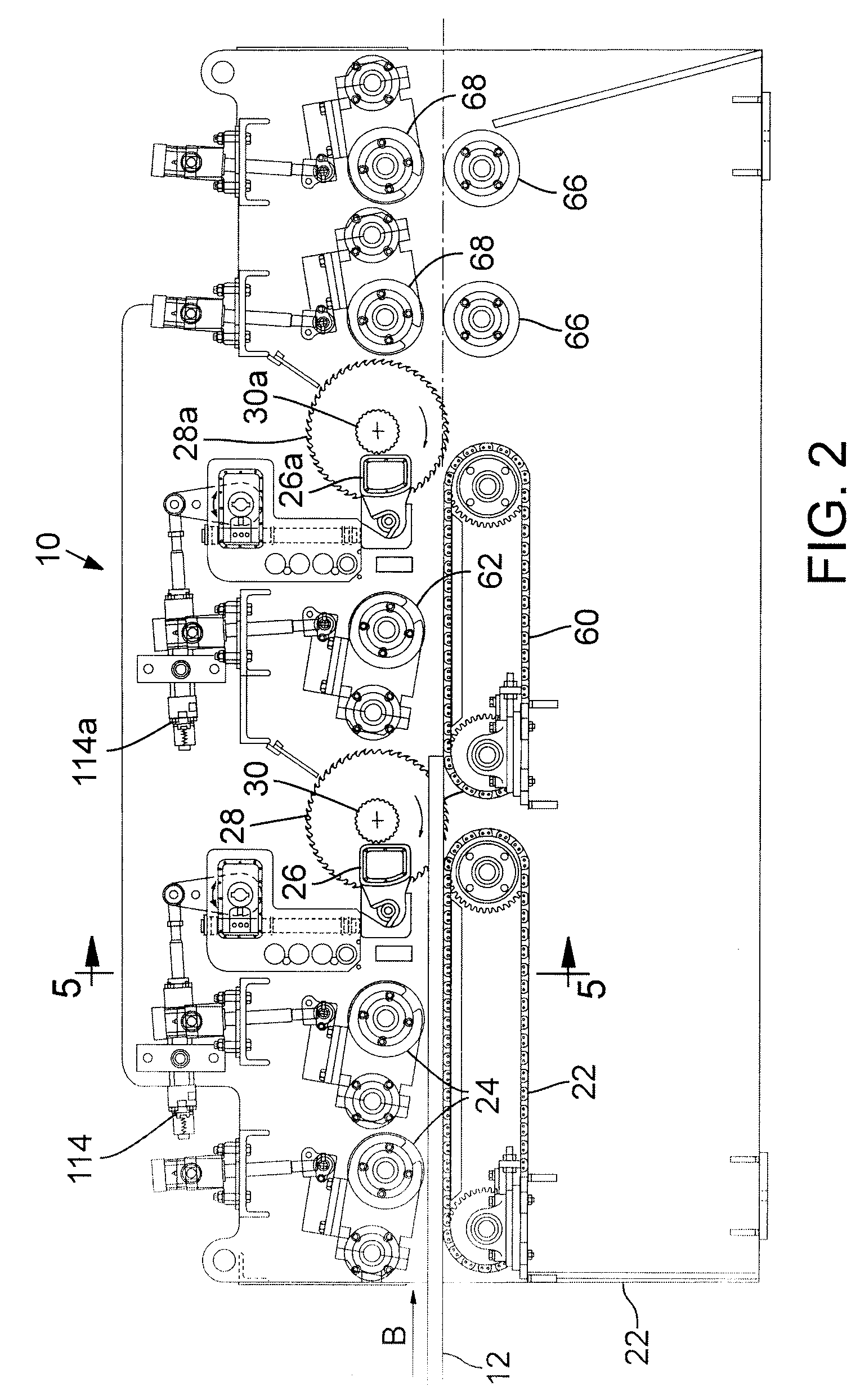

Wood processor attachment for skid steer loader

ActiveUS7669618B1Efficient cuttingEfficient splitWood splittingMulti-purpose machinesWood processorTractor

A wood processor attachment for skid steer loader for efficiently cutting and splitting logs. The wood processor attachment for skid steer loader generally includes a pivotally mounted support structure including a receiving end, a working end opposite the receiving end and a loading apparatus. A conveying member, a cutting unit, a ram and a wedge are attached to the support structure. The loading apparatus extends from the receiving end, wherein the loading apparatus transfers a log to the conveying member. The conveying member travels between the receiving end and the working end, wherein the cutting unit, the ram and the wedge are adjacent the working end to selectively cut and split the log. The support structure may be pivotally mounted upon various objects, such as but not limited to a skid steer loader or a tractor.

Owner:HALVERSON WOOD PROD INC

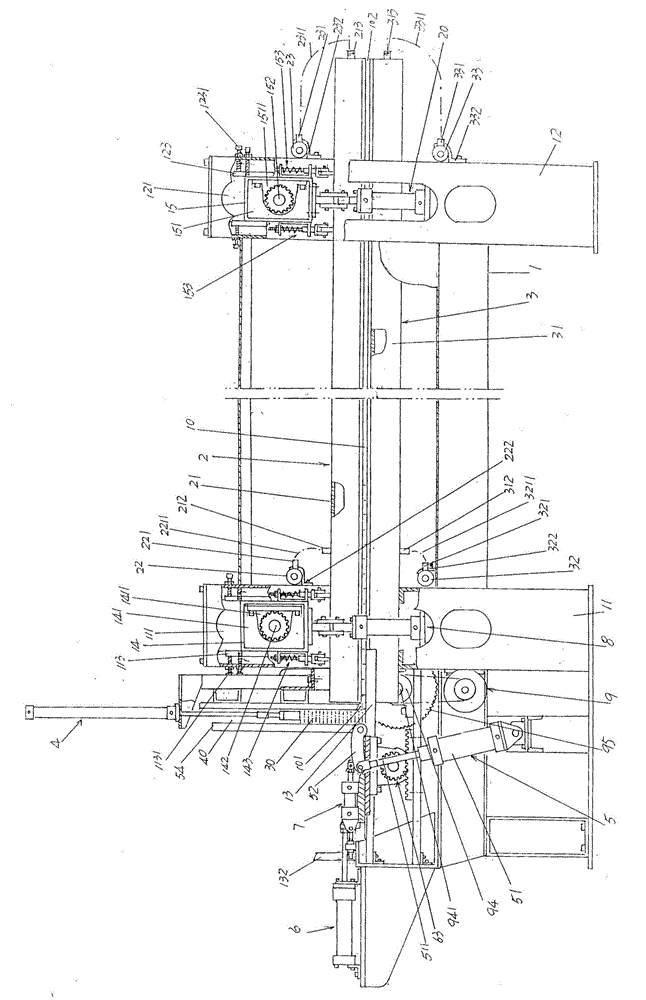

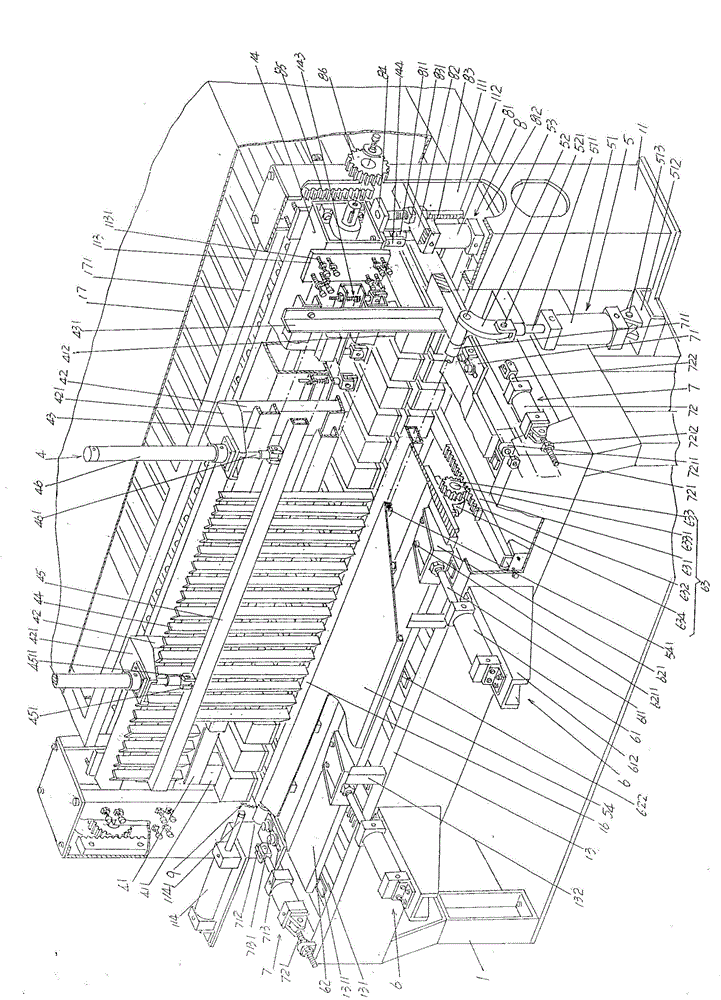

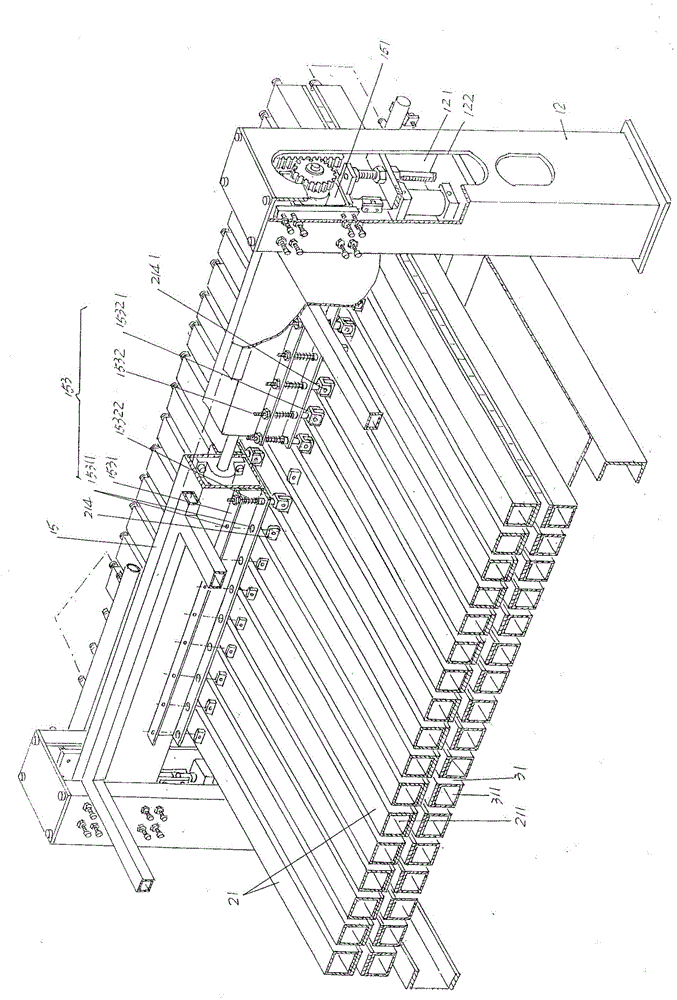

Wood processing machine

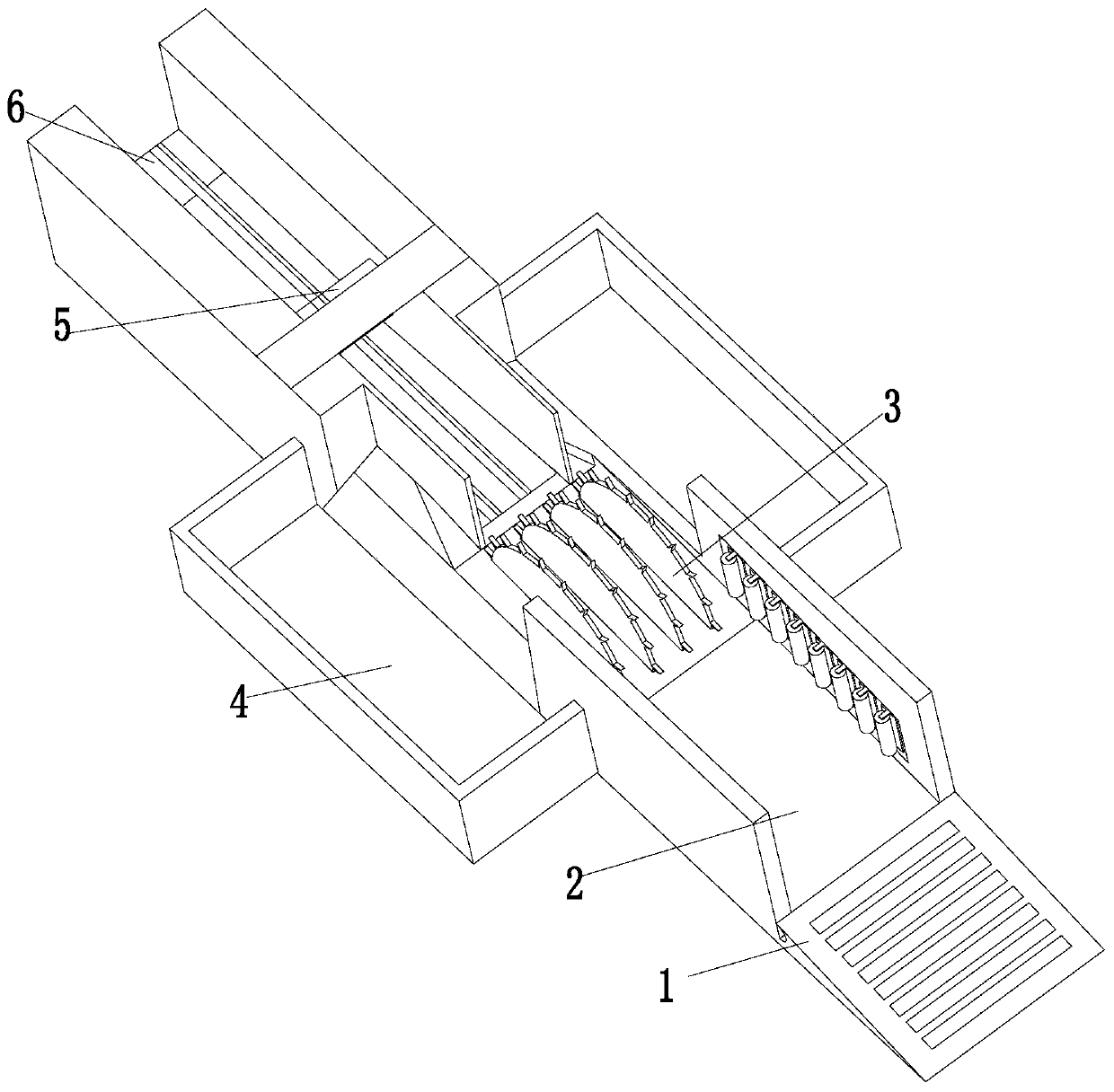

ActiveCN110228109AImprove work efficiencySolve the problem that the production steps are too cumbersomeFeeding devicesMulti-purpose machinesWood processorPulp and paper industry

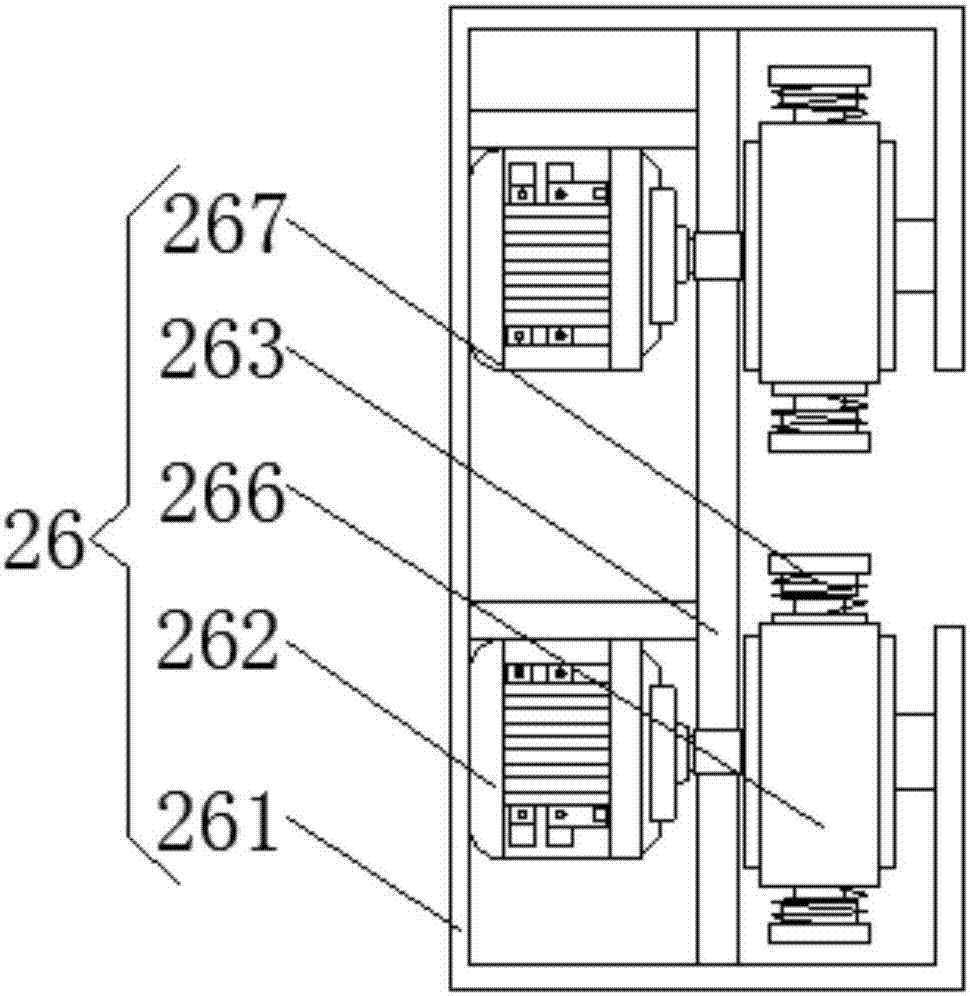

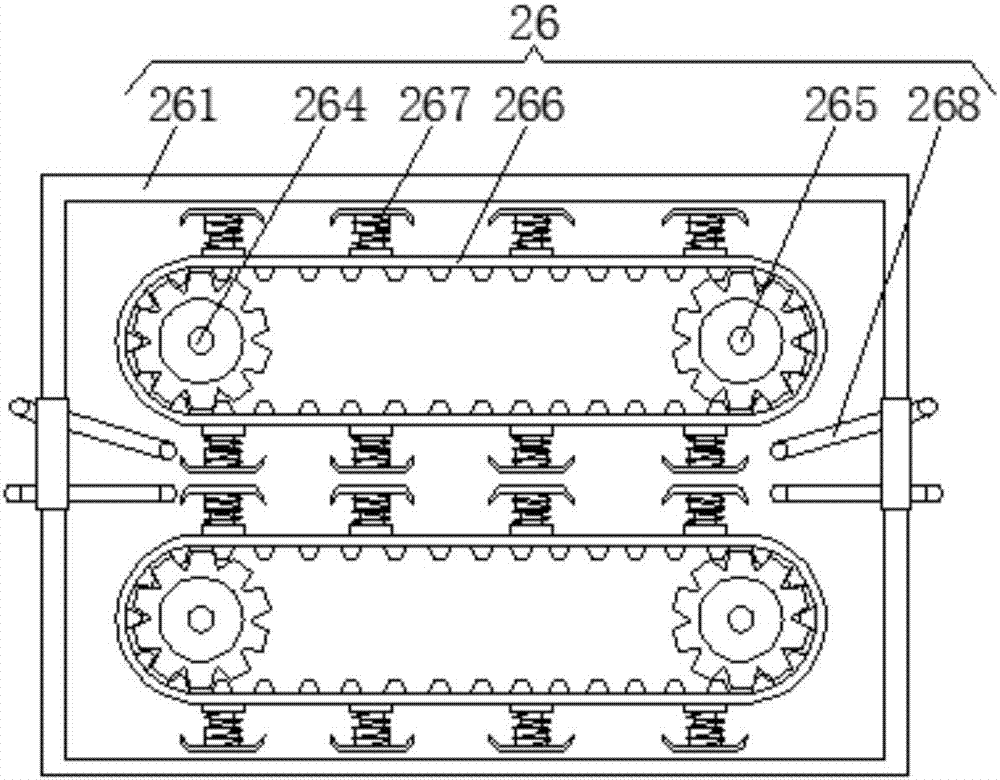

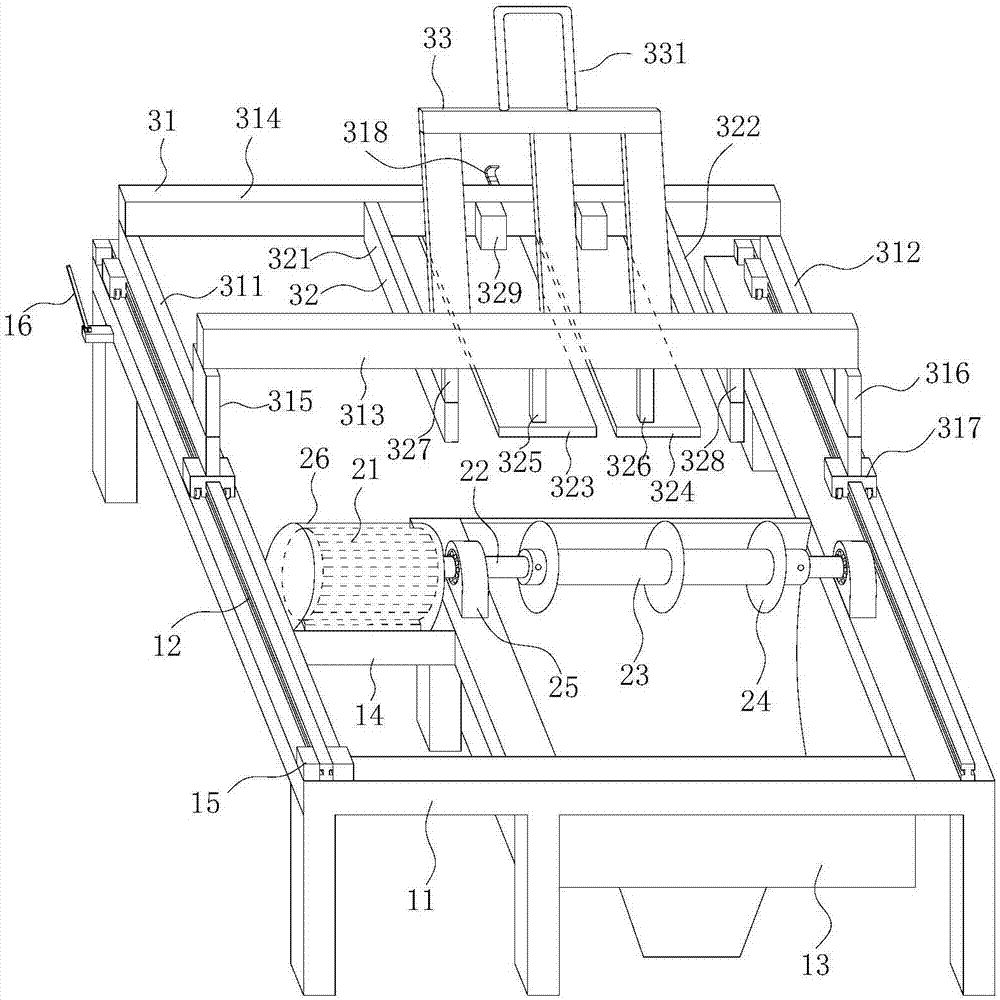

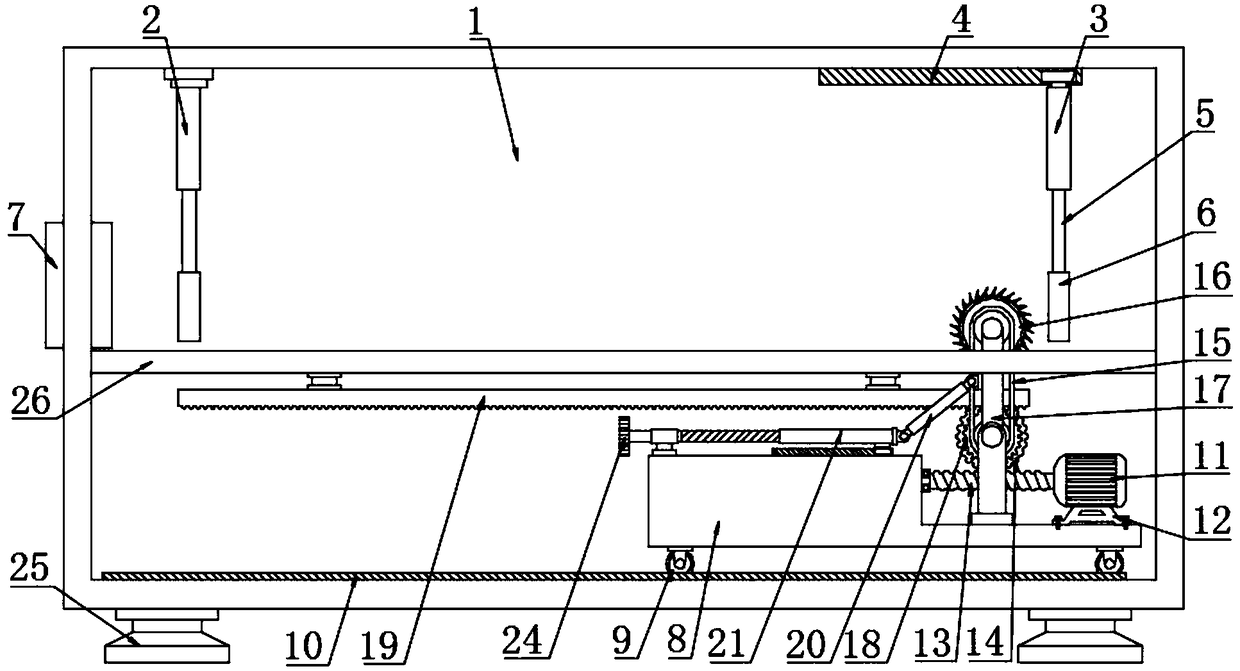

The invention discloses a wood processing machine. The machine comprises a triangular guide frame, a conveying device, a longitudinal saw cutting device, leftover material collection frames, a transverse cutting mechanism and a discharging opening; the left end of the triangular guide frame is provided with the conveying device, the left end of the conveying device is provided with the longitudinal saw cutting device, the leftover material collection frames are symmetrically mounted on the front end and the back end of the longitudinal saw cutting device, the left end of the longitudinal saw cutting device is provided with the transverse cutting mechanism, and the left end of the transverse cutting mechanism is provided with the discharging opening. Multi-station cutting design is added, through multi-station cutting, wood is decomposed into leftover materials and long-strip wood boards, through an extrusion mechanism, through rotating extrusion rollers on the two ends and shrinkage ofan extrusion spring, conveying of the conveying device to the wood is not affected while the wood is limited again, meanwhile, when the wood is cut, the extrusion mechanism achieves buffer of cuttingforce, and the wood of different widths can be well limited.

