Patents

Literature

41results about How to "No fringe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

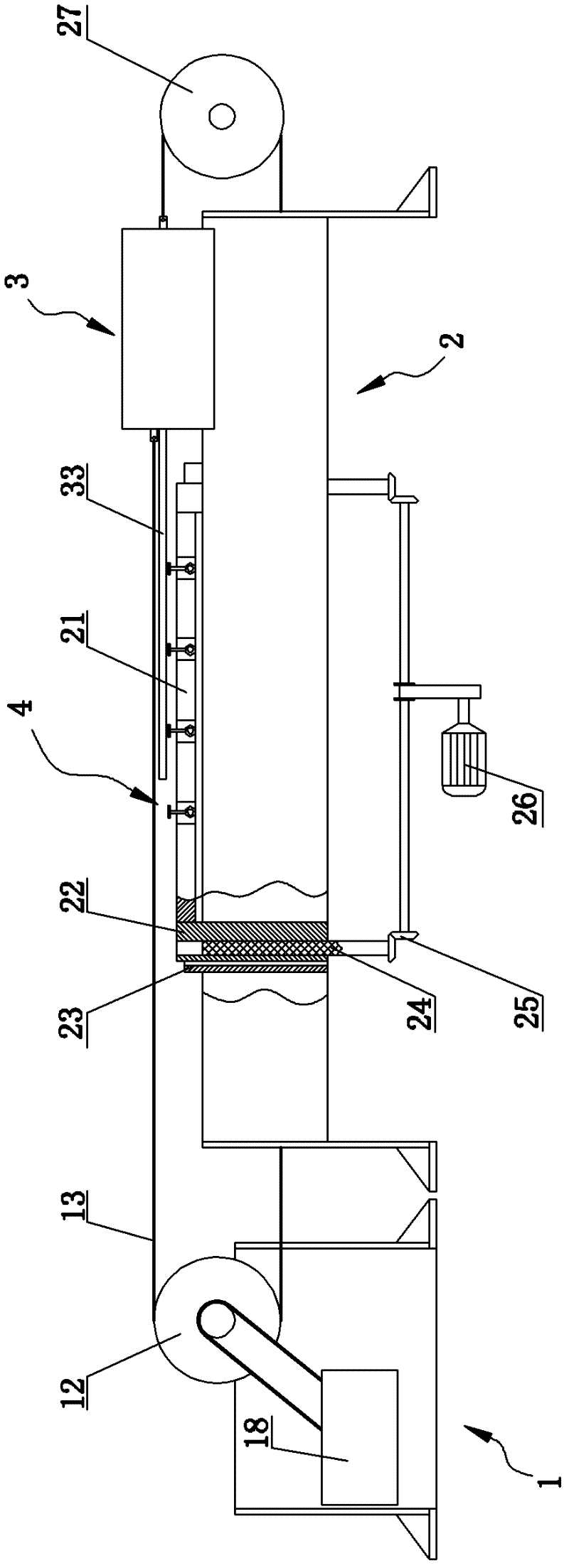

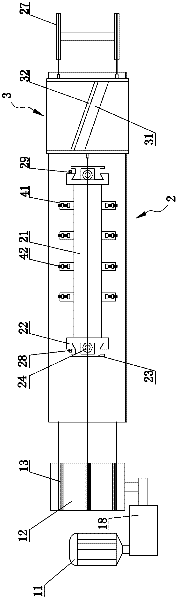

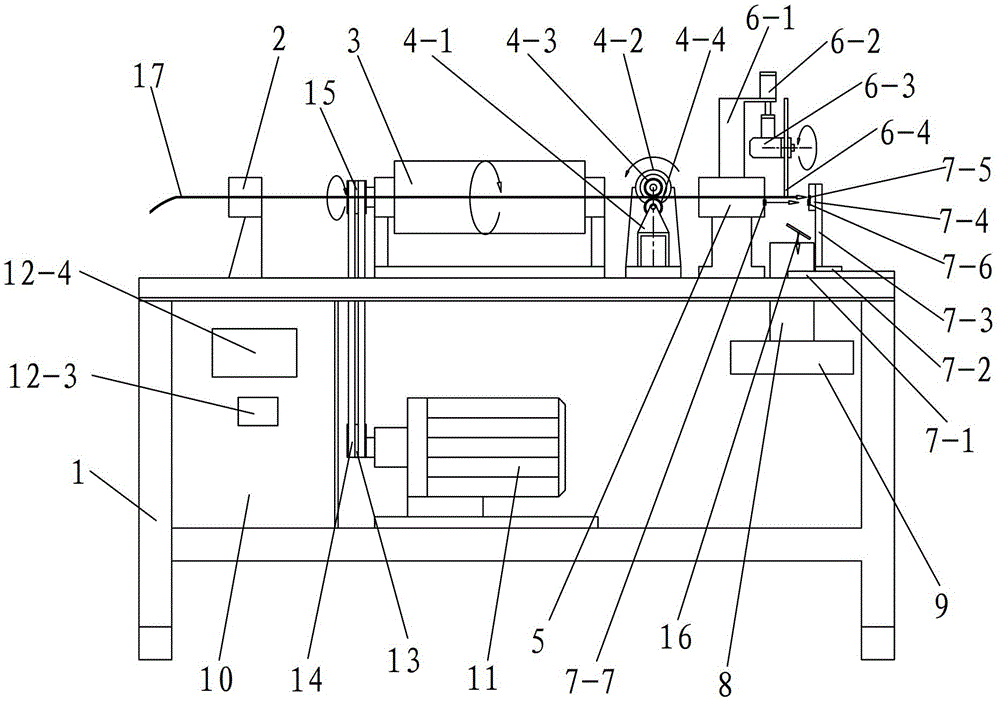

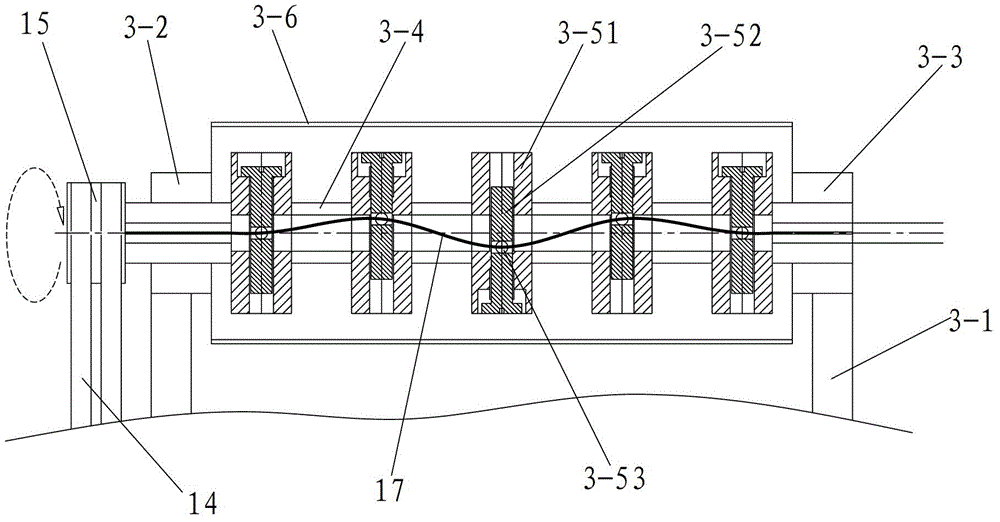

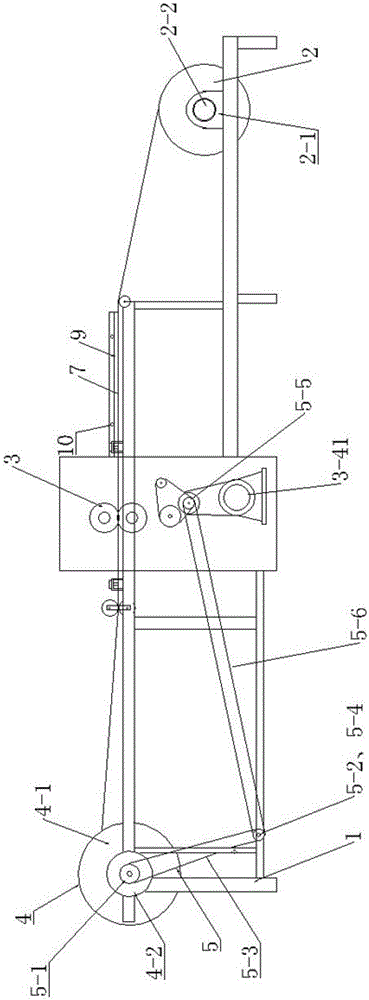

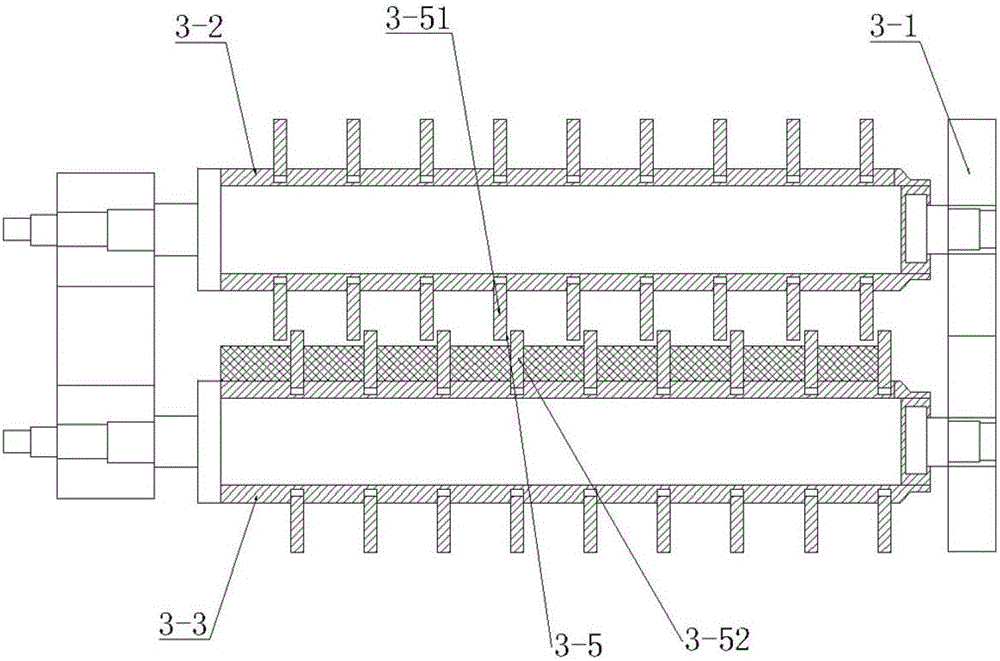

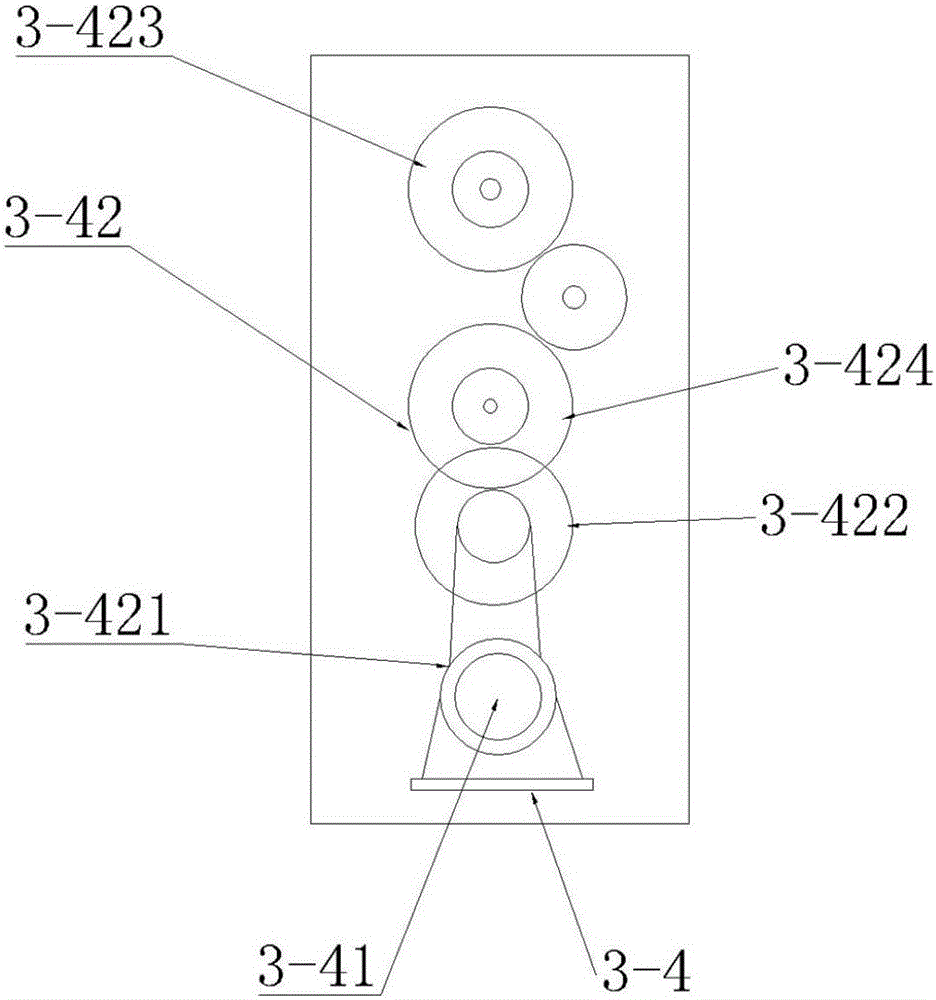

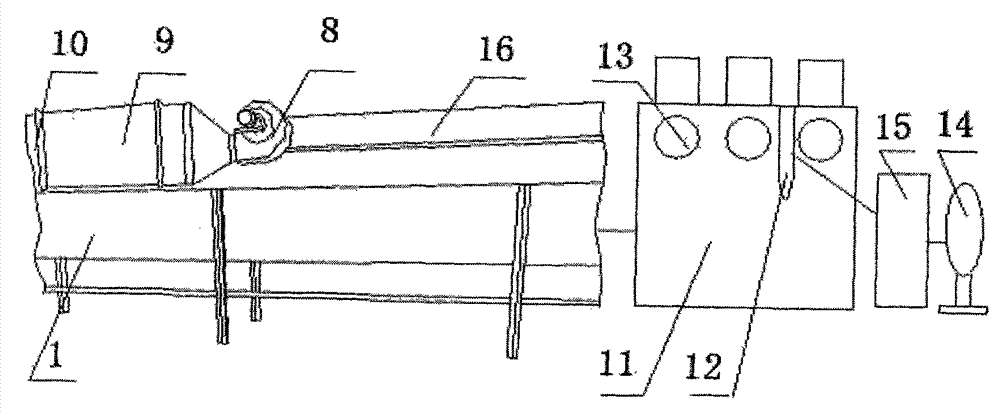

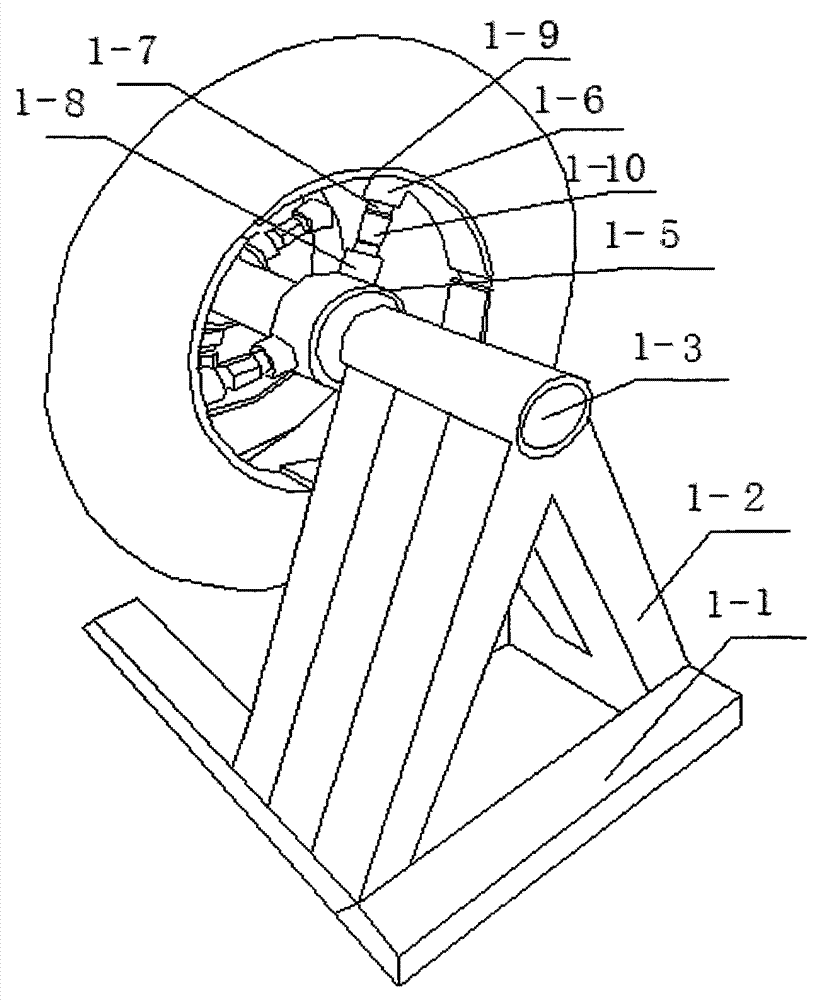

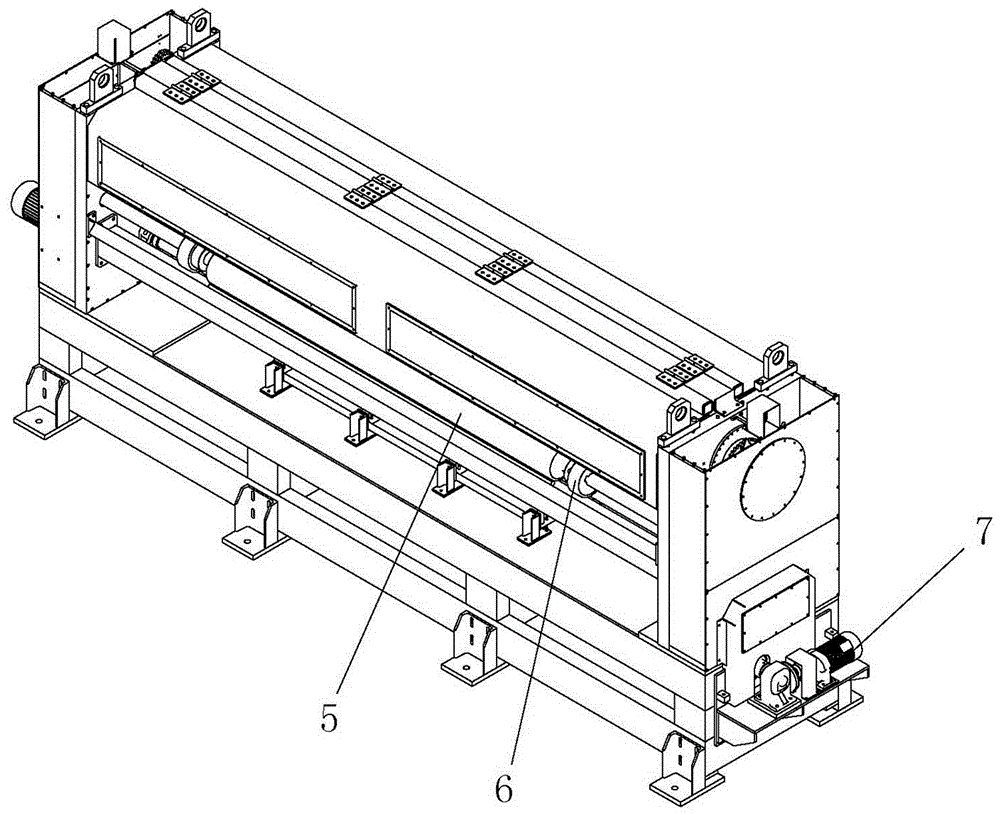

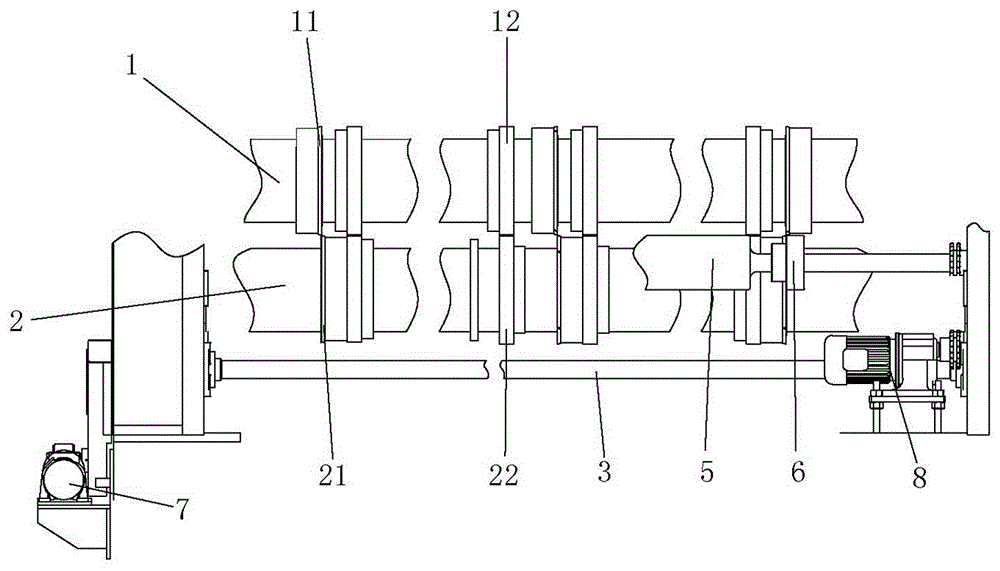

Metal wire rod precision alignment cutting device and method

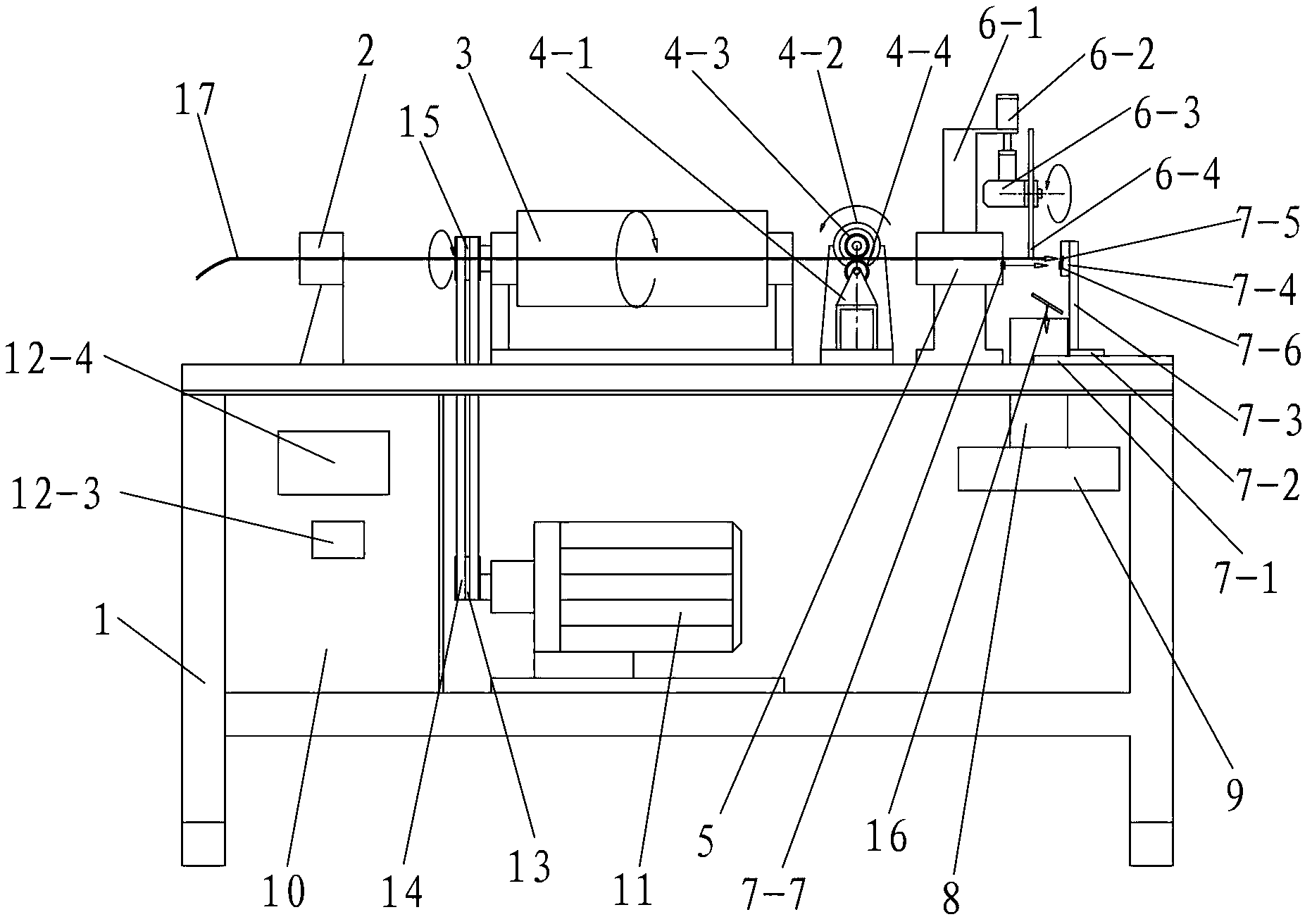

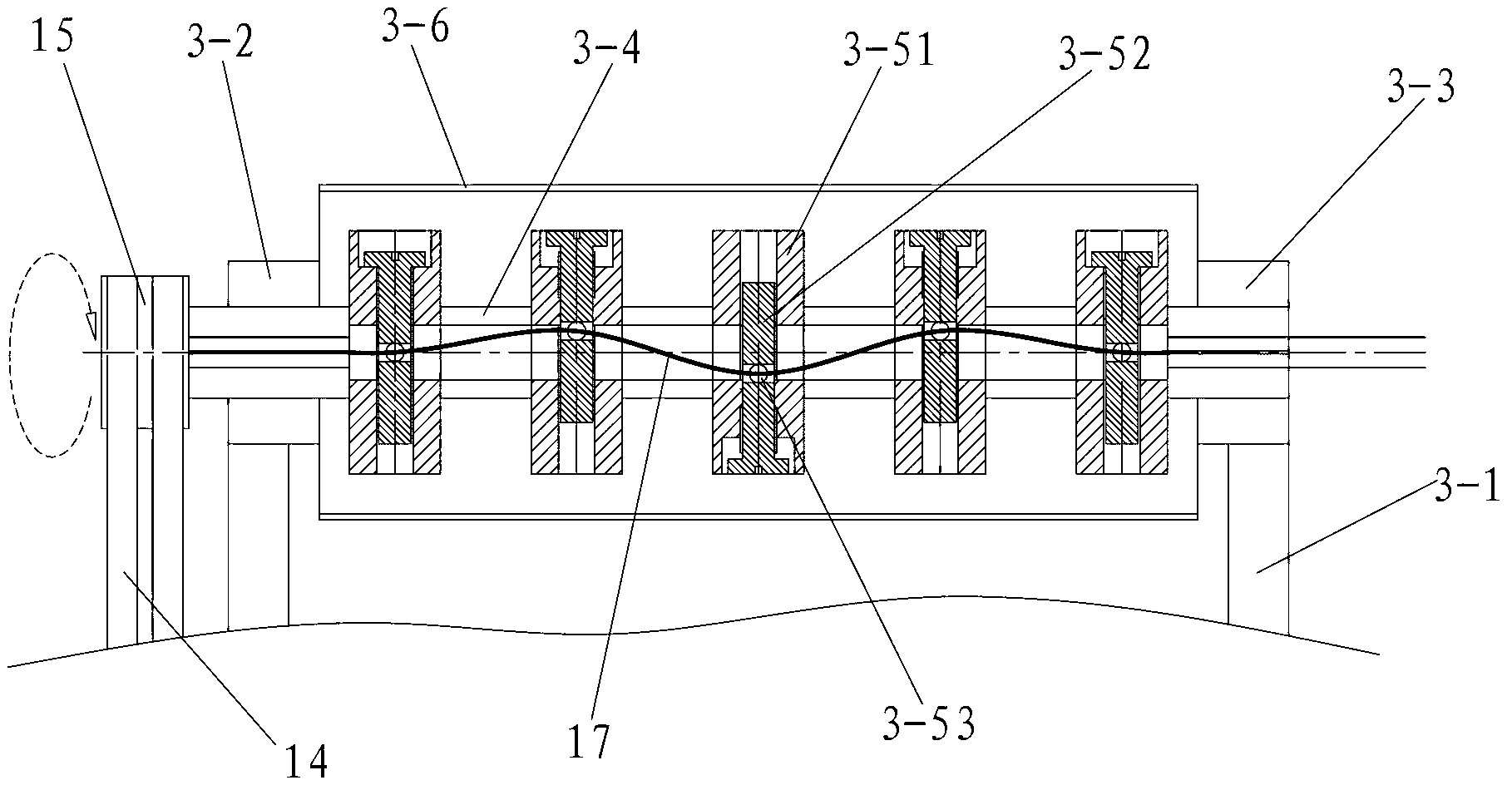

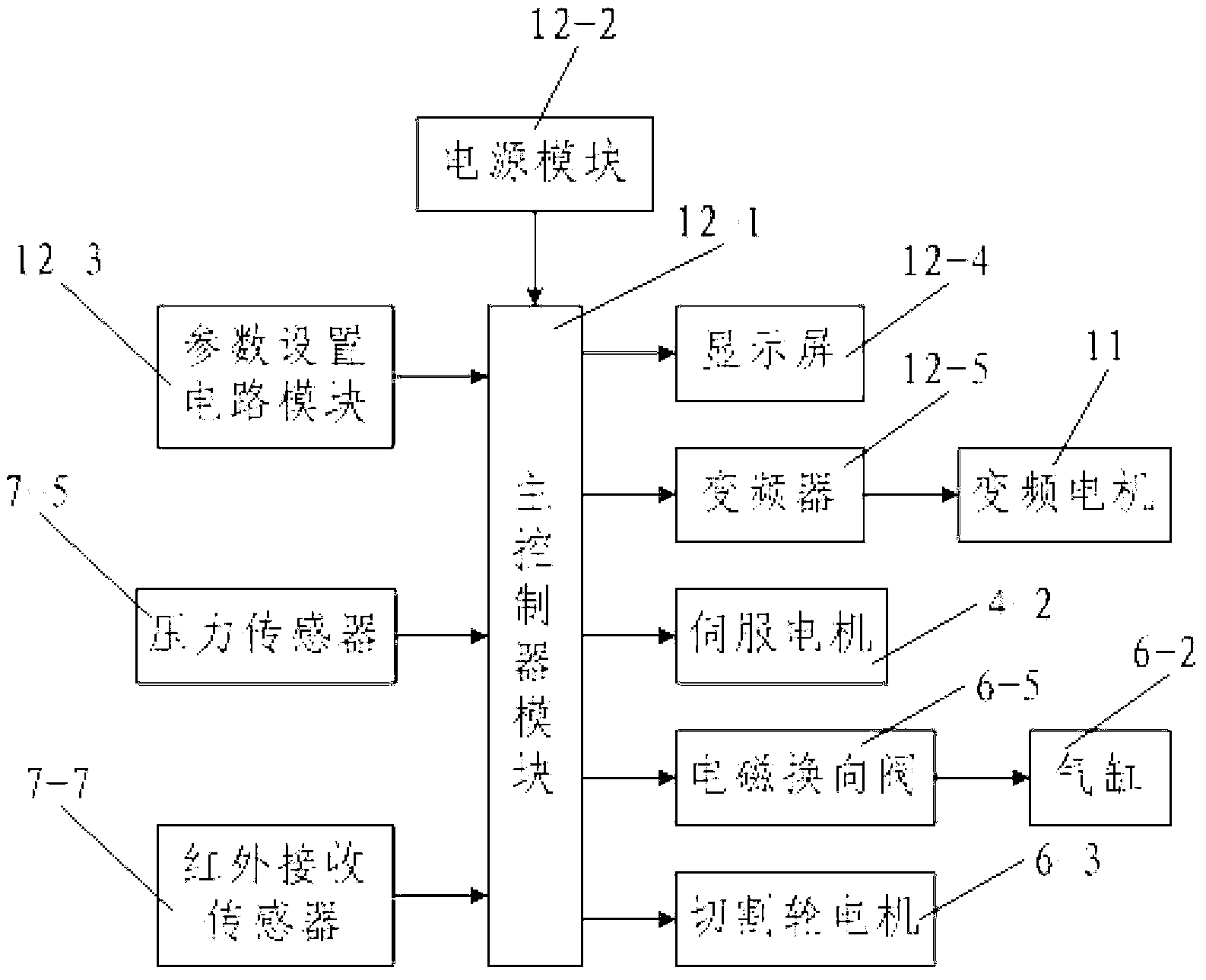

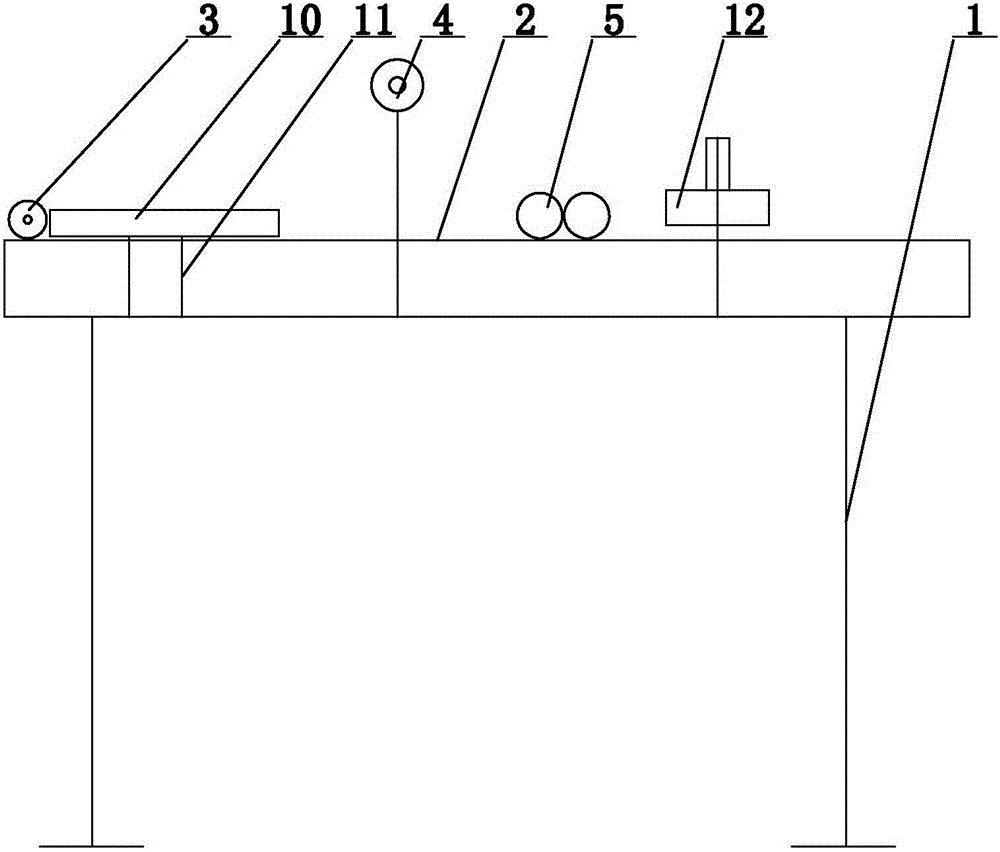

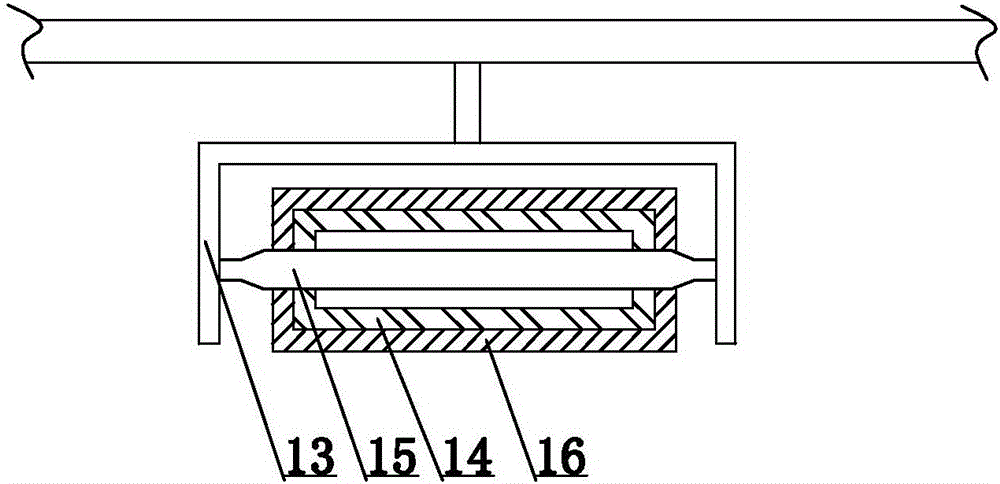

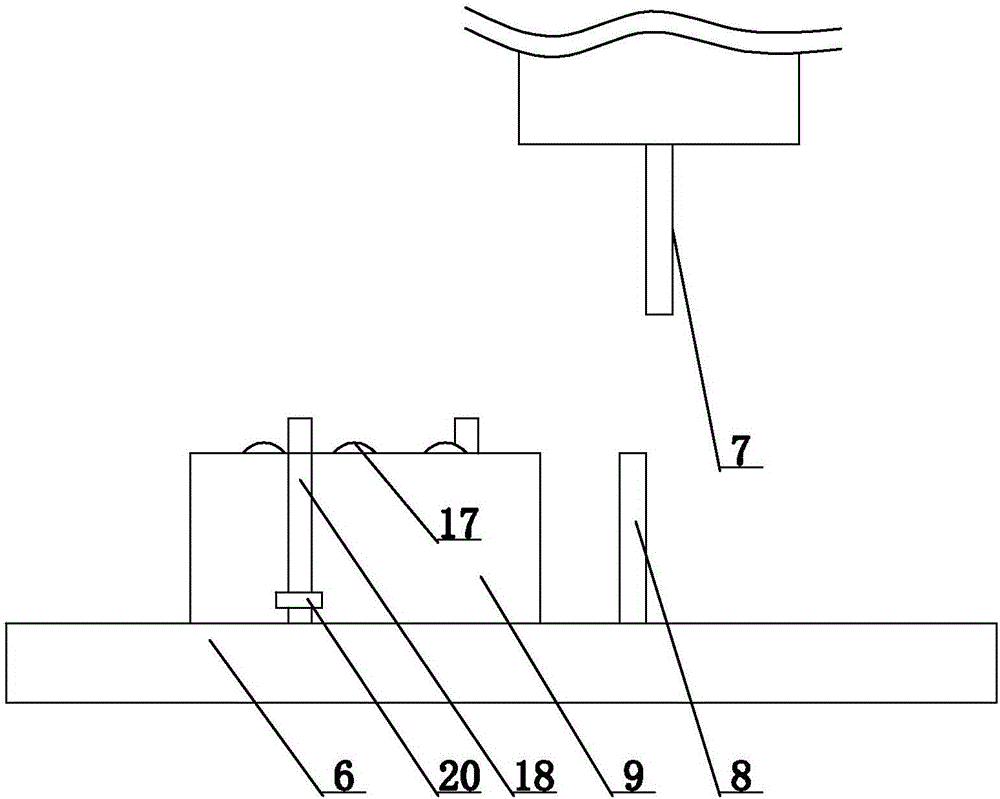

