Longitudinal veneer slicer

A slicing machine and veneer technology, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problems of difficulty, high investment cost, complex structure, etc., achieve good level stability, reduce labor The effect of high volume, good operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

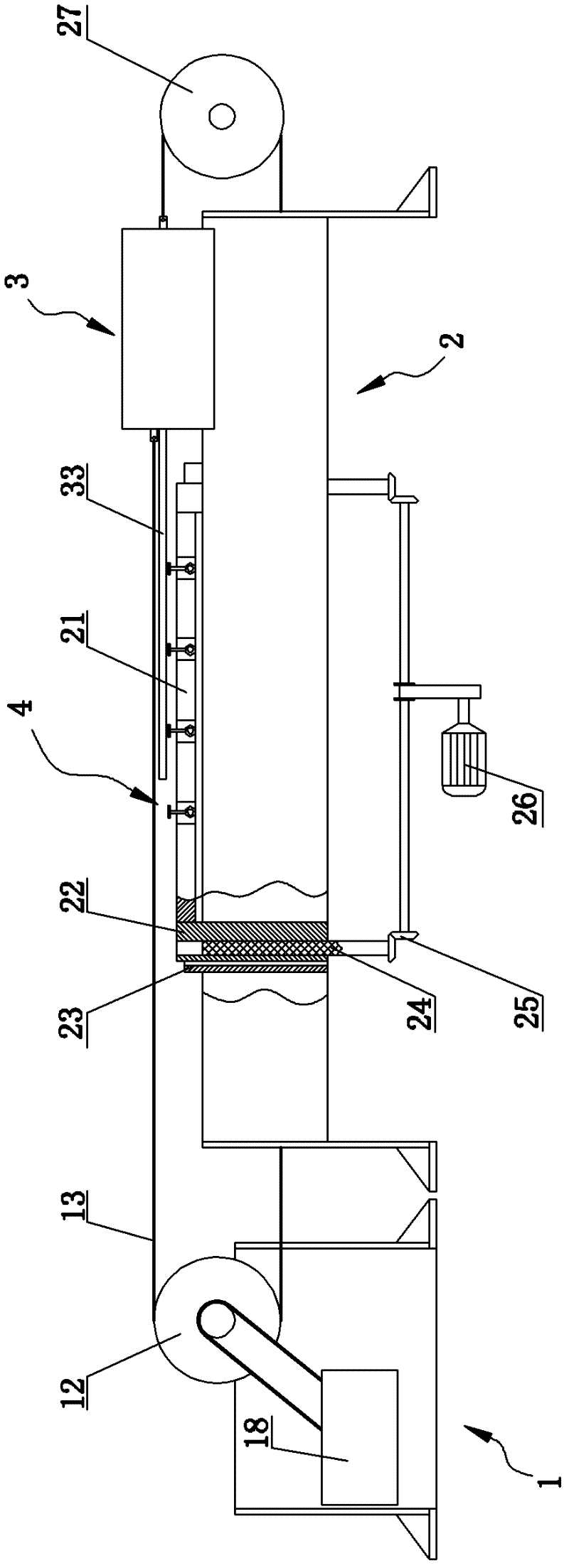

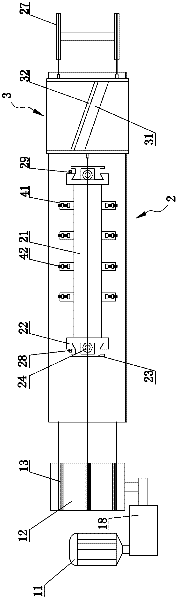

[0031] Such as figure 1 and figure 2 Commonly shown is an embodiment of a vertical veneer planer, which includes a main frame 2, a sub-frame 1, and a knife rest 3 that slides along the longitudinal direction of the main frame 2. A planer 32 is provided on the knife holder 3 .

[0032] The main frame 2 is horizontally provided with a workbench 21, and at the same time, guide rails 23 are vertically fixed at the two ends of the workbench 21 on the main frame 2, and a lifting slide 22 is slid in the guide rail 23. The workbench 21 is fixed between the upper ends of the two lifting slides 22. When the vertical veneer planer is working, the workbench 21 supports wood, and is arranged on the The clamping devices 4 on both sides of the workbench 21 fix the wood, so that when the lifting slide 22 slides upward for a certain distance, the workbench 21 can follow the upward movement for a certain distance, and at the same time, the tool rest 3 Sliding over the workbench 21, the plan...