Owner:湖南新宝峰家具制品有限公司

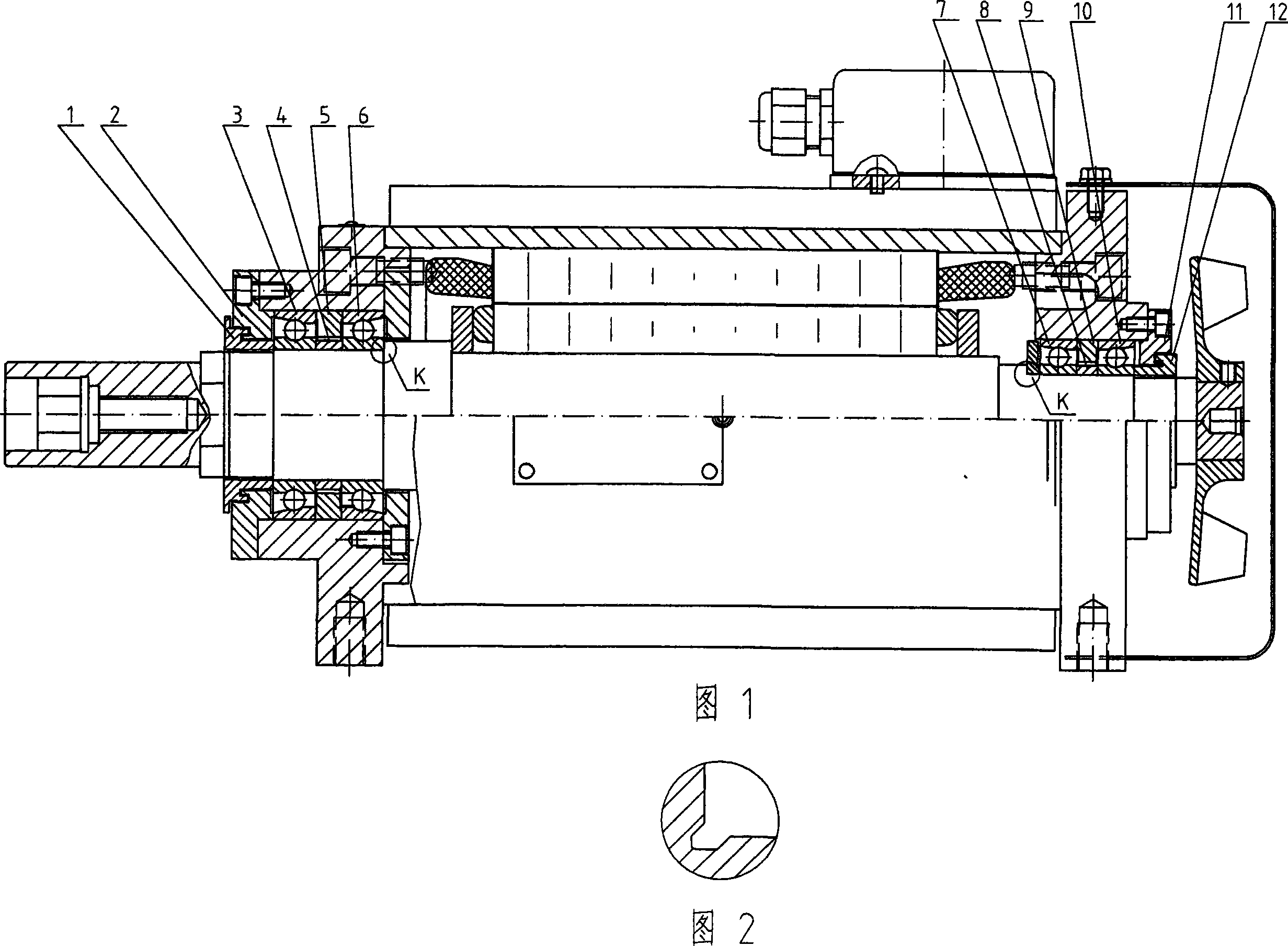

A high-speed woodworker power principle axis

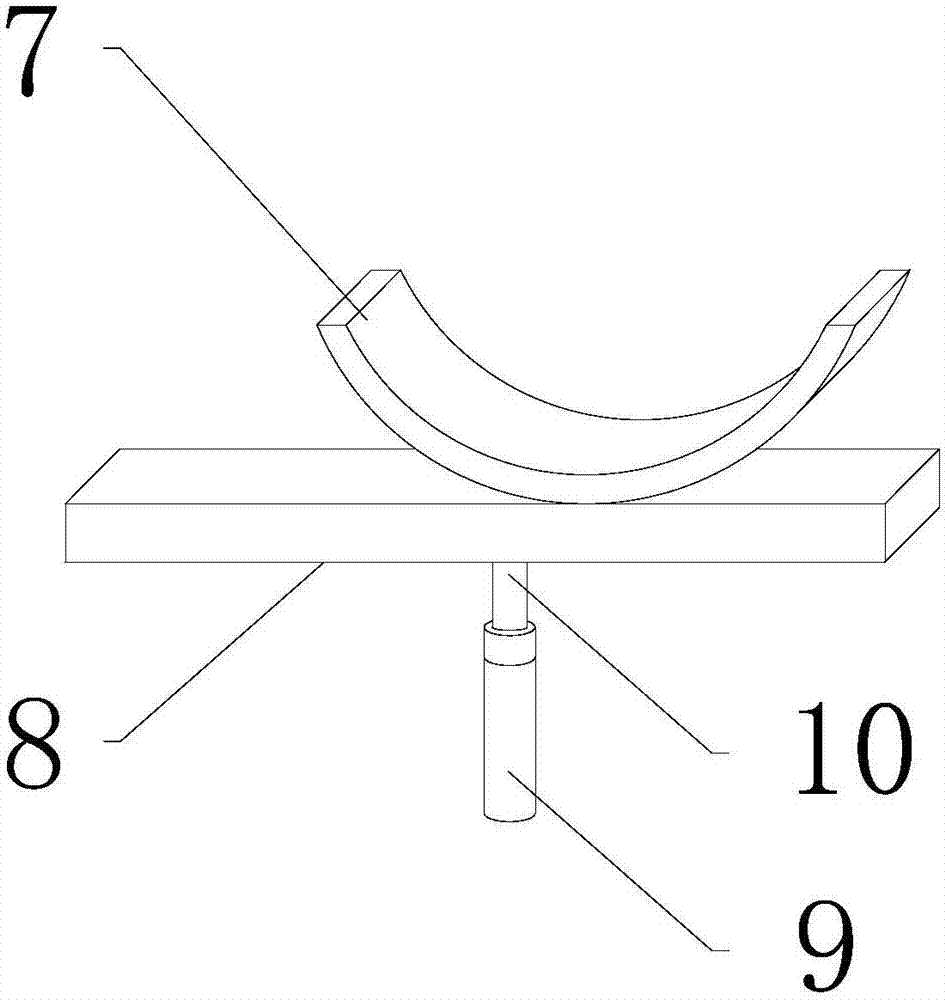

InactiveCN101123376AExtended service lifeMeet the requirements of processing machineryMechanical energy handlingSupports/enclosures/casingsNumerical controlBall bearing

The invention discloses a high speed electric main shaft used for carpentry, which comprises a main shaft, a stator and a rotor. The front extension end of the main shaft is provided with two front rake touch ball bearings (3, 6). An inner ring spacer (4) and an outer ring spacer (5) are arranged between the two front rake touch ball bearings (3, 6). The rear extension end of the main shaft is provided with two bottom rake touch ball bearings (7, 10). An inner ring spacer (8) and an outer ring spacer (9) are arranged between the two bottom rake touch ball bearings (7, 10). The utility model adopts the structure, and the extension ends of the main shaft can receive radial force, axial force and rigidity, the utility model can also be dustproof, and meets the requirement of present numerical control wood processors. Accordingly, the field of application of the high speed electric main shaft used for carpentry is widened; and the service life of the high speed electric main shaft used for carpentry is increased.

Owner:江苏星晨高速电机有限公司

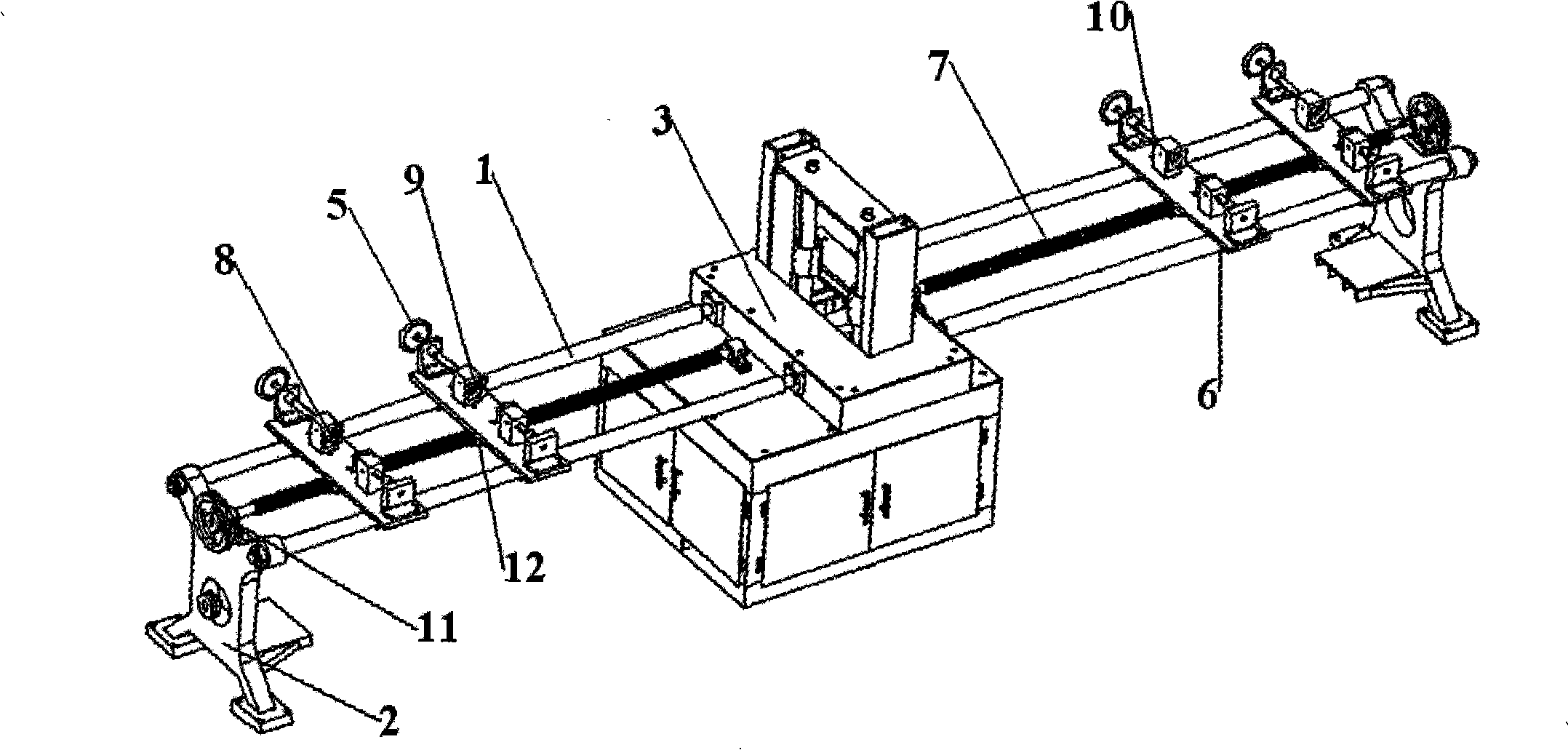

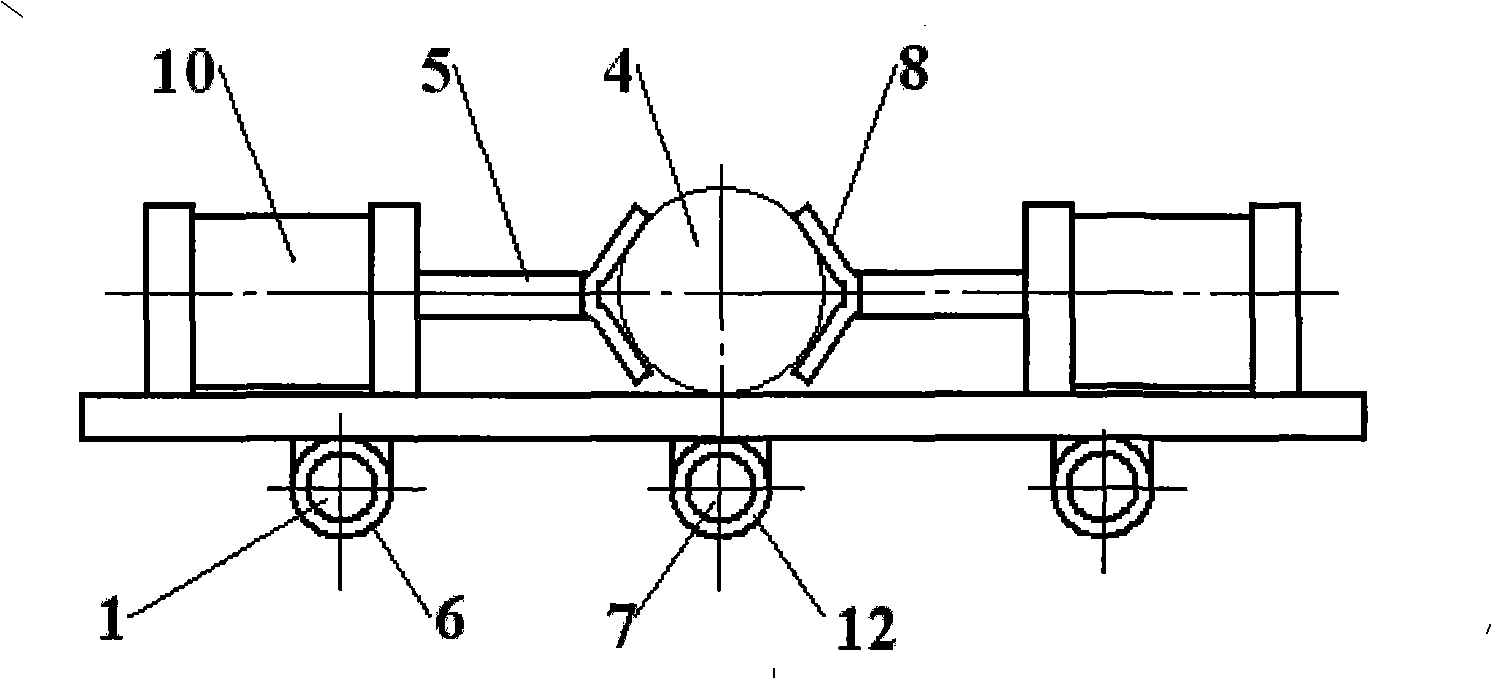

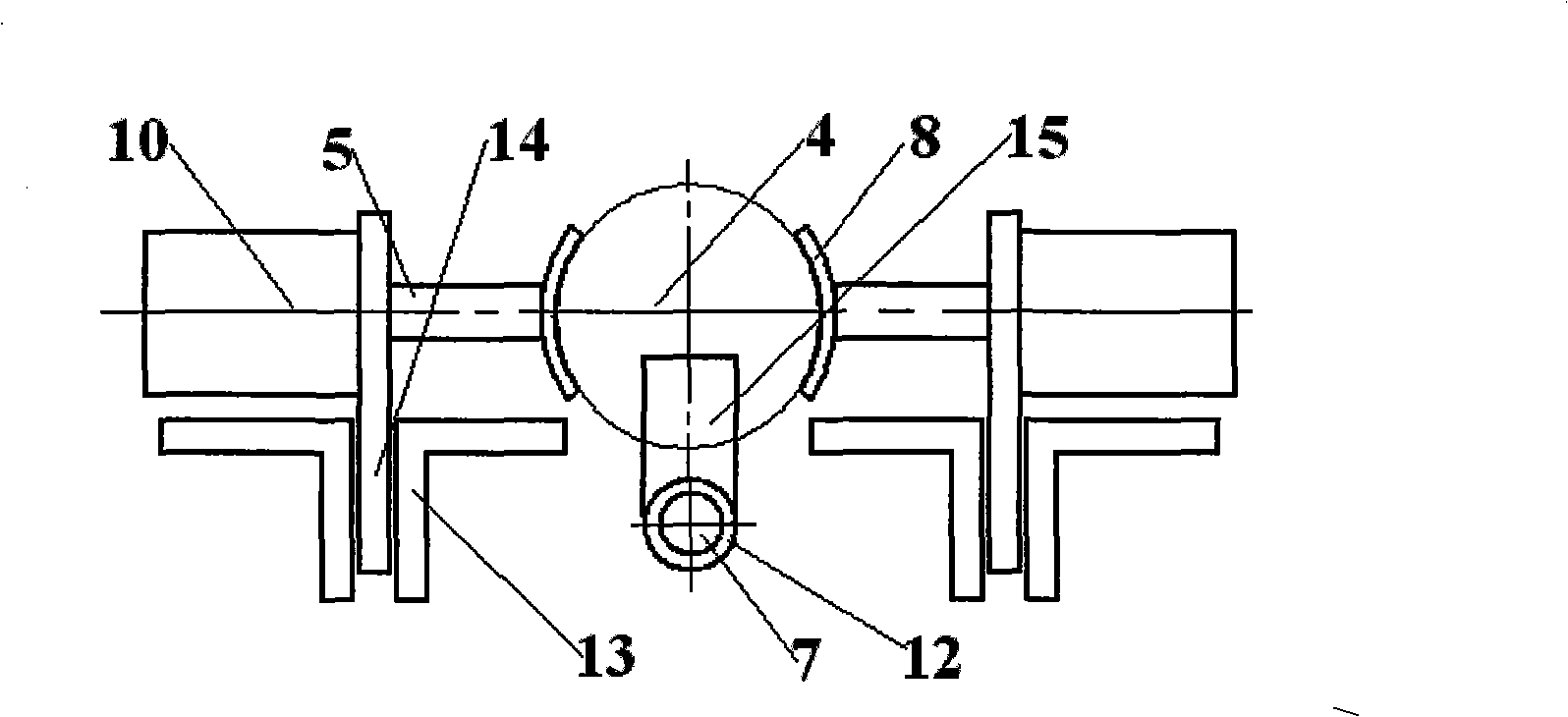

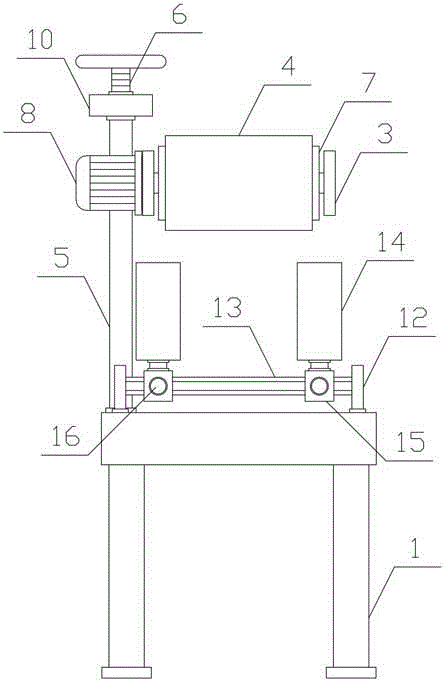

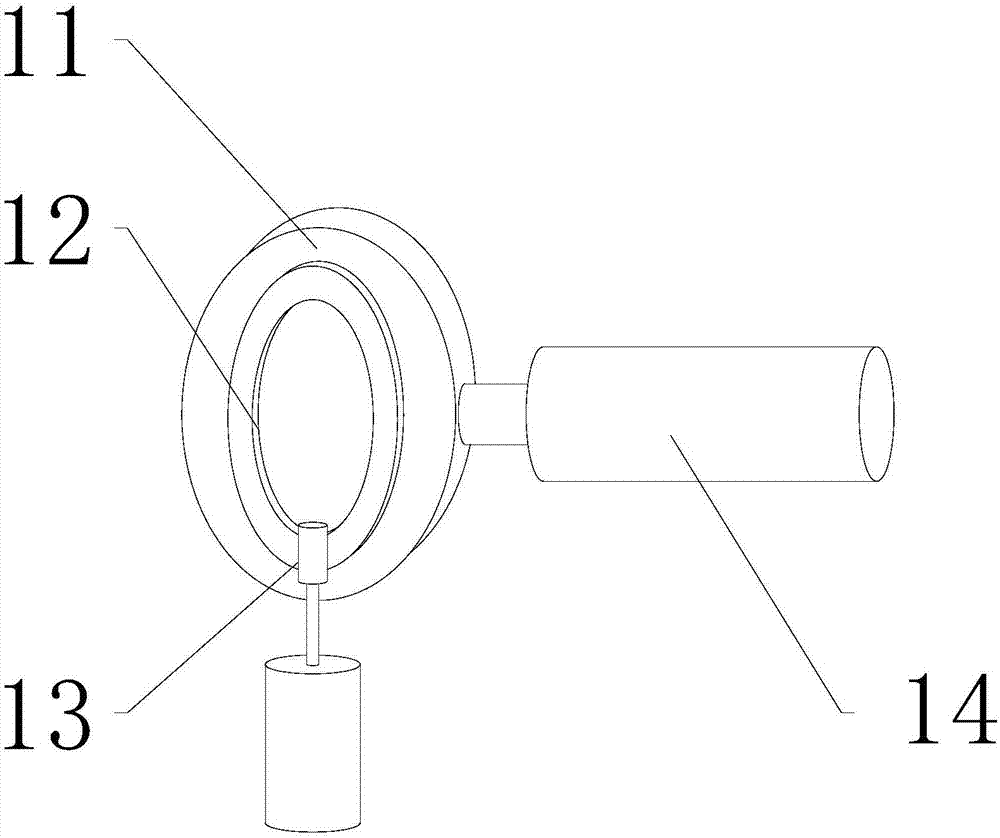

Sawmill grip feed mechanism

InactiveCN101259625ANot easy to looseLooseness will not occurFeeding devicesWood processorIndustrial engineering

The invention discloses a sawmill clamping feeding mechanism which belongs to the technical field of wood processing machine, wherein, a wood clamping device (5) is provided with a clamping head (8) which is used for clamping wood processed (4), a plurality of bulges are arranged on the contact surface of the clamping head (8) and the wood processed. By adopting the technical proposal, the sawmill clamping feeding mechanism has the advantages that the clamping is more reliable and the wood processed is uneasy to loose and to cause slide. The stable and reliable operation of the production of sawing and processing can be guaranteed, and the safety is better; thus realizing the automation of clamping. The precision of the clamping actions and the clamping time are higher, thereby reducing the intensity of labor of operation workers.