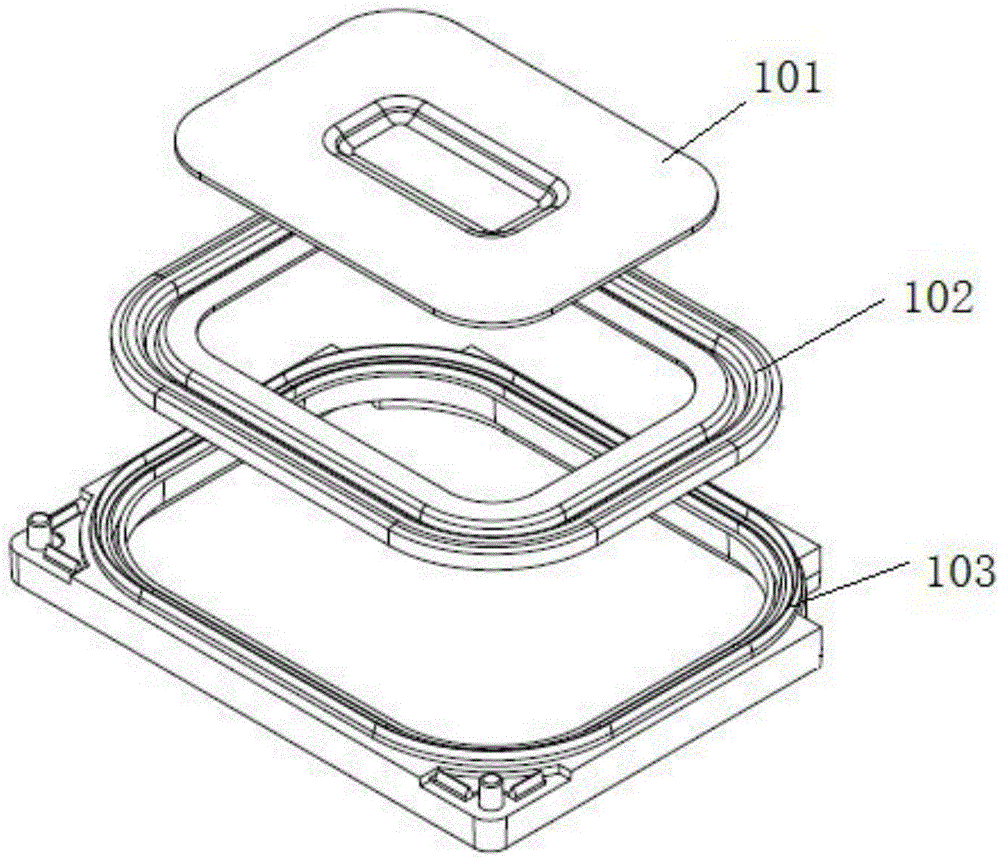

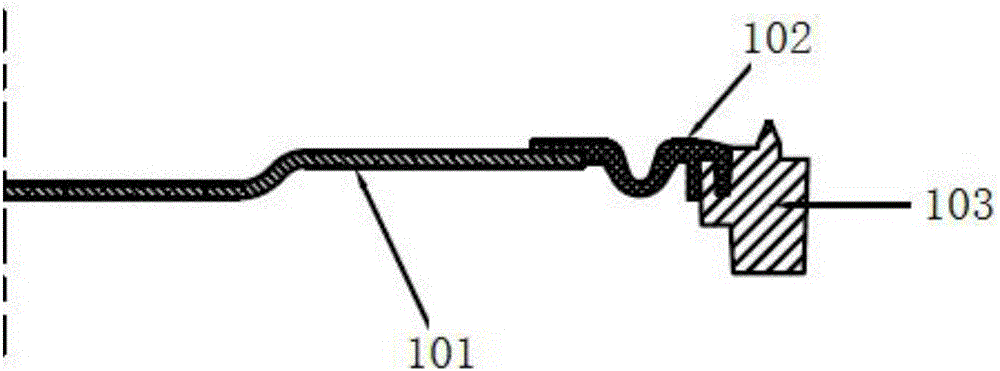

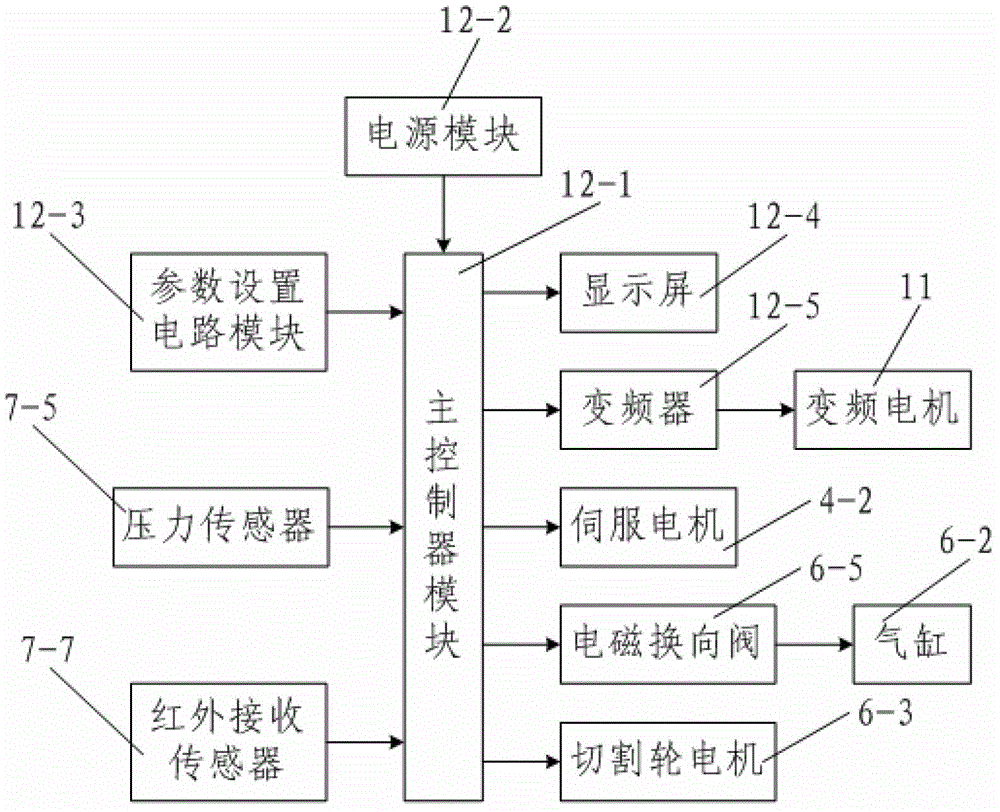

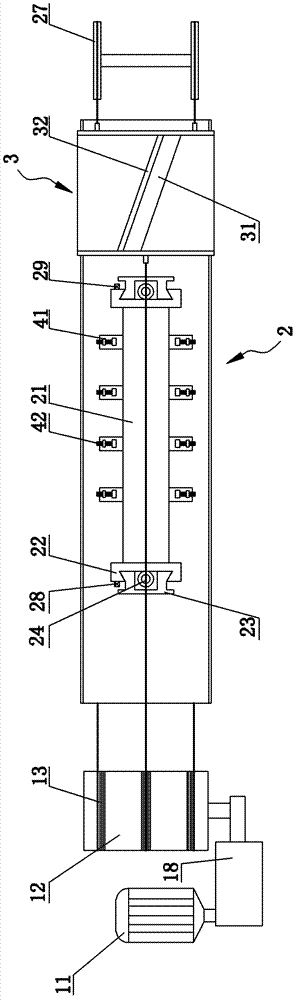

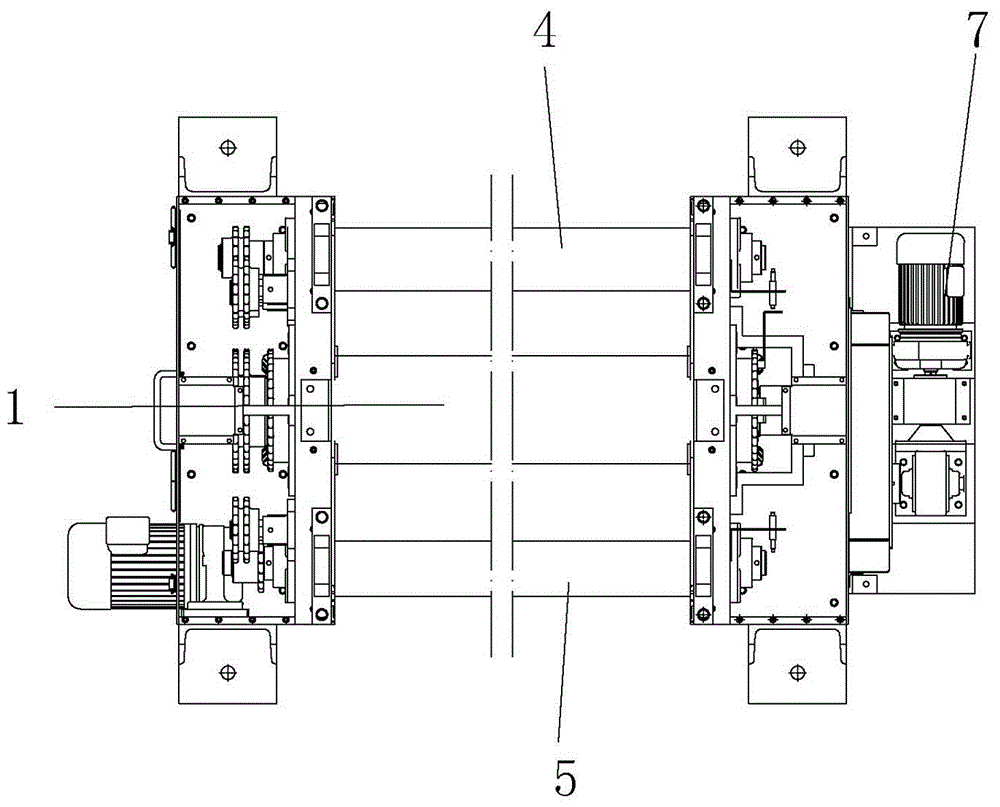

The invention discloses a metal wire rod precision alignment cutting device and a method. The device comprises a double-layer machine frame. A front end guiding tank, a revolving alignment tank, a traction mechanism, a back end guiding tank, a cutting mechanism and a machinery sizing mechanism are arranged on the top portion of the double-layer machine frame. The revolving alignment tank comprises a revolving alignment straight tank support seat, an alignment guiding tank, a plurality of alignment modules and a protection cover. The traction mechanism comprises a traction mechanism support seat, a servo motor, a driving friction wheel and a driven friction wheel. The cutting mechanism comprises a cutting wheel support frame, an air cylinder, a cutting wheel motor and a slice-shaped cutting wheel. The machinery sizing mechanism comprises a horizontal scale plate, a pressure sensor, an infrared transmitting sensor and an infrared receiving sensor. The method includes the steps that the metal wire rod enters the revolving alignment tank through a front end guiding rank. The metal wire rod is alignmented, tracted, cut and prepared and enters the next working circulation. The metal wire rod precision alignment cutting device and the method is high in automatic degree. The shape of the cut metal line segment and the size precision are high. The cutting opening is smooth, free of deckle edge and free of splitting off. The metal wire rod precision alignment cutting device and the method are strong in practicality.