Embodiment 2

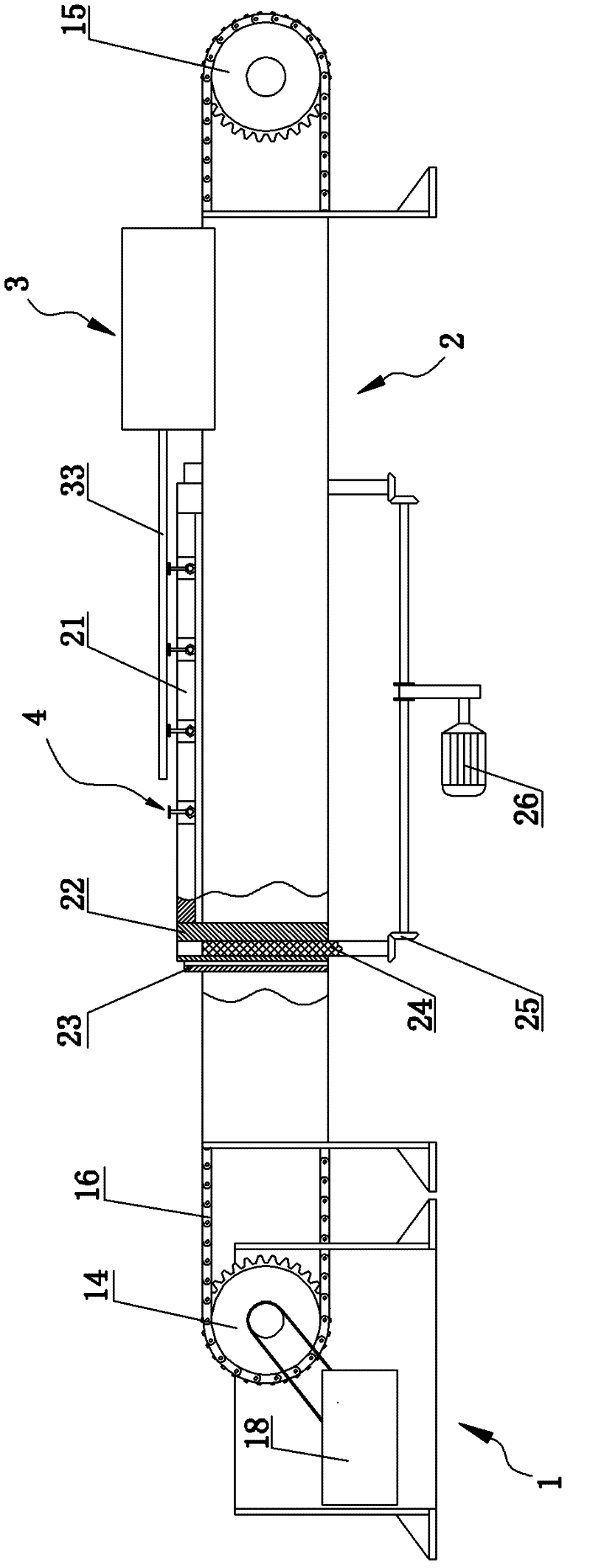

[0045] Such as image 3 and Figure 4 Commonly shown is another embodiment of the vertical veneer cutter, the difference between this embodiment and embodiment one is:

[0046] The transmission device used by the drive motor 11 to drive the knife rest 3 is different. The transmission device here includes a driving sprocket 14 arranged on the sub-frame 1. The driving sprocket 14 is two and passes through A connecting shaft 17 is fixed as a whole, and two corresponding driven sprockets 15 are arranged symmetrically at the end of the main frame 2 away from the sub-frame 1, and the driving sprocket 14 and the corresponding driven sprocket 15 are Chains 16 are wound around respectively to form an upper chain and a lower chain, and the lower end of the knife rest 3 is fixedly connected to the upper chain, where the knife rest 3 and the upper chain can be directly welded and fixed as one, or the The lower end of the knife rest 3 is processed into a structure compatible with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com