Owner:冯士祥

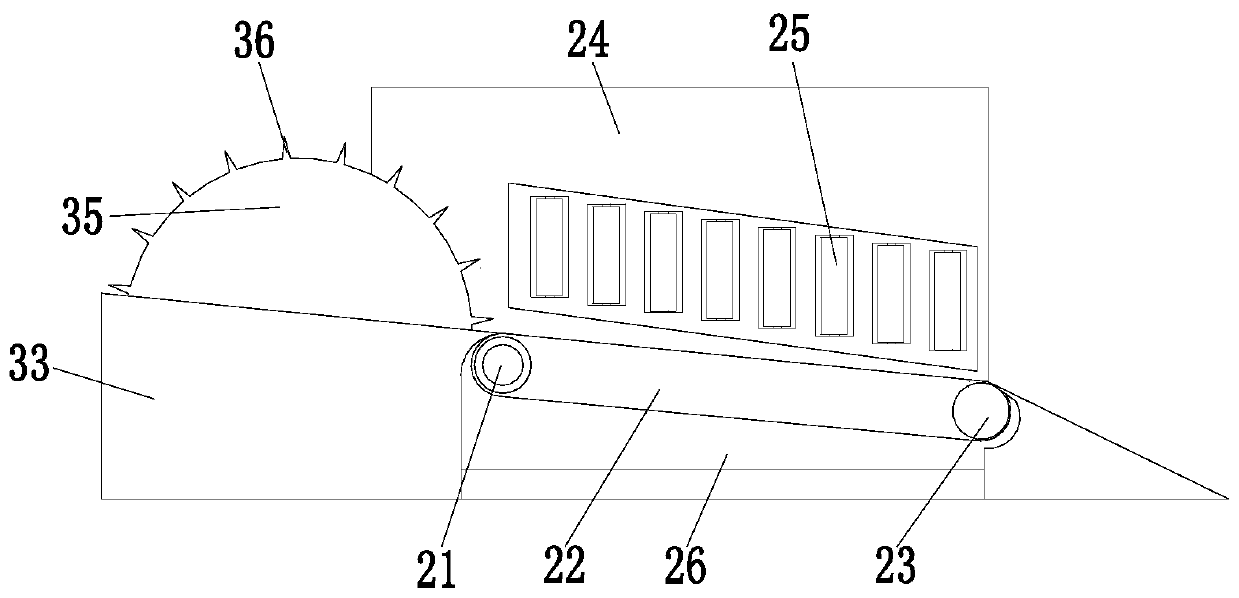

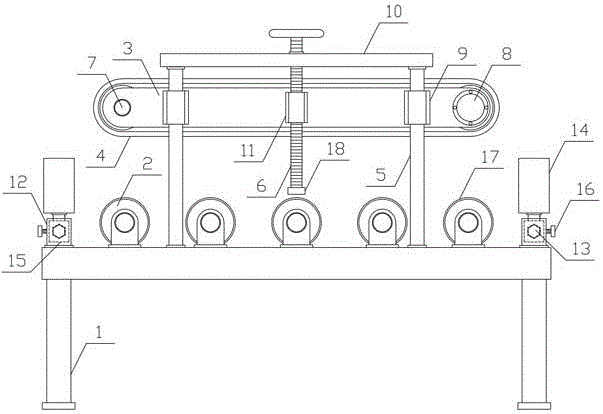

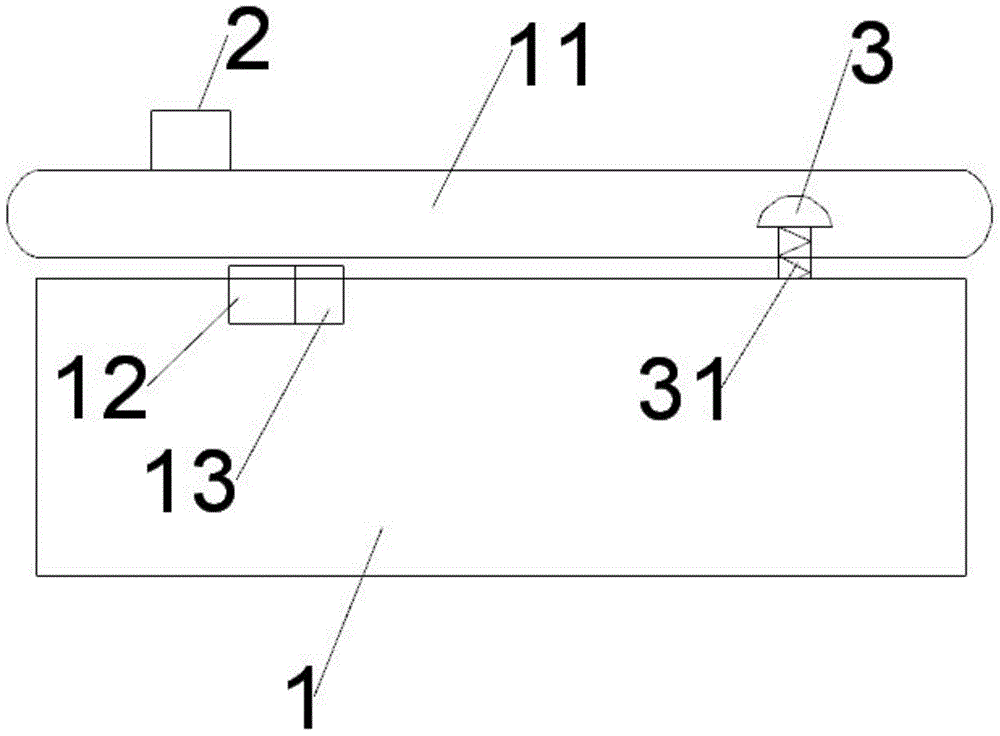

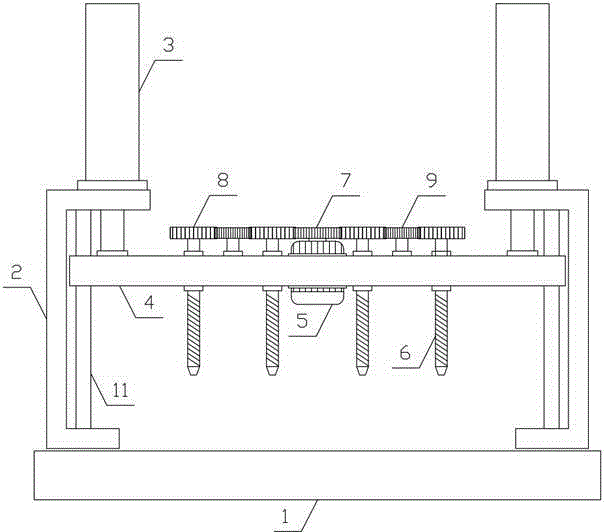

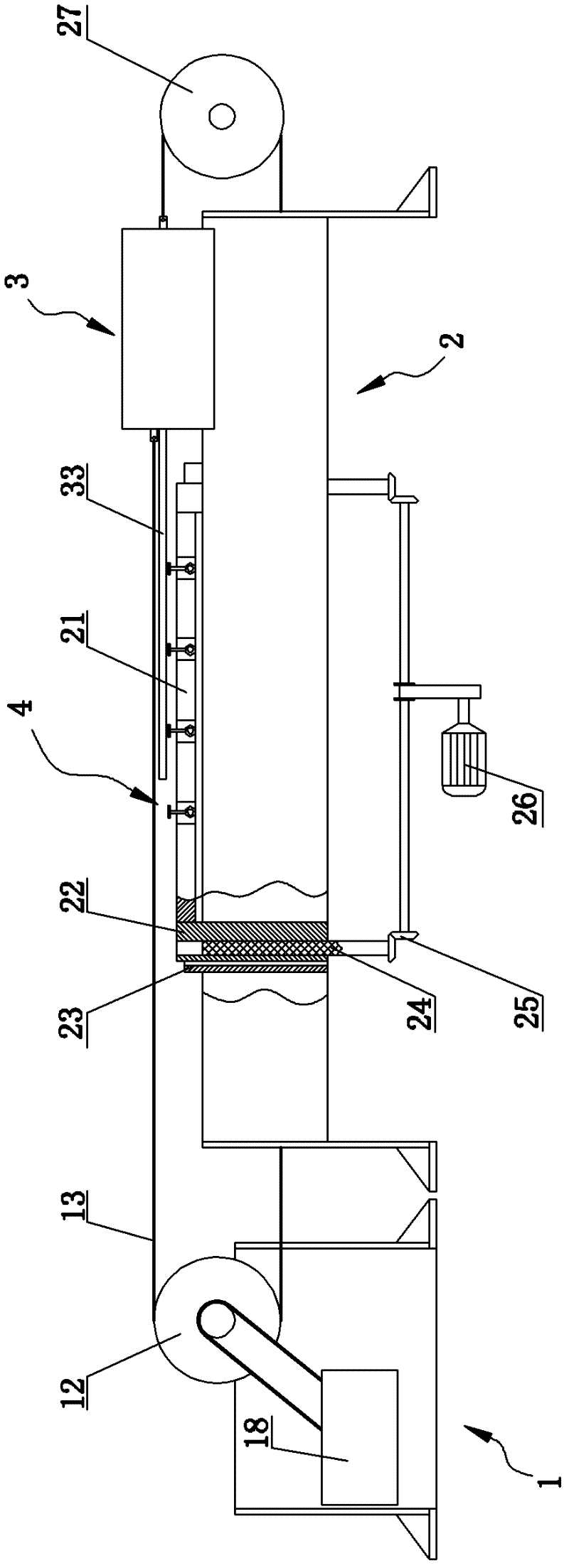

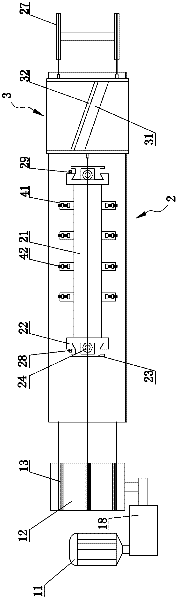

Wood plate compress-conveying mechanism

The invention discloses a wood plate compress-conveying mechanism and belongs to the field of wood processing mechanical equipment. The wood plate compress-conveying mechanism comprises a fixed base, guide rollers, a compressing support, a conveying belt, lifting guide rods and a lifting screw, the plurality of guide rollers are horizontally, evenly and rotatably connected onto the top of the fixed base along a wood plate conveying direction, conveying limit mechanisms are disposed on two sides of the upper portion of the fixed base respectively, the compressing support is horizontally disposed above the guide rollers, two ends of the compressing support are horizontally and rotatably connected with conveying rollers respectively, the conveying belt is horizontally disposed on the conveying rollers, a conveying motor drives the conveying rollers, two ends of one side of the compressing support are vertically provided with guide sleeves respectively, the lifting guide rods are vertically and downwardly passed through the guide sleeves and fixed to the top of the fixed base, the middle of one side of the compressing support is vertically provided with a lifting sleeve that is in threaded connection with the lifting screw. The wood plate compress-conveying mechanism is reasonable in structural design, can compress and convey wood plates efficiently, easily and accurately and meets the requirement for processing wood plates.

Owner:于星杰

Wood processing machine tool

ActiveCN104669367ASimple structureReduce weightMulti-purpose machinesWood processorPulp and paper industry

Owner:玮拓(江苏)复合材料科技有限公司

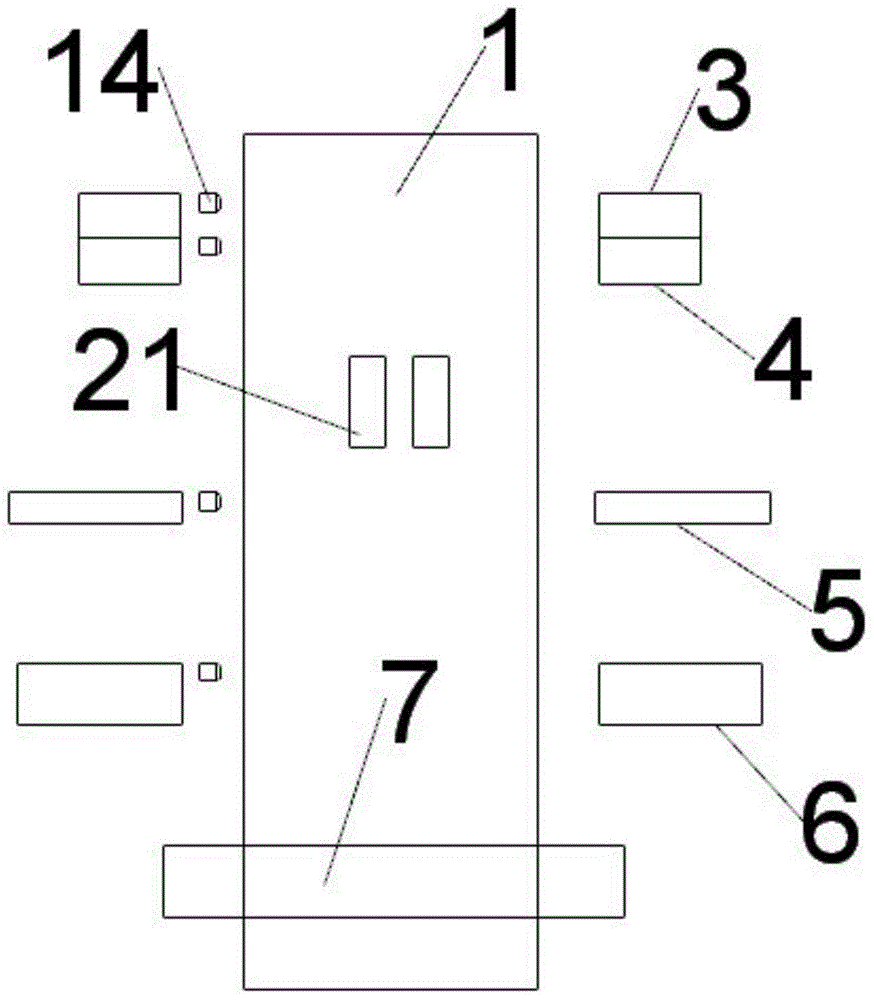

Wood processing machinery

InactiveCN104441087ASimple structureHigh degree of automationMulti-purpose machinesWood processorInjection device

The invention provides wood processing machinery. The wood processing machinery comprises a rack, a fixture, a sawing device, a drilling device, a glue injection device and a wood plug implanting device, wherein the rack is square, a transmission line moving back and forth at both ends of the rack is arranged on the rack, and the sawing device, the drilling device, the glue injection device, the wood plug implanting device and a reserved loading site are sequentially arranged on the rack at both sides of the edge of the transmission line; in use, wood is clamped at the reserved loading site through the fixture, the wood is conveyed by the transmission line to a corresponding position of the sawing device and is finally conveyed back to the reserved loading site to be unloaded, and the wood is processed by related devices when moving to the sawing device, the drilling device, the glue injection device and the wood plug implanting device. The wood processing machinery provided by the invention has a simple structure, and cutting, drilling, glue injection and wood plug implanting procedures are carried out on the same equipment, the automation degree is high, and wood processing can be completed by one worker at the reserved loading site by loading and unloading.

Owner:DONGGUAN CHENZHAN WOODWORKING MACHINERY

Automatic wood section raw material peeling equipment in wood processing machinery

InactiveCN107150392AIncrease contactImprove the finishLiquid surface applicatorsTree debarkingWood processorEngineering

The invention provides an automatic peeling device for tree segment raw materials in wood processing machinery, which includes an arc-shaped placing plate, a movable plate, a hollow rod, a screw mandrel, a turntable, a ring gear, a transmission gear and a waxing roller. The shaped placing plate is fixed on the upper end of the movable plate, the lower end of the movable plate is provided with a screw rod, and the lower end of the screw rod is provided with a hollow rod, and the lower end of the screw rod extends into the inside of the hollow rod. This design is convenient for placing trees and can also be adjusted. Place the upper and lower positions of the board, the front end of the turntable is provided with a ring gear, the front end of the ring gear is equipped with a transmission gear, the right end of the turntable is provided with a wax roller, and the ring gear and the transmission gear are gear meshed. The end face of the tree is waxed to prevent the trees from cracking during the peeling process and improve the peeling efficiency. The invention is convenient to use, expands the application range, reduces labor intensity, and has high reliability.