Owner:JINDUICHENG MOLYBDENUM CO LTD

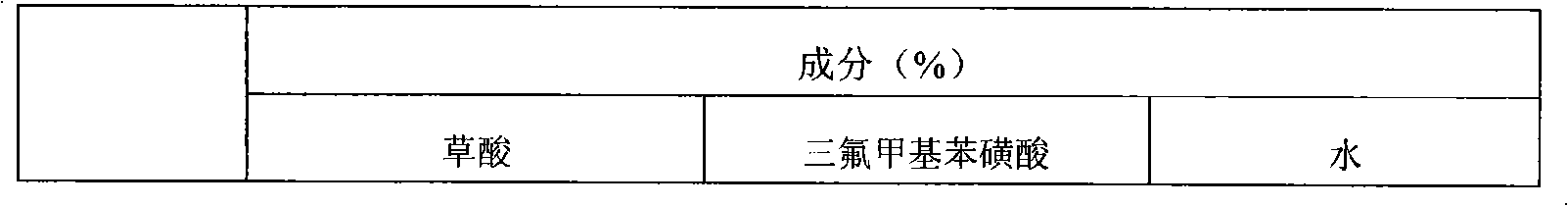

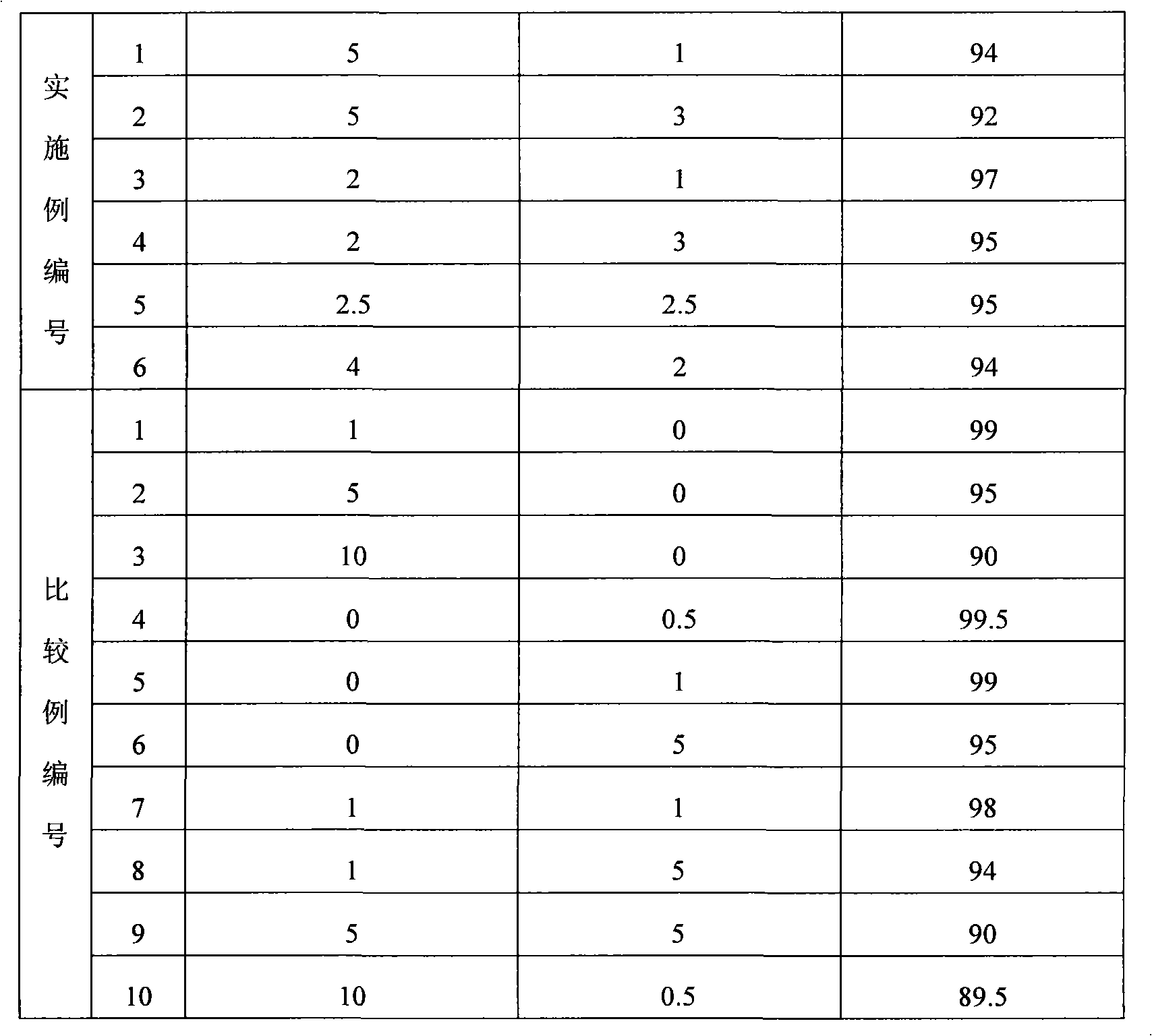

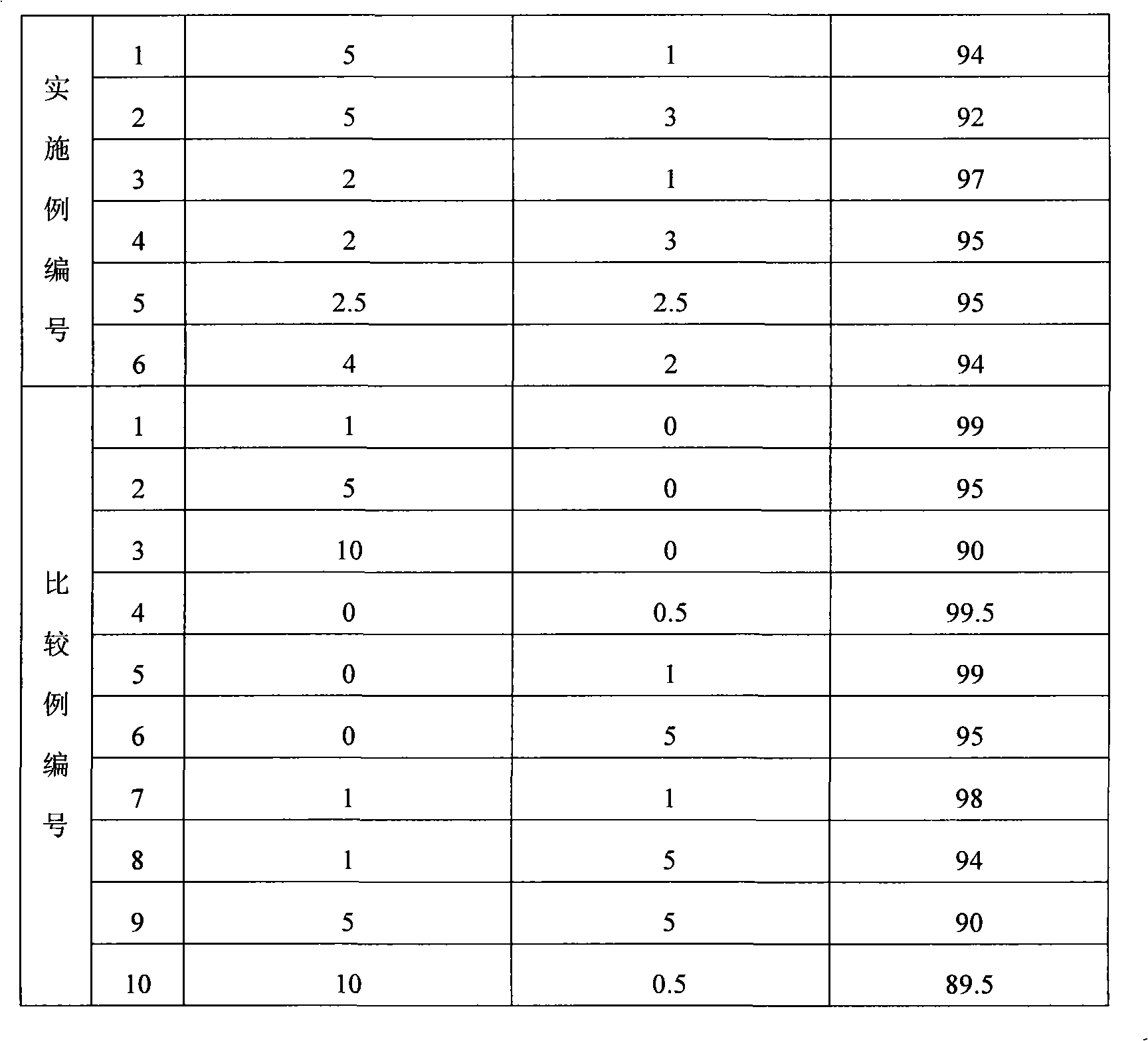

Etching liquid for flat panel display

The present invention discloses an etching liquid for the flat panel display. The etching liquid comprises oxalic acid, trifluoromethyl benzenesulfonic acid and water. The using amount of the oxalic acid is 1-10% of the total weight of the etching liquid. The using amount of the trifluoromethyl benzenesulfonic acid is 0.5-5% of the total weight of the etching liquid, and the balance is water. The invention provides the etching liquid for the flat panel display, which has the advantages of high efficiency, high etching precision and no pungent odour. The etching liquid is used for etching the ITO transparent conductive film. The adopted oxalic acid and the trifluoromethyl benzenesulfonic acid are organic acids. The compound composed of the two organic acids is not easily volatilized and has excellent wetting quality. When used as the ITO conductive film etching liquid, the etching liquid compound has the characteristics of excellent etching performance, no residue, less environmental pollution, etc.

Owner:HEFEI MAOTENG ENVIRONMENTAL PROTECTION TECH CO LTD

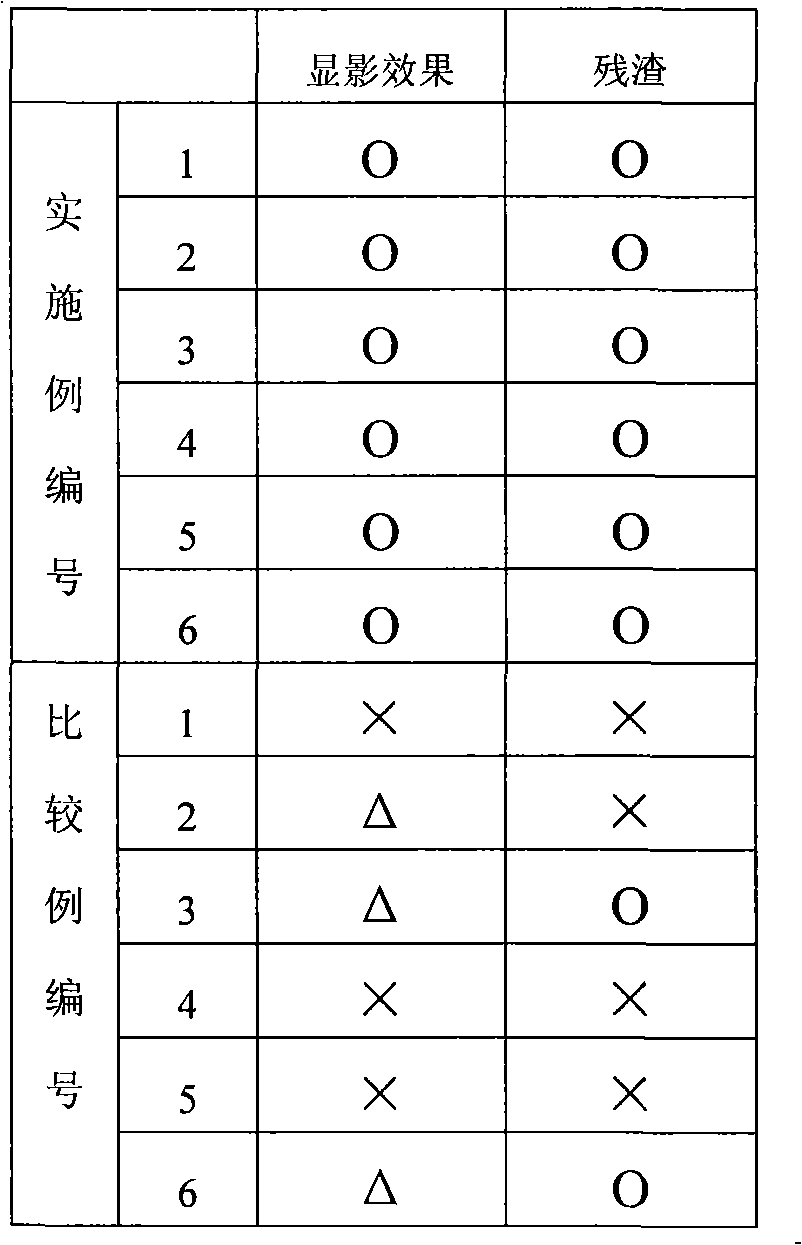

Naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and preparation method thereof

InactiveCN103045014AFast developingImprove imaging clarityInksPhotosensitive materials for photomechanical apparatusCelluloseCooking & baking

The invention discloses a naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and a preparation method thereof. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink comprises the following components in parts by weight: 50-80 parts of alkali soluble photosensitive resin, 0-5 parts of cellulose used for coating, 2-10 parts of active diluents, 2-8 parts of photosensitizer, 10-40 parts of filler, 0.5-1 part of pigment, 5-15 parts of solvent and 0.5-3 parts of auxiliaries, wherein the alkali soluble photosensitive resin is prepared from the following components in parts by weight: 40-60 parts of mixture consisting of 20-30 parts of n-butyl acetate, 0-30 parts of methyl isobutyl ketone, 0-20 parts of methylbenzene and 0-20 parts of propylene glycol monomethyl ether acetate, 25-40 parts of styrene-maleic anhydride resin, 15-20 parts of acrylic acid monomer, 0.1-1.0 part of catalyst and 0.1-1.0 part of polymerization inhibitor. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink disclosed by the invention does not need baking, is dried naturally after being diluted and is energy-saving and is resistant to acid and electroplating, and a film formed after the electroplating printing ink sprayed and dried naturally is high in adhesive force, high in hardness, quick in development, capable of obtaining clear images and resistant to acid corrosion.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

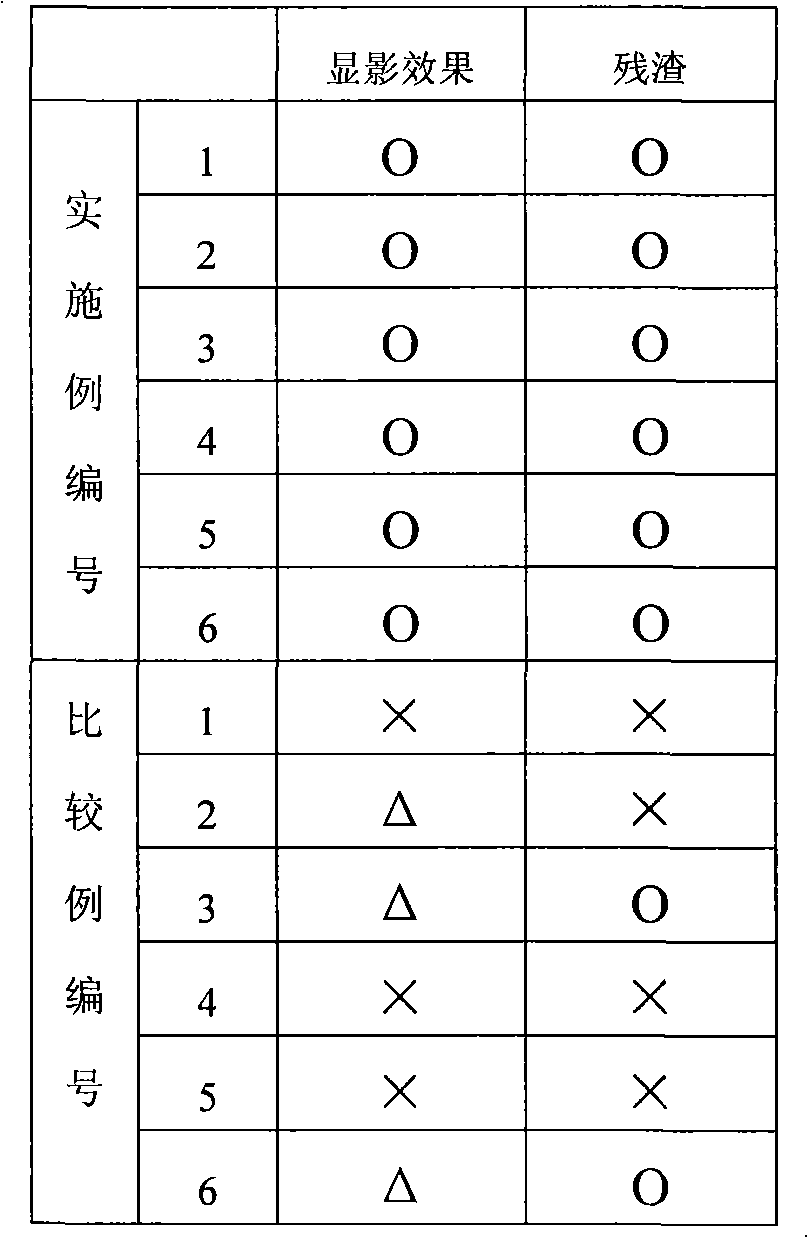

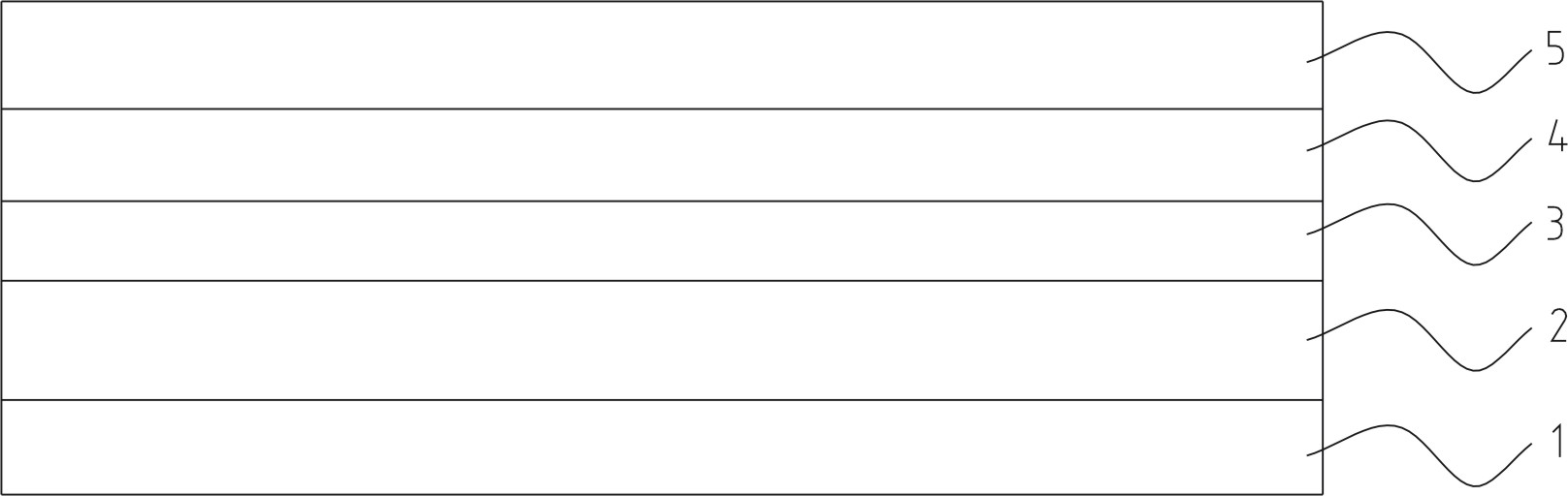

Mica tape and preparation method thereof

InactiveCN103514979AGood flexibilityGood wrapping workmanshipInsulated cablesQuartz/glass/vitreous enamelsTolueneMica

The invention relates to a cable fire-resistant insulation material, and particularly relates to a mica tape and a preparation method thereof. The mica tape comprises mica paper and glass fiber cloth. The glass fiber cloth is arranged on upper and lower surfaces of the mica paper. The mica paper and the glass fiber cloth on upper and lower surfaces of the mica paper are bonded together through glue materials. Each glue material comprises the active ingredients of an adhesive of organic silicon, a diluent of toluene and a curing agent. The weight ratio of the adhesive, the diluent and the curing agent is 3:20:1. The weight sum of the adhesive, the diluent and the curing agent accounts for 13 to 18% of the weight of the glue materials. The preparation method of the mica tape has the steps of glue material configuring, dip coating, compositing, drying, cooling, rewinding and slitting. The product has the advantages of easy manufacture, good fire-resistant insulation performance, strong shock-resistant performance and low processing cost.

Owner:扬州新奇特电缆材料有限公司

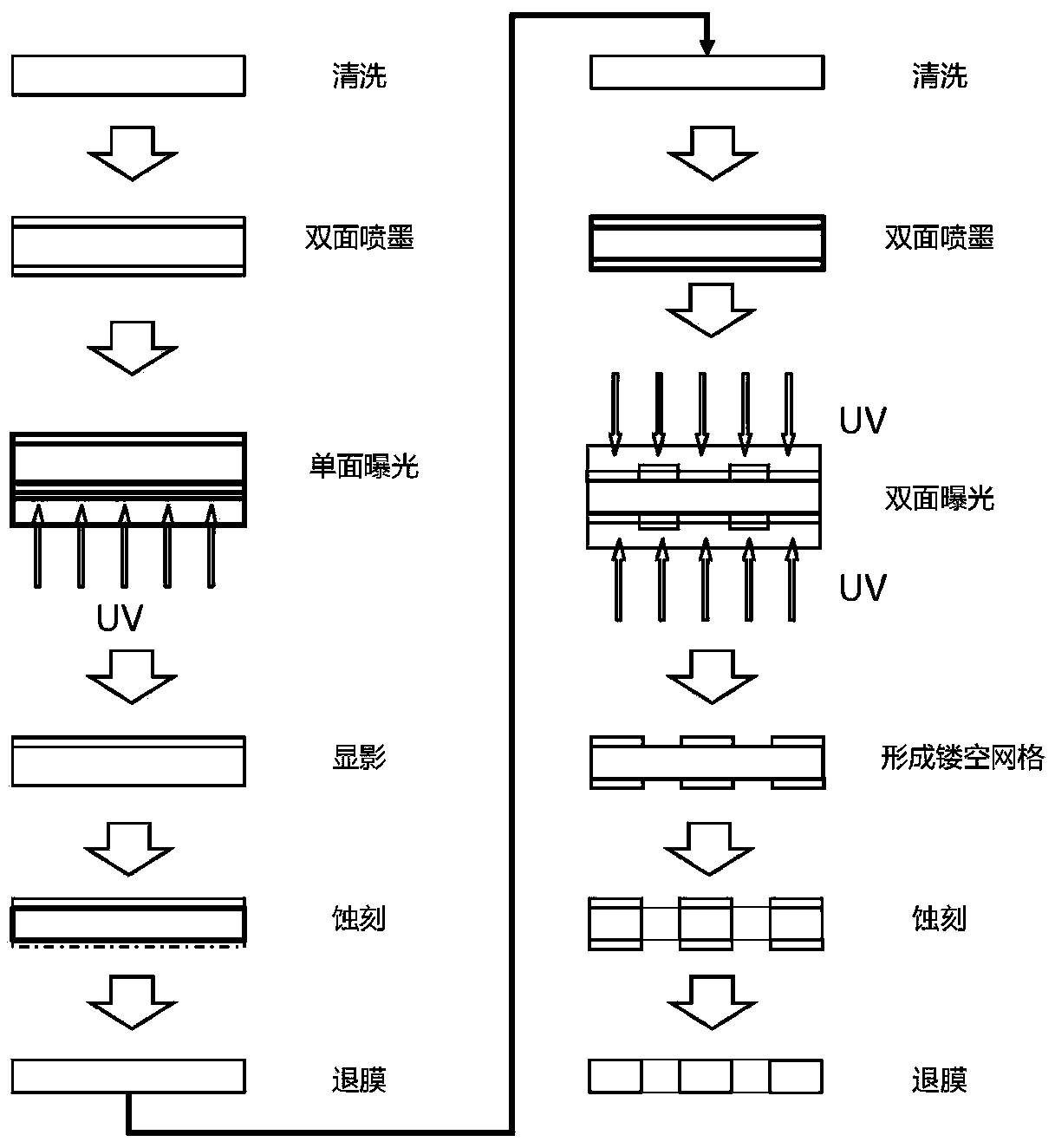

Process for producing conducting circuit of capacitive touch screen

InactiveCN102156602AEasy to manufactureMake moreInput/output processes for data processingScreen printingIndium tin oxide

The invention discloses a process for producing a conducting circuit of a capacitive touch screen. The method comprises the following steps of: (1) adhering a photosensitive dry film to the surface of a Cu layer of an ITO-Cu (Indium Tin Oxide-Copper) film, exposing, curing the photosensitive dry film corresponding to a Cu conducting circuit pattern, removing uncured photosensitive dry film and removing the Cu layer which is not covered by the photosensitive dry film to obtain a Cu conducting circuit; (2) forming an ITO conducting circuit pattern on the surface of an ITO layer, which is not covered by the Cu layer, of the ITO-Cu film from the ink in a screen printing mode, drying the ink, and removing the ITO layer which is not covered by the Cu layer and the ink to obtain an ITO conducting circuit; and (3) removing shielding ink on the Cu layer and the ITO layer. By adopting the method for manufacturing the conducting circuit of the capacitive touch screen, the manufactured Cu conducting circuit is finer, has higher smoothness, does not have burr and saw-tooth phenomena and can be continuously produced.