Owner:安徽海之纳科技有限公司

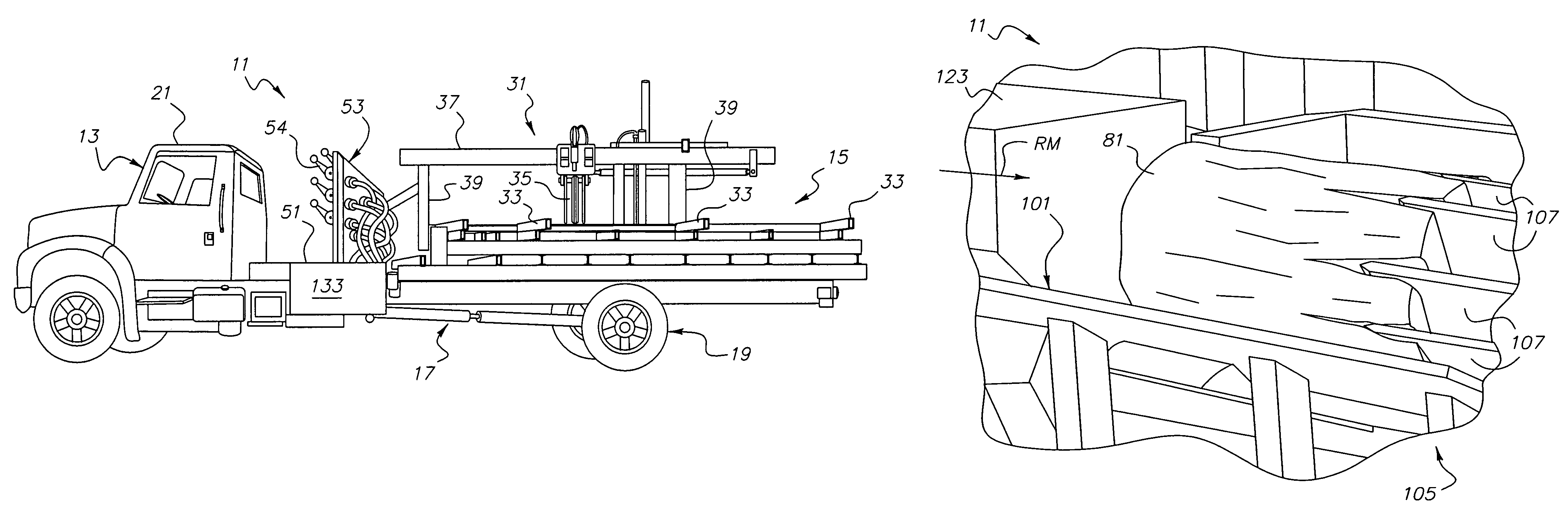

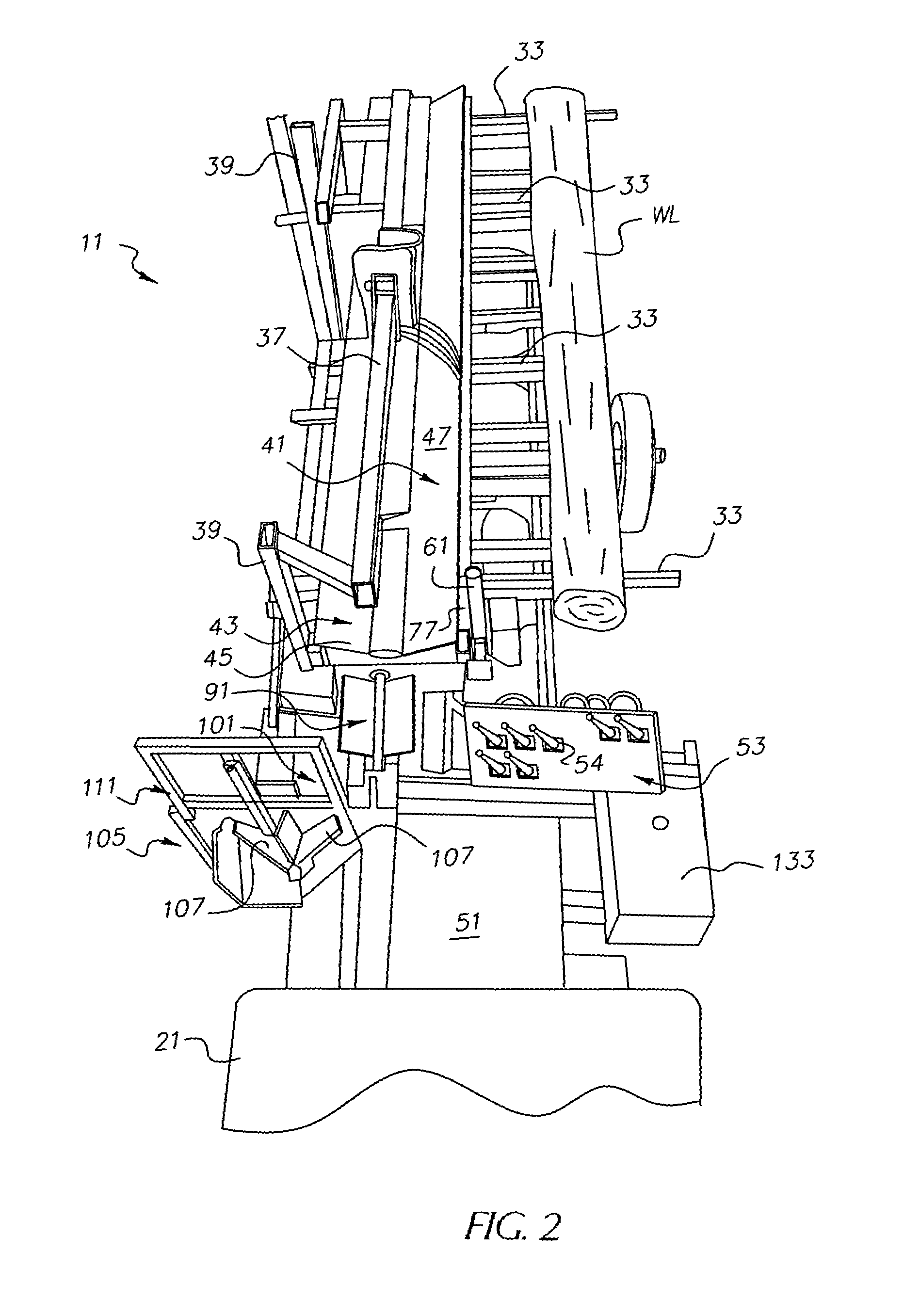

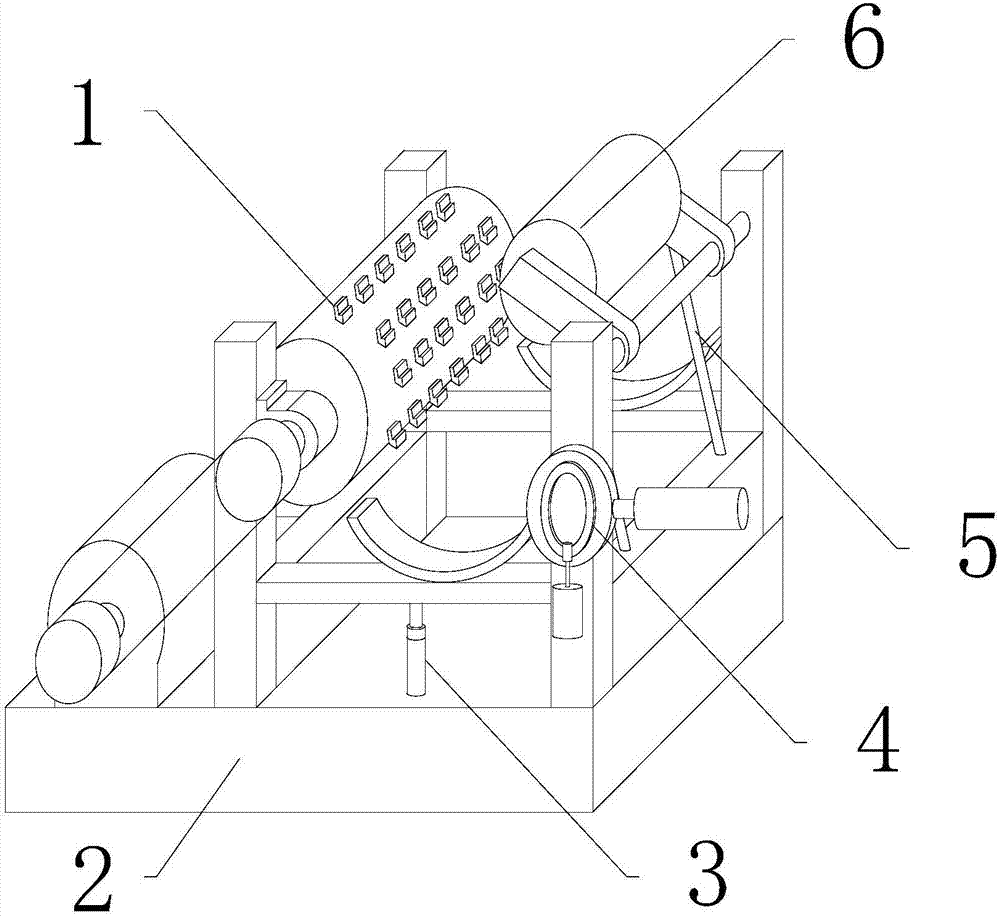

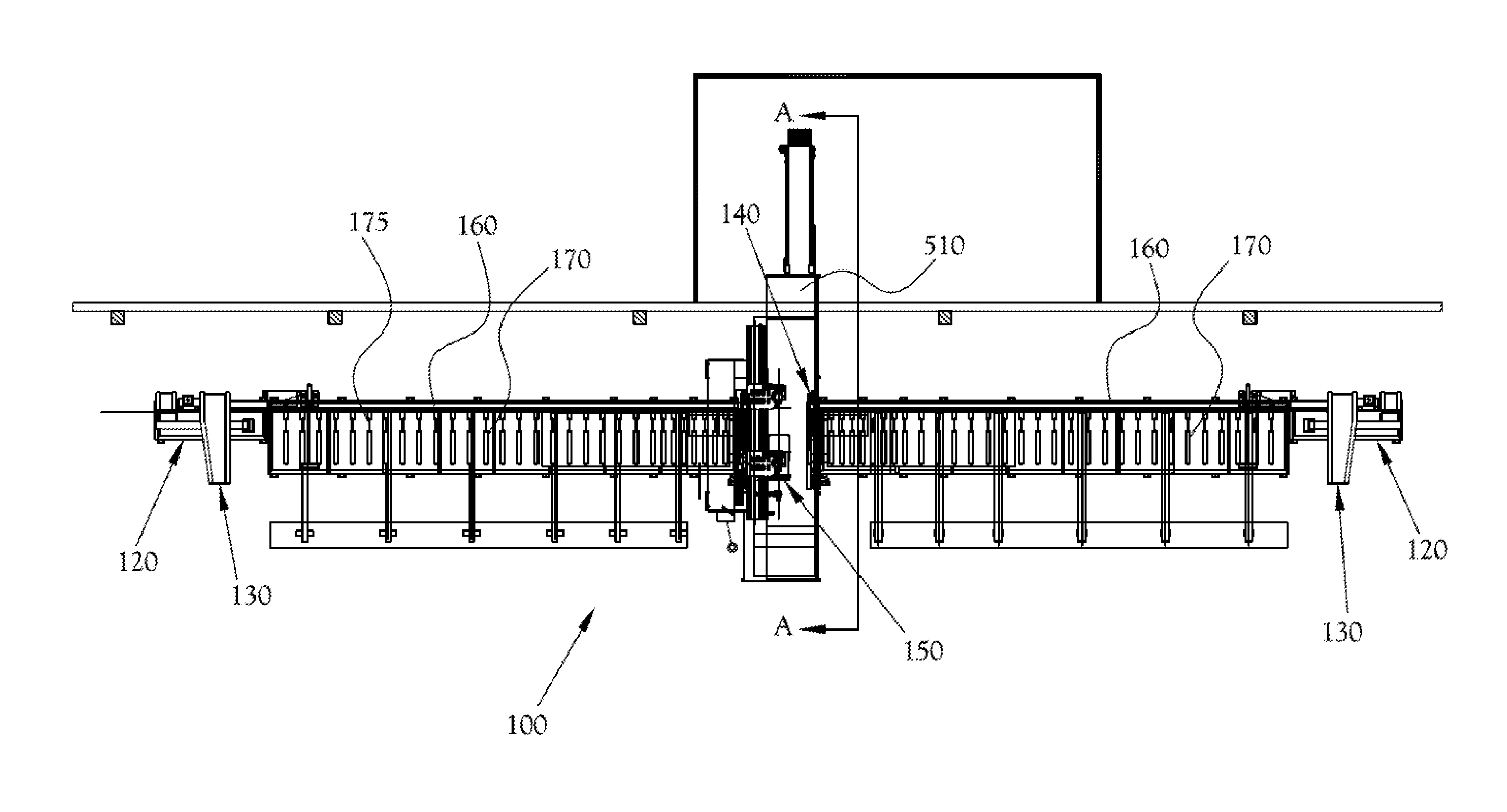

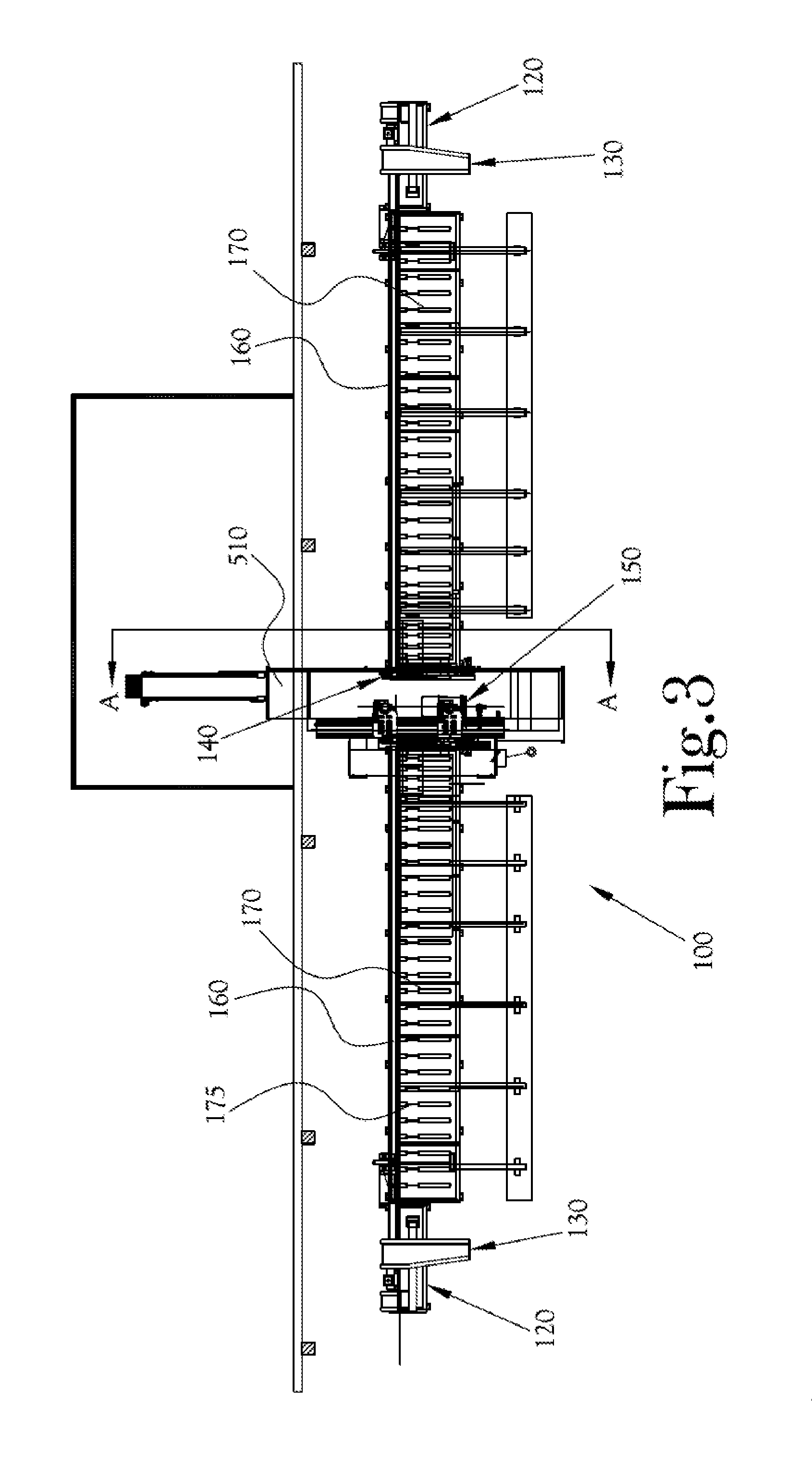

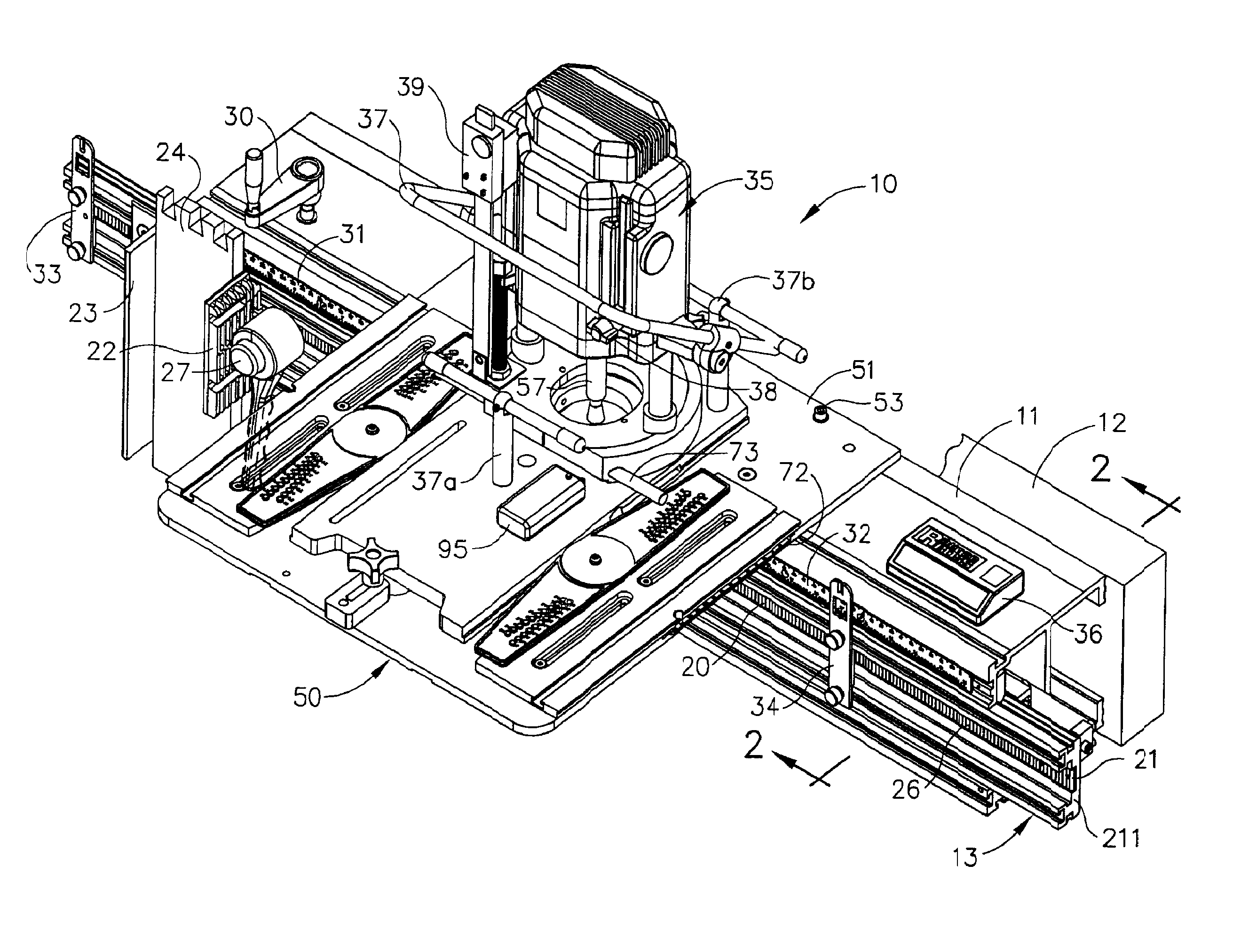

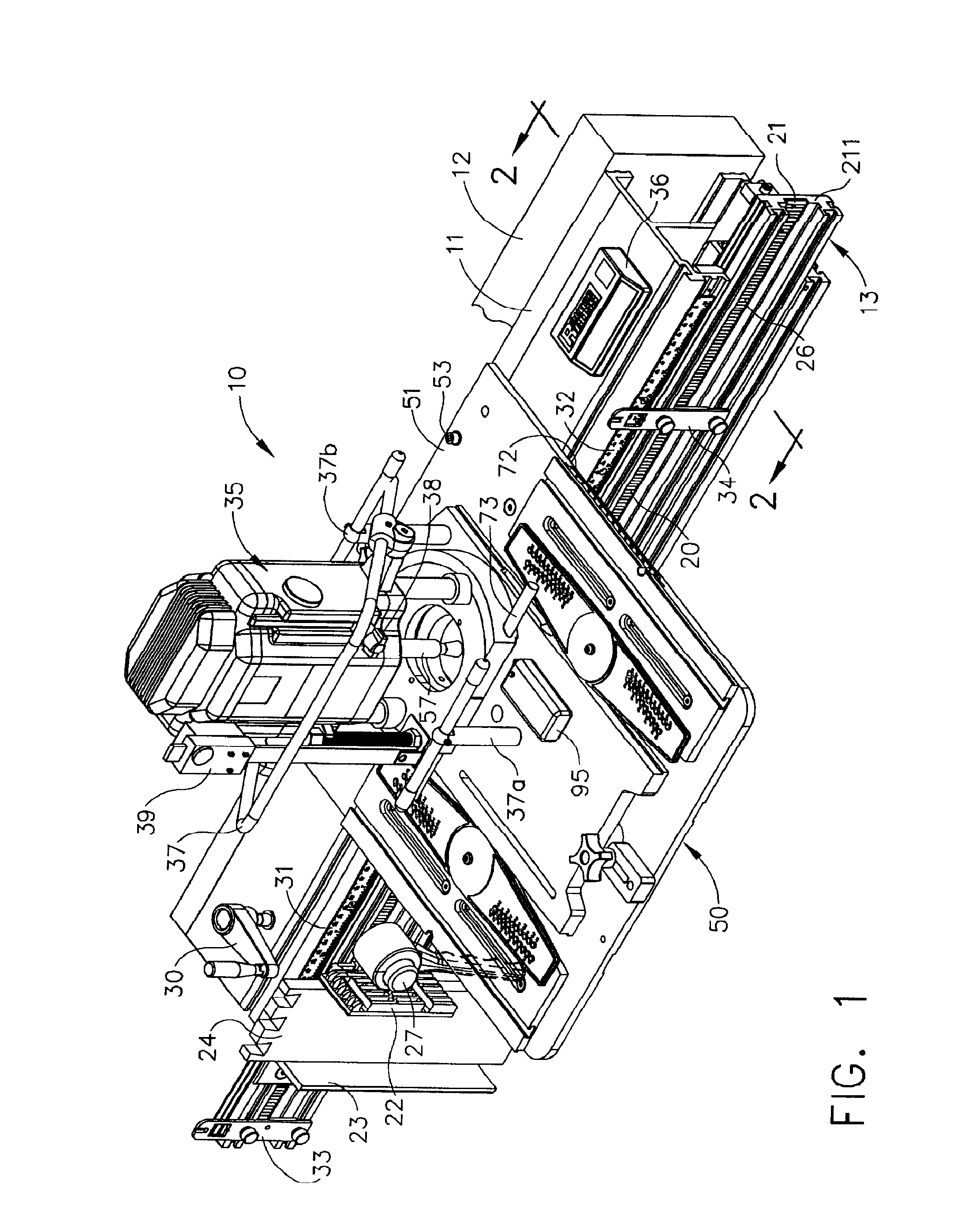

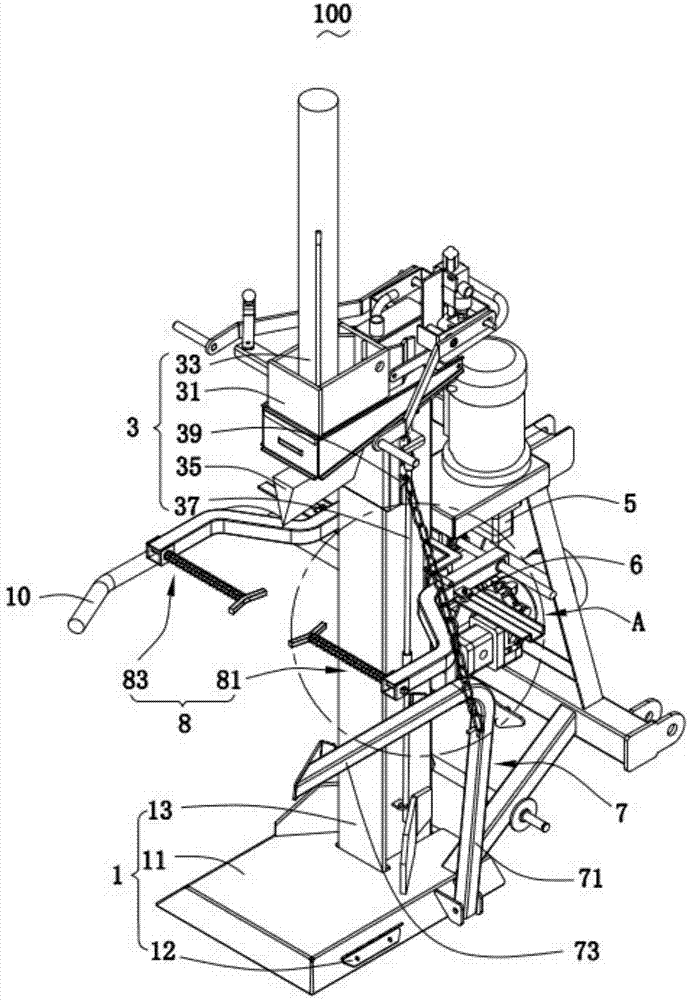

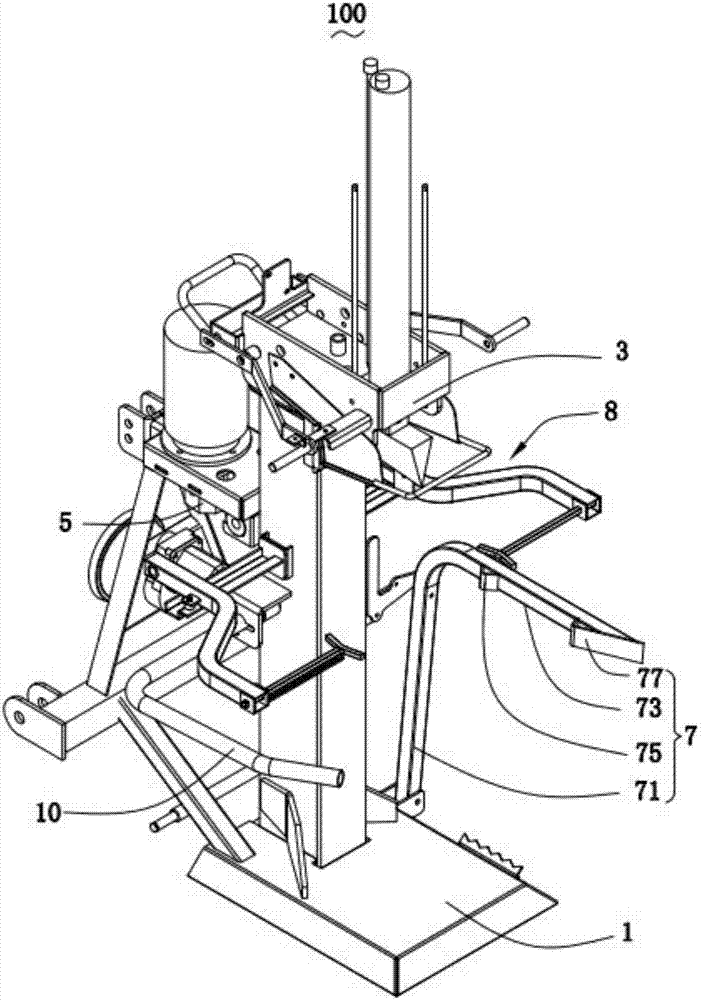

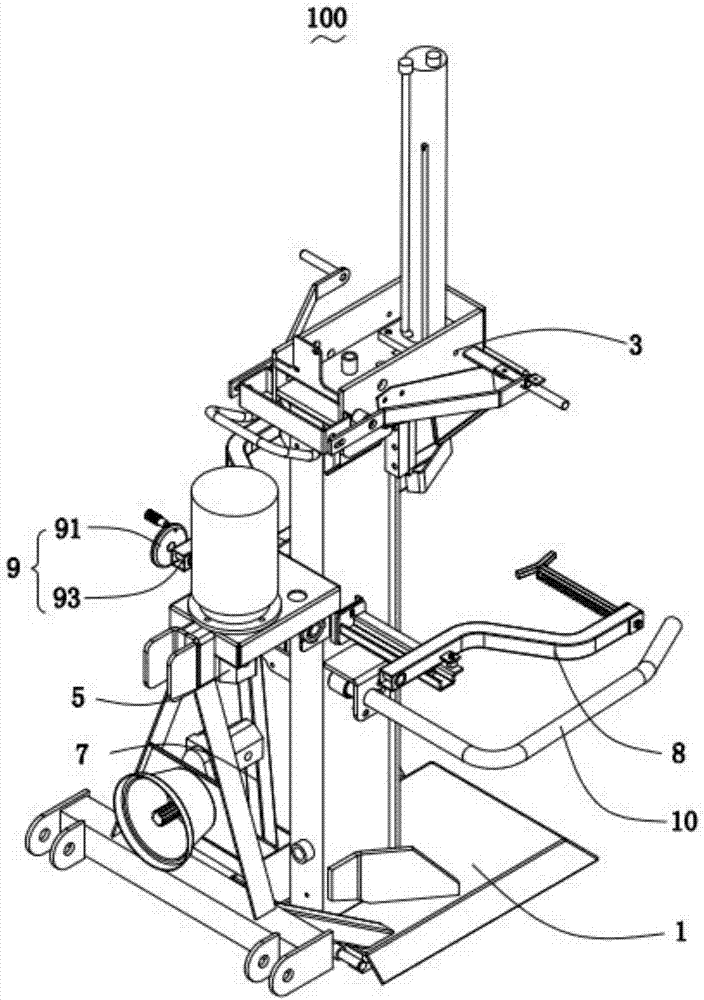

Robotic Apparatus for Processing Timber Used in Construction of a Log Home

InactiveUS20170043496A1Less equipmentLess laborProgramme-controlled manipulatorFeeding devicesWood processorIndustrial engineering

A robotic apparatus for processing the timber logs intended to be used in the construction of a log structure. The robotic apparatus includes at least a vertical clamp assembly, a horizontal clamp assembly, a roller clamp assembly, a central log processing assembly, and a conveyor. The central log processing assembly allows multiple processes to be performed sequentially on the same machine requiring much less equipment and less labor in the handling and processing of the logs. By utilizing multiple tool masts, a primary mast can be performing a primary process while the secondary mast is selecting the tool appropriate to the next or secondary process.

Owner:HEARTHSTONE

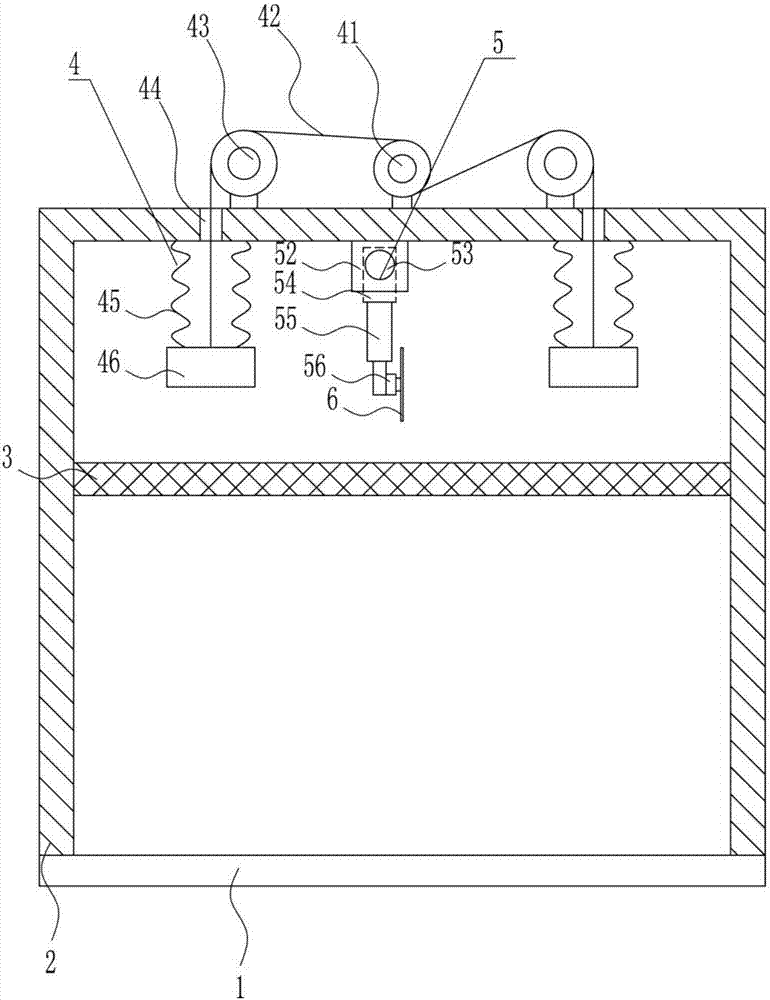

Wood board cutting device for wood processing

ActiveCN107538571AEasy to saw offAvoid enteringCircular sawsBark-zones/chip/dust/waste removalWood processorWood machining

The invention relates to a wood board cutting device, in particular to a wood board cutting device for wood processing and aims at achieving the technical purpose of providing the wood board cutting device for wood processing, wherein the wood board cutting device for wood processing is high in cutting efficiency and capable of tightly pressing a wood board and collecting wood chips. To achieve the above technical purpose, the wood board cutting device for wood processing is provided and comprises a bottom plate and the like. An n-shaped frame is arranged on the top of the bottom plate, a netplate is arranged at the middle portion in the n-shaped frame, a cutting mechanism is arranged in the middle of the top in the n-shaped frame, pressing mechanisms are symmetrically arranged on the left side and the right side of the top in the n-shaped frame, and a sawing disc is arranged at the bottom of the cutting mechanism. The wood board cutting device can achieve the effects that the cuttingefficiency is high, the wood board can be tightly pressed, and the wood chips can be collected. The left side and the right side of the wood board are tightly pressed through the pressing mechanisms,then the cutting mechanism is used for driving the sawing disc to cut the wood board, a dust suction mechanism removes dust, and the collecting mechanism collects and recycles the wood chips.

Owner:广东澳林板业有限公司

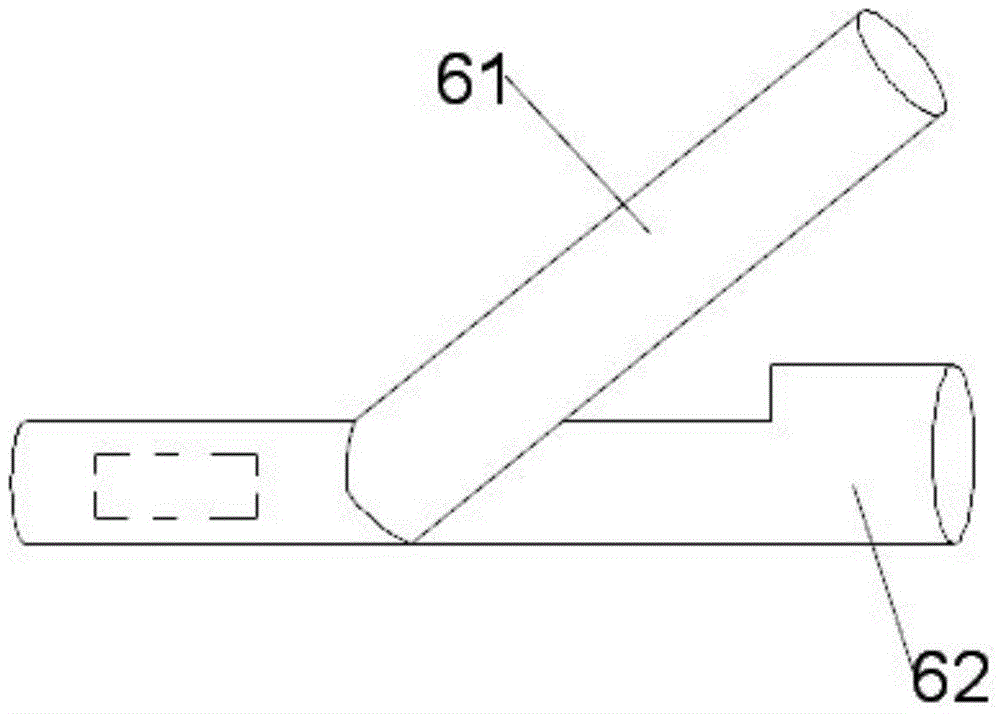

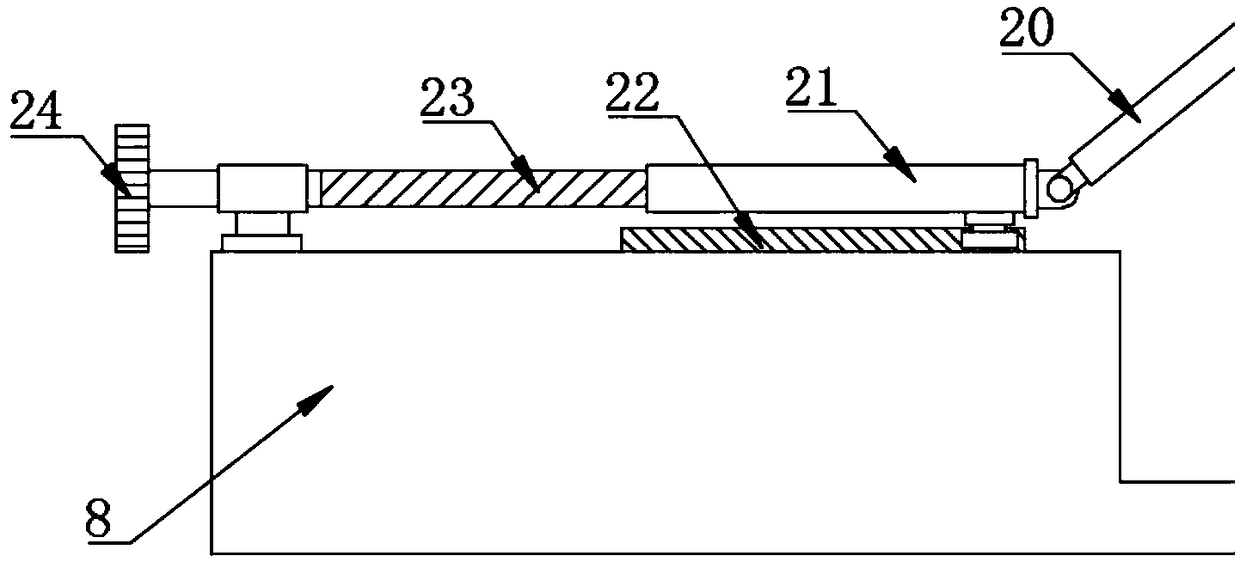

Board machining push mechanism

InactiveCN105083974APush level is accurateImprove processing efficiencyConveyor partsHydraulic cylinderWood processor

The invention discloses a board machining push mechanism, and belongs to the field of wood machining mechanical equipment. The board machining push mechanism comprises a main bracket, translation hydraulic cylinders, a push plate and a limiting plate, wherein multiple brake universal wheels are uniformly arranged at the lower side of the main bracket; two translation hydraulic cylinders are horizontally arranged at the two sides of one end of the main bracket; the push plate is horizontally arranged at output ends of the two translation hydraulic cylinders; limiting sleeves are respectively arranged at the two sides of the push plate; the limiting plate is horizontally arranged at one sides of the limiting sleeves; the upper side of the main bracket is horizontally and rotationally connected with multiple wood guide rollers; the upper end of a wood guide bracket is hinged to the main bracket; wood guide hydraulic cylinders are respectively arranged between the two sides of the wood guide bracket and the main bracket; the tail ends of the wood guide hydraulic cylinders are hinged with the main bracket; and the output ends of the wood guide hydraulic cylinders are hinged to the middle part of the wood guide bracket. The board machining push mechanism is simple in structure, can quickly and efficiently move boards horizontally and accurately, improves the board machining efficiency and quality, and satisfies the production and use demands.

Owner:徐阳

Wood working machine

ActiveUS20100108194A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWood processorEngineering

Owner:STEPP LEWIS E

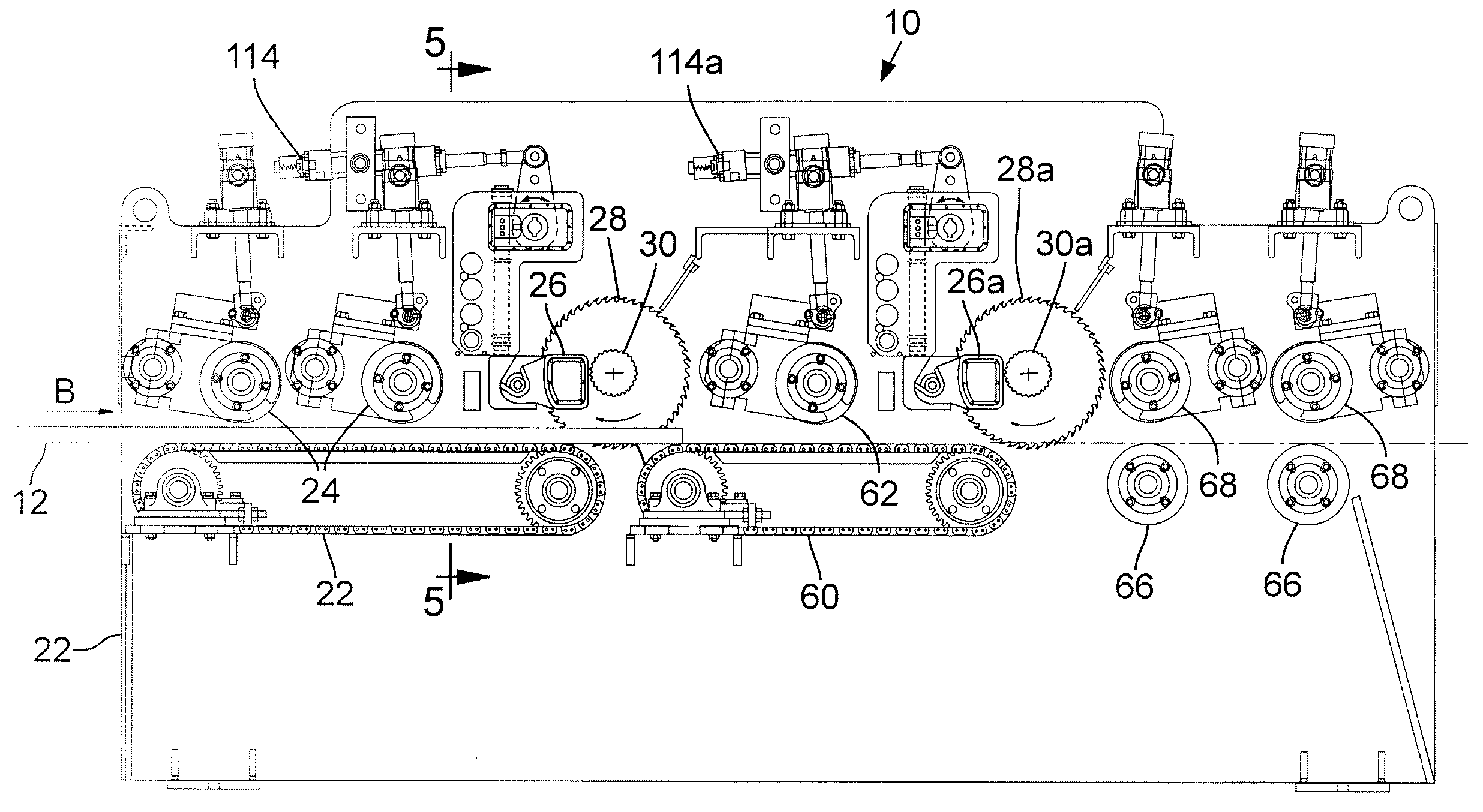

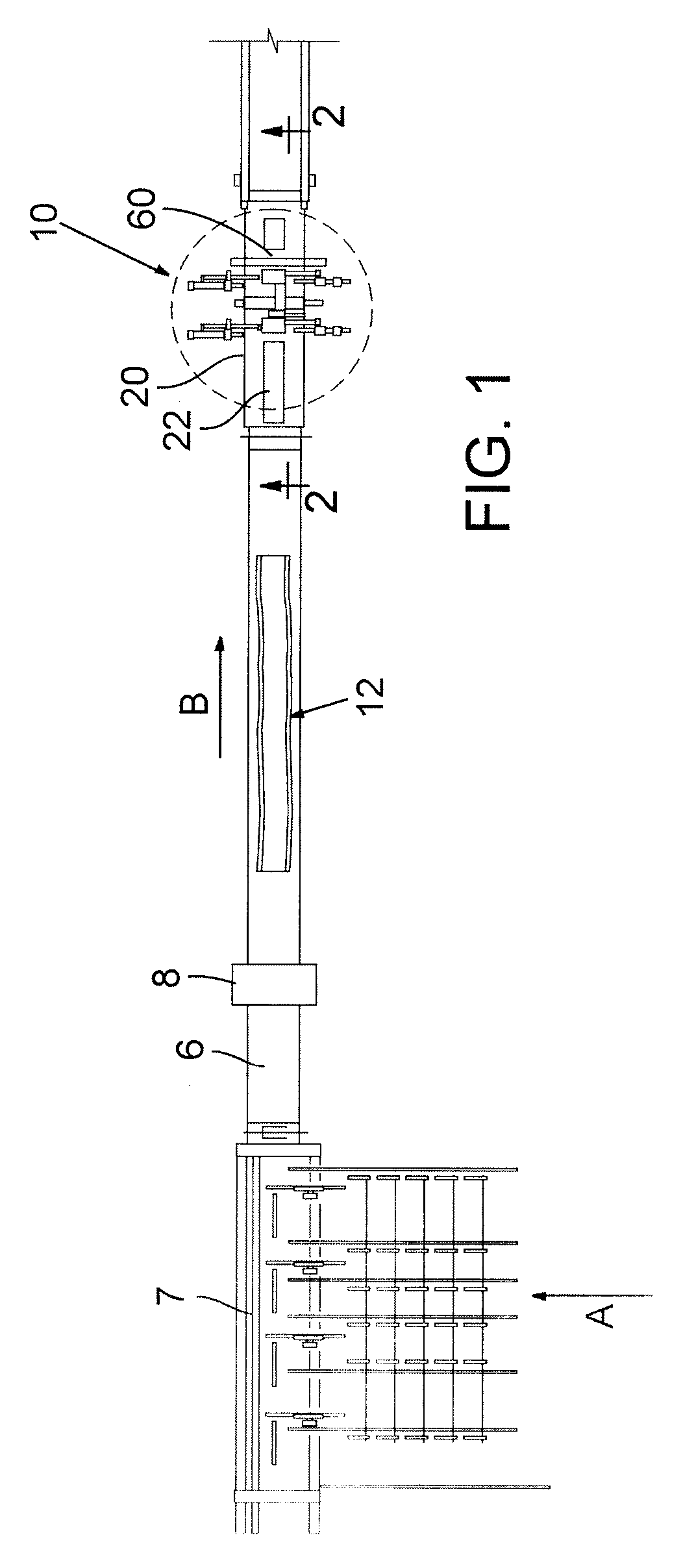

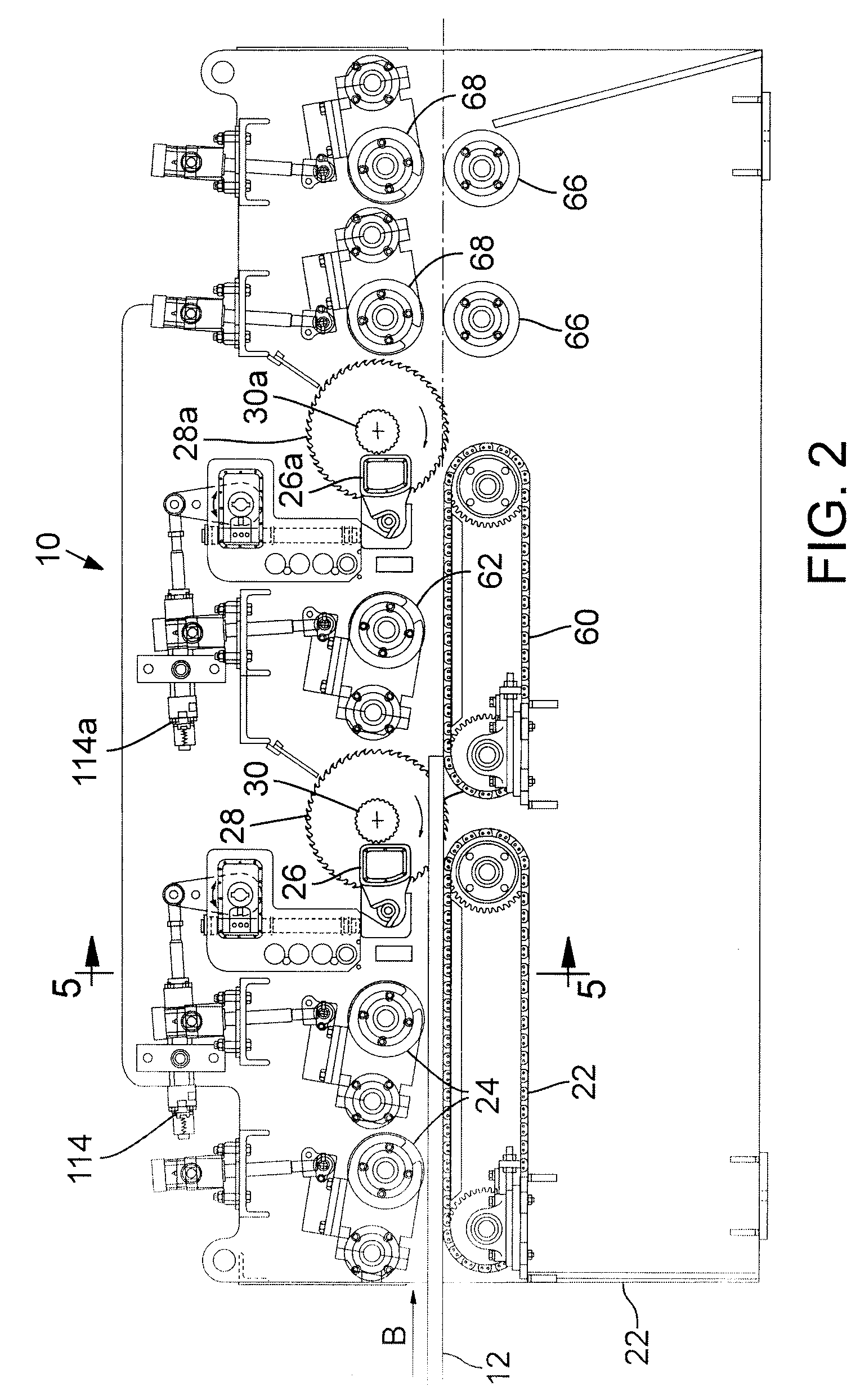

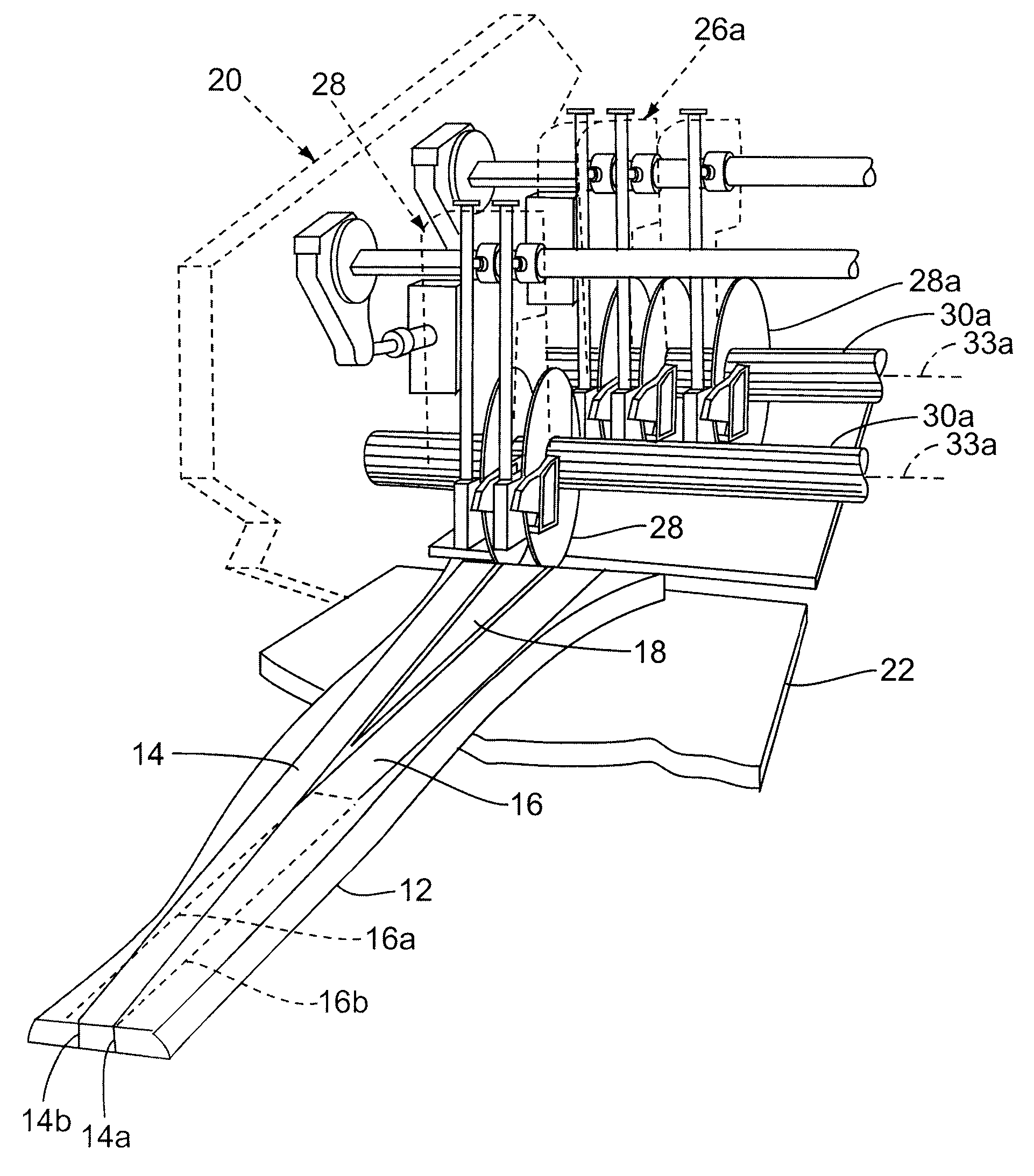

Edger with staggered saws

InactiveUS20080314478A1Most recoveryPromote recoveryMulti-purpose machinesFeeding apparatusWood processorEngineering

Embodiments of the present invention provide a wood processing machine adapted to cut wood workpieces along multiple optimized cutting paths. In various embodiments, the wood processing machine includes a first saw assembly and a second saw assembly that is disposed down stream from the first saw assembly. The first saw assembly is adapted to cut the workpiece along the first optimized cutting path and the second saw assembly is adapted to cut the workpiece along the second optimized cutting path.