Owner:EELY ECW TECH

Double-faced organic silicon polyimide film dry mica paper tape and preparation method thereof

InactiveCN103514978AGood flexibilityGood wrapping performancePlastic/resin/waxes insulatorsInsulated cablesAcetic acidPaper tape

The invention relates to a cable fire-resistant insulation material, and particularly relates to a double-faced organic silicon polyimide film dry mica paper tape which comprises mica paper and polyimide films. The polyimide films are arranged on upper and lower surfaces of the mica paper. The mica paper and the polyimide films on upper and lower surfaces are bonded together through glue materials. Each glue material consists of organic silicon resin, a modified additive, an additive, toluene and ethyl acetate. The weight ratio of the organic silicon resin, the modified additive, the additive, the toluene to the ethyl acetate is 10:0.6:0.24:18:12. The glue material content in the mica tape is 3 to 9 g / square meter. The thickness of the mica paper is 0.035 to 0.065mm. The thickness of each polyimide film is 0.03 to 0.035mm. The preparation method of the double-faced organic silicon polyimide film dry mica paper tape has the steps of glue material configuring, dip coating, compositing, drying, cooling, rewinding and slitting. The product has the advantages of easy manufacture, good fire-resistant insulation performance, strong shock-resistant performance and low processing cost.

Owner:扬州新奇特电缆材料有限公司

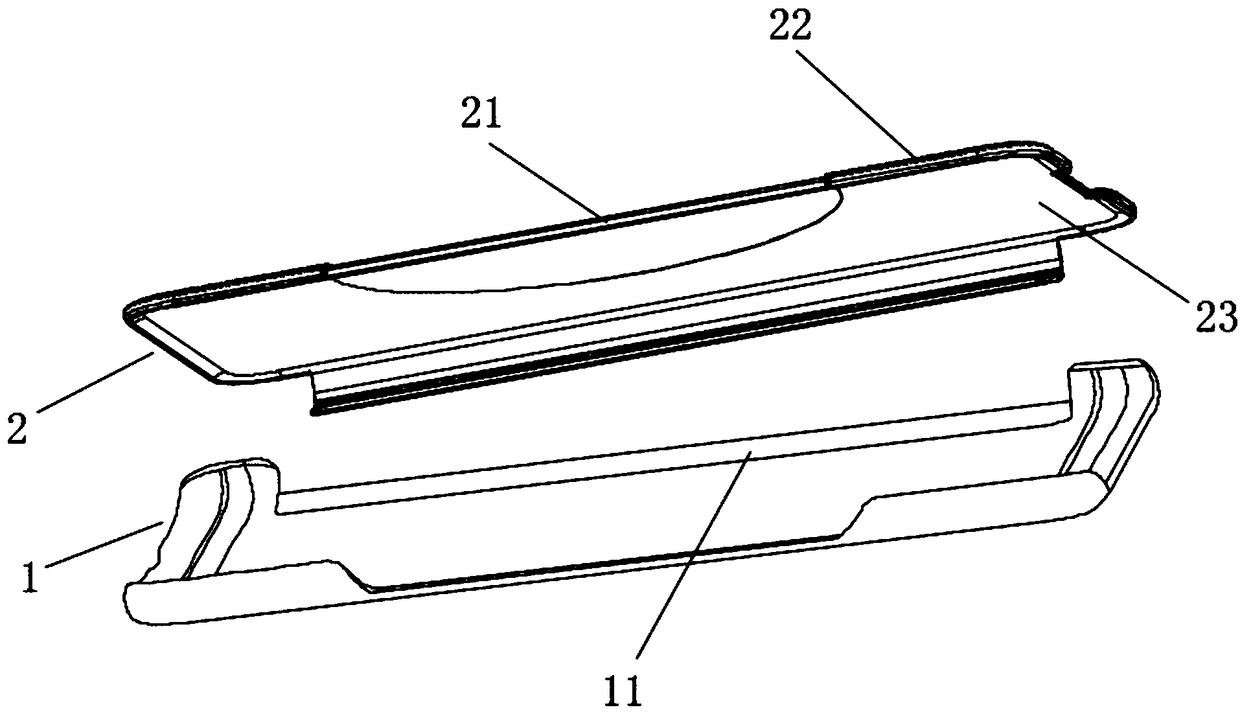

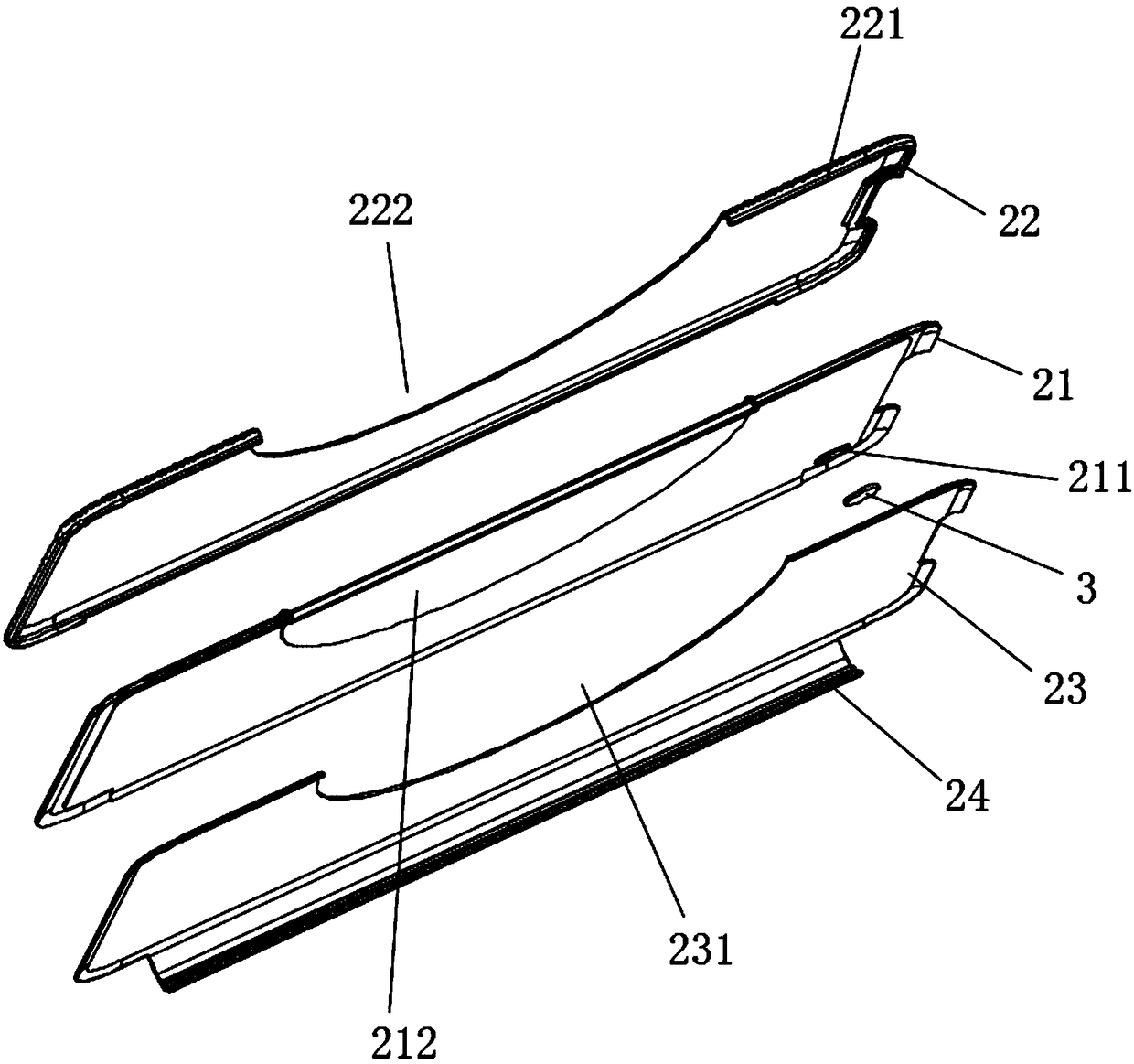

Preparation method and product of CX edgefolded leather sheath

InactiveCN108189443ASmooth appearanceBeautiful appearanceOther accessoriesDomestic articlesEngineeringMagnet

The invention discloses a preparation method of a CX edgefolded leather sheath. The preparation method comprises the following steps of (1) rough shape cutting; (2) thread forming; (3) repeated cutting of shell fabric; (4) hot-pressing of the shell fabric and sticking of a face cover; (5) edge folding; (6) edge pressing; (7) magnet installation; (8) lining pressing; and (11) shell sticking. The invention further discloses the CX edgefolded leather sheath prepared by implementing the method. By adopting the edge folding and edge pressing technologies, the prepared CX edgefolded leather sheath is smoother, rounder and more attractive in appearance, no rough selvedge exists, no gap exists, the flatness is high, the phenomena of damage, bubble and glue overflow cannot occur if the CX edgefolded leather sheath is used for a long term, the CX edgefoled leather sheath is durable, and the product quality is improved obviously.

Owner:东莞德明皮具制品有限公司

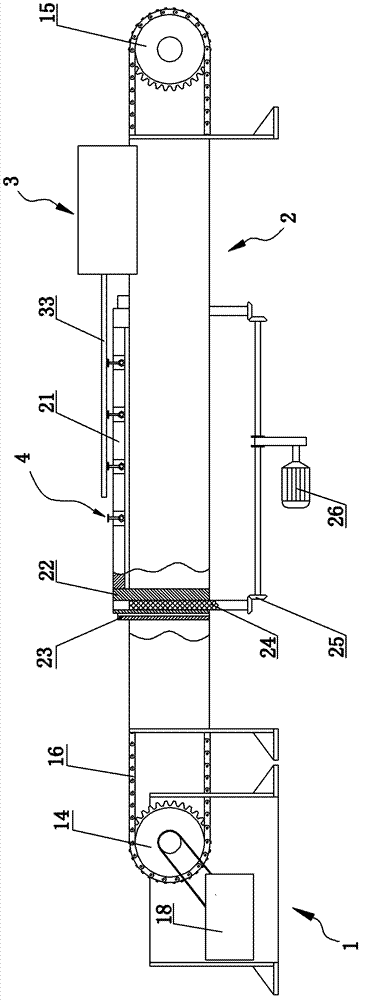

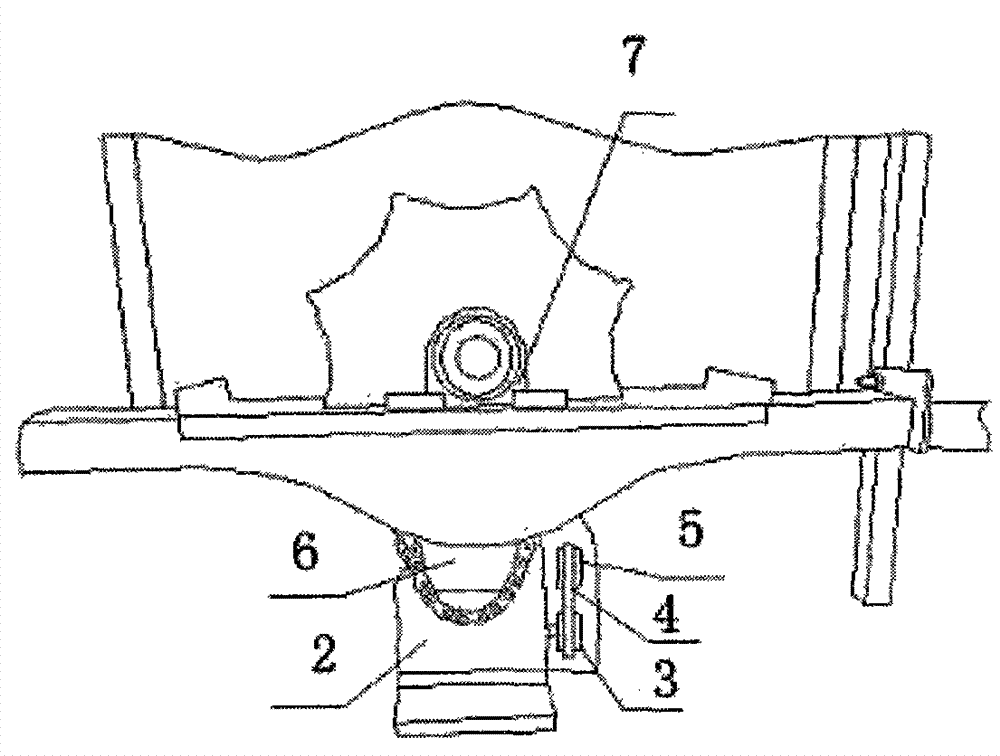

Longitudinal veneer slicer

InactiveCN102229154AReduce laborImprove operational safetyFlat surfacing machinesReciprocating motionWood processor

The invention discloses a longitudinal veneer slicer applied in the field of wood machining machinery. The longitudinal veneer slicer comprises a main frame, a secondary frame and a tool rest arranged on the main frame and capable of sliding along the longitudinal direction of the main frame, wherein the secondary frame is arranged at one end of the main frame, and a driving motor capable of driving the tool rest to reciprocate is arranged on the secondary frame; in addition, a liftable workbench is horizontally arranged on the main frame, the workbench is driven by a lifting motor, and corresponding clamping devices for clamping wood are arranged at two sides of the workbench; and when the longitudinal veneer slicer works, the wood is fixed on the workbench by using the clamping devices,the tool rest continuously reciprocates under the drive of the driving motor, meanwhile, the workbench can ascend for a distance after a slicing period is finished, and a planing tool arranged on thetool rest can continuously slice the veneer of certain thickness. The longitudinal veneer slicer has simple structure and relatively low cost, can ensure the uniformity of the thickness of the slicedveneer during slicing, and is very suitable for medium and small enterprises to use.

Owner:丁占科

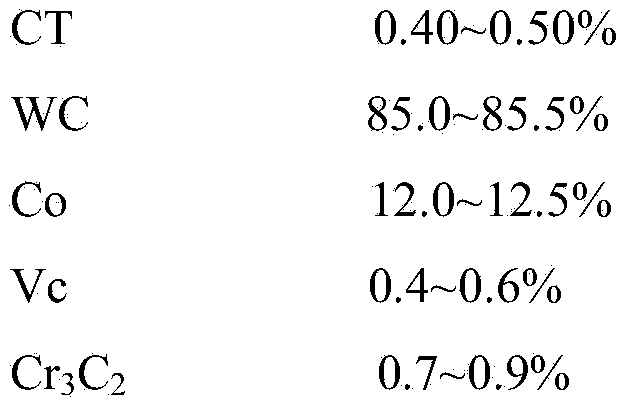

High-performance ultra-fine grained hard alloy new material splitting cutter

ActiveCN103898388AImprove performanceHigh hardnessTurbinesOther manufacturing equipments/toolsHardnessAlloy

The invention discloses a high-performance ultra-fine grained hard alloy new material splitting cutter, belonging to the technical field of hard alloy cutters. The high-performance ultra-fine grained hard alloy new material splitting cutter is manufactured by adopting a powder metallurgy process, and consists of the following raw material components in percentage by mass: 0.40-0.50% of CT, 85.0-85.5% of WC, 12.0-12.5% of Co, 0.4-0.6% of Vc, 0.7-0.9% of Cr3C2, 0.6-0.8% of TaC and 0.03-0.07% of octadecanoic acid. By adopting an ingenious new formula of an ultra-fine grained material, the problems of pores, non-uniform distribution of a Co phase and the like caused by poor wet milling dispersion are effectively solved from the ingredients, thus a high-quality mixture is prepared, and the slitting and shearing cutter with high performance and high precision is produced; and the cutter has high hardness, high strength, strong abrasion resistance and good toughness, and the quality and comprehensive use performance of the cutter are in the domestic leading position.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