Owner:USNRKOCKUMS CANCAR

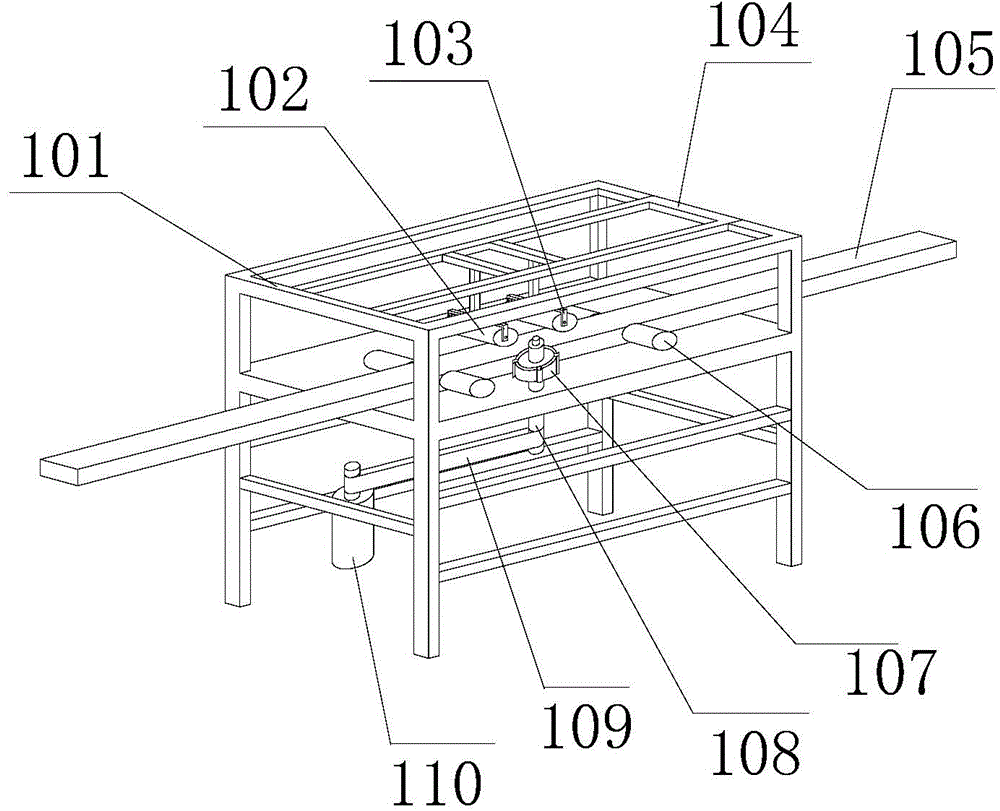

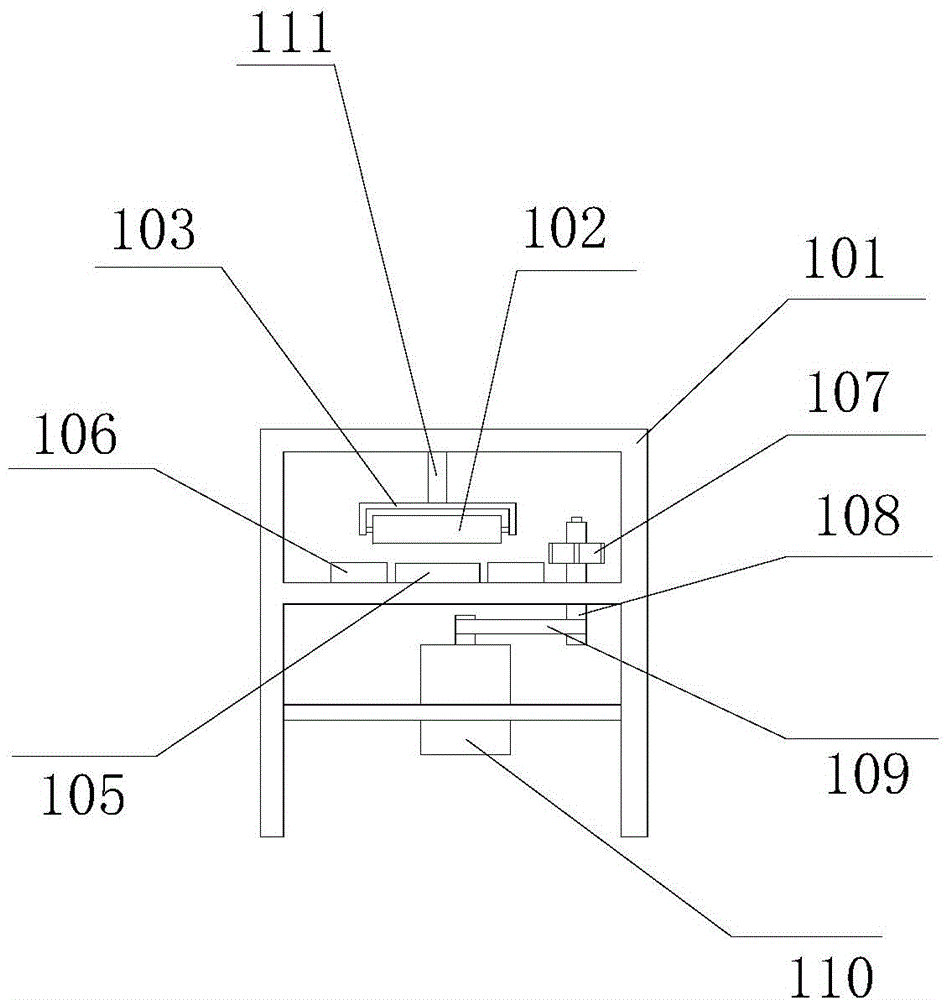

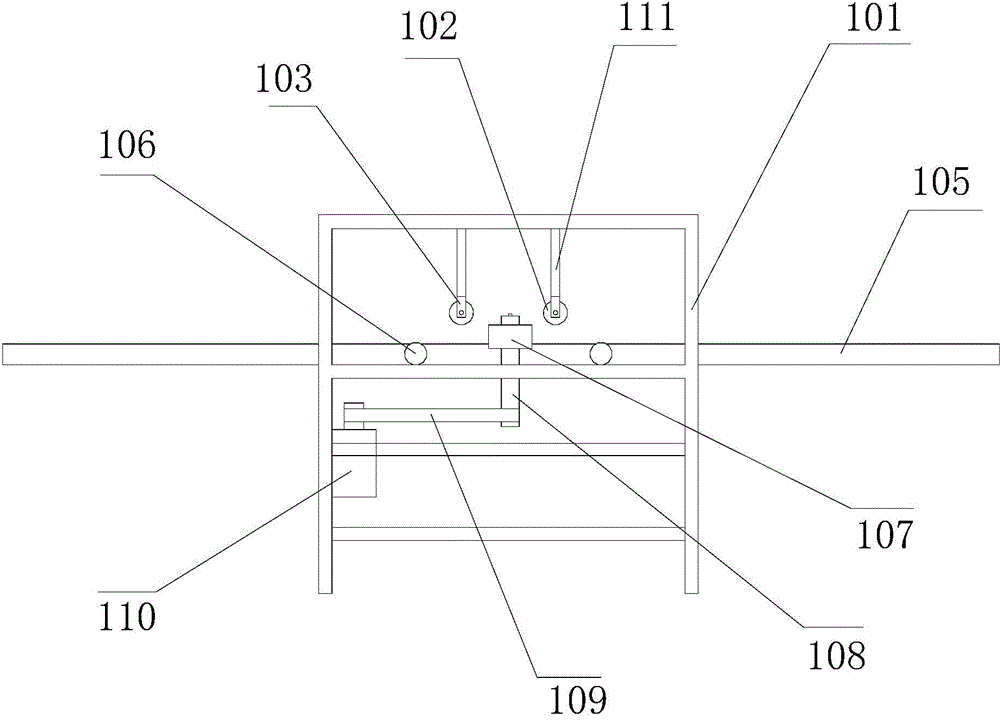

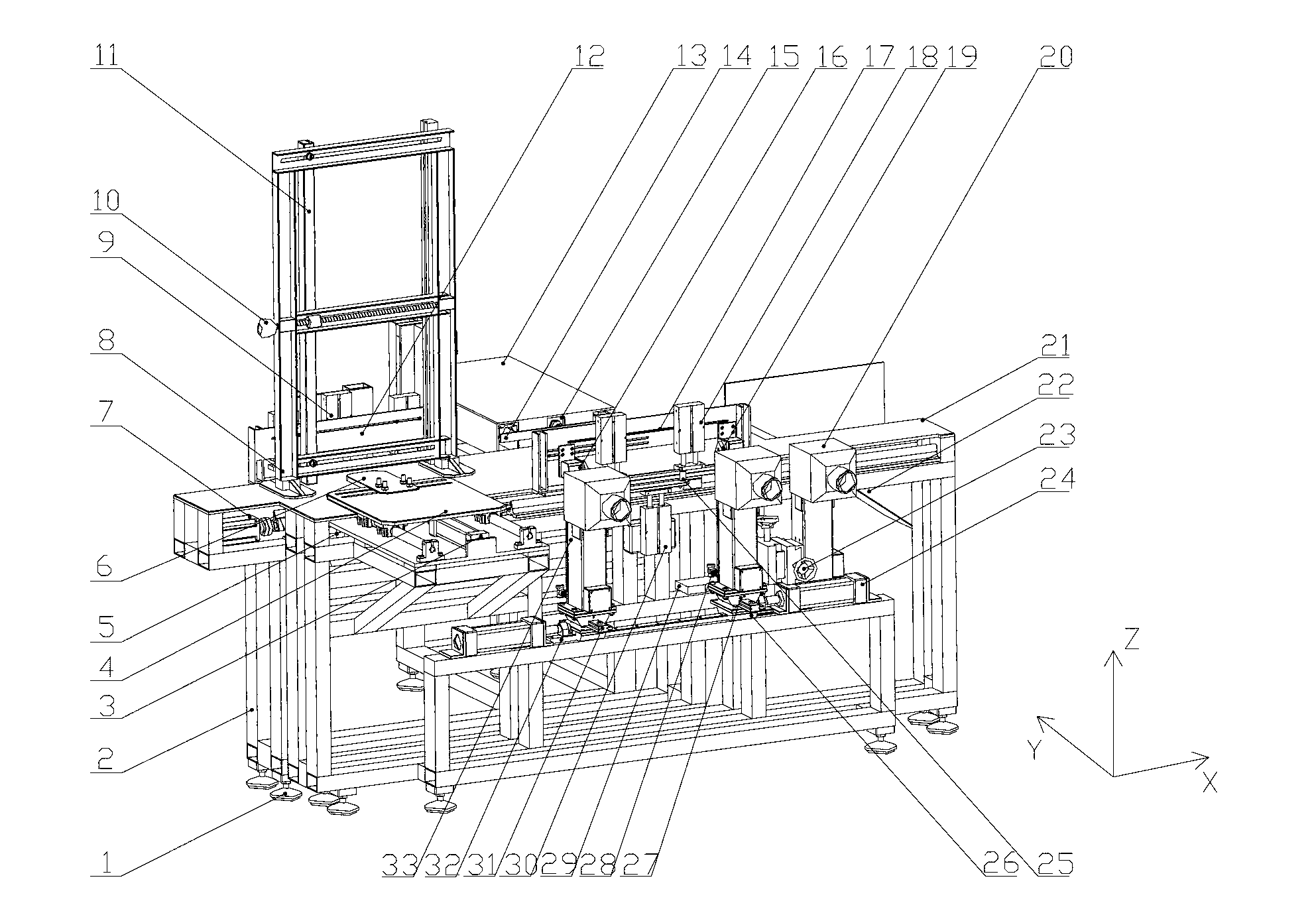

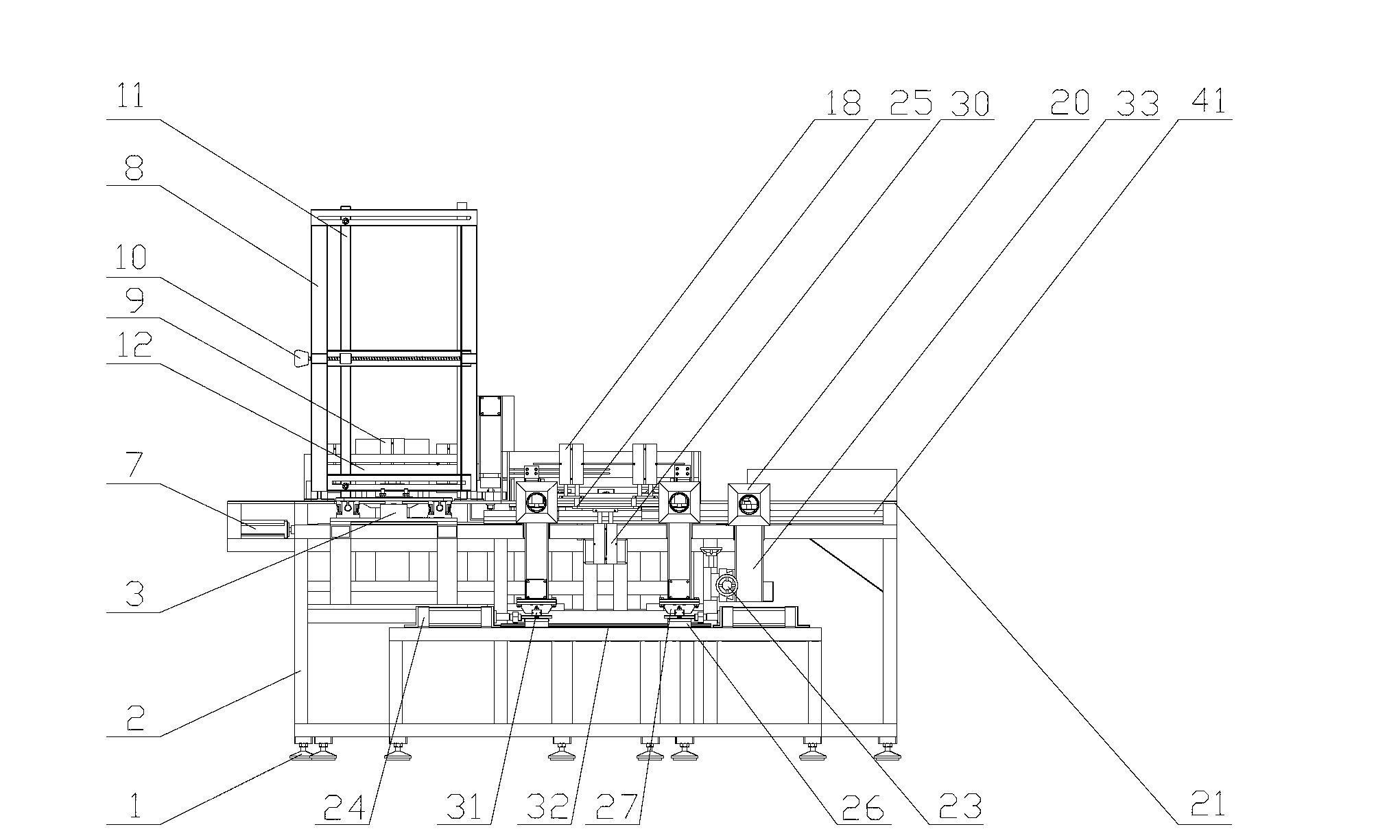

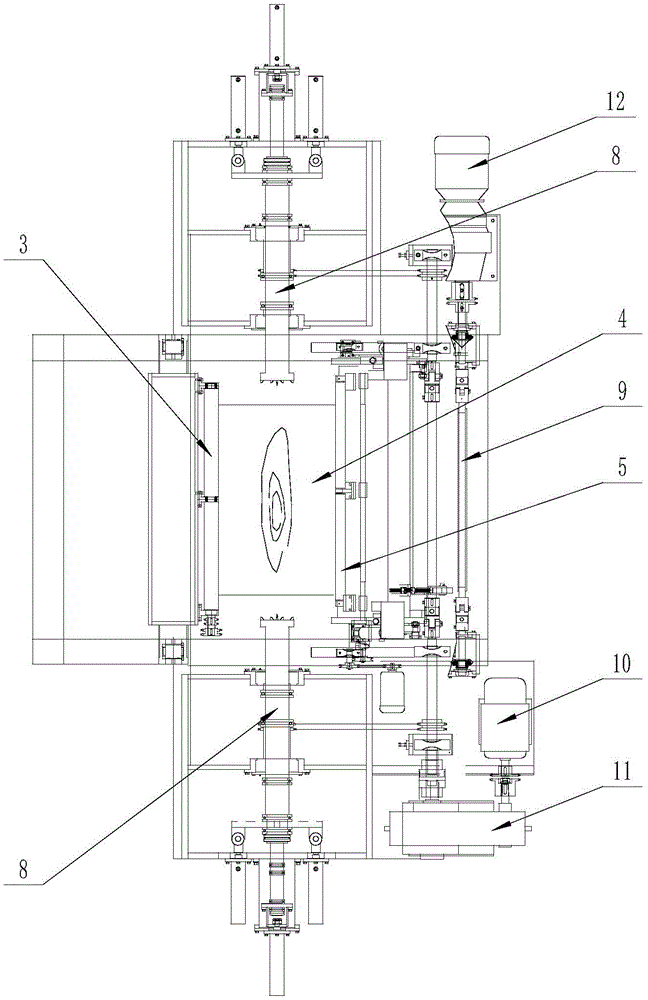

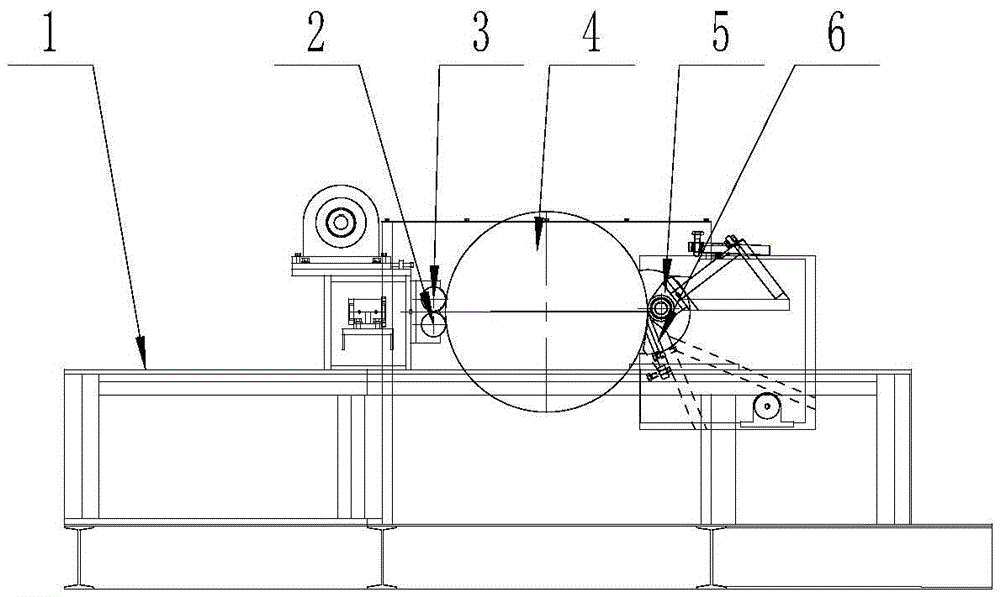

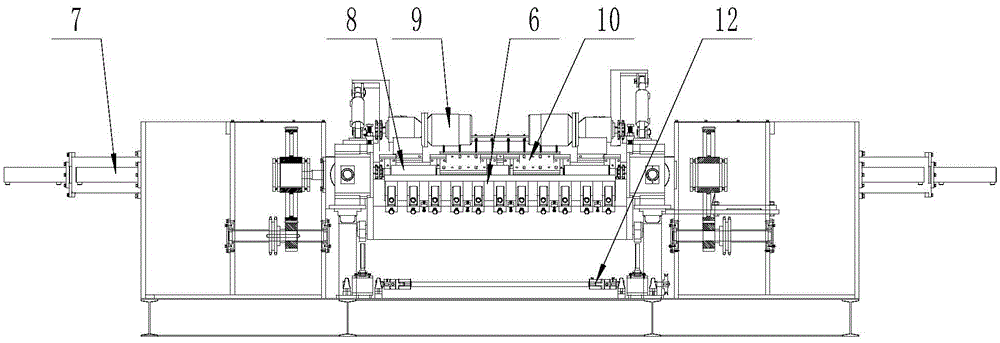

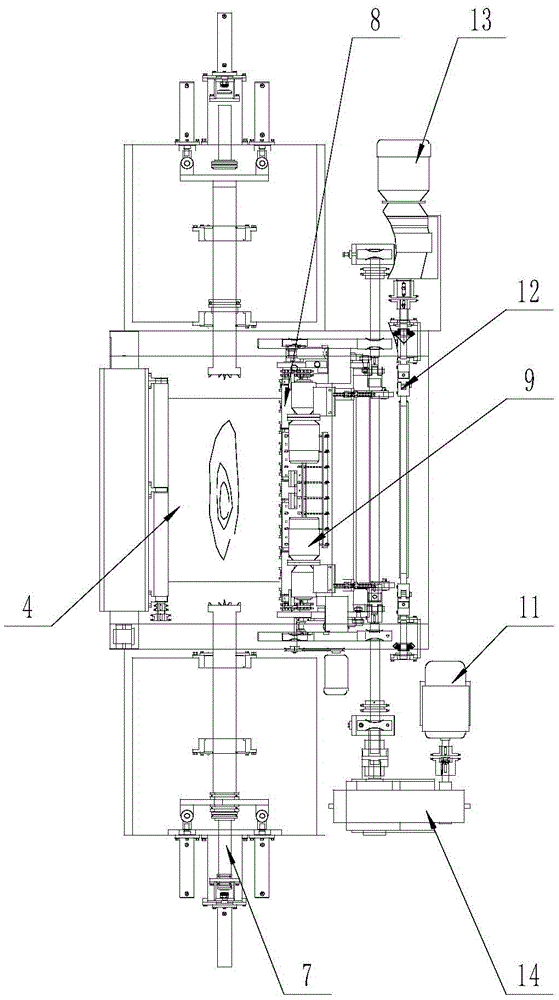

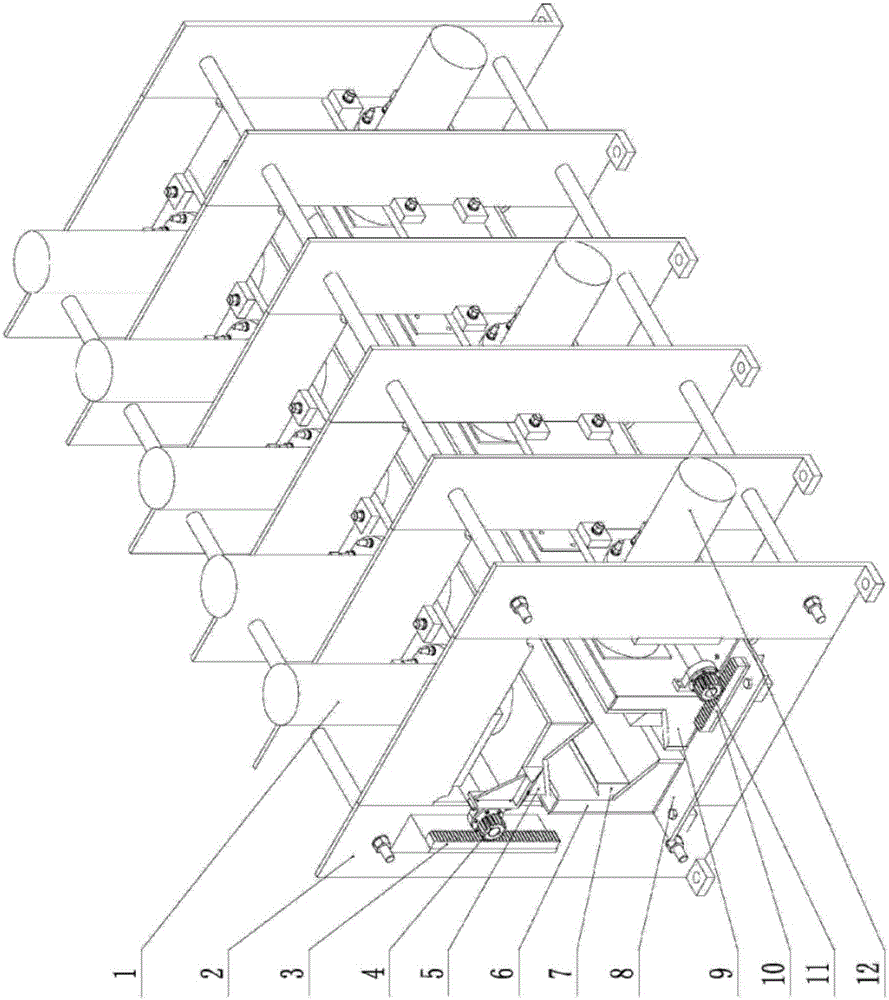

Full automatic wood processor

InactiveCN103264426AImprove efficiencyVarious processing specificationsWood working apparatusWood processorEngineering

The invention relates to a full automatic wood processor, relates to a wood processing machine, and provides a full automatic wood processor which is concentrated in working procedures, high in efficiency, automatic and various in processing specifications. The full automatic wood processor is provided with a base, a supporting frame, a fixed platform, an XIYI screw rod guide rail module, an XII air cylinder linear guide rail module, a blanking module, a pushing module, a positioning module, an exploratory processing module, a cutting module and corresponding electrical elements, wherein the XIYI screw rod guide rail module consists of an XI axis screw rod guide rail module and a YI axis screw rod guide rail module; and the pushing module is provided with an air cylinder guide rail, a working procedure I pushing module and a working procedure II pushing module.

Owner:XIAMEN UNIV OF TECH

Edger with staggered saws

InactiveUS7861754B2Promote recoveryIncrease valueMulti-purpose machinesFeeding apparatusWood processorEngineering

Embodiments of the present invention provide a wood processing machine adapted to cut wood workpieces along multiple optimized cutting paths. In various embodiments, the wood processing machine includes a first saw assembly and a second saw assembly that is disposed down stream from the first saw assembly. The first saw assembly is adapted to cut the workpiece along the first optimized cutting path and the second saw assembly is adapted to cut the workpiece along the second optimized cutting path.

Owner:USNRKOCKUMS CANCAR

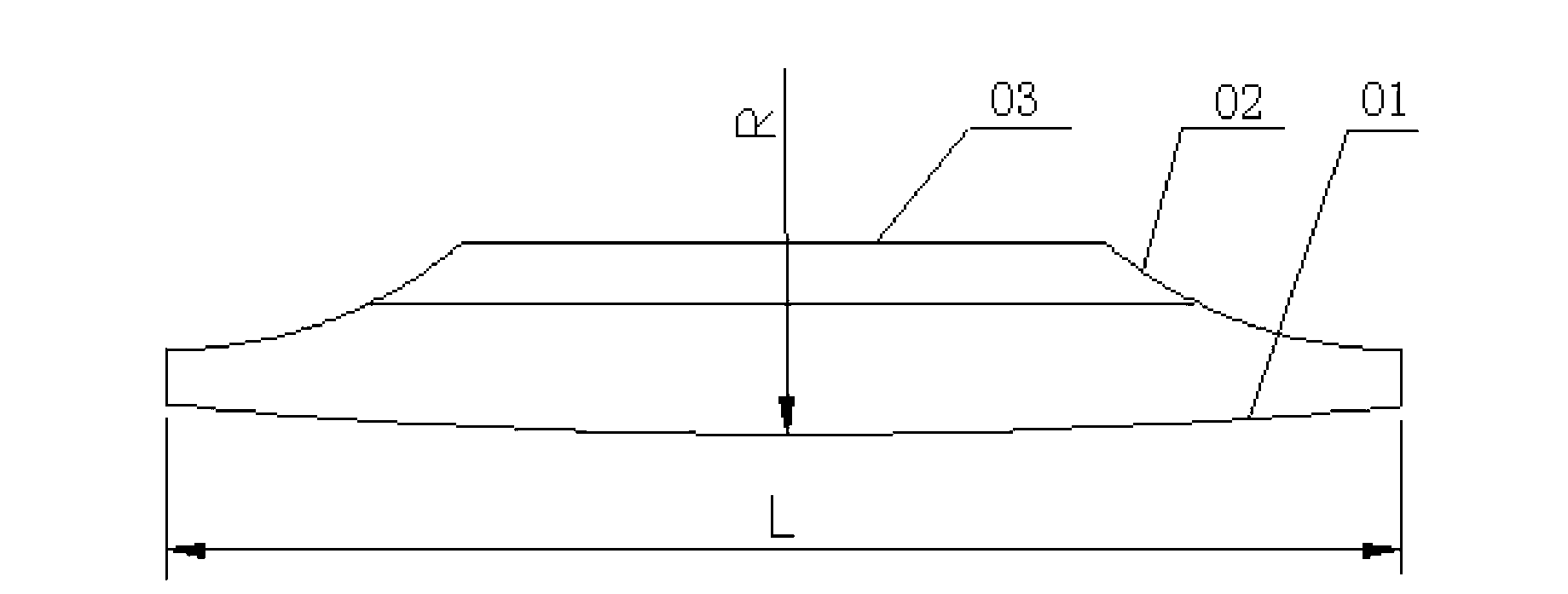

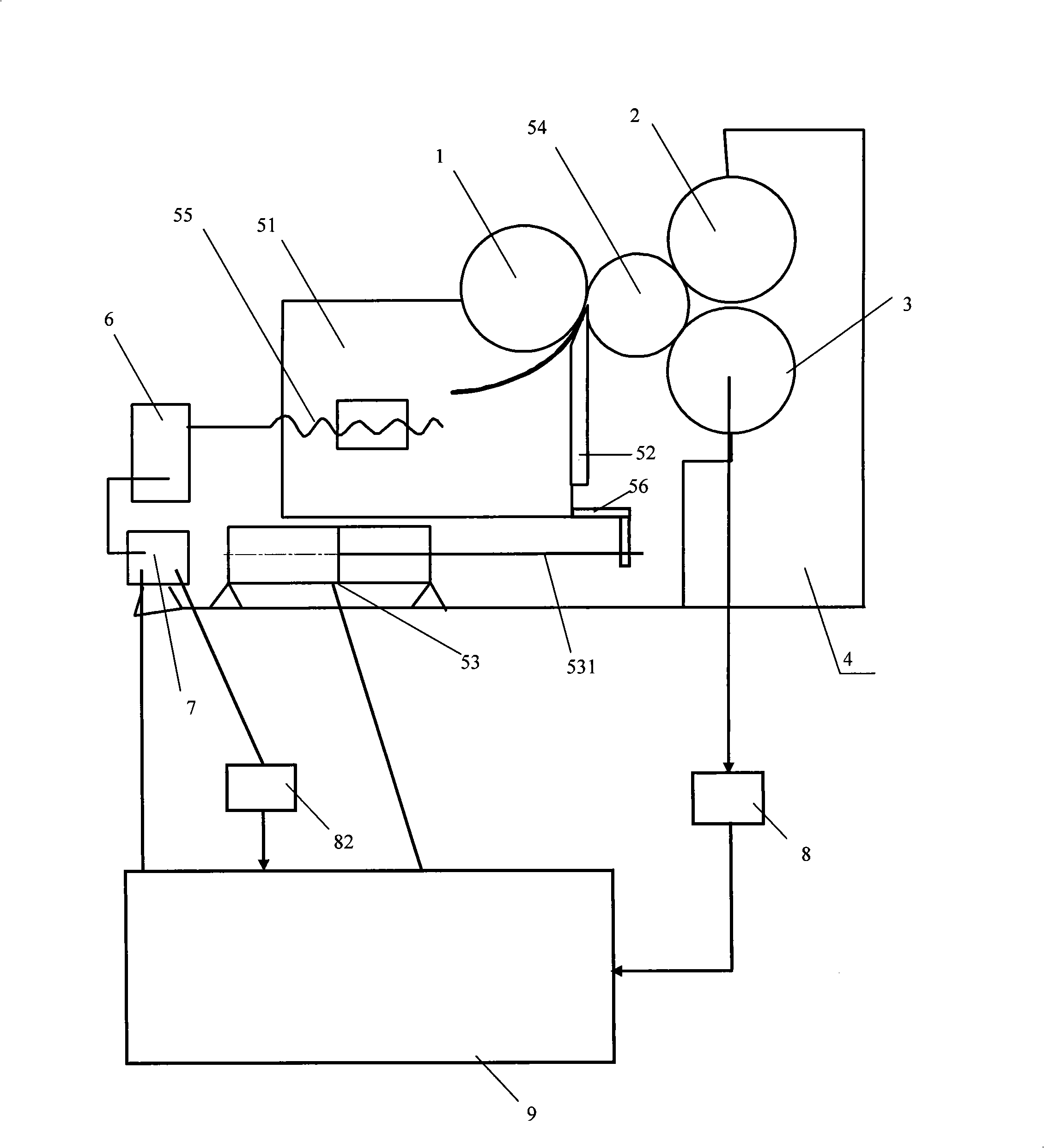

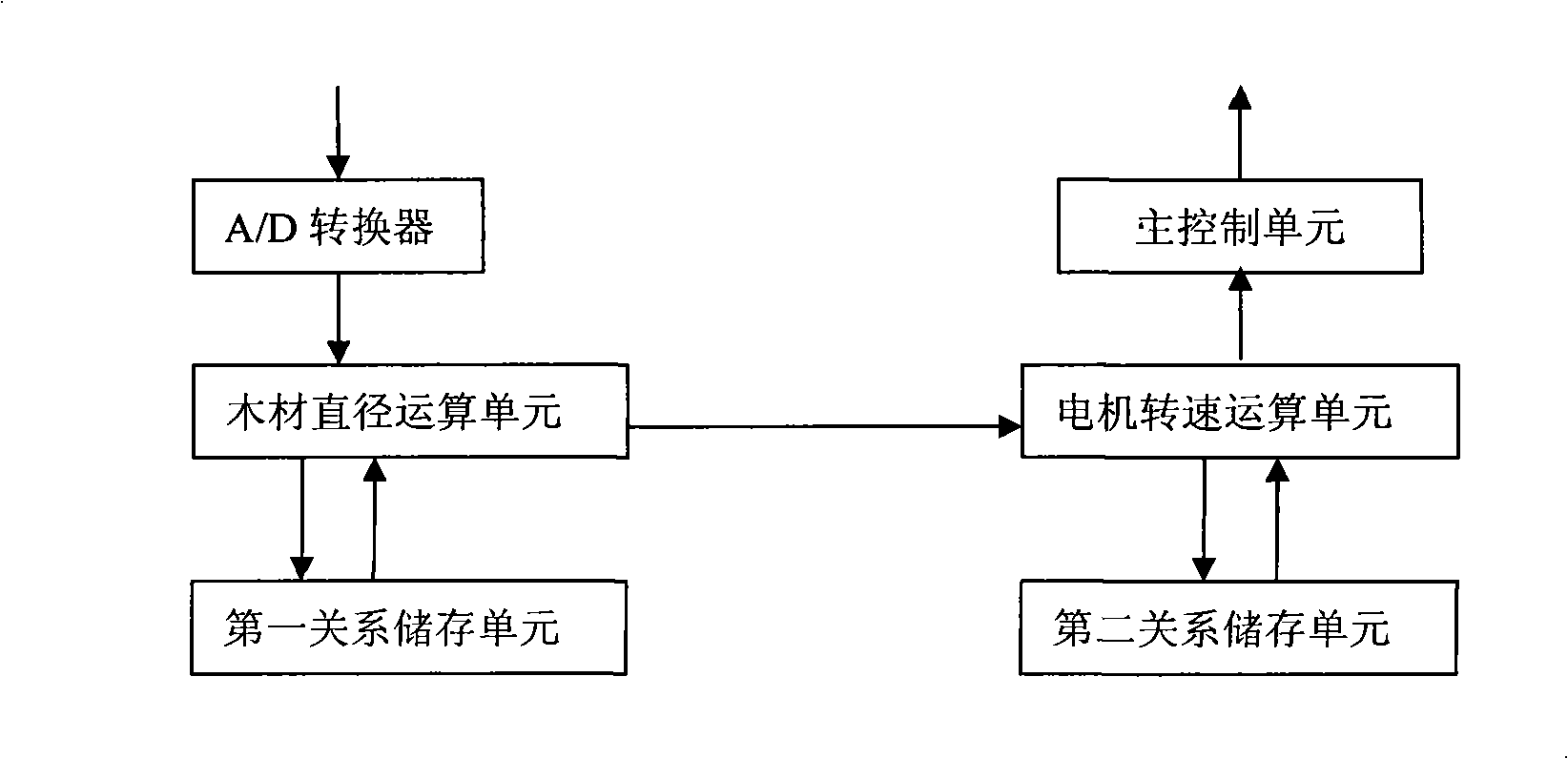

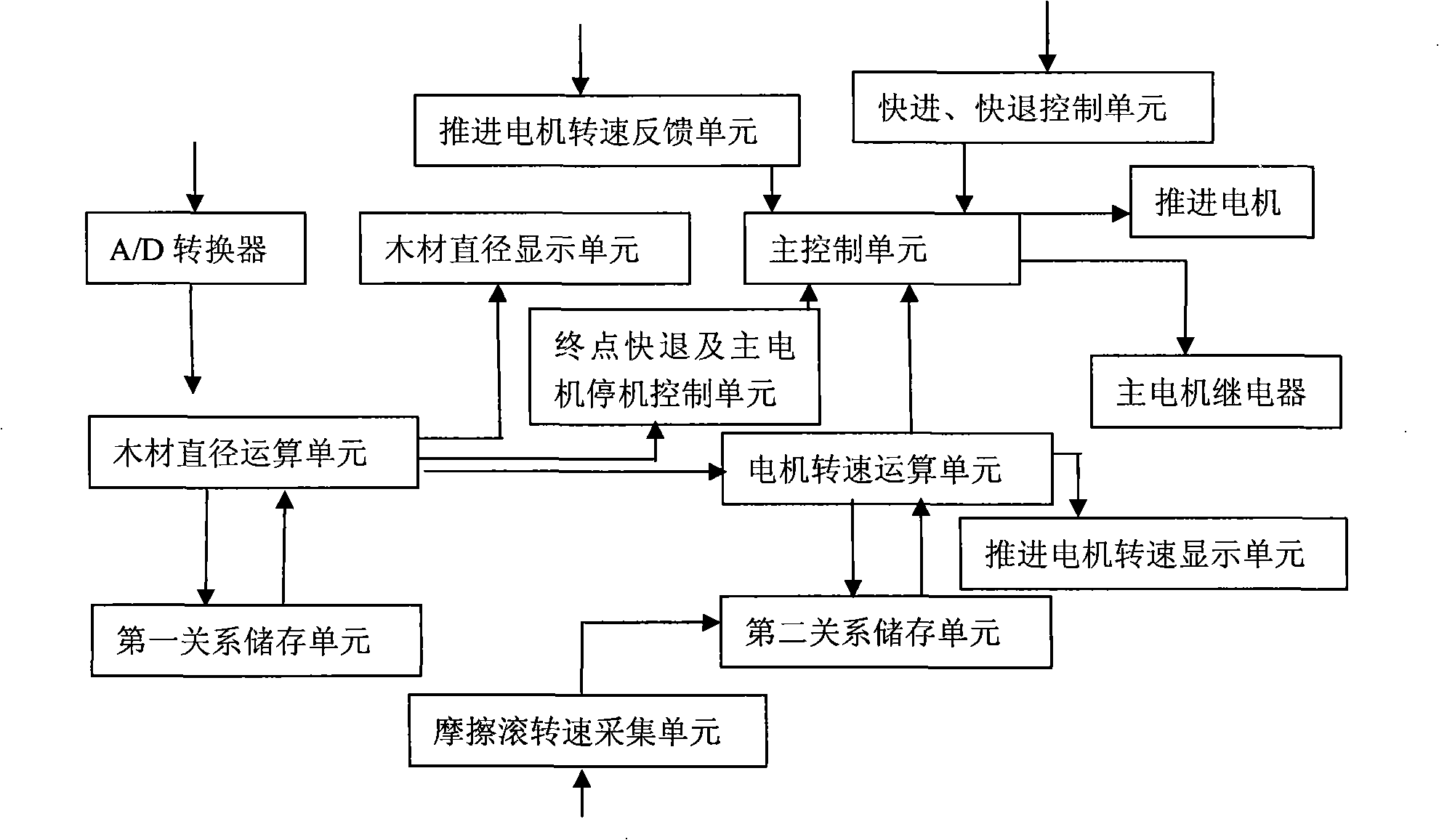

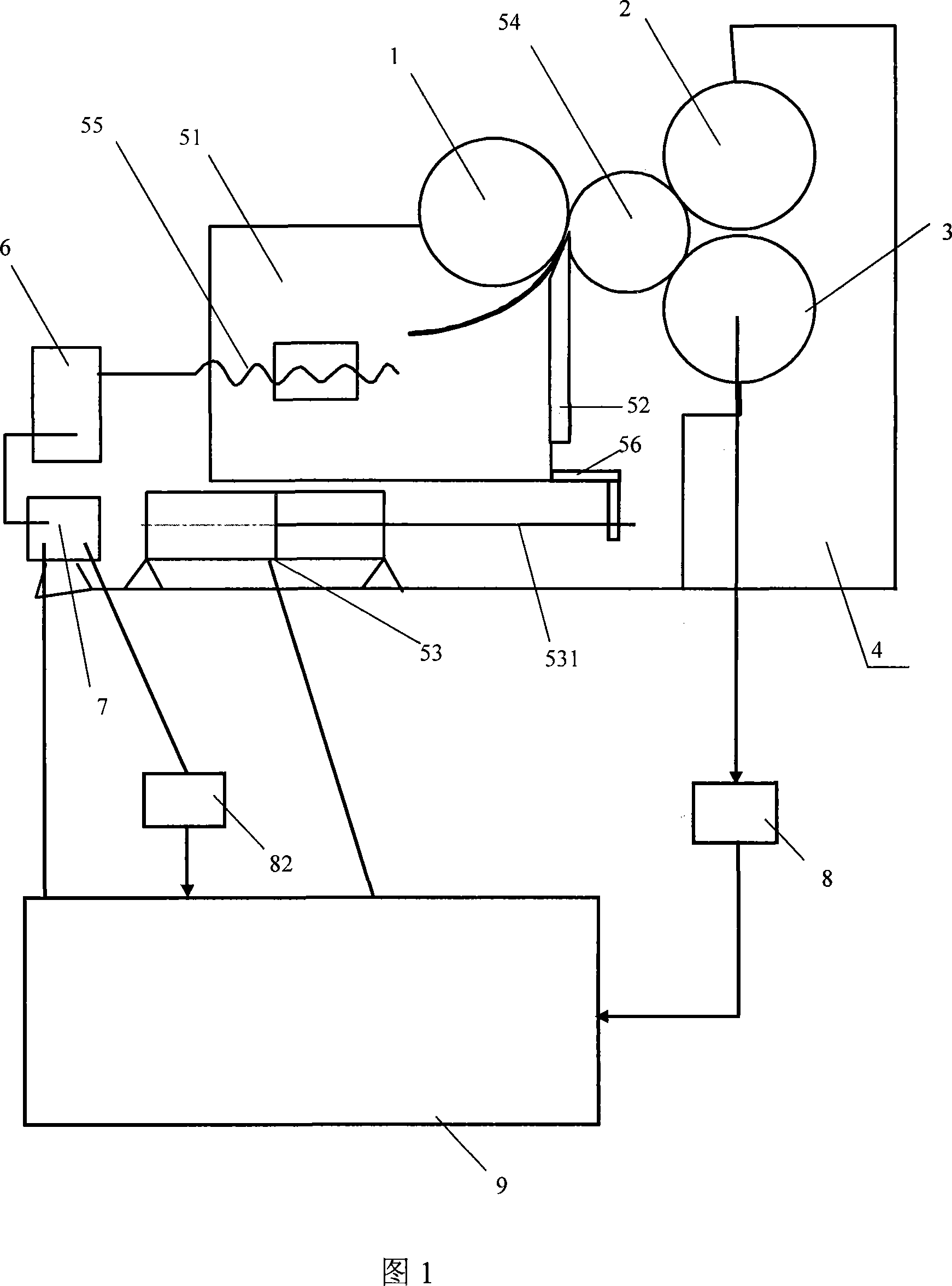

Numerical control non-fastening-shaft rotating cutter and special transducer thereof and feed automatic speed regulation method

InactiveCN101332618AEasy to detectEasy to operateAC motor controlVeneer manufactureFrequency changerNumerical control

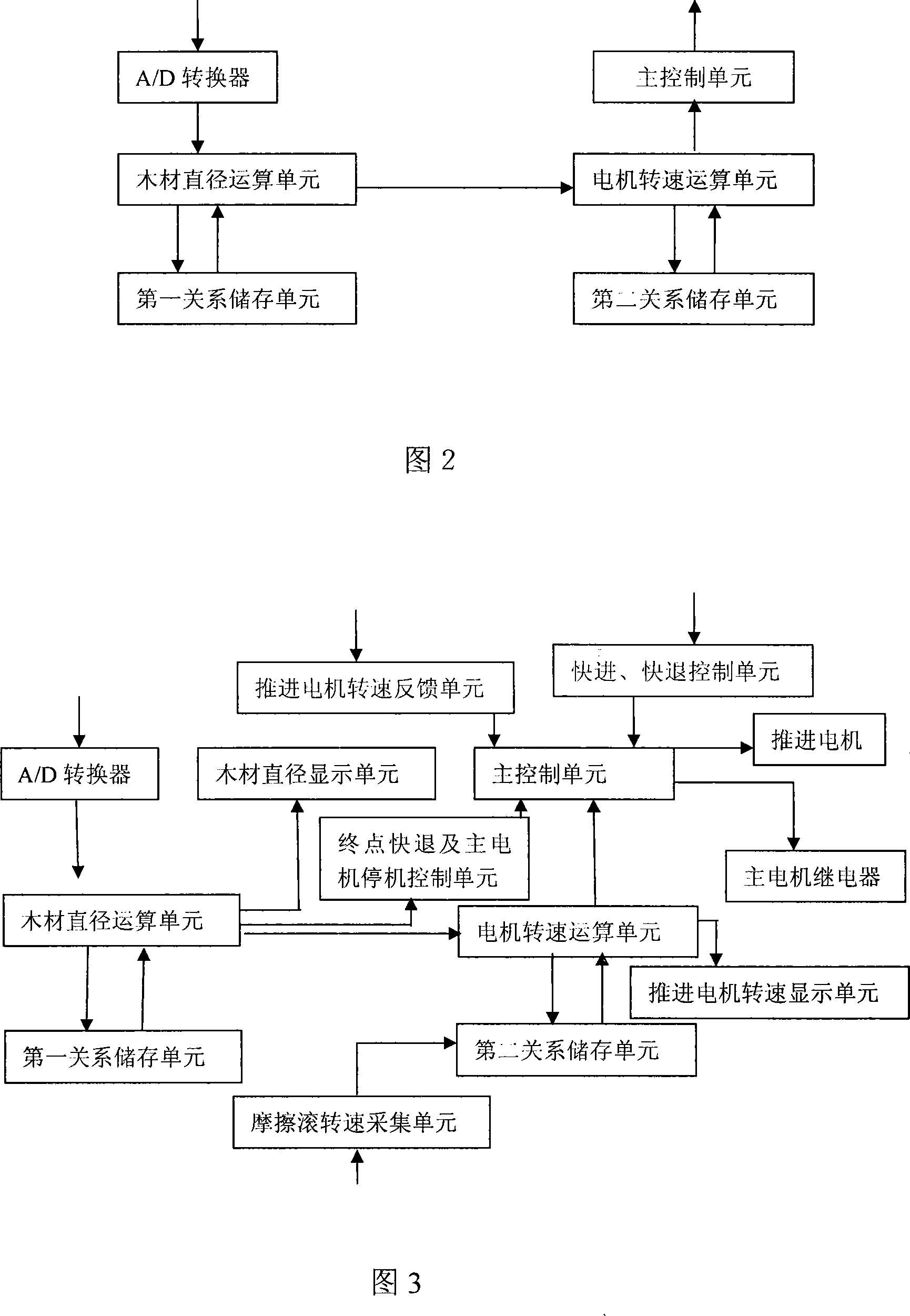

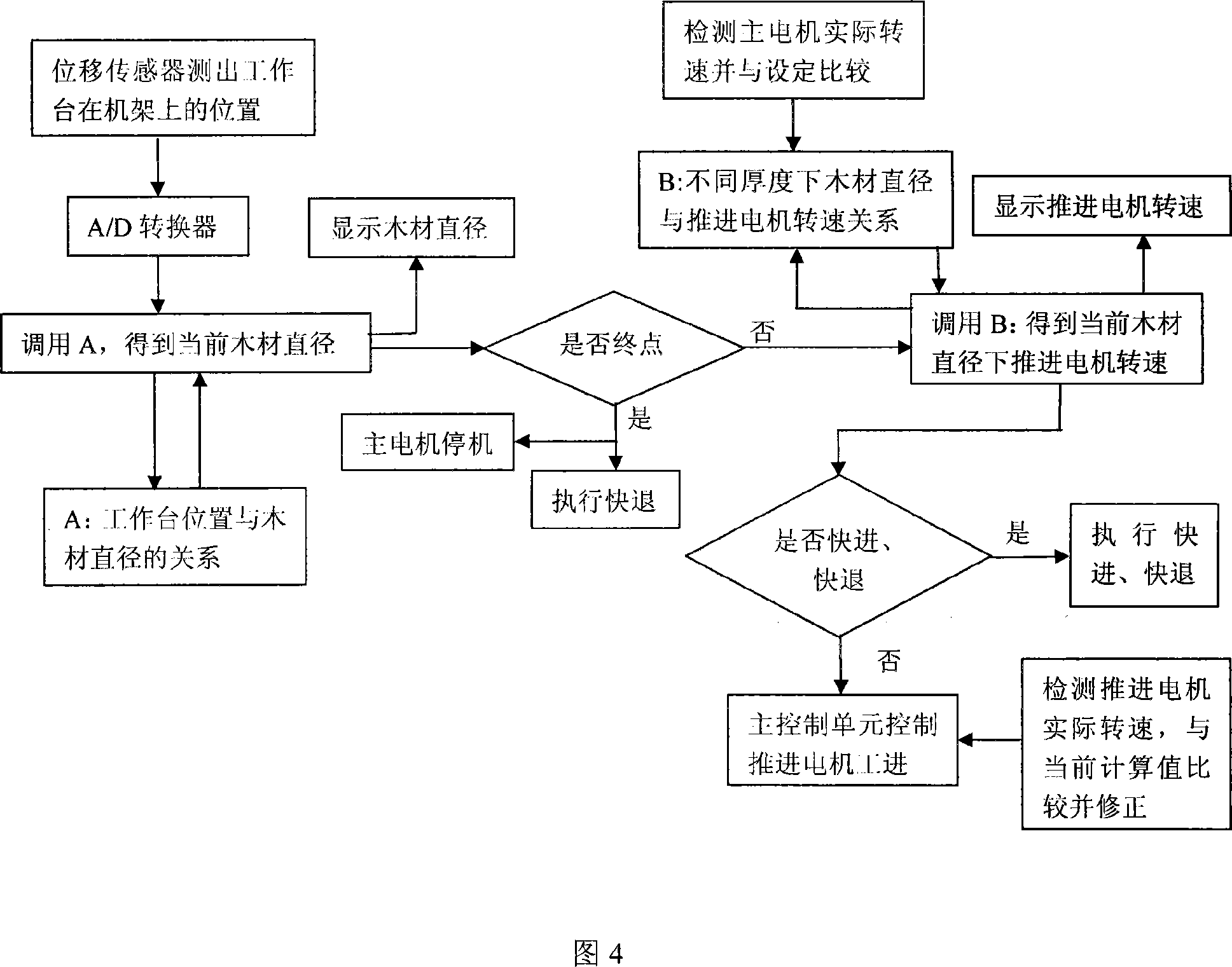

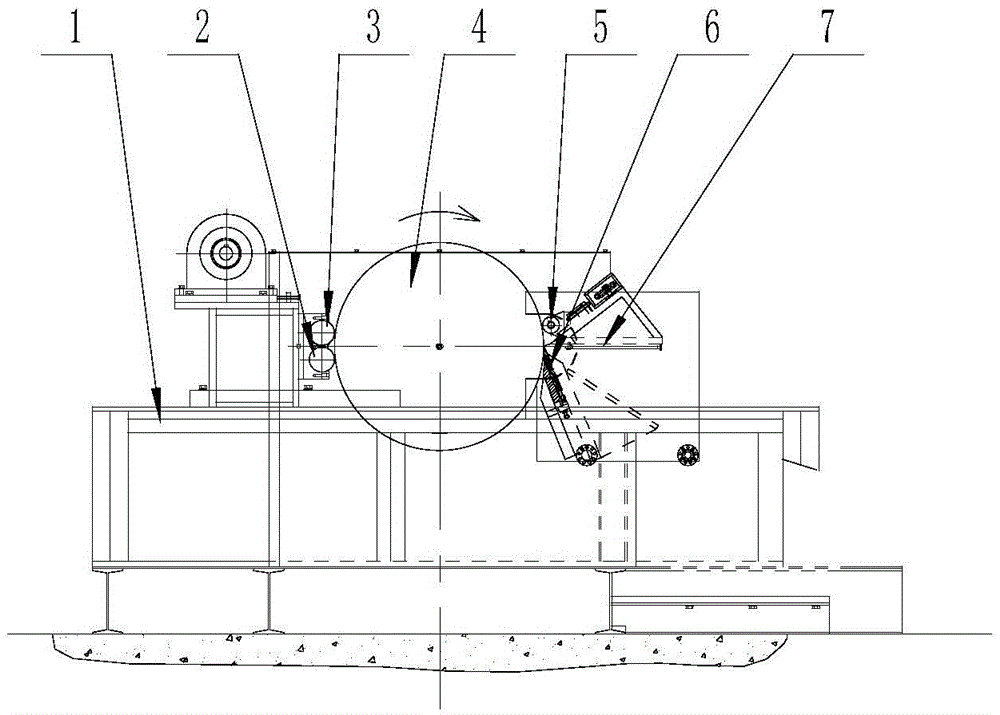

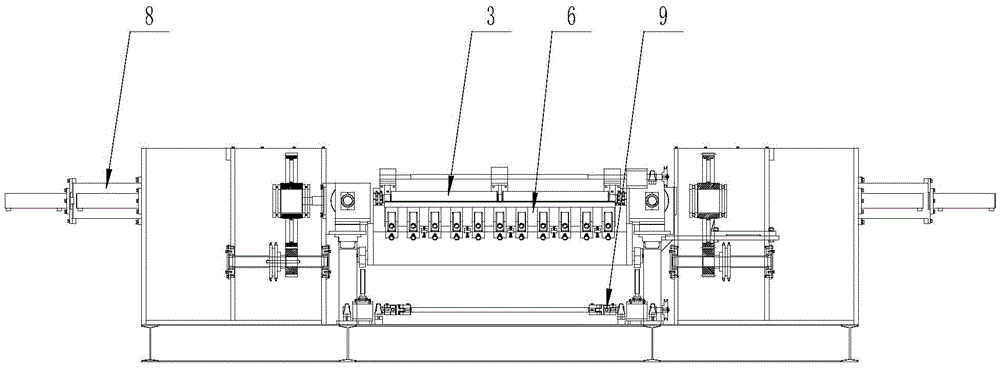

The invention provides a numerical control no-card shaft rotary lathe, a special frequency converter and a feeding automatic speed regulation method, and relates to a wood processing machine and a special part and an application method used for the wood processing machine. The numerical control no-card rotary lathe of the invention also comprises a sensor which converts the position point of a workbench into an electric signal; the frequency converter is a special frequency converter which also comprises a first relation memory unit, a wood diameter operation unit, a second relation memory unit and a motor rotation speed operation unit; the first relation memory unit memorizes the corresponding relation between the position of the workbench and the diameter of the wood; the second relation memory unit memorizes the corresponding relation between the diameter of the wood and the rotation speed of a propulsion motor under different single plate thickness. The wood processing machine and the special part and the application method used for the wood processing machine save a plurality of stroke switches necessarily arranged by the existing automatic control system, especially lead the works completed by computer and PLC to be completed directly by the special frequency converter, greatly reduce the equipment cost, lead the operation of the equipment to be simple and convenient at the same time, and are beneficial for the market generalization.

Owner:吕宝伟

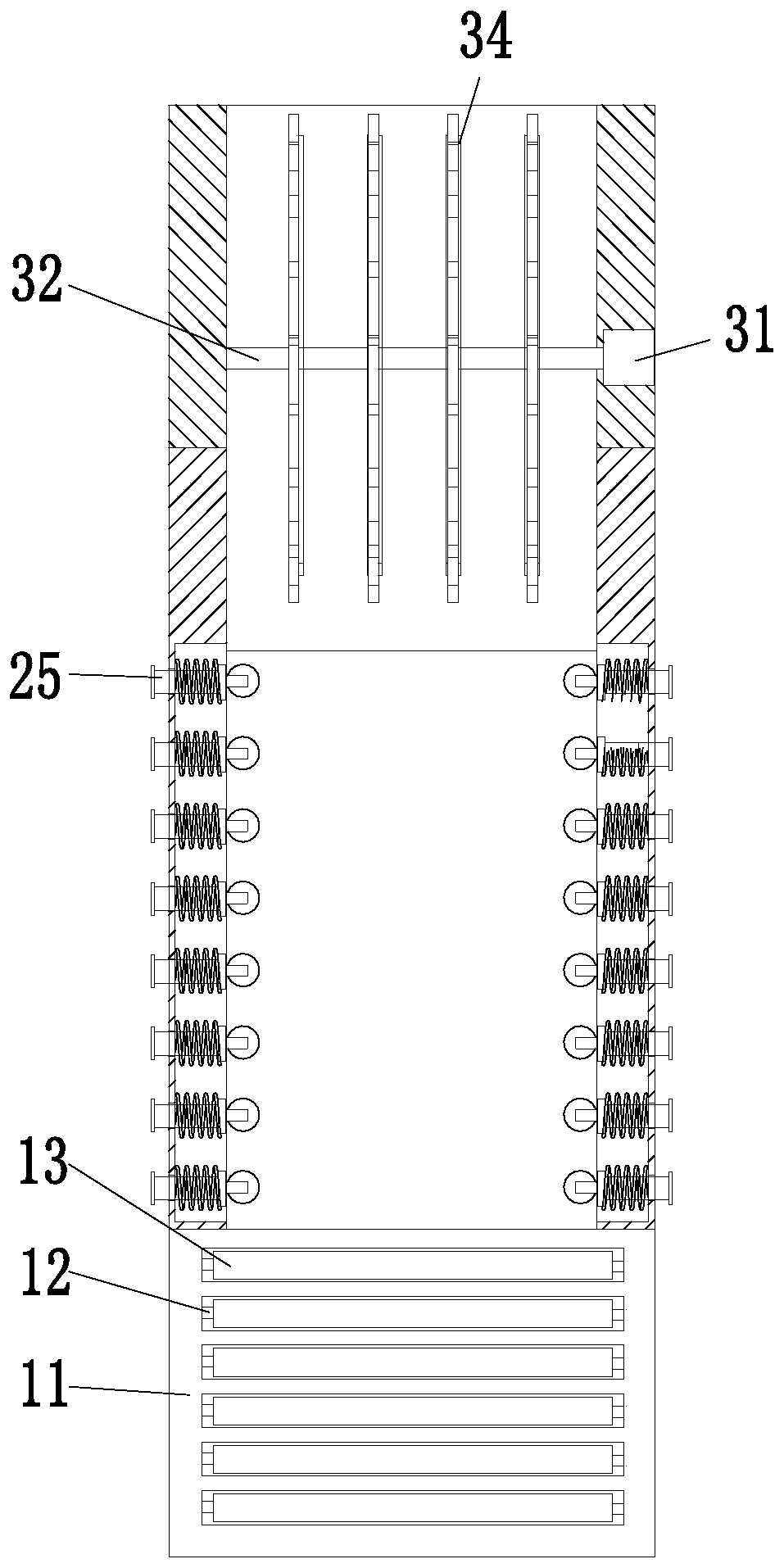

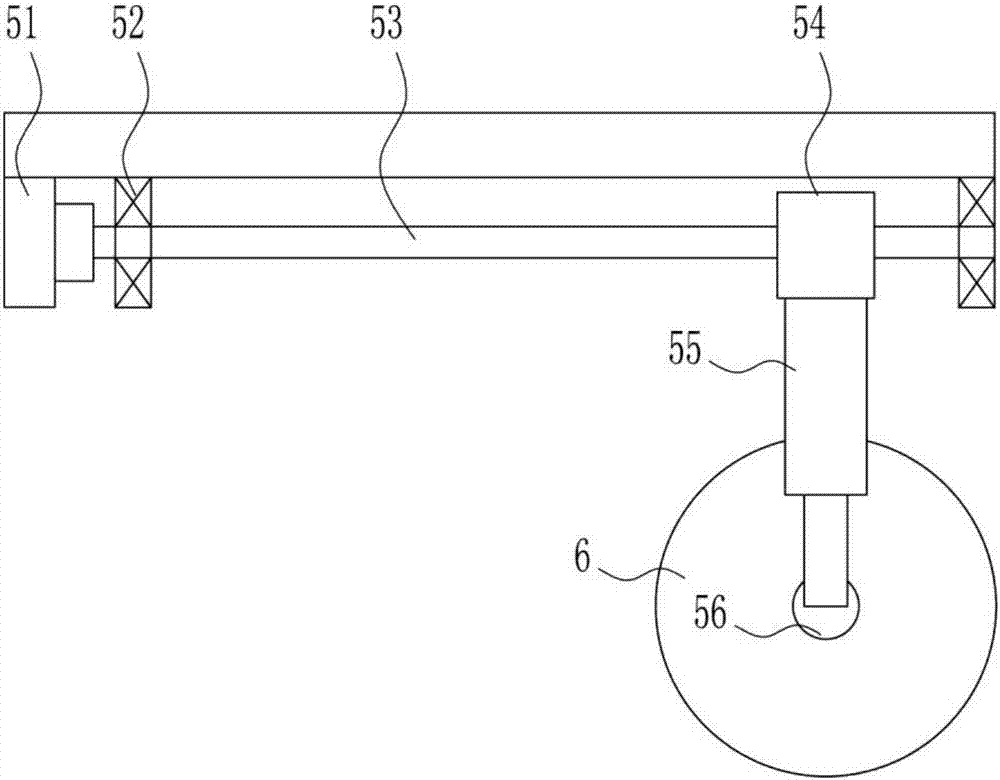

Punching mechanism for board

InactiveCN105082266AAccurate lifting levelImprove drilling efficiencyStationary drilling machinesHydraulic cylinderPunching

The invention discloses a punching mechanism for a board and belongs to the field of wood machining mechanical equipment. The punching mechanism comprises a fixed base, punching supports, punching hydraulic cylinders, a lifting plate, a punching motor and punching rods. The punching supports are vertically symmetrically arranged on the two sides of the fixed base. The two punching hydraulic cylinders are vertically downwards arranged on the upper sides of the punching supports. The punching motor is vertically upwards arranged in the middle of the lifting plate. The output end of the punching motor is horizontally provided with a driving gear. The upper ends of the punching rods are horizontally provided with punching gears respectively. The driving gear at the output end of the punching motor is connected with the punching gears on the adjacent punching rods in a meshed manner. A connecting gear is rotationally connected between every two punching gears on the same side of the lifting plate. The two sides of each connecting gear are connected with the corresponding two punching gears respectively in a meshed manner. A punching groove is horizontally formed in the fixed base. The punching mechanism is simple in structure, multiple round holes are synchronously punched in the board conveniently, and the requirement for production and use is met.