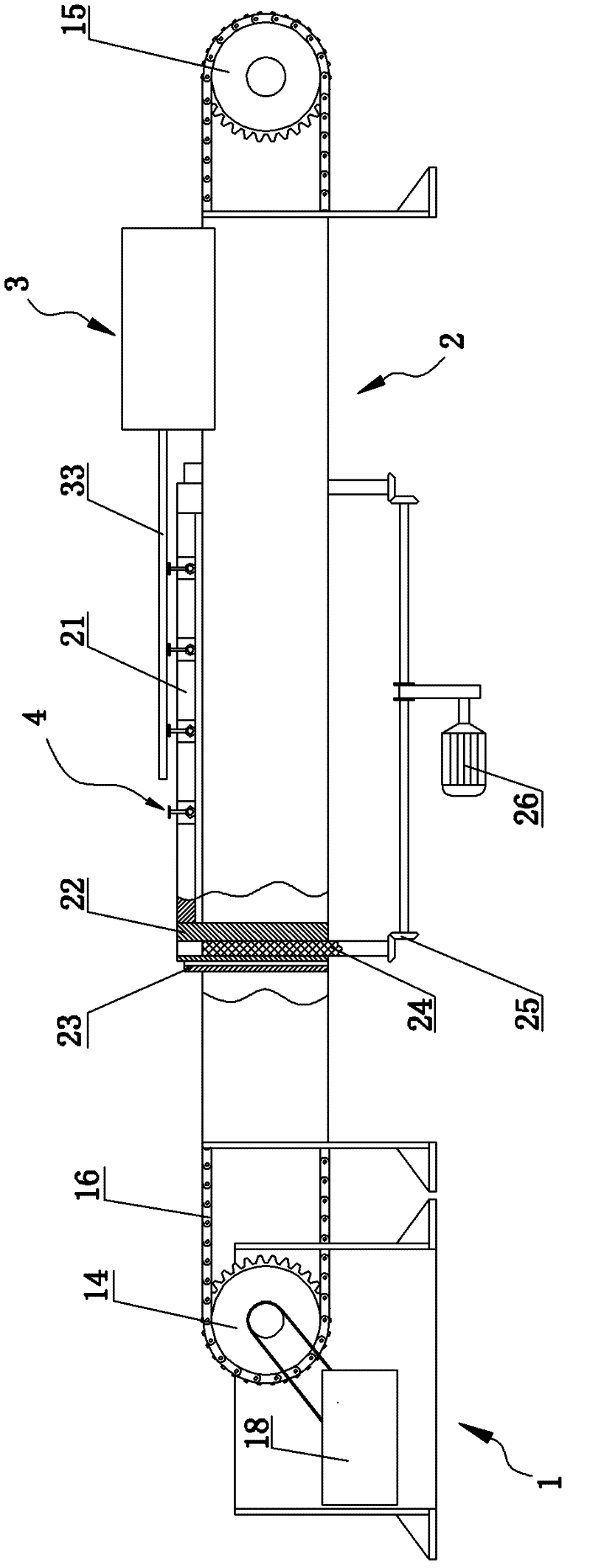

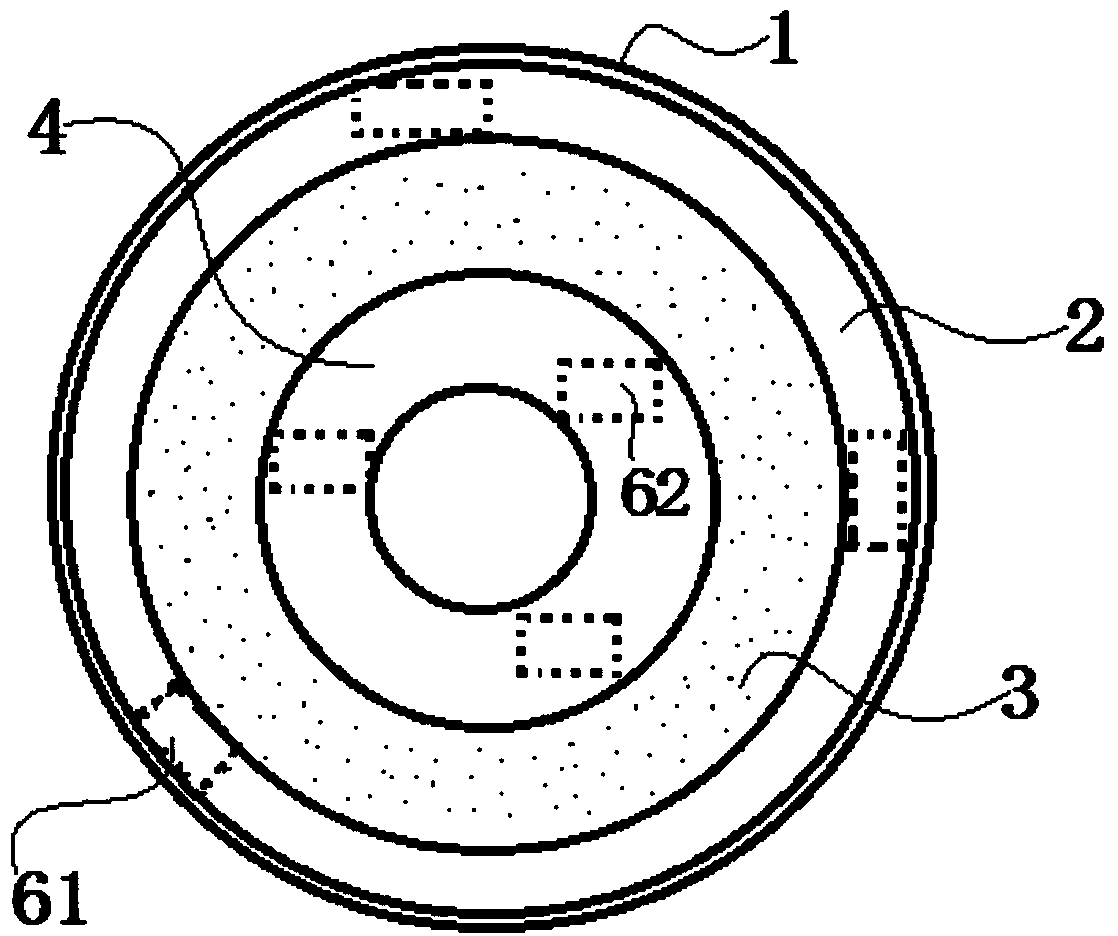

Slitting mill

The invention relates to a slitting mill, and belongs to the technical field of thin plate cutters. The slitting mill comprises an upper roller and a lower roller, and further comprises at least two upper ring cutters arranged on the upper roller and rotating with the upper roller, and at least two lower ring cutters arranged on the lower roller and rotating with the lower roller, wherein the upper roller and the lower roller are both rollers actively rotating; and each upper ring cutter and the corresponding lower ring cutter are opposite in edges to form a cutter set. Through mutual fit between the ring cutters mounted on the upper roller and the lower roller, the slitting mill can realize longitudinal cutting of various plates, can perform fixed-width treatment for the plates, can cut copper foil substrates, paper substrates, aluminum substrates and the like, and has the advantages of quick cutting speed and good cutting effect.

Owner:浙江安浦科技有限公司

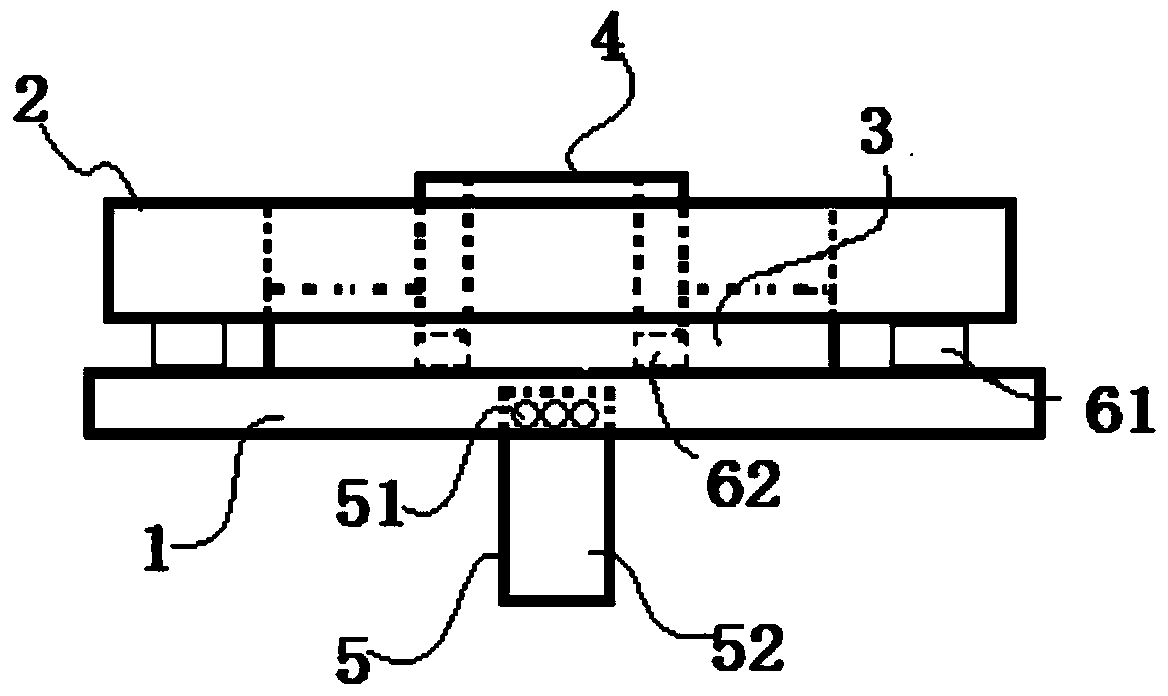

Pretreatment device of refrigeration house door plate

PendingCN106182123ASmooth cutImprove cut qualityMetal working apparatusElectrostatic chargesEngineeringRefrigeration

The invention relates to the technical field of door plate production, in particular to a pretreatment device of a refrigeration house door plate. The pretreatment device comprises a film coating station and a cutting station which are arranged in sequence. The film coating station comprises a film coating rack. A conveying belt is arranged on the film coating rack. A flattening roller is arranged at the position, corresponding to the door plate, of the starting end of the conveying belt. A film coating roller is arranged above the middle position of the conveying belt. The cutting station is arranged at the other end of the conveying belt. Film pressing rollers and a static electricity removal mechanism are sequentially arranged between the film coating roller and the cutting station. The cutting station comprises a cutting platform and at least one set of cutter. Each cutter comprises an upper cutter body and a lower cutter body which are arranged oppositely. Each upper cutter body is connected with a drive device I. A supporting table corresponding to each set of cutter is arranged on the cutting platform. The lower cutter bodies and the supporting tables are arranged side by side, and the lower cutter bodies are flush with the table faces of the supporting tables. According to the pretreatment device, manual labor intensity is reduced, and work efficiency is improved.

Owner:SHANDONG AONAER REFRIGERATION TECH

One-shot forming method of disposal plastic cup

The invention relates to a method for preparing a disposable plastic cup through once molding. The method comprises the following steps: 1, a sheet material is processed, is sent to an electric furnace through a transportation device of a molding machine and is heated and softened; the heating temperature is between 250 and 280 DEG C; 2, after the sheet material is heated, softened and leveled, a molding head of a cup manufacturing machine positioned in the electric furnace is pressed downwards and is coacted with a molding female mold of the cup manufacturing machine to punch and mold a cup body; 3, after the cup body is molded, high-pressure air is charged to the middle part between the molding head and the cup body through a cylinder so as to detach the molded cup body from the molding head; and 4, a cutting blade of the molding head is continuously subjected to lower punching and side cutting; and after the side cutting, the disposable plastic cup is formed and enters a printing or packaging procedure. The disposable plastic cup formed by a once molding process has the advantages of good appearance shape, even thickness, good hand feel and no raw edges.

Owner:SHANGHAI QINGYAN PLASTIC PRODS

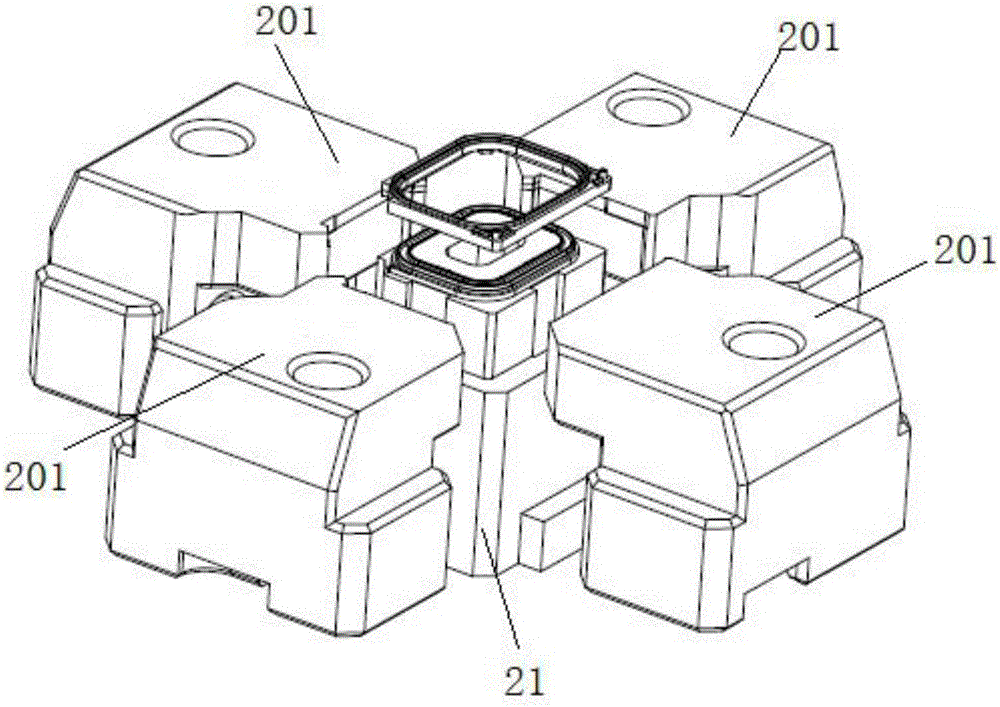

Silica gel sealing process for liquid silica gel injection mold

The invention discloses a silica gel sealing process for a liquid silica gel injection mold. The silica gel sealing process comprises the following steps that S1, FPC and a plastic frame are subjected to surface treatment; S2, the FPC and the plastic frame subjected to surface treatment through the S1 are put into the liquid silica gel injection mold, and liquid silica gel injection molding is conducted; and S3, a product completed and molded through the S2 is taken out and subjected to performance testing. According to the silica gel sealing process for the liquid silica gel injection mold, the surface of the FPT and the surface of the plastic frame are cleaned and activated in a plasma treatment mode, and the effect that no residual silica gel exists is achieved; and through liquid silica gel injection molding, the wall of silica gel is made to be uniform in thickness and free of burrs, and the product yield is increased.

Owner:TAIDEXING PRECISE ELECTRON KUSN

Metal wire rod precision alignment cutting device and method

Owner:JINDUICHENG MOLYBDENUM CO LTD

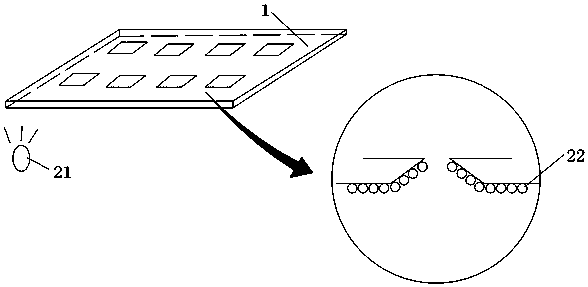

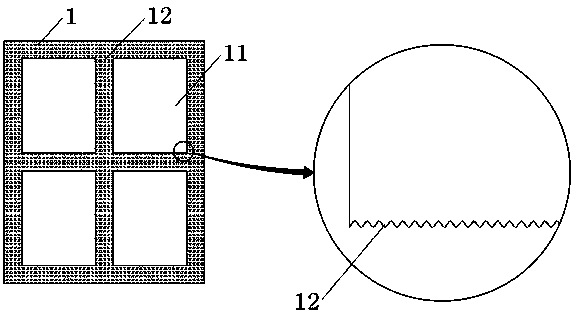

Metal mask for preventing falling of evaporation metal layer and manufacturing method

PendingCN109913808AInhibit sheddingSolved the technical problem of not being able to make the entire backside fully roughVacuum evaporation coatingSputtering coatingInvar alloyRough surface

The invention discloses a metal mask for preventing falling of an evaporation metal layer and a manufacturing method thereof. In the manufacturing process, one surface of an INVAR alloy is subjected to etching treatment firstly, one surface of the INVAR alloy is subjected to whole surface etching to form a rough surface, then an opening is manufactured, and therefore a rough area and the opening have no distance limitation. The metal mask is of a sheet-like structure having hollow meshes, one side of the metal mask is wholly the rough surface, and therefore the bonding force between a metal material and the metal mask during evaporation is improved, falling of the metal material during evaporation is prevented, and the defect rate of products is lowered.

Owner:NANJING TOPTO MATERIALS CO LTD

Production process of oat pastries

The invention relates to a production process of oat pastries. The production process is finished according to the following steps: (1) weighing the following raw materials in parts by weight: 3kg of oatmeal, 3kg of wheat flour, 1.5kg of white sugar, 1.2kg of soybean oil and 150g of table salt; (2) mixing all the oatmeal, the white sugar, the table salt and 0.4kg of the soybean oil and preparing oatmeal stuffing for later use; (3) blending pastry dough for later use; (4) filling with the stuffing to prepare oat round cakes; (5) flattening the filled oat round cakes and brushing syrup to prepare blanks; (6) putting the blanks brushed with the syrup into a baking oven and baking; (7) after baking the blanks, taking out from the baking oven and naturally cooling to 37 DEG C to 40 DEG C. The production process of the oat pastries has the beneficial effects that 1, shapes: the oat pastries are elliptical and ordered and have no fringed edges; 2, color and luster: the oat pastries are yellowish-brown and have glossy surfaces; 3, tissues: the oat pastries are loose and have slight toughness; 4, taste: the oat pastries are soft and sweet and have a special flavor of oats.