Owner:徐阳

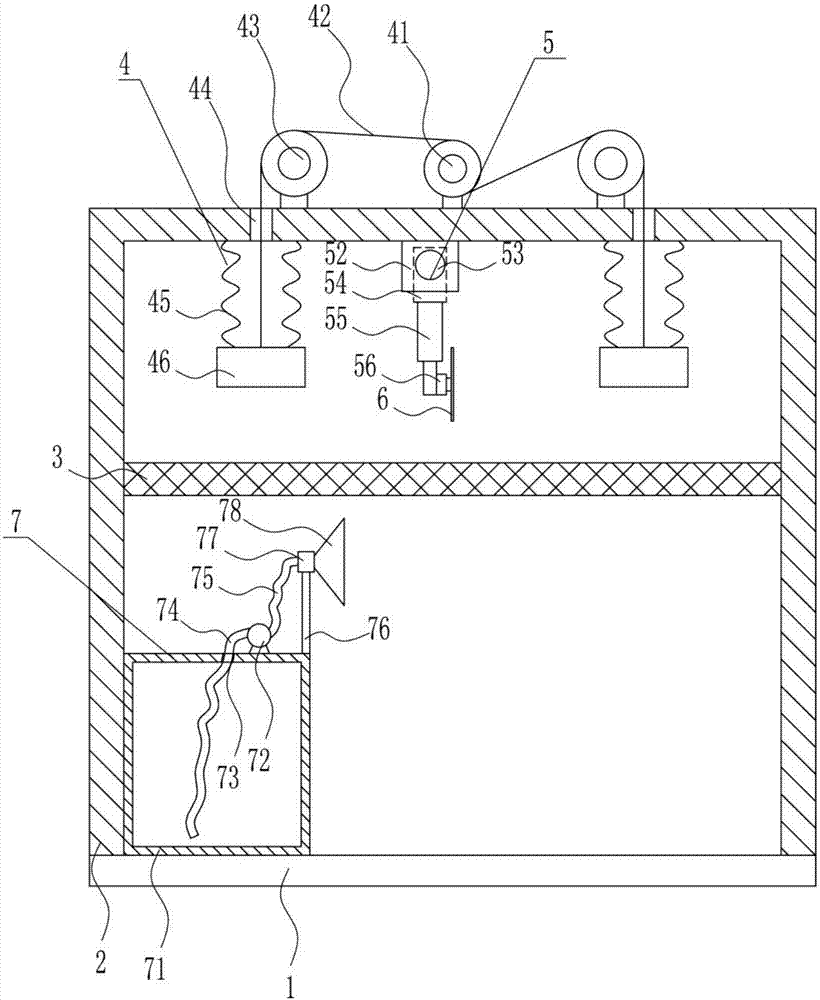

Safe, automatic and uniform board slitting device

InactiveCN107283529AAvoid harmProtect life and property safetyFeeding devicesGripping devicesWood processorWood machining

The invention discloses a safe, automatic and uniform board slitting device. The device comprises a box; the top of the inner wall of the box is fixedly connected with a cutting box; an opening matched with the cutting box is formed in the top center of the box; one side of the inner wall of the cutting box is fixedly connected with a first motor through a first motor fixed base; one side of the first motor is rotationally connected with a first belt wheel through an output shaft; the top of the inner wall of the cutting box is rotationally connected with a rotary connecting shaft; two ends of the rotary connecting shaft are rotationally connected with the tops of two sides of the inner wall of the cutting box; and rotating grooves matched with the rotary connecting shaft are formed in the tops of two sides of the inner wall of the cutting box. The device relates to the technical field of wood machining machinery. The safe, automatic and uniform board slitting device solves the problems of weak operation stability, low machining efficiency and possible generation of injury of operators in a traditional board slitting device, effectively improves the operation safety, reduces environmental pollution, and greatly improves the working efficiency.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Efficient stick section cutting machine

PendingCN107351189AImprove processing efficiencyEasy to operateFeeding devicesCircular sawsWood processorCircular saw

Owner:广西河池市宜州梦若天蓝信息科技有限公司

Raw wood cutting device for wood processing

The invention discloses a raw wood cutting device for wood processing. A fixed hydraulic cylinder and a movable hydraulic cylinder are arranged on the left and right sides of the upper end of a devicebody correspondingly. The upper end of the fixed hydraulic cylinder is fixedly connected with the device body. The upper end of the movable hydraulic cylinder is slidably connected with a sliding groove. The sliding groove is fixedly connected with the upper wall of the device body. Piston rods are slidably connected to the lower portion of the fixed hydraulic cylinder and the lower portion of the movable hydraulic cylinder in a sealed mode correspondingly. The lower end of each piston rod is fixedly connected with a clamping ring. A working table is arranged in the middle portion of the device body. The two ends of the working table are fixedly connected with the device body. A strip-shaped slot is formed in the center of the working table. A cutting vehicle is arranged on the lower portion of the interior of the device body. The raw wood cutting device fixes a raw wood to the working table by controlling the clamping rings to ascend and descend and meanwhile can clamp raw woods withdifferent diameters through the liftable clamping rings. A worm gear rotates to drive a cutter to rotate to cut the raw wood on the working table through a synchronous belt. Under the action of a rack, a gear drives the cutting vehicle to integrally move left and right to achieve the movable cutting function.

Owner:宁波暄妍日化科技有限公司

Longitudinal veneer slicer

InactiveCN102229154AReduce laborImprove operational safetyFlat surfacing machinesReciprocating motionWood processor

The invention discloses a longitudinal veneer slicer applied in the field of wood machining machinery. The longitudinal veneer slicer comprises a main frame, a secondary frame and a tool rest arranged on the main frame and capable of sliding along the longitudinal direction of the main frame, wherein the secondary frame is arranged at one end of the main frame, and a driving motor capable of driving the tool rest to reciprocate is arranged on the secondary frame; in addition, a liftable workbench is horizontally arranged on the main frame, the workbench is driven by a lifting motor, and corresponding clamping devices for clamping wood are arranged at two sides of the workbench; and when the longitudinal veneer slicer works, the wood is fixed on the workbench by using the clamping devices,the tool rest continuously reciprocates under the drive of the driving motor, meanwhile, the workbench can ascend for a distance after a slicing period is finished, and a planing tool arranged on thetool rest can continuously slice the veneer of certain thickness. The longitudinal veneer slicer has simple structure and relatively low cost, can ensure the uniformity of the thickness of the slicedveneer during slicing, and is very suitable for medium and small enterprises to use.

Owner:丁占科

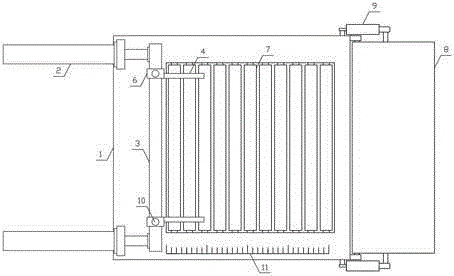

Automatic board splicing machine with swaging function

InactiveCN104786301AIncrease exerciseLow movement resistanceOther plywood/veneer working apparatusPlywood pressesFixed frameWood processor

The invention provides an automatic board splicing machine with a swaging function and belongs to the technical field of woodworking machines. The automatic board splicing machine comprises a machine frame, an upper heating mechanism, a lower heating mechanism, a board pressing mechanism, a turning mechanism and a pushing mechanism, and is characterized in that the pushing mechanism comprises a pair of pushing plate actuation cylinders, a pushing plate and a pair of pushing plate synchronization devices; the upper heating mechanism comprises a set of upper heating pipes, an upper heating pipe heating medium lead-in header pipe and an upper heating pipe heating medium lead-out header pipe; the lower heating mechanism comprises a set of lower heating pipes, a lower heating pipe heating medium lead-in header pipe and a lower heating pipe heating medium lead-out header pipe; a board row moving channel is formed between the upper heating pipes and the lower heating pipes; the board pressing mechanism comprises a supporting beam, a pair of pressing actuation cylinder fixing frames, a pair of gate lath abutting beams, a set of gate laths, a board pressing strip and a pair of board pressing strip actuation cylinders, and the cross section of the gate laths is in a V shape. The overall movement effect is good, resistance borne by the pushing plate is reduced, the splicing combination effect is good, and descending resistance borne by boards is reduced.

Owner:永州浙南竹木有限公司

Combined driving vertical type machine for splitting wood

InactiveCN107283581AImprove wood chopping abilityExpand the scope of processingWood splittingWood processorSemi automatic

The invention is suitable for the technical field of wood processing machinery and equipment, and provides a combined driving vertical type machine for splitting wood. The combined driving vertical type machine comprises a rack, a knife rest, a double-stage pump, a wood holding device, a clamping device and a driving device, wherein the knife rest is arranged at the top end of the rack, and the double-stage pump is arranged on the rack; one end of the wood holding device is rotationally connected with the rack, and the other end of wood holding device is connected with the knife rest through a chain; the wood holding device can be driven by the knife rest to turn from horizontal to upright, and is used for pushing wood onto the rack; the clamping device is fixedly arranged at the rack and is used for clamping the wood pushed by the wood holding device; and the driving device is connected with the clamping device and is used for driving the clamping device to move. The wood is conveyed onto the rack through the holding device, so that the semi-automatic carry for the wood is realized, and the labor intensity is reduced. Meanwhile, the wood is clamped through the clamping device, so that the wood is effectively fixed, and therefore the safety performance of the wood splitting process is improved. The knife rest is driven to move through the double-stage pump, so that the wood splitting capacity of the combined driving vertical type machine is improved.

Owner:LAIZHOU XINHAIWEI MACHINERY

Numerical control non-fastening-shaft rotating cutter and its special-purpose frequency converter and feed automatic speed-regulating method

InactiveCN101100080AEasy to detectEasy to operateAC motor controlVeneer manufactureNumerical controlFrequency changer

The present invention is numerically controlled no-clamper rotary trunk-layer stripping machine and its special frequency converter and automatic feeding speed regulating method, and relates to timber working machine. The numerically controlled no-clamper rotary trunk-layer stripping machine has worktable, displacement sensor and special frequency converter, which comprises the first memory unit, one timbre diameter calculating unit, the second memory unit and one motor rotation speed calculating unit. The numerically controlled no-clamper rotary trunk-layer stripping machine with special frequency converter to replace computer and PLC controller has simple structure, low cost, simple operation and high marketability.

Owner:吕宝伟

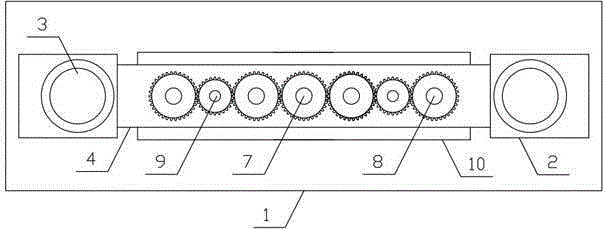

Plate pressing ruler chuck and non-chuck integrated rotary cutting machine

InactiveCN105538456AIncrease profitQuality improvementVeneer manufactureWood processorEconomic benefits

The invention discloses a plate pressing ruler chuck and non-chuck integrated rotary cutting machine, and belongs to the mechanical field of wood processing. The plate pressing ruler chuck and non-chuck integrated rotary cutting machine comprises a rack which is provided with a positioning driving system, a feeding mechanism and a rotary cutter assembly. The positioning driving system comprises a roller driving mechanism and a chuck driving mechanism. The roller driving mechanism comprises a first driving roller, a second driving roller and an auxiliary roller which are distributed to be of a triangular structure. A plate pressing ruler assembly is arranged below the auxiliary roller. Two chuck clamping assemblies with gaps capable of being longitudinally adjusted are connected to the chuck driving mechanism. According to the plate pressing ruler chuck and non-chuck integrated rotary cutting machine, the advantages of a chuck rotary cutting machine and the advantages of a non-chuck rotary cutting machine are combined, the thickness of a rotationally cut veneer is more uniform, the smoothness is high, dorsal fissure is reduced by 95%, the uniformity is high, and not only are economic benefits increased, but also the quality of the veneer is improved.

Owner:李玉明

Clamping-shaft and non-clamping-shaft integrated rotary cutting machine for composite pressure bar

PendingCN105643748AAvoid defects that require transshipment for secondary processingAvoid quality defectsVeneer manufacturePlate pressureWood processor

The invention discloses a clamping-shaft and non-clamping-shaft integrated rotary cutting machine for a composite pressure bar, and belongs to the field of wood processing machines. The clamping-shaft and non-clamping-shaft integrated rotary cutting machine comprises a rack, a positioning driving system, a feeding mechanism and a rotary cutting knife assembly are arranged on the rack, and the positioning driving system comprises a roller driving mechanism and a clamping head driving mechanism; the roller driving mechanism comprises a first driving roller, a second driving roller and a composite pressure bar assembly which are distributed in a triangular-structure manner; the composite pressure bar assembly comprises a plate pressure bar and a roller pressure bar which are arranged in a spacing manner side by side; and two clamping shaft clamping assemblies with the distance capable of being longitudinally adjusted are connected to the clamping head driving mechanism. A plate pressure bar of a clamping shaft rotary cutting machine and a shaft pressure bar of a non-clamping-shaft rotary cutting machine are compounded on the clamping-shaft and non-clamping-shaft integrated rotary cutting machine to be used, the defect that remaining wooden cores need to be transferred for secondary machining through the clamping-shaft rotary cutting machine is overcome, smooth finish of veneers obtained after rotary cutting is high, uniformity is high, and the dorsal fissure is reduced by 95%.

Owner:李玉明

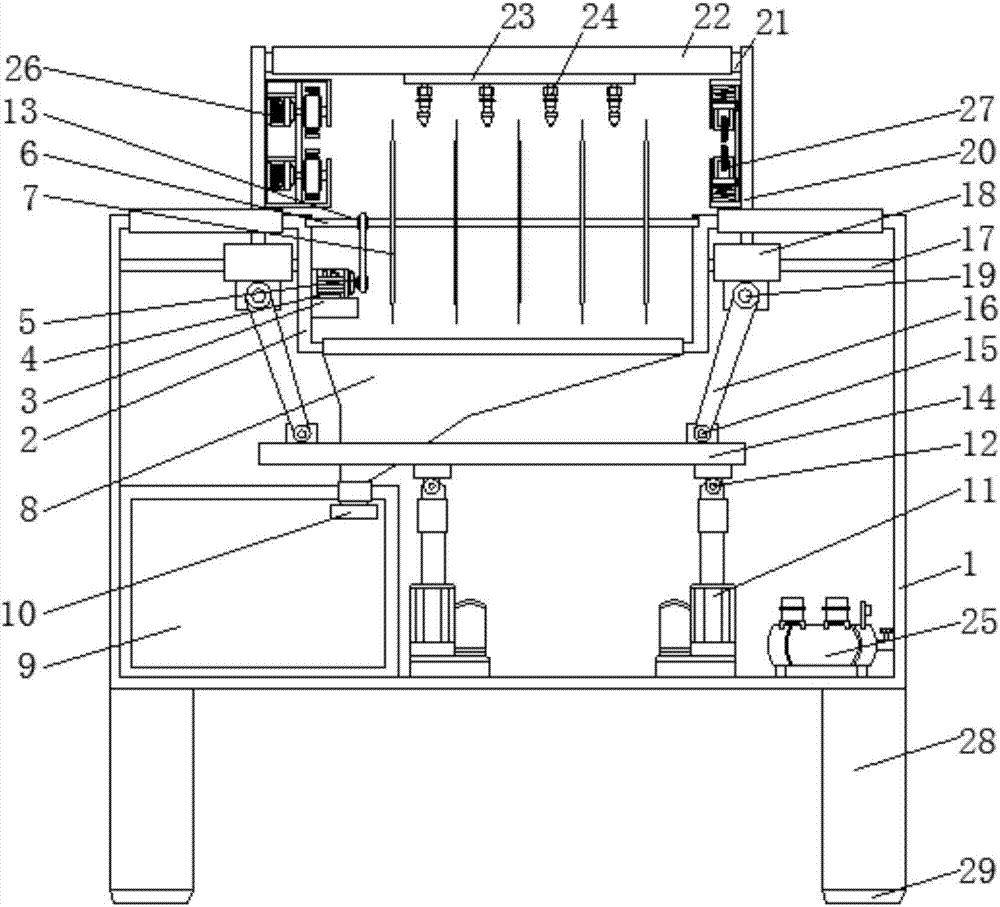

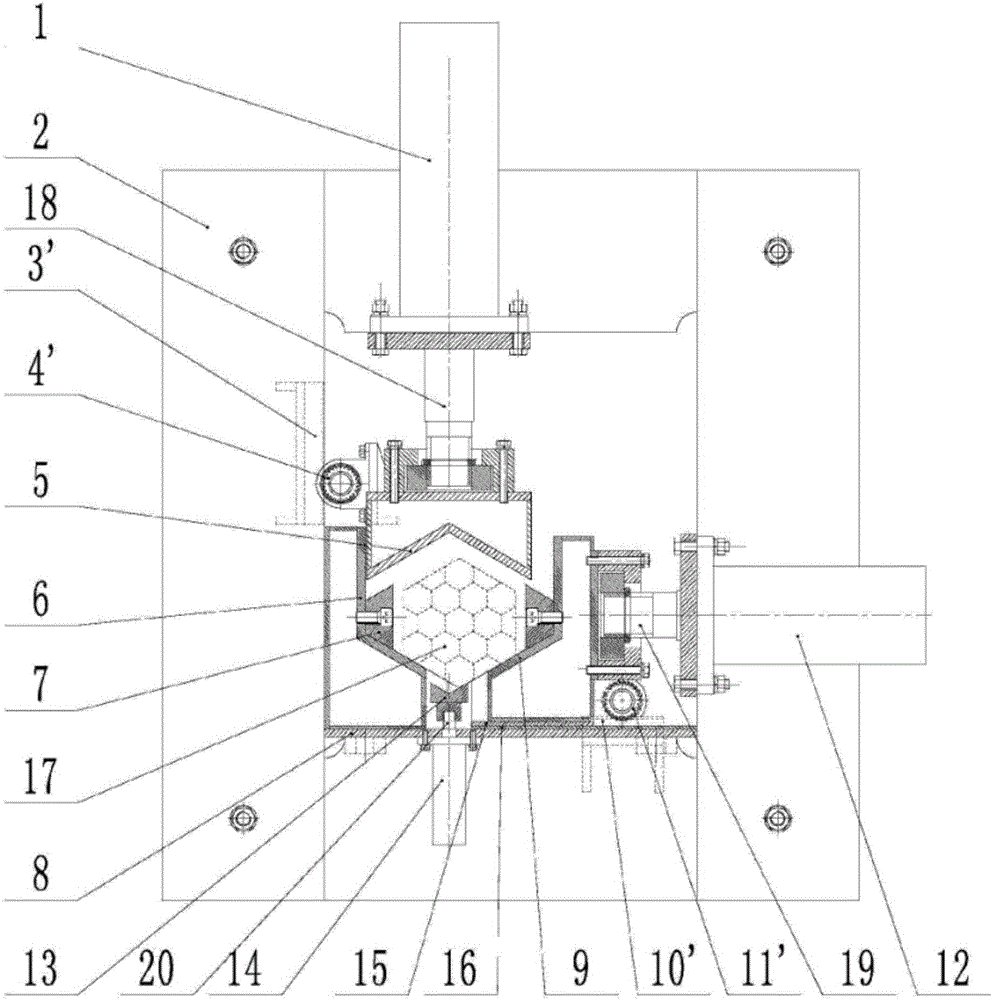

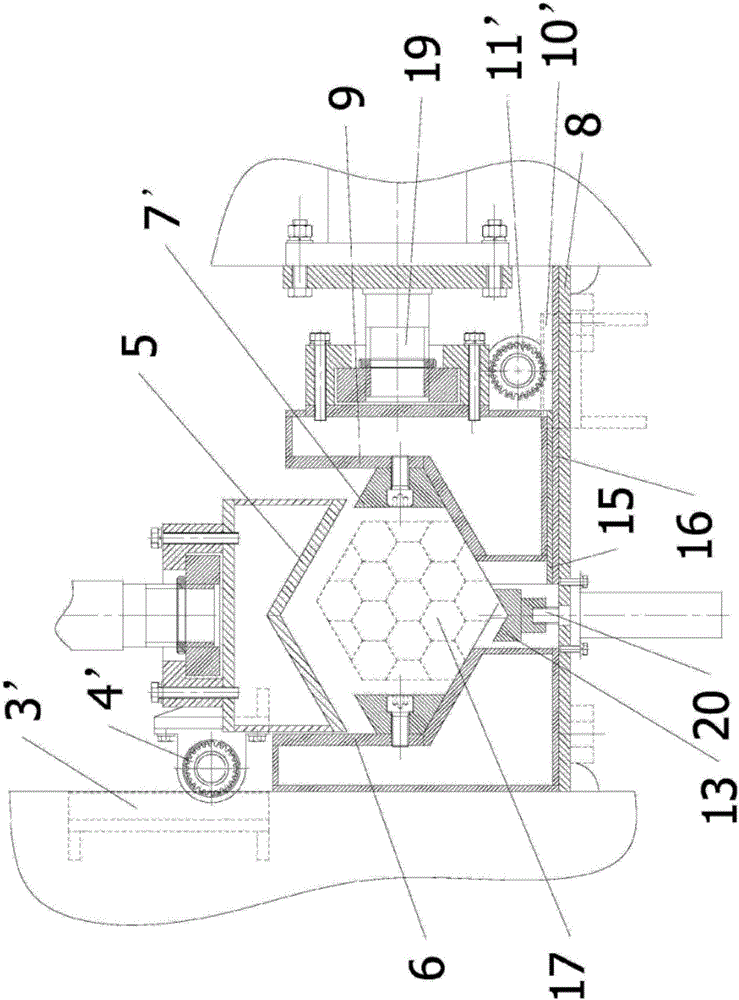

Pressurizing glue jointer applied to preparing large section integrated material

ActiveCN106393302AUniform pressureGuaranteed bonding strengthPlywood pressesVeneer pressesWood processorEngineering

The invention belongs to the field of wood processing machinery and provides a pressurizing glue jointer applied to preparing a large section integrated material. The pressurizing glue jointer comprises a press frame, wherein a V-shaped upper pressure plate is connected to the end part of a piston rod of a vertical pressurizing cylinder unit; an L-shaped horizontal fixed pressing plate is fixed on the press frame; an L-shaped horizontal pressurizing plate is connected to the end part of the piston rod of a horizontal pressurizing cylinder unit, opposite notches are formed in the L-shaped horizontal fixed pressing plate and the L-shaped horizontal pressurizing plate, a V-shaped hexagonal prism ungluing top block is arranged in each of the notches, and the V-shaped hexagonal prism ungluing top block is connected to the end part of a piston rod of an ungluing top block cylinder; a V-shaped face of the V-shaped upper pressure plate, two pressuring faces of the L-shaped horizontal fixed pressing plate and two pressurizing faces of the L-shaped horizontal pressurizing plate jointly encircle six side faces of a large section hexagonal prism. The pressurizing glue jointer can effectively solve the problems that the bonding strength is non-uniformly distributed as the bonded faces of an integrated material are hard to pressurize uniformly and the geometrical shape dimensional accuracy of the finished integrated material is hard to ensure, so that a workpiece is separated from a pressurizing plate thoroughly, and materials is conveniently discharged.

Owner:泰州市龙洋木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com