Owner:GUILIN HAOXIN TECH SERVICE

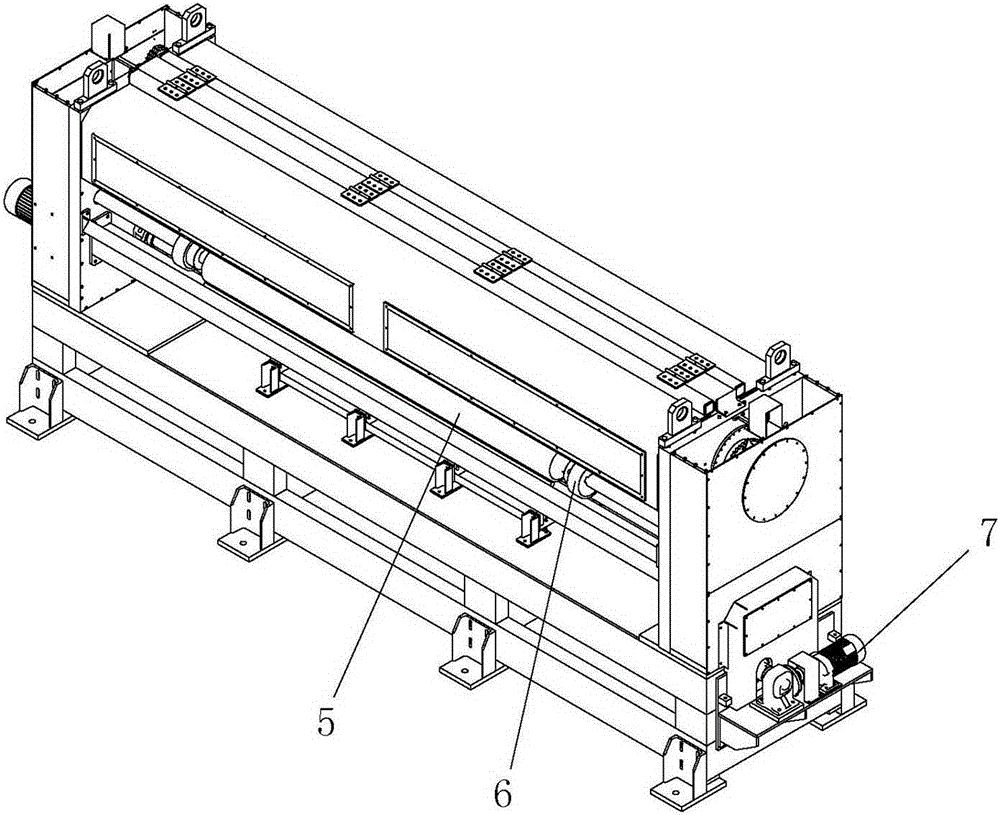

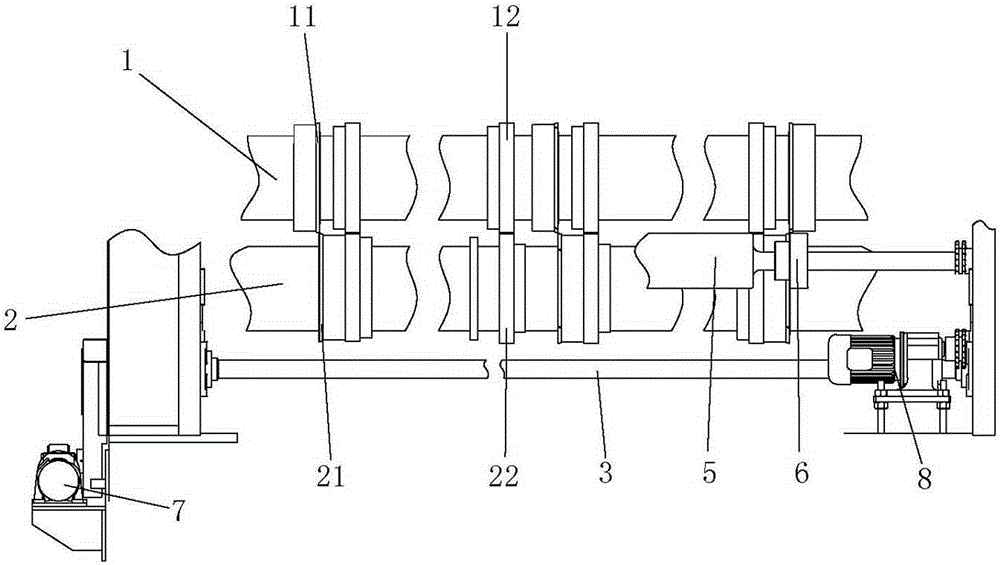

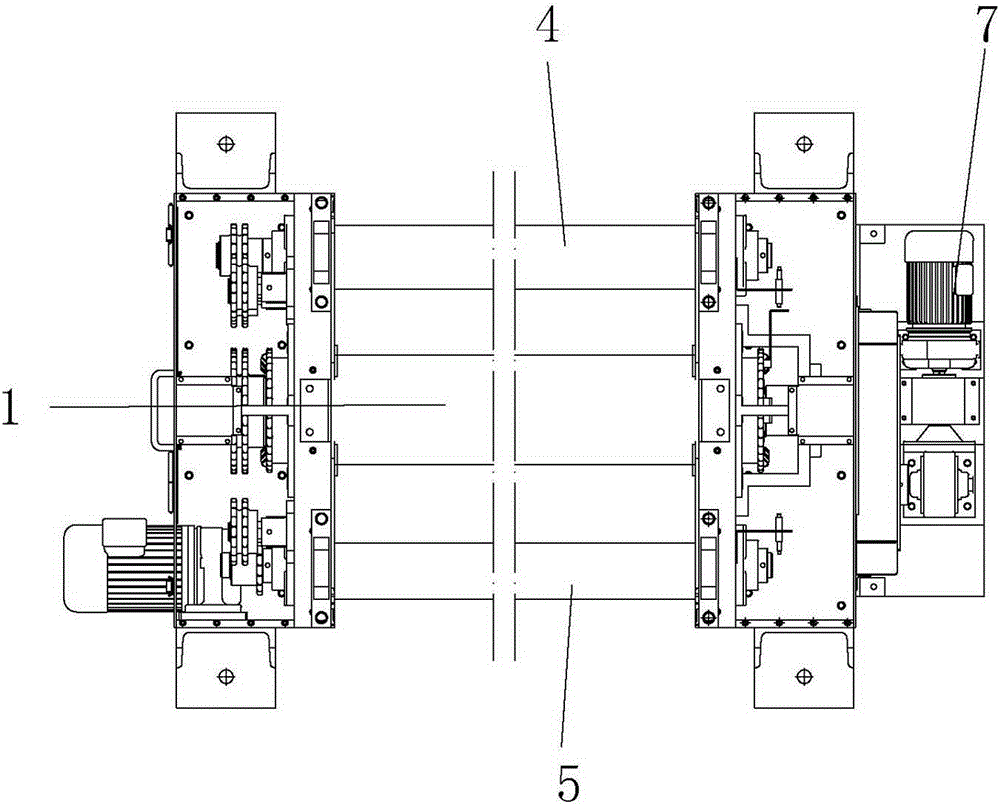

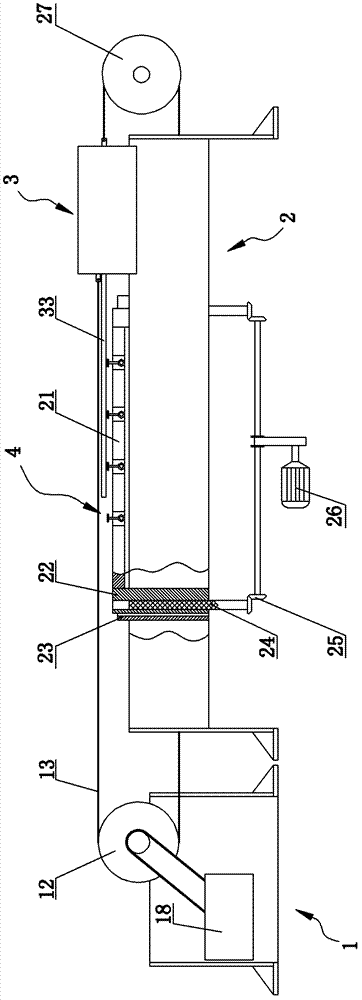

A sheet slitting machine

ActiveCN104275714BCrop stabilizationHigh precisionShearing machinesMetal working apparatusEngineeringPlastic film

The invention discloses a sheet stock slitting machine. The sheet stock slitting machine comprises a rack as well as a strip feeding mechanism, a slitting device and a strip rolling mechanism which are arranged on the rack, wherein the strip feeding mechanism and the strip rolling mechanism are respectively arranged in the front of and behind the slitting device. The sheet stock slitting machine is characterized in that the slitting device comprises a cutter shaft bracket, an upper cutter shaft, a lower cutter shaft and a cutter shaft power device for driving the upper cutter shaft and the lower cutter shaft to rotate; a plurality of groups of shearing modules are arranged at certain intervals between the upper cutter shaft and the lower cutter shaft; each group of shearing module is composed of an upper cutter on the upper cutter shaft and a lower cutter on the lower cutter shaft, and the upper cutters and the lower cutters are staggered at a horizontal interval of 0-2mm, and the distance between the upper cutter shaft and the lower cutter shaft is less than the radius sum of the upper cutters and the lower cutters. The sheet stock slitting machine is capable of slitting materials such as sheet metal strips and plastic films and is simple in structure, stable in operation and high in precision, the cutters are durable, and products are good in quality and free of deckle edges.

Owner:韶关市高信塑胶制品有限公司

Longitudinal veneer slicer

InactiveCN102229154BRealize automatic controlFeed error is smallFlat surfacing machinesReciprocating motionWood processor

The invention discloses a longitudinal veneer slicer applied in the field of wood machining machinery. The longitudinal veneer slicer comprises a main frame, a secondary frame and a tool rest arranged on the main frame and capable of sliding along the longitudinal direction of the main frame, wherein the secondary frame is arranged at one end of the main frame, and a driving motor capable of driving the tool rest to reciprocate is arranged on the secondary frame; in addition, a liftable workbench is horizontally arranged on the main frame, the workbench is driven by a lifting motor, and corresponding clamping devices for clamping wood are arranged at two sides of the workbench; and when the longitudinal veneer slicer works, the wood is fixed on the workbench by using the clamping devices,the tool rest continuously reciprocates under the drive of the driving motor, meanwhile, the workbench can ascend for a distance after a slicing period is finished, and a planing tool arranged on thetool rest can continuously slice the veneer of certain thickness. The longitudinal veneer slicer has simple structure and relatively low cost, can ensure the uniformity of the thickness of the slicedveneer during slicing, and is very suitable for medium and small enterprises to use.

Owner:丁占科

Naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and preparation method thereof

InactiveCN103045014BSimple production processClear imagingInksPhotosensitive materials for photomechanical apparatusCelluloseCooking & baking

The invention discloses a naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and a preparation method thereof. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink comprises the following components in parts by weight: 50-80 parts of alkali soluble photosensitive resin, 0-5 parts of cellulose used for coating, 2-10 parts of active diluents, 2-8 parts of photosensitizer, 10-40 parts of filler, 0.5-1 part of pigment, 5-15 parts of solvent and 0.5-3 parts of auxiliaries, wherein the alkali soluble photosensitive resin is prepared from the following components in parts by weight: 40-60 parts of mixture consisting of 20-30 parts of n-butyl acetate, 0-30 parts of methyl isobutyl ketone, 0-20 parts of methylbenzene and 0-20 parts of propylene glycol monomethyl ether acetate, 25-40 parts of styrene-maleic anhydride resin, 15-20 parts of acrylic acid monomer, 0.1-1.0 part of catalyst and 0.1-1.0 part of polymerization inhibitor. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink disclosed by the invention does not need baking, is dried naturally after being diluted and is energy-saving and is resistant to acid and electroplating, and a film formed after the electroplating printing ink sprayed and dried naturally is high in adhesive force, high in hardness, quick in development, capable of obtaining clear images and resistant to acid corrosion.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

Method for preparing metal plastic composite foil

ActiveCN100471378CNo fringeNo foamingMagnetic/electric field screeningMetal layered productsExtensibilityPolyurethane adhesive

The method includes following steps: after being dissolved by acetic ether, polyurethane adhesive is coated on plastic film, coating weight 2 - 4g / m2, and passing through drying tunnel with three tracks; compounding metal foil with plastic film, placing it in oven for 20-30 hr. under temperature 45-55 deg.C so as to obtain metal plastic composite foil. The polyurethane adhesive is prepared from main agent polyether glycol, firming agent of aromatic isocyanate. Mass compounding ratio of main agent, firming agent, and acetic ether is 10:1 - 4:8 - 20. Advantages are: good surface quality, even thickness in each layer, concurrent bonding property, large adhesion, and tensile strength, high extensibility, low resistivity, and good shielding properties. The invention provides condition for producing communication line in high performance.

Owner:盛文妹

Elevator displayer and operating panel carbon fiber panel water cutting technology

InactiveCN106272707AReduce processing costsImprove efficiencyMetal working apparatusFiberNumerical control

The invention discloses an elevator displayer and an operating panel carbon fiber panel water cutting technology. A carbon fiber panel is machined into a shape required in a drawing through a numerical control water cutting device according to a precompiled program. When the elevator displayer and an operating panel are machined and produced through water cutting by means of the numerical control water cutting device, machining cost is low, efficiency is high, appearance effect is good, no burrs exist, and the technology is good and suitable for batch production.

Owner:SHANGHAI BST ELECTRIC

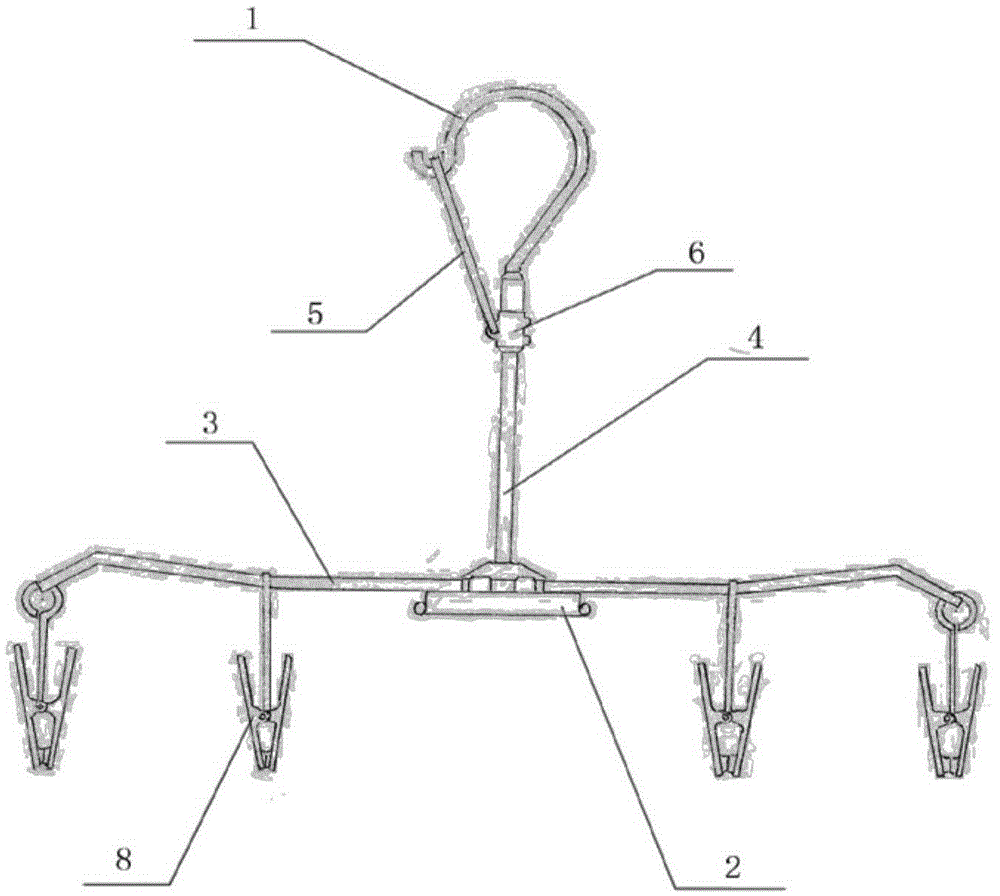

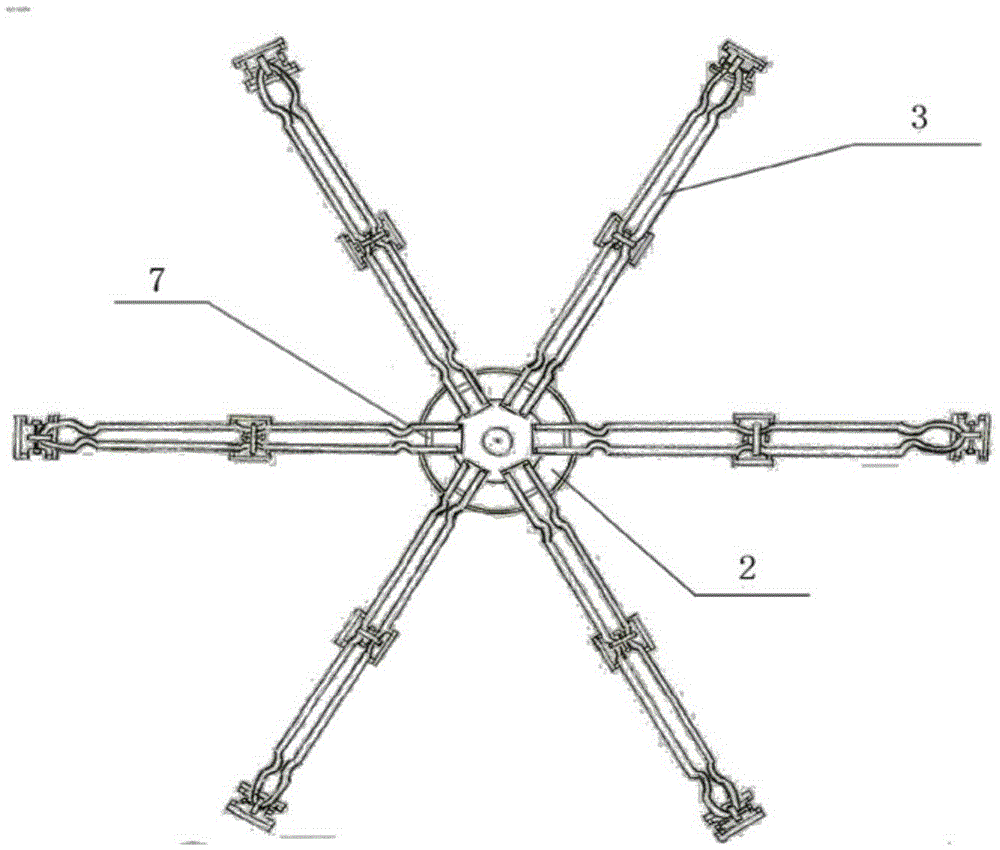

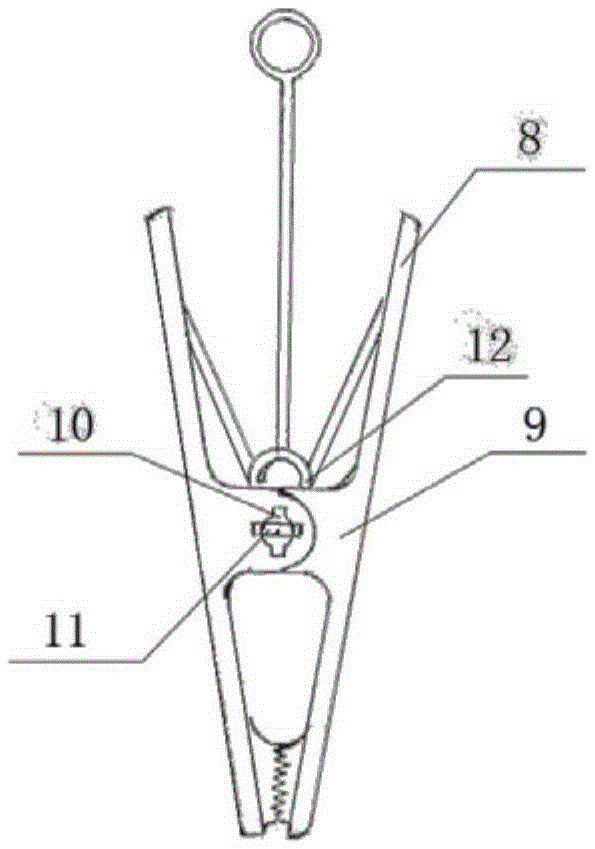

A kind of stainless steel clip hanger and its assembly method

The invention relates to the technical field of articles for daily use, in particular to a stainless steel clamp clothes hanger and an assembling method thereof. The stainless steel clamp clothes hanger comprises a hook, a connecting disk and a plurality of supporting rods, wherein one end at the upper part of the hook is of a U-shaped structure, the bottom part of the hook is movably connected with the connecting disk through a connecting rod, one section at the upper part of the connecting rod is provided with a sliding region, the cross section area of the sliding region is smaller than that of the connecting rod, the sliding region is connected with a lock sliding block in a matching way, the lock sliding block is movably connected with a lock connecting rod, the connecting disk is movably connected with the supporting rods, the supporting rods are made by bending one sectional bar, one ends of the supporting rods are closing ends, the other ends of the supporting rods are open ends, and the left sides and the right sides of the open ends are respectively provided with outward bending structures. Compared with the prior art, the stainless steel clamp clothes hanger disclosed by the invention has the advantages that parts are made of stainless steel, thus the manufacture is convenient, and corrosion resistance is realized; connecting positions are designed into groove and through hole structures, thus the assembling is convenient, and the use is simple; various functions are realized, all the supporting rods can be erected, and the carrying is convenient.

Owner:上海达亮五金有限公司

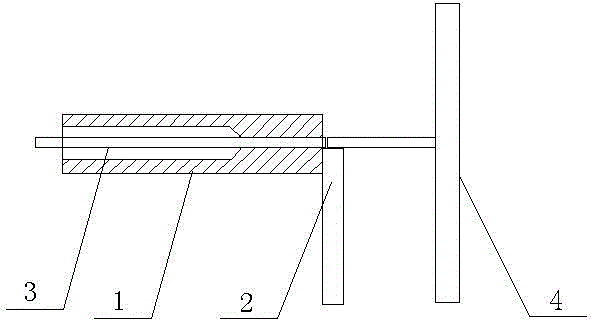

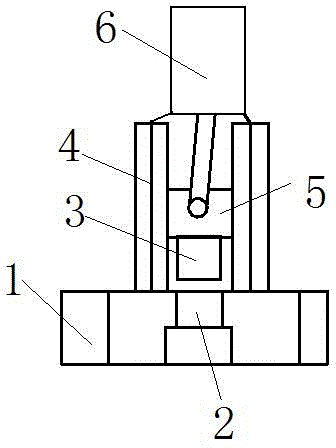

Novel semiconductor lead processing device

InactiveCN102800597AStable lengthSmooth cutSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a novel semiconductor lead processing device, and relates to semiconductor processing equipment. The device comprises a threading block (1), a cutter (2), a threading hole (3) and a positioning device (4), wherein the threading hole (3) is arranged in the threading block (1); the cutter (2) is vertically fixed on the exit side of the threading hole (3); and the positioning device (4) is arranged beside the cutter (2). The device disclosed by the invention can realize stable length and flush cut of the product, prevents rough edges, and has high production efficiency.

Owner:HAIAN COUNTY BUSINESS SCHOOL

Processing technology for composite for elevator display and operating panel

The invention discloses a processing technology for a composite for an elevator display and operating panel. The processing technology comprises a processing procedure of a composite panel and a processing procedure of the elevator display and operating panel part. The processing procedure of the composite panel comprises the steps that a stainless steel panel and an aluminum alloy panel are selected, the stainless steel panel is pretreated, and the surface of the stainless steel panel is cleaned; in a drying oven at the temperature of 140 DEG C to 250 DEG C, the stainless steel panel and the aluminum alloy panel are recombined together through hot-melt polymer adhesive; and the composite panel of the stainless steel panel and the aluminum alloy panel is obtained. The processing procedure of the elevator display and operating panel part comprises the steps that the composite panel of the stainless steel panel and the aluminum alloy panel is processed by the adoption of numerical control water jet cutting equipment according to a preset program, and the shape required in a drawing is made; or blanking is conducted through a stamping die. Produced products are good in appearance effect, free of burrs, good in technology and suitable for mass production.

Owner:SHANGHAI BST ELECTRIC

External wall tile manufacturing system and external wall tile manufacturing method

InactiveCN104213684AStable working conditionThe feeding process is stableLamination plant layoutCovering/liningsBrickManufacturing systems

The invention relates to an external wall tile manufacturing system and an external wall tile manufacturing method. The existing external wall tiles are formed by firing, so that the working procedures are complicated, and the cost is higher; furthermore, the external wall tiles obtained by firing are heavier, so that the external wall tiles can easily fall off after being stuck on the wall and can easily hurt people after being damaged and falling off from the high altitude in all probability, the unsafe factor is caused, and the quality and the service life of a building are seriously influenced. The external wall tile manufacturing system comprises an external wall tile manufacturing conveyor device which is connected with a spray-painting device; the spray-painting device is connected with a drying device; the drying device is connected with an external wall tile manufacturing receiving device; the external wall tile manufacturing receiving device is connected with a cut-off machine by an external wall tile bottom plate; the cut-off machine is matched with a forging machine for use; the forging machine is matched with an external wall tile manufacturing gluing device for use. The system and the method are used for manufacturing the external wall tiles.

Owner:张厚

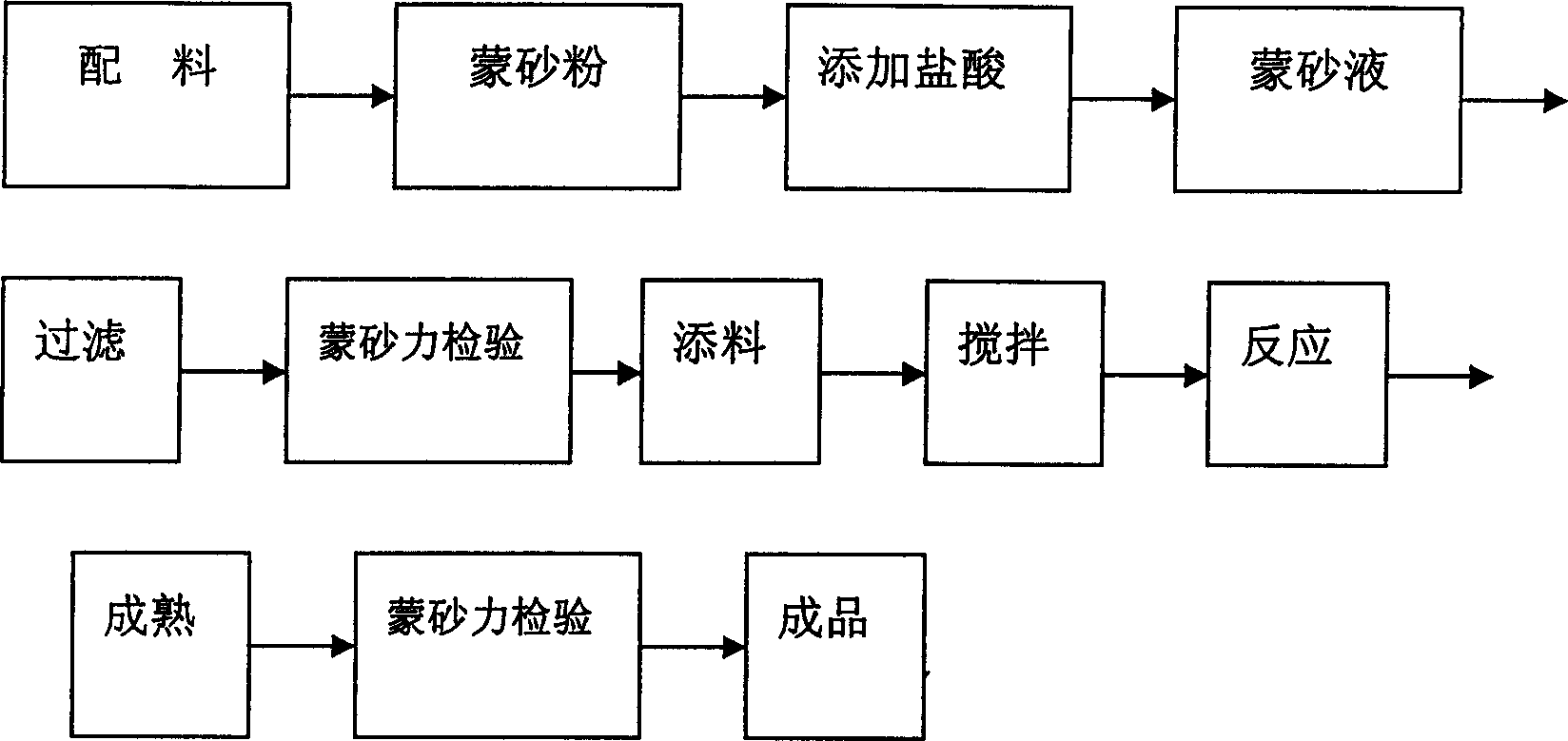

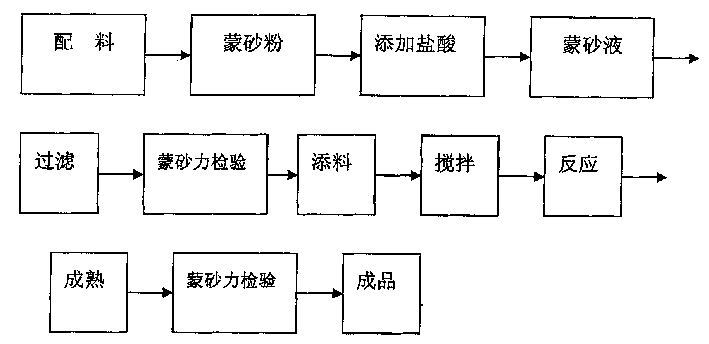

Process for preparing etching cream of glass fibre

Owner:上海多林玻璃技术有限公司

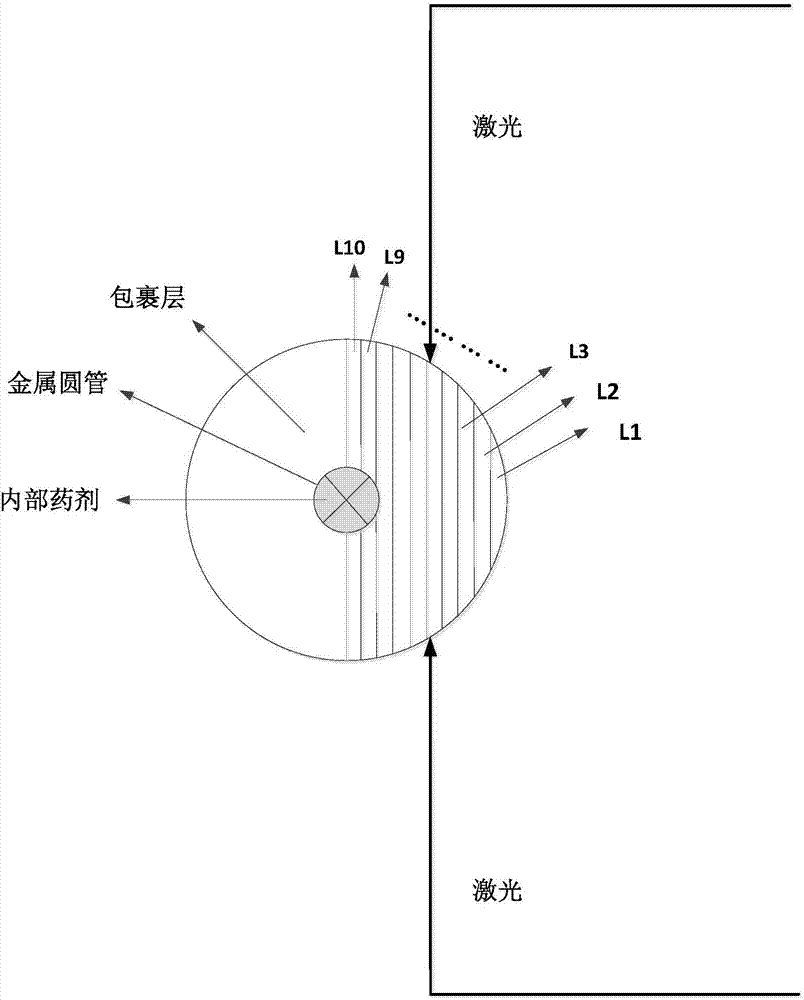

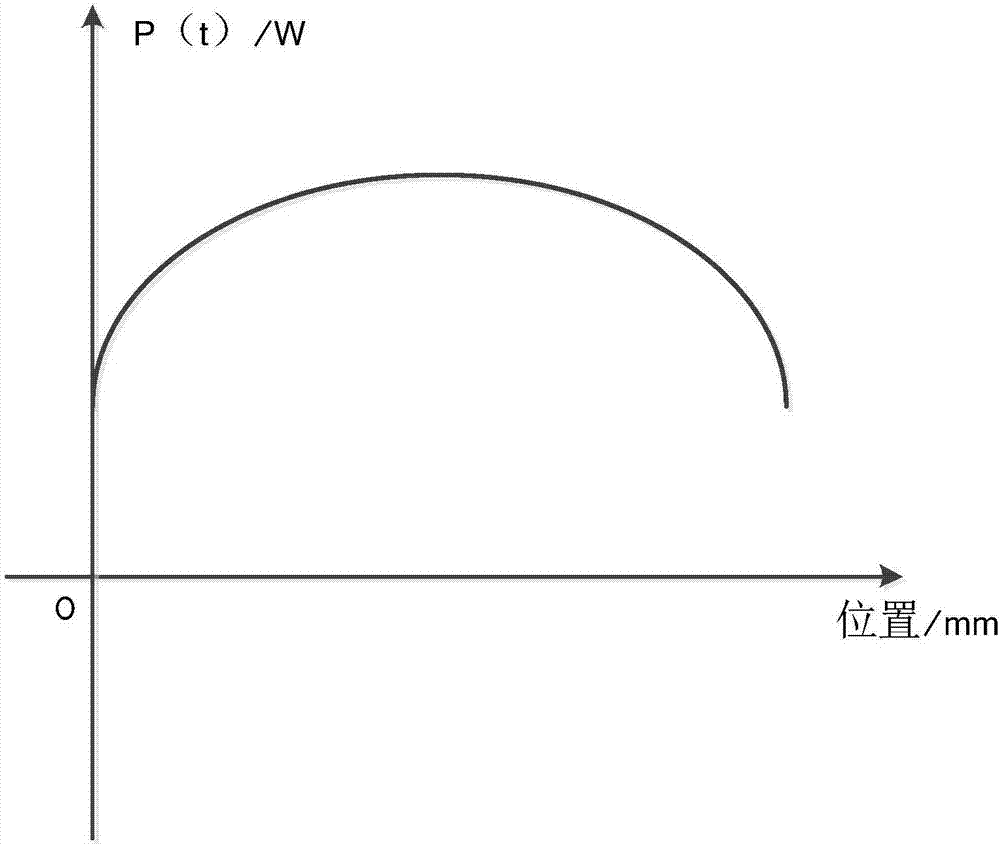

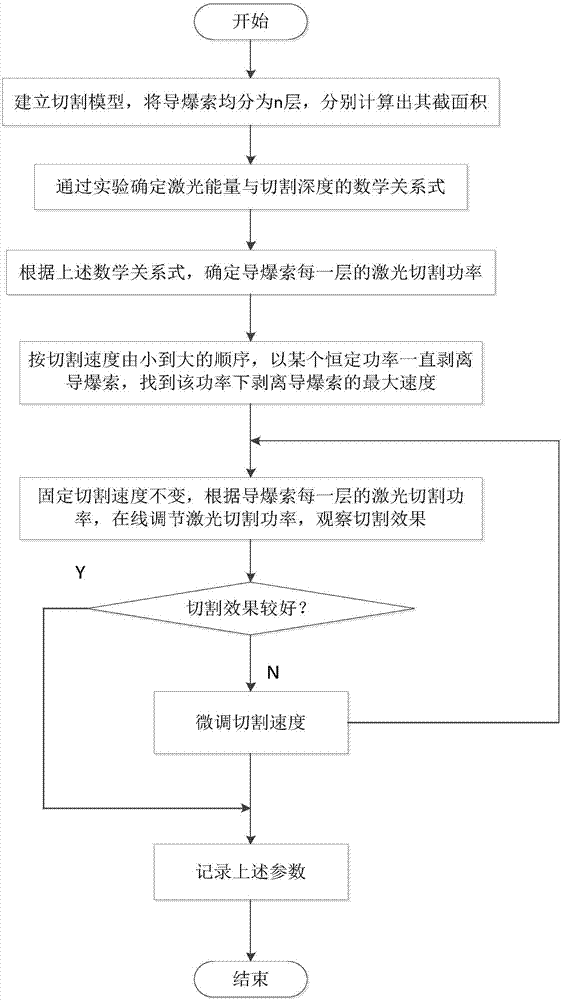

Technology for controlling laser cutting power and speed when detonating cord is peeled off by laser

The invention discloses a technology for controlling laser cutting power and speed when a detonating cord is peeled off by laser, and belongs to the field of processing of cord type initiating explosive devices. The technology comprises the following steps of (1) establishing a detonating cord cutting model; (2) according to the cutting model, determining parameters to be confirmed in a laser cutting model by performing a large number of cutting experiments; and (3) under the situation that the moving speed of a laser cutting platform is maintained unchanged, adjusting the power in an on-line manner so as to achieve the best cutting effect. According to the technology disclosed by the invention, the cutting effect of peeling off the detonating cord by the laser can be obviously improved; the detonating cord cutting model is established, the relationship between laser cutting power and the laser cutting speed is coordinated, so that removal of a surround of the detonating cord can be quickly and accurately realized, the flanging of a cutting surface is reduced, and the production efficiency is improved.

Owner:CHONGQING UNIV

a roll cutting machine

The invention relates to a slitting mill, and belongs to the technical field of thin plate cutters. The slitting mill comprises an upper roller and a lower roller, and further comprises at least two upper ring cutters arranged on the upper roller and rotating with the upper roller, and at least two lower ring cutters arranged on the lower roller and rotating with the lower roller, wherein the upper roller and the lower roller are both rollers actively rotating; and each upper ring cutter and the corresponding lower ring cutter are opposite in edges to form a cutter set. Through mutual fit between the ring cutters mounted on the upper roller and the lower roller, the slitting mill can realize longitudinal cutting of various plates, can perform fixed-width treatment for the plates, can cut copper foil substrates, paper substrates, aluminum substrates and the like, and has the advantages of quick cutting speed and good cutting effect.

Owner:浙江安浦科技有限公司

Hydraulic driven punching machining device

The invention provides a hydraulic driven punching machining device, which is characterized by comprising a base of the hydraulic driven punching machining device, a female die, a punching male die, a male die slideway, a link block and a hydraulic device; wherein the female die is positioned in the base of the hydraulic driven punching machine device, the male die slideway is vertically installed on the base of the hydraulic driven punching machine device, the link block is installed in the male die slideway, the punching male die is installed under the link block, and the hydraulic device is connected to the link block via a connecting rod. The hydraulic driven punching machining device has the advantages of being simple in structure, convenient to use and low in cost, a cutting edge between the female die and the punching male die ensures burr-free punching machining, the operation is steady and the market prospect is wide.

Owner:赵强

Etching liquid for flat panel display

The present invention discloses an etching liquid for the flat panel display. The etching liquid comprises oxalic acid, trifluoromethyl benzenesulfonic acid and water. The using amount of the oxalic acid is 1-10% of the total weight of the etching liquid. The using amount of the trifluoromethyl benzenesulfonic acid is 0.5-5% of the total weight of the etching liquid, and the balance is water. Theinvention provides the etching liquid for the flat panel display, which has the advantages of high efficiency, high etching precision and no pungent odour. The etching liquid is used for etching the ITO transparent conductive film. The adopted oxalic acid and the trifluoromethyl benzenesulfonic acid are organic acids. The compound composed of the two organic acids is not easily volatilized and hasexcellent wetting quality. When used as the ITO conductive film etching liquid, the etching liquid compound has the characteristics of excellent etching performance, no residue, less environmental pollution, etc.

Owner:HEFEI MAOTